The Rape Pomace and Microcrystalline Cellulose Composites Made by Press Processing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

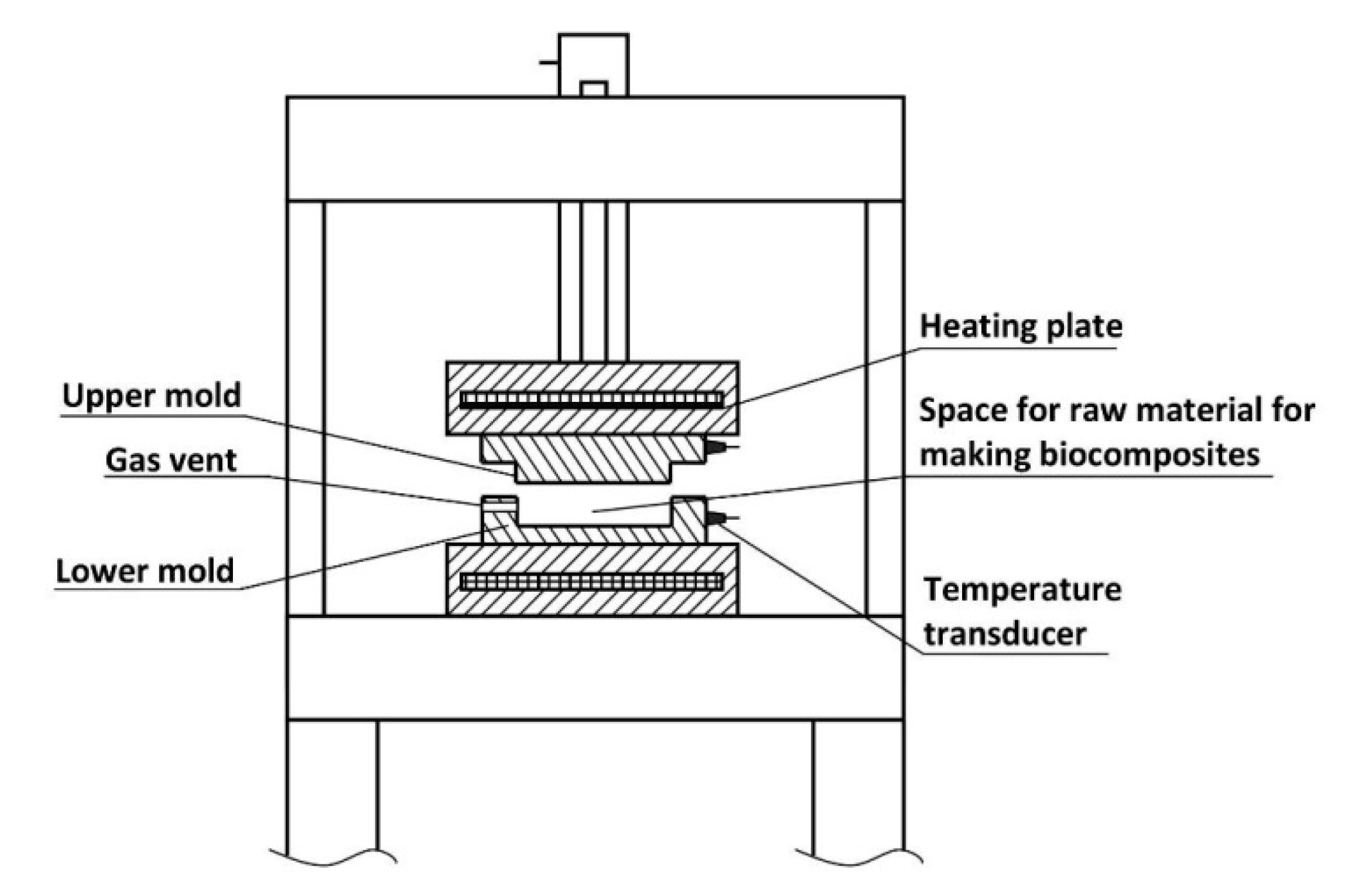

2.2. Biocomposite Production

2.3. Mechanical Properties

2.4. Color Analysis

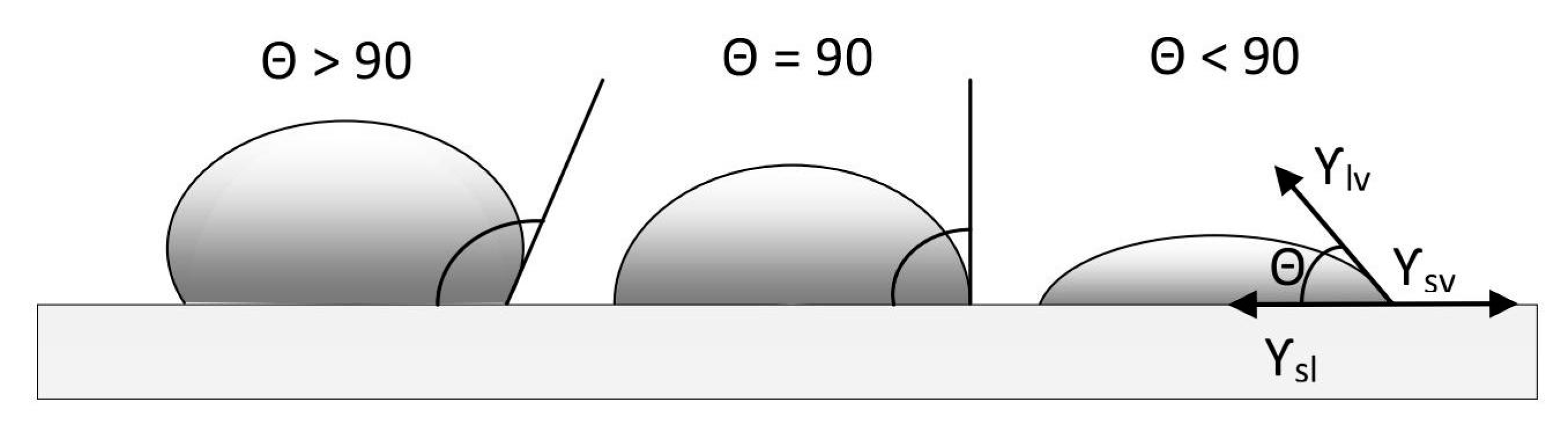

2.5. Water Contact Angle

2.6. SEM Microscopic Analysis

2.7. TGA and DTA

2.8. The Infrared Spectrum Analysis FTIR

2.9. Statistical Analysis

3. Results and Discussion

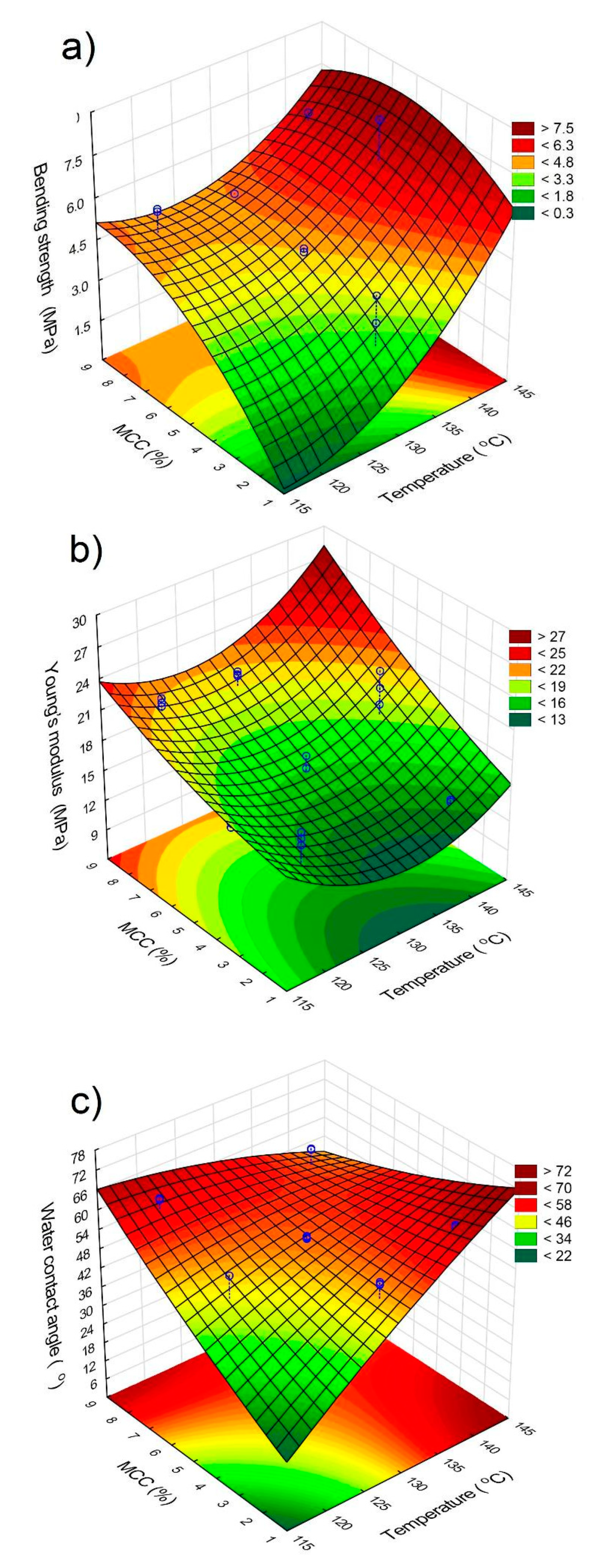

3.1. Bending Strength and Young’s Modulus

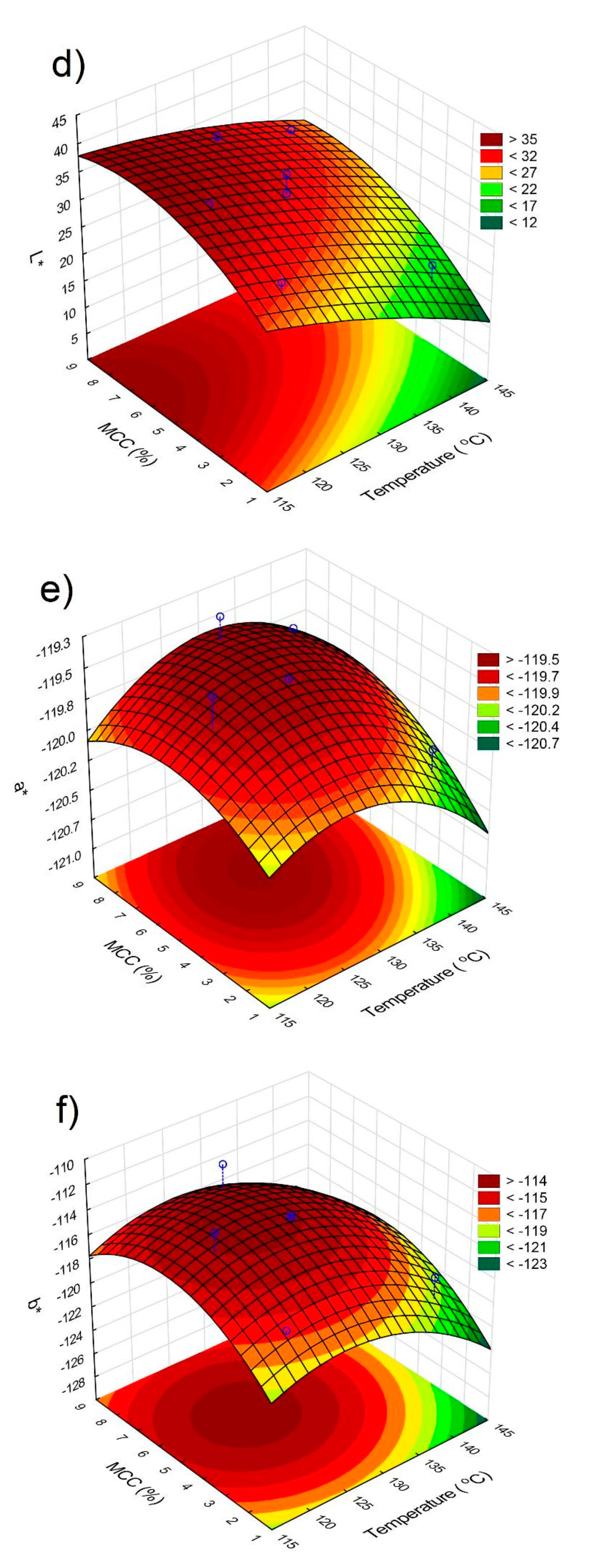

