Archetypical CBMs in Construction and a Translation to Industrialized Manufacture

Abstract

1. Introduction

2. Background

2.1. Industrialized Construction

2.2. Circular Business Models

3. Method

- What archetypical CBMs in construction are to be expected?

- How do the archetypical CBMs for construction translate to performance criteria for industrialized construction?

3.1. Step 1: Archetypical CBMs in Construction

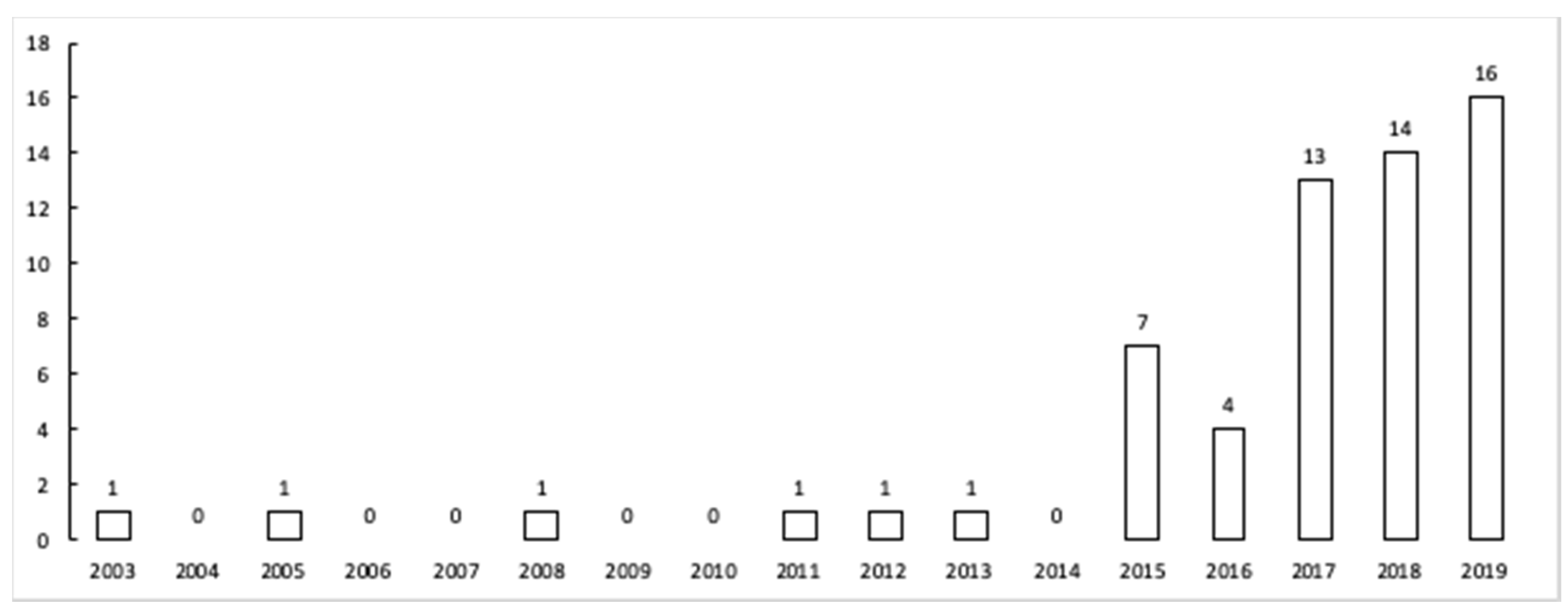

3.1.1. Constructing the Body of Literature

- Set A comprises theoretical circular constructs with a general and strategic nature and caters to the development of CBM archetypes for construction;

- Set B comprises case study examples relating to circular economy construction and was used to validate the developed archetypes.

