Investigation and Application of a New Low-Carbon Material (Preplaced Aggregate Concrete) in Concrete-Filled Steel Tube Stub Columns

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Specimens

2.2. Material Properties and Concrete Proportions

2.3. Preparation of Specimens

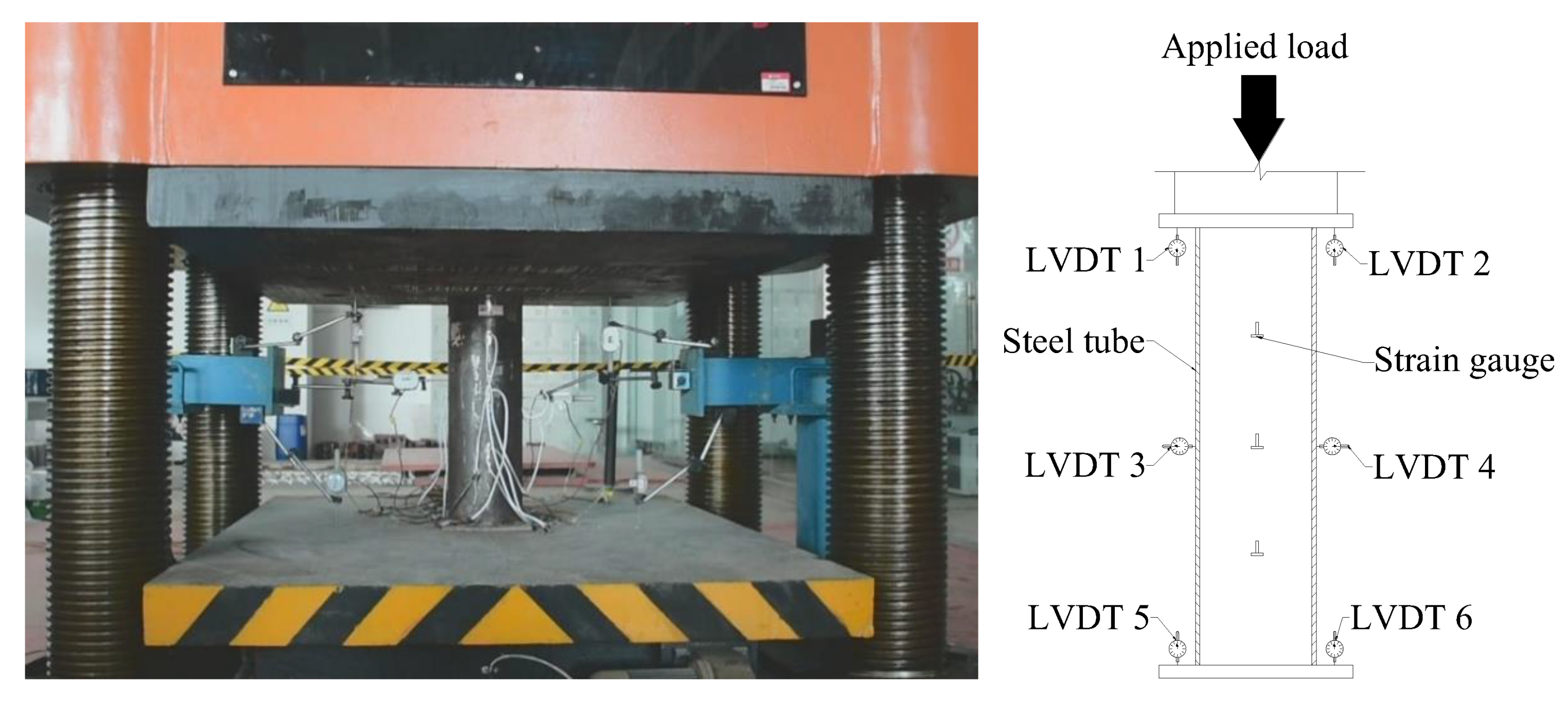

2.4. Experimental Setup

3. Results and Discussion

3.1. Failure Modes

