Life Cycle Environmental and Economic Performance Analysis of Bagasse-Based Electricity in Pakistan

Abstract

:1. Introduction

1.1. Rationale

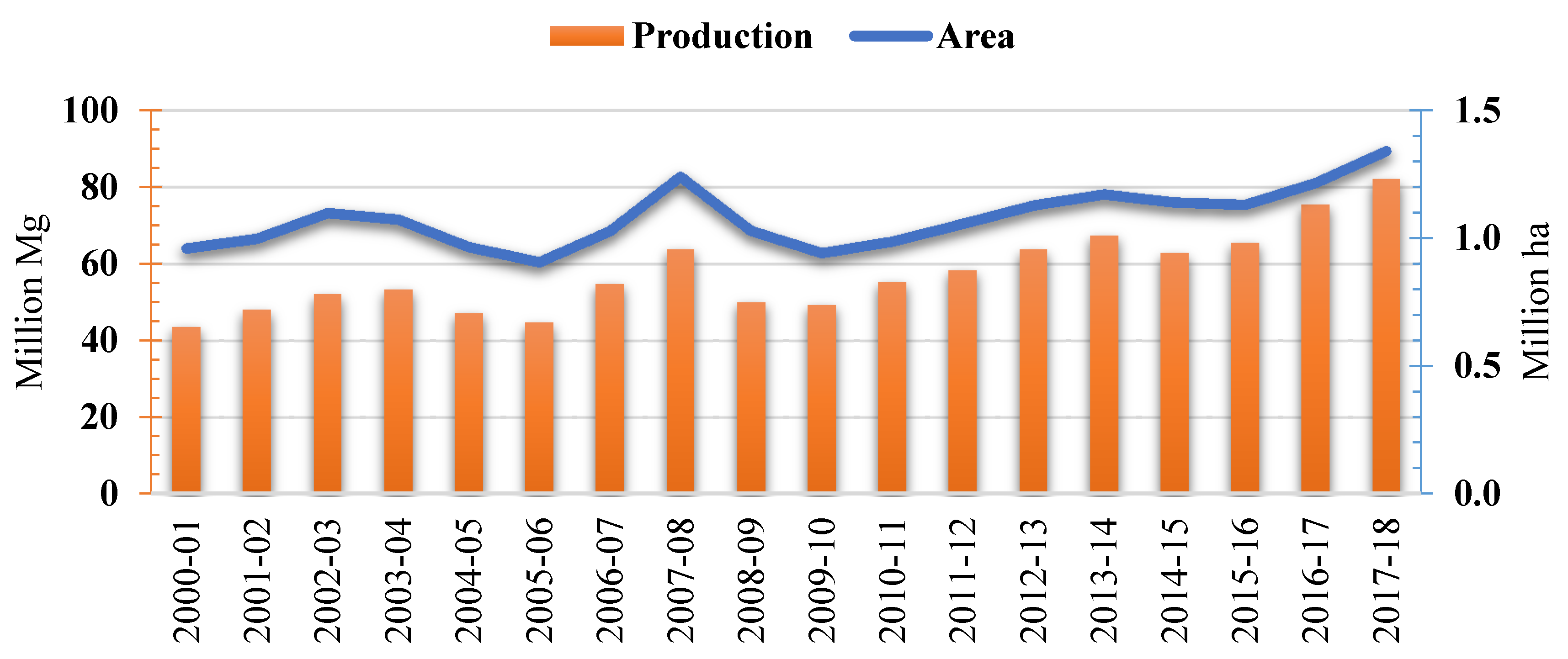

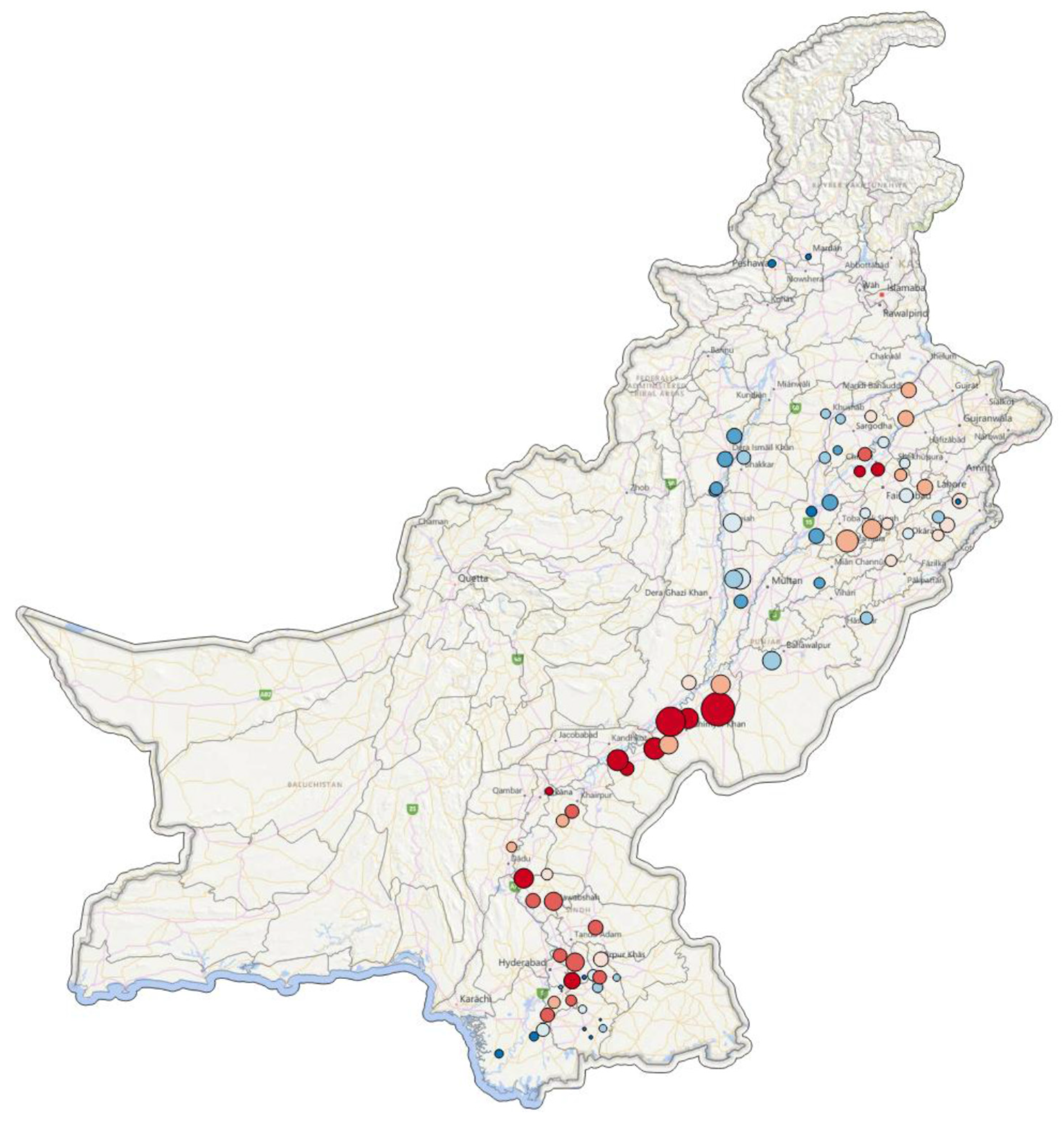

1.2. Potential of Bagasse for Electricity Production from Bagasse in Pakistan

1.3. Why Life Cycle Assessment?

2. Methodology

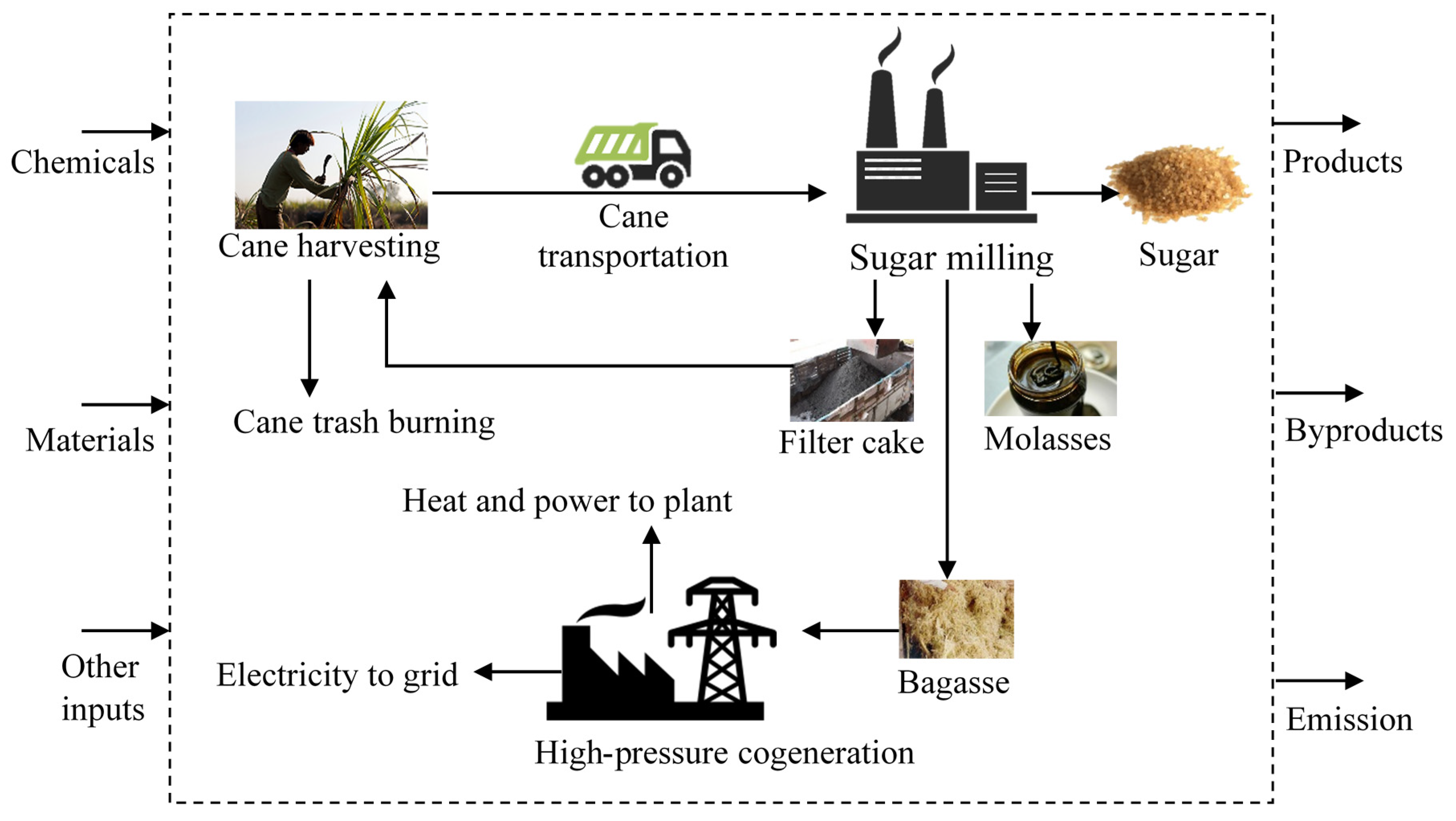

2.1. Goal and Scope

2.2. Inventory Analysis

2.3. Impact Assessment

3. Results and Discussion

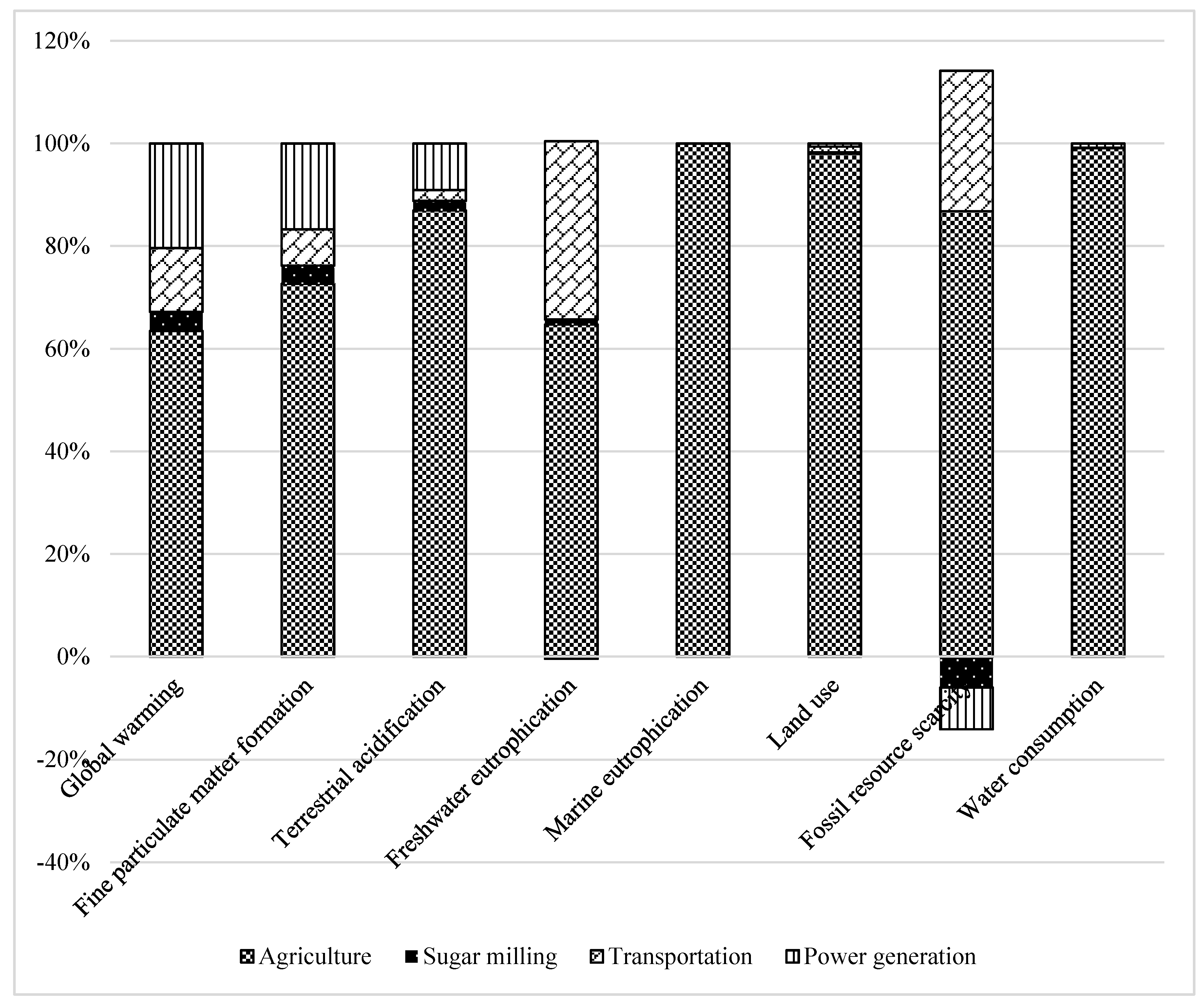

3.1. Midpoint Impacts

3.2. Endpoint Impacts

3.3. Weighted Environmental Prices

3.4. Managing the Bagasse-Based Electricity—Policy Discussion and Insights for Stakeholders

- Considering midpoint indicators, bagasse-based electricity performs better than grid mix electricity only for some impact categories, but not all. This requires careful consideration of all the environmental aspects by the decision makers as focusing only on the popular categories, such as global warming and fossil scarcity, could lead to unintended environmental consequences.

- The results of endpoint categories are quite interesting as they suggest the advantage of bagasse-based electricity only for resource availability. The benefit of bagasse-based electricity towards human health damage was not significant. The grid mix electricity showed a better performance for ecosystem quality.

