Anaerobic Co-Digestion of Oil Sludge with Corn Stover for Efficient Biogas Production

Abstract

:1. Introduction

2. Materials and methods

2.1. Inoculum and Feedstocks

2.1.1. Oil Sludge

2.1.2. Corn Stover

2.1.3. Inoculum

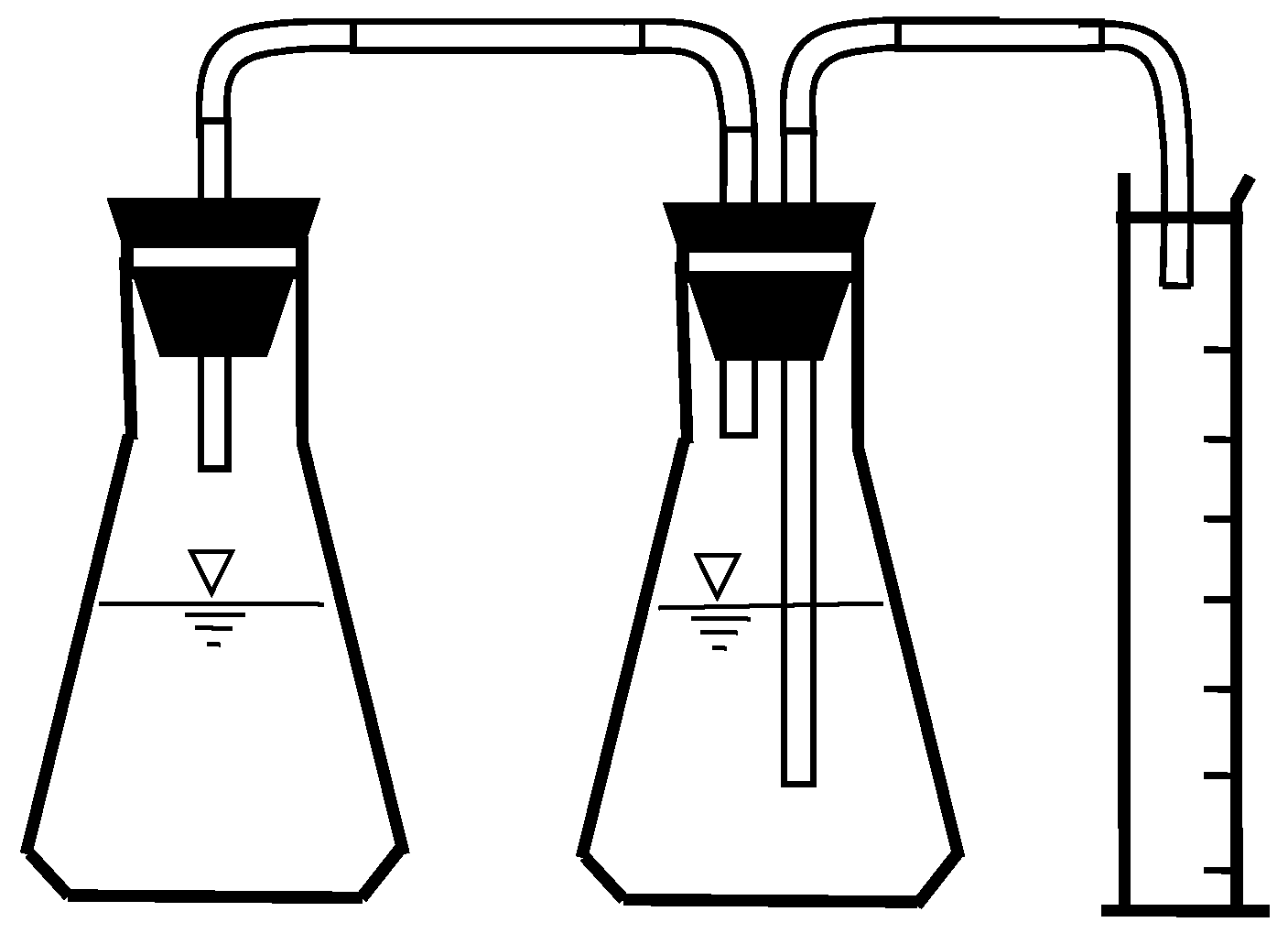

2.2. Experimental Setup

2.3. Experimental Design

2.3.1. Different Ratios of Corn Stover to Oil Sludge

2.3.2. Different Inoculum Volumes

2.4. Analytical Methods

2.5. Calculation Methods

3. Results and Discussions

3.1. Different Ratios between Oil Sludge and Corn Stover

3.1.1. Biogas Performance of Oil Sludge

3.1.2. Biogas Yield

3.1.3. Organic Matter Mass Conversion

3.2. Different Inoculum Volumes

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Roldán, C.T.; Castorena, C.G.; Zapata, P.I.; Reyes, A.J.; Olguín, L.P. Aerobic biodegradation of sludge with high hydrocarbon content generated by a Mexican natural gas processing facility. J. Environ. Manage. 2012, 40, 93–98. [Google Scholar] [CrossRef] [PubMed]

