Rammed Earth Construction: A Proposal for a Statistical Quality Control in the Execution Process

Abstract

:1. Introduction

2. Quality Control in Standards and Regulations

3. Materials and Statistical Framework

- A volume of 100 m3.

- A period of execution of four weeks.

- A built area of 100 m2.

- One single floor.

4. Proposed Methodology for Quality Assessment

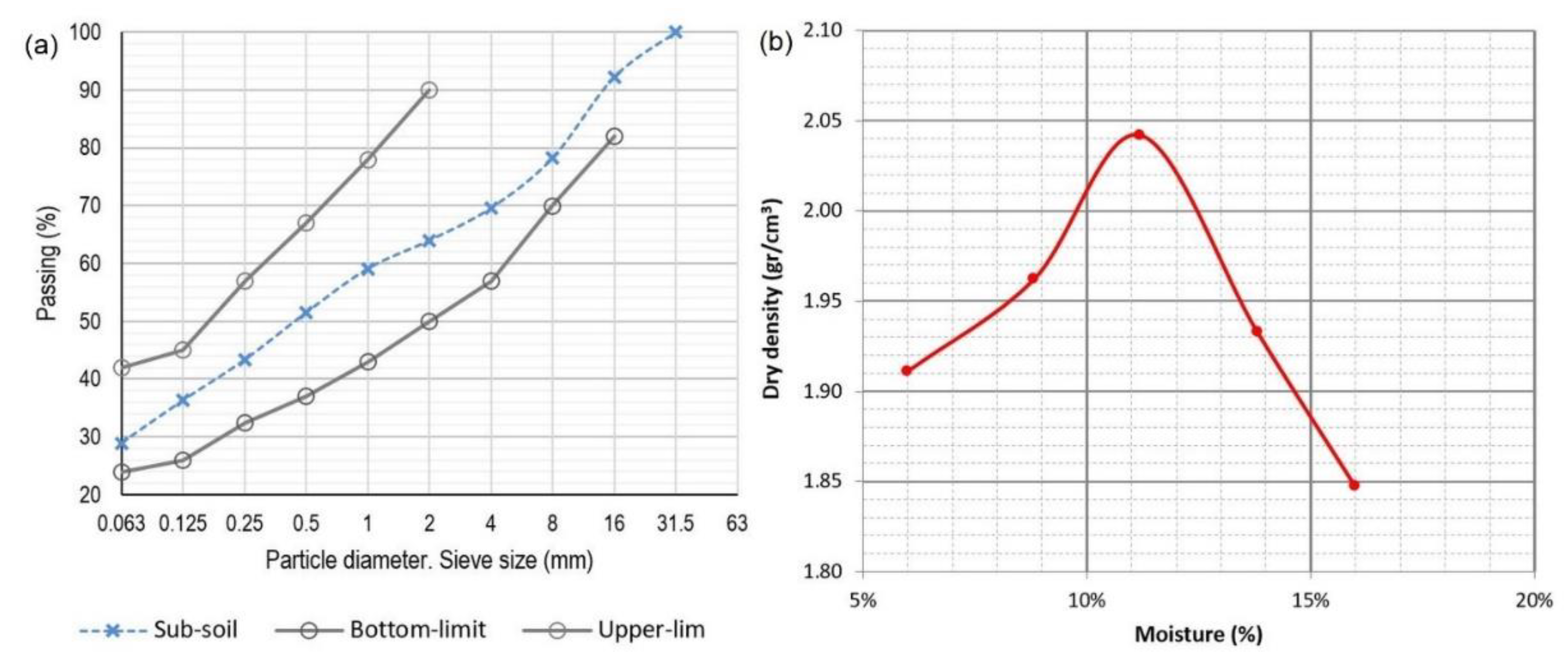

4.1. Laboratory Testing of Rammed Earth Material Before the Construction Work

4.2. Laboratory Testing of Rammed Earth Products Before the Construction Work

4.3. Testing of Rammed Earth Materials During the Construction Work

4.4. Testing of Rammed Earth Products During the Construction Work

5. Discussion and Conclusions

- The lot acceptance criterion is mainly based on the evaluation of the random variable CS. If the evaluated lot shows mechanical strength below the established threshold, then it is rejected and it is necessary to locate the deficient mix, either because of excessive mixing moisture, inefficient compacting energy or some hidden defect in the involved materials. In such cases a second round of tests based either on complementary tests or cored samples would need to be developed in order to recheck the parameters or to undertake further assessments.

