Development of an Assessment Method for Evaluation of Sustainable Factories

Abstract

:1. Introduction

2. Materials and Methods

2.1. AHP Method

- Calculation of the criteria weights;

- Calculation of the matrix of assessment scores;

- Ranking the options according to the weighted scores.

2.2. Triangular Fuzzy Number (TFN)

2.3. Triangular Fuzzy AHP

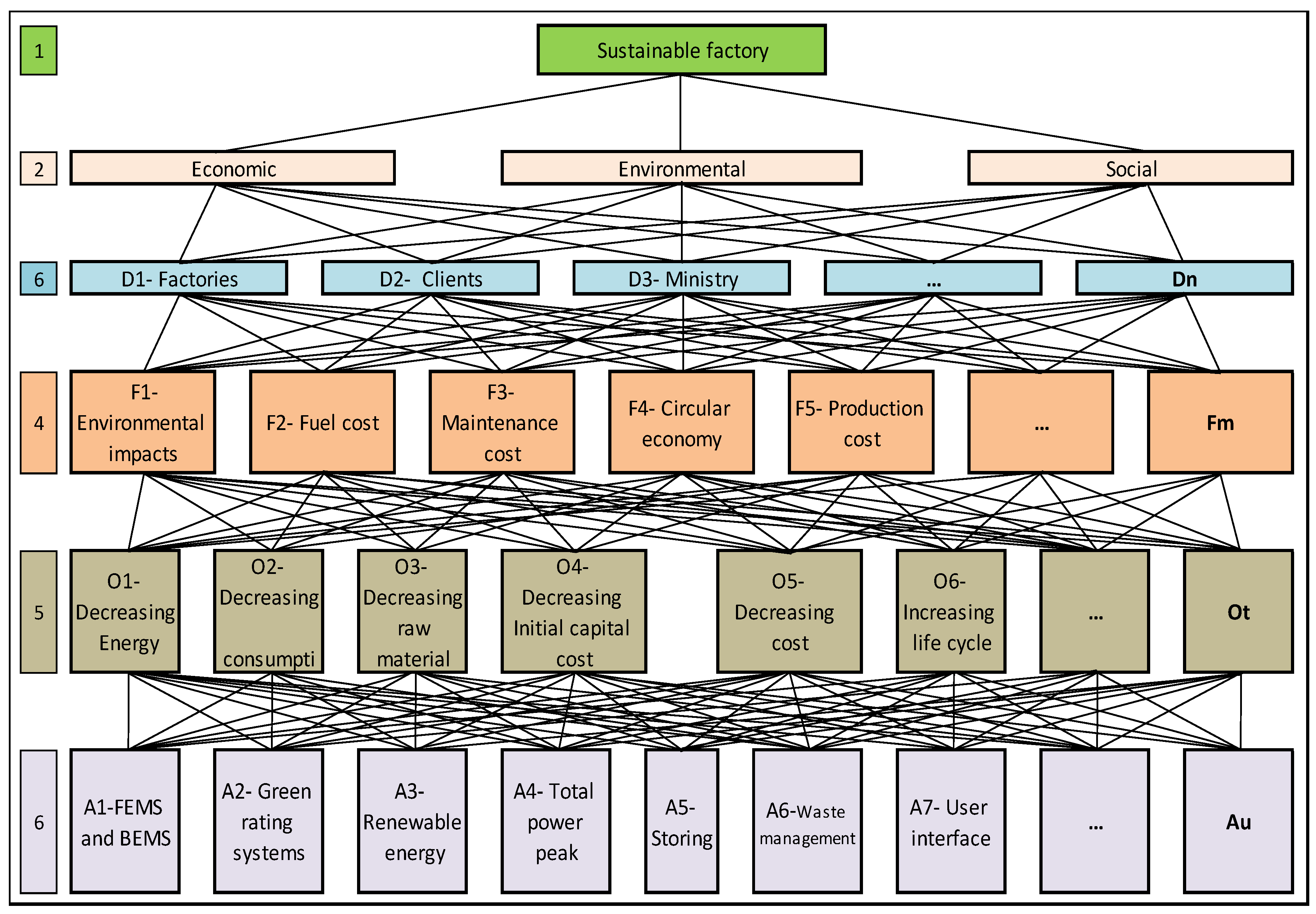

2.4. The Developed Multi-Layer AHP

- Level 1 (Goal): Sustainable Factory;

