1. Introduction

The main sustainability hierarchy goes through three ‘Rs’: First, reduction, reuse, and finally, recycling. The utilization of reusable blocks with recycled aggregate meet all three ‘Rs’. These reusable blocks, which have been used in previous construction, can be reused in new construction. Furthermore, it is possible to reduce primary sources and construction and demolition waste through recycling. The research about the utilization of recycled aggregate for concrete was started in the 1940s [

1].

The utilization of recycled aggregate (RA) from construction and demolition waste (CDW) as a partial or full replacement of natural aggregate (NA) in concrete mixtures mostly negatively influences its mechanical and durability properties. However, RA has a positive impact on thermal properties [

2,

3]. The RA from waste concrete (RCA) is mostly used for constructing base layers in road structures and RA from waste masonry (RMA), as backfill layers or as layers to make landfills safe. The properties of recycled aggregate concrete (RAC) are influenced by the replacement rate of RA, as well as by its quality and composition [

4]. The properties of RA are mostly influenced by the unwanted impurities, which are materials usually contained in the CDW, such as soil, dust, plastics, paper, textile, etc. However, these impurities are able to separate during selective demolition and the two-phase recycling process, which leads to the higher quality of RA. In previous studies [

5,

6,

7], the maximal possible replacement rate of NA by RCA without the decline of properties has been found to be 30% or 50%, which is also defined in the European Standard [

8]. In the case of recycled masonry aggregate concrete (RMAC), it was found that the coarse natural aggregate (NA) can be replaced by up to 15% without the decline of properties. Further, the compressive strength decrease of concrete with the full replacement of natural gravel by coarse RMA is 35% [

9]. The conclusions from the studies of the replacement of natural sand by fine RA are still not clear. In some studies, it has been found that natural sand can be replaced by fine RA up to a level of 30% without significant effects on the mechanical properties of concrete [

10]. On the contrary, the results of another study showed the increase of compressive strength of concrete with the full replacement of natural sand by fine RA [

11]. RMA containing high amounts of waste masonry and fine RA has not found adequate utilization yet due to the fact that these types of RA cannot be used as an aggregate for concrete according to European standards [

8].

The reusable structural elements made of concrete with RA originating from CDW can, at the same time, reduce the amount of landfilled waste and decrease the consumption of primary resources. For sustainable management, both of these aspects should be considered. There have been many studies published in which concrete including different recycled materials is used for structural elements, for instance, RCA [

12,

13,

14,

15,

16,

17,

18], RMA [

2,

19,

20,

21,

22,

23,

24,

25,

26,

27], glass waste [

28,

29,

30,

31], crumb rubber waste [

32,

33,

34], ceramic and tile industry waste [

35], marble waste [

36,

37], plastic waste [

38], and concrete slurry waste [

39,

40]. The use of RA as a partial or full replacement of aggregate in structural concrete was examined for manufacturing precast prestressed beams [

41], paving with precast concrete [

23], paving blocks or hollow tiles [

25], concrete masonry blocks for indoor applications [

19,

20], or concrete wall blocks for mortarless masonry [

2]. The utilization of RA for reinforced concrete structural elements is limited due to the inferior durability properties of RAC [

42,

43].

There have been many studies published that have compared the environmental impacts of RAC and NAC for structural use [

44,

45,

46,

47,

48,

49,

50,

51,

52,

53,

54,

55,

56,

57,

58,

59,

60,

61,

62]. The environmental impacts of concrete structural elements can be assessed, for instance, by the life cycle assessment method (LCA) [

63]. The environmental impacts of the lower-grade concrete with RA were assessed and compared with NA [

47]. The life cycle assessment of different types of aggregate (e.g., river NA, crushed NA, and coarse RA) used for structural concrete and their comparisons have been published in a few studies. Furthermore, the importance of different types of transportation and transport distances has been assessed in these studies [

47,

48,

51,

54,

60,

61]. It has been also published that the decline of RAC properties could be compensated for with additional cement, which slightly influences the environmental impacts of this material [

44,

62]. The environmental impacts of CDW recycling could also be affected by special types of recycling, such as separating the attached cement mortar from the aggregate surface from waste concrete by heat treatment and abrasion or separation by microwave heating [

64,

65].

