Abstract

Although the impact of proactive environmental strategies on corporate performance has been extensively discussed in academia, the path of the impact of proactive environmental strategies on environmental performance remains unclear. In this study, we introduce a strategy–structure–performance (SSP) framework to explore the mechanism through which proactive environmental strategies improve environmental performance by utilizing green supply chain integration. Based on the questionnaire survey data of 252 Chinese manufacturing firms, a structural equation model was established to verify our hypothesis. The results show that firms that implement a proactive environmental strategy tend to promote the green integration of suppliers through internal green integration and thus improve their environmental performance. By distinguishing two kinds of activities of green supplier integration (greening the supplier and environmental collaboration with the supplier), we found that environmental collaboration with the supplier can directly promote the environmental performance of manufacturing enterprises, but supplier greening indirectly enhances the environmental performance of enterprises through supplier environmental collaboration. The boundary conditions of the influence of internal green integration on green supplier integration are discussed, and we found that the relationship cability plays a moderating role in the influence of internal green integration on supplier green integration.

1. Introduction

As the government and customers pay increasingly more attention to the problems of resource exhaustion and environmental deterioration, firms need to incorporate environmental management into their long-term development strategies, identify environmental objectives, improve environmental performance, and reduce the negative impact of daily operations on the environment [1]. Firms adopt proactive environmental strategies to reflect their voluntary efforts in managing the environmental impact of their economic activities; these strategies contribute to establishing a good reputation and image, improving performance (financial, market, environment), and enhancing competitive advantages [2,3,4,5]. Thus, such strategies have gradually become an important topic in the field of environmental management [6,7].

However, several studies have reported that no necessary relationship exists between proactive environmental strategies and performance [8,9]. The current inconsistency in the conclusions of the relationship between proactive environmental strategies and performance may be due to the unclear path by which proactive environmental strategies improve environmental performance [10]. Although scholars have explored how proactive environmental strategies produce good environmental performance in terms of “environmental investment” [10], “product design”, “green supply chain management” [8], “green operation” [1], and their internal mechanisms, further analyses are still required. However, related research is scarce, especially in the Chinese context. The impact mechanism of proactive environmental strategies on environmental performance is a multi-factor process, and it is worthy of further analysis.

Firms adopting proactive environmental strategies often have specific management practices and reward systems that can integrate environmental standards into internal management systems [11] and can improve employees’ awareness and commitment to the environment [1,12]. However, for firm operations, from a single operation to supply chain collaboration, any non-environmental behavior of suppliers produces a “chain liability” [13], which has a negative impact on the company. As globalization of the supply chain accelerates, the company’s environmental initiatives and projects require the participation and collaboration of suppliers [14,15,16]. For example, Huawei’s “Green Partner Certification Program” not only demands that suppliers ensure products and components do not contain hazardous chemicals, but also establishes environmental assessment standards and action guidelines for suppliers. Therefore, in addition to internal environmental integration, firms also need to enhance their environmental awareness and environmental protection capabilities through supplier-side green integration, align their environmental strategic goals and operations with their suppliers [17], and obtain key environmental resource assets and skills from supplier partners to improve environmental performance. Obviously, green supply chain integration (including internal green integration and green supplier integration) is a potentially important method for improving environmental performance through proactive environmental strategies.

In addition, most previous studies have neglected the boundary conditions through which internal green integration effectively promotes the green integration of suppliers. Although internal green integration is important, if the internal environmental practices of the company cannot be extended to upstream suppliers, the firm’s environmental performance may not improve significantly [18]. Firms need to use their own relationship capabilities to discover, establish, and maintain relationships with suppliers, making it easier for suppliers to understand and recognize the green practices implemented by the focal firm and to actively cooperate to promote the smooth implementation of green supplier integration. Firms with good relationship capabilities can provide a guarantee for internal green integration to be transformed into green supplier integration [19]. Thus, this study proposes that the firm’s relationship capability strengthens the positive relationship between internal green integration and green supplier integration.

