Towards Sustainable Mining: Exploiting Raw Materials from Extractive Waste Facilities

Abstract

1. Introduction

1.1. General Background and Targets of the Present Research

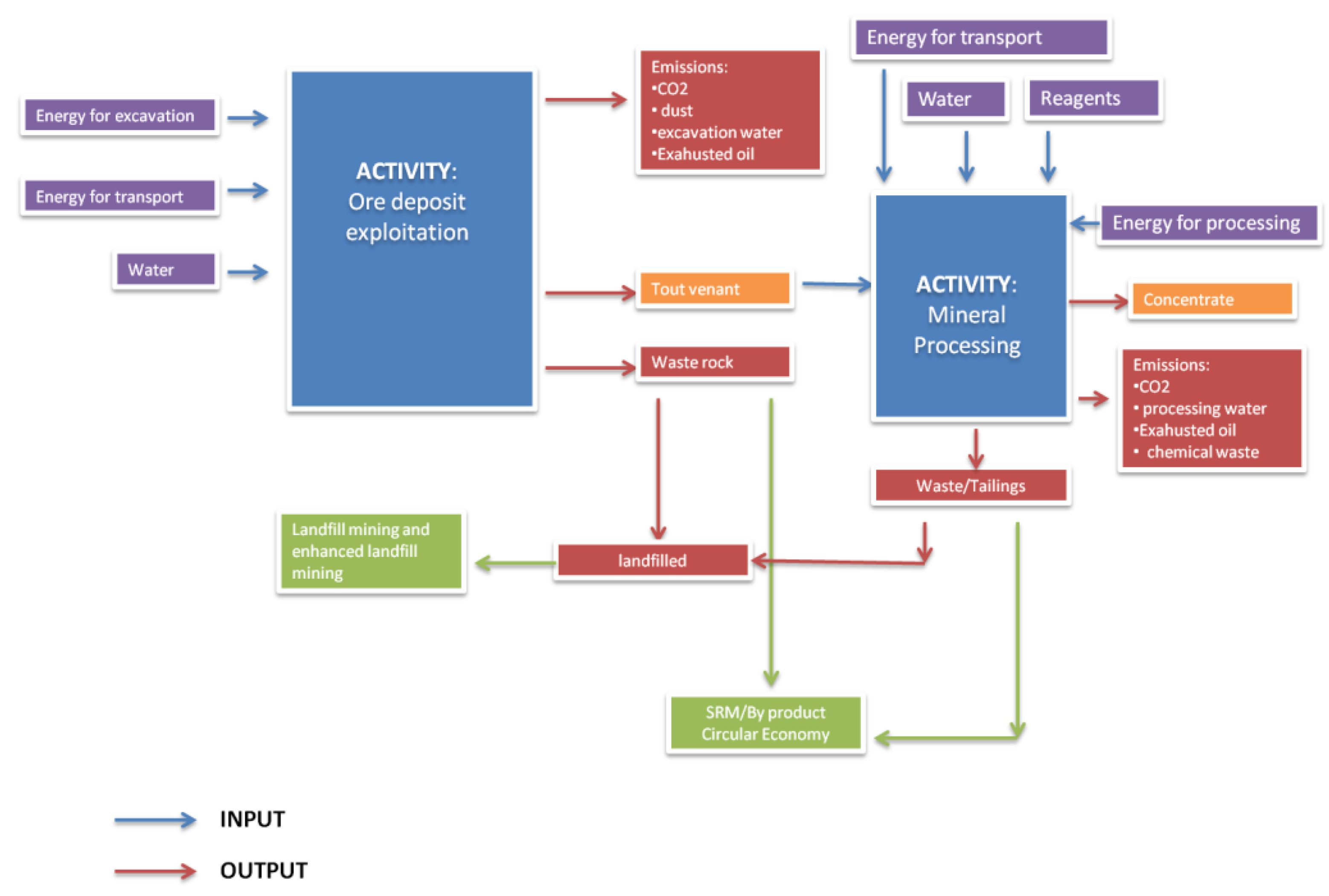

1.2. Focus on Environmental Impacts and Potential Waste Recovery Associated with Extractive Waste Facilities

- there is a risk of depleting natural resources and a continuous implementation of waste production which lead local/national policy and strategy to invest in landfill mining and enhanced landfill mining [34].