- Hu, G.; Li, J.; Zeng, G. Recent development in the treatment of oily sludge from petroleum industry: A review. J. Hazard. Mater. 2013, 261, 470–490. [Google Scholar] [CrossRef] [PubMed]

- Adetutu, E.M.; Bird, C.; Kadali, K.K.; Bueti, A.; Shahsavari, E.; Taha, M.; Patil, S.; Sheppard, P.J.; Makadia, T.; Simons, K.L.; et al. Exploiting the intrinsic hydrocarbon-degrading microbial capacities in oil tank bottom sludge and waste soil for sludge bioremediation. Int. J. Environ. Sci. Technol. 2015, 12, 1427–1436. [Google Scholar] [CrossRef]

- Jasmine, J.; Mukherji, S. Characterization of oily sludge from a refifinery and biodegradability assessment using various hydrocarbon degrading strains and reconstituted consortia. J. Environ. Manag. 2015, 149, 118–125. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Liu, Z.; Wang, X.; Xu, Z. New Technology and Development Direction of Harmless and Resource-based Treatment of Oily Sludge. Pet. Nat. Gas Chem. Ind. 2011, 40, 313–317. [Google Scholar]

- Tang, X.X.; Wei, X.S.; Chen, S.Y. Continuous pyrolysis technology for oily sludge treatment in the chain-slap conveyors. Sustainability 2019, 11, 3614. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Wang, Q.H.; Wang, S.J.; Li, F.S.; Guo, G.L. Effect of biostimulation on community level physiological profiles of microorganisms in field-scale biopiles composed of aged oil sludge. Bioresour. Technol. 2012, 111, 308–315. [Google Scholar] [CrossRef]

- Al-Futaisi, A.; Jamrah, A.; Yaghi, B.; Taha, R. Assessment of alternative management techniques of tank bottom petroleum sludge in Oman. J. Hazard. Mater. 2007, 141, 557–564. [Google Scholar] [CrossRef]

- Sankaran, S.; Pandey, S.; Sumathy, K. Experimental investigation on waste heat recovery by refinery oil sludge incineration using fluidised bed technique. J. Environ. Sci. Heal. A 2008, A33, 829–845. [Google Scholar] [CrossRef]

- Wang, R.; Liu, J.; Gao, F.; Zhou, J.; Cen, K. The slurrying properties of slurry fuels made of petroleum coke and petrochemical sludge. Fuel Process. Technol. 2012, 104, 57–66. [Google Scholar] [CrossRef]

- Johnson, O.A.; Affam, A.C. Petroleum sludge treatment and disposal: A review. Environ. Eng. Res. 2019, 24, 191–201. [Google Scholar] [CrossRef]

- Gong, Z.; Wang, Z.; Wang, Z. Study on migration characteristics of heavy metals during oil sludge incineration. Petro. Sci. Technol. 2018, 36, 469–474. [Google Scholar] [CrossRef]

- Liu, J.; Jiang, X.; Zhou, L.; Wang, H.; Han, X. Co-firing of oil sludge with coal-water slurry in an industrial internal circulating fluidized bed boiler. J. Hazard. Mater. 2009, 167, 817–823. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Pawlowski, A. Sewage sludge-to-energy approaches based on anaerobic digestion and pyrolysis: Brief overview and energy efficiency assessment. Renew. Sustain. Energ. Rev. 2012, 16, 1657–1665. [Google Scholar] [CrossRef]

- Jasmine, J.; Mukherji, S. Impact of bioremediation strategies on slurry phase treatment of aged oily sludge from a refifinery. J. Environ. Manag. 2019, 246, 625–635. [Google Scholar] [CrossRef]

- Liu, X.R.; Xu, Q.X.; Wang, D.B.; Yang, Q.; Wu, Y.X.; Li, Y.F.; Fu, Q.Z.; Yang, F.; Liu, Y.W.; Ni, B.J.; et al. Thermal-alkaline pretreatment of polyacrylamide flocculated waste activated sludge: Process optimization and effects on anaerobic digestion and polyacrylamide degradation. Bioresour. Technol. 2019, 281, 158–167. [Google Scholar] [CrossRef]

- Salminen, E.; Rintala, J. Anaerobic digestion of organic solid poultry slaughterhouse waste - a review. Bioresour. Technol. 2002, 83, 13–26. [Google Scholar] [CrossRef]

- Alastair, J.W.; Phil, J.H.; Peter, J.H.; David, L.J. Optimisation of the anaerobic digestion of agricultural resources. Bioresour. Technol. 2008, 99, 7928–7940. [Google Scholar]