- The current proposal is designed for a productivity of the rammed earth wall execution that is based on the capacity of the selected mixing system. If the performance of the equipment varied, then it would be necessary to adjust the number of batches so that the result (n) remains statistically representative of the total population (N). Equation (2) determines n as a function of N and other statistical parameters, namely σ, Zα/2, and e. The values used in Section 3 for these parameters may be valid for a typical sample production based mainly on the control of compaction energy and MMC.

- Taking the defined lot size as a reference, it is possible to adapt the sampling frequency according to the conditions of each site. Thus, different factors such as the construction company expertise, its workforce, the quality of both the materials involved and their stockpiling, the technical execution (either manual or mechanical) and the related auxiliary equipment, and formwork system, are indicators to establish different guarantees for a final quality of execution and, therefore, to make more or less restrictive decisions regarding quality control.

- The mixing method, in terms of technical system and volume capacity, may involve substantial differences in relation to the total volume of rammed earth wall that is required to be executed. As a consequence, for a considerable volume of rammed earth wall, if an adequate mixing system is not used to guarantee homogeneity, or if the volume of each mix is very small (VLMS < 250 liters) compared with the total volume to be executed, then the control should be more restrictive and, hence, an increase in the sampling frequency could be considered.

- Concerning the compaction method, as has already been suggested in the literature, samples have to be as similar as possible to the executed wall. To this end, the materials involved in the control should be directly obtained from the same batch on the site and, whenever it is possible, samples should be made by the same workers. Furthermore, as the energy used in the compaction must be constant, the one involved in the Proctor test is taken as a reference. In order to reach this benchmark, an equation has been proposed to determine the number of strokes (s) according to the weight of the rammer and its fall height. The specific energy of the normal Proctor test (eOMC) is equivalent to a manual or mechanical compaction using an energy per stroke of about 1 to 3.5 joules per stroke. For mechanical compactions, the equations suggested by Ciancio, Jaquin, and Walker [20] can be used to establish the compaction time according to the energy per stroke of the involved equipment.

- It is recommended to use cubic samples rather than cylindrical, since the former facilitate the use of non-destructive tests, such as the rebound hammer and the ultrasound pulse velocity. The size of samples is important, because every dimension that is smaller than three times the maximum aggregate size may give rise to unrepresentative samples. Moreover, an excessively small sample size in relation to the compaction energy may result in excessive confinement. To avoid the latter during the compaction process, the dimension of the rammer head should not be larger than the half of the edge of the cubic sample. It has been proven that the use of cubic samples with a cross section of 15 cm x 15 cm and square-head rammers of 7.5 cm give rise to suitable samples. The size of such rammers is similar to those pneumatic versions that are usually involved on site.

- A mixing moisture control is necessary to assess uniform mix and also to get the expected densities to be achieved for the established compaction energy. As the volume of kneading is usually reduced in comparison with the volume to be executed, a large number of mixes will be generated, of which a number per established batch will be statistically controlled. It is recommended to take at least three soil samples before and after the mixing in order to verify not only whether the optimum MMC has been reached, but also to establish the origin of the deviations and to evaluate possible solutions.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Glossary

