Tolerance Management in Construction: A Conceptual Framework

Abstract

1. Introduction

2. Theoretical Background

2.1. Tolerances and Tolerance Management in Construction

2.2. Current Approaches for Tolerance Management in Construction

2.3. Review of Proposed Solutions to Improve Tolerance Management

3. Research Method

3.1. Rationale for Case Selection

3.2. Data Collection and Analysis

- One associate structural engineer (Interviewee A);

- three senior structural engineers (Interviewee B, Interviewee C, Interviewee D); and,

- one senior planner (Interviewee E).

- How do you identify tolerance requirements/ risks?

- How do you plan to achieve tolerance requirements and mitigate tolerance risks?

- How do you communicate tolerance information?

- How do you verify the compliance of achieved deviations with the specified tolerances?

4. Tolerance Management Process Practiced by the Consultancy Company

4.1. Sub-Theme 1: Identifying Dimensional and Geometric Tolerance Requirements

4.2. Sub-Theme 2: Selecting the Class of Tolerances

4.3. Sub-Themes 3 and 4: Identifying and Mitigating Tolerance Risks

4.4. Sub-Theme 5: Specifying Realistic Tolerance Values

4.5. Sub-Theme 6: Performing Serviceability Analysis

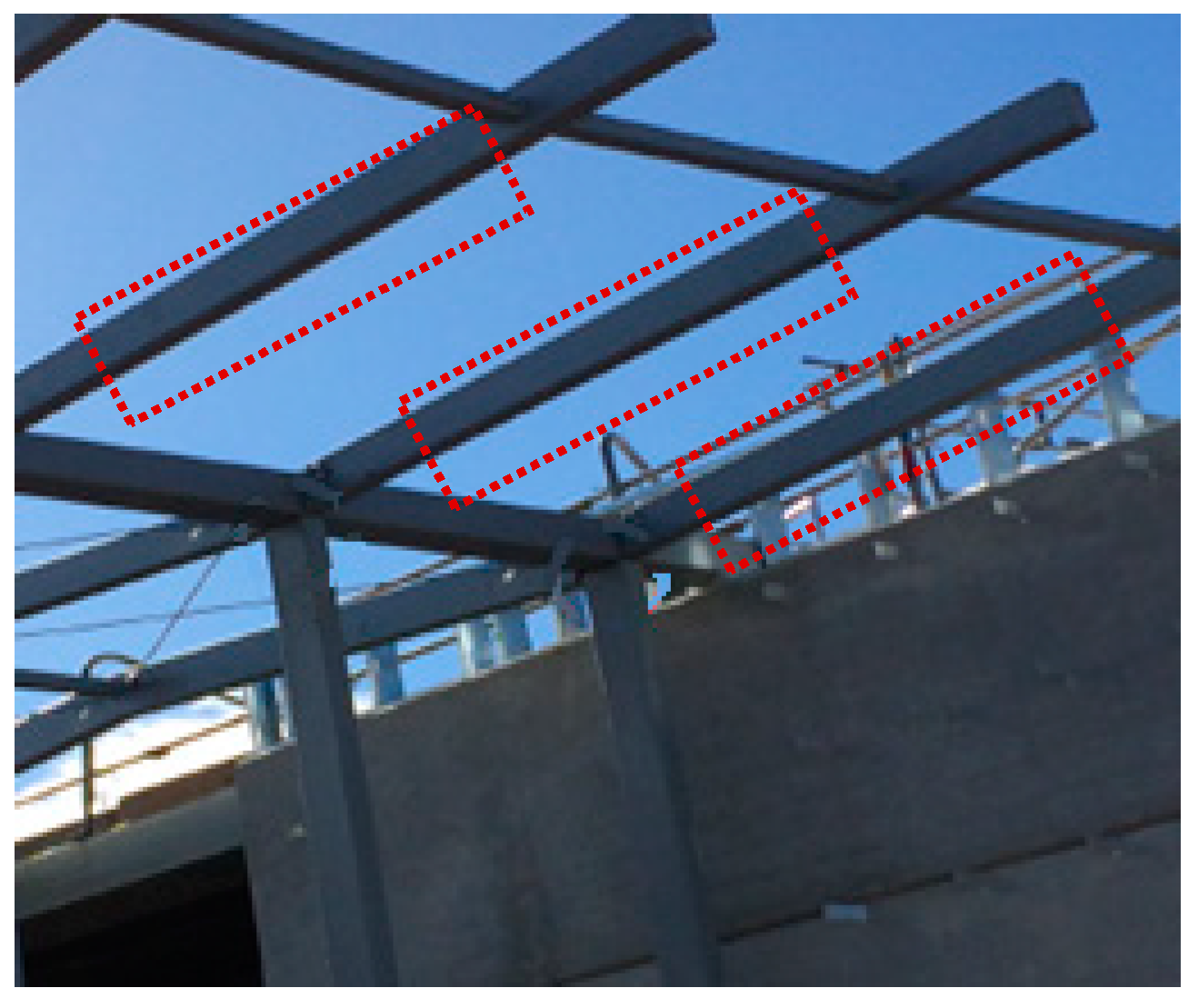

4.6. Sub-Theme 7: Planning the Assembly Process (load sequences)

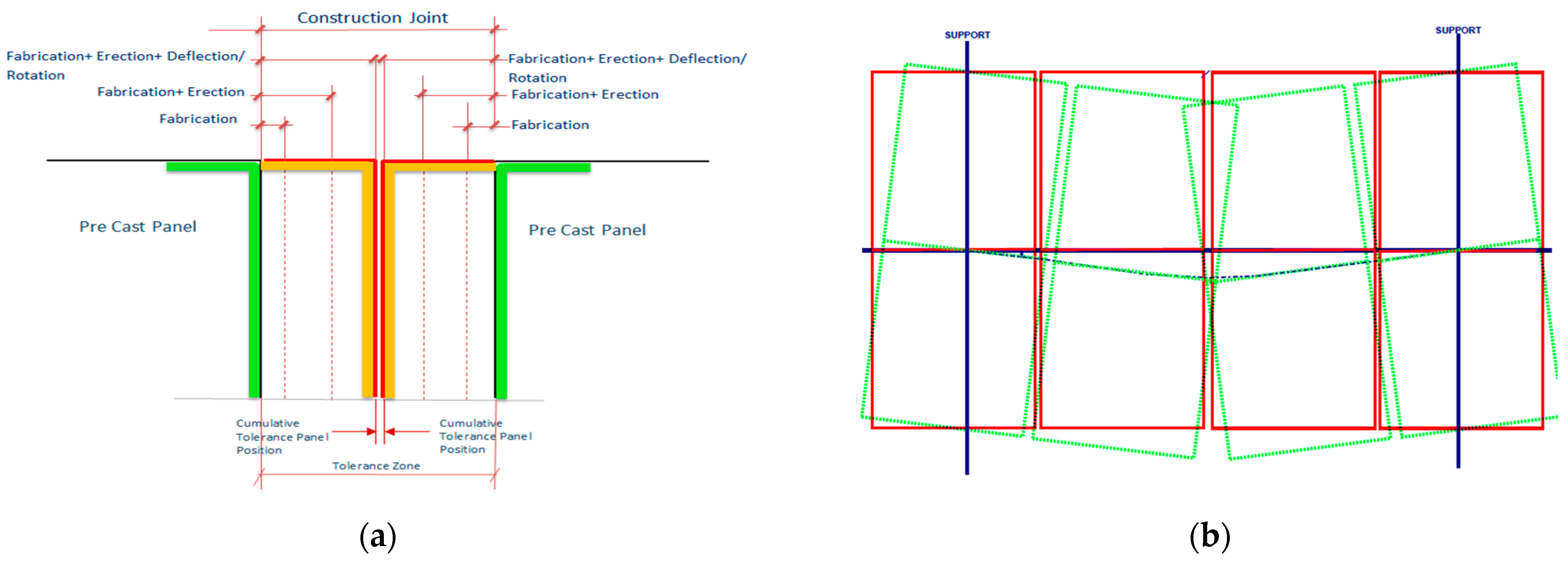

4.7. Sub-Theme 8: Performing Tolerance Analysis

4.8. Sub-Theme 9: Communicating Tolerance Information

4.9. Sub-Theme 10: Tolerance Compliance Control

5. Discussion

5.1. Existing Solutions And Explored Good Practice For Tolerance Management

5.2. Proposed Conceptual Framework to Improve Tolerance Management in Construction

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Forcada, N.; Macarulla, M.; Gangolells, M.; Casals, M. Handover defects: Comparison of construction and post-handover housing defects. Build. Res. Inf. 2016, 44, 279–288. [Google Scholar] [CrossRef]

