The Design and Application of Non-Pressure Infiltrating Irrigation in Desertification Control

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

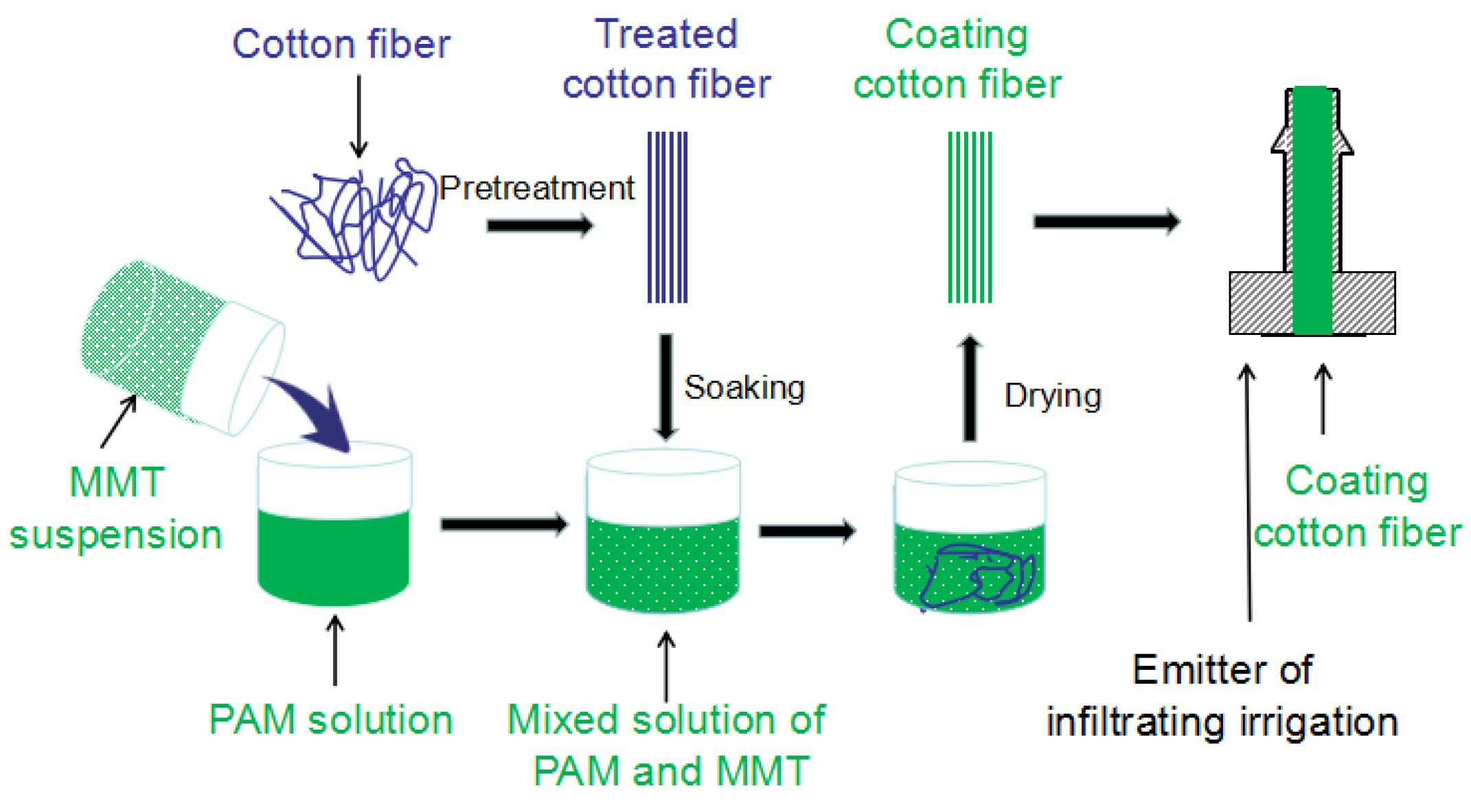

2.2. The Design of Infiltrating Irrigation System

2.3. The Water Absorption and Desorption Tests

2.4. The Water Infiltrating Tests

2.5. The Application Tests in Desert Conditions

3. Results and Discussion