3.1.2. Creating and Coding Set A

3.1.3. Archetype Definition

3.1.4. Creating and Coding Set B and Archetype Validation

3.2. Step 2: Translation to Industrialized Construction

4. Results

4.1. CBM Archetypes for Buildings

4.2. Translation to Industrialized Construction

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Number | Source | Element |

|---|---|---|

| 1 | [36,37,38,39,40] | Industrial symbiosis |

| 2 | [3,39,41,42] | Product service system |

| 3 | [3,19,39,42] | Product life extension |

| 4 | [2,3,36] | Access and performance model |

| 5 | [2,39,43] | Take-back model |

| 6 | [3,19,42] | Circular supply chain |

| 7 | [3,19,42] | Recovery and recycling |

| 8 | [3,7,36] | Encourage sufficiency |

| 9 | [2,6] | Reuse building products |

| 10 | [3,36] | Classic long-life model |

| 11 | [19,42] | Sharing platform |

| 12 | [22,39] | Dematerialization |

| 13 | [7,39] | Product stewardship |

| 14 | [2] | Material reduction |

| 15 | Building reuse | |

| 16 | Building refurbishment | |

| 17 | Leasing building | |

| 18 | Reprocessing resources | |

| 19 | [3] | Collaborative consumption |

| 20 | Asset management | |

| 21 | Reverse logistics of obsolete products | |

| 22 | Made to order | |

| 23 | Extending product value | |

| 24 | Tracing facility | |

| 25 | Material matchmaker | |

| 26 | Service matchmaker | |

| 27 | Progressive purchase | |

| 28 | Performance based contracting | |

| 29 | Collaborative production | |

| 30 | Cascades | |

| 31 | Pure cycles | |

| 32 | Produce on demand | |

| 33 | [41] | Façade leasing |

| 34 | [29] | Affordable flexible housing |

| 35 | [36] | Extending product value |

| 36 | [9] | Regenerate |

| 37 | Share | |

| 38 | Optimize | |

| 39 | Loop | |

| 40 | Virtualize | |

| 41 | Exchange | |

| 42 | [22] | Closing resource loops |

| 43 | Intensifying resource loops | |

| 44 | Slowing resource loops | |

| 45 | Narrowing resource loops | |

| 46 | [44] | Adaptive reuse |

| 47 | Design for deconstruction | |

| 48 | Design for reuse | |

| 49 | Design for manufacture and assembly | |

| 50 | [19] | Product as a service |

| 51 | [7] | Optimize material and energy efficiency |

| 52 | Create value from waste | |

| 53 | Substitute with renewables | |

| 54 | Deliver functionality | |

| 55 | [39] | Design for remanufacture and repair |

| 56 | Design for life cycle | |

| 57 | Design for repurpose | |

| 58 | Result- or use oriented solutions | |

| 59 | Cleaner production and zero waste | |

| 60 | Collaborative business | |

| 61 | Partnerships | |

| 62 | Availability of reuse channels | |

| 63 | Traceability and transparency | |

| 64 | Waste collection and handling | |

| 65 | Intelligent goods | |

| 66 | 3D printing mass customization | |

| 67 | Customer incentive, discount for return | |

| 68 | [43] | Operational lease |

| 69 | Pay-per-use model | |

| 70 | Buy-back model | |

| 71 | Brokerage | |

| 72 | [45] | E-BAMB |

| 73 | [6] | Design for attachment |

| 74 | Design for standardization and compatibility | |

| 75 | Design for maintenance and repair | |

| 76 | Design for upgrades and adjustments | |

| 77 | Design for disassembly | |

| 78 | Design for recycling | |

| 79 | Extending resource value |

| Number | Source | Element | Archetype |

|---|---|---|---|

| 1 | [6] | The Circular Kitchen (CIK) | Adaptable building |

| 2 | [41] | PV-leasing | Stewardship |

| 3 | [46] | Houseful | Stewardship |

| 4 | [3] | Desso | Stewardship |

| 5 | Interface | Circular input | |

| 6 | Philips | Stewardship | |