- Landin, A. Demands on the tolerances when industrialising the construction sector. In New Perspective in Industrialisation in Construction: A State -Of-The-Art Report; Girmscheid, G., Scheublin, F., Eds.; International Council for Research and Innovation in Building and Construction: Zurich, Switzerland, 2010; pp. 197–205. [Google Scholar]

- Jingmond, M.; Ågren, R. Unravelling causes of defects in construction. Construct. Innovat. 2015, 15, 198–218. [Google Scholar] [CrossRef]

- Talebi, S. Improvement of Dimensional Tolerance Management in Construction. Ph.D. Thesis, University of Huddersfield, Huddersfield, UK, 2019. Available online: http://eprints.hud.ac.uk/id/eprint/35070/ (accessed on 30 January 2020).

- British Standards Institution. Tolerances for Building - Part 1: Basic Principles for Evaluation and Specification; BSI: London, UK, 1988. [Google Scholar]

- Berg, J.v.d.; Holicky, M. CIB W49 Tolerances and FIG Commission 6 Engineering Surveys; CIB publication: Amsterdam, The Netherlands, 1989; ISBN 2800525069. [Google Scholar]

- British Standards Institution. Guide to Accuracy in Building; BSI: London, UK, 1990. [Google Scholar]

- American Concrete Institute. Specification for Tolerances for Concrete Construction and Materials; ACI: Farmington Hills, MI, USA, 2010. [Google Scholar]

- CIM Steel. Design for Construction; The Steel Construction Institute: Berkshire, UK, 1997; ISBN 1859420486. [Google Scholar]

- Fischer, M.; Khanzode, A.; Reed, D.; Ashcraft, H.W. Integrating Project Delivery; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017; ISBN 0470587350. [Google Scholar]

- Davison, B.; Owens, G.W. Steel Designers’ Manual, 6th ed.; Blackwell Science, Ltd.: Chennai, India, 2012; ISBN 9781405189408. [Google Scholar]

- Milberg, C.; Tommelein, I. Role of tolerances and process capability data in product and process design integration. In Proceedings of the Construction Research Congress, Honolulu, HI, USA, 19–21 March 2003. [Google Scholar]

- Gibb, A.G. Off-Site Fabrication: Prefabrication, Pre-Assembly and Modularisation; Whittles Publishing: Scotland, UK, 1999; ISBN 0470378360. [Google Scholar]

- Popescu, C.-R. The Role of Total quality management in developing the concept of social Responsibility to protect public interest in associations of liberal professions. Amfiteatru Economic 2017, 19, 1091–1106. [Google Scholar]

- American Concrete Institute. Guide for Tolerance Compatibility in Concrete Construction (ACI 117.1R-14); ACI: Farmington Hills, MI, USA, 2014. [Google Scholar]

- Milberg, C.; Tommelein, I.D. Tolerance and constructability of soldier piles in slurry walls. J. Perform. Constr. Fac. 2009, 24, 120–127. [Google Scholar] [CrossRef]

- Vorlíček, M.; Holický, M. Analysis of Dimensional Accuracy of Building Structures; Elsevier: Amsterdam, The Netherlands, 1989; ISBN 0444988750. [Google Scholar]

- Ballast, D.K. Handbook of Construction Tolerances, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; ISBN 9781118260227. [Google Scholar]

- Koskela, L. An Exploration towards a Production Theory and Its Application to Construction. Ph.D. Thesis, Technical Research Centre of Finland, Espoo, Finland, 2000. Available online: http://lib.tkk.fi/Diss/2000/isbn951385566X/ (accessed on 28 January 2020).

- Milberg, C. Application of Tolerance Management to Civil Systems. Ph.D. Thesis, 2006. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.308.5119&rep=rep1&type=pdf (accessed on 30 January 2020).