2. Materials and Methods

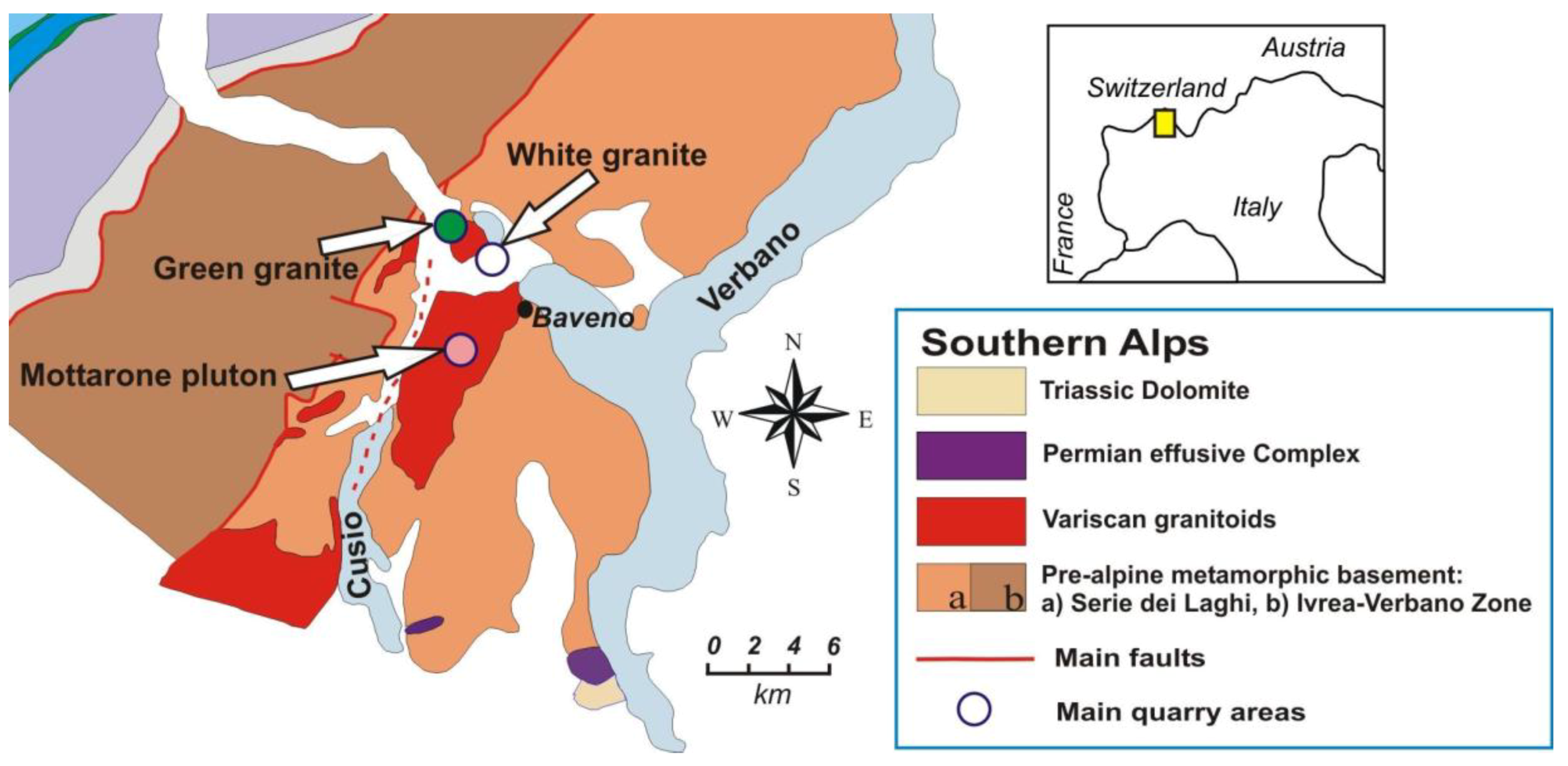

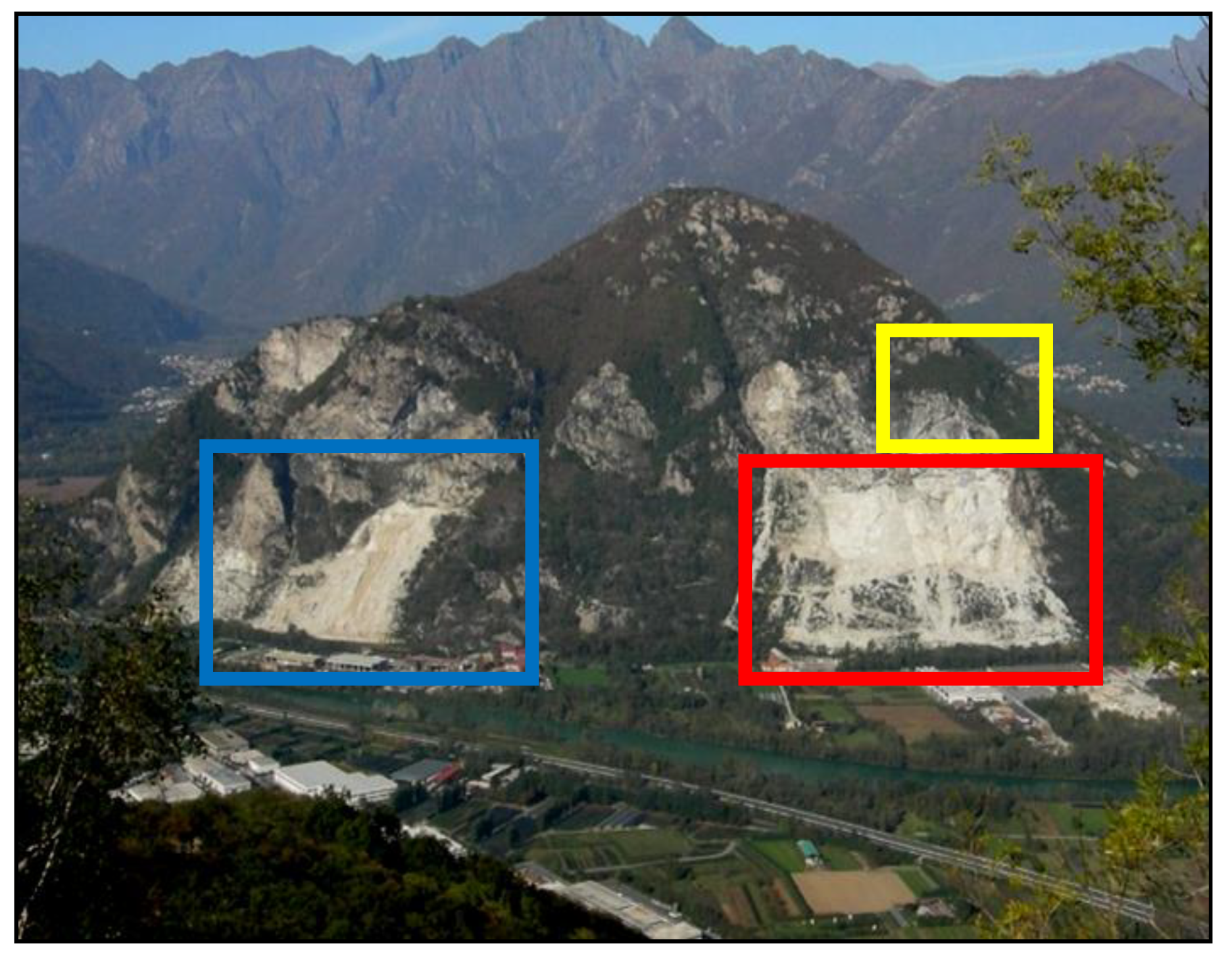

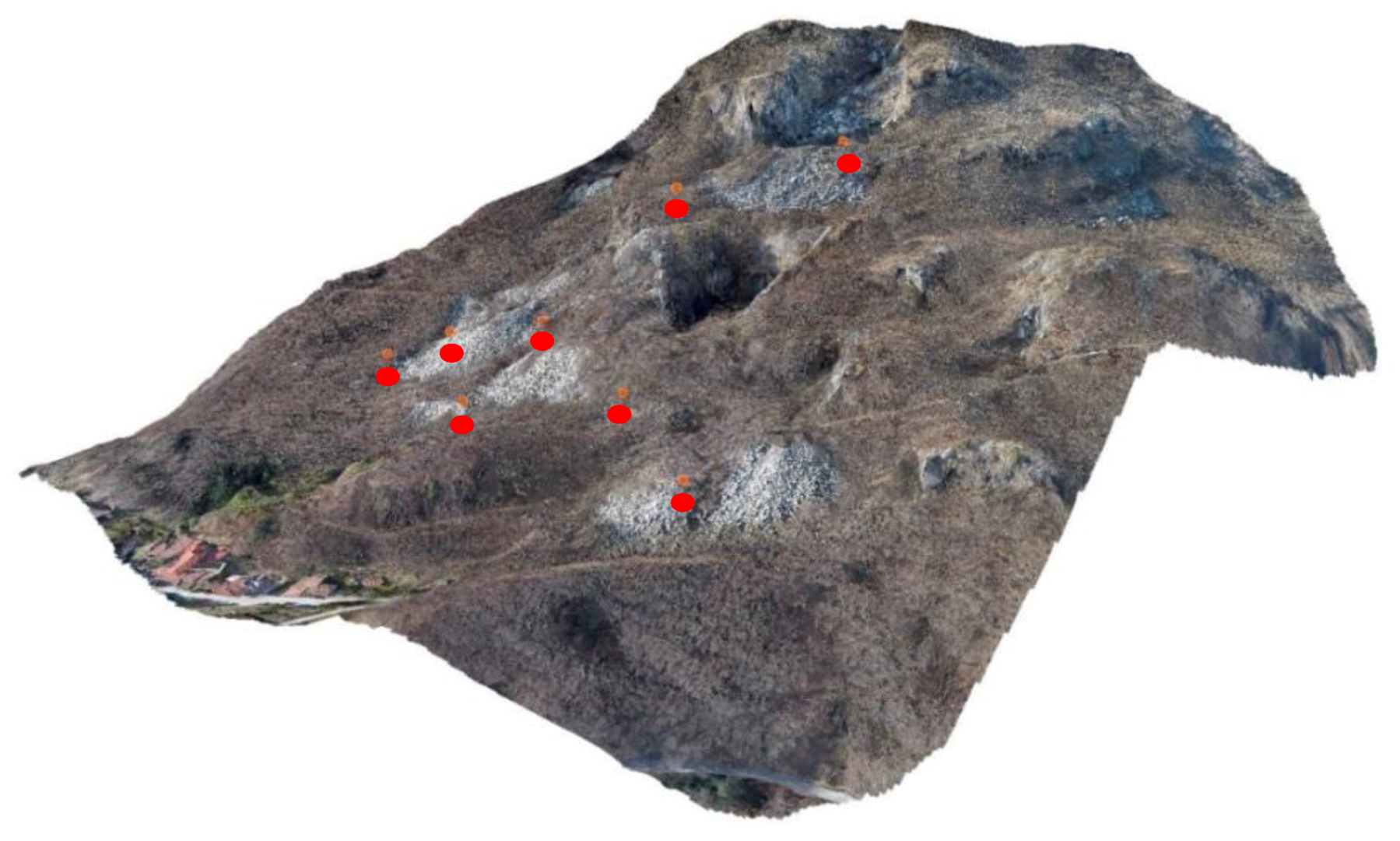

2.1. Site Description

2.2. Sampling, Mine Waste Characterization, and Ore Recovery Estimation

- lithium metaborate/tetraborate fusion ICP-OES for major and minor elements;

- lithium metaborate/tetraborate fusion ICP-MS for REE.

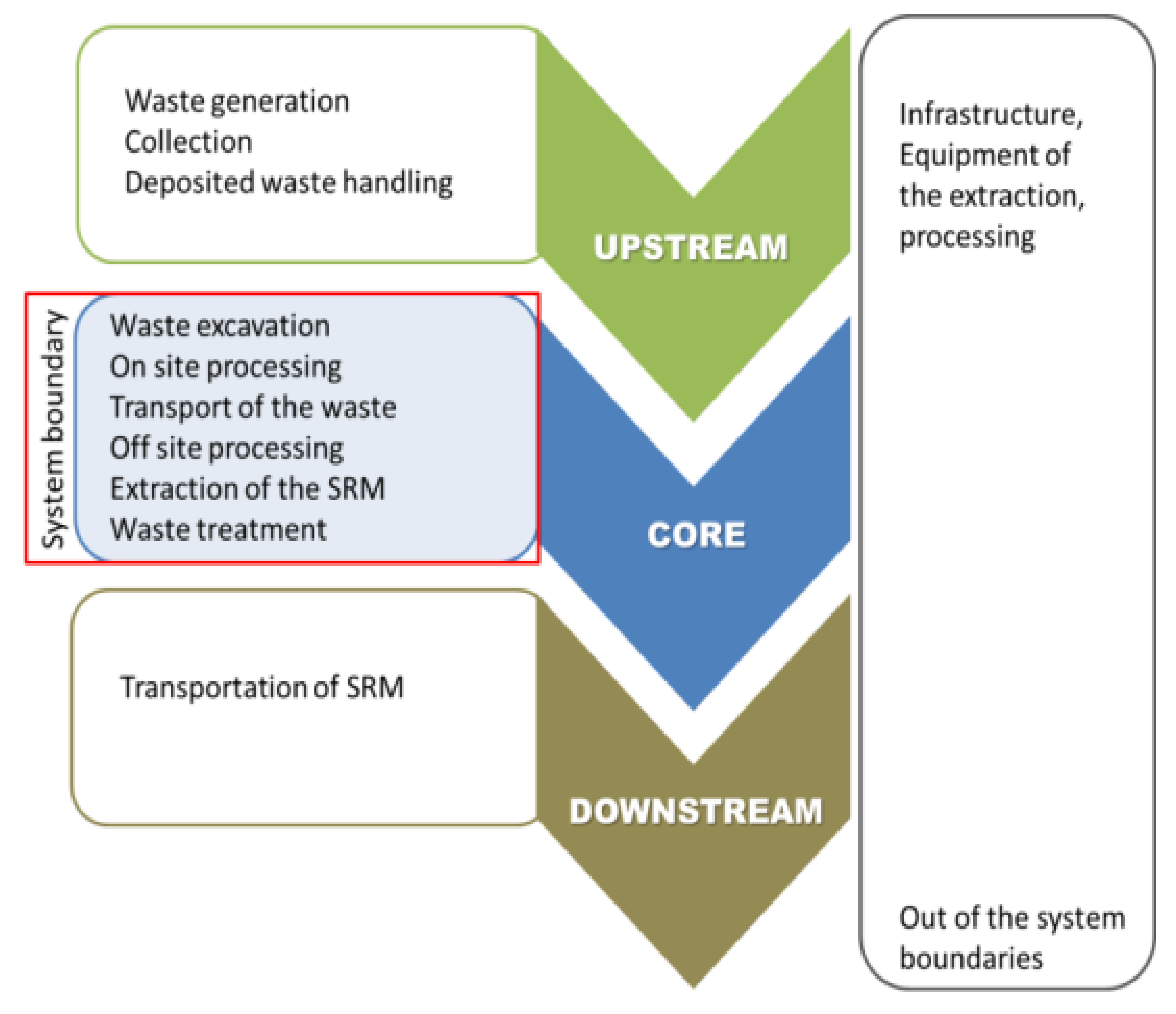

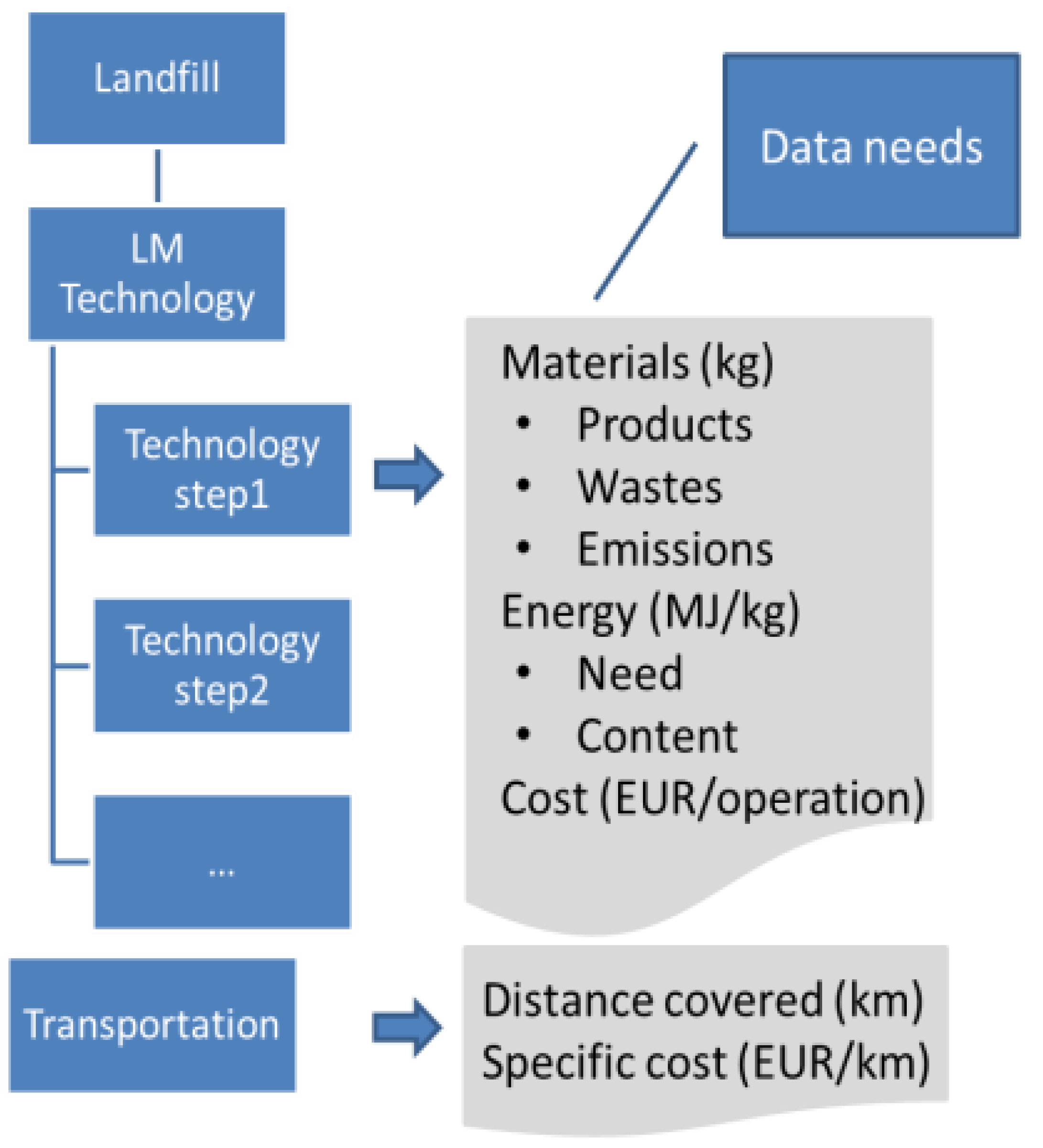

2.3. Assessing Environmental Impacts for Resource Recovery Activities and SRM Use as Substitute Material

- the amount of the total waste/year;

- the technology tree model representing the technology steps to extract the SRMs from the source;

- the material and energy flows of each technology steps;

- the extractable SRMs.

