Efficiency Gap Caused by the Input Data in Evaluating Energy Efficiency of Low-Income Households’ Energy Retrofit Program

Abstract

:1. Introduction

2. Method

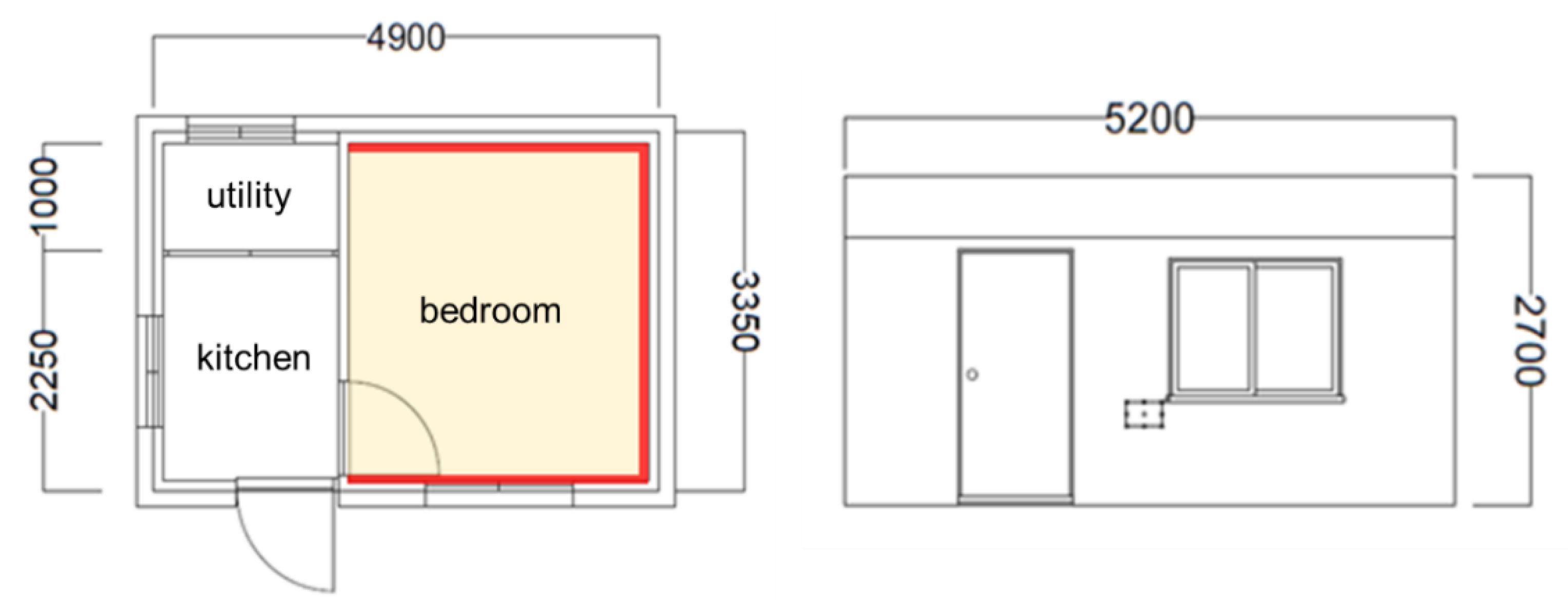

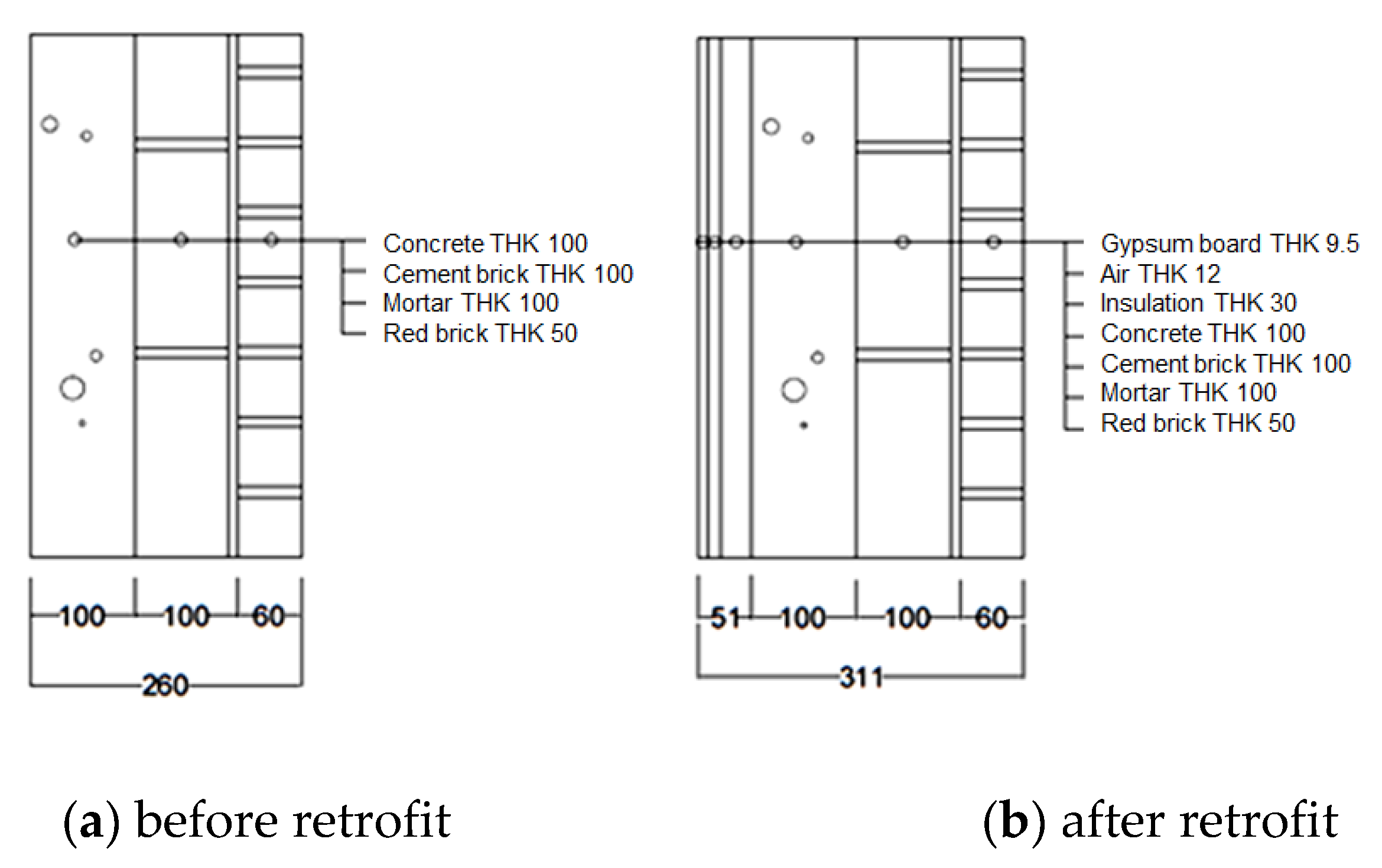