- The environmental cost of bagasse-based electricity is less than grid mix electricity. Therefore, environmental cost should be included while calculating the overall cost. This suggests that the relatively higher prices of bagasse-based electricity or financial supports in terms of subsidy and loans for promoting bagasse-based electricity are justifiable within the difference of environmental cost.

- Most of the impacts of electricity are being caused by the agricultural stage, suggesting that improvement efforts should be focused on reducing the environmental impacts of this stage. For instance, optimizing the use of agro-chemicals, improving irrigation efficiency, avoiding the post-harvest burning of cane trash, and increasing the yield at the agricultural stage could substantially improve the performance of bagasse-based electricity.

- At the agricultural stage, most of the environmental impacts are from the use of resources, such as land, water, and fertilizers, etc. These resources are crucial for other food crops as well. Therefore, careful consideration should be given to managing the competitive use of resources before making any policies.

- Considering that bagasse is a byproduct of sugar (food) from sugarcane, the current inefficient use of bagasse using low-pressure cogeneration with no export of electricity is not only a waste of resources, but is also increasing the overall impacts of sugar which otherwise could be shared by the surplus bagasse-based electricity. This requires strict action to discourage the waste of precious resources.

- As the crushing season in the country lasts for only around four months, this results in less availability of bagasse during the off-season, especially if low-pressure cogeneration plants with no export of electricity also install high-pressure cogeneration with the export of electricity. To address this shortfall, other potential fuels, especially crop residues which are abundantly available in the country, are suggested to be investigated [45,46]. Another promising option is cane trash, which can be collected and used as fuel, as mentioned by Ghani and Gheewala [23] in their study.

4. Conclusions and Recommendation

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Government of Pakistan. Pakistan’s Implementation of the 2030 Agenda for Sustainable Development Goals; SDG Section, Ministry of Planning, Development, and Reforms, Government of Pakistan: Islamabad, Pakistan, 2019; pp. 1–72.

- United Nations. #Envision2030 Goal 7: Affordable and Clean Energy|United Nations Enable. Available online: https://www.un.org/development/desa/disabilities/envision2030-goal7.html (accessed on 1 December 2020).

- World Bank. Biomass Resource Mapping in Pakistan: Final Report on Biomass Atlas for Pakistan; World Bank: Washington, DC, USA, 2016; pp. 1–91. [Google Scholar]