| 7 | [34] | Insulation material from CDW | Circular input |

| 8 | [7] | Park 20|20 | Stewardship Adaptable building Sharing |

| 9 | Alliander Office | Adaptable building Stewardship | |

| 10 | Heerema Office | Circular output | |

| 11 | [47] | Off-site retrofit | Adaptable building |

| 12 | [48] | WPC out of by-products | Circular input |

| 13 | Concrete out of CDW | Circular input | |

| 14 | Bricks out of CDW | Circular input | |

| 15 | [43] | Mitshubishi | Stewardship Sharing |

| 16 | [49] | Gypsum out of CDW | Circular input |

| 17 | [40] | Greenhouse out of CDW | Circular input |

Appendix B

References

- European Commission. Report by the EC to the European Parliament, the Council, the European Economic and Social Committee and the Committee of Regions on the implementation of the Circular Economy Action Plan; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Adams, K.T.; Osmani, M.; Thorpe, T.; Thornback, J. Circular economy in construction: Current awareness, challenges and enablers. In Proceedings of the Institution of Civil Engineers—Waste and Resource Management; Thomas Telford Ltd.: London, UK, 2017; pp. 1–11. [Google Scholar]

- de Angelis, R. Business models in the circular economy: Concepts, examples and theory; Springer: Berlin, Germany, 2018. [Google Scholar]

- Urbinati, A.; Chiaroni, D.; Chiesa, V. Towards a new taxonomy of circular economy business models. J. Clean. Prod. 2017, 168, 487–498. [Google Scholar] [CrossRef]

- Hart, J.; Adams, K.; Giesekam, J.; Tingley, D.D.; Pomponi, F. Barriers and drivers in a circular economy: The case of the built environment. Procedia CIRP 2019, 80, 619–624. [Google Scholar] [CrossRef]

- Stijn, A.V.; Gruis, V.H. Circular Housing Retrofit Strategies and Solutions: Towards Modular, Mass-Customised and ’Cyclable’ Retrofit Products C3—IOP Conference Series: Earth and Environmental Science; IOP Publishing Ltd: Bristol, UK, 2019. [Google Scholar]

- Leising, E.; Quist, J.; Bocken, N. Circular Economy in the building sector: Three cases and a collaboration tool. J. Clean. Prod. 2018, 176, 976–989. [Google Scholar] [CrossRef]

- European Commission, Environment, Waste, Construction and Demolition Waste. Available online: https://ec.europa.eu/environment/waste/construction_demolition.htm (accessed on 10 December 2019).

- Ellen MacArthur Foundation. Growth Within: A Circular Economy Vision for a Competitive Europe. 2015. Available online: https://www.ellenmacarthurfoundation.org/publications (accessed on 10 December 2019).

- Richard, R.-B. Industrialised building systems: Reproduction before automation and robotics. Autom. Constr. 2005, 14, 442–451. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Xue, X. Critical review of the research on the management of prefabricated construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef]

- Mydin, M.; Phius, A.; Sani, N.M.; Tawil, N. Potential of Green Construction in Malaysia: Industrialised Building System (IBS) vs Traditional Construction Method; EDP Sciences: Les Ulis, France, 2014; Volume 3, p. 1009. [Google Scholar]

- El-Abidi, K.; Ofori, G.; Zakaria, S.A.S.; Aziz, A.R.A. Using Prefabricated Building to Address Housing Needs in Libya: A Study based on Local Expert Perspectives. Arab. J. Sci. Eng. 2019, 44, 8289–8304. [Google Scholar] [CrossRef]

- Kamaruddin, S.S.; Mohammad, M.F.; Mahbub, R. Barriers and Impact of Mechanisation and Automation in Construction to Achieve Better Quality Products. Procedia - Soc. Behav. Sci. 2016, 222, 111–120. [Google Scholar] [CrossRef]

