Feasibility and Carbon Footprint Analysis of Lime-Dried Sludge for Cement Production

Abstract

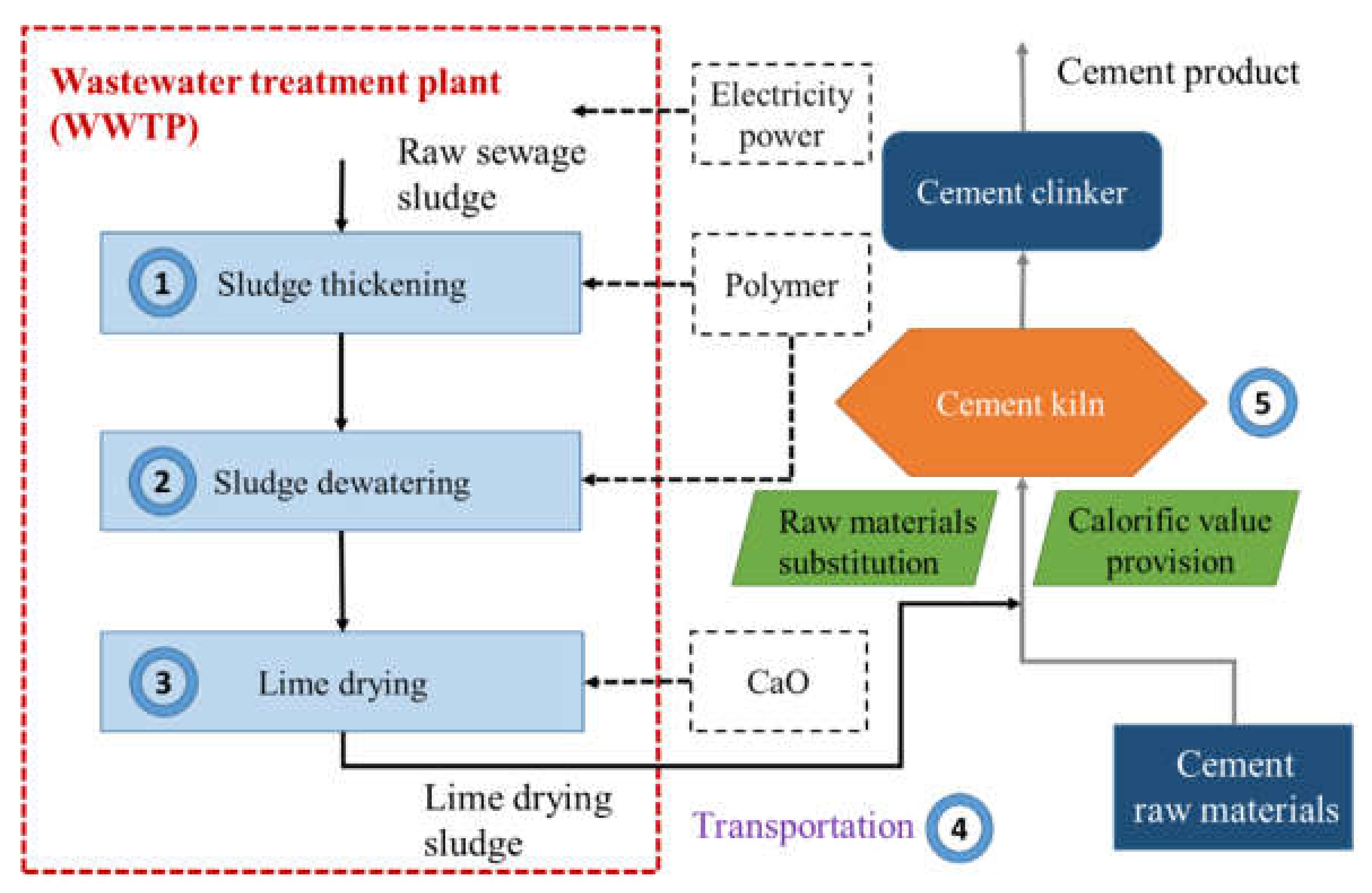

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Analytical Methods

2.3. Carobn Footprint

2.4. Sensitivity Analysis

3. Applicability of Lime-Dried Sludge to Cement Production

3.1. Raw Material Substitution Analysis

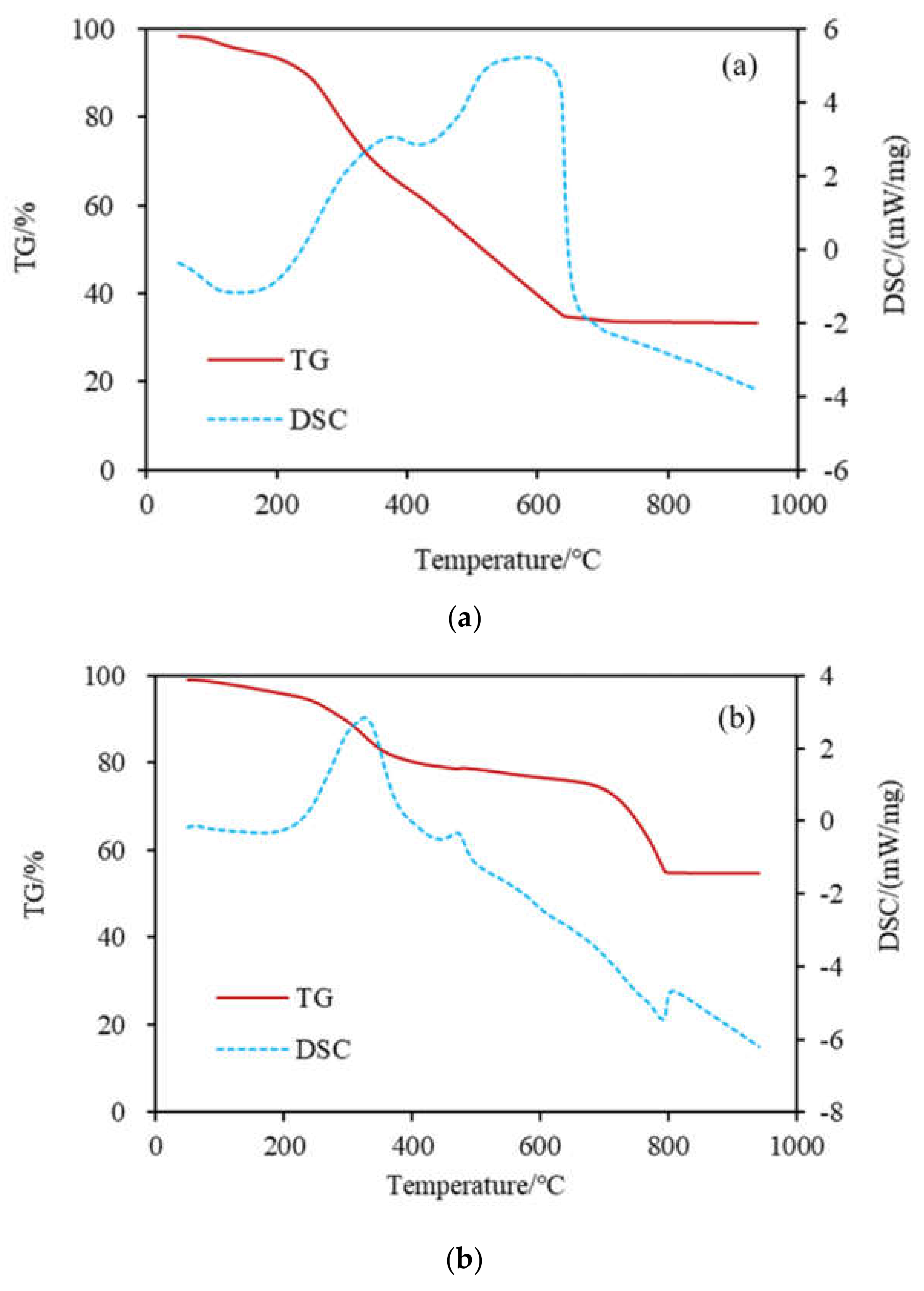

3.2. Themostability of Sludge

3.3. Energy Balance Analysis

4. Carbon Footprint Analysis

4.1. Carbon Footprint Calculation Model

4.1.1. Calculation of fossil CO2 emissions

4.1.2. Calculation of N2O emissions from Kiln

4.1.3. Calculation of Carbon Credit

4.2. Carbon Footprint Results

4.3. Sensitivity Analysis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lyu, S.; Chen, W.; Zhang, W.; Fan, Y.; Jiao, W. Wastewater reclamation and reuse in China: Opportunities and challenges. J. Environ. Sci. 2016, 39, 86–96. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.; Zhang, G.; Wang, H. Current state of sludge production, management, treatment and disposal in China. Water Res. 2015, 78, 60–73. [Google Scholar] [CrossRef] [PubMed]