2.1. Overview of the Target Household

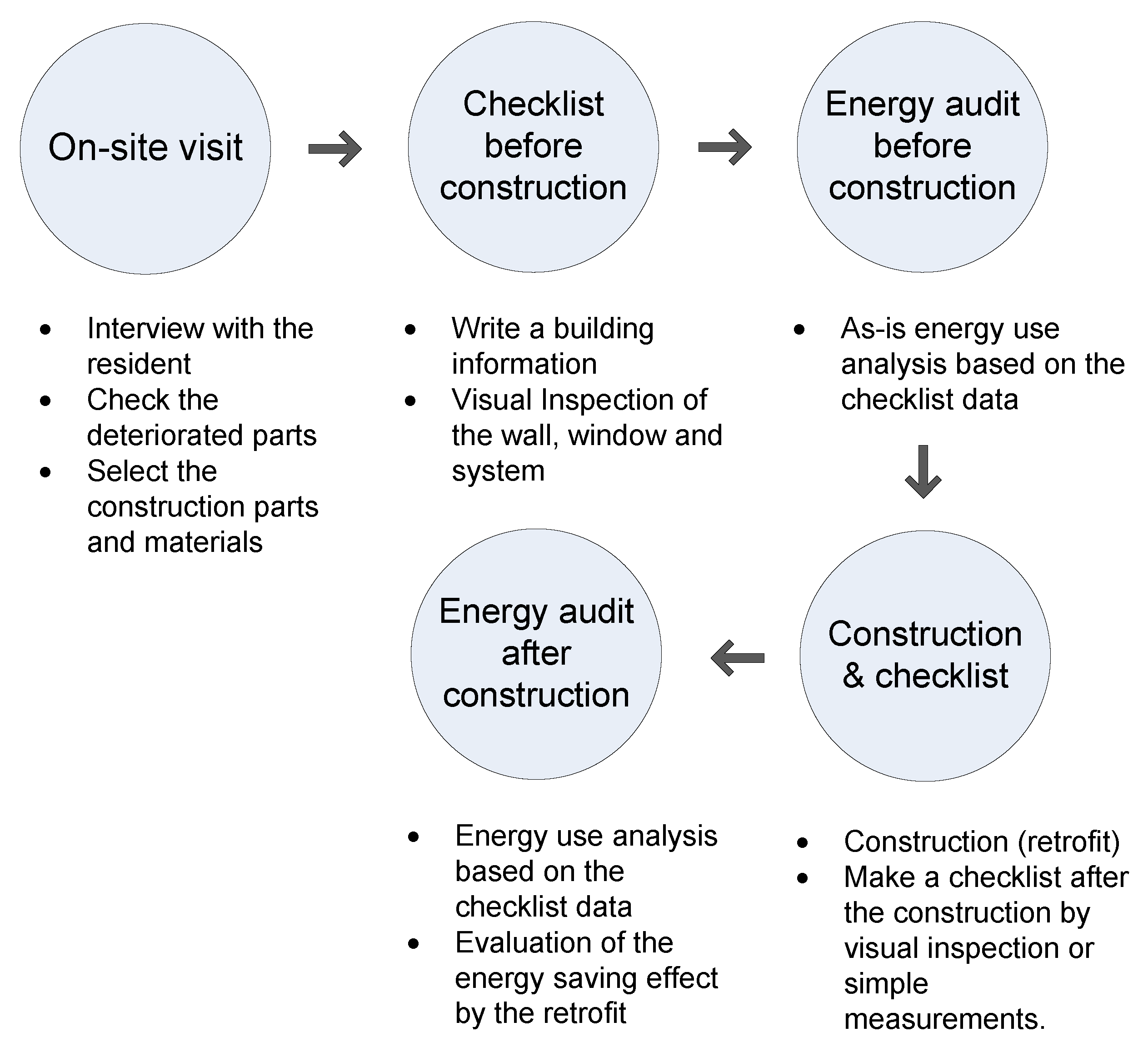

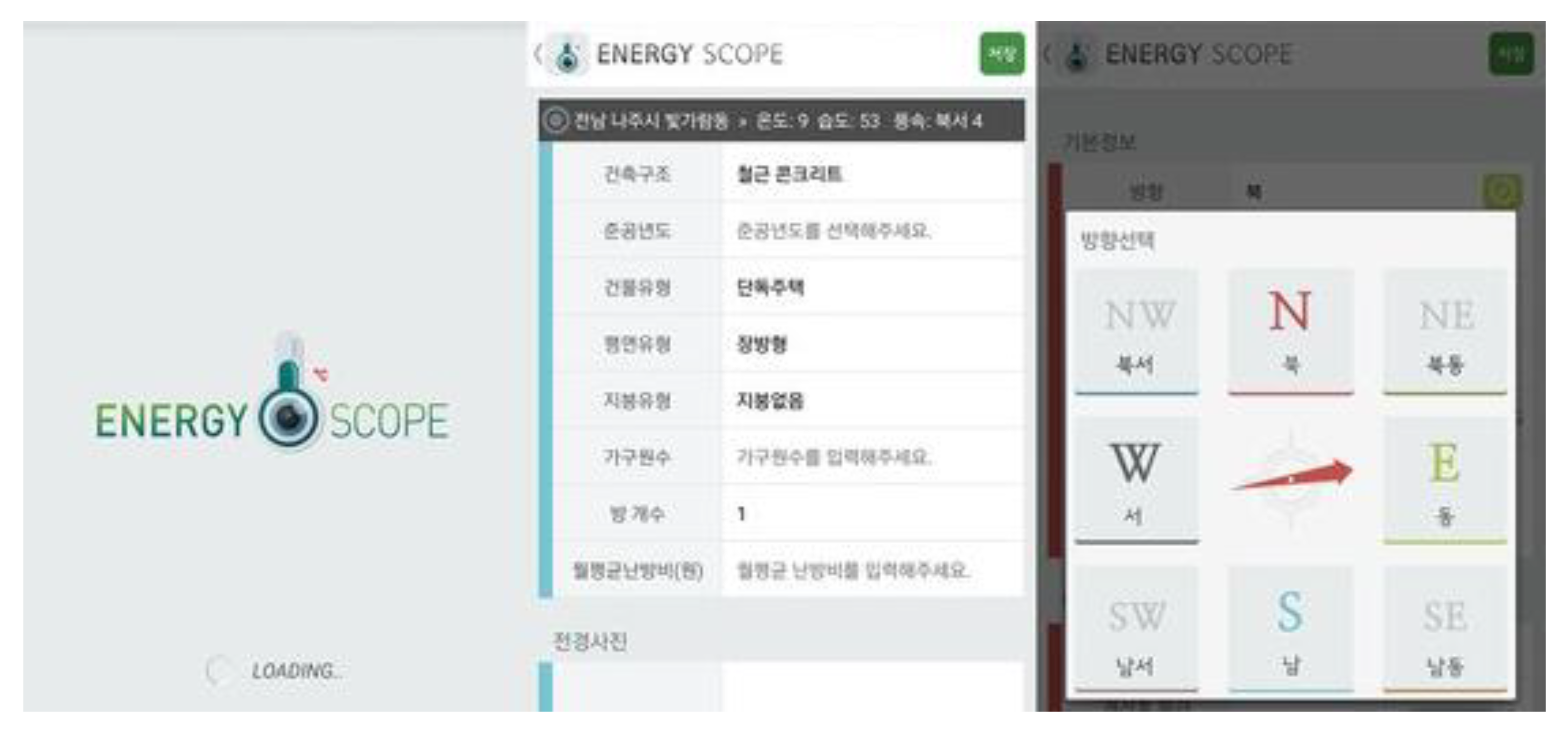

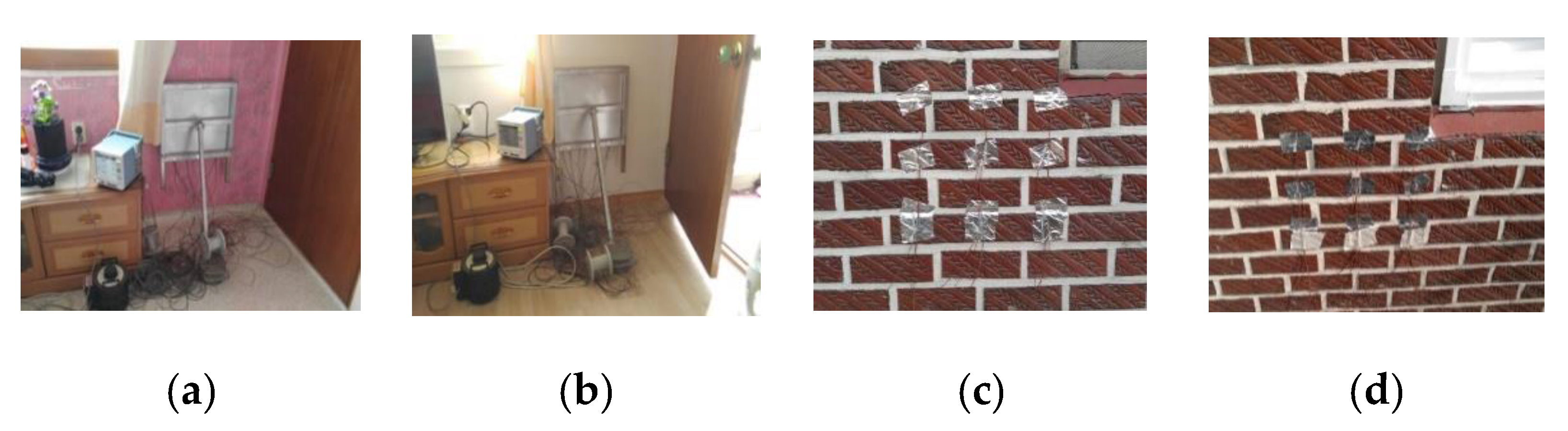

2.2. Walk-Through Audit

2.3. Detailed Field Measurement