3.2. Sample Surface Color Changes

3.3. Water Contact Angle

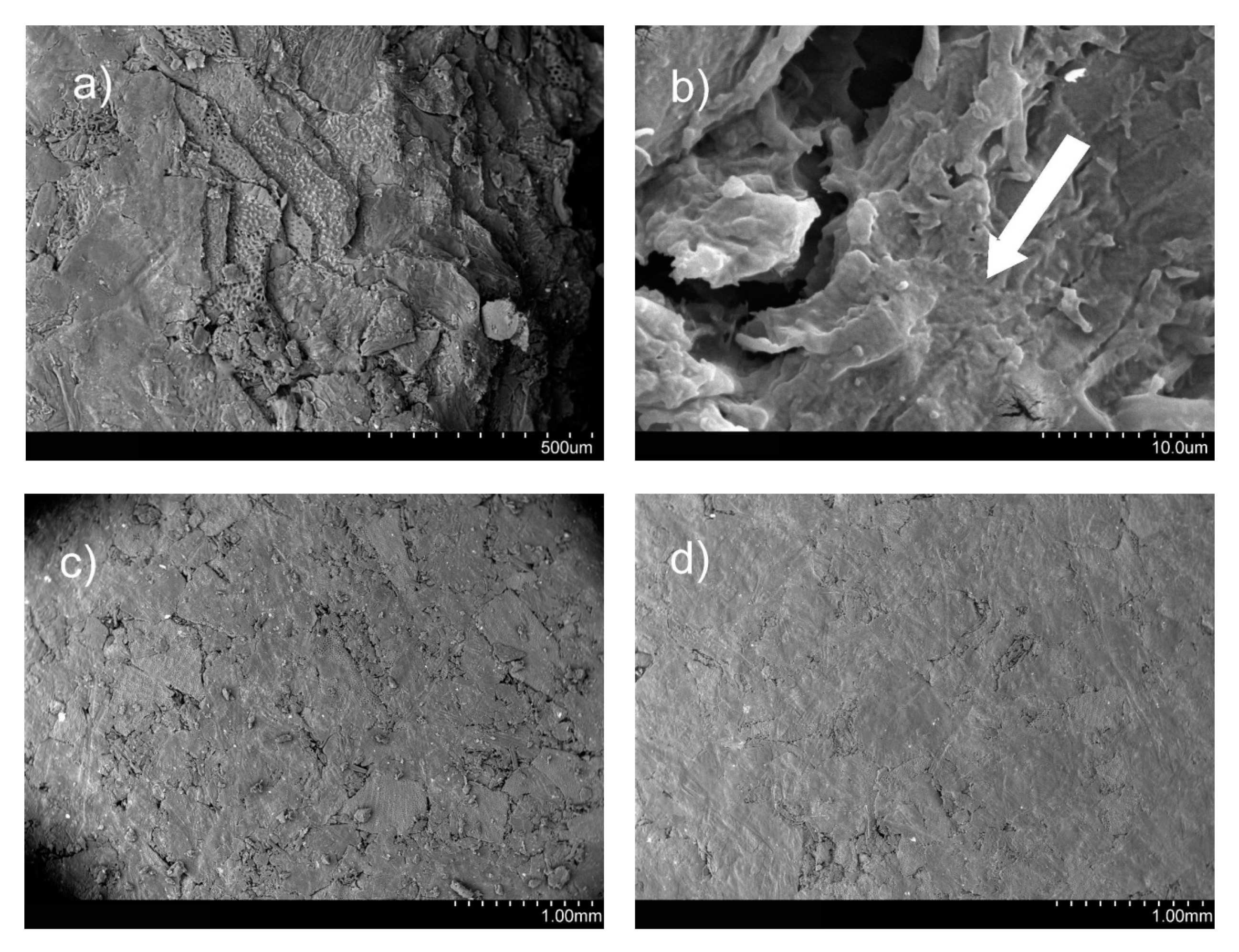

3.4. SEM Analysis

3.5. TGA and DTA Analysis

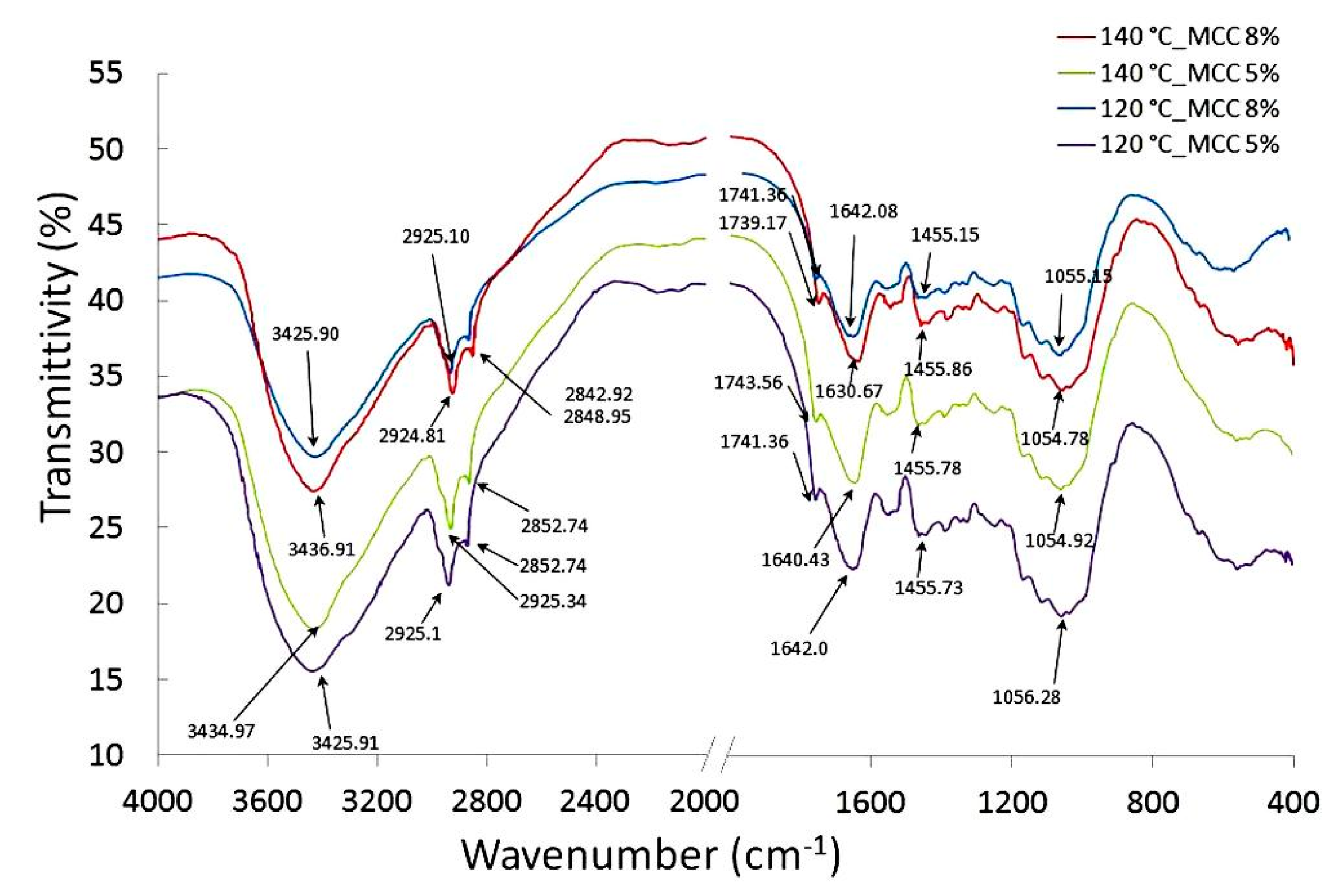

3.6. The Infrared Spectrum Analysis FTIR

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zelazinski, T.; Ekielski, A.; Tulska, E.; Vladut, V.; Durczak, K. Wood dust application for improvment of selected properties of thermoplastic starch. Inmateh. Agric. Eng. 2019, 58, 37–44. [Google Scholar]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Jiang, S.J.; Zhang, T.; Song, Y.; Qian, F.; Tuo, Y.; Mu, G. Mechanical