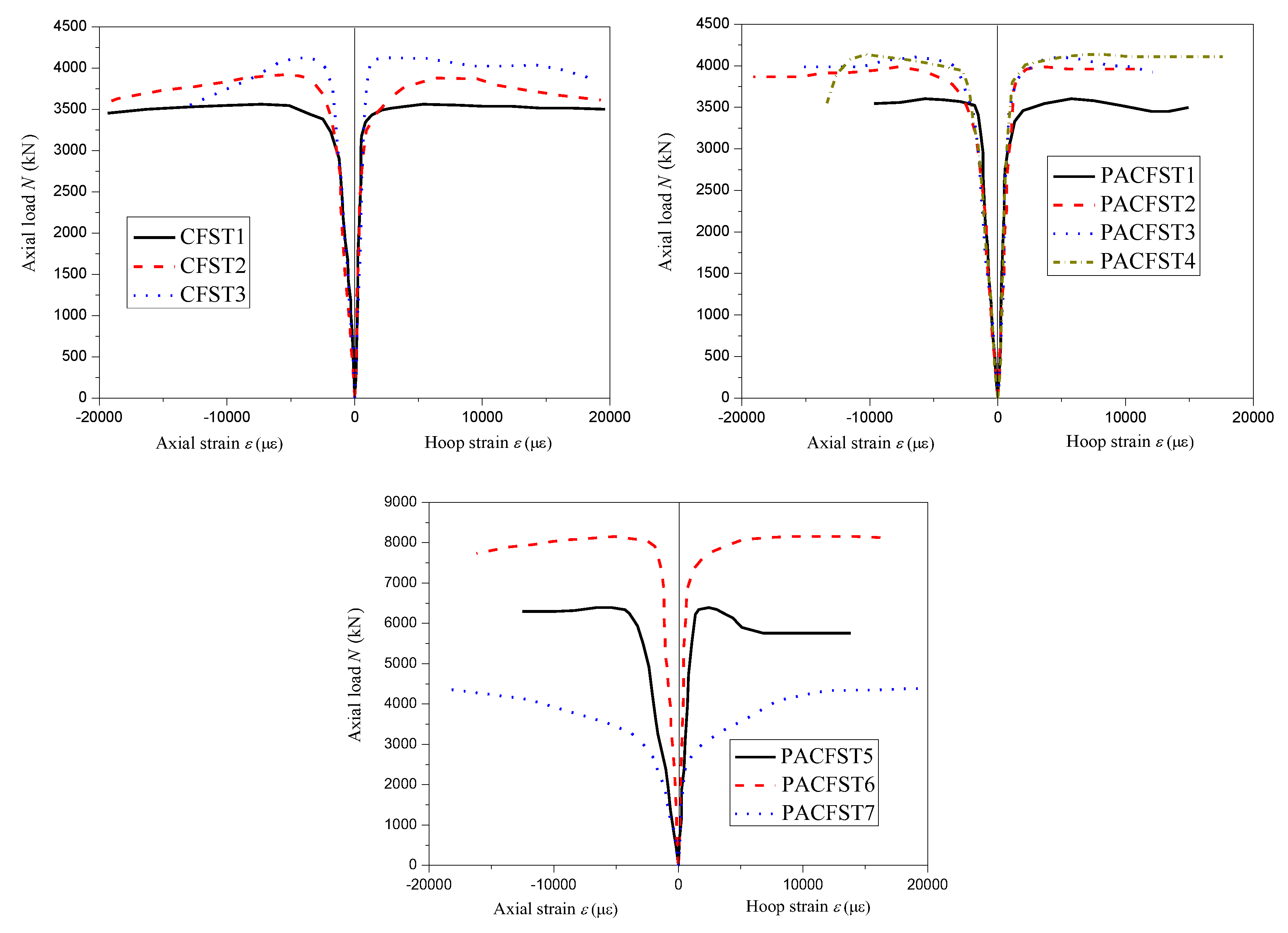

3.2. Axial Load-Axial Strain Curves

- (I)

- Elastic stage: This stage covered the load varied from beginning load to about 80% of ultimate load. At this stage, the axial load raised almost linearly with strain. The steel tube and core concrete were all at elastic stage and no visible change would be seen on the surface of specimens.