| σ | Standard deviation |

| CS | Unconfined compression strength |

| D | Dry density |

| e | Acceptable limit of the sampling error |

| es | Specific compaction energy |

| eOMC | Specific compaction energy of the standard Proctor test |

| Er | Energy generated by the fall of a rammer |

| g | Gravity acceleration value |

| GSD | Grain size distribution |

| h | Free-fall height of the rammer |

| MC | Moisture content |

| MMC | Molding moisture content |

| n | Number of controlled batches |

| N | Total number of batches |

| OMC | Optimum moisture content |

| P | Porosity |

| R | Rebound index |

| s | Number of strokes required to achieve the reference compaction energy |

| UPV | Ultrasound pulse velocity |

| VCMS | Usable volume of the mixers in terms of the compacted volume of soil |

| VLMS | Usable volume of the mixers in terms of the loose volume of soil |

| VL | Volume of a layer |

| W | Weight of the rammer |

| Zα/2 | Critical value depending on the confidence level |

| CO | Compulsory tests |

| OP | Optional test |

| RE | Recommended test |

References

- Fernandes, J.; Peixoto, M.; Mateus, R.; Gervásio, H. Life cycle analysis of environmental impacts of earthen materials in the Portuguese context: Rammed earth and compressed earth blocks. J. Clean. Prod. 2019, 241, 118286. [Google Scholar] [CrossRef] [Green Version]

- Serrano, S.; Barreneche, C.; Rincón, L.; Boer, D.; Cabeza, L.F. Optimization of three new compositions of stabilized rammed earth incorporating PCM: Thermal properties characterization and LCA. Constr. Build. Mater. 2013, 47, 872–878. [Google Scholar] [CrossRef]

- Arrigoni, A.; Beckett, C.; Ciancio, D.; Dotelli, G. Life cycle analysis of environmental impact vs. durability of stabilised rammed earth. Constr. Build. Mater. 2017, 142, 128–136. [Google Scholar] [CrossRef]

- NZS 4298. Materials and Workmanship for Earth Buildings; Standards New Zealand: Wellington, New Zealand, 1998. [Google Scholar]

- NMAC. New Mexico Administrative Codes New Mexico 14.7.4. 2003. Earthen Building Materials Code; Construction Industries Division of the Regulation and Licensing Department: Santa Fé, NM, USA, 2003; pp. 1–27. [Google Scholar]

- SADCSTAN. Rammed Earth Structures; Code of Practice THC 03. SADCSTAN TC 1/SC 5/CD SAZS 724; African Organisation for Standardisation: Harare, Zimbabwe, 2014. [Google Scholar]

- IS 2110. Code of Practice for in-situ Construction of Walls, in Buildings with Soil-Cement; Indian Standard; BIS. Bureau of Indian Standards: New Delhi, India, 1980. [Google Scholar]

- Volhard, F.; Röhlen, U. Lehmbau Regeln (Dachverband Lehm e.V), 3rd ed.; Springer Vieweg Verlag: Wiesbaden, Germany, 2009; ISBN 978-3-8348-0189-0. [Google Scholar]

- Walker, P.; Keable, R.; Martin, J.; Maniatidis, V. Rammed Earth. Design and Construction Guidelines; BRE bookshop: Watford, UK, 2005; ISBN 1860817343. [Google Scholar]

- Minke, G. Manual de Construcción en Tierra: La Tierra Como Material de Construcción y su Aplicación en la Arquitectura Actual; Fin de Siglo: Montevideo, Uruguay, 2005; ISBN 9974493471. [Google Scholar]

- Doat, P.; Hays, A.; Houben, H.; Matuk, S.; Vitoux, F. Building with Earth; Editions Alternatives: Paris, France, 1991. [Google Scholar]

- Font, F.; Hidalgo, P. Arquitecturas de Tapia; Colegio Oficial de Aparejadores y Arquitectos Técnicos de Castellón: Castellón, Spain, 2009; ISBN 978-84-613-3142-0. [Google Scholar]

- Bauluz, G.; Bárcena, P. Bases Para el Diseño y Construcción con Tapial; Ministerio de Obras Públicas y Transportes Centro de Publicaciones: Madrid, Spain, 1992; ISBN 84-7433-839-5. [Google Scholar]

- IETCC. Obras de fábrica. P.I.E.T. Prescripciones del Instituto Eduardo Torroja de Ciencias de la Construcción; Instituto Eduardo Torroja de la Construcción y del Cemento: Madrid, Spain, 1971; Volume 70. [Google Scholar]