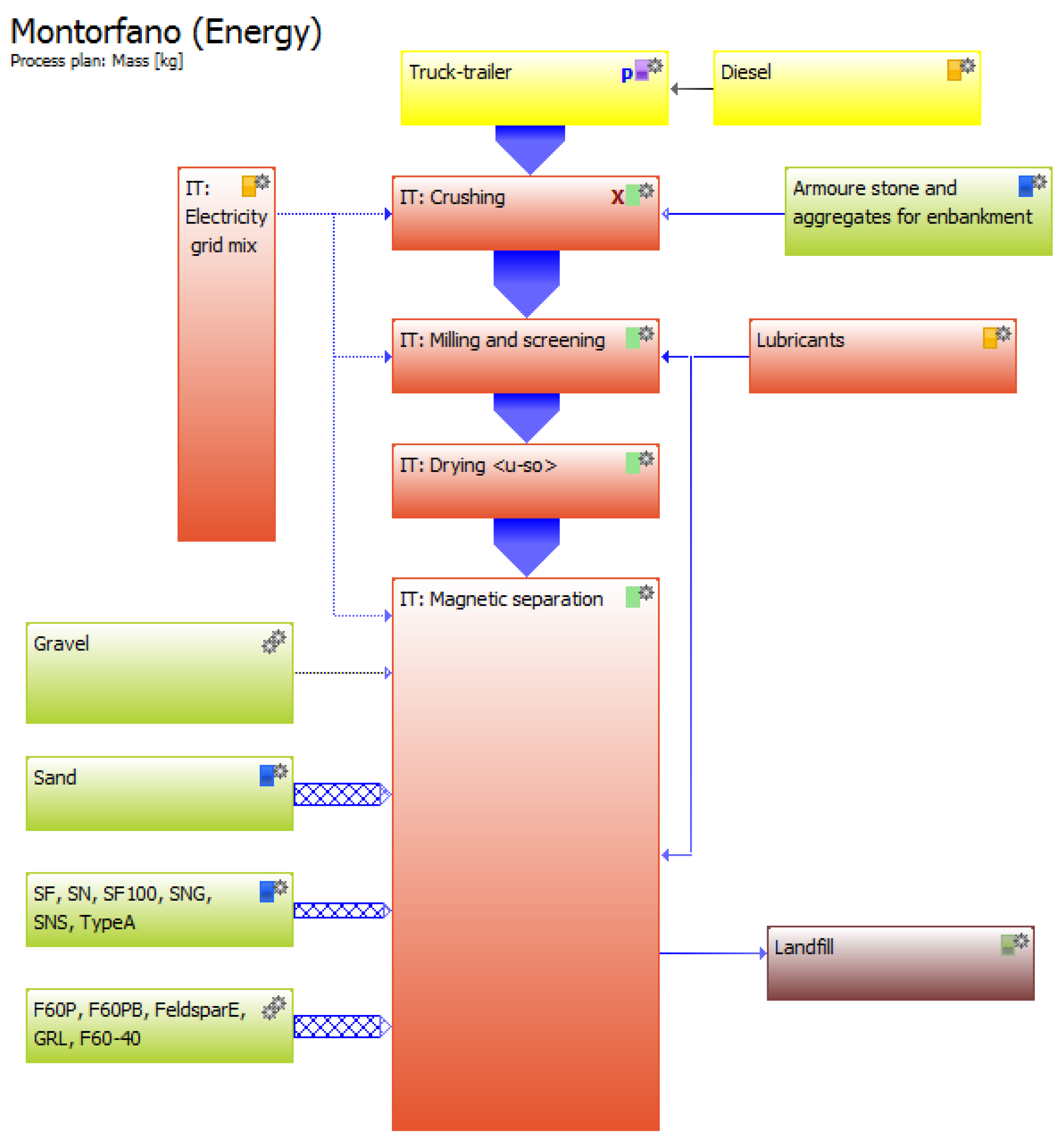

- Main products (F60P, Feldspar, GRL and F60-40): feldspar for ceramic industry

- Gravel and sands: for buildings and infrastructures

- SF and SF100: for bituminous concrete

- SN: for brick production

- SNG: for external pavement and industrial surface treatments

- SNS: for external pavement

- Armor stone, aggregate for embankment and filler

3. Results

3.1. Characterization and Volume Estimation

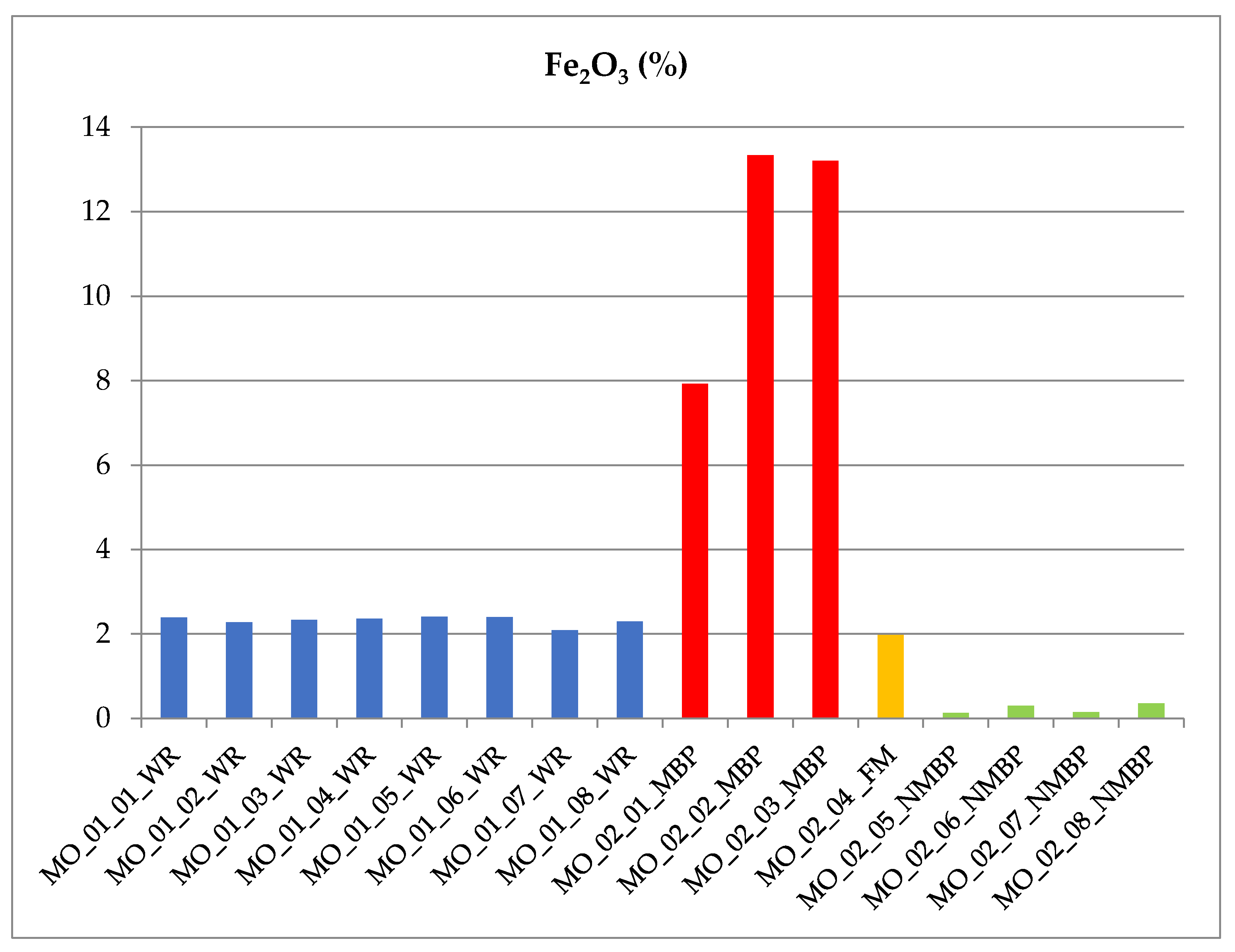

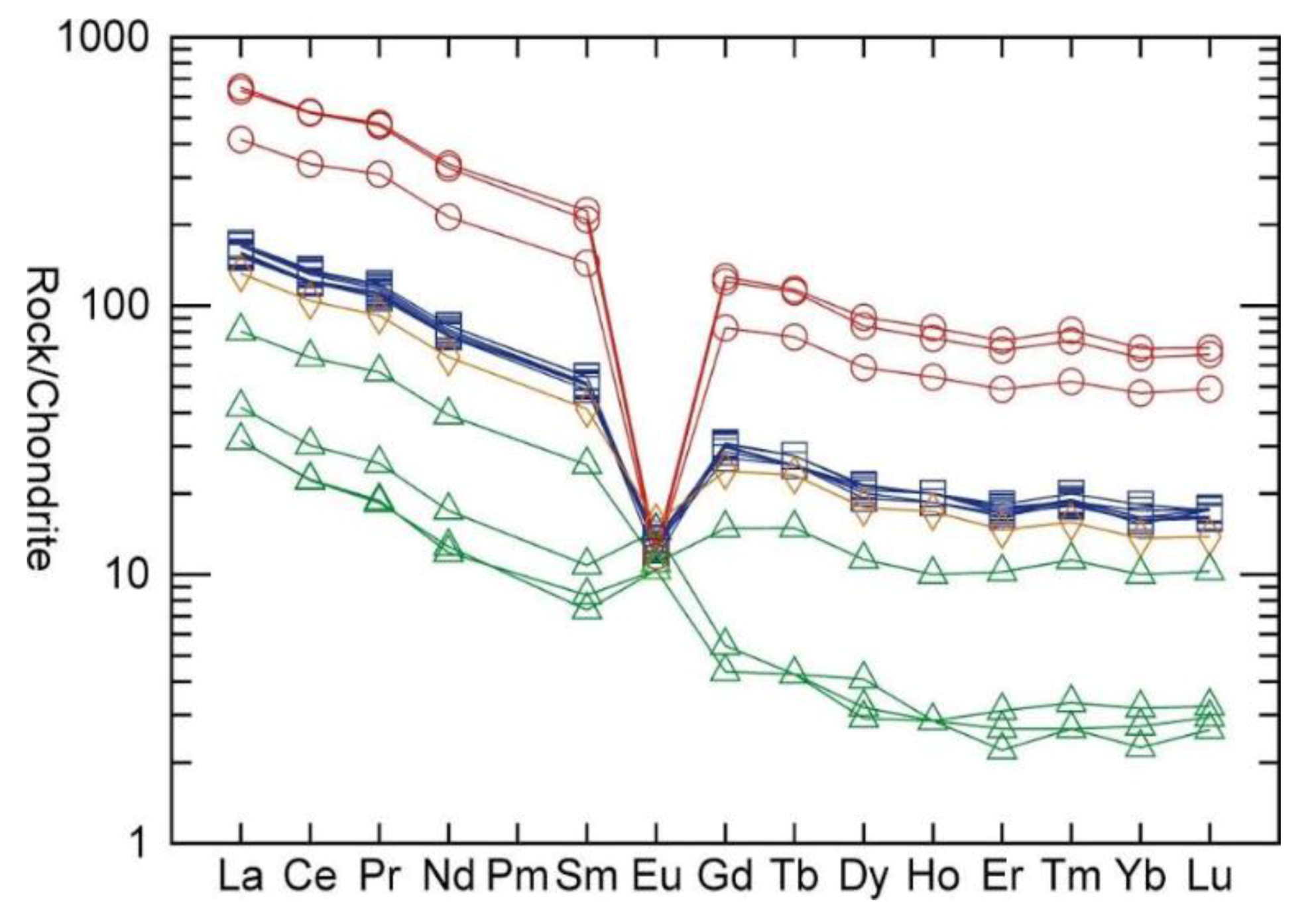

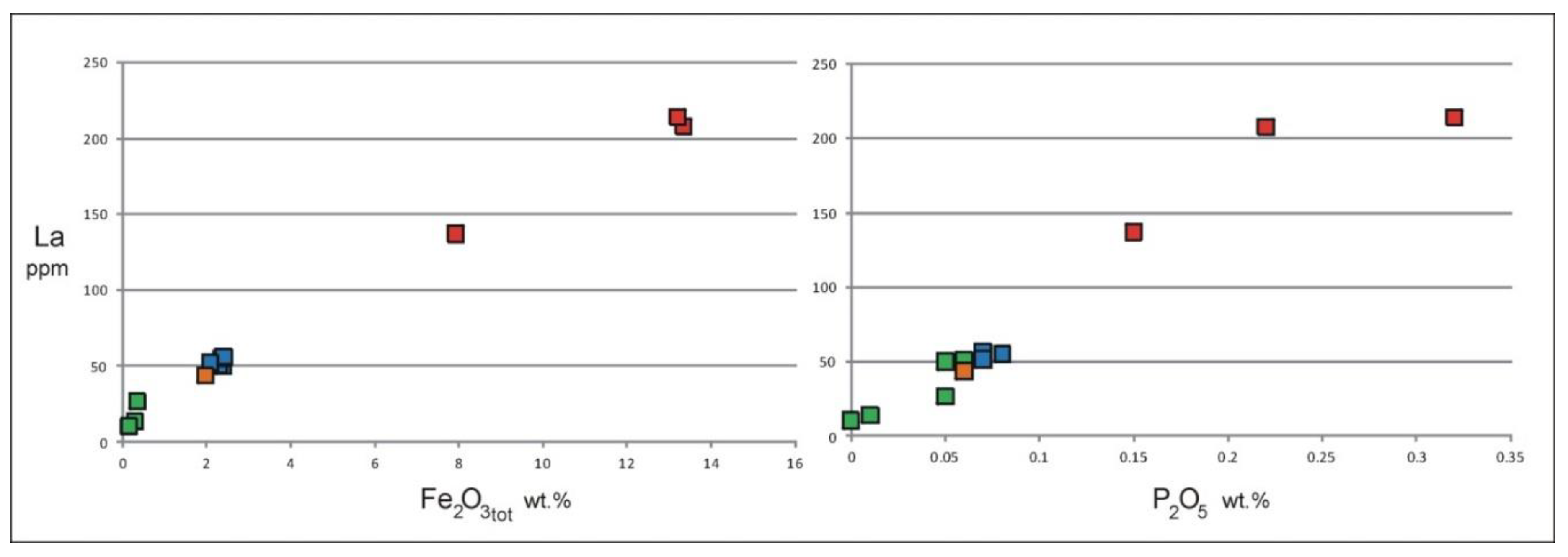

3.1.1. Geochemical Characterization

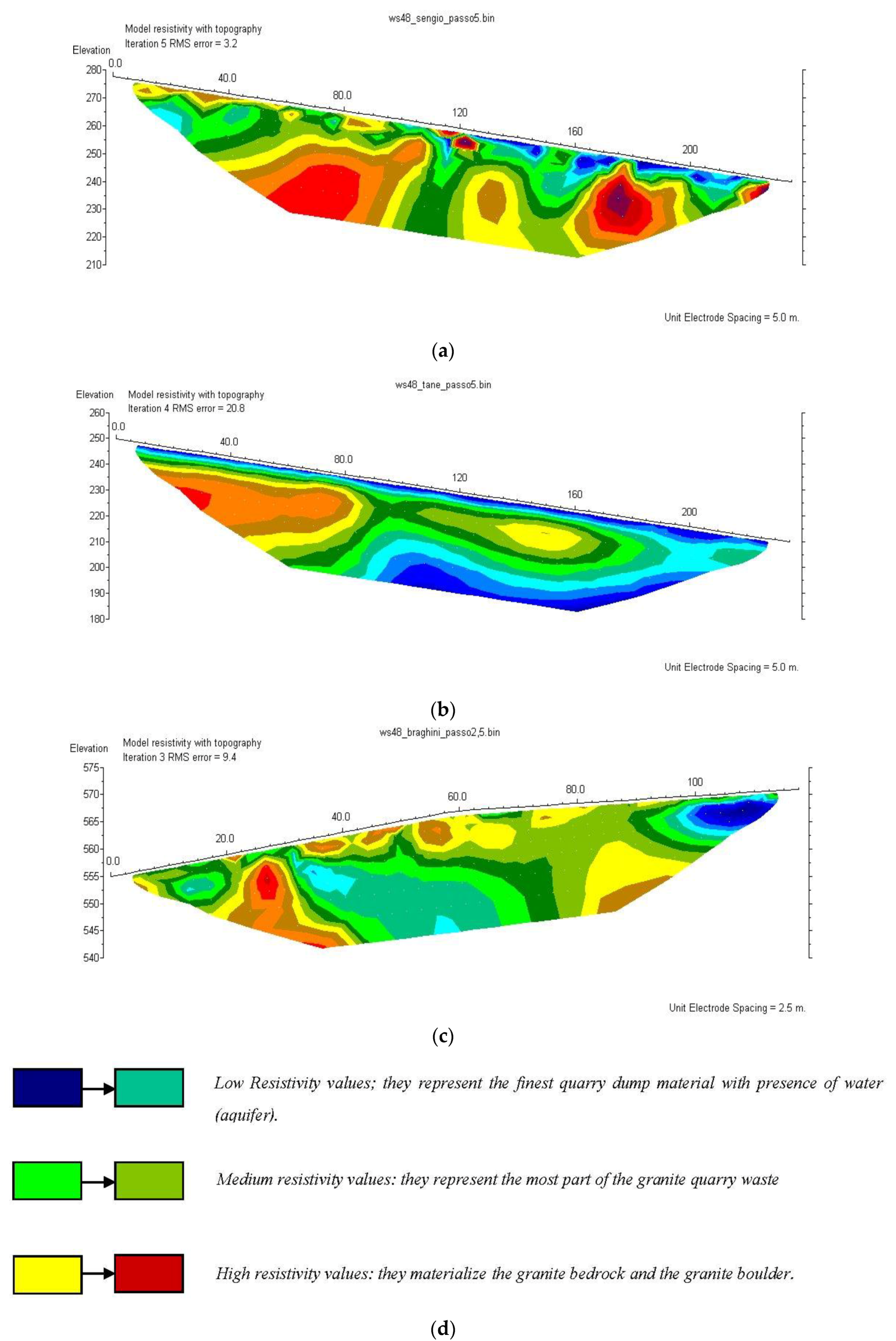

3.1.2. Volume and Potential Value of the Raw Materials (at the Site)

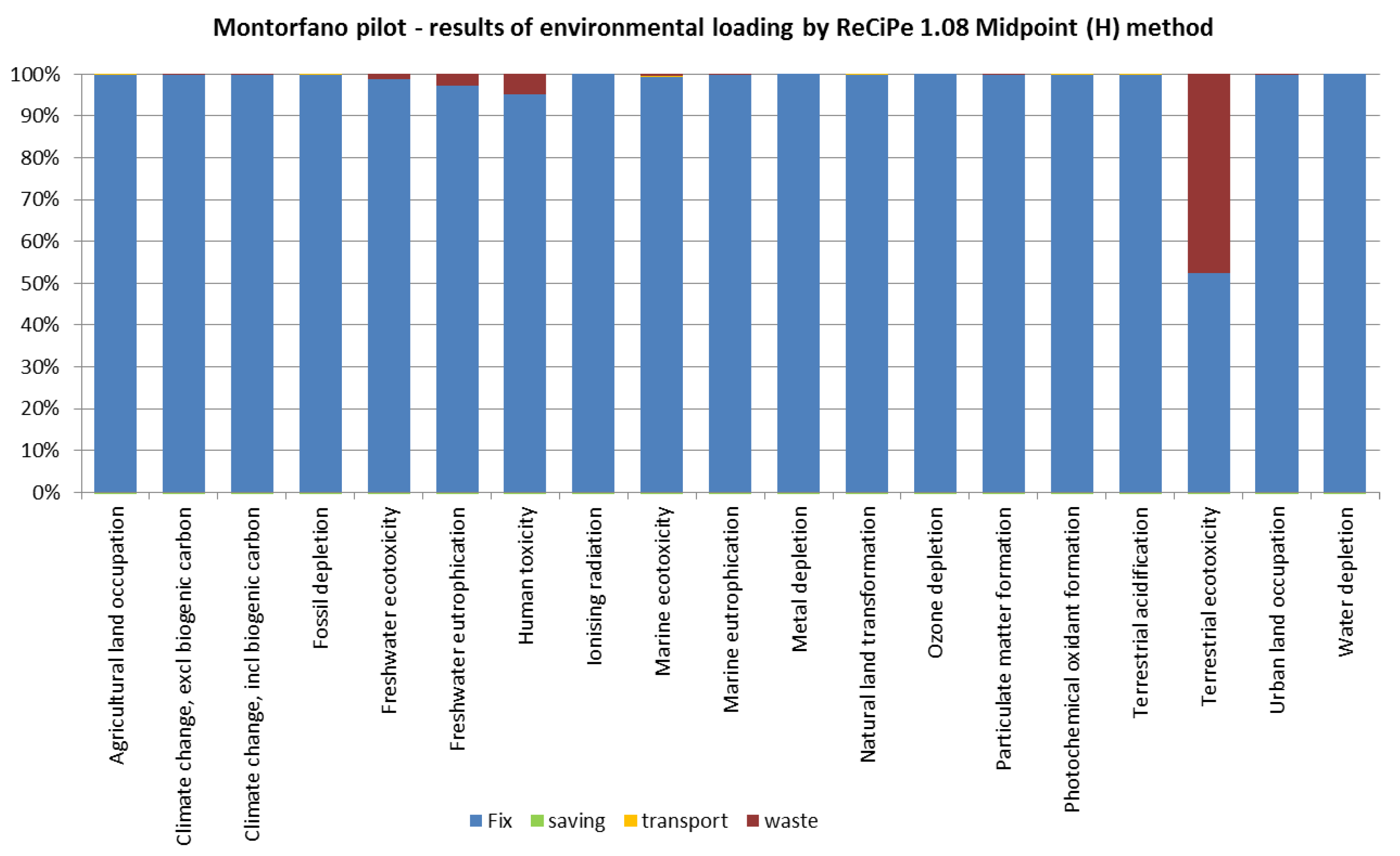

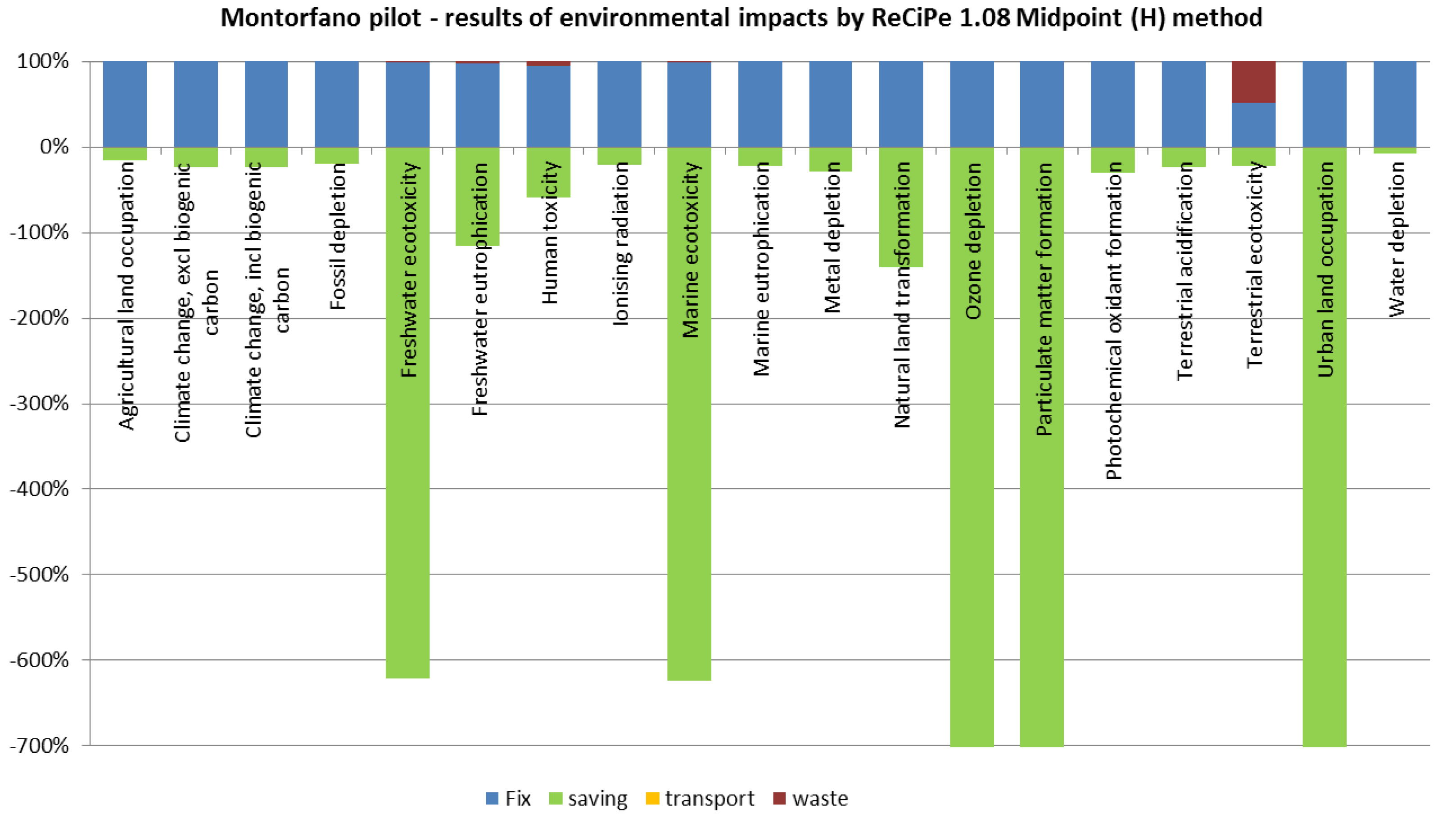

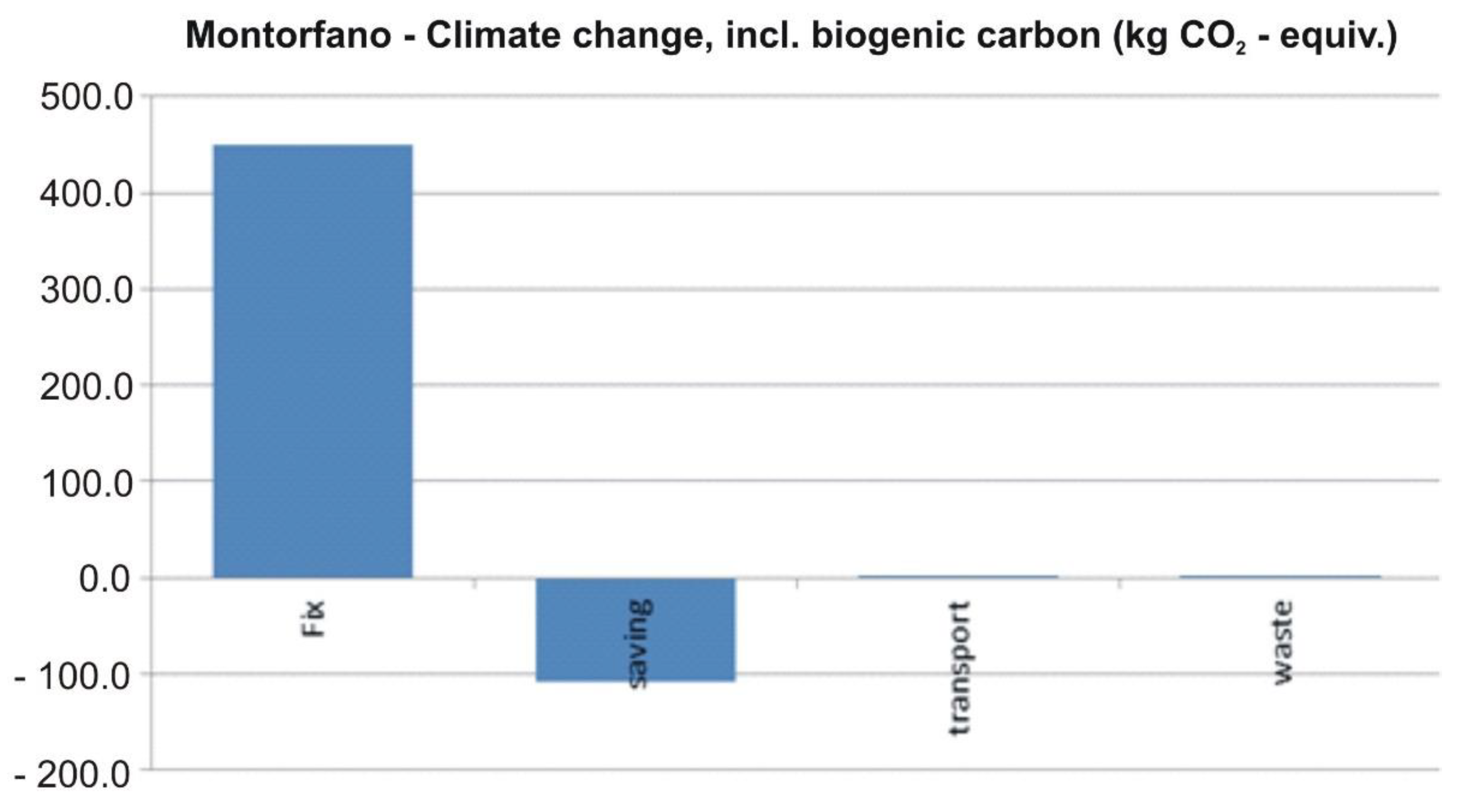

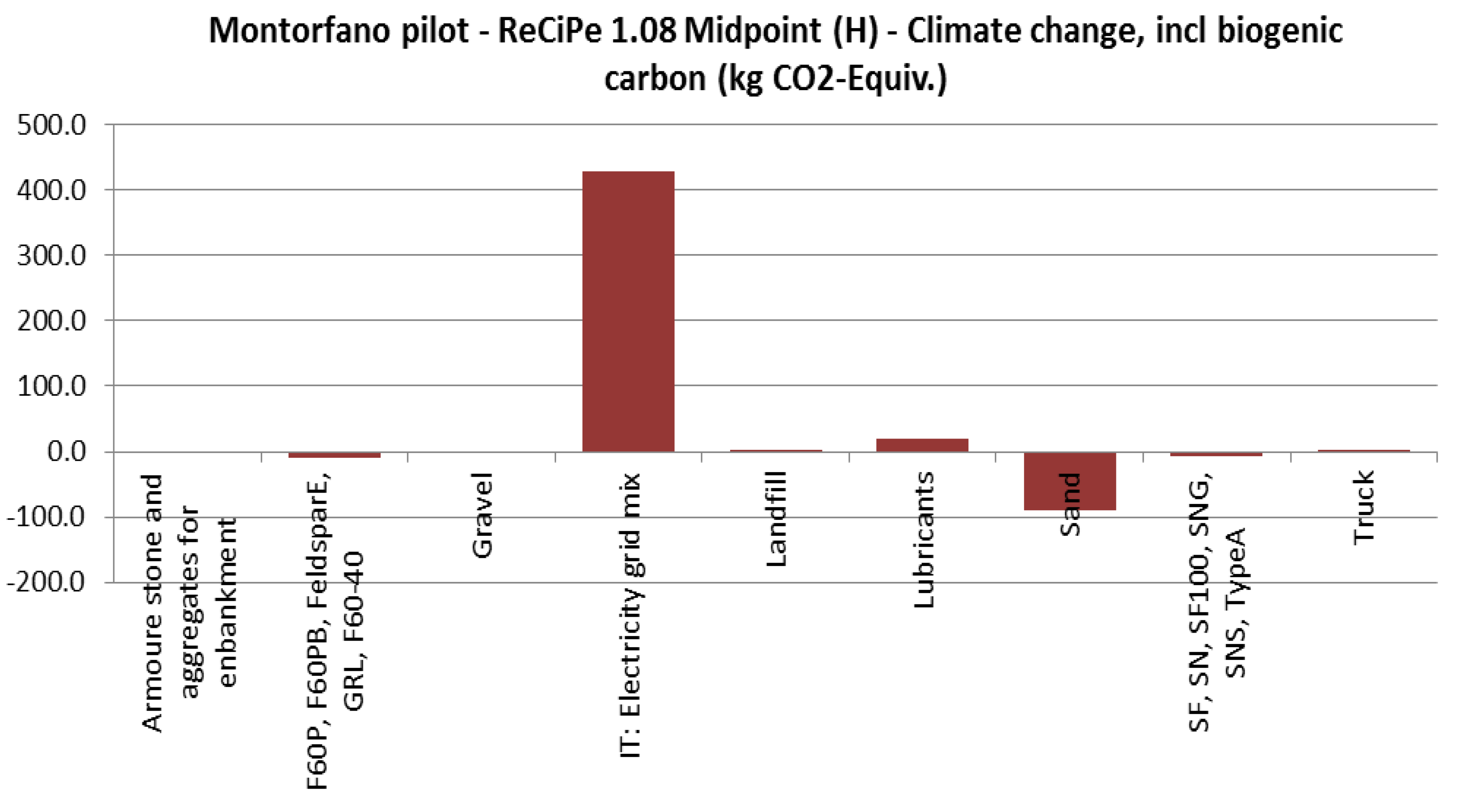

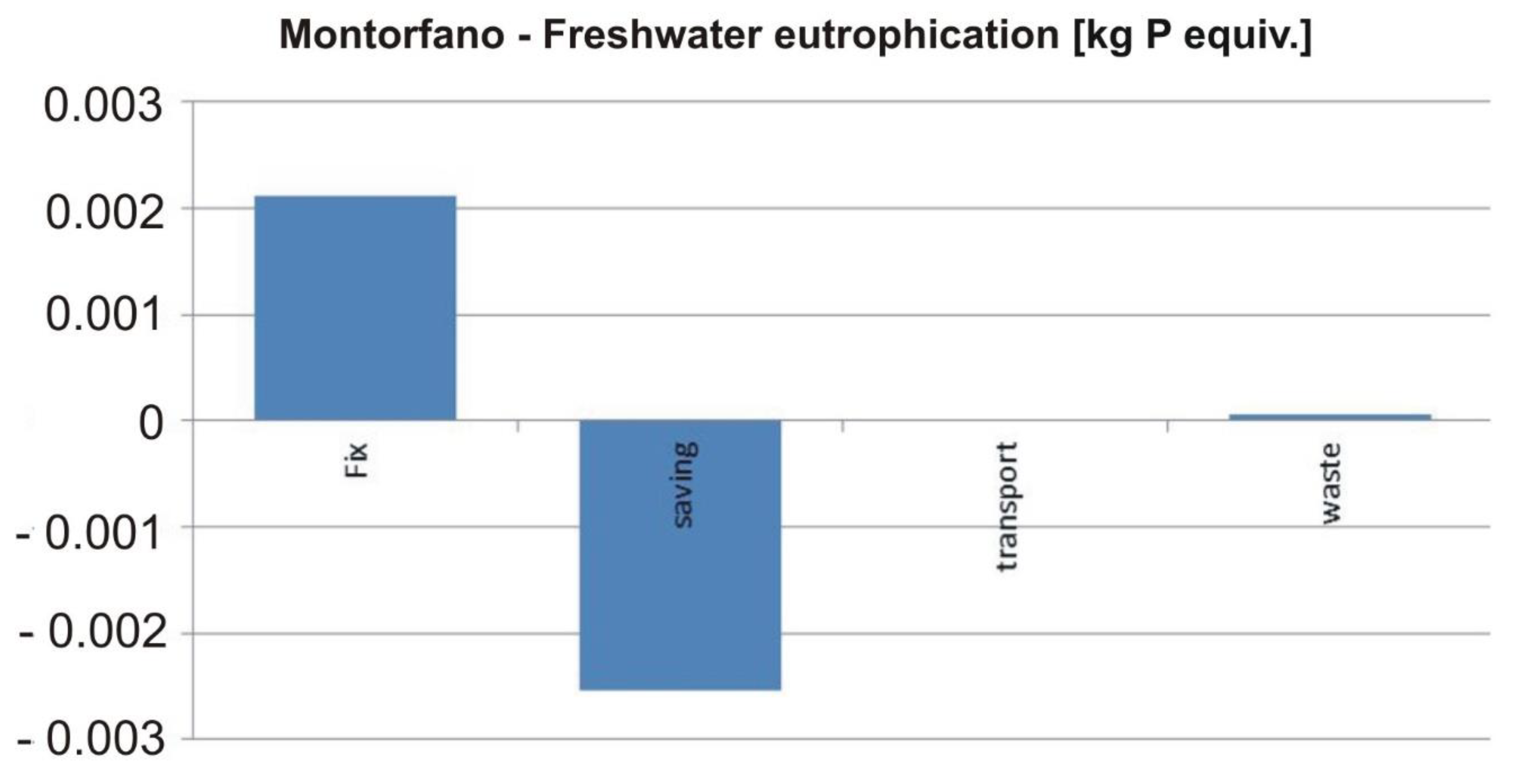

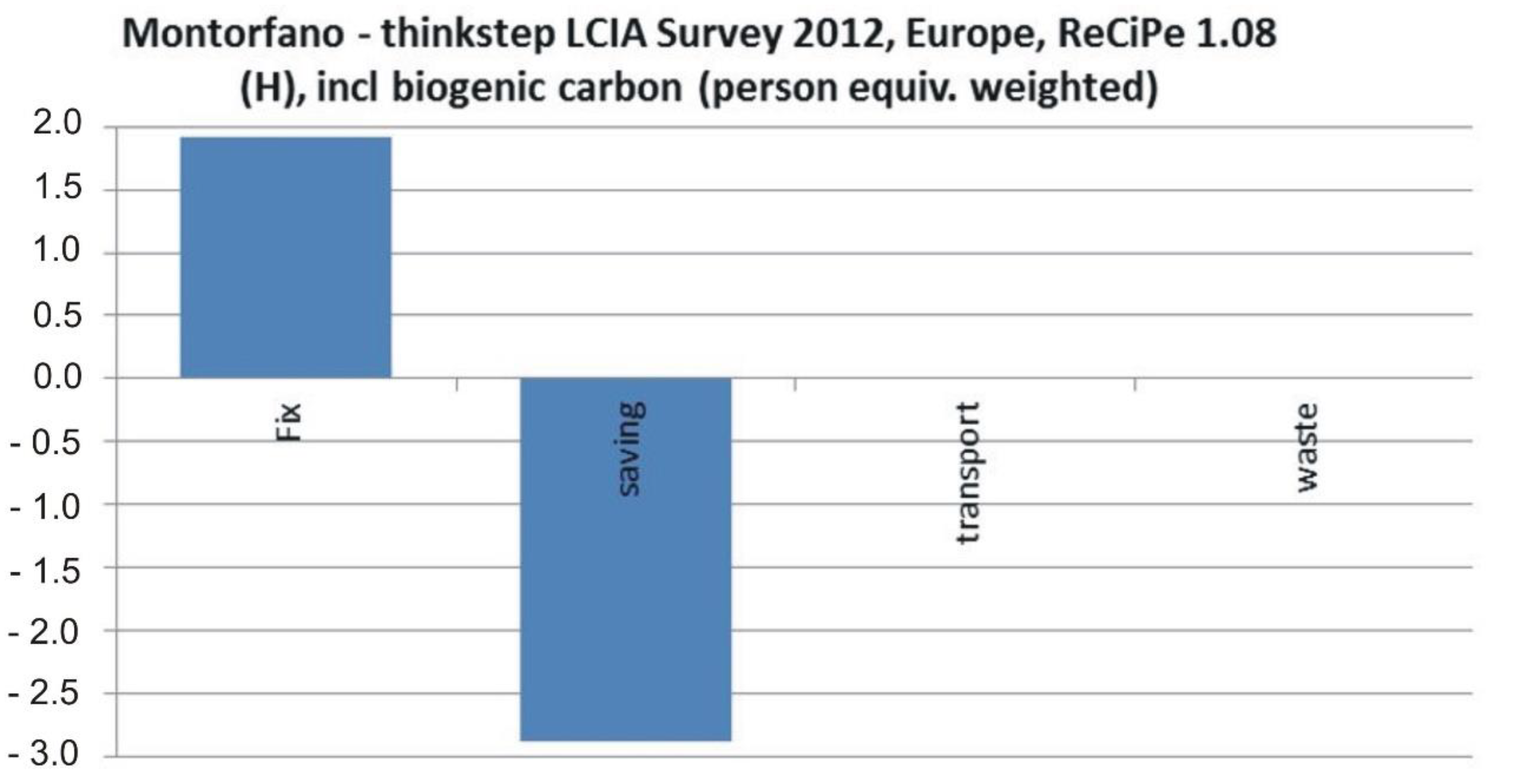

3.2. Environmental Impact Assessment

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Greenfield, A.; Graedel, T.E. The omnivorous diet of modern technology. Resour. Conserv. Recycl. 2013, 74, 1–7. [Google Scholar] [CrossRef]

- World Bank Group. End Extreme Poverty. Boost Shared Prosperity; Annual Report; The World Bank: Washington, WA, USA, 2017. [Google Scholar]