In the abovementioned LCA studies, the environmental impacts are assessed using different characterization methods. One of the used methods is the the characterization method of Institute of Environmental Sciences (CML2001). The characterization factors of this method are used also for environmental assessment of construction products according to EN 15 804 + A1. In this study, the results were performed using CML2001—January 2016. Nevertheless, this method uses characterization models, which insufficiently describe the environmental impacts in some categories, such as the Photochemical Ozone Creation category. Therefore, this study also used the method of National Institute for Public Health and the Environment (ReCiPe 2016 v1.1) as characterization method and both sets of results were interpreted together.

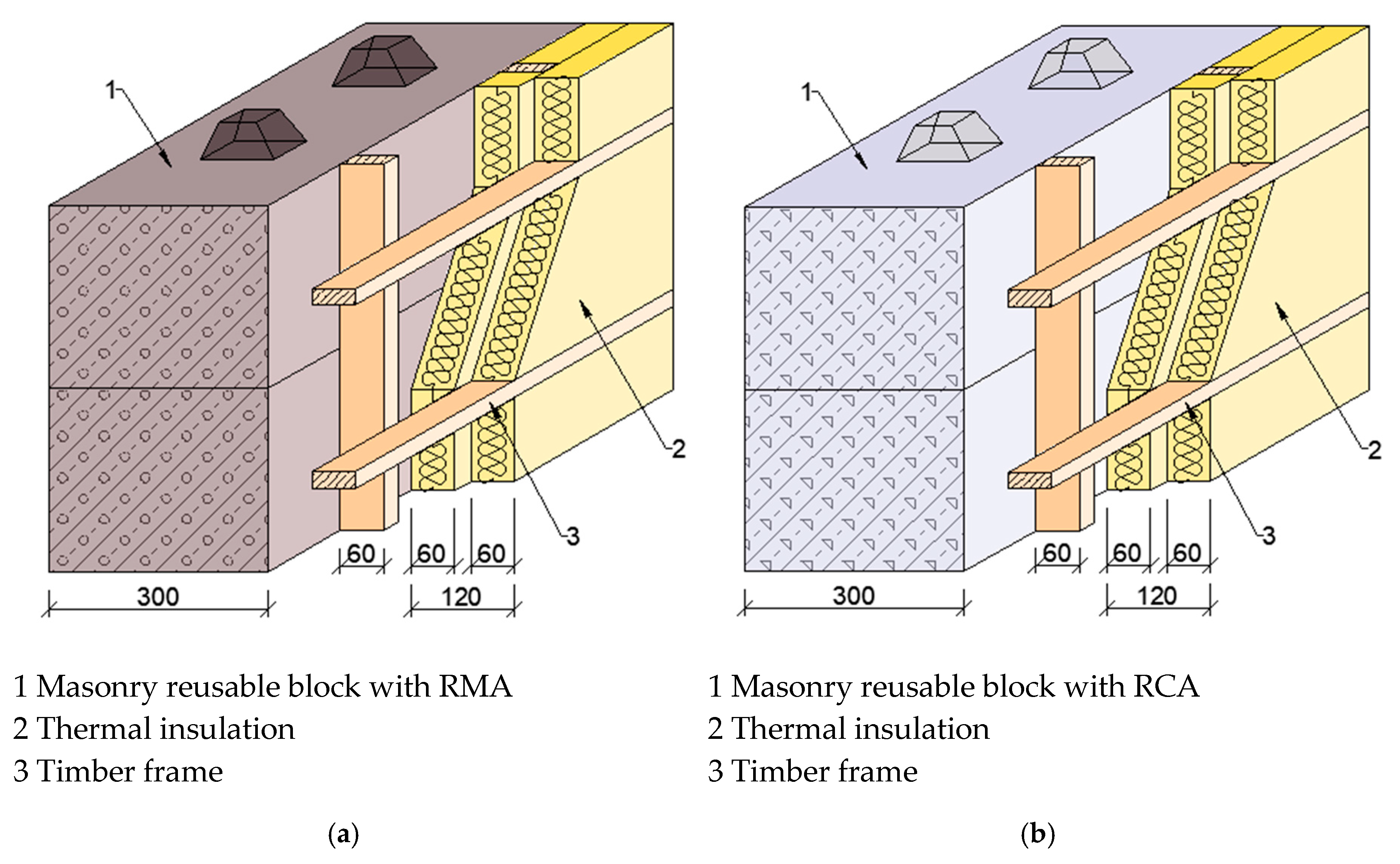

This paper presents a comparison of the four wall systems with the same utility characteristics, as well an environmental evaluation of the systems using the LCA method. The following constructions were compared: (1) Reusable masonry blocks made of RMAC with full replacement of NA by RMA; (2) reusable masonry blocks made of RCAC with full replacement of natural gravel and partial replacement of natural sand by RCA; (3) reusable masonry blocks made of NAC with only NA; (4) conventional concrete wall system with only NA. These constructions were compared in four scenarios with the different time scales of use and other assumptions. All of the compared solutions have the same utility properties, such as concrete strength class, thermal properties, and methods of use. The different thermal conductivity of concretes is compensated for by the various thicknesses of thermal insulation to reach the same heat transfer coefficient. The functional unit of comparison was 1 square meter of a wall system.

2. Materials and Methods

2.1. Materials

Three different concrete mixtures with different aggregate types and ordinary Portland cement (OPC) were designed for the same utility properties and structural use with:

RMAC: Recycled aggregate concrete with RMA (100% replacement ratio) and OPC;