3.1. Water Absorption and Desorption Performances of the Water-Conducting Material

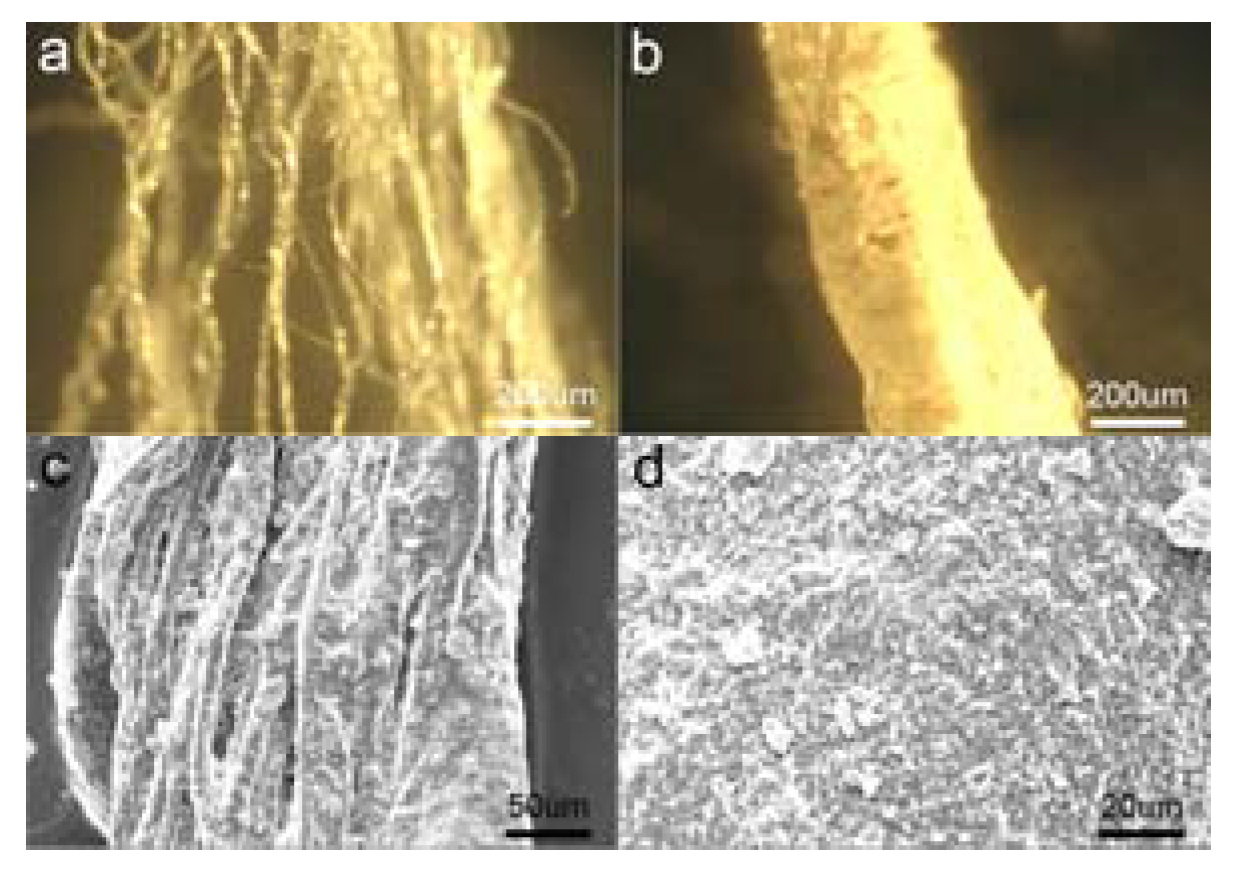

3.2. The Coating Performances of the Water-Conducting Materials on the Cotton Fibers

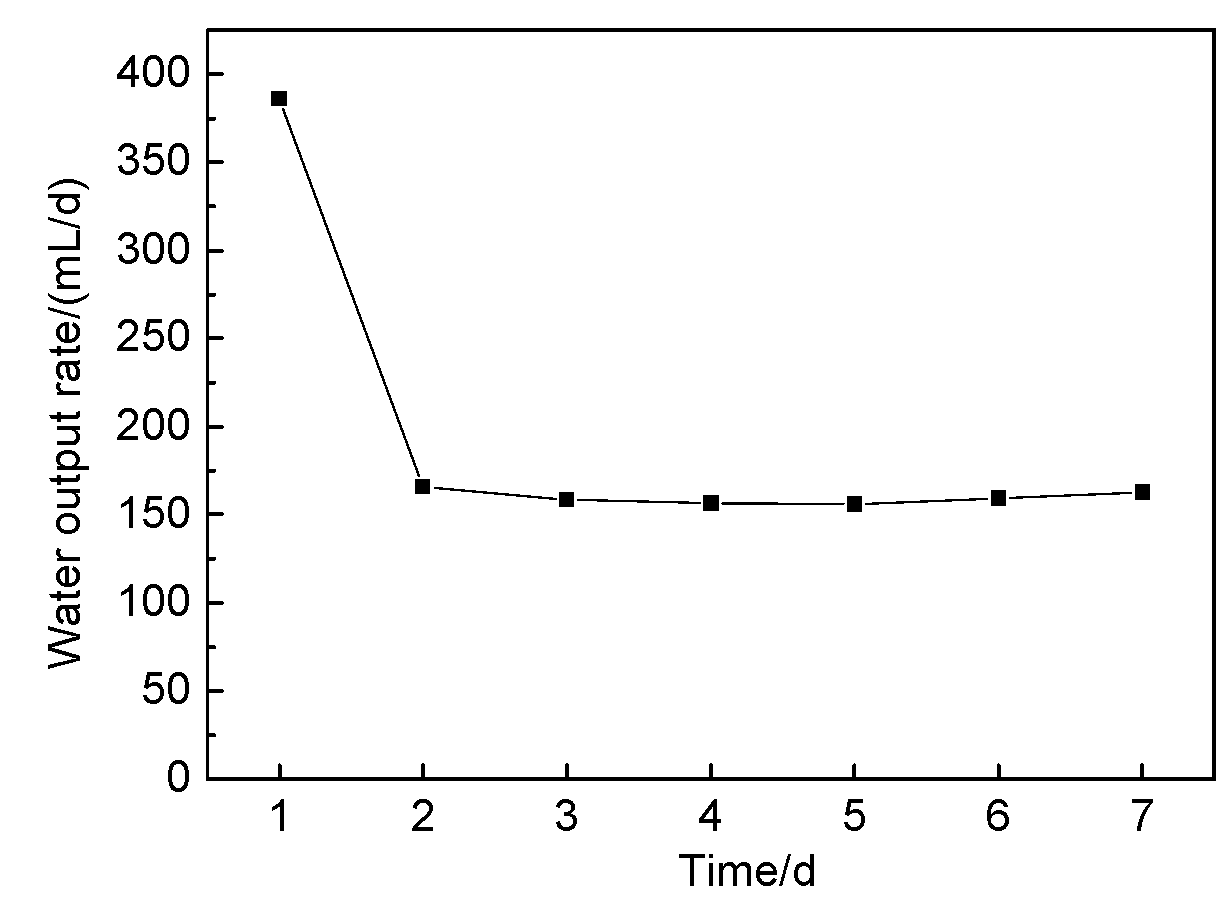

3.3. Water Infiltration Performance of the Irrigation System

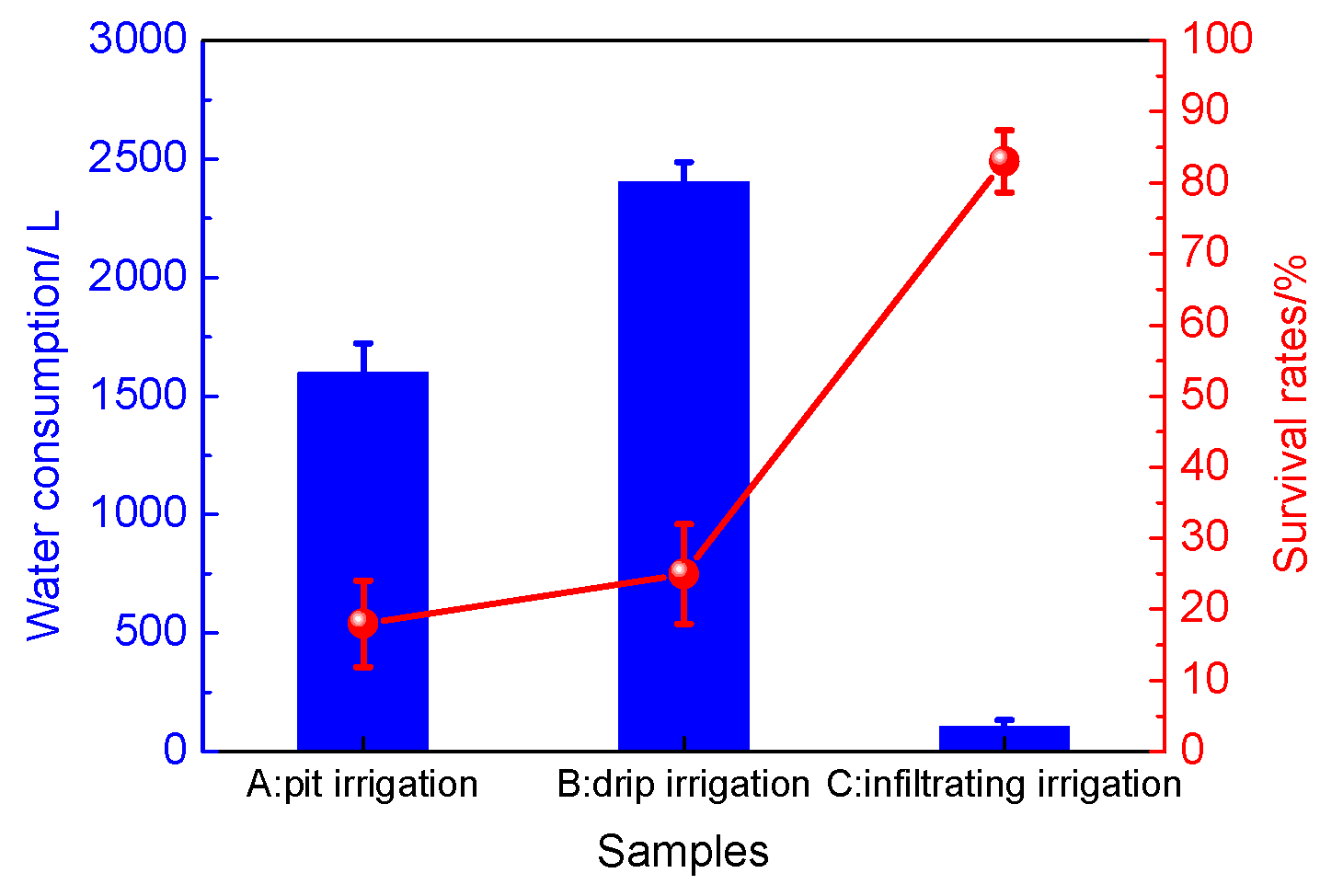

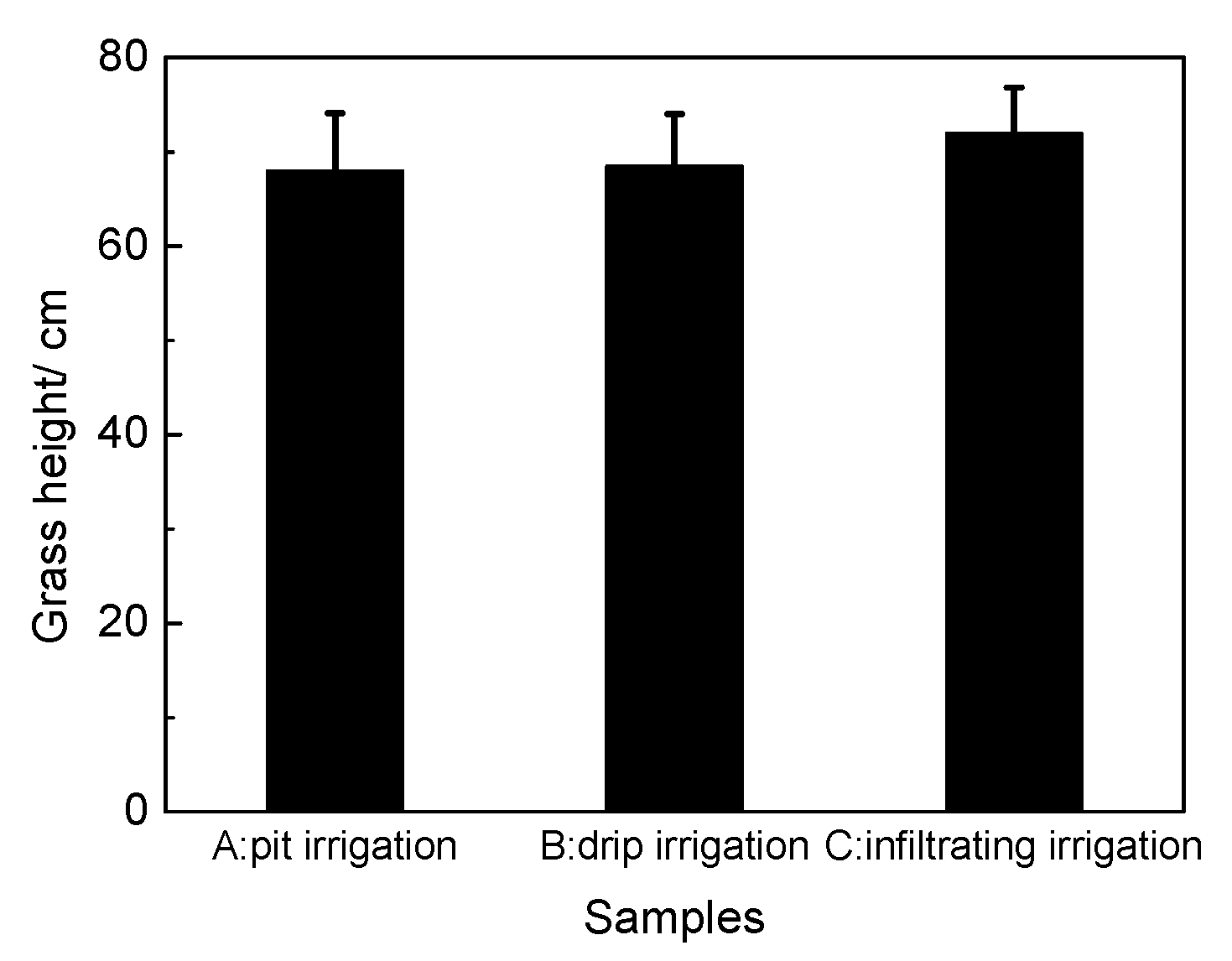

3.4. The Application Performances in Deserts