- Ministry of Finance. Pakistan Economic Survey 2017–2018, Finance Division, Government of Pakistan. 2018. Available online: http://www.finance.gov.pk/survey/chapters_18/Economic_Survey_2017_18.pdf (accessed on 20 August 2020).

- FAOSTAT. Countries by Commodity. Food and Agriculture Organization of The United Nations. 2018. Available online: http://www.fao.org/faostat/en/#rankings/countries_by_commodity (accessed on 30 November 2020).

- NFS&R. Agricultural Statistics of Pakistan 2017–2018. Ministry of National Food Security and Research. 2019. Available online: http://www.mnfsr.gov.pk/frmDetails.aspx (accessed on 1 May 2020).

- PSMA. Pakistan Sugar Mills Association Annual Report 2018; PSMA: Islamabad, Pakistan, 2018.

- Eckstein, D.; Hutfils, M.L.; Winges, M. Who suffers most from extreme weather events? Weather-related loss events in 2017 and 1998 to 2017. In Global Climate Risk Index 2019; Germanwatch: Bonn, Germany, 2018. [Google Scholar]

- Ministry of Climate Change. Pakistan’s Second National Communication on Climate Change to United Nations Framework Convention on Climate Change (UNFCCC). Ministry of Climate Change, Government of Pakistan. Available online: https://unfccc.int/sites/default/files/resource/183625_Pakistan-NC2-1-Pakistan%20-%20Second%20National%20Communication%20on%20Climate%20Change%202018.pdf (accessed on 15 September 2020).