- Ismail, F.; Yusuwan, N.M.; Baharuddin, H.E.A. Management Factors for Successful IBS Projects Implementation. Procedia - Soc. Behav. Sci. 2012, 68, 99–107. [Google Scholar] [CrossRef]

- Kamar, K.A.M.; Azman, M.N.A.; Nawi, M.N.M. IBS Survey 2010: Drivers, Barriers and critical success factors in adopting idustrialised building systems (IBS) construction by G7 Contractors in Malaysia. Eng. Sci. Technol. Int J. 2014, 9, 490–501. [Google Scholar]

- Jaganathan, S.; Nessan, L.J.; Ibrahim, R.; Mohammad, A.H. Integrated design approach for imporving architectural forms in industrialized building systems. Front. Archit. Res. 2013, 2, 377–386. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things, 1st ed.; North Point Press: New York, NY, USA, 2002. [Google Scholar]

- Lacy, P.; Rutqvist, J. Waste to Wealth—The Circular Economy Advantage; Palgrave Macmillan Ltd.: Basingstoke, Hampshire, UK, 2015. [Google Scholar]

- Rau, T.; Oberhuber, S. Material Matters; Bertram + de Leeuw Uitgevers B.V.: Haarlem, The Netherlands, 2016. [Google Scholar]

- Ellen MacArthur Foundation. Towards the Circular Economy—Economic and Business Rationale for an Accelerated Transition. 2013. Available online: https://www.ellenmacarthurfoundation.org/publications (accessed on 10 December 2019).

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The ciruclar Economy—A new sustainability paradigm. J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation, Circular Economy, Concept. Available online: https://www.ellenmacarthurfoundation.org/circular-economy/concept (accessed on 10 December 2019).

- Antikainen, M.; Valkokari, K. A Framework for Sustainable Circular Business Model Innovation. Technol. Innov. Manag. Rev. 2016, 6, 5–12. [Google Scholar] [CrossRef]

- Bocken, N.; Schuit, C.; Kraaijenhagen, C. Experimenting with a circular business model: Lessons from eight cases. Environ. Innov. Soc. Transitions 2018, 28, 79–95. [Google Scholar] [CrossRef]

- Antikainen, M.; Valkokari, K.; Korhonen, H.; Wallenius, M. Exploring networked innovation in order to shape sustainable markets. In Proceedings of the XXIV ISPIM Conference—Innovating in Global Markets: Challenges for Sustainable Growth in Helsinki, Helsinki, Finland, 16–19 June 2013. [Google Scholar]

- Osterwalder, A.; Pigneur, Y. Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- França, C.L.; Broman, G.; Robèrt, K.-H.; Basile, G.; Trygg, L. An approach to business model innovation and design for strategic sustainable development. J. Clean. Prod. 2017, 140, 155–166. [Google Scholar] [CrossRef]

- Bin Mohd Noor, M.Z. FlexZhouse: New business model for affordable housing in Malaysia. In A+BE Architecture and the Built Environment; TU Delft Open: Delft, The Netherlands, 2017. [Google Scholar]

- Esmaeilian, B.; Wang, B.; Lewis, K.; Duarte, F.; Ratti, C.; Behdad, S. The future of waste management in smart and sustainable cities: A review and concept paper. Waste Manag. 2018, 81, 177–195. [Google Scholar] [CrossRef]

- Ünal, E.; Urbinati, A.; Chiaroni, D.; Manzini, R. Value Creation in Circular Business Models: The case of a US small medium enterprise in the building sector. Resour. Conserv. Recycl. 2019, 146, 291–307. [Google Scholar] [CrossRef]

- Cullen, S.; Keeffe, G.; Kinnane, O. Mapping Responsive Envelopes: Material culture evolution and climatically responsive building facades. In Face Time: The Emergence of the Facade as the Integrative Factor in Holistic Building Design; Tectonic Press: Los Angeles, CA, USA, 2016. [Google Scholar]