- Sapford, D.; Brabham, P.; Crane, R.; Evans, D.; Statford, A.; Wright, A. Mine Waste Resources Assessment And Appraisal of Recovery via Mine Water. In Proceedings of the IMWA 2017-13th International Mine Water Association Congress–“Mine Water & Circular Economy–A Green Congress, Rauha, Lappeenranta, Finland, 25–30 June 2017; pp. 956–963. [Google Scholar]

- Habib, K.; Wenzel, H. Exploring rare earths supply constraints for the emerging clean energy technologies and the role of recycling. J. Clean. Prod. 2014, 84, 349–359. [Google Scholar] [CrossRef]

- Khorasanipour, M.; Rashidi, S. Geochemical fractionation pattern and environmental behaviour of rare earth elements (REEs) in mine wastes and mining contaminated sediments; Sarcheshmeh mine, SE of Iran (2020). J. Geochem. Explor. 2020, 210, 106450. [Google Scholar] [CrossRef]

- Edahbi, M.; Plante, B.; Benzaazoua, M. Environmental challenges and identification of the knowledge gaps associated with REE mine wastes management. J. Clean. Prod. 2019, 212, 1232–1241. [Google Scholar] [CrossRef]

- Burlakovs, J.; Jani, Y.; Kriipsalu, M.; Vincevica-Gaile, Z.; Kaczala, F.; Celma, G.; Ozola, R.; Rozina, L.; Rudovica, V.; Hogland, M.; et al. On the way to ‘zero waste’ management: Recovery potential of elements, including rare earth elements, from fine fraction of waste. J. Clean. Prod. 2018, 186, 81–90. [Google Scholar] [CrossRef]

- Edahbi, M.; Plante, B.; Benzaazoua, M.; Ward, M.; Pelletier, M. Mobility of rare earth elements in mine drainage: Influence of iron oxides, carbonates, and phosphates. Chemosphere 2018, 199, 647–654. [Google Scholar] [CrossRef]