RCAC: Recycled aggregate concrete with coarse RCA (100% replacement ratio), fine RCA (75% replacement ratio), and OPC;

NAC: Natural aggregate concrete made entirely with NA and OPC.

2.1.1. Recycled Aggregate Properties

The RA originated from waste concrete and masonry and was produced by the recycling center in the Czech Republic. The concrete or masonry fragments were crushed in the mobile recycling plant to the fractions 0/128 and sieved to fractions 0/4, 4/16, and 16/128 mm. In the next step, the fraction 16/128 was crushed again and sieved to fractions 0/4, 4/8, and 8/16 mm. The aggregate was treated in the natural air humidity. In the case of concrete mixtures containing RA, the higher water absorption of RA was compensated by the additional water amount, which was calculated on the basis of the water absorption of RA after 10 min.

It is generally known that the RA has higher water absorption and lower density than NA, which has been verified in the previous research. It has been established that the water absorption of coarse RMA ranges from 10% to 19% [

9,

66,

67,

68], and fine RMA from 12% to 15%, [

9,

69,

70]. The dry density of coarse RMA ranges between 1800 and 2700 kg/m

3 and fine RMA between 2000 and 2500 kg/m

3 [

9,

66,

67,

68,

69,

71]. The water absorption of coarse RCA ranges between 0.5% and 14.75%, and the dry density of coarse RCA ranges from 1900 to 2700 kg/m

3 [

6]. The water absorption of fine RCA ranges between 4.3% and 13.1% and the dry density of fine RCA ranges from 1900 to 2360 kg/m

3 [

72]. The pycnometric method according to the CSN EN 1097-6 standard was used for the verification of water absorption and density of aggregate. Water absorption of RMA after 24 h of fraction 4/8 mm ranges from 11.5% to 12.5% and of fraction 8/16 mm varied from 10.0% to 11.0%. The oven-dried density of fraction 4/8 mm was 2000 kg/m

3 and 2100 kg/m

3 for fraction 8/16 mm. Water absorption of RCA after 24 h of fraction 4/8 mm was 7.0% and of fraction 8/16 mm varies from 6.0%. The oven-dried density varied from 2400 kg/m

3 for both fractions. The results of the RCA and RMA properties correlate with the results of previous studies.