- Alexander, S. Design for Movement in Buildings, 2nd ed.; Construction Industry Research and Information Association: London, UK, 2014; ISBN 9780128104330. [Google Scholar]

- Bradford, C.W. The Impact of the Systematic Incorporation of Tolerances on Gypsum board Installation. Ph.D. Thesis, Indiana State University, Terre Haute, IN, USA, 2017. Available online: https://search.proquest.com/openview/8235437a5504cb84e4d1f5604d3f0f81/1?cbl=18750&diss=y&pq-origsite=gscholar (accessed on 30 January 2020).

- Valdes, F.J. Manufacturing Compliance Analysis for Architectural Design: A Knowledge-Aided Feature-Based Modeling Framework. Ph.D. Thesis, Georgia Tech, 2016. Available online: http://hdl.handle.net/1853/54973 (accessed on 30 January 2020).

- Talebi, S.; Koskela, L.; Shelbourn, M.; Tzortzopoulos, P. Critical review of tolerance management in construction. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 20–22 July 2016. [Google Scholar]

- Seymour, D.; Shammas-Toma, M.; Clark, L. Limitations of the use of tolerances for communicating design requirements to site. Eng. Construct. Architect. Manag. 1997, 4, 3–22. [Google Scholar] [CrossRef]

- McCarney, M.P. Interface Management of Offsite Bathroom Construction: Process-and People-Factors. Ph.D. Thesis, Loughborough University, Loughborough, UK, 2017. Available online: https://repository.lboro.ac.uk/articles/Interface_management_of_offsite_bathroom_construction_process-_and_people-factors/9455024 (accessed on 30 January 2020).

- Enshassi, M.S.; Walbridge, S.; West, J.S.; Haas, C.T. Integrated risk management framework for tolerance-based mitigation strategy decision support in modular construction projects. J. Manag. Eng. 2019, 35, 05019004. [Google Scholar] [CrossRef]

- Liker, J.K. The Toyota Way: 14 Management Principles from the world’s Greatest Manufacturer; McGraw-Hill: New York, NY, USA, 2004; ISBN 9797813770. [Google Scholar]

- Imai, M. Gemba Kaizen: A Common Sense Approach to a Continuous Improvement Strategy, 2nd ed.; McGraw Hill: New York, NY, USA, 2012; ISBN 0071790357. [Google Scholar]

- Koskela, L. Why is management research irrelevant? Manag. Econ. 2017, 35, 4–23. [Google Scholar] [CrossRef]

- Arayici, Y.; Coates, P.; Koskela, L.; Kagioglou, M.; Usher, C.; O’reilly, K. Technology adoption in the BIM implementation for lean architectural practice. Autom. Construct. 2011, 20, 189–195. [Google Scholar] [CrossRef]

- Checkland, P. OR and the systems movement: Mappings and conflicts. J. Oper. Res. Soc. 1983, 34, 661–675. [Google Scholar] [CrossRef]

- Kanigel, R. The One Best Way: Frederick Winslow Taylor and the Enigma of Efficiency; Penguin Group: New York, NY, USA, 2005; ISBN 9780262612067. [Google Scholar]

- Slowinski, G.; Sagal, M.W. Good practices in open innovation. Res. Tech. Manag. 2010, 53, 38–45. [Google Scholar] [CrossRef]

- Construction Industry Institute. CII Best Practices Guide: Improving Project Performance; CII: Austin, TX, USA, 2012. [Google Scholar]

- Henzold, G. Geometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME Standards, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2006; ISBN 0750667389. [Google Scholar]

- Creveling, C.M. Tolerance Design: A Handbook for Developing Optimal Specifications; Prentice Hall: Needham Heights, MA, USA, 1997; ISBN 0201634732. [Google Scholar]

- Shahtaheri, Y.; Rausch, C.; West, J.; Haas, C.; Nahangi, M. Managing risk in modular construction using dimensional and geometric tolerance strategies. Autom. Construct. 2017, 83. [Google Scholar] [CrossRef]

- Alshawi, M.; Underwood, J. Improving the constructability of design solutions through an integrated system. Eng. Construct. Architect. Manag. 1996, 3, 47–67. [Google Scholar] [CrossRef]