- NEPRA. State of Industry Report, National Electric Power Regulatory Authority (NEPRA); NEPRA: Islamabad, Pakistan, 2019; pp. 1–231. Available online: https://nepra.org.pk/publications/State%20of%20Industry%20Reports/State%20of%20Industry%20Report%202019.pdf (accessed on 8 November 2020).

- World Bioenergy Association. Global Bioenergy Statistics 2019. Available online: https://worldbioenergy.org/uploads/191129%20WBA%20GBS%202019_LQ.pdf (accessed on 10 November 2020).

- Malik, M.O. High Pressure Cogeneration for Sugar Sector in Pakistan; HP Cogen-Pak: Islamabad, Pakistan, 2016. [Google Scholar]

- NEPRA. NEPRA|Tariff Generation Upfront. 2020. Available online: https://nepra.org.pk/tariff/GenerationUpfront.php (accessed on 1 December 2020).

- AEDB. Final Report on Biomass Atlas for Pakistan; AEDB: Islamabad, Pakistan, 2016. [Google Scholar]

- International Organization for Standardization. ISO 14040 Environmental Management—Life Cycle Assessment—Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization. ISO 14044 Environmental Management—Life Cycle Assessment—Requirements and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Turconi, R.; Boldrin, A.; Astrup, T.F. Life cycle assessment (LCA) of electricity generation technologies: Overview, comparability and limitations. Renew. Sustain. Energy Rev. 2013, 28, 555–565. [Google Scholar] [CrossRef] [Green Version]

- Gil, M.P.; Moya, A.M.C.; Dominguez, E.R. Life cycle assessment of the cogeneration processes in the Cuban sugar industry. J. Clean. Prod. 2013, 41, 222–231. [Google Scholar] [CrossRef]

- Ramjeawon, T. Life cycle assessment of electricity generation from bagasse in Mauritius. J. Clean. Prod. 2008, 16, 1727–1734. [Google Scholar] [CrossRef]

- Silva, D.A.L.; Delai, I.; Montes, M.L.D.; Ometto, A.R. Life cycle assessment of the sugarcane bagasse electricity generation in Brazil. Renew. Sustain. Energy Rev. 2014, 32, 532–547. [Google Scholar] [CrossRef]

- Janghathaikul, D.; Gheewala, S.H. Bagasse—A sustainable energy resource from sugar mills daranee. Asian J. Energ. Environ. 2006, 7, 356–366. [Google Scholar]

- Jenjariyakosoln, S.; Gheewala, S.H.; Sajjakulnukit, B.; Garivait, S. Energy and GHG emission reduction potential of power generation from sugarcane residues in Thailand. Energy Sustain. Dev. 2014, 23, 32–45. [Google Scholar] [CrossRef]

- Ghani, H.U.; Gheewala, S.H. Comparative life cycle assessment of byproducts from sugarcane industry in Pakistan based on biorefinery concept. Biomass Convers. Biorefinery 2018, 8, 979–990. [Google Scholar] [CrossRef]

- Hiloidhari, M.; Banerjee, R.; Rao, A.B. Life cycle assessment of sugar and electricity production under different sugarcane cultivation and cogeneration scenarios in India. J. Clean. Prod. 2020, 125170. [Google Scholar] [CrossRef]

- Ghani, H.U.; Gheewala, S.H. Environmental sustainability assessment of molasses-based bioethanol fuel in Pakistan. Sustain. Prod. Consum. 2020, 27, 402–410. [Google Scholar] [CrossRef]

- Afghan, S.; Qureshi, M.A. Sugarcane Cultivation in Pakistan; Shakarganj Sugar Research Institute: Jhang, Pakistan, 2005. [Google Scholar]

- Malik, K.B. Cane and Sugar Production; Punjab Agricultural Research Board (PARB): Lahore, Pakistani, 2011.

- Ali, R.Z. Advanced Sugarcane Production Technology; Sugarcane Research Institute: Faisalabad, Pakistan, 2011.

- Ghani, H.U.; Silalertruksa, T.; Gheewala, S.H. Water-energy-food nexus of bioethanol in Pakistan: A life cycle approach evaluating footprint indicators and energy performance. Sci. Total Environ. 2019, 687, 867–876. [Google Scholar] [CrossRef] [PubMed]

- Hugot, E. Handbook of Cane Sugar Engineering; Elsevier Publishing Company: Amsterdam, The Netherlands, 1986. [Google Scholar]

- Rein, P. Cane Sugar Engineering; Bartens, K.G.A., Ed.; Springer: Berlin, Germany, 2007. [Google Scholar]

- Gomez, D.R.; Watterson, J.D.; Americano, B.B. Stationary Combustion. In IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Kyoto, Japan, 2006. [Google Scholar]

- U.S. Environmental Protection Agency. Emission Factor Documentation for Bagasse Combustion in Sugar Mills; U.S. EPA: Durham, NC, USA, 1997.