- Maniatidis, V.; Walker, P. A Review of Rammed Earth Construction. DTi Partners in Innovation Project. “Developing Rammed Earth for UK Housing”; Department of Architecture & Civil Engineering, University of Bath: Bath, UK, 2003. [Google Scholar]

- UNE-103-500-94. Geotechnic Compaction Test; Standard Proctor; UNE-AENOR: Madrid, Spain, 1994. [Google Scholar]

- Smith, J.; Augarde, C.E. Optimum water content tests for earthen construction materials. Constr. Mater. 2014, 167, 114–123. [Google Scholar] [CrossRef] [Green Version]

- Ciancio, D.; Jaquin, P.; Walker, P. Advances on the assessment of soil suitability for rammed earth. Constr. Build. Mater. 2013, 42, 40–47. [Google Scholar] [CrossRef]

- Hall, M.; Djerbib, Y. Rammed earth sample production: Context, recommendations and consistency. Constr. Build. Mater. 2004, 18, 281–286. [Google Scholar] [CrossRef]

- Walker, P.; Stace, T. Properties of some cement stabilised compressed earth blocks and mortars. Mater. Struct. 1997, 30, 545–551. [Google Scholar] [CrossRef]

- Rüsch, H.; Meseguer, A.G. Recommended principles for the control of quality and the judgement of acceptability of concrete. Matériaux Et Constr. 1975, 8, 387–403. [Google Scholar]

- Rüsch, H.; Meseguer, A.G. Principios recomendados para el control de calidad del hormigón y criterios para su aceptación o rechazo. Inf. De La Constr. 1981, 32, 77–91. [Google Scholar] [CrossRef] [Green Version]

- UNE 103-104-93. Test for Plastic Limit of a Soil; UNE-AENOR: Madrid, España, 1993. [Google Scholar]

- UNE 103-103-94. Determination of the Liquid Limit of a Soil by the Casagrande Apparatus Method; UNE-AENOR: Madrid, España, 1994. [Google Scholar]

- EHE-08. Instrucción de hormigón estructural (EHE-08); Ministerio de Fomento, Secretaría General Técnica, Centro de Publicaciones: Madrid, Spain, 2009; ISBN 9788496698291. [Google Scholar]

- Font, F.; Hidalgo, P. El Tapial: Una Técnica Constructiva Milenaria; Edición de los autores: Castellón, Spain, 1992. [Google Scholar]

- López Osorio, J.M. The Nasrid ramparts of the Albaicín (Granada, Spain): An analysis of materials and building techniques. In Rammed Earth Conservation—Mileto, Vegas & Cristini (eds); Rammed Earth Conservation—Mileto, Vegas & Cristini (eds); Taylor & Francis Group: London, UK, 2012; pp. 27–32. ISBN 978-0-415-62125-0. [Google Scholar]

- Walker, P. The Australian Earth Building Handbook; Standards Australia International: Sydney, Australia, 2001; ISBN 9780733740008. [Google Scholar]

- Junta de Andalucía. Plan de Vivienda y Rehabilitación de Andalucía 2016–2020; Consegería de Fomento y Vivienda. Junta de Andalucía: Sevilla, Spain, 2016. [Google Scholar]

- Ryan, T.P. Sample size Determination and Power; Wiley series in probability and statistics; John Wiley & Sons: Hoboken, NJ, USA, 2013; ISBN 1-118-43924-4. [Google Scholar]

- Martins Neves, C.M.; Faria, O.; Rotondaro, R.; Cevallos, P.; Hoffman, M. Selección de Suelos y Métodos de Control en la Construcción con Tierra. Available online: http://www.redproterra.org. (accessed on 4 January 2020).