- Icibaci, L. Re-use of Building Products in the Netherlands; Delft University of Technology: Delft, The Netherlands, 2019. [Google Scholar]

- Ruiz-González, F.; Nadargi, D.; Philippe, K.; Goiti, E.; Ocejo, M.; Vegas, I. Novel Circular Economy Business Model of High-Added Value Products for Energy Efficiency: From C&DW to Aerogels; Delft University of Technology: Delft, The Netherlands, 2017. [Google Scholar]

- Wang, K.; Vanassche, S.; Ribeiro, A.; Peters, M.; Oseyran, J. Business Models for Building Material Circularity: Learnings from Frontrunner Cases; Delft University of Technology: Delft, The Netherlands, 2017. [Google Scholar]

- Bocken, N.; De Pauw, I.; Bakker, C.; Van Der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Aid, G.; Eklund, M.; Anderberg, S.; Baas, L. Expanding roles for the Swedish waste management sector in inter-organizational resource management. Resour. Conserv. Recycl. 2017, 124, 85–97. [Google Scholar] [CrossRef]

- Mulrow, J.; Derrible, S.; Ashton, W.S.; Chopra, S.S. Industrial Symbiosis at the Facility Scale. J. Ind. Ecol. 2017, 21, 559–571. [Google Scholar] [CrossRef]

- Jabbour, A.B.L.D.S.; Luiz, J.V.R.; Luiz, O.R.; Jabbour, C.J.C.; Ndubisi, N.O.; De Oliveira, J.H.C.; Junior, F.H. Circular economy business models and operations management. J. Clean. Prod. 2019, 235, 1525–1539. [Google Scholar] [CrossRef]

- Romnée, A.; Vandervaeren, C.; Breda, O.; De Temmerman, N. A Greenhouse That Reduces Greenhouse Effect: How to Create a Circular Activity with Construction Waste? IOP Publishing Ltd.: Bristol, UK, 2019. [Google Scholar]

- Azcárate-Aguerre, J.F.; Den Heijer, A.; Klein, T. Integrated facades as a Product-Service System -Business process innovation to accelerate integral product implementation. J. Facade Des. Eng. 2018, 6, 41–56. [Google Scholar]

- Di Biccari, C.; Abualdenien, J.; Borrmann, A.; Corallo, A. A BIM-Based Framework to Visually Evaluate Circularity and Life Cycle Cost of buildings; IOP Publishing Ltd.: Bristol, UK, 2019. [Google Scholar]

- Ploeger, H.; Prins, M.; Straub, A.; Brink, R.V.D. Circular economy and real estate: The legal (im)possibilities of operational lease. Facil. 2019, 37, 653–668. [Google Scholar] [CrossRef]

- Iacovidou, E.; Purnell, P. Mining the physical infrastructure: Opportunities, barriers and interventions in promoting structural components reuse. Sci. Total. Environ. 2016, 557, 791–807. [Google Scholar] [CrossRef]

- Rose, C.M.; Stegemann, J.A. Characterising existing buildings as material banks (E-BAMB) to enable component reuse. Proc. Inst. Civ. Eng. - Eng. Sustain. 2019, 172, 129–140. [Google Scholar] [CrossRef]

- Bertino, G.; Menconi, F.; Zraunig, A.; Terzidis, E.; Kisser, J. Innovative circular solutions and services for new buildings and refurbishments. In C3-WIT Transactions on the Built Environment; WIT Press: Southampton, UK, 2019. [Google Scholar]

- Mangialardo, A.; Micelli, E. Off-site Retrofit to Regenerate Multi-family Homes: Evidence from Some European Experiences. In New Metropolitan Perspectives. ISHT 2018. Smart Innovation, Systems and Technologies; Calabrò, F., Della Spina, L., Bevilacqua, C., Eds.; Springer: Cham, Germany, 2019; Volume 101. [Google Scholar]