- Level 2 (Criteria): C1) Economic, C2) Environmental, C3) Social;

- Level 3 (Decision Makers, D1 to Dn): D1) Factories, D2) Clients, D3) Ministry, D4) International conventions, D5) Regional organizations… Dn;

- Level 4 (Factors, F1 to Fm): F1) Environmental impacts, F2) Fuel cost, F3) Maintenance cost, F4) Circular economy, F5) Production cost, F6) Initial capital cost, F7) Life cycle GHGs … Fm;

- Level 5 (Objectives, O1 to Ot): O1) Decreasing energy consumption, O2) Decreasing water consumption, O3) Decreasing the use of raw materials, O4) Decreasing initial capital cost, O5) Decreasing production cost, O6) Increasing life cycle, O7) Increasing the profits, O8) Decreasing Environment impacts … Ot;

- Level 6 (Alternatives, A1 to Au): A1) Factory Energy Management System (FEMS) and Building Energy Management System (BEMS), A2) Green rating systems, A3) Renewable energy, A4) Total power peak, A5) Storing of productions, A6) Energy waste management, A7) User interface, A8) Direct and indirect energy flow, A9) water management, A10) Lid methods, A11) Reusing and recycling … Au.

3. Results

- In this part, the TFAHP approach was formulated for the evaluation of sustainable factories. The developed method allows adding the new indicators to all layers, and thus there are no limits for using any unique green rating systems or standards that are vital for the industrial sector with different types of factories and products.

- Normalized weight of components in each layer;

- Pairwise comparison matrix of layers, under the correlated components in the upper layer;

- Normalized weight of components, under the correlated components in the upper layer;

- Total aggregated score concerning the sustainability goal;

- Ranking of the alternatives according to the final score.

3.1. Computing the Pairwise Comparison Matrix for Criteria

3.2. Computing the Normalized Weight for Criteria

3.3. Computing the Pairwise Comparison Matrix for Decision-Maker

3.4. Computing the Pairwise Comparison Matrix for Factors

3.5. Computing the Pairwise Comparison Matrix for Objectives

3.6. Computing the Pairwise Comparison Matrix for Alternatives

3.7. Calculation of Normalized Weight of Components in Each Layer

3.8. Total Aggregated Score Concerning the Sustainability Goal

3.9. Verification of the Provided Method

3.10. The Advantages of the Provided Assessment Approach

4. Discussion and Conclusions

Recommendations

Author Contributions

Funding

Conflicts of Interest

References

- International Energy Agency, Energy Technology Perspectives. 2017. Available online: http://www.iea.org/ (accessed on 28 October 2019).

- Olivier, J.G.J.; Schure, K.M.; Peters, J. Trends in Global CO2 and Total Greenhouse Gas 2017 Report; PBL Netherlands Environment Assessment Agency: Den Haag, The Netherlands, 2017. [Google Scholar]

- Ritchie, H.; Roser, M. CO2 and Greenhouse Gas Emissions. Our World Data 2018. Available online: https://ourworldindata.org/ (accessed on 21 October 2019).