- European Commission. List of Critical Raw Materials for the EU; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- Dondi, M. Feldspars and other Fluxes for Ceramic Tiles: Sources, Processing, Composition and Technological Behavior. Resour. Conserv. Recycl. 2018, 133, 191–205. [Google Scholar] [CrossRef]

- Moran, C.J.; Lodhia, S.; Kunz, N.C.; Huisingh, D. Sustainability in mining, minerals and Energy: new processes, pathways and human interactions for a cautiously optimistic future. J. Clean. Prod. 2014, 84, 1–15. [Google Scholar] [CrossRef]

- Carvalho, J.; Diamantino, C.; Rosa, C.; Carvalho, E. Potential recovery of mineral resources from mining tailing of abandoned mines in Portugal. In Proceedings of the 3rd International Symposium on Enhanced Landfill Mining, Lisbon, Portugal, 8–10 February 2016; pp. 501–516. [Google Scholar]

- Hudson-Edwards, K.A.; Macklin, M.G.; Miller, J.R.; Lechler, P.J. Sources, distribution and storage of heavy metals in the Rio Pilcomayo, Bolivia. J. Geochem. Explor. 2001, 72, 229–250. [Google Scholar] [CrossRef]

- Amos, R.T.; Blowes, D.W.; Bailey, B.L.; Sego, D.C.; Smith, L.; Ritchie, A.I.M. Waste-rock hydrogeology and geochemistry. Appl. Geochem. 2015, 57, 140–156. [Google Scholar] [CrossRef]

- Banks, D.; Younger, P.L.; Arnesen, R.-T.; Iversen, E.R.; Banks, S.B. Mine-water chemistry: The good, the bad and the ugly. Environ. Geol. 1997, 32, 157–174. [Google Scholar] [CrossRef]