properties of whey protein concentrate based film improved by the coexistence of nanocrystalline cellulose and transglutaminase. Int. J. Biol. Macromol. 2019, 126, 1266–1272. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.T.; Netravali, A.N. Mechanical, thermal, and interfacial properties of green composites with ramie fiber and soy resins. J. Agric. Food Chem. 2010, 58, 5400–5407. [Google Scholar] [CrossRef] [PubMed]

- Prochoń, M.; Ntumba, Y.H.T. Effects of Biopolymer Keratin Waste Sources in XNBR Compounds. Rubber Chem. Technol. 2015, 88, 258–275. [Google Scholar] [CrossRef]

- Janowska, G.; Kucharska-Jastrząbek, A.; Rybiński, P. Thermal stability, flammability and fire hazard of butadiene-acrylonitrile rubber nanocomposites. J. Therm. Anal. Calorim. 2011, 103, 1039–1046. [Google Scholar] [CrossRef] [Green Version]

- Ghanbarzadeh, B.; Oleyaei, S.A.; Almasi, H. Nanostructured materials utilizedin biopolymer-based plastics for food packaging applications. Crit. Rev. Food Sci. Nutr. 2015, 55, 1699–1723. [Google Scholar] [CrossRef]

- Kim, J.R.; Netravali, A.N. Self-healing green composites based on soy protein and microfibrillated cellulose. Compos. Sci. Technol. 2017, 143, 22–30. [Google Scholar] [CrossRef] [Green Version]

- Prochoń, M.; Janowska, G.; Przepiórkowska, A.; Kucharska-Jastrząbek, A. Thermal stability and flammability of biodecomposable elastomer materials (Stabilność termiczna i palność biorozkładalnych materiałów elastomerowych). Polimery 2013, 58, 413–420. [Google Scholar] [CrossRef]

- Andrea, C.; Cibulkova, Z.; Lehocky, P. Stabilization effect of potential antioxidants on the thermooxidative stability of styrene-butadiene rubber. J. Therm. Anal. Calorim. 2011, 105, 607–613. [Google Scholar]