- Pirouz, B.; Maiolo, M. The role of power consumption and type of air conditioner in direct and indirect water consumption. J. Sustain. Dev. Energy Water Environ. Syst. 2018, 6, 665–673. [Google Scholar] [CrossRef] [Green Version]

- Shiklomanov, I. World fresh water resources, Water in Crisis: A Guide to the World’s Fresh Water Resources; Oxford University Press: New York, NY, USA, 1993; pp. 13–24. [Google Scholar]

- Maiolo, M.; Carini, M.; Capano, G.; Piro, P. Synthetic sustainability index (SSI) based on life cycle assessment approach of low impact development in the Mediterranean area. Cogent Eng. 2017, 4, 1410272. [Google Scholar] [CrossRef]

- Piro, P.; Carbone, M.; Morimanno, F.; Palermo, S.A. Simple flowmeter device for LID systems: From laboratory procedure to full-scale implementation. Flow Meas. Instrum. 2019, 65, 240–249. [Google Scholar] [CrossRef]

- Carbone, M.; Turco, M.; Brunetti, G.; Piro, P. A Cumulative Rainfall Function for Subhourly Design Storm in Mediterranean Urban Areas. Adv. Meteorol. 2015. [Google Scholar] [CrossRef] [Green Version]

- Kates, R.W.; Parris, T.M.; Leiserowitz, A.A. What is sustainable development? Goals, indicators, values, and practice. Environment 2005, 47, 8–21. [Google Scholar]

- Palermo, S.A.; Zischg, J.; Sitzenfrei, R.; Rauch, W.; Piro, P. Parameter Sensitivity of a Microscale Hydrodynamic Model. In New Trends in Urban Drainage Modelling. UDM 2018; Mannina, G., Ed.; Green Energy and Technology; Springer: Cham, Switzerland, 2019; pp. 982–987. [Google Scholar] [CrossRef]

- Oberascher, M.; Zischg, J.; Palermo, S.A.; Kinzel, C.; Rauch, W.; Sitzenfrei, R. Smart Rain Barrels: Advanced LID Management Through Measurement and Control. In New Trends in Urban Drainage Modelling. UDM 2018; Mannina, G., Ed.; Green Energy and Technology; Springer: Cham, Switzerland, 2019; pp. 777–782. [Google Scholar] [CrossRef]

- Giordano, A.; Spezzano, G.; Vinci, A.; Garofalo, G.; Piro, P. A Cyber-Physical System for Distributed Real-Time Control of Urban Drainage Networks in Smart Cities. In Internet and Distributed Computing Systems. IDCS 2014; Fortino, G., Di Fatta, G., Li, W., Ochoa, S., Cuzzocrea, A., Pathan, M., Eds.; Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2014; Volume 98, pp. 87–98. [Google Scholar] [CrossRef]

- Piro, P.; Turco, M.; Palermo, S.A.; Principato, F.; Brunetti, G. A Comprehensive Approach to Stormwater Management Problems in the Next Generation Drainage Networks. In The Internet of Things for Smart Urban Ecosystems; Cicirelli, F., Guerrieri, A., Mastroianni, C., Spezzano, G., Vinci, A., Eds.; Internet of Things (Technology, Communications and Computing); Springer: Cham, Switzerland, 2019; pp. 275–304. [Google Scholar] [CrossRef]

- Turco, M.; Brunetti, G.; Palermo, S.A.; Capano, G.; Grossi, G.; Maiolo, M.; Piro, P. On the environmental benefits of a permeable pavement: metals potential removal efficiency and Life Cycle Assessment. Urban Water J. 2020, 1–9. [Google Scholar] [CrossRef]

- Palermo, S.A.; Turco, M.; Principato, F.; Piro, P. Hydrological effectiveness of an extensive green roof in Mediterranean climate. Water 2019, 11, 1378. [Google Scholar] [CrossRef] [Green Version]

- Turco, M.; Brunetti, G.; Carbone, M.; Piro, P. Modelling the hydraulic behaviour of permeable pavements through a reservoir element model. In Proceedings of the International Multidisciplinary Scientific GeoConference Surveying Geology and Mining Ecology Management, Sofia, Bulgaria, 28 June–7 July 2018; Volume 18, pp. 507–514, Fasc. 3.1. [Google Scholar] [CrossRef]