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zelm, R.V. ReCiPe2016: A harmonized life cycle impact assessment method at midpoint and endpoint level. Report I: Characterisation. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Goedkooop, M.; Oele, M.; Leijting, J.; Ponsioen, T.; Meijer, E. Introduction to LCA with SimaPro; PRé Consultants: Amersfoort, The Netherlands, 2016. [Google Scholar]

- Bruyn, S.D.; Bijleveld, M.; Graaff, L.D.; Schep, E.; Schroten, A.; Vergeer, R.; Ahdou, S. Environmental Prices Handbook Environmental Prices Handbook; CE Delft: Delft, The Netherland, 2018. [Google Scholar]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; de Schryver, A.; Struijs, J.; van Zelm, R. ReCiPE 2008: A Life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level; PRé Consultants: Amersfoort, The Netherlands, 2013. [Google Scholar]

- Eurostat. Eurostat—Tables, Graphs and Maps Interface (TGM) Table. 2020. Available online: https://ec.europa.eu/eurostat/tgm/table.do?tab=table&plugin=1&language=en&pcode=sdg_08_10 (accessed on 29 November 2020).

- Macrotrends. Pakistan GDP Growth Rate 1961–2020|MacroTrends. 2020. Available online: https://www.macrotrends.net/countries/PAK/pakistan/gdp-growth-rate (accessed on 29 November 2020).

- Statista. Pakistan: Inflation Rate 2014–2024|Statista. 2020. Available online: https://www.statista.com/statistics/383760/inflation-rate-in-pakistan/ (accessed on 29 November 2020).

- Datacommons. Pakistan—A Country in Asia. 2020. Available online: https://datacommons.org/place/country/PAK (accessed on 29 November 2020).

- Klein, C.D.; Novoa, R.S.A.; Ogle, S. N2O emissions from managed soils, and CO2 emissions from lime and urea application. In IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Kyoto, Japan, 2006. [Google Scholar]

- Uzair, M.; Sohail, S.S.; Shaikh, N.U.; Shan, A. Agricultural residue as an alternate energy source: A case study of Punjab province, Pakistan. Renew. Energy 2020, 162, 2066–2074. [Google Scholar] [CrossRef]

- State Bank of Pakistan. Exchange Rates for Mark-to-Market Revaluation—History. 2020. Available online: https://www.sbp.org.pk/ecodata/rates/m2m/M2M-History.asp (accessed on 2 December 2020).

- Kamran, M.; Mudassar, M.; Abid, I.; Fazal, M.R.; Ahmed, S.R.; Abid, M.I.; Khalid, R.; Hussain, S. Reconsidering the power structure of Pakistan. Int. J. Renew. Energy Res. 2019, 9, 480–492. [Google Scholar]

- Kashif, M.; Awan, M.; Nawaz, S.; Amjad, M.; Talib, B.; Farooq, M.; Nizami, A.-S.; Rehan, M. Untapped renewable energy potential of crop residues in Pakistan: Challenges and future directions. J. Environ. Manag. 2020, 256, 109924. [Google Scholar] [CrossRef]

| Data Type | Required Data | Source |

|---|---|---|

| Secondary data | Agricultural field data

Sugar milling

| Mainly from the study conducted by Ghani and Gheewala [25] Missing values obtained from other studies and reports |

Materials and chemicals production

National grid mix of electricity production | Inventory databases available with SimaPro software, mainly from Ecoinvent and U.S. Life Cycle Inventory (USLCI) databases | |

| Cane trash burning, fertilizer and pest/weed control chemical application, wastewater treatment | Ghani and Gheewala [25] | |