2.4. Simulation

3. Results

3.1. Measurement results

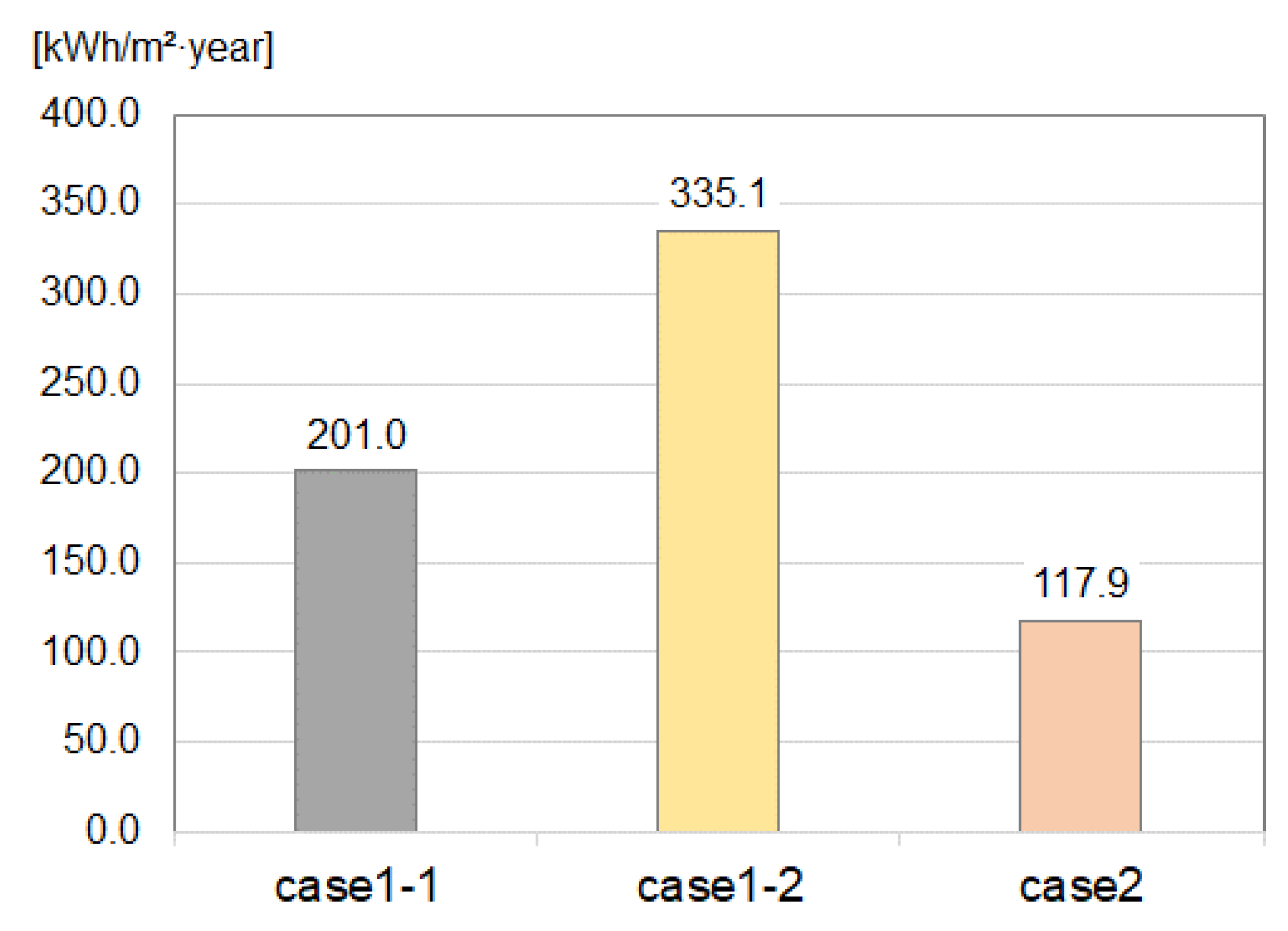

3.2. Simulation Results

3.2.1. Differences in heating demand and GHG emissions

4. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- International Energy Agency. CO2 Emissions from Fuel Combustion 2017; International Energy Agency: Paris, France, 2017. [Google Scholar] [CrossRef]

- International Energy Agency. World Energy Balances 2017; International Energy Agency: Paris, France, 2017. [Google Scholar] [CrossRef]

- Kim, T.; Chae, C.U. Evaluation analysis of the CO2 emission and absorption life cycle for precast concrete in Korea. Sustainability 2016, 8, 663. [Google Scholar] [CrossRef] [Green Version]