- Lim, M.; Han, G.C.; Ahn, J.W.; You, K.S.; Kim, H.S. Leachability of Arsenic and Heavy Metals from Mine Tailings of Abandoned Metal Mines. Int. J. Environ. Res. Public. Health. 2009, 6, 2865–2879. [Google Scholar] [CrossRef] [PubMed]

- Gray, N.F. Environmental impact and remediation of acid mine drainage: a management problem. Environ. Geol. 1997, 30, 62–71. [Google Scholar] [CrossRef]

- Béjaoui, I.; Kolsi-Benzina, N.; Sappin-Didier, V.; Munoz, M. Health Risk Assessment in Calcareous Agricultural Soils Contaminated by Metallic Mining Activity under Mediterranean Climate. CLEAN–Soil Air Water 2016, 44, 1385–1395. [Google Scholar] [CrossRef]

- Liu, H.; Probst, A.; Liao, B. Metal contamination of soils and crops affected by the Chenzhou lead/zinc mine spill (Hunan, China). Sci. Total Environ. 2005, 339, 153–166. [Google Scholar] [CrossRef] [PubMed]

- Grimalt, J.O.; Ferrer, M.; Macpherson, E. The mine tailing accident in Aznalcollar. Sci. Total Environ. 1999, 242, 3–11. [Google Scholar] [CrossRef]

- Gerba, C.P. Risk Assessment. In Environmental Microbiology; Elsevier Inc.: Amsterdam, The Netherlands, 2009; pp. 575–587. [Google Scholar]

- Mehta, N.; Dino, G.A.; Ajmone-Marsan, F.; Lasagna, M.; Romè, C.; De Luca, D.A. Extractive waste management: A risk analysis approach. Sci. Total Environ. 2018, 622–623, 900–912. [Google Scholar] [CrossRef]