- (II)

- Elastic-plastic stage: At this stage, the axial load-axial strain curves changed from initial straight line to curve. The steel tube started to yield and the hoop deformation of core concrete increased rapidly. The bulge appeared at two ends of specimens firstly and then appeared near the middle of steel tube.

- (III)

- Plastic stage: After ultimate load, the specimens fell in plastic stage. At this stage, the axial load remained roughly unchanged or a slight decrease with strain increased for most of the specimens. Only the axial load of PACFST4 stub columns increased with strain which might be mainly due to the larger confinement index. All PACFST stub columns exhibited favorable ductility after ultimate load which were in keeping with that of CFST stub columns.

3.3. Parametric Analysis

3.3.1. Effect of Concrete Type and Concrete Strength

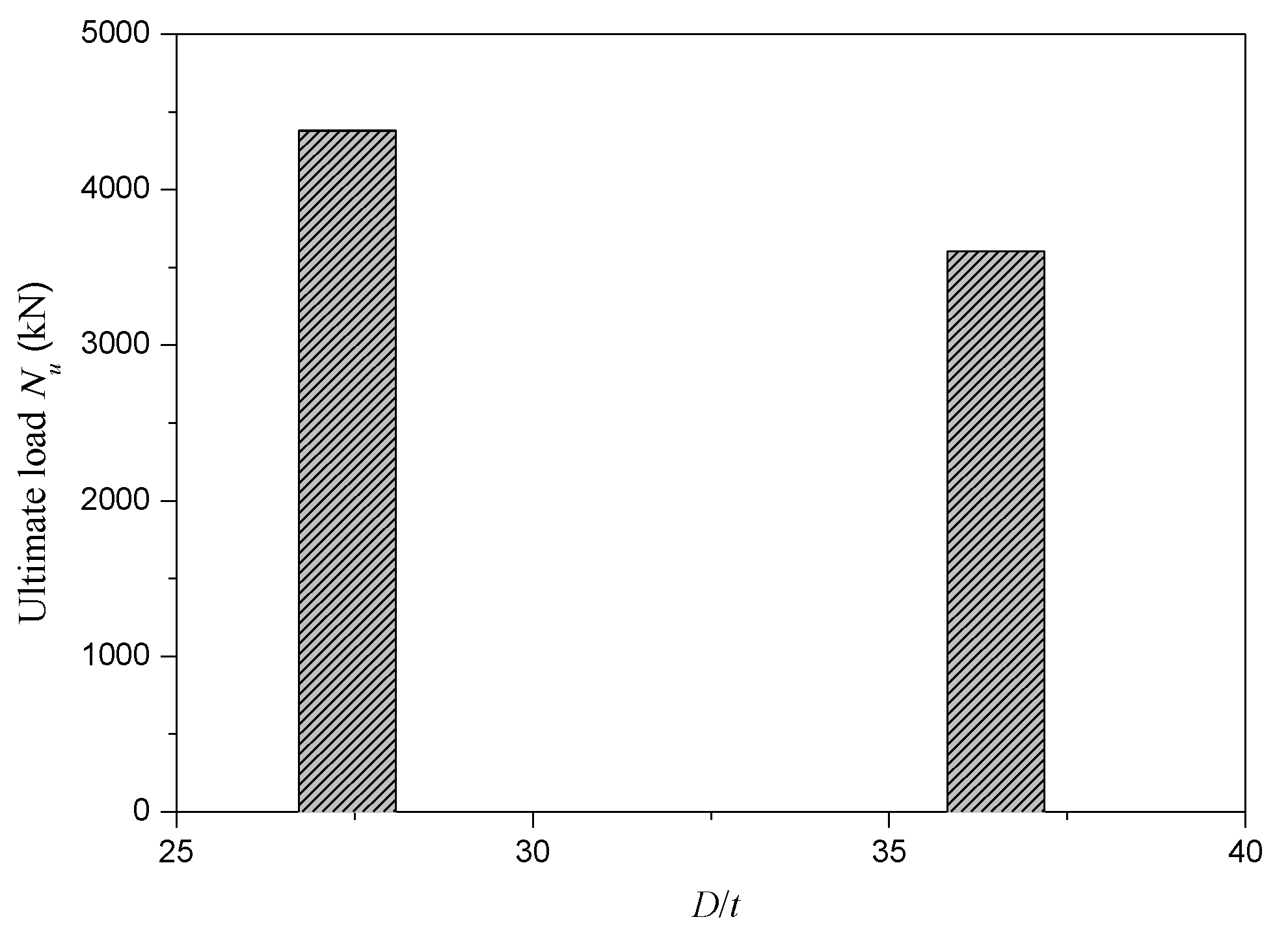

3.3.2. Effect of D/t Ratio

3.3.3. Effect of Confinement Factor

3.4. Strain Response

3.5. Bearing Capacity Calculation

4. Conclusion

- (1)

- The PACFST stub columns under axial compression exhibited a typical drum-like failure mode which were analogous to that of CFST stub columns. Meanwhile, the axial load-axial strain curves of PACFST stub columns could be roughly divided into three stages which were also analogous to that of CFST stub columns.

- (2)

- Under the same strength grade of core concrete, steel strength and external diameter of steel tube, the ultimate load of PACFST stub columns and CFST stub columns were almost the same, the strains at ultimate load of PACFST stub columns were a bit smaller than that of CFST stub columns.

- (3)