- UNE-EN 933-1. Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method; UNE-AENOR: Madrid, Spain, 2012. [Google Scholar]

- Houben, H.; Guillaud, H. Earth Construction: A Comprehensive Guide; Intermediate Technology Development Group: London, UK, 2008; ISBN 978 1 85339 193 4. [Google Scholar]

- Schroeder, H. Sustainable Building with Earth; Springer: Cham, Switzerland, 2016; ISBN 9783319194905. [Google Scholar]

- UNE 103102. Particle size analysis of a fine soil by sedimentation. In Densimeter Method; UNE-AENOR: Madrid, Spain, 1995. [Google Scholar]

- Schulte, E.E.; Hopkins, B.G. Estimation of soil organic matter by weight loss-on-ignition. Soil Org. Matter: Anal. Interpret. 1996, 46, 21–31. [Google Scholar]

- UNE 41410. Compressed earth blocks for walls and partitions. In Definitions, Specifications and Test Methods; UNE-AENOR: Madrid, Spain, 2008. [Google Scholar]

- NZS 4297. Engineering Design of Earth Buildings. Available online: https://codehub.building.govt.nz/home/resources/42971998nzs/ (accessed on 4 January 2020).

- Martín-del-Rio, J.J.; Flores-Alés, V.; Alejandre, F.J. New Method for Historic Rammed-earth Wall Characterization: The Almohade Ramparts of Malaga and Seville. Stud. Conserv. 2018, 64, 363–372. [Google Scholar] [CrossRef]

- UNE 103-501-94. Geotechnic. In Compactation Test; Modified Proctor; UNE-AENOR: Madrid, Spain, 1994. [Google Scholar]

- Ciancio, D.; Beckett, C.; Carraro, J.A.H. Optimum lime content identification for lime-stabilised rammed earth. Constr. Build. Mater. 2014, 53, 59–65. [Google Scholar] [CrossRef] [Green Version]

- BS 1377-4. Methods of test for soils for civil engineering purposes. In Compaction-Related Tests; British Standards Institution: London, UK, 1990. [Google Scholar]

- ASTM D698. Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort; ASTM standards: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM D1557. Laboratory Compaction Characteristics of Soil Using Modified Effort; ASTM standards: West Conshohocken, PA, USA, 1978. [Google Scholar]

- Canivell, J.; Martin-del-Rio, J.J.; Alejandre, F.J.; García-Heras, J.; Jimenez-Aguilar, A. Considerations on the physical and mechanical properties of lime-stabilized rammed earth walls and their evaluation by ultrasonic pulse velocity testing. Constr. Build. Mater. 2018, 191, 826–836. [Google Scholar] [CrossRef]

- Ciancio, D.; Gibbings, J. Experimental investigation on the compressive strength of cored and molded cement-stabilized rammed earth samples. Constr. Build. Mater. 2012, 28, 294–304. [Google Scholar] [CrossRef]

- Graciani, A.; Martín-del-Río, J.J.; Mora, G.M.; Alejandre, F.J.; Canivell, J. Preliminary studies for intervention, interpretation and value enhancement of Tower of Don Fadrique (Albaida, Seville, Spain). In Rammed Earth Conservation; Rammed Earth Conservation; Taylor & Francis Group: London, UK, 2012; pp. 345–350. ISBN 978-0-415-62125-0. [Google Scholar]

- UNE-EN-1936. Natural Stone Test Methods—Determination of Real Density and Apparent Density, and of Total and Open Porosity; UNE-AENOR: Madrid, Spain, 2007. [Google Scholar]

- UNE-EN-13791. Assessment of In-Situ Compressive Strength in Structures and Precast Concrete Components; UNE-AENOR: Madrid, Spain, 2009. [Google Scholar]

- UNE-EN-12504-4. Testing Concrete; Part 4: Determination of Ultrasonic Pulse Velocity; UNE-AENOR: Madrid, Spain, 2004. [Google Scholar]

- UNE-EN 12504-2. Testing Concrete in Structures; Part 2: Non-destructive Testing. Determination of Rebound Number; UNE-AENOR: Madrid, Spain, 2013. [Google Scholar]

- Bui, Q.B. Assessing the Rebound Hammer Test for Rammed Earth Material. Sustainability 2017, 9, 1904. [Google Scholar] [CrossRef] [Green Version]

- Martín-del-Rio, J.J.; Canivell, J.; Falcón, R.M. The use of non-destructive testing to evaluate the compressive strength of a lime-stabilised rammed-earth wall: Rebound index and ultrasonic pulse velocity. Constr. Build. Mater. 2020, 242, 118060. [Google Scholar] [CrossRef]