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Reynolds, J.F.; Smith, D.M.S.; Lambin, E.F.; Turner, B.L., II; Mortimore, M.; Batterbury, S.P.J.; Downing, T.E.; Dowlatabadi, H.; Fernández, R.J.; Herrick, J.E.; et al. Global desertification: Building a science for dryland development. Science 2007, 316, 847–851. [Google Scholar] [CrossRef] [PubMed]

- D’Odorico, P.; Bhattachan, A.; Davis, K.F.; Ravi, S.; Runyan, C.W. Global desertification: Drivers and feedbacks. Adv. Water Resour. 2013, 51, 326–344. [Google Scholar] [CrossRef]

- Zhao, W.; Hu, G.; Zhang, Z.; He, Z. Shielding effect of oasis-protection systems composed of various forms of wind break on sand fixation in an arid region: A case study in the Hexi Corridor, northwest China. Ecol. Eng. 2008, 33, 119–125. [Google Scholar] [CrossRef]

- Qiu, G.Y.; Lee, I.B.; Shimizu, H.; Gao, Y.; Ding, G. Principles of sand dune fixation with straw checkerboard technology and its effects on the environment. J. Arid Environ. 2004, 56, 449–464. [Google Scholar] [CrossRef]

- Liu, J.; Shi, B.; Lu, Y.; Jiang, H.; Huang, H.; Wang, G.; Kamai, T. Effectiveness of a new organic polymer sand-fixing agent on sand fixation. Environ. Earth Sci. 2012, 65, 589–595. [Google Scholar] [CrossRef]