- Rausch, C.; Nahangi, M.; Haas, C.; West, J. Kinematics chain based dimensional variation analysis of construction assemblies using building information models and 3D point clouds. Autom. Construct. 2017, 75, 33–44. [Google Scholar] [CrossRef]

- Construction Industry Institute. Constructability Implementation Guide (Best Practice); University of Texas: Austin, TX, USA, 1993. [Google Scholar]

- Landin, A.; Kämpe, P. Industrializing the construction sector through innovation–tolerance dilemma. In Proceedings of the CIB World Congress, Cape Town, South Africa, 14–17 May 2007. [Google Scholar]

- Forsythe, P. Consumer-perceived appearance tolerances in construction quality management. Eng. Construct. Architect. Manag. 2006, 13, 307–318. [Google Scholar] [CrossRef]

- Popescu, G.; Raluca, C.; Banța, V.C. Performance evaluation of the implementation of the 2013/34/EU directive in Romania on the basis of corporate social responsibility reports. Sustainability 2019, 11, 2531. [Google Scholar] [CrossRef]

- Popescu, C.R.G.; Popescu, G.N. An exploratory study based on a questionnaire concerning green and sustainable finance, corporate social responsibility, and performance: Evidence from the Romanian business environment. J. Risk Financ. Manag. 2019, 12, 162. [Google Scholar] [CrossRef]

- Popescu, C.R.G. Corporate social responsibility, corporate governance and business performance: Limits and challenges imposed by the implementation of directive 2013/34/EU in Romania. Sustainability 2019, 11, 5146. [Google Scholar] [CrossRef]

- British Standards Institution. Execution of Steel Structures and Aluminium Structures: Technical Requirements for Steel Structures; BSI: London, UK, 2011. [Google Scholar]

- American Institute of Steel Construction. Code of Standard Practice for Steel Buildings and Bridges; AISC: Chicago, IL, USA, 2010. [Google Scholar]

- Price, C.; Goodier, C.I.; Fouchal, F.; Fraser, N. The Role of Standards in Offsite Construction: A Review of Existing Practice and Future Need; British Standards Institute: London, UK, 2019. [Google Scholar]

- American Concrete Institute. Commentary on Standard Specifications for Tolerances for Concrete Construction and Materials; ACI: Farmington Hills, MI, USA, 2002. [Google Scholar]

- Krogstie, L. Closed Loop Tolerance Engineering: An Approach for Designing Robust Products and Processes. Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2015. Available online: https://ntnuopen.ntnu.no/ntnu-xmlui/handle/11250/282441 (accessed on 30 January 2020).

- Frank, G.C. Construction Quality: Do It Right or Pay the Price; Pearson Higher Education, Inc.: Upper Saddle River, NJ, USA, 2012; ISBN 0133002837. [Google Scholar]

- Smith, R.E. Prefab Architecture: A Guide to Modular Design and Construction; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; ISBN 0470275618. [Google Scholar]

- Talebi, S.; Koskela, L.; Tzortzopoulos, P. Tolerance compliance measurement using laser scanner. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction, Chennai, India, 18–20 July 2018. [Google Scholar]

- Bosché, F.; Guenet, E. Automating surface flatness control using terrestrial laser scanning and building information models. Autom. Construct. 2014, 44, 212–226. [Google Scholar] [CrossRef]

- Graham, J.R.; Lindholm, E.A. Concrete tolerances: Importance and achievement in Bureau of Reclamation Construction. J. Am. Concr. Inst. 1978, 75, 49–54. [Google Scholar]

- The Construction Industry Research and Information Association. A Suggested Design Procedure for Accuracy in Building; CIRIA: London, UK, 1983; ISBN 086017 199 X. [Google Scholar]

- International Organisation for Standardization. Quality Management Systems: Requirements (BS EN ISO 9001:2015); ISO: London, UK, 2015. [Google Scholar]

- Prestressed Concrete Institute. PCI Design Handbook: Precast and Prestressed Concrete, 6th ed.; Martin, L.D., Perry, C.J., Eds.; PCI: Chicago, IL, USA, 2004; ISBN 9780937040232. [Google Scholar]

- Rausch, C.; Nahangi, M.; Haas, C.; Liang, W. Monte Carlo simulation for tolerance analysis in prefabrication and offsite construction. Autom. Construct. 2019, 103, 300–314. [Google Scholar] [CrossRef]