| Primary data | Bagasse-based high-pressure cogeneration

| Interviews, industrial reports, and calculations |

| Component | Value |

|---|---|

| Seed (kg) | 826 |

| Diesel for agricultural operations (L) | 10.86 |

| Fertilization (mineral) | |

| N (kg) | 61.20 |

| P (kg) | 23.62 |

| K (kg) | 7.30 |

| Fertilization (natural) | |

| N (kg) | 3.70 |

| P (kg) | 1.87 |

| K (kg) | 1.61 |

| Pesticide and herbicide chemicals | |

| Pesticide (kg) | 9.04 |

| Herbicides (kg) | 0.56 |

| Micronutrients | |

| Zinc sulfate (kg) | 0.88 |

| Sulfur (kg) | 0.35 |

| Humic acid (mL) | 659 |

| Irrigation requirements1 | |

| Rainwater (m3) | 1306 |

| Irrigation water (m3) | 3994 |

| Fuel for irrigation | |

| Diesel (L) | 29.67 |

| Electricity (kWh) | 43 |

| Component | Value |

|---|---|

| Inputs | |

| Cane (Mg) | 19.20 |

| Lime (kg) | 12.84 |

| Phosphoric acid (kg) | 0.76 |

| Caustic soda (kg) | 1.22 |

| Water (m3) 1 | 8.05 |

| Land (m2) 1 | 19.2 |

| Outputs | |

| Sugar (kg) | 1924 |

| Molasses (kg) | 864 |

| Bagasse (kg) | 2409 |

| Filter cake (kg) | 576 |

| Wastewater (m3) | 2.46 |

| Component | Value |

|---|---|

| Inputs | |

| Bagasse from own plant (Mg) 1 | 1.61 |

| Bagasse from outside plants (Mg) 2 | 0.80 |

| Fuel for transportation (L) 3 | 0.90 |

| Water (m3) | 4.86 |

| Land (m2) | 1.06 |

| NaOCl 4 | 0.07 |

| H2SO4 4 | 0.24 |

| HCl 4 | 0.24 |

| Outputs | |

| Exportable electricity (MWh) | 1 |

| Ash (kg) 5 | 48 |

| Emissions 6 | |

| N2O (kg) | 7.23 × 10−2 |

| CH4 (kg) | 5.42 × 10−1 |

| CO2 biogenic (kg) 7 | 1.70 × 103 |

| NOx (kg) | 1.30 |

| PM (kg) | 9.18 |

| PM10 (kg) | 1.49 |

| Polycyclic organic matter (kg) | 1.20 × 10−3 |

| Wastewater (m3) 8 | 1.27 |

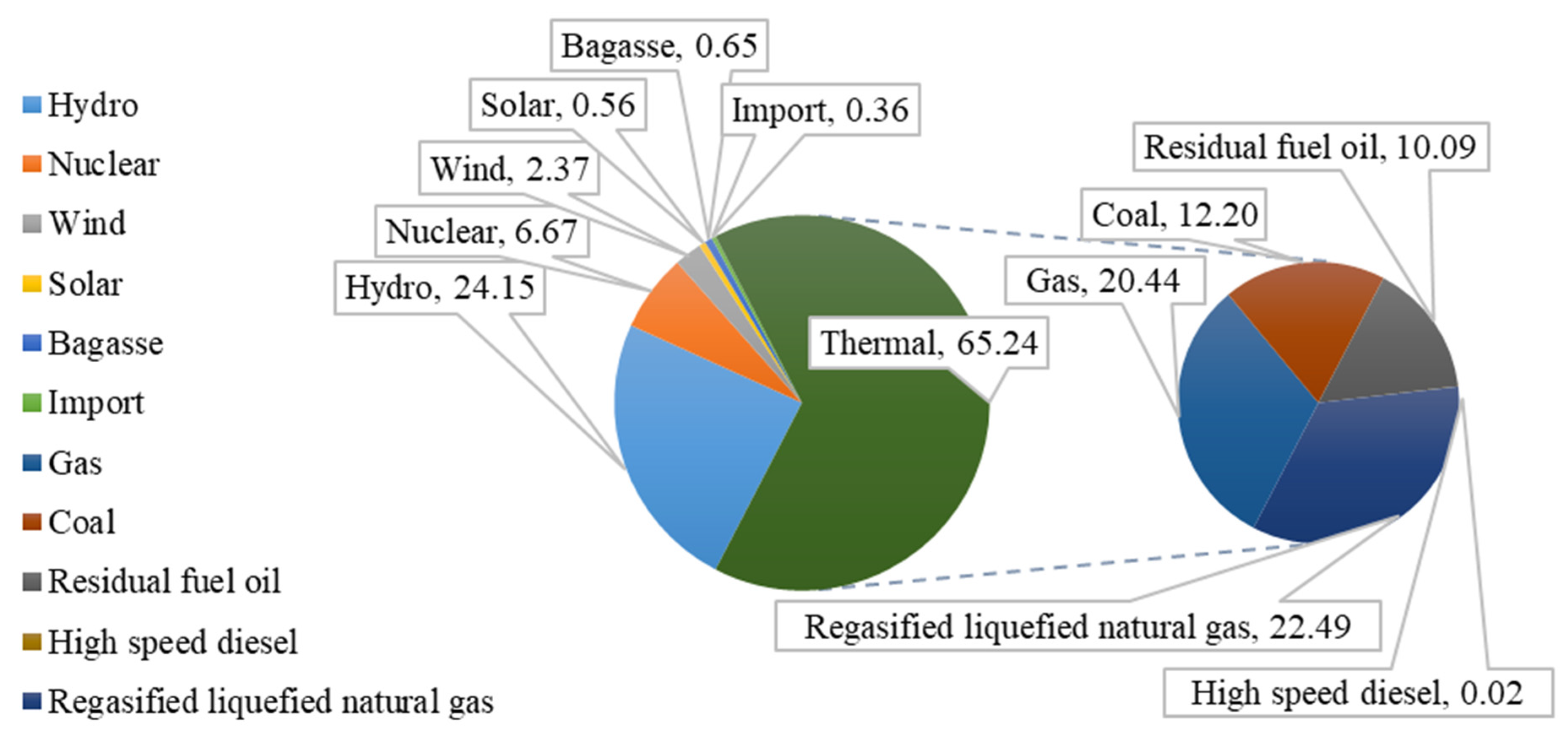

| Fuel Type | GWh | Share (%) |

|---|---|---|

| Gas | 28011 | 20.44 |

| Regasified liquefied natural gas (LNG) | 30813 | 22.49 |

| Residual Fuel Oil | 13826 | 10.09 |

| High Speed Diesel | 28 | 0.02 |

| Coal | 16725 | 12.20 |

| Hydro | 33096 | 24.15 |

| Nuclear | 9136 | 6.67 |

| Wind | 3252 | 2.37 |

| Solar | 771 | 0.56 |

| Bagasse | 894 | 0.65 |

| Import (Iran) | 487 | 0.36 |

| Total | 137039 | 100 |

| Component | Unit | Value | Source |

|---|---|---|---|

| GDP per capita in Europe (GDPEU) | USD | 25,920 | [38] |

| GDP per capita in Pakistan (GDPPak) | USD | 1357 | [39] |

| Price inflation (∆P) | % | 4.53 | [40] |

| Percentage of income change (∆I) | % | 5.53 | [41] |

| Impact Category | Unit | Bagasse-Based | Grid Mix |

|---|---|---|---|

| Global warming | kg CO2 eq | 174 | 573 |

| Fine particulate matter formation | kg PM2.5 eq | 8.23 × 10−1 | 1.64 |

| Terrestrial acidification | kg SO2 eq | 4.97 | 5.63 |

| Freshwater eutrophication | kg P eq | 1.08 × 10−2 | 2.51 × 10−4 |

| Marine eutrophication | kg N eq | 6.38 × 10−1 | 5.51 × 10−3 |