- Compared the bearing capacity calculation results of PACFST stub columns calculated by existing relevant standards, the results calculated by GB 50936 and JGJ 138 coincided well with the experimental results. Thus, bearing capacity calculation method of CFST stub columns mentioned in GB 50936 and JGJ 138 could be utilized to evaluate the bearing capacity of PACFST stub columns under axial compression.

- (4)

- Under the similar bearing capacity of PACFST stub columns and CFST stub columns, about 15%~20% saving in cement consumption would be achieved when NC was replaced by PAC to prepared CFST stub columns. Development of PAC in CFST stub columns was benefit to reduce the consumption of cement in CFST structures and would achieve a number of economic and social benefits.

Author Contributions

Funding

Conflicts of Interest

References

- Han, L.H.; Li, W.; Bjorhovde, R. Developments and advanced applications of concrete-filled steel tubular (CFST) structures: Members. J. Constr. Steel Res. 2014, 100, 211–228. [Google Scholar] [CrossRef]

- Wang, R.; Han, L.H.; Hou, C.C. Behavior of concrete filled steel tubular (CFST) members under lateral impact: Experiment and FEA model. J. Constr. Steel Res. 2013, 80, 188–201. [Google Scholar] [CrossRef]

- Roeder, C.W.; Lehman, D.E.; Bishop, E. Strength and Stiffness of Circular Concrete-Filled Tubes. J. Struct. Eng. 2010, 136, 1545–1553. [Google Scholar] [CrossRef]

- Yu, Z.W.; Ding, F.X.; Cai, C.S. Experimental behavior of circular concrete-filled steel tube stub columns. J. Constr. Steel Res. 2007, 63, 165–174. [Google Scholar] [CrossRef]

- Wang, Z.B.; Tao, Z.; Han, L.H.; Uy, B.; Lam, D.; Kang, W.H. Strength, stiffness and ductility of concrete-filled steel columns under axial compression. Eng. Struct. 2017, 135, 209–221. [Google Scholar] [CrossRef]

- Fang, S.; Liu, F.; Xiong, Z.; Fang, J.S.; Li, L.J. Seismic performance of recycled aggregate concrete-filled glass fibre-reinforced polymer-steel composite tube columns. Constr. Build. Mater. 2019, 225, 997–1010. [Google Scholar] [CrossRef]