- Abuhav, I. ISO 9001: 2015-A Complete Guide to Quality Management Systems; CRC Press: London, UK, 2017; ISBN 131536980X. [Google Scholar]

- A checklist on tolerances. Build. Res. Inf. 1974, 2, 144–146. [CrossRef]

- Silva, P. Movement and tolerances. In ICE Manual of Structural Design: Buildings; Bull, J.W., Ed.; Thomas Telford: London, UK, 2012; Volume 18, pp. 267–292. [Google Scholar]

- Curtis, M.A. Dimensional Management: A Comprehensive Introduction; Industrial Press, Inc.: New York, NY, USA, 2002; ISBN 9780831130732. [Google Scholar]

- Kagioglou, M.; Cooper, R.; Aouad, G.; Sexton, M. Rethinking construction: The generic design and construction process protocol. Eng. Construct. Architect. Manag. 2000, 7, 141–153. [Google Scholar] [CrossRef]

- Feng, C.; Xiao, Y.; Willette, A.; McGee, W.; Kamat, V.R. Vision guided autonomous robotic assembly and as-built scanning on unstructured construction sites. Autom. Construct. 2015, 59, 128–138. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine That Changed the World; Rawson Associates: New York, NY, USA, 1990; ISBN 0892563508. [Google Scholar]

- Meiling, J.H.; Sandberg, M.; Johnsson, H. A study of a plan-do-check-act method used in less industrialized activities: Two cases from industrialized housebuilding. Construct. Manag. Econ. 2014, 32, 109–125. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods, 4th ed.; SAGE Publications: Thousand Oaks, CA, USA, 2013; ISBN 978-1-4129-6099-1. [Google Scholar]

- Arbnor, I.; Bjerke, B. Methodology for Creating Business Knowledge, 3rd ed.; SAGE Publications: London, UK, 2008; ISBN 1446202526. [Google Scholar]

- Flyvbjerg, B. Five misunderstandings about case-study research. Qual. Inq. 2006, 12, 219–245. [Google Scholar] [CrossRef]

- Eisenhardt, K.M. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Taylor, S.J.; Bogdan, R.; DeVault, M. Introduction to Qualitative Research Methods: A Guidebook and Resource; John Wiley & Sons: Hoboken, NJ, USA, 2015; ISBN 1118767217. [Google Scholar]

- Blumberg, B.; Cooper, D.R.; Schindler, P.S. Business Research Methods; McGraw-Hill Higher Education: London, UK, 2008; Volume 2, ISBN 9788776814212. [Google Scholar]

- Miles, M.B.; Huberman, A.M. Qualitative data analysis: An expanded sourcebook. Serv. Ind. J. 1995, 15, 366. [Google Scholar]

- Saunders, M.; Lewis, P.; Thornhill, A. Research Methods for Business Students, 7th ed.; Pearson Education: Harlow, UK, 2016; ISBN 9780273716860. [Google Scholar]

- Boddy, C.R. Sample size for qualitative research. Qual. Mark. Res. Int. J. 2016, 19, 426–432. [Google Scholar] [CrossRef]

- Brinkmann, S. Qualitative Interviewing: Understanding Qualitative Research; Oxford University Press: New York, NY, USA, 2013; ISBN 0199861390. [Google Scholar]

- Braun, V.; Clarke, V. Using thematic analysis in psychology. Qual. Res. Psychol. 2006, 3, 77–101. [Google Scholar] [CrossRef]

- Ghauri, P.N.; Grønhaug, K. Research Methods in Business Studies: A Practical Guide; Pearson Education: London, UK, 2005; ISBN 0273681567. [Google Scholar]

- Bryman, A. Social Research Methods, 4th ed.; Oxford University Press: Oxford, UK, 2016; ISBN 0199689458. [Google Scholar]

- British Standards Institution. Execution of Concrete Structures; BSI: London, UK, 2009. [Google Scholar]

- Construct Structures Group. National structural concrete specification for building construction. In NSCS; The Concrete Centre: Surrey, UK, 2010. [Google Scholar]