2.1.2. Concrete Mixes

The composition of RAC mixtures was designed according to the Czech standard [

8] and the granular skeleton was established according to the Bolomey particle size distribution curve. The parameter A was equal to 16 for the design of RAC mixtures, due to particle shape and roughness [

20]. The aim of the mixture design was to reach the compressive strength class of concrete (C20/25) by the optimization of the amount of cement (CEM I 42.5 R) and effective water/cement ratio. The cement content was various due to the mechanical properties of concretes. The cement content in RAC mixtures was 320 kg/m

3 and in NAC was 300 kg/m

3. The effective water/cement (w/c) ratio refers to the free water content, excluding the amount of additional water, which was added due to the high water absorption of RA. The additional water quantity was calculated on the basis of RA water absorption after 10 min and added to saturate the RA before or during mixing to obtain the desired RAC workability. The properties of aggregates were used for mixture design. No water-reducing admixtures were used. The mixture proportions, given in cubic meters, are shown in

Table 1.

The properties of all concretes were tested in laboratory on Controls MCC8 50-C8422/M (CONTROLS S.p.A., Milan, Italy) according to the following standards to obtain the target values: Compressive strength EN 12390-3 (2003); flexural strength EN 12390-5 (2009); static modulus of elasticity EN 12390-13 (2014); dynamic modulus of elasticity EN 12504-4 (2005). For each concrete mix, three samples were tested, and the target concrete strength class was determined according to Eurocode and ISO 12,491, in which the number of tested samples is taken into consideration for strength class determination to exclude their impact. The average values of concrete properties and target strength classes are shown in

Table 1.

According to the study [

52], the decline of concrete compressive strength with the full replacement of coarse NA by RCA ranges up to 25%. However, the highest decline was mostly examined for modulus of elasticity, which was up to 45% [

53]. It was found that the declines of mechanical properties for a full replacement of NA by RA could be compensated for by 8.3% of additional cement and a lower effective water/cement ratio [

73]. In this case study, the decline of mechanical properties was compensated for by the addition of 6% of cement and a lower effective water/cement ratio of the RAC mixtures.

The durability of recycled aggregate concrete, which is key for its use in structural applications, was not notably affected in this case; the replacement rate of aggregate by RCA was less than 30% [

42]. Nevertheless, in this study, the replacement rate of NA by RCA was almost 100%. For this reason, it was predicted that the durability of the reusable concrete blocks is unsatisfactory. Therefore, the analysis was limited to a structural element for which non-aggressive environmental conditions with protection by thermal insulation were applied.

2.2. Description of Assessed Systems

In this study, four construction types were marked as Plan 1, Plan 2, Plan 3, Plan 4. The first construction (Plan 1) combined regular insulation and reusable blocks, which were made of the concrete mixture with recycled brick aggregate. Similarly, Plan 2 construction consisted of reusable blocks made of recycled concrete aggregate. Reusable blocks with thermal insulation were also used in Plan 3, but for this construction, a concrete from primary resources was used. Plan 4 was a regular reinforced concrete wall system with thermal insulation and adhesive. Constructions with reusable blocks included timber frames. All of the constructions had similar thermal insulation properties. The heat transfer coefficient for all Plans was 0.29 W/m

2K. The overview of plans is in the

Table 2.

The compared constructions were designed to find the answers to questions from the field of civil engineering in the Czech Republic. In the very first step of this study, these questions were used as a background for the choice of the compared concrete wall systems. The first plan was a regular concrete wall system, used as a reference and to represent an ordinary system. To compare the influence of reusable construction, other systems were made of reusable blocks. Moreover, next to a reusable block with natural aggregate, blocks with brick and concrete recycled aggregates were also suggested to test the influence of recycled aggregates. After this choice of wall systems, the constructions were designed. Their detailed description is in

Figure 1.

2.3. Goal and Scope of the Study

Constructions were compared using the methodology in accordance with LCA standards (ISO 14040:2006 standard, EN 16757:2017) [

74]. LCA was performed in four steps: Goal and scope definition, Life cycle inventory analyses, Life cycle impact assessment, and Interpretation. The goal of this study was to compare the environmental impacts of four concrete constructions in four scenarios to see the influence of blocks’ reusability, end of life processes, and aggregate recycling. The functional unit was 1 m

2 of wall construction with similar thermal conductivity (the heat transfer coefficient was 0.29 W/m