| Land use | m2a crop eq | 181 | 2.20 |

| Fossil resource scarcity | kg oil eq | 23 | 198 |

| Water consumption | m3 | 443 | 3.44 × 10−2 |

| Impact Category | Unit | Bagasse-Based | Grid Mix |

|---|---|---|---|

| Human health | DALY | 1.22 × 10−3 | 1.56 × 10−3 |

| Ecosystem quality | species.yr | 1.32 × 10−5 | 2.82 × 10−6 |

| Resource availability | USD2013 | 9.07 | 60.3 |

| Impact Category | Environmental Prices (USD 2015) | |

|---|---|---|

| Bagasse-Based | Grid Mix | |

| Global warming | 1.11 | 3.67 |

| Fine particulate matter formation | 3.65 | 7.29 |

| Terrestrial acidification | 4.21 | 4.76 |

| Freshwater eutrophication | 2.26 × 10−3 | 5.28 × 10−5 |

| Marine eutrophication | 2.24 × 10−1 | 1.94 × 10−3 |

| Land use | 2.58 | 3.14 × 10−2 |

| Fossil resource scarcity | 0 | 0 |

| Water consumption | 0 | 0 |

| Total | 11.78 | 15.75 |

| Environmental/ Economic Indicators | Pros and/or Cons | |

|---|---|---|

| Bagasse | Grid Mix | |

| Global warming | 70% less impact | The heavy dependence on fossil fuels is the main reason for higher GHG emissions |

| Fine particulate matter formation | 50% less impact | — |

| Terrestrial acidification | 12% less impact | — |

| Freshwater eutrophication | The application of phosphorus in the crop production phase resulted in a higher freshwater eutrophication | 98% less impact |

| Marine eutrophication | The application of nitrogen-based fertilizers in the crop production phase resulted in a higher marine eutrophication | 99% less impact |

| Land use | Land intensive nature of agricultural phase | 99% less impact |

| Fossil resource scarcity | 88% less impact | Being of fossil-based origin was the main reason for higher impact |

| Water consumption | Water intensive nature of agricultural phase | Comparatively negligible use of water |

| Human health | 85% less impact | — |

| Ecosystem quality | 22% less impact | — |

| Resource availability | — | 79% less impact |

| Environmental prices (USD 2015) | 25% less weighted environmental price | — |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghani, H.U.; Mahmood, A.; Ullah, A.; Gheewala, S.H. Life Cycle Environmental and Economic Performance Analysis of Bagasse-Based Electricity in Pakistan. Sustainability 2020, 12, 10594. https://doi.org/10.3390/su122410594

Ghani HU, Mahmood A, Ullah A, Gheewala SH. Life Cycle Environmental and Economic Performance Analysis of Bagasse-Based Electricity in Pakistan. Sustainability. 2020; 12(24):10594. https://doi.org/10.3390/su122410594

Chicago/Turabian StyleGhani, Hafiz Usman, Awais Mahmood, Asmat Ullah, and Shabbir H. Gheewala. 2020. "Life Cycle Environmental and Economic Performance Analysis of Bagasse-Based Electricity in Pakistan" Sustainability 12, no. 24: 10594. https://doi.org/10.3390/su122410594