- British Standards Institution. Tolerances for Building: Recommendations for Statistical Basis for Predicting Fit between Components Having a Normal Distribution of Sizes; BSI: London, UK, 1998. [Google Scholar]

- Singh, P.; Jain, P.; Jain, S. Important issues in tolerance design of mechanical assemblies. Part 1: Tolerance analysis. Proc. IME B J. Eng. Manufact. 2009, 223, 1225–1247. [Google Scholar] [CrossRef]

- Krogstie, L.; Walter, M.S.; Wartzack, S.; Martinsen, K. Towards a more comprehensive understanding of tolerance engineering research importance. Procedia CIRP 2015, 27, 29–34. [Google Scholar] [CrossRef]

- Hong, Y.; Chang, T. A comprehensive review of tolerancing research. J. Prod. Res. Manag. 2002, 40, 2425–2459. [Google Scholar] [CrossRef]

- Milberg, C.T.; Tommelein, I.D. Methods for managing tolerance compatibility: Windows in cast-in-place concrete. J. Construct. Eng. Manag. 2019, 146, 04019105. [Google Scholar] [CrossRef]

- Anderson, A.R. Construction tolerances for concrete in highway structures. J. Am. Concr. Inst. 1965, 13–18. Available online: https://www.semanticscholar.org/paper/CONSTRUCTION-TOLERANCES-FOR-CONCRETE-IN-HIGHWAY-Anderson/483ce020cbb434a0c1247653fff7753557ec27dc (accessed on 24 April 2019).

- Savoini, J.-J.; Lafhaj, Z. Considering functional dimensioning in architectural design. Front. Architect. Res. 2017, 6, 89–95. [Google Scholar] [CrossRef]

- Da Rocha, C.; Tezel, A.; Talebi, S.; Koskela, L. Product modularity, tolerance management, and visual management: Potential synergies. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction, Chennai, India, 18–20 July 2018. [Google Scholar]

- Costadoat, R.; Mathieu, L.; Falgarone, H.; Fricero, B. Geometric specification at the beginning of the product lifecycle. In Product Life-Cycle Management: Geometric Variations; Giordano, M., Mathieu, L., Villeneuve, F., Eds.; John Wiley & Sons, Inc.: London, UK, 2012; pp. 433–454. [Google Scholar]

- Sacks, R.; Eastman, C.; Lee, G.; Teicholz, P. BIM Handbook: A Guide to Building Information Modeling for Owners, Designers, Engineers, Contractors, and Facility Managers; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2018; ISBN 1119287545. [Google Scholar]

- British Standards Institution. Design of Joints and Jointing in Building Construction: Guide; British Standards Institution: London, UK, 2013. [Google Scholar]

- Ballast, D.K. Architect’s Handbook of Construction Detailing; John Wiley & Sons: Hoboken, NJ, USA, 2009; ISBN 0470381914. [Google Scholar]

- Royal Institute of British Architectures. RIBA Plan of Work Overview. Available online: https://www.architecture.com/-/media/gathercontent/riba-plan-of-work/additional-documents/ribaplanofwork2013overviewfinalpdf.pdf (accessed on 24 April 2019).

- Krulikowski, A. Fundamentals of Geometric Dimensioning and Tolerancing, 3rd ed.; Cengage Learning: New York, NY, USA, 2012; ISBN 1285401972. [Google Scholar]

| C: Conventional Constructiono: Off-Site Constructionp: Processr: Scattered Recommendations | [62] | [57] | [5] | [17] | [7] | [59] | [20] | [18] | [63] | [15] | [58] | [40] | [38] | [60] | [27] | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | C | C | C | C | C,O | C,O | C,O | C,O | C,O | O | C,O | O | O | |||

| R | P | R | R | P | R | P | R | R | P | R | P | P | P | P | ||

| Identification | Tolerance requirements should be captured at early project stages. | • | • | • | • | • | ||||||||||

| Class of tolerances applied to tolerance requirements should be selected to ensure stability and serviceability. | • | • | • | |||||||||||||

| Connections with a high risk of tolerance problems should be identified at early project stages. | • | • | • | • | ||||||||||||

| Tolerance risks with negative effects on dimensional and geometric accuracy of components and assembles and their functions should be proactively identified. | • | • | • | • | • | • | ||||||||||