- Lokhande, V.H.; Gor, B.K.; Desai, N.S.; Nikam, T.D.; Suprasanna, P. Sesuvium portulacastrum, a plant for drought, salt stress, sand fixation, food and phytoremediation. A review. Agron. Sustain. Dev. 2013, 33, 329–348. [Google Scholar] [CrossRef]

- Han, Y.; Wang, K.; Zhang, R.; Yao, Y.; Fan, C. Study on the transpiration eco-physiological characteristics of degenerated Haloxylon ammodendron in Jilantai. Acta Agrestia Sinica 2002, 10, 40–44. [Google Scholar]

- He, X.; Gao, Y.; Duan, Z.; Zhao, A.; Chen, H. The comparison of irrigation manners for constructing sand-fixing plantation along Tarim Desert Highway. Scientia Geographica Sinica 2002, 22, 213–218. [Google Scholar]

- Ding, X.; Zhou, Z.; Xu, X.; Wang, Y.; Jiang, Y.; Lu, J.; Chang, Q. Dynamics of soil water and salt in soil under artificial plantation shelterbelt drip-irrigated with saline water in the Center of the Taklimakan Desert. Acta Pedologica Sinica 2016, 53, 103–116. [Google Scholar]

- Sun, T.; Han, J.; Zhao, S.; Yue, W. Effect of fertilizer application on seed yield and yield components of Agropyron cristatum. J. China Agric. Univ. 2005, 2005, 15–20. [Google Scholar]

- Li, P.; Yang, G.; He, X.; Li, F.; Yan, K.; Wang, Z. Effects of drip irrigation on components of water cycle in arid inland areas: A case study of Manas river basin in northwestern China. Int. J. Agric. Biol. Eng. 2019, 12, 132–138. [Google Scholar] [CrossRef]

- Ayars, J.E.; Phene, C.J.; Hutmacher, R.B.; Davis, K.R.; Schoneman, R.A.; Vail, S.S.; Mead, R.M. Subsurface drip irrigation of row crops: A review of 15 years of research at the Water Management Research Laboratory. Agric. Water Manag. 1999, 42, 1–27. [Google Scholar] [CrossRef]

- Shen, H.; Li, Z.; Zhang, R.; Li, J.; Zhu, E. The current situation and development trend of ferlilizer-water irrigation technology based on infiltrating irrigation system. Acta Agric. Shanghai 2014, 30, 126–130. [Google Scholar]

- Jia, Z.; Lu, Q.; Guo, B.; Zhao, M.; Liang, Y. Progress in the study of psammophyte-Haloxylon. For. Res. 2004, 17, 125–132. [Google Scholar]

- Camp, C.R. Subsurface drip irrigation: A review. Trans. ASAE 1998, 41, 1353–1367. [Google Scholar] [CrossRef]

- Capra, A.; Scicolone, B. Emitter and filter tests for wastewater reuse by drip irrigation. Agric. Water Manag. 2004, 68, 135–149. [Google Scholar] [CrossRef]

| Ulanbuh Desert | Statistic |

|---|---|

| Maximum annual precipitation | 150.3 mm |

| Minimum annual precipitation | 33.3 mm |

| Average annual precipitation | 102.9 mm |

| Average annual evaporation | 2258.8 mm |

| Maximum temperature | 39 °C |

| Minimum temperature | −29.6 °C |

| Average temperature | 7.8 °C |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, Y.; Zhang, Z. The Design and Application of Non-Pressure Infiltrating Irrigation in Desertification Control. Sustainability 2020, 12, 1547. https://doi.org/10.3390/su12041547

Qu Y, Zhang Z. The Design and Application of Non-Pressure Infiltrating Irrigation in Desertification Control. Sustainability. 2020; 12(4):1547. https://doi.org/10.3390/su12041547

Chicago/Turabian StyleQu, Yongping, and Zengzhi Zhang. 2020. "The Design and Application of Non-Pressure Infiltrating Irrigation in Desertification Control" Sustainability 12, no. 4: 1547. https://doi.org/10.3390/su12041547

APA StyleQu, Y., & Zhang, Z. (2020). The Design and Application of Non-Pressure Infiltrating Irrigation in Desertification Control. Sustainability, 12(4), 1547. https://doi.org/10.3390/su12041547