- Blewitt, J. Understanding Sustainable Development; Routledge: Abingdon upon Thames, UK, 2012; ISBN 9781849773645. [Google Scholar]

- Jayal, A.D.; Badurdeen, F.; Dillon, O.W.; Jawahir, I.S. Sustainable manufacturing: Modeling and optimization challenges at the product, process and system levels. CIRP J. Manuf. Sci. Technol. 2010, 2, 144–152. [Google Scholar] [CrossRef]

- Jayawickrama, H.M.M.M.; Kulatunga, A.K.; Mathavan, S. Fuzzy AHP based Plant Sustainability Evaluation Method. Procedia Manuf. 2017, 8, 571–578. [Google Scholar] [CrossRef]

- Chen, D.; Schudeleit, T.; Posselt, G.; Thiede, S. A state-of-the-art review and evaluation of tools for factory sustainability assessment. Procedia CIRP 2013, 9, 85–90. [Google Scholar] [CrossRef] [Green Version]

- Noori, A.M.; Mikaeil, R.; Mokhtarian, M.; Haghshenas, S.S.; Foroughi, M. Feasibility of Intelligent Models for Prediction of Utilization Factor of TBM. Geotech. Geol. Eng. 2020, 1–19. [Google Scholar] [CrossRef]

- Mehdi Hosseini, S.; Ataei, M.; Khalokakaei, R.; Mikaeil, R.; Shaffiee Haghshenas, S. Study of the effect of the cooling and lubricant fluid on the cutting performance of dimension stone through artificial intelligence models. Eng. Sci. Technol. Int. J. 2019. [Google Scholar] [CrossRef]

- Withers, S.; Demediuk, P. Sustainability Reporting Guidelines. Int. J. Sustain. Econ. Soc. Cult. Context 2014, 9, 44–60. [Google Scholar] [CrossRef]

- Singh, R.K.; Murty, H.R.; Gupta, S.K.; Dikshit, A.K. An overview of sustainability assessment methodologies. Ecol. Indic. 2009, 9, 189–212. [Google Scholar] [CrossRef]

- ISO. ISO 50001:2011—Energy Management Systems: Requirements with Guidance for Use; ISO: Geneva, Switzerland, 2011. [Google Scholar]

- Green Star rating, Multi-Unit Residential v1. 2014. Available online: https://www.gbca.org.au/green-star/ (accessed on 20 October 2019).

- Maiolo, M.; Pirouz, B.; Bruno, R.; Palermo, S.A.; Arcuri, N.; Piro, P. The role of the extensive green roofs on decreasing building energy consumption in the mediterranean climate. Sustainability 2020, 12, 359. [Google Scholar] [CrossRef] [Green Version]

- Bevilacqua, P.; Bruno, R.; Arcuri, N. Green roofs in a Mediterranean climate: Energy performances based on in-situ experimental data. Renew. Energy 2020. [Google Scholar] [CrossRef]

- Bruno, R.; Bevilacqua, P.; Cuconati, T.; Arcuri, N. Energy evaluations of an innovative multi-storey wooden near Zero Energy Building designed for Mediterranean areas. Appl. Energy 2019, 238, 929–941. [Google Scholar] [CrossRef]

- Pirouz, B.; Arcuri, N.; Maiolo, M.; Talarico, V.C.; Piro, P. A new multi-objective dynamic model to close the gaps in sustainable development of industrial sector. IOP Conf. Ser. Earth Environ. Sci. 2020, 410, 012074. [Google Scholar] [CrossRef] [Green Version]

- Pirouz, B.; Palermo, S.A.; Turco, M.; Piro, P. New Mathematical Optimization Approaches for LID Systems. In Numerical Computations: Theory and Algorithms. NUMTA 2019; Sergeyev, Y., Kvasov, D., Eds.; Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2020; Volume 11973, pp. 583–595. [Google Scholar] [CrossRef]