- Fahmy, Y.; El-Wakil, N.A.; El-Gendy, A.A.; Abou-Zeid, R.E.; Youssef, M.A. Plant proteins as binders in cellulosic paper composites. Int. J. Biol. Macromol. 2010, 47, 82–85. [Google Scholar] [CrossRef] [PubMed]

- Wolf, W.J. Soybean proteins: Their functional, chemical, and physical properties. J. Agric. Food Chem. 1970, 18, 969–976. [Google Scholar] [CrossRef]

- Kinsella, J.E. Functional properties of soy proteins for food applications. J. Am. Oil Chem. Soc. 1979, 56, 242–258. [Google Scholar] [CrossRef]

- Nir, I.Y.; Feldman, Y.; Aserin, A.; Garti, N. Surface properties and emulsification behavior of denatured soy proteins. J. Food Sci. 1994, 59, 606. [Google Scholar] [CrossRef]

- Trache, D.; Donnot, A.; Khimeche, K.; Benelmir, R.; Brosse, N. Physico-chemicalproperties and thermal stability of microcrystalline cellulose isolated fromAlfa fibres. Carbohydr. Polym. 2014, 104, 223–230. [Google Scholar] [CrossRef]

- Yang, S.; Tang, Y.; Wang, J.; Kong, F.; Zhang, J. Surface treatment of cellulosic paper with starch-based composites reinforced with nanocrystalline cellulose. Ind. Eng. Chem. Res. 2014, 53, 13980–13988. [Google Scholar] [CrossRef]

- Eichhorn, S.; Young, R. The Young’s modulus of a microcrystalline cellulose. Cellulose 2001, 8, 197–207. [Google Scholar] [CrossRef]

- Yu, J.; Wang, C.; Wang, J.; Chu, F. In situ development of self-reinforced cellulose nanocrystals based thermoplastic elastomers by atom transfer radical polymerization. Carbohydr. Polym. 2016, 141, 143–150. [Google Scholar] [CrossRef]

- Goudarzi, T.; Spring, D.W.; Paulino, G.H.; Lopez-Pamies, O. Filled elastomers: A theory of filler reinforcement based on hydrodynamic and interphasial effects. J. Mech. Phys. Solids 2015, 80, 37–67. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Luo, J.; Qin, Z.; Chen, H.; Gao, Q.; Li, J. Mechanical and thermal properties of microcrystalline cellulose-reinforced soy protein isolate-gelatin eco-friendly films. RSC Adv. 2015, 5, 56518–56525. [Google Scholar] [CrossRef]

- Balaxi, M.; Nikolakakis, I.; Kachrimanis, K.; Malamataris, S. Combined effects ofwetting, drying, and microcrystalline cellulose type on the mechanicalstrength and disintegration of pellets. J. Pharm. Sci. 2009, 98, 676–689. [Google Scholar] [CrossRef]

- Trache, D.; Hussin, M.H.; Chuin, C.T.H.; Sabar, S.; Fazita, M.N.; Taiwo, O.F.; Hassan, T.M.; Haafiz, M.M. Microcrystalline cellulose: Isolation, characterization and bio-composites application—A review. Int. J. Biol. Macromol. 2016, 93, 789–804. [Google Scholar] [CrossRef]

- Su, J.F.; Huang, Z.; Yuan, X.Y.; Wang, X.Y.; Li, M. Structure and properties of carboxymethyl cellulose/soy protein isolate blend edible films crosslinked by Maillard reactions. Carbohydr. Polym. 2010, 79, 145–153. [Google Scholar] [CrossRef]

- Grylewicz, A.; Spychaj, T.; Zdanowicz, M. Thermoplastic starch/wood biocomposites processed with deep eutectic solvents. Compos. Part A Appl. Sci. Manuf. 2019, 121, 517–524. [Google Scholar] [CrossRef]

- Valencia, G.A.; Luciano, C.G.; Lourenço, R.V.; do Amaral Sobral, P.J. Microstructure and physical properties of nano-biocomposite films based on cassava starch and laponite. Int. J. Biol. Macromol. 2018, 107, 1576–1583. [Google Scholar] [CrossRef]

- Zdanowska, P.; Florczak, I.; Słoma, J.; Tucki, K.; Orynycz, O.; Wasiak, A.; Świć, A. An Evaluation of the Quality and Microstructure of Biodegradable Composites as Contribution towards Better Management of Food Industry Wastes. Sustainability 2019, 11, 1504. [Google Scholar] [CrossRef] [Green Version]

- Kamdem, D.P.; Shen, Z.; Nabinejad, O. Development of biodegradable composite chitosan-based films incorporated with xylan and carvacrol for food packaging application. Food Packag. Shelf Life 2019, 21, 100344. [Google Scholar] [CrossRef]