- ASTM. Standard Guide for Risk Based Corrective Action Applied at Petroleum Release Sites; ASTM International: West Conshohocken, PA, USA, 1995. [Google Scholar]

- ASTM. Standard guide for Risk Based Corrective Action; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Lottermoser, B. Mine Wastes: Characterization, Treatment, and Environmental Impacts, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Tiruta-Barna, L.; Benetto, E.; Perrodin, Y. Environmental impact and risk assessment of mineral wastes reuse strategies: Review and critical analysis of approaches and applications. Resour. Conserv. Recycl. 2007, 50, 351–379. [Google Scholar] [CrossRef]

- Dino, G.A.; Rossetti, P.; Biglia, G.; Sapino, M.L.; Di Mauro, F.; Särkkä, H.; Coulon, F.; Gomes, D.; Parejo-Bravo, L.; Zapata Aranda, P.; et al. SMART GROUND project: A new approach to data accessibility and collection for Raw Materials and Secondary Raw Materials in Europe. Environ. Eng. Manag. J. 2017, 16, 1673–1684. [Google Scholar] [CrossRef]

- Edraki, M.; Baumgartl, T.; Manlapig, E.; Bradshaw, D.; Franks, D.M.; Moran, C.J. Designing mine tailings for better environmental, social and economic outcomes: A review of alternative approaches. J. Clean. Pro. 2014, 84, 411–420. [Google Scholar] [CrossRef]

- Rampacek, C. An overview of mining and mineral processing waste as a resource. Resour. Conserv. 1982, 9, 75–86. [Google Scholar] [CrossRef]

- Dino, G.A.; Rossetti, P.; Perotti, P.; Alberto, W.; Sarkka, H.; Coulon, F.; Wagland, S.; Griffiths, Z.; Rodeghiero, F. Landfill mining from extractive waste facilities: The importance of a correct site characterization and evaluation of the potentialities. A case study from Italy. Resour. Policy 2018, 59, 50–61. [Google Scholar] [CrossRef]

- Dino, G.A.; Mehta, N.; Rossetti, P.; Ajmone-Marsan, F.; De Luca, D.A. Sustainable approach towards extractive waste management: Two case studies from Italy. Resour. Policy 2018, 59, 33–43. [Google Scholar] [CrossRef]

- Alcalde, J.; Kelm, U.; Vergara, D. Historical assessment of metal recovery potential from old mine tailings: A study case for porphyry copper tailings, Chile. Miner. Eng. 2018, 127, 334–338. [Google Scholar] [CrossRef]

- Bellenfant, G.; Guezennec, A.; Bodenan, F.; D’Hugues, P.; Cassard, P. Re-processing of mining waste: Combining environmental management and metal recovery? In Proceedings of the Eighth International Seminar on Mine Closure, Cornwall, UK, 18–20 September 2013; pp. 571–582. [Google Scholar]

- Jones, P.T.; Geysen, D.; Tielemans, Y.; Van Passel, S.; Pontikes, Y.; Blanpain, B.; Quaghebeur, M.; Hoekstra, N. Enhanced Landfill Mining in view of multiple resource recovery: A critical review. J. Clean. Prod. 2013, 55, 45–55. [Google Scholar] [CrossRef]

- Cavallo, A.; Dino, G.A. Granites of the Verbano-Cusio-Ossola district (Piedmont, Northern Italy): Possible candidates for the designation of “global heritage stone province” and a proposal of a geotouristic route. In Engineering Geology for Society and Territory-Volume 5: Urban Geology, Sustainable Planning and Landscape Exploitation; Lollino, G., Manconi, A., Guzzetti, F., Culshaw, M., Bobrowsky, P., Luino, Eds.; Springer: Cham, Switzerland, 2015; Volume 5, pp. 267–271. [Google Scholar]

- Bozzola, G.; Dino, G.A.; Fornaro, M.; Lorenzi, A. Technological innovations and secondary raw materials obtained from a virtuous management of wastes connected to mining activities: The examples of Gruppo Minerali Maffei S.p.A. Rend. Online Soc. Geol. Ital. 2010, 11, 519–520. [Google Scholar]

- Dino, G.A.; Fornaro, M.; Trentin, A. Quarry Waste: Chances of a Possible Economic and Environmental Valorisation of the Montorfano and Baveno Granite Disposal Sites. J. Geol. Res. 2012. [Google Scholar] [CrossRef]

- Cavallo, A.; Bigioggero, B.; Colombo, A.; Tunesi, A. The Verbano Cusio Ossola province: a land of quarries in northern Italy (Piedmont). Per. Mineral. 2004, 73, 197–210, SPECIAL ISSUE 3: A showcase of the Italian research in applied petrology. [Google Scholar]

- Thinkstep Recipe Description. Available online: http://www.gabi-software.com/support/gabi/gabi-lcia-documentation/recipe/ (accessed on 1 March 2020).

- Boriani, A. The geo-petrological setting of the Verbano-Ossola domain in the frame of the Alps. In Proceedings of the Quarry-Laboratory-Monument Int. Congress, Pavia, Italy, 26–30 September 2000. [Google Scholar]

- Nakamura, N. Determination of REE, Ba, Fe, Mg, Na and K in carbonaceous and ordinary chondrites. Geochim. Cosmochim. Acta 1974, 38, 757–775. [Google Scholar] [CrossRef]

| Minerals/Elements | World Production 2017 (t) | Compound Annual Growth Rate of World Mine Production over the Last 10 Years (2007–2016) (%) | Main Producers—World (%) | EU Prod. (t)—World (%) | Main EU Producers | Import to EU-28 (t) | ||

|---|---|---|---|---|---|---|---|---|

| Cobalt | 135,525 | 5.3 | Congo | 61 | 2300 | 1.69 | Finland | 1368 |

| Aluminum | 60,537,000 | 4.7 | China | 55 | 2,260,000 | 3.73 | Norway a | 5,455,675 |

| REE b | 132,000 | 1.6 | China | 79.5 | - | - | - | - |

| Pt | 187.102 | −1.1 | RSA | 71 | 1.228 | 0.65 | Finland | 63.14 |

| Pd | 211.279 | −0.4 | Russia | 41 | 0.931 | 0.44 | Finland | 67.70 |

| Rh | 23.803 | −0.6 | RSA | 81 | 0 | 0 | - | 5.94 |

| Lithium | 107,332 c | 7.5 | Australia | 49 | 782 c | 0.73 | Switzerland a | 3294 |

| Graphite | 943,135 | −0.1 | China | 71 | 572 | 0.06 | - | 82,377 |

| Feldspar d | 28,780,000 | - | Turkey | 31.3 | 4,937,000 | 17.15 | Italy | 2,688,000 |

| Emission to air | CO2 production, due to tracks and machineries. |

| Dust connected to rocks and minerals exploitation, processing, transport (e.g., quartz, asbestos, metals). | |

| Noise and potential odor, mainly connected to transport phases, mainly if the mining area has residential housing nearby. | |

| Emission to water | Reagents from mineral processing (e.g., as cyanide, xanthates, acids or bases resulting in low or high pH solid or dissolved metals or metalliferous compounds) [13]. |

| Metals due to minerals concentrations in rocks [14,15]. | |

| Overall management of water connected to excavation phase, and to water and reagents connected to processing phase, such as: consumption and treatment and/or recycling of reagents (e.g., flotation reagents, cyanide, flocculants), water present in tailing facilities, surface water connected to precipitation, etc. [16]. | |

| Exhausted oils and lubricants connected to machineries | |

| Emission to land | Dust or seepage of liquids from tailings and/or waste-rock management facilities into the ground: e.g., Acid Mine Drainage (AMD) [3,17]. |

| Effluents and dust emitted from controlled or uncontrolled tailings and waste-rock management facilities, potentially toxic in varying degrees to humans, animals, and plants [18,19]. The effluents can be acidic or alkaline and may contain dissolved metals and/or soluble and insoluble complex organic constituents from mineral processing, as well as natural occurring organic substances such as humic and long- chain carboxylic acids from mining operations. The substances in the emissions, together with their pH level, dissolved oxygen content, temperature and hardness may all be important aspects affecting their toxicity to the receiving environment. |

| EW Facility | Number of Collected Samples from the EW Facilities | Samples Characteristics | Dressing Activity at Lab | Typologies of Dressing Activity Performed |

|---|---|---|---|---|

| Braghini | 22 | Chip and rock pieces collected from the EW facility | yes | Grinding and magnetic separation (first step: 1SM; second step: 2SM; third step: 3SM) |

| Ciana-Tane Pilastretto | 30 | Chips and rocks pieces collected from the EW facility | yes | Grinding and magnetic separation (first step: 1SM; second step: 2SM; third step: 3SM) |

| Sengio | 26 | Chip and rock pieces collected from the EW facility | yes | Grinding and magnetic separation (first step: 1SM; second step: 2SM; third step: 3SM) |

| Montorfano | 8 | Chip and rock pieces collected from the EW facility | no | Collection of 8 samples from the active treatment plant (feeding material, main product and by- products) |

| Material Balance of Pilot | Total Mass (tons) During All Years of Operation (t/y) |

|---|---|

| Main products | 86,439 |

| Gravel and sands | 61,524 |

| SF and SF100 | 5777 |

| SN (black sand; magnetic concentrate) | 1838 |

| SNG (black sand, magnetic concentrate. Class > 600 µm) | 6836 |

| SNS (black sand, magnetic concentrate, coming from the production line for F60-40 | 1941 |