- Nußholz, J.L.; Rasmussen, F.N.; Milios, L. Circular building materials: Carbon saving potential and the role of business model innovation and public policy. Resour. Conserv. Recycl. 2019, 141, 308–316. [Google Scholar] [CrossRef]

- Rodriguez, R.R.; Alfaro-Saiz, J.-J.; Verdecho, M.-J. A Performance-Based Scenario Methodology to Assess Collaborative Networks Business Model Dynamicity. In Digital Transformation for a Sustainable Society in the 21st Century; Springer Science and Business Media LLC: Berlin, Germany, 2015. [Google Scholar]

- Moreno, M.; Rios, C.D.L.; Rowe, Z.; Charnley, F. A Conceptual Framework for Circular Design. Sustainability 2016, 8, 937. [Google Scholar] [CrossRef]

- Rios, I.C.D.L.; Charnley, F. Skills and capabilities for a sustainable and circular economy: The changing role of design. J. Clean. Prod. 2017, 160, 109–122. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Morioka, S.; De Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

| Description | Parameter |

|---|---|

| Academic databases used | Scopus (268 publications) Science Direct (61 publications) Web of Science (247 publications) |

| Search terms | (Wild card * indicates the term includes variations on the word such as plural/ singular and noun/adjective) |

| First term in search string Second term in search string Third term in search string | “business model *”; product *; circular *; loop *; cycl * construction *; building *; “built environment *” |

| Search fields | Title, abstract, keywords |

| Exemplary search string | “business model *” AND circular * AND construction * |

| Timespan | Published from 2000 and prior to August 2019 |

| Element | Value Proposition | Revenue Stream |

|---|---|---|

| Recovery and recycling [19] | Regenerate natural system | Single payment |

| Narrowing resource loops [22] | Regenerate natural system | Single payment |

| First Term: Value Propositions | Second Term: Revenue Stream | Third Term: Value Occurrence |

|---|---|---|

| Design out waste and pollution (D) | Reoccurring (R) | Beginning of Life (B) |

| Keep products and materials in the loop (K) | One-time (O) | Middle of Life (M) |

| Regenerate the natural system (R) | End of Life (E) |

| Code | Category | Archetype |

|---|---|---|

| RXB | 1 | Smart input |

| DXE | 2 | Smart output |

| KRM | 3 | Stewardship |

| KOM | 4 | Adaptable building |

| ROM | 5 | Never-ending building |

| Archetype | Scope of Work Industrialized Manufacture | Practical Implications for Industrialized Manufacture for Construction |

|---|---|---|

| Smart Input | A reactive use of secondary and renewable raw materials and inter-organizational synergy in the form of industrial symbioses, efficient and reduced material use and mass customization. |

|

| Smart Output | Facilitating cascaded re-use of components and materials. |

|

| Stewardship | Manufacturing building products and taking producer responsibility of using and retrieving secondary and renewable raw materials. |

|

| Adaptable building | Facilitating the basis and compatible products for a flexibly used building. |

|

| Never ending building | Increasing a time-less quality and durability of materials and products in order to obtain a building that continues to appeal to users without making physical changes to the building. |

|

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heesbeen, C.; Prieto, A. Archetypical CBMs in Construction and a Translation to Industrialized Manufacture. Sustainability 2020, 12, 1572. https://doi.org/10.3390/su12041572

Heesbeen C, Prieto A. Archetypical CBMs in Construction and a Translation to Industrialized Manufacture. Sustainability. 2020; 12(4):1572. https://doi.org/10.3390/su12041572

Chicago/Turabian StyleHeesbeen, Charlotte, and Alejandro Prieto. 2020. "Archetypical CBMs in Construction and a Translation to Industrialized Manufacture" Sustainability 12, no. 4: 1572. https://doi.org/10.3390/su12041572

APA StyleHeesbeen, C., & Prieto, A. (2020). Archetypical CBMs in Construction and a Translation to Industrialized Manufacture. Sustainability, 12(4), 1572. https://doi.org/10.3390/su12041572