- Lin, Z.; Renneckar, S.; Hindman, D.P. Nanocomposite-based lignocellulosic fibers 1. Thermal stability of modified fibers with clay-polyelectrolyte multilayers. Cellulose 2007, 15, 333. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Eleutério, T.; Pinto, A.S.; Pereira, M.J.; Vasconcelos, H.C. Preliminary Structural and Thermal Characterization of Conteira’s (Hedychium gardnerianum) Fibers for Further Functionalization with Silica Colloidal Nanoparticles. Procedia Eng. 2017, 200, 162–169. [Google Scholar] [CrossRef]

- Hempel, H.; Fürll, C.; Munder, F. Processing of bast fiber plants for industrial application. In Natural Fibers, Biopolymers, and BiocompositesNat; CRC Press: Boca Raton, FL, USA, 2005; pp. 129–161. [Google Scholar]

| Samp. Number | Index Temperature | Index Celuloza MCC | Temperature (°C) | Cellulose MCC (%) |

|---|---|---|---|---|

| 1 | 1 | 1 | 120 | 2 |

| 2 | 1 | −1 | 120 | 8 |

| 3 | −1 | 1 | 140 | 2 |

| 4 | −1 | −1 | 140 | 8 |

| 5 | 1 | 0 | 120 | 5 |

| 6 | −1 | 0 | 140 | 5 |

| 7 | 0 | 1 | 130 | 2 |

| 8 | 0 | −1 | 130 | 8 |

| 9 | 0 | 0 | 130 | 5 |

| 10 | 0 | 0 | 130 | 5 |

| Bending Strength (MPa); R2 = 0.70; Pure Error MS = 0.26 | ||||||

|---|---|---|---|---|---|---|

| Source of Variation | SS | df | MS | F | P | |

| 1. Temperature (°C) | L | 38.8710 | 1 | 38.8720 | 147.9580 * | 0.0000 |

| Temperature (°C) | Q | 4.8399 | 1 | 4.8399 | 18.4219 * | 0.0003 |

| 2. MCC (%) | L | 16.9260 | 1 | 16.9260 | 64.4251 * | 0.0000 |

| MCC (%) | Q | 0.0757 | 1 | 0.0757 | 0.2882 | 0.5970 |

| Interaction 1 L vs. 2 L | 2.8791 | 1 | 2.8791 | 10.9588 * | 0.0033 | |

| Lack of fit | 22.2617 | 3 | 7.4206 | 28.2448 * | 0.0000 | |

| Pure error | 5.5172 | 21 | 0.2627 | |||

| Total SS | 93.1133 | 29 | ||||

| Young’s modulus (MPa); R2 = 0.73; Pure error MS = 0.72 | ||||||

| 1. Temperature (°C) | L | 11.9937 | 1 | 11.9937 | 16.7259 * | 0.0005 |

| Temperature (°C) | Q | 15.9162 | 1 | 15.9162 | 22.1961 * | 0.0001 |

| 2. MCC (%) | L | 243.6040 | 1 | 243.6040 | 339.7200 * | 0.0000 |

| MCC (%) | Q | 2.0482 | 1 | 2.0482 | 2.8564 | 0.1058 |

| Interaction 1 L vs. 2 L | 6.6008 | 1 | 6.6008 | 9.2052 * | 0.0063 | |

| Lack of fit | 87.3961 | 3 | 29.1320 | 40.6263 * | 0.0000 | |

| Pure error | 15.0585 | 21 | 0.7171 | |||

| Total SS | 380.6645 | 29 | ||||

| Water contact angle; R2 = 0.70; Pure error MS = 3.48 | ||||||

| 1. Temperature (°C) | L | 504.132 | 1 | 504.1323 | 144.8413 * | 0.0000 |

| Temperature (°C) | Q | 35.127 | 1 | 35.1269 | 10.0922 * | 0.0045 |

| 2. MCC (%) | L | 179.065 | 1 | 179.0655 | 51.4470 * | 0.0000 |

| MCC (%) | Q | 3.846 | 1 | 3.8463 | 1.1051 | 0.3051 |

| Interaction 1 L vs. 2 L | 861.060 | 1 | 861.0602 | 247.3896 * | 0.0000 | |

| Lack of fit | 590.492 | 3 | 196.8306 | 56.5510 * | 0.0000 | |

| Pure error | 73.092 | 21 | 3.4806 | |||

| Total SS | 2243.379 | 29 | ||||

| L*; R2 = 0.96; Pure error MS = 0.89 | ||||||

| 1. Temperature (°C) | L | 421.901 | 1 | 421.9011 | 476.7090 * | 0.0000 |