- UNFCCC. Synthesis Report on the Aggregate Effect of the Intended Nationally Determined Contributions; Author Paris; UNFCCC: New York, NY, USA, 2015. [Google Scholar]

- MOSF. 1st Master Plan for Response to Climate Change; MOSF: Seoul, Korea, 2016. [Google Scholar]

- Ma, Z.; Cooper, P.; Daly, D.; Ledo, L. Existing building retrofits: Methodology and state-of-the-art. Energy Build. 2012, 55, 889–902. [Google Scholar] [CrossRef]

- Levine, M.; Urge-Vorsatz, D.; Blok, L.; Geng, D.; Harvey, S.; Lang, G.; Levermore, A.; Mongameli Mehlwana, S.; Mirasgedis, A.; Novikova, J. Chapter 6: Resdiential and Commercial Buildings. IPCC AR4 WGIII. 2008. Available online: http://www.ipcc.ch/pdf/assessment-report/ar4/wg3/ar4-wg3-chapter6.pdf (accessed on 20 April 2009).

- Tommerup, H.; Svendsen, S. Energy savings in Danish residential building stock. Energy Build. 2006, 38, 618–626. [Google Scholar] [CrossRef]

- Edenhofer, O.; Pichs-Madruga, R.; Sokona, Y.; Agrawala, S.; Bashmakov, I.; Blanco, G.; Broome, J.; Bruckner, T.; Brunner, S.; Bustamante, M. Summary for policymakers. In Climate Change 2014: Mitigation of Climate Change; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Lomas, K.J. Carbon reduction in existing buildings: A transdisciplinary approach. Build. Res. Inf. 2010, 38, 1–11. [Google Scholar] [CrossRef]

- Statics Korea. 2018 Population and Housing Census; Statics Korea: Seoul, Korea, 2018. [Google Scholar]

- Lee, T. A Survey Study of Poverty Policy; Korea Institute for Health and Social Affairs: Yeongi-gun, Korea, 2011. [Google Scholar]

- Scott, S.; Lyons, S.; Keane, C.; McCarthy, D.; Tol, R.S. Fuel Poverty in Ireland: Extent, Affected Groups and Policy Issues; ESRI Working paper: Dublin, Ireland, 2008. [Google Scholar]

- USDOE. Weatherization Assistance Program Briefing Book; USDOE: Washington, DC, USA, 2016. [Google Scholar]

- Park, S.; Kim, J.; Song, D. The Effect of an Energy Refurbishment Scheme on Adequate Warmth in Low-income Dwellings. Sustainability 2019, 11, 2574. [Google Scholar] [CrossRef] [Green Version]

- Jordaan, S.M.; Romo-Rabago, E.; McLeary, R.; Reidy, L.; Nazari, J.; Herremans, I.M. The role of energy technology innovation in reducing greenhouse gas emissions: A case study of Canada. Renew. Sustain. Energy Rev. 2017, 78, 1397–1409. [Google Scholar] [CrossRef]

- EU. Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the energy performance of buildings. Off. J. Eur. Union 2010, 53, 13–35. [Google Scholar]

- Kelly, S.; Crawford-Brown, D.; Pollitt, M.G. Building performance evaluation and certification in the UK: Is SAP fit for purpose? Renew. Sustain. Energy Rev. 2012, 16, 6861–6878. [Google Scholar] [CrossRef]

- Koo, C.; Hong, T.; Lee, M.; Park, H.S. Development of a new energy efficiency rating system for existing residential buildings. Energy Policy 2014, 68, 218–231. [Google Scholar] [CrossRef] [Green Version]

- Fowlie, M.; Greenstone, M.; Wolfram, C. Do energy efficiency investments deliver? Evidence from the weatherization assistance program. Q. J. Econ. 2018, 133, 1597–1644. [Google Scholar] [CrossRef] [Green Version]

- Milne, G.; Boardman, B. Making cold homes warmer: The effect of energy efficiency improvements in low-income homes A report to the Energy Action Grants Agency Charitable Trust. Energy Policy 2000, 28, 411–424. [Google Scholar] [CrossRef]

- Rosenow, J.; Galvin, R. Evaluating the evaluations: Evidence from energy efficiency programmes in Germany and the UK. Energy Build. 2013, 62, 450–458. [Google Scholar] [CrossRef]

- Sanders, C.; Phillipson, M. Review of Differences between Measured and Theoretical Energy Savings for Insulation Measures; Centre for Research on Indoor Climate and Health, Glasgow Caledonian University: Glasgow, UK, 2006. [Google Scholar]