- Werle, S.; Wilk, R.K. A review of methods for the thermal utilization of sewage sludge: The Polish perspective. Renew. Energy 2010, 35, 1914–1919. [Google Scholar] [CrossRef]

- Healy, M.G.; Fenton, O.; Forrestal, P.J.; Danaher, M.; Brennan, R.B.; Morrison, L. Metal concentrations in lime stabilised, thermally dried and anaerobically digested sewage sludges. Waste Manag. 2016, 48, 404–408. [Google Scholar] [CrossRef] [Green Version]

- Wei, X.; Xu, J.; Jia, L.; Li, H.; Bo, C.; Huang, X.; Li, G. The utilization of lime-dried sludge as resource for producing cement. J. Clean. Prod. 2014, 83, 286–293. [Google Scholar]

- Rodríguez, N.H.; Granados, R.; Blanco-Varela, M.T.; Cortina, J.; Martínez-Ramírez, S.; Marsal, M.; Guillem, M.; Puig, J.; Fos, C.; Larrotcha, E. Evaluation of a lime-mediated sewage sludge stabilisation process. Product characterisation and technological validation for its use in the cement industry. Waste Manag. 2012, 32, 550–560. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Xu, J.; Liu, J.; Cao, H.; Huang, X.-F.; Li, G. Characteristics of ammonia emission during thermal drying of lime sludge for co-combustion in cement kilns. Environ. Technol. 2015, 36, 226–236. [Google Scholar] [CrossRef]