- Palermo, S.A.; Talarico, V.C.; Pirouz, B. Optimizing Rainwater Harvesting Systems for Non-potable Water Uses and Surface Runoff Mitigation. In Numerical Computations: Theory and Algorithms. NUMTA 2019; Sergeyev, Y., Kvasov, D., Eds.; Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2020; Volume 11973, pp. 570–582. [Google Scholar] [CrossRef]

- May, G.; Stahl, B.; Taisch, M. Energy management in manufacturing: Toward eco-factories of the future—A focus group study. Appl. Energy 2016, 164, 628–638. [Google Scholar] [CrossRef]

- Wong, J.K.W.; Li, H. Application of the analytic hierarchy process (AHP) in multi-criteria analysis of the selection of intelligent building systems. Build. Environ. 2008, 43, 108–125. [Google Scholar] [CrossRef]

- Zarghami, E.; Azemati, H.; Fatourehchi, D.; Karamloo, M. Customizing well-known sustainability assessment tools for Iranian residential buildings using Fuzzy Analytic Hierarchy Process. Build. Environ. 2018, 128, 107–128. [Google Scholar] [CrossRef]

- Shirani Faradonbeh, R.; Shaffiee Haghshenas, S.; Taheri, A.; Mikaeil, R. Application of self-organizing map and fuzzy c-mean techniques for rockburst clustering in deep underground projects. Neural Comput. Appl. 2019. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. Identifying and ranking of strategies to implement green supply chain management in Indian manufacturing industry using analytical hierarchy process. J. Ind. Eng. Manag. 2013, 6, 930–962. [Google Scholar] [CrossRef] [Green Version]

- Lee, D.M.; Drake, P.R. A portfolio model for component purchasing strategy and the case study of two South Korean elevator manufacturers. Int. J. Prod. Res. 2010, 48, 6651–6682. [Google Scholar] [CrossRef] [Green Version]

- Ishizaka, A.; Pearman, C.; Nemery, P. AHPSort: An AHP-based method for sorting problems. Int. J. Prod. Res. 2012, 50, 4767–4784. [Google Scholar] [CrossRef]

- Shankar, K.M.; Kumar, P.U.; Kannan, D. Analyzing the drivers of advanced sustainable manufacturing system using AHP approach. Sustainability 2016, 8, 824. [Google Scholar] [CrossRef] [Green Version]

- Song, Y.; Li, J.; Wang, J.; Hao, S.; Zhu, N.; Lin, Z. Multi-criteria approach to passive space design in buildings: Impact of courtyard spaces on public buildings in cold climates. Build. Environ. 2015, 89, 295–307. [Google Scholar] [CrossRef]

- Javiri, F.; Aminullah, A.; Triwiyono, A. Assessment system of condition of typical building infrastructure using fuzzy analitical hierarchy procces (FAHP) method. In Proceedings of the MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 258. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Akyar, E.; Akyar, H.; DÜzce, S. Al A new method for ranking triangular fuzzy numbers. Int. J. Uncertain. Fuzziness Knowl.-Based Syst. 2012, 20, 729–740. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Kahraman, C.; Ruan, D. A fuzzy multi-criteria decision approach for software development strategy selection. Int. J. Gen. Syst. 2004, 33, 259–280. [Google Scholar] [CrossRef]

- Saaty, T.L.; Vergas, L.G. Models, Methods, Concepts & Applications of the Analytic Hierarchy Process; Springer: Cham, Switzerland, 2012; ISBN 978-1-4614-3597-6. [Google Scholar] [CrossRef] [Green Version]

- Saaty, T.L. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Bidanda, B. Sustainable manufacturing production-inventory decision of multiple factories with JIT logistics, component recovery and emission control. Transp. Res. Part E Logist. Transp. Rev. 2019, 128, 356–383. [Google Scholar] [CrossRef]