- Xu, J.J.; Chen, Z.P.; Zhao, X.Y.; Demartino, C.; Ozbakkaloglu, T.; Xue, J.Y. Seismic performance of circular recycled aggregate concrete-filled steel tubular columns: FEM modelling and sensitivity analysis. Thin-Walled Struct. 2019, 141, 509–525. [Google Scholar] [CrossRef]

- Yu, M.; Wang, T.; Huang, W.J.; Yuan, H.X.; Ye, J.Q. Fire resistance of concrete-filled steel tube columns with preload. Part I: Experimental investigation. Compos. Struct. 2019, 223, 110994. [Google Scholar] [CrossRef]

- Wang, K.; Ben, Y. Fire resistance of concrete-filled high strength steel tubular columns. Thin-Walled Struct. 2013, 71, 46–56. [Google Scholar] [CrossRef] [Green Version]

- Xu, W.; Han, L.H.; Li, W. Seismic performance of concrete-encased column base for hexagonal concrete-filled steel tube: Experimental study. J. Constr. Steel Res. 2016, 121, 352–369. [Google Scholar] [CrossRef]

- Li, Y.; Cai, C.C.; Liu, Y.; Chen, Y.J.; Liu, J.F. Dynamic analysis of a large span specially shaped hybrid girder bridge with concrete-filled steel tube arches. Eng. Struct. 2016, 106, 243–260. [Google Scholar] [CrossRef] [Green Version]

- Xin, L.F.; Li, X.Z.; Zhang, Z.T.; Zhao, L.F. Seismic behavior of long-span concrete-filled steel tubular arch bridge subjected to near-fault fling-step motions. Eng. Struct. 2019, 180, 148–159. [Google Scholar] [CrossRef]

- He, A.; Zhao, Q. Experimental and numerical investigations of concrete-filled stainless steel tube stub columns under axial partial compression. J. Constr. Steel Res. 2019, 158, 405–416. [Google Scholar] [CrossRef]

- Qiao, Q.Y.; Zhang, W.W.; Mou, B.; Cao, W.L. Seismic behavior of exposed concrete filled steel tube column bases with embedded reinforcing bars: Experimental investigation. Thin-Walled Struct. 2019, 136, 367–381. [Google Scholar] [CrossRef]

- Cao, V.V. Experimental Behaviour of Recycled Aggregate Concrete-Filled Steel Tubes Under Axial Loading. Int. J. Civ. Eng. 2019, 17, 1341–1351. [Google Scholar]

- ACI. Committee 304. Guide for Measuring, Mixing, Transporting, and Placing Concrete; American Concrete Institute: Farmington Hill, MI, USA, 2005. [Google Scholar]

- Nehdi, M.L.; Najjar, M.F.; Soliman, A.M.; Azabi, T.M. Novel eco-efficient Two-Stage Concrete incorporating high volume recycled content for sustainable pavement construction. Constr. Build. Mater. 2017, 146, 9–14. [Google Scholar] [CrossRef]

- Felekoğlu, B. Optimization of self-compacting filling grout mixtures for repair purposes. Constr. Build. Mater. 2008, 22, 660–667. [Google Scholar] [CrossRef]

- Mirza, J.; Mirza, M.S.; Roy, V.; Saleh, K. Basic rheological and mechanical properties of high-volume fly ash grouts. Constr. Build. Mater. 2002, 16, 353–363. [Google Scholar] [CrossRef]

- Abdelgader, H.S.; Górsk, J. Stress-Strain Relations and Modulus of Elasticity of Two-Stage Concrete. J. Mater. Civ. Eng. 2003, 15, 329–334. [Google Scholar] [CrossRef]

- Najjar, M.F.; Nehdi, M.L.; Soliman, A.M.; Azabi, T.M. Damage mechanisms of two-stage concrete exposed to chemical and physical sulfate attack. Constr. Build. Mater. 2017, 137, 141–152. [Google Scholar] [CrossRef]

- Najjar, M.F.; Soliman, A.M.; Nehdi, M.L. Critical overview of two-stage concrete: Properties and applications. Constr. Build. Mater. 2014, 62, 47–58. [Google Scholar] [CrossRef]