| Severity of tolerance risk should be estimated using qualitative, quantitative, or semi-quantitative approaches. | • | • | • | |||||||||||||

| Planning | Appropriate solutions to mitigate tolerance risks, especially tolerance risks with high severity, should be generated based on site conditions, labour availability/skills, schedule constraints, incurred costs, etc. | • | • | • | • | • | • | • | • | • | ||||||

| Tolerance values should be collected from appropriate reference documents, manufacturers, designers, and contractors. | • | • | • | |||||||||||||

| Realistic tolerance values should be specified based on the capability of manufacturing and construction teams to obtain a certain level of accuracy, consequences of tolerance risks, cost of manufacturing and construction. | • | • | • | • | • | • | • | • | • | |||||||

| Tolerance analysis should be performed. | • | • | • | • | • | • | ||||||||||

| The impact of combined deviations on components and sub-assemblies should be evaluated (serviceability analysis). | • | • | • | • | ||||||||||||

| The sequence of assembly process and its impact on the geometric accuracy of components and sub-assemblies should be determined. | • | • | • | |||||||||||||

| The compatibility of the specified tolerances of adjoining components in sub-assemblies should be checked (tolerance coordination). | • | • | ||||||||||||||

| The measurement plan which includes information such as the accuracy of the survey process, the responsible to verify deviations of components with the specified tolerances, and the list of specified tolerances should be prepared and communicated with parties. | • | • | • | |||||||||||||

| Communication | Tolerance information (e.g., permitted deviations, used reference documents, prepared measurement plan) should be communicated clearly between designers and construction teams via specifications and drawings. | • | • | • | • | • | • | • | • | • | • | |||||

| Control | Deviations achieved on site should be measured and their impact on the functional requirements should be assessed. | • | • | • | • | • | • | • | ||||||||

| Project | Type of Project | Development Stage | Accessed documents |

|---|---|---|---|

| Project A | A two-storey office development | Construction | Two Site-Visit ReportsOne Tolerance and Deflections report |

| Project B | Two sixty-storey student residential buildings | Design | One Tolerance and Deflections report |

| Project | AHTR | Tolerance Risk | Reason | Mitigation Strategy |

|---|---|---|---|---|

| A | 1st | Aesthetically unacceptable gaps between internal partitions and slabs | Excessive deflection (geometric changes) of slabs with large spans which may make internal walls misaligned and not level | Changing the configuration of columns |

| A | 2nd | Reduced internal area of offices | Components such as walls are not positioned as they were designed | Setting out very accurately |

| B | 3rd | Physical clash of cladding panels due to the reduced clearance | Excessive vertical deflection of the structure which may make panels not level and misaligned | Increasing clearance |

| B | 3rd | Reduced floor to floor height and lack of fit of curtain walls | Excessive deflection of floors | Embedding adjustable connections in the curtain walls |

| Content | Description |

|---|---|

| Tolerance-related concepts | Tolerance-related concepts (e.g., induced and inherent deviations, class of tolerances, tolerance analysis) are briefly explained. |

| Permitted deviations | A list of tolerance values for sources of variations, applied to structural components, is provided. |

| Class of tolerances | The selected class of tolerances for the listed tolerance requirements is delineated. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Talebi, S.; Koskela, L.; Tzortzopoulos, P.; Kagioglou, M. Tolerance Management in Construction: A Conceptual Framework. Sustainability 2020, 12, 1039. https://doi.org/10.3390/su12031039

Talebi S, Koskela L, Tzortzopoulos P, Kagioglou M. Tolerance Management in Construction: A Conceptual Framework. Sustainability. 2020; 12(3):1039. https://doi.org/10.3390/su12031039

Chicago/Turabian StyleTalebi, Saeed, Lauri Koskela, Patricia Tzortzopoulos, and Michail Kagioglou. 2020. "Tolerance Management in Construction: A Conceptual Framework" Sustainability 12, no. 3: 1039. https://doi.org/10.3390/su12031039

APA StyleTalebi, S., Koskela, L., Tzortzopoulos, P., & Kagioglou, M. (2020). Tolerance Management in Construction: A Conceptual Framework. Sustainability, 12(3), 1039. https://doi.org/10.3390/su12031039