2K). In the first scenario, the assumed service life was 50 years. It is assumed that 50 years is a typical time scale for one building, and after this time, the building is refurbished or demolished. On the other hand, the typical life span of a concrete block is 100 years. Thus, in the second scenario, it is assumed that while the reusable concrete blocks can be reused, the reinforced concrete wall must be removed and rebuilt. Therefore, in the second scenario, different life spans for construction were assumed: 100 years for construction from reusable blocks and 50 years for the reference reinforced concrete wall system. The same assumption was also made for the third and fourth scenarios. These scenarios were different only at the end of life (EoL) phase. In Scenario 3, the second built wall is demolished and CDW is recycled to produce new concrete aggregates, and the separated wood is incinerated in a waste wood incineration plant to produce electricity and thermal energy. The end-of-life phase for CDW from the second built wall is different in Scenario 4, where CDW including waste wood is just removed to landfill.

In each scenario, the entire life cycle of construction was considered (a cradle-to-grave scale). The following phases were considered: Production (primary resources extraction, secondary raw materials production, transport, manufacturing), use phase (manipulation on construction site, deconstruction), and end of life (demolition, transport, waste removal). A more detailed description of the scenarios is in

Table 3.

The system boundaries of the considered scenarios included the following processes: Electricity production (Czech grid mix), recycling of construction and demolition waste (production recycled aggregates), mineral wool production, cement production (CEM I 42,5), lime plaster production, lightweight plaster production, water drawing, construction timber (softwood) production, diesel production (EU-28 mix), transport of materials using truck (Euro 3, up to 28 t gross weight/12.4 t payload capacity), manipulation on the site, construction assembling and disassembling, separating the materials from construction, unspecific construction waste removal on landfill, waste incineration of wood products, credit for energy from wood incineration, and transport of waste materials using a truck (Euro 3, up to 28 t gross weight/12.4 t payload capacity).

2.4. Life Cycle Inventory

The total amount of materials for each construction is shown in

Table 4. Every construction was designed with a different type of concrete. Concrete containing recycled concrete aggregate was used in Plan 1 and brick aggregate for concrete was used in Plan 2. Plan 3 and Plan 4 were designed using regular concrete with a natural aggregate.

GaBi 9 software (thinkstep, Leinfelden-Echterdingen, Germany) was used to obtain data about the production systems. As a priority, specific data for the Czech Republic were used, but generic data from the Ecoinvent database were also used.

2.5. Life Cycle Impact Assessment

The impact assessment was carried out using two characterization methods: CML2001—January 2016 and ReCiPe 2016 v1.1. The impact category indicators, which were used in this study, are shown in

Table 5. CML2001, as the characterization method, is very often used for environmental assessment in the building industry. For example, the CML2001 midpoint indicators are described for assessment of construction products according to EN 15804+A1 and for concrete products according to EN 16757 [

75,

76].

ReCiPe 2016 combines CML 2001 and Eco-indicator 99 [

77]. In ReCiPe, it is possible to determine 18 midpoint indicators and 3 endpoint indicators. These indicators contain factors according to the three cultural perspectives: Individualist, Hierarchist, Egalitarian. In this study, the Hierarchist set of characterization factors was used. This consensus model is used as a default in scientific models and is based on medium timeframe of impacts. By combining ReCiPe and CML, we are able to more fully describe the environmental impacts of the assessed forms of construction. Different types of methodologies have been reviewed by Bogacka [

78]. In this study, seven ReCiPe midpoint indicators were used for impact assessment. These seven indicators were chosen because they describe environmental impact in same categories, which are assessed according to EN 15804+A1 and EN 16757 [

75,

76] using CML2001.

The results of environmental assessment for these scenarios are presented in

Section 3, Results. To show typical contribution of process and phases, the results are more fully described in

Section 4, Discussion. The scenarios 3 and 4 were modelled to describe the influence of End of Life in the production system for construction. Therefore, the results of scenario 3 and 4 are considered in

Section 4, Discussion.

3. Results

In this study, we present the results of four constructions in four scenarios. The results are marked with a combination of a number of plans and a scenario number. According to this, the results, which are marked as Plan 1 s1, belong to construction Plan 1, and these results were performed in Scenario 1.