- Yoon, J.Y.; Kim, J.H. Mechanical properties of preplaced lightweight aggregates concrete. Constr. Build. Mater. 2019, 216, 440–449. [Google Scholar] [CrossRef]

- Li, P.P.; Yu, Q.L.; Brouwers, H.J.H.; Chen, W. Conceptual design and performance evaluation of two-stage ultra-low binder ultra-high performance concrete. Cem. Concr. Res. 2019, 125, 105858. [Google Scholar] [CrossRef]

- Chen, Y.H.; Liu, S.; Zhu, B.L.; Liu, R.; Wang, Y. Preparation of preplaced aggregate concrete and experimental study on its strength. Constr. Build. Mater. 2020, 229, 116847. [Google Scholar] [CrossRef]

- Lee, S.; Jang, S.Y.; Kim, C.Y.; Ahn, E.J.; Kim, S.P.; Gwon, S.; Shin, M. Effects of Redispersible Polymer Powder on Mechanical and Durability Properties of Preplaced Aggregate Concrete with Recycled Railway Ballast. Int. J. Concr. Struct. Mater. 2018, 12, 69. [Google Scholar] [CrossRef]

- Bras, A.; Gião, R.; Lúcio, V.; Chastre, C. Development of an injectable grout for concrete repair and strengthening. Cem. Concr. Compos. 2013, 37, 185–195. [Google Scholar] [CrossRef] [Green Version]

- Abdelgader, H.S.; Najjar, M.F.; Azabi, T.M. Study of underwater concrete using two-stage (pre-placed aggregate) concrete in Libya. Struct. Concr. 2010, 11, 161–165. [Google Scholar] [CrossRef]

- Lv, J.; Zhou, T.H.; Du, Q.; Li, K.L.; Jin, L.W. Research on the Bond Behavior of Preplaced Aggregate Concrete-Filled Steel Tube Columns. Materials 2020, 13, 300. [Google Scholar] [CrossRef] [Green Version]

- Tian, H.W.; Zhou, Z.; Wei, Y.; Wang, Y.Q.; Lu, J.P. Experimental investigation on axial compressive behavior of ultra-high performance concrete (UHPC) filled glass FRP tubes. Constr. Build. Mater. 2017, 154, 644–657. [Google Scholar] [CrossRef]

- Yang, J.L.; Wang, J.Z.; Wang, X.P.; Cheng, L.; Wang, Z.R. Compressive Behavior of Circular Tubed Steel-Reinforced High-Strength Concrete Short Columns. J. Struct. Eng. 2019, 145, 04019086. [Google Scholar] [CrossRef]

- Abed, F.; AlHamaydeh, M.; Abdalla, S. Experimental and numerical investigations of the compressive behavior of concrete filled steel tubes (CFSTs). J. Constr. Steel Res. 2013, 80, 429–439. [Google Scholar] [CrossRef]

- Tao, Z.; Song, T.Y.; Uy, B.; Han, L.H. Bond behavior in concrete-filled steel tubes. J. Constr. Steel Res. 2016, 120, 81–93. [Google Scholar] [CrossRef]

- Chen, Y.; Feng, R.; Shao, Y.B.; Zhang, X.T. Bond-slip behaviour of concrete-filled stainless steel circular hollow section tubes. J. Constr. Steel Res. 2017, 130, 248–263. [Google Scholar] [CrossRef]

- Wang, J.H.; He, J.; Xiao, Y. Fire behavior and performance of concrete-filled steel tubular columns: Review and discussion. r of concrete-filled stainless steel circular hollow section tubes. J. Constr. Steel Res. 2019, 157, 19–31. [Google Scholar] [CrossRef]

- ACI. Committee 318. Building Code Requirements for Structural Concrete and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2011. [Google Scholar]

- AIJ. Recommendations for Design and Construction of Concrete Filled Steel Tubular Structures; Architectural Institute of Japan (AIJ): Tokyo, Japan, 2008. [Google Scholar]

- European Committee for Standardization. Eurocode 4: Design of Composite Steel and Concrete Structures; European Committee for Standardization: Brussels, Belgium, 2004. [Google Scholar]

- GB50936-2014. Technical Code for Concrete Filled Steel Tubular Columns; China Architecture and Building Press: Beijing, China, 2014.