- DECC. How the Green Deal will Reflect the In-situ Performance of Energy Efficiency Measures; UK Department for Energy and Climate Change: London, UK, 2012. [Google Scholar]

- Evans, M.; Chon, H.; Shui, B.; Lee, S. Country report on building energy codes in Republic of Korea. Pac. Northwest Natl. Lab. 2009, 1, 1–26. [Google Scholar] [CrossRef] [Green Version]

- Krarti, M. Weatherization and Energy Efficiency Improvement for Existing Homes: An Engineering Approach; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- ISO13790:2007; Thermal Performance of Buildings-Calculation of Energy Use for Space Heating; ISO: Geneva, Switzerland, 2007.

- ISO9869:1994; Thermal Insulation—Building Elements—In-Situ Measurement of Thermal Resistance and Thermal Transmittance; ISO: Geneva, Switzerland, 1994.

- Balci, O. A methodology for certification of modeling and simulation applications. ACM Trans. Modeling Comput. Simul. (TOMACS) 2001, 11, 352–377. [Google Scholar] [CrossRef]

- Shim, J.; Song, D.; Kim, J. The Economic Feasibility of Passive Houses in Korea. Sustainability 2018, 10, 3558. [Google Scholar] [CrossRef] [Green Version]

| Layer | Materials | Before Retrofit (mm) | After Retrofit (mm) |

|---|---|---|---|

| Outside | Redbrick | 57 | 50 |

| 2 | Mortar | 10 | 10 |

| 3 | Cement brick | 100 | 100 |

| 4 | Concrete | 100 | 100 |

| 5 | Insulation | - | 30 |

| 6 | Air | - | 12 |

| Inside | Gypsum board | - | 9.5 |

| Before Retrofit | After Retrofit |

|---|---|

| Wood frame + 3 mm single glass | PVC frame with 6 mm double glass |

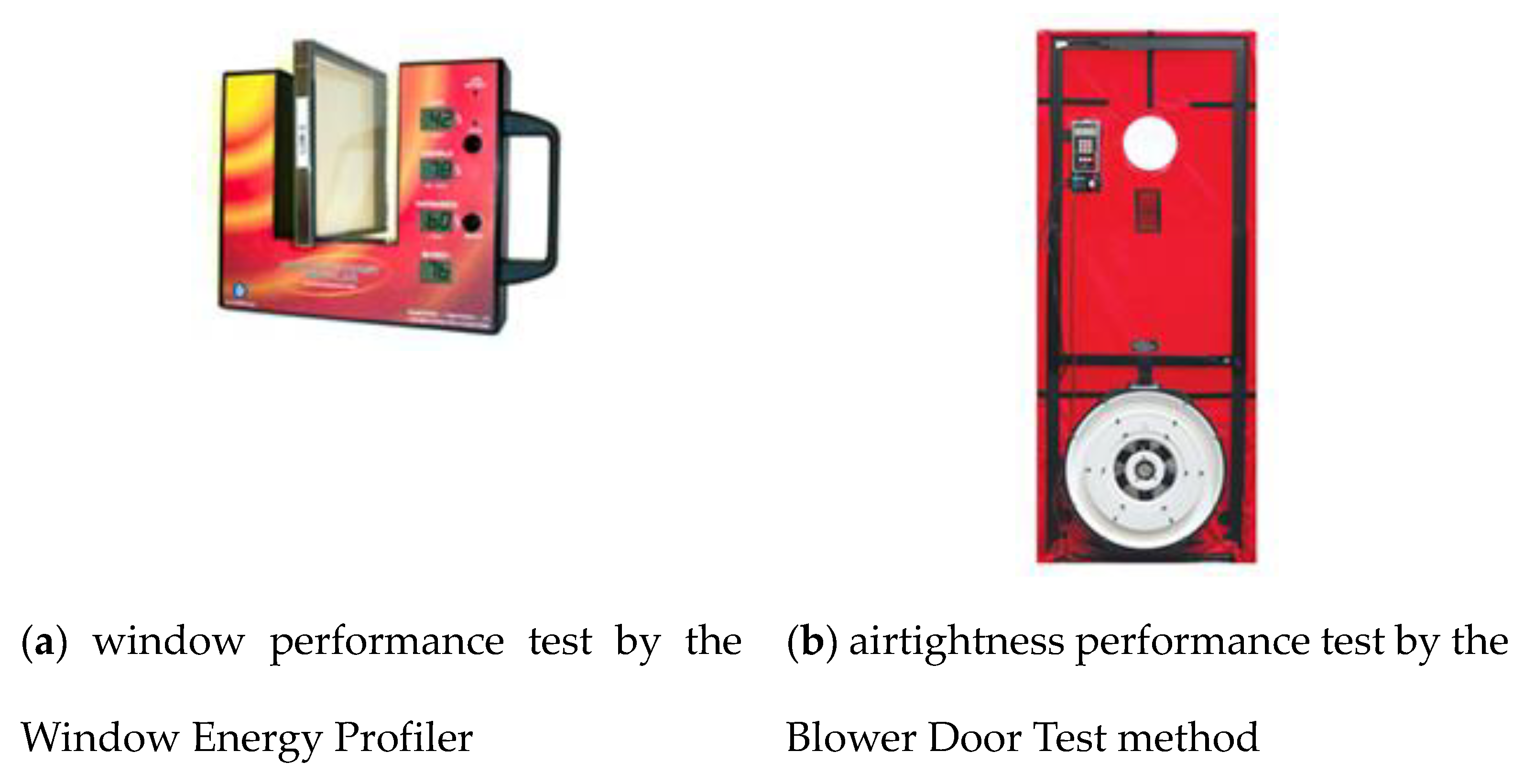

| Measurement Item | Measuring Device | Measurement Results |

|---|---|---|

| Wall insulation Performance | Heat flux method-ISO 9869 [28] | U-value [W/m2hoC] |

| Window performance | Window Energy Profiler-EDTM-WP 4200 | SHGC, UV, Visible Light, and Infrared Transmission |

| Airtightness performance (infiltration) | Minneapolis blower door system | Airtightness [ACH at 50 Pa] |