- Bui, Q.B.; Morel, J.C. Assessing the anisotropy of rammed earth. Constr. Build. Mater. 2009, 23, 3005–3011. [Google Scholar] [CrossRef]

- UNE-EN 12390-3. Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens; UNE-AENOR: Madrid, Spain, 2009. [Google Scholar]

- UNE-EN-1015-11. Methods of Test for Mortar for Masonry; Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; UNE-AENOR: Madrid, Spain, 2000. [Google Scholar]

- Venkatarama Reddy, B.V.; Suresh, V.; Nanjunda Rao, K.S. Characteristic Compressive Strength of Cement-Stabilized Rammed Earth. J. Mater. Civ. Eng. 2017, 29, 4016203. [Google Scholar] [CrossRef]

- Lombillo, I.; Villegas, L.; Fodde, E.; Thomas, C. In situ mechanical investigation of rammed earth: Calibration of minor destructive testing. Constr. Build. Mater. 2014, 51, 451–460. [Google Scholar] [CrossRef]

- Tripura, D.D.; Singh, K.D. Behavior of cement-stabilized rammed earth circular column under axial loading. Mater. Struct. 2014, 49, 371–382. [Google Scholar] [CrossRef]

- Bui, Q.B.; Morel, J.-C.; Hans, S.; Meunier, N. Compression behaviour of non-industrial materials in civil engineering by three scale experiments: The case of rammed earth. Mater. Struct. 2008, 42, 1101–1116. [Google Scholar] [CrossRef]

- UNE-EN-12504-1. Testing concrete in structures; Part 1: Cored Specimens. Taking, Examining and Testing in Compression; UNE-AENOR: Madrid, Spain, 2009; p. 12. [Google Scholar]

- UNE-EN-ISO-17892-1. Geotechnical Investigation and Testing; Laboratory Testing of Soil. Part 1: Determination of Water Content; UNE-AENOR: Madrid, Spain, 2015. [Google Scholar]

- Cuchíi Burgos, A. La técnica tradicional del tapial. In Proceedings of the Actas del I Congreso Nacional de Historia de la Construcción, Madrid, Spain, 19–21 September 1996; edición a cargo de, Antonio de las Casas Gómez, Santiago Huerta Fernández, Enrique Rabasa Díaz; prólogo de, Ricardo Aroca Hernández-Ros, Antonio de las C. Instituto Juan de Herrera: Madrid, Spain, 1996; pp. 157–163. [Google Scholar]

- Bui, Q.B.; Morel, J.C.; Hans, S.; Walker, P. Effect of moisture content on the mechanical characteristics of rammed earth. Constr. Build. Mater. 2014, 54, 163–169. [Google Scholar] [CrossRef]

- Champiré, F.; Fabbri, A.; Morel, J.C.; Wong, H.; McGregor, F. Impact of relative humidity on the mechanical behavior of compacted earth as a building material. Constr. Build. Mater. 2016, 110, 70–78. [Google Scholar] [CrossRef]

- UNE 103900. In situ Determination of Density and Moisture Content of Soil and Granular Materials by Nuclear Methods: Low Depths; UNE-AENOR: Madrid, Spain, 2013. [Google Scholar]

| Samples | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CS (MPa) | 2.75 | 2.61 | 1.74 | 1.7 | 2.87 | 3.07 | 2.18 | 1.49 | 3.50 | 2.53 | 2.39 | 1.59 | 3.31 | 3.72 | 3.76 | 2.97 |

| Samples | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 |

| CS (MPa) | 2.78 | 2.59 | 2.46 | 1.82 | 1.09 | 2.15 | 1.15 | 1.74 | 1.91 | 1.92 | 1.86 | 1.91 | 1.51 | 2.22 | 1.45 | 2.45 |

| Samples | 33 | 34 | 35 | 36 | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | 46 | 47 | 48 |

| CS (MPa) | 2.41 | 1.95 | 3.15 | 1.39 | 0.41 | 0.71 | 2.07 | 2.79 | 1.32 | 1.89 | 3.00 | 2.98 | 1.34 | 2.86 | 2.38 | 2.25 |