| Armor stones, aggregate for embankment and filler | 23,237 |

| TOTAL | 187,592 |

| Operation Type | Energy Need (MWh/Year) |

|---|---|

| Crushing (primary) | 16 |

| Milling and screening | 69 |

| Drying | 44 |

| Magnetic separation | 51 |

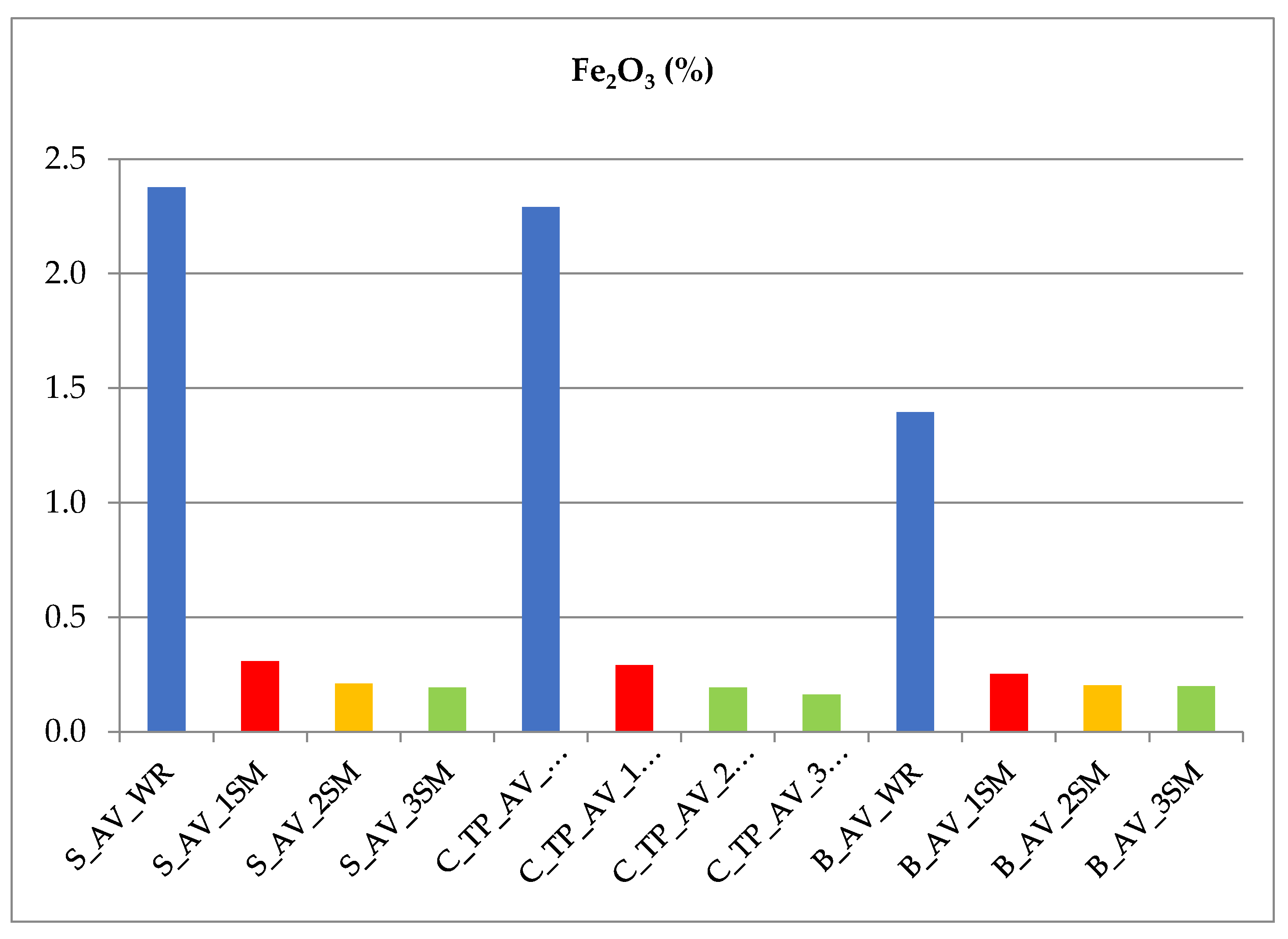

| Al2O3 % | Fe2O3 % | MgO % | CaO % | Na2O % | K2O % | TiO2 % | |

|---|---|---|---|---|---|---|---|

| S_AV_WR | 13.93 | 2.38 | 0.28 | 1.18 | 3.08 | 5.12 | 0.26 |

| S_AV_1SM | 13.72 | 0.31 | 0.11 | 1.05 | 3.37 | 5.06 | 0.03 |

| S_AV_2SM | 13.79 | 0.21 | 0.10 | 1.03 | 3.37 | 5.11 | 0.02 |

| S_AV_3SM | 13.86 | 0.19 | 0.10 | 1.05 | 3.48 | 5.05 | 0.02 |

| C_TP_AV_WR | 14.25 | 2.29 | 0.28 | 1.32 | 3.31 | 4.79 | 0.25 |

| C_TP_AV_1SM | 14.00 | 0.29 | 0.11 | 1.25 | 3.52 | 4.79 | 0.03 |

| C_TP_AV_2SM | 13.68 | 0.19 | 0.10 | 1.24 | 3.48 | 4.74 | 0.02 |

| C_TP_AV_3SM | 13.86 | 0.16 | 0.01 | 1.24 | 3.53 | 4.78 | 0.02 |

| B_AV_WR | 13.02 | 1.40 | 0.14 | 0.54 | 3.64 | 4.79 | 0.10 |

| B_AV_1SM | 12.85 | 0.25 | 0.01 | 0.46 | 3.68 | 5.04 | 0.01 |

| B_AV_2SM | 12.82 | 0.20 | <0.01 | 0.44 | 3.71 | 5.05 | 0.01 |

| B_AV_3SM | 12.78 | 0.20 | <0.01 | 0.46 | 5.57 | 5.09 | 0.01 |

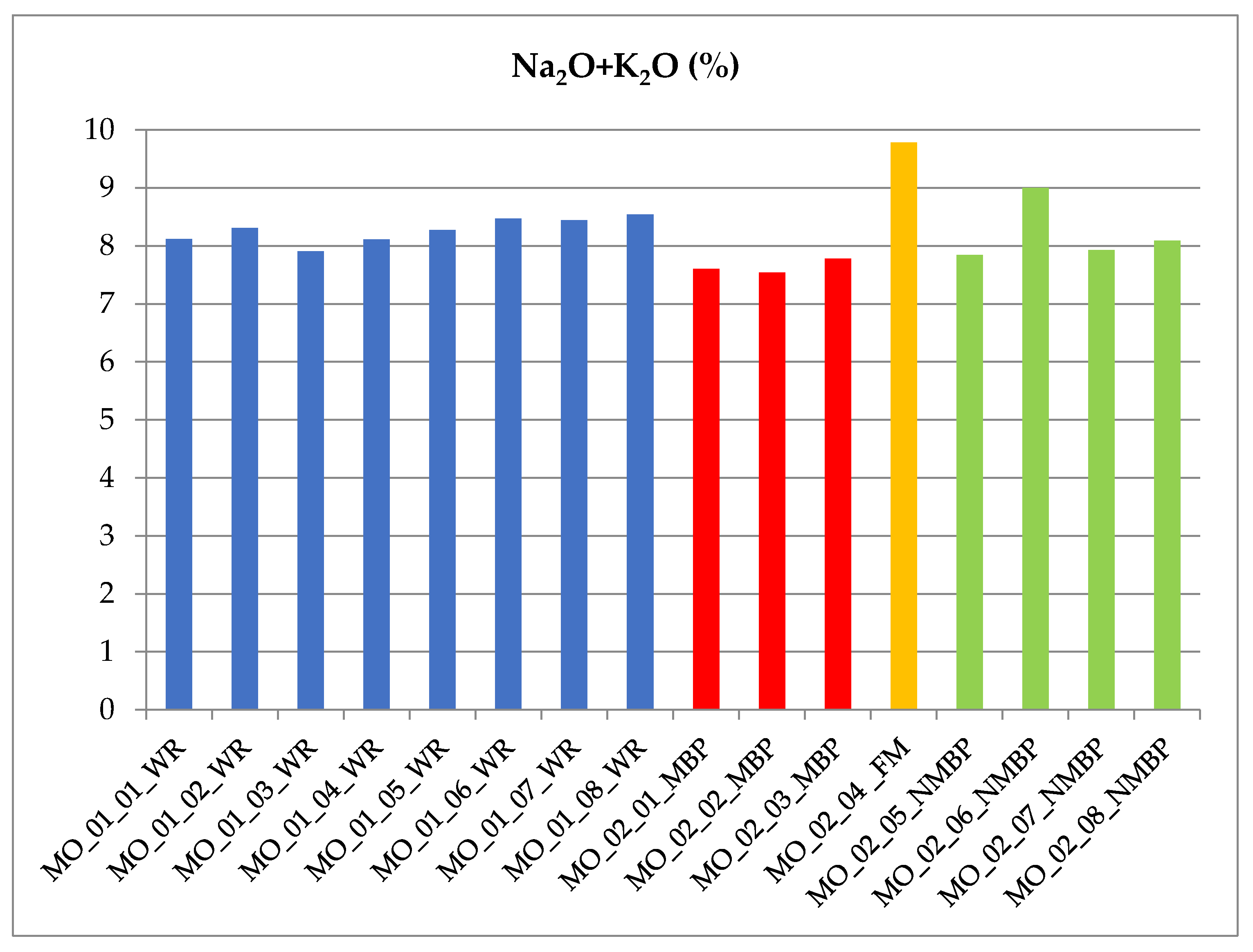

| SiO2 % | Al2O3 % | Fe2O3 % | MnO % | MgO % | CaO % | Na2O % | K2O % | TiO2 % | P2O5 % | |

|---|---|---|---|---|---|---|---|---|---|---|

| MO_01_01_WR | 71.41 | 13.38 | 2.39 | 0.04 | 0.45 | 1.62 | 3.32 | 4.8 | 0.205 | 0.05 |

| MO_01_02_WR | 71.55 | 13.74 | 2.28 | 0.039 | 0.29 | 1.43 | 3.35 | 4.96 | 0.208 | 0.06 |

| MO_01_03_WR | 71.74 | 13.81 | 2.33 | 0.04 | 0.31 | 1.51 | 3.42 | 4.49 | 0.225 | 0.08 |

| MO_01_04_WR | 71.72 | 13.86 | 2.36 | 0.039 | 0.32 | 1.41 | 3.4 | 4.71 | 0.234 | 0.08 |

| MO_01_05_WR | 71.92 | 14.02 | 2.41 | 0.04 | 0.31 | 1.49 | 3.4 | 4.87 | 0.233 | 0.07 |

| MO_01_06_WR | 70.84 | 14.26 | 2.4 | 0.041 | 0.32 | 1.43 | 3.39 | 5.08 | 0.229 | 0.07 |

| MO_01_07_WR | 70.56 | 13.57 | 2.09 | 0.037 | 0.3 | 2.01 | 3.26 | 5.18 | 0.205 | 0.07 |

| MO_01_08_WR | 70.56 | 14.65 | 2.3 | 0.039 | 0.34 | 1.33 | 3.51 | 5.03 | 0.225 | 0.07 |

| MO_02_01_MBP | 63.81 | 14.37 | 7.93 | 0.143 | 1.2 | 1.4 | 2.8 | 4.8 | 0.73 | 0.15 |

| MO_02_02_MBP | 58.12 | 14.97 | 13.34 | 0.228 | 1.86 | 1.47 | 2.27 | 5.27 | 1.226 | 0.22 |

| MO_02_03_MBP | 56.45 | 15.89 | 13.2 | 0.225 | 1.82 | 1.74 | 2.52 | 5.26 | 1.285 | 0.32 |

| MO_02_04 _FM | 69.15 | 16.24 | 1.98 | 0.038 | 0.29 | 1.57 | 3.76 | 6.02 | 0.205 | 0.06 |

| MO_02_05_NMBP | 77.09 | 13.02 | 0.13 | 0.005 | 0.02 | 1.21 | 3.42 | 4.42 | 0.012 | <0.01 |

| MO_02_06_NMBP | 74.19 | 14.36 | 0.3 | 0.008 | 0.05 | 1.5 | 3.73 | 5.27 | 0.027 | 0.01 |

| MO_02_07_NMBP | 76.93 | 12.99 | 0.15 | 0.005 | 0.04 | 1.25 | 3.42 | 4.51 | 0.014 | <0.01 |

| MO_02_08_NMBP | 75.72 | 13.98 | 0.36 | 0.009 | 0.06 | 1.36 | 3.64 | 4.45 | 0.036 | 0.05 |

| Quarry Waste Dumps | Average Thickness Calculated Thanks to Tomography Cross S (m) | Ore Body Volume(m3) |

|---|---|---|

| Sengio | 20 m | 361,600 |

| Ciana-Tane Pilastretto | 25 m | 1,489,000 |

| Braghini | 15 m (tomography limit) | 158,000 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dino, G.A.; Cavallo, A.; Rossetti, P.; Garamvölgyi, E.; Sándor, R.; Coulon, F. Towards Sustainable Mining: Exploiting Raw Materials from Extractive Waste Facilities. Sustainability 2020, 12, 2383. https://doi.org/10.3390/su12062383

Dino GA, Cavallo A, Rossetti P, Garamvölgyi E, Sándor R, Coulon F. Towards Sustainable Mining: Exploiting Raw Materials from Extractive Waste Facilities. Sustainability. 2020; 12(6):2383. https://doi.org/10.3390/su12062383

Chicago/Turabian StyleDino, Giovanna Antonella, Alessandro Cavallo, Piergiorgio Rossetti, Ernő Garamvölgyi, Renáta Sándor, and Frederic Coulon. 2020. "Towards Sustainable Mining: Exploiting Raw Materials from Extractive Waste Facilities" Sustainability 12, no. 6: 2383. https://doi.org/10.3390/su12062383

APA StyleDino, G. A., Cavallo, A., Rossetti, P., Garamvölgyi, E., Sándor, R., & Coulon, F. (2020). Towards Sustainable Mining: Exploiting Raw Materials from Extractive Waste Facilities. Sustainability, 12(6), 2383. https://doi.org/10.3390/su12062383