- JGJ 138-2016: Code for Design of Composite Structures; China Architecture and Building Press: Beijing, China, 2016.

- GB 175-2007: Common Portland Cement; China Standards Press: Beijing, China, 2007.

- JGJ 55-2011: Specification for Mix Proportion Design of Ordinary Concrete; China Architecture and Building Press: Beijing, China, 2011.

- GB/T 50081-2002: Standard for Test Method of Mechanical Properties on Ordinary Concrete; China Architecture and Building Press: Beijing, China, 2003.

| Specimen ID | D × t × L (mm3) | fcu (MPa) | fy (MPa) | fu (MPa) | Es (MPa) | ξ | As/Ac |

|---|---|---|---|---|---|---|---|

| PACFST1 | 219 × 6 × 657 | 44.7 | 340 | 510 | 2.05 × 105 | 1.26 | 11.9% |

| PACFST2 | 219 × 6 × 657 | 57.2 | 340 | 510 | 2.05 × 105 | 0.98 | 11.9% |

| PACFST3 | 219 × 6 × 657 | 65.7 | 340 | 510 | 2.05 × 105 | 0.82 | 11.9% |

| PACFST4 | 219 × 6 × 657 | 44.7 | 398 | 492 | 2.11 × 105 | 1.47 | 11.9% |

| PACFST5 | 299 × 8 × 897 | 44.7 | 341 | 503 | 2.06 × 105 | 1.23 | 11.6% |

| PACFST6 | 351 × 8 × 1053 | 44.7 | 343 | 511 | 2.06 × 105 | 1.04 | 9.8% |

| PACFST7 | 219 × 8 × 657 | 44.7 | 332 | 492 | 2.08 × 105 | 1.73 | 11.9% |

| CFST1 | 219 × 6 × 657 | 46.4 | 340 | 510 | 2.05 × 105 | 1.21 | 11.9% |

| CFST2 | 219 × 6 × 657 | 56.8 | 340 | 510 | 2.05 × 105 | 0.99 | 11.9% |

| CFST3 | 219 × 6 × 657 | 67.1 | 340 | 510 | 2.05 × 105 | 0.81 | 11.9% |

| Mineral Compositions | Content/% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | K2O | Na2O | Loss on Ignition | |

| Ordinary Portland Cement | 60.32 | 22.34 | 4.55 | 4.18 | 2.05 | 2.87 | 0.51 | 0.41 | 2.77 |

| Materials | Type | Properties |

|---|---|---|

| coarse aggregate I | Crushed coarse aggregate | Crushing index: 9.5% |

| Loose bulk density: 1360 kg/m3 | ||

| Apparent density: 2520 kg/m3 | ||

| coarse aggregate II | Crushed coarse aggregate | Crushing index: 8.6% |

| Loose bulk density: 1420 kg/m3 | ||

| Apparent density: 2520 kg/m3 | ||

| Sand I | River sand | Modulus of fineness: 3.58 |

| Bulk density: 1450 kg/m3 | ||

| Apparent density: 2610 kg/m3 | ||

| Sand II | River sand | Modulus of fineness: 2.68 |

| Bulk density: 1430 kg/m3 | ||

| Apparent density: 2625 kg/m3 | ||

| Water reducing agent | Polycarboxylate superplasticizer | Solid content: 40% |

| Water reduction rate: 25% |

| Concrete Grade | Weight Per Cubic Meter (kg/m3) | W/B | ||||||

|---|---|---|---|---|---|---|---|---|

| Cement | Sand I | Sand II | Coarse Aggregate I | Coarse Aggregate II | Water Reducer | Water | ||