| Rammed Earth Volume | 100 m3 | |

|---|---|---|

| Execution time | 4 weeks (20 days, 8h/day) | |

| Built area | 100 m2 | |

| Number of floors | 1 | |

| Number of batches | VLMS ≤ 500 liters | 500 batches |

| VLMS > 500 liters | 200 batches | |

| Soil type | One lot per each different type of soil | |

| VLMS: Usable volume of the mixers in terms of loose volume of soil (liters) | ||

| Soil Test | Information | Values | References | Type | Rates | |

| Sensory testing | ||||||

| Visual, touch, and smell | Type of aggregate and clay | Overall type of soil: texture, presence of organic matter, clay, fines, and aggregates | [31] | OP | 1 sample of 1 kg/soil 1 | 10 kg of soil |

| Qualitative tests | ||||||

| Exudation test | Fine content | Presence and activity of clays: certain presence of fines and low activity | [31] | OP | 1 sample of 0.5 kg/soil 1 | |

| Ribbon test | Cohesion | The ribbon should break at certain length | [31] | OP | 1 sample of 0.5 kg/soil 1 | |

| Dry strength test | Cohesion and hardness | The force to break the sample should not be high | [31] | OP | 1 sample of 0.5 kg/soil 1 | |

| Sedimentation | Overall distribution of aggregates | Not excessive presence of fines | [31] | OP | 1 sample of 0.5 kg/soil 1 | |

| Laboratory tests | ||||||

| Grain size distribution (GSD) | Curve of particle size distribution (% passing) | Depending on the source: Aggregate (45–80) Silt (10–30) Clay (5–20) | [9,32,34] | CO | 1 sample of 4 kg/soil 1 | |

| Calcination | Organic matter content (%) | Without presence | [36] | RE | 1 sample of 10 g/soil 1 | |

| Atterberg limits | Liquid, plastic limit. Plasticity index | LL < 35–45IP < 10–30 | [20,23,24] | CO | 1 sample of 0.5 kg/soil 1 | |

| Linear shrinkage | ∆l/l (%) Linear degree of shrinkage | < 0.5–2% | [8,9] | RE | 1 sample of 0.5 kg/soil 1 | |

| XRD | Mineralogical composition | Qualitative and semi-quantitative type of minerals | [39] | RE | 1 sample of 0.5 kg/soil 1 | |

| Dosage Test | Information | Values | Ref. | Rates | ||

| Standard tests | ||||||

| Standard Proctor | D (g/cm3), OMC (%) | Depending on the soil. Usually: D = (1.8–2.5) (g/cm3) OMC = (10–20)% | [16] | CO | 1 sample of 15 kg/soil 1 | |

| Modified Proctor | D (g/cm3), OMC (%) | [40] | CO | 1 sample of 35 kg/soil 1 |

| Sample Test | Information | Values | References | Type | Rates |

|---|---|---|---|---|---|

| Unconfined compression strength | Mechanical resistance. CS (N/mm2) | Variable depending on the reference. CS > 1–1.5 | [49] | CO | 5 Type-A samples/soil 1 |

| Porosity and dry density | Quality estimation. P (%) D (gr/cm3) | Soil variable. P = (30–40)% D = (1.5–2.8) (gr/cm3) | [48] | CO | 5 Type-B samples/soil 1 |

| Ultrasonic pulse velocity | UPV (km/s) Quality estimation (compactness). | Highly variable. UPV = (1–3) km/s (10% lime-stabilized) | [49,50] | OP | 5 Type-A samples/soil 1, 2 |

| Rebound hammer | Surface hardness. Quality estimation. Rebound index (R). | Highly variable. R = 30–80 | [49,51] | OP | 5 Type-A samples/soil 1, 2 |

| (Schmidt OS-120PT) (10% lime-stabilized) | |||||

| Linear shrinkage | ∆l/l (%) Linear degree of shrinkage | < 0.5–2% | [8,9] | RE | 3–5 samples type A or B/soil 1 |