3.1. Plans in Scenario 1

Table 6 shows the demand for selected resources in the case of basic scenarios. There were no important differences among the amount of non-renewable energy resources, which were used for the life cycle of the considered construction. On the other hand, construction with recycled aggregates in concrete mixtures (Plan 1, Plan 2) had smaller primary consumption in most of the flows, and moreover, they were beneficial in the flow of Natural Aggregate. This beneficiation was caused by recycling processes of construction and demolition waste (CDW), which are tied up with the production of other aggregate fractions.

Plan 1 and Plan 2 construction also had smaller water consumption, mainly due to the amount of water that was saved by the recycling of CDW.

All of the elementary flows were characterized, and the results of the impact indicators are shown in

Table 7 and

Table 8. The results of Plan 2 were affected by the recycling of concrete CDW, which also included the recycling of iron scraps. Recycling of this admixture in the conditions of the Czech Republic provided impact beneficiation in the ADP impact category, but also had a negative influence on the ODP impact category. Nevertheless, Plan 2 had the smallest environmental impact, as shown in

Figure 2.

Recycled brick aggregates in Plan 1 came from the recycling of brick CDW, which did not contain such a large amount of steel scraps like in Plan 2. Therefore, these recycling processes did not significantly affect the environmental impact of Plan 1. In these basic scenarios, Plan 3 and Plan 4 were almost similar, hence their environmental impacts were almost equal, too. The only exception was in the ODP category. This difference was caused by the process of incineration of the construction wood, which was used only in the other three plans.

Each of the plans had a beneficial impact on the POCP category. The main effect on this category was caused by transport processes, which were modeled as diesel trucks (Euro 3). After combustion in the diesel engine, emissions of NO

x were generated. This flow can be split into two emissions; NO and NO

2. Nitrogen monoxide, which is in many cases dominating, reduced under certain conditions, when produced O

3 converted back to O

2 and NO

2. Therefore, the flow of NO had a potentially beneficial impact on the POCP category. A similar effect can be caused by benzaldehyde, which is also a product of combustion [

79]. The results of this indicator were based on potential impact and the actual reaction depended on local aspects, such as an abundance of O

3 and NO or intensity of daylight. It cannot be concluded that more transport leads to fresher air.

In the comparison of the results, according to CML2001 (

Table 7) and ReCiPe 2016 (

Table 8), there were some differences. For example, Plan 4 (regular wall) had the smallest impact. On the other hand, according to ReCiPe 2016, Plan 1 caused the smallest impact in Stratospheric Ozone Depletion. Similarly, the impact in the Photochemical Ozone Potential category can be performed with different conclusions. Nevertheless, the indicators of Global warming had almost the same results, and in addition, the Acidification Potential and categories describing resource scarcity produced similar results for their indicators. Other indicators described the impact differently.

To compare the overall impacts of constructions in scenario 1, normalization and weighing were performed (

Figure 2). The normalization was carried out with data from CML2001—January 2016, World, year 2000, including biogenic carbon (global equivalents) and the weighing was carried out according to thinkstep LCIA Survey 2012, Global, CML 2016, including biogenic carbon (global equivalents weighted). No data for the normalization and weighing according to ReCiPe 2016 were available.

3.2. Scenario with a Longer Service Life of Reusable Blocks

In the second scenario, the possibility of reusing the blocks was considered, hence a longer service life was assumed (100 years for blocks). Alternatively, Plan 4 (regular concrete wall system) had the same assumed moral life expectancy as in the first scenario (50 years) and so, for comparable function, twice as much material was needed than in the first case. Even a well-functioning construction was demolished after some time due to outdated design or inappropriate other properties. This time period is called moral life expectancy.

Table 9 and

Table 10 show that Plan 2 s2 was still the most favorable scenario. In comparison with other scenarios, it had a more negative impact, only in the ODP category. The worst construction was Plan 4 s2, which potentially caused almost double the impact than in the first scenario.

There were some differences among results according to CML2001 and ReCiPe 2016. For example, in the category of photochemical ozone, Plan 4 s2 was the most beneficial construction according to CML2001 and Plan2 s2 had the smallest impact according to ReCiPe 2016. According to ReCiPe 2016, Plan 1 s2 caused the smallest total impact but on the other hand, the smallest total impact according to CML2001 was caused by Plan 4 s2.