| Temperature (°C) | Q | 49.574 | 1 | 49.5737 | 56.0137 * | 0.0000 |

| 2. MCC (%) | L | 446.080 | 1 | 446.0804 | 504.0294 * | 0.0000 |

| MCC (%) | Q | 119.247 | 1 | 119.2475 | 134.7385 * | 0.0000 |

| Interaction 1 L vs. 2 L | Q | 1 | 10.8871 | 12.3014 * | 0.0020 | |

| Lack of fit | 24.667 | 3 | 8.2222 | 9.2903 * | 0.0004 | |

| Pure error | 18.586 | 21 | 0.8850 | |||

| Total SS | 1048.196 | 29 | ||||

| Total SS | ||||||

| 1. Temperature (°C) | L | 0.135435 | 1 | 0.1354 | 1629.3092 * | 0.0000 |

| Temperature (°C) | Q | 0.186196 | 1 | 0.1862 | 2239.9661 * | 0.0000 |

| 2. MCC (%) | L | 0.497160 | 1 | 0.4972 | 5980.9173 * | 0.0000 |

| MCC (%) | Q | 0.157331 | 1 | 0.1573 | 1892.7180 * | 0.0000 |

| Interaction 1 L vs. 2 L | 0.072348 | 1 | 0.0723 | 870.3610 * | 0.0000 | |

| Lack of fit | 0.738541 | 3 | 0.2462 | 2961.5901 * | 0.0000 | |

| Pure error | 0.001746 | 21 | 0.0001 | |||

| Total SS | 1.686337 | 29 | ||||

| b*; R2 = 0.72; Pure error MS = 0.0025 | ||||||

| 1. Temperature (°C) | L | 35.3359 | 1 | 35.3359 | 13961.8112 * | 0.0000 |

| Temperature (°C) | Q | 17.8599 | 1 | 17.8599 | 7056.7514 * | 0.0000 |

| 2. MCC (%) | L | 23.6495 | 1 | 23.6495 | 9344.3313 * | 0.0000 |

| MCC (%) | Q | 27.5162 | 1 | 27.5162 | 10872.1205 * | 0.0000 |

| Interaction 1 L vs. 2 L | 0.2982 | 1 | 0.2982 | 117.8401 * | 0.0000 | |

| Lack of fit | 55.5766 | 3 | 18.5255 | 7319.7521 * | 0.0000 | |

| Pure error | 0.0531 | 21 | 0.0025 | |||

| Total SS | 147.2223 | 29 | ||||

| Sample | Mass Losses (%) | Temperature at 5% Mass Losses (°C) | Temperature at 50% Mass Losses (°C) | |||||

|---|---|---|---|---|---|---|---|---|

| I 30–170 °C | II 170–220 °C | III 220–260 °C | IV 260–400 °C | V 400–600 °C | Total 30–600 °C | |||

| MCC 5%; 120 °C | 7.61 | 5.11 | 8.13 | 38.85 | 7.97 | 67.67 | 132.5 | 351.2 |

| MCC 5%; 140 °C | 6.10 | 7.97 | 8.15 | 38.78 | 8.03 | 67.03 | 151.9 | 354.1 |

| MCC 8%; 120 °C | 8.12 | 5.29 | 7.69 | 37.22 | 11.00 | 69.32 | 117.3 | 346.0 |

| MCC 8%; 140 °C | 6.66 | 4.53 | 8.88 | 37.01 | 12.15 | 69.23 | 145.9 | 349.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Żelaziński, T.; Słoma, J.; Skudlarski, J.; Ekielski, A. The Rape Pomace and Microcrystalline Cellulose Composites Made by Press Processing. Sustainability 2020, 12, 1311. https://doi.org/10.3390/su12041311

Żelaziński T, Słoma J, Skudlarski J, Ekielski A. The Rape Pomace and Microcrystalline Cellulose Composites Made by Press Processing. Sustainability. 2020; 12(4):1311. https://doi.org/10.3390/su12041311

Chicago/Turabian StyleŻelaziński, Tomasz, Jacek Słoma, Jacek Skudlarski, and Adam Ekielski. 2020. "The Rape Pomace and Microcrystalline Cellulose Composites Made by Press Processing" Sustainability 12, no. 4: 1311. https://doi.org/10.3390/su12041311

APA StyleŻelaziński, T., Słoma, J., Skudlarski, J., & Ekielski, A. (2020). The Rape Pomace and Microcrystalline Cellulose Composites Made by Press Processing. Sustainability, 12(4), 1311. https://doi.org/10.3390/su12041311