| Erosion resistance | Erosion depth and index (mm/min) | < 2 | [4] | RE | 2 samples type A or B/soil 1 |

| Soil Analysis | Information | Values | References | Type | Frequency |

| Tests | |||||

| Grain size distribution (GSD) | Aggregate distribution curve (%) | Soil variable. Aggregates (45–80) silt (10–30), clay (5–20) | [9,32] | CO | 1 sample 10 kg/lot 1 |

| Moisture content | Soil moisture before mixing | Compare with OMC | [62] | RE | 3–5 samples 200 g/lot 1, 2 |

| Dosage Analysis | Information | Values | References | Type | Frequency |

| Tests and field trials | |||||

| Moisture determination | Moisture content after mixing | Compare with OMC (Table 3) | [62] | CO | 200 g 3–5 sample/batch 4 |

| Drop test | OMC estimation | Qualitative values Partial breakage into pieces (3) | [4] (Apend. G) | RE | 200 g sample/batch m3 3 |

| Proctor normal | D (g/cm3) OMC (%) | Soil dependence D = (1.8–2.5) (g/cm3) OMC = (10–20)% | [16] | OP | 1 sample 15 kg/soil 1 |

| Modified Proctor | D (g/cm3) OMC (%) | [40] | OP | 1 sample 35 kg/soil 1 |

| Sample Test | Information | Values | References | Frequency | |

| Tests (Samples) | |||||

| Unconfined compression strength | Mechanical strength. CS (N/mm2). | Variable depending on the reference. CS > 1–15 | [61] | CO | 2 A samples per controlled batch |

| Porosity and dry density | Quality. P (%). D (gr/cm3). | Soil variable. P = (30–40)% D = (1.5–2.8) (gr/cm3) | [48] | CO | 2 B samples per controlled batch |

| Ultrasonic pulse velocity | UPV (km/s) Quality estimation (compactness). | Highly variable. UPV = (1–3) Km/s (10% lime) | [49,50] | RE | 2 A samples per controlled batch 2 |

| Rebound hammer | Surface hardness. Quality estimation. Rebound index (R). | Highly variable. R = 30–80 (Schmidt OS-120PT) (with 10% lime) | [49,53,61] | RE | 2 A samples per controlled batch 2 |

| Wall Test | Information | Values | References | Frequency | |

| Ultrasonic pulse velocity | UPV (km/s) Quality estimation (compactness). | Highly variable. UPV = (1–3)Km/s (10% lime) | [49,50] | OP | 1 test 1 per week |

| Rebound hammer | Surface hardness. Quality estimation. Rebound index (R). | Highly variable. R = 30–80 (Schmidt OS-120PT) (10% lime) | [49,53,61] | OP | 1 test 1 per week |

| Nuclear gauge | Quality estimation (compactness). Density and moisture content. | Compare with normal or modified Proctor. > 90–95% of Proctor density benchmark. | [66] | RE | 1 test 1 per week |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Canivell, J.; Martín-del-Río, J.J.; Falcón, R.M.; Rubio-Bellido, C. Rammed Earth Construction: A Proposal for a Statistical Quality Control in the Execution Process. Sustainability 2020, 12, 2830. https://doi.org/10.3390/su12072830

Canivell J, Martín-del-Río JJ, Falcón RM, Rubio-Bellido C. Rammed Earth Construction: A Proposal for a Statistical Quality Control in the Execution Process. Sustainability. 2020; 12(7):2830. https://doi.org/10.3390/su12072830

Chicago/Turabian StyleCanivell, Jacinto, Juan Jesús Martín-del-Río, Raúl M. Falcón, and Carlos Rubio-Bellido. 2020. "Rammed Earth Construction: A Proposal for a Statistical Quality Control in the Execution Process" Sustainability 12, no. 7: 2830. https://doi.org/10.3390/su12072830

APA StyleCanivell, J., Martín-del-Río, J. J., Falcón, R. M., & Rubio-Bellido, C. (2020). Rammed Earth Construction: A Proposal for a Statistical Quality Control in the Execution Process. Sustainability, 12(7), 2830. https://doi.org/10.3390/su12072830