- Terkaj, W.; Danza, L.; Devitofrancesco, A.; Gagliardo, S.; Ghellere, M.; Giannini, F.; Monti, M.; Pedrielli, G.; Sacco, M.; Salamone, F. A semantic framework for sustainable factories. Procedia CIRP 2014, 17, 547–552. [Google Scholar] [CrossRef] [Green Version]

- Lu, T.; Gupta, A.; Jayal, A.D.; Badurdeen, F.; Feng, S.C.; Dillon, O.W.; Jawahir, I.S. A Framework of Product and Process Metrics for Sustainable Manufacturing. In Advances in Sustainable Manufacturing; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

| Linguistic Scales for the Importance | TFN Scale | TFN Reciprocal Scale |

|---|---|---|

| Just equal | (1,1,1) | (1,1,1) |

| Equal importance | (1/2,1,3/2) | (2/3,1,2) |

| Moderate importance | (1,3/2,2) | (1/2,2/3,1) |

| Strong importance | (3/2,2,5/2) | (2/5,1/2,2/3) |

| Very strong importance | (2,5/2,3) | (1/3,2/5,1/2) |

| Extreme importance | (5/2,3,7/2) | (2/7,1/3,2/5) |

| Economic | Environmental | Social | |

|---|---|---|---|

| Economic | |||

| Environmental | |||

| Social |

| j | |||

|---|---|---|---|

| k | |||

|---|---|---|---|

| l | |||

|---|---|---|---|

| r | |||

|---|---|---|---|

| i | Economic | Environmental | Social | Weight |

|---|---|---|---|---|

| Economic | (1,1,1) | (1,3/2,2) | (1,3/2,2) | 0.45 |

| Environmental | (1/2,2/3,1) | (1,1,1) | (1,3/2,2) | 0.35 |

| Social | (1/2,2/3,1) | (1/2,2/3,1) | (1,1,1) | 0.21 |

| Component of Criteria | j | D1-Factory | D2-Clients | Weight |

|---|---|---|---|---|

| Economic | D1-Factory | (1,1,1) | (2,5/2,3) | 1 |

| D2-Clients | (1/3,2/5,1/2) | (1,1,1) | 0 | |

| Environmental | D1-Factory | (1,1,1) | (2,5/2,3) | 1 |

| D2-Clients | (1/3,2/5,1/2) | (1,1,1) | 0 | |

| Social | D1-Factory | (1,1,1) | (1/2,1,3/2) | 0.5 |

| D2-Clients | (2/3,1,2) | (1,1,1) | 0.5 |

| Component of Decision-Makers | k | F1-Environmental Impacts | F-2 Maintenance Cost | Weight |

|---|---|---|---|---|

| D1 | F1-Environmental impacts | (1,1,1) | (2/5,1/2,2/3) | 0 |

| F-2 Maintenance cost | (3/2,2,5/2) | (1,1,1) | 1 | |

| D2 | F1-Environmental impacts | (1,1,1) | (2,5/2,3) | 1 |

| F-2 Maintenance cost | (1/3,2/5,1/2) | (1,1,1) | 0 |

| Component of Factors | l | O1-Decreasing Energy | O2-Decreasing Raw Material | O3-Decreasing Production Cost | O4-Increasing Life Cycle | Weight |

|---|---|---|---|---|---|---|

| F1 | O1-Decreasing Energy | (1,1,1) | (1/2,1,3/2) | (2,5/2,3) | (1,3/2,2) | 0.38 |

| O2-Decreasing raw material | (2/3,1,2) | (1,1,1) | (3/2,2,5/2) | (1,3/2,2) | 0.35 | |

| O3-Decreasing production cost | (1/3,2/5,1/2) | (2/5,1/2,2/3) | (1,1,1) | (2/5,1/2,2/3) | 0.01 | |