- Pan, J.T.; Ma, J.Y.; Liu, X.X.; Zhai, L.M.; Ouyang, X.H. Hongbin Liu. Effects of different types of biochar on the anaerobic digestion of chicken manure. Bioresour. Technol. 2019, 275, 258–265. [Google Scholar] [CrossRef]

- Liu, T.; Zhou, X.Q.; Li, Z.F.; Wang, X.M.; Sun, J.C. Effects of liquid digestate pretreatment on biogas production for anaerobic digestion of wheat stover. Bioresour. Technol. 2019, 280, 345–351. [Google Scholar] [CrossRef]

- Tahhan, R.A.; Abu-Ateih, R.Y. Biodegradation of petroleum industry oily-sludge using Jordanian oil refinery contaminated soil. Int. Biodeter. Biodeg. 2009, 63, 1054–1060. [Google Scholar] [CrossRef]

- Yang, Q.; Wei, L.H.; Li, W.Z.; Chen, Y.; Ju, M.T. Effects of feedstock sources on inoculant acclimatization: Start-up strategies and reactor performance. Appl. Biochem. Biotechnol. 2017, 183, 729–743. [Google Scholar] [CrossRef] [PubMed]

- APHA. Standard Methods for the Examination of Water and Wastewater, 20th ed.; American Public Health Association: Washington, DC, USA, 2005. [Google Scholar]

- Michaud, S.; Bernet, N.; Buffière, P.; Roustan, M.; Moletta, R. Methane yield as a monitoring parameter for the start-up of anaerobic fixed film reactors. Water Res. 2002, 36, 1385–1391. [Google Scholar] [CrossRef]

| Parameters | Oil Sludge | Corn Stover | Inoculum |

|---|---|---|---|

| C/% a | 27.76 ± 0.10 | 47.44 ± 0.20 | 30.17 ± 0.60 |

| N/% a | 3.11 ± 0.20 | 1.87 ± 0.02 | 5.01 ± 0.04 |

| Ph | 6.5-7.4 | NDb | 7.3-7.7 |

| TS% a | 64.89 | 96.75 | 8.77 |

| VS% a | 4.94 | 84.18 | 5.64 |

| Group | Ratiosa | Water (mL) | Inoculum (mL) |

|---|---|---|---|

| 1 | 0:1 | 20.63 | 40 |

| 2 | 1:1 | 51.88 | 40 |

| 3 | 2:1 | 83.13 | 40 |

| 4 | 3:1 | 114.38 | 40 |

| 5 | 4:1 | 145.63 | 40 |

| 6 | 1:0 | 31.25 | 40 |

| 7 | Blank(0:0) | 0 | 40 |

| Groups | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Corn stover (g) | 2 | 2 | 2 | 2 |

| Oil sludge (g) | 1 | 1 | 1 | 1 |

| Water (mL) | 83.13 | 83.13 | 83.13 | 83.13 |

| Inoculum (mL) | 20 | 30 | 40 | 50 |

| Groups | Ratios of Corn Stover to Oil Sludge | Organic Matter Mass Conversion (%) a | Cumulative Biogas Production (mL) | Average Values of Daily Biogas Production Per Unit of Volatile Solid (mL/g VS) |

|---|---|---|---|---|

| 1 | 1:0 | 97.0625 ± 0.02 | 307 ± 14.14 | 12.16 |

| 2 | 1:1 | 91.7824 ± 0.09 | 271.5 ± 37.48 | 10.16 |

| 3 | 2:1 | 91.6111 ± 0.02 | 339.5 ± 57.28 | 6.53 |

| 4 | 3:1 | 98.629 ± 0.01 | 647 ± 84.85 | 8.38 |

| 5 | 4:1 | 98.4152 ± 0.04 | 1222.5 ± 34.65 | 11.93 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Q.; Zhang, C.; Li, L.; Xu, W. Anaerobic Co-Digestion of Oil Sludge with Corn Stover for Efficient Biogas Production. Sustainability 2020, 12, 1861. https://doi.org/10.3390/su12051861

Yang Q, Zhang C, Li L, Xu W. Anaerobic Co-Digestion of Oil Sludge with Corn Stover for Efficient Biogas Production. Sustainability. 2020; 12(5):1861. https://doi.org/10.3390/su12051861

Chicago/Turabian StyleYang, Qian, Chenxi Zhang, Lei Li, and Weijie Xu. 2020. "Anaerobic Co-Digestion of Oil Sludge with Corn Stover for Efficient Biogas Production" Sustainability 12, no. 5: 1861. https://doi.org/10.3390/su12051861

APA StyleYang, Q., Zhang, C., Li, L., & Xu, W. (2020). Anaerobic Co-Digestion of Oil Sludge with Corn Stover for Efficient Biogas Production. Sustainability, 12(5), 1861. https://doi.org/10.3390/su12051861