- Li, W.-Q.; Liu, W.; Cao, H.-H.; Xu, J.-C.; Liu, J.; Li, G.-M.; Huang, J. The effect of lime-dried sewage sludge on the heat-resistance of eco-cement. Water Sci. Technol. 2016, 74, 212–219. [Google Scholar] [CrossRef]

- Cao, H.; Liu, J.; Xu, J.; Liu, W.; Huang, X.; Li, G. The Property of Lime Sewage Sludge and its Influence on Co-Processing in Cement Kilns. Pol. J. Environ. Stud. 2016, 25. [Google Scholar] [CrossRef]

- Huang, Y.; Li, H.; Jiang, Z.; Yang, X.; Chen, Q. Migration and transformation of sulfur in the municipal sewage sludge during disposal in cement kiln. Waste Manag. 2018, 77, 537–544. [Google Scholar] [CrossRef]

- Hand, B.K.; Flint, C.G.; Frissell, C.A.; Muhlfeld, C.C.; Devlin, S.P.; Kennedy, B.P.; Crabtree, R.L.; McKee, W.A.; Luikart, G.; Stanford, J.A. A social–ecological perspective for riverscape management in the Columbia River Basin. Front. Ecol. Environ. 2018, 16, S23–S33. [Google Scholar] [CrossRef] [Green Version]

- Ali, M.B.; Saidur, R.; Hossain, M.S. A review on emission analysis in cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2252–2261. [Google Scholar] [CrossRef]

- Shen, W.; Cao, L.; Li, Q.; Zhang, W.; Wang, G.; Li, C. Quantifying CO2 emissions from China’s cement industry. Renew. Sustain. Energy Rev. 2015, 50, 1004–1012. [Google Scholar] [CrossRef]