| O4-Increasing life cycle | (1/2,2/3,1) | (1/2,2/3,1) | (3/2,2,5/2) | (1,1,1) | 0.26 | |

| F2 | O1-Decreasing Energy | (1,1,1) | (1/2,1,3/2) | (1/2,2/3,1) | (1/2,2/3,1) | 0.19 |

| O2-Decreasing raw material | (2/3,1,2) | (1,1,1) | (1/2,1,3/2) | (1,1,1) | 0.25 | |

| O3-Decreasing production cost | (1,3/2,2) | (2/3,1,2) | (1,1,1) | (1,1,1) | 0.28 | |

| O4-Increasing life cycle | (1,3/2,2) | (1,1,1) | (1,1,1) | (1,1,1) | 0.28 |

| Component of Objectives | r | A1-Green Rating Systems | A2-Decrease of Total Power Peak | A3-Creating User Interface | Weight |

|---|---|---|---|---|---|

| O1 | A1-Green rating systems | (1,1,1) | - | (3/2,2,5/2) | 1 |

| A3-Creating user interface | (2/5,1/2,2/3) | - | (1,1,1) | 0 | |

| O2 | A1-Green rating systems | (1,1,1) | - | (1,3/2,2) | 0.68 |

| A3-Creating user interface | (1/2,2/3,1) | - | (1,1,1) | 0.32 | |

| O3 | A1-Green rating systems | (1,1,1) | (1,3/2,2) | - | 0.68 |

| A2-Decrease of total power peak | (1/2,2/3,1) | (1,1,1) | - | 0.32 | |

| O4 | A3-Creating user interface | - | - | (1,1,1) | 1 |

| Alternatives | RPS |

|---|---|

| A1-Green rating systems | 0.62 |

| A2-Decrease of total power peak | 0.03 |

| A3-Creating user interface | 0.37 |

| Method | Sustainability | Main Focus Parameters | Limits | ||

|---|---|---|---|---|---|

| Social | Economic | Environment | |||

| Current approach (TFAHP) | ✓ | ✓ | ✓ | In 6 levels tried to consider all correlated factors in Sustainability of factories | No limit in adding new parameters |

| Advanced Sustainable Manufacturing System Using AHP Approach [40] | ✓ | ✓ | ✓ | Based on 15 parameters such as; Quality Market capabilities Financial benefit Green innovation | The method limited to 15 defined criteria and the role of decision-makers and objectives missed in the evaluation. |

| The production-inventory decision of multiple factories JIT logistics (Just-in-Time) [48] | x | ✓ | ✓ | Resource recycling and emission reduction. Optimization based on minimum cost and minimum emission. | New modeling must be done for optimizing further case studies and is not a general assessment. |

| Sustainable Factory Semantic Framework [49] | x | ✓ | ✓ | Energy and Environmental. | The role of many factors missed according to the main focuses. |

| Product and Process Metrics for Sustainable Manufacturing [50] | ✓ | ✓ | ✓ | Correlated parameters in product and process metrics. | The role of decision-makers missed in the evaluation. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pirouz, B.; Arcuri, N.; Pirouz, B.; Palermo, S.A.; Turco, M.; Maiolo, M. Development of an Assessment Method for Evaluation of Sustainable Factories. Sustainability 2020, 12, 1841. https://doi.org/10.3390/su12051841

Pirouz B, Arcuri N, Pirouz B, Palermo SA, Turco M, Maiolo M. Development of an Assessment Method for Evaluation of Sustainable Factories. Sustainability. 2020; 12(5):1841. https://doi.org/10.3390/su12051841

Chicago/Turabian StylePirouz, Behrouz, Natale Arcuri, Behzad Pirouz, Stefania Anna Palermo, Michele Turco, and Mario Maiolo. 2020. "Development of an Assessment Method for Evaluation of Sustainable Factories" Sustainability 12, no. 5: 1841. https://doi.org/10.3390/su12051841