| Item | Remarks | |

|---|---|---|

| Person/m2 | 0.109 | |

| Metabolic rate | 0.9 | |

| Heating | Set-point temp. | 22 ℃ |

| Floor heating system | natural gas boiler (COP : 0.823) | |

| Ventilation system | Without | |

| Lightning density | 0.73 W/m2 | |

| Analyzed cases |

| |

| Item | Schedule |

|---|---|

| Occupancy | ~24 : 1.00 |

| Lighting | ~08 : 0.50, 08~18 : 1.00, 18~24 : 0.50 |

| Floor heating | ~24 : 1.00 |

| Component | Before Retrofit | After Retrofit | ||

|---|---|---|---|---|

| Walk-Through Audit (Case 1-1) | Detailed Measurement (Case 1-2) | Detailed Measurement (Case 2) | ||

| Wall | U-value [W/m2·K] | 0.58 | 2.07 | 1.07 |

| Window | U-value [W/m2·K] | 3.84 | 5.3 | 3.1 |

| SHGC [-] | 0.7 | 0.35 | 0.91 | |

| Airtightness [ach] | 0.7 | 0.8 | 0.3 | |

| kg-CO2/m2·year | Reduction | |

|---|---|---|

| Case 1-1 | 337.8 | - |

| Case 1-2 | 563.1 | - |

| Case 2 | 198.1 | 41% of the Case 1-1 and 65% of the Case 1-2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Myoung, J.; Lim, H.; Song, D. Efficiency Gap Caused by the Input Data in Evaluating Energy Efficiency of Low-Income Households’ Energy Retrofit Program. Sustainability 2020, 12, 2774. https://doi.org/10.3390/su12072774

Kim J, Myoung J, Lim H, Song D. Efficiency Gap Caused by the Input Data in Evaluating Energy Efficiency of Low-Income Households’ Energy Retrofit Program. Sustainability. 2020; 12(7):2774. https://doi.org/10.3390/su12072774

Chicago/Turabian StyleKim, Joowook, Jemin Myoung, Hyunwoo Lim, and Doosam Song. 2020. "Efficiency Gap Caused by the Input Data in Evaluating Energy Efficiency of Low-Income Households’ Energy Retrofit Program" Sustainability 12, no. 7: 2774. https://doi.org/10.3390/su12072774

APA StyleKim, J., Myoung, J., Lim, H., & Song, D. (2020). Efficiency Gap Caused by the Input Data in Evaluating Energy Efficiency of Low-Income Households’ Energy Retrofit Program. Sustainability, 12(7), 2774. https://doi.org/10.3390/su12072774