- Chen, H.X.; Ma, X.; Dai, H.J. Reuse of water purification sludge as raw material in cement production. Cem. Concr. Compos. 2010, 32, 436–439. [Google Scholar] [CrossRef]

- Gao, T.; Shen, L.; Shen, M.; Liu, L.; Chen, F. Analysis of material flow and consumption in cement production process. J. Clean. Prod. 2016, 112, 553–565. [Google Scholar] [CrossRef]

- Gao, T. Resource Consumption and Carbon Dioxide Emissions in the Process of Cement Production; Institute of Geographic Science and Natural Resource Research, CAS University of Chinese Academy of Sciences: Beijing, China, 2013. [Google Scholar]

- Ke, J.; McNeil, M.; Price, L.; Khanna, N.Z.; Zhou, N. Estimation of CO2 emissions from China’s cement production: Methodologies and uncertainties. Energy Policy 2013, 57, 172–181. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Höller, S.; Viebahn, P.; Hao, Z. Integrated assessment of CO2 reduction technologies in China’s cement industry. Int. J. Greenh. Gas Control 2014, 20, 27–36. [Google Scholar] [CrossRef] [Green Version]

- Lin, K.-L.; Lin, D.; Luo, H. Influence of phosphate of the waste sludge on the hydration characteristics of eco-cement. J. Hazard. Mater. 2009, 168, 1105–1110. [Google Scholar] [CrossRef]

- Li, H.; Xu, W.; Yang, X.; Wu, J. Preparation of Portland cement with sugar filter mud as lime-based raw material. J. Clean. Prod. 2014, 66, 107–112. [Google Scholar] [CrossRef]

- Jing, W.; Qiang, X. Study on Microscopic Characteristics and Analysis Methods of Municipal Sludge. Electron. J. Geotech. Eng. 2010, 15, 441–448. [Google Scholar]

- Magdziarz, A.; Werle, S. Analysis of the combustion and pyrolysis of dried sewage sludge by TGA and MS. Waste Manag. 2014, 34, 174–179. [Google Scholar] [CrossRef]

- Liao, B.Q.; Lin, H.J.; Langevin, S.P.; Gao, W.J.; Leppard, G.G. Effects of temperature and dissolved oxygen on sludge properties and their role in bioflocculation and settling. Water Res. 2011, 45, 509–520. [Google Scholar] [CrossRef] [PubMed]

- Gao, N.; Li, J.; Qi, B.; Li, A.; Duan, Y.; Wang, Z. Thermal analysis and products distribution of dried sewage sludge pyrolysis. J. Anal. Appl. Pyrolysis 2014, 105, 43–48. [Google Scholar] [CrossRef]

- Huang, X.; Cao, J.-P.; Shi, P.; Zhao, X.-Y.; Feng, X.-B.; Zhao, Y.-P.; Fan, X.; Wei, X.-Y.; Takarada, T. Influences of pyrolysis conditions in the production and chemical composition of the bio-oils from fast pyrolysis of sewage sludge. J. Anal. Appl. Pyrolysis 2014, 110, 353–362. [Google Scholar] [CrossRef]

- Jin, Y.; Ling, P.; He, Y.; Chen, L.; Chen, J.; Zhang, T. Preparation, characterization and anti-Helicobacter pylori activity of Bi3+-hyaluronate complex. Carbohydr. Polym. 2008, 74, 50–58. [Google Scholar] [CrossRef]

- Li, H.; Zou, S.; Li, C. Liming Pretreatment Reduces Sludge Build-Up on the Dryer Wall during Thermal Drying. Dry. Technol. 2012, 30, 1563–1569. [Google Scholar] [CrossRef]

- Liang, L.; Hui, S.; Pan, S.; Shang, T.; Liu, C.; Wang, D. Influence of mixing, oxygen and residence time on the SNCR process. Fuel 2014, 120, 38–45. [Google Scholar] [CrossRef]

- Song, H.; Jeong, Y.; Bae, S.; Jun, Y.; Yoon, S.; Oh, J.E. A study of thermal decomposition of phases in cementitious systems using HT-XRD and TG. Constr. Build. Mater. 2018. [Google Scholar] [CrossRef]