| C60 (PAC) | 385 | 578 | 1360 | 5.78 | 116 | 0.30 | ||

| C50 (PAC) | 330 | 660 | 1360 | 4.98 | 100 | 0.30 | ||

| C40 (PAC) | 310 | 620 | 1360 | 2.48 | 124 | 0.40 | ||

| C60 (NC) | 500 | 660 | 1080 | 7.50 | 160 | 0.32 | ||

| C50 (NC) | 470 | 580 | 1180 | 7.05 | 170 | 0.36 | ||

| C40 (NC) | 420 | 570 | 1270 | 4.20 | 185 | 0.44 | ||

| Number | Nu (kN) | ACI | AIJ | Eurocode 4 | GB 50936 | JGJ 138 | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pu (kN) | Pu/Nu | Pu (kN) | Pu/Nu | Pu (kN) | Pu/Nu | Pu (kN) | Pu/Nu | Pu (kN) | Pu/Nu | ||

| CFST1 | 3562 | 2322 | 0.691 | 2691 | 0.801 | 4027 | 1.199 | 3055 | 0.910 | 3358 | 0.943 |

| CFST2 | 3879 | 2537 | 0.686 | 2905 | 0.786 | 4279 | 1.157 | 3387 | 0.916 | 3697 | 0.953 |

| CFST3 | 4127 | 2804 | 0.751 | 3173 | 0.850 | 4594 | 1.230 | 3805 | 1.019 | 3735 | 0.905 |

| PACFST1 | 3603 | 2287 | 0.693 | 2656 | 0.805 | 3985 | 1.207 | 3001 | 0.909 | 3300 | 0.916 |

| PACFST2 | 3989 | 2545 | 0.687 | 2914 | 0.786 | 4289 | 1.157 | 3400 | 0.917 | 3706 | 0.929 |

| PACFST3 | 4106 | 2774 | 0.749 | 3143 | 0.849 | 4558 | 1.231 | 3758 | 1.015 | 3703 | 0.902 |

| PACFST4 | 4136 | 2520 | 0.700 | 2951 | 0.820 | 4480 | 1.245 | 3270 | 0.908 | 3599 | 0.870 |

| PACFST5 | 6389 | 4217 | 0.692 | 4890 | 0.802 | 7332 | 1.203 | 5548 | 0.910 | 6094 | 0.954 |

| PACFST6 | 8154 | 5372 | 0.686 | 6170 | 0.788 | 9173 | 1.172 | 7181 | 0.917 | 7828 | 0.960 |

| PACFST7 | 4379 | 2647 | 0.697 | 3122 | 0.822 | 4726 | 1.245 | 3332 | 0.878 | 3796 | 0.867 |

| Average | 0.703 | 0.811 | 1.205 | 0.930 | 0.920 | ||||||

| Cov | 0.036 | 0.029 | 0.028 | 0.050 | 0.037 | ||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, J.; Zhou, T.; Li, K. Investigation and Application of a New Low-Carbon Material (Preplaced Aggregate Concrete) in Concrete-Filled Steel Tube Stub Columns. Sustainability 2020, 12, 1768. https://doi.org/10.3390/su12051768

Lv J, Zhou T, Li K. Investigation and Application of a New Low-Carbon Material (Preplaced Aggregate Concrete) in Concrete-Filled Steel Tube Stub Columns. Sustainability. 2020; 12(5):1768. https://doi.org/10.3390/su12051768

Chicago/Turabian StyleLv, Jing, Tianhua Zhou, and Kunlun Li. 2020. "Investigation and Application of a New Low-Carbon Material (Preplaced Aggregate Concrete) in Concrete-Filled Steel Tube Stub Columns" Sustainability 12, no. 5: 1768. https://doi.org/10.3390/su12051768

APA StyleLv, J., Zhou, T., & Li, K. (2020). Investigation and Application of a New Low-Carbon Material (Preplaced Aggregate Concrete) in Concrete-Filled Steel Tube Stub Columns. Sustainability, 12(5), 1768. https://doi.org/10.3390/su12051768