- Murray, A.; Horvath, A.; Nelson, K.L. Hybrid Life-Cycle Environmental and Cost Inventory of Sewage Sludge Treatment and End-Use Scenarios: A Case Study from China. Environ. Sci. Technol. 2008, 42, 3163–3169. [Google Scholar] [CrossRef] [Green Version]

- Park, S.; Choi, J.-H.; Park, J. The estimation of N2O emissions from municipal solid waste incineration facilities: The Korea case. Waste Manag. 2011, 31, 1765–1771. [Google Scholar] [CrossRef]

- Garrido-Baserba, M.; Molinos-Senante, M.; Abelleira-Pereira, J.M.; Fdez-Güelfo, L.A.; Poch, M.; Hernández-Sancho, F. Selecting sewage sludge treatment alternatives in modern wastewater treatment plants using environmental decision support systems. J. Clean. Prod. 2015, 107, 410–419. [Google Scholar] [CrossRef]

- Zhao, G.; Garrido-Baserba, M.; Reifsnyder, S.; Xu, J.-C.; Rosso, D. Comparative energy and carbon footprint analysis of biosolids management strategies in water resource recovery facilities. Sci. Total Environ. 2019, 665, 762–773. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.C.; Kuo, J. Potential of greenhouse gas emissions from sewage sludge management: A case study of Taiwan. J. Clean. Prod. 2016, 129, 196–201. [Google Scholar] [CrossRef]

- Liu, B.; Wei, Q.; Zhang, B.; Bi, J. Life cycle GHG emissions of sewage sludge treatment and disposal options in Tai Lake Watershed, China. Sci. Total Environ. 2013, 447, 361–369. [Google Scholar] [CrossRef]

| Sample | Water Content (%) | Organic Matter (%) | pH | TN (mg/g) | TC (mg/g) | Lower Heating Value (LHV) (MJ/kg) |

|---|---|---|---|---|---|---|

| RS | 86.6 | 60.4 | 7.16 | 50.7 | 370.6 | 15.9 |

| LS | 74.4 | 25.5 | 12.04 | 23.7 | 172.5 | 7.2 |

| Sample | LOI | SiO2 | CaO | Al2O3 | Fe2O3 | MgO | P2O5 |

|---|---|---|---|---|---|---|---|

| CRM | 33.85 | 14.15 | 42.64 | 4.29 | 3.48 | 0.94 | 0.06 |

| RS | 65.26 | 6.09 | 3.22 | 5.74 | 6.09 | 0.98 | 6.02 |

| LS | 38.47 | 3.32 | 42.49 | 1.81 | 3.81 | 1.02 | 3.29 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ping, L.; Zhao, G.; Lin, X.; Gu, Y.; Liu, W.; Cao, H.; Huang, J.; Xu, J. Feasibility and Carbon Footprint Analysis of Lime-Dried Sludge for Cement Production. Sustainability 2020, 12, 2500. https://doi.org/10.3390/su12062500

Ping L, Zhao G, Lin X, Gu Y, Liu W, Cao H, Huang J, Xu J. Feasibility and Carbon Footprint Analysis of Lime-Dried Sludge for Cement Production. Sustainability. 2020; 12(6):2500. https://doi.org/10.3390/su12062500

Chicago/Turabian StylePing, Li, Gang Zhao, Xiaohu Lin, Yunhui Gu, Wei Liu, Haihua Cao, Juwen Huang, and Jingcheng Xu. 2020. "Feasibility and Carbon Footprint Analysis of Lime-Dried Sludge for Cement Production" Sustainability 12, no. 6: 2500. https://doi.org/10.3390/su12062500

APA StylePing, L., Zhao, G., Lin, X., Gu, Y., Liu, W., Cao, H., Huang, J., & Xu, J. (2020). Feasibility and Carbon Footprint Analysis of Lime-Dried Sludge for Cement Production. Sustainability, 12(6), 2500. https://doi.org/10.3390/su12062500