In this article, we aim to address the following two research questions. First, how do proactive environmental strategies affect environmental performance through green supply chain integration? Second, to what extent do relationship capabilities moderate the relationship between internal green integration and green supplier integration? The answers to these questions will help deepen our understanding of the proactive environmental strategy mechanism and enrich the relationship mechanism between internal green integration and green supplier integration.

2. Theoretical Framework and Research Hypothesis

2.1. Strategy–Structure–Performance

Strategy–structure–performance (SSP) has been widely used in the field of strategic management. Strategic management scholars have recognized that strategy is the core goal of firms and the decisive factor that precedes structures and promotes the development of organizational structures and processes. A structure is a response to a strategy, and restructuring assists with strategic transformation. A structure also provides the needed systems and processes [20,21]. A fit between corporate strategies and structures leads to better performance.

As the competition has shifted from the firm level to the supply chain level, scholars have gradually applied the SSP framework to the supply chain field. They have reported that firms need to find and configure the supply chain structure to meet the needs of organizational strategies [22,23]. A supply chain structure that supports a firm’s strategy depends on supply chain integration. Integration refers to the management of restructuring activities to seamlessly smooth related business processes and to reduce redundant processes to perfectly allocate resources [22,24,25]. A firm must attain unique resources to obtain a competitive advantage. Supply chain integration includes restructuring mechanisms for connecting and simplifying processes, which can provide firms with structures that serve strategic needs and effectively use allocated resources [26,27].

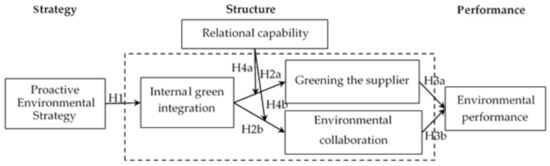

Inspired by previous research, we expanded the SSP framework to the green supply chain context. We define strategy and structure matching as the degree of similarity between proactive environmental strategies and supply chain structures (i.e., green supply chain integration) to explain how the firm’s proactive environmental strategies enhance their environmental performance through a green supply chain integration mechanism. Firms actively implement environmental strategies as a strategic focus and attempt to exceed basic compliance with laws and regulations on environmental issues [28]. Structure can be regarded as a tool for firm resource allocation and use [23]. As a structure, green supply chain integration can help firms allocate, coordinate, and implement resources for environmental strategies. A firm can improve its environmental performance when it matches its environmental strategic focus to its green supply chain integration mechanism [7]. Therefore, our study is based on the strategy–structure–performance framework, revealing the deeper functional relationship between proactive environmental strategies and environmental performance. The framework of the proposed model is illustrated in Figure 1.

Figure 1.

Conceptual framework.

Green supply chain integration refers to the strategic cooperation between firms and supply chain partners, as well as the collaborative management of the intra-organizational and inter-organizational processes used to improve environmental performance [29,30]. Existing research on green supply chain integration can be broadly divided into three categories: Green supplier integration, internal green integration, and customer green integration [29,31]. We focused on how focal firms with proactive environmental strategies achieve better environmental performance by changing their own and their suppliers’ structures. We mainly examined internal green integration and upstream green supplier integration.

Internal green integration is a type of strategic integration in which firms integrate environment-related objectives into their own strategies and management systems [30] and effectively allocate and use internal environmental resources. The goal is to enable firms to perform, track, and monitor environmental management across various functions [29]. Internal green integration consists of three parts: (1) Integrating environmental goals and responsibilities into business strategies and top management rewards, as well as attempting to balance commercial and environmental goals to achieve sustainable growth; (2) building a single integrated management system that incorporates environmental goals, performance, and responsibilities into its code of conduct, functional commercial decisions, and human resource decisions for different functions; and (3) cross-functional communication, coordination, and collaboration to reduce environmental impacts and to collectively achieve environmental goals.

Supplier green integration concerns implementing green management with suppliers so that they can contribute to a firm’s environmental goals [32]. By reviewing and analyzing the relevant literature on green supply chain integration, we found that the types of research can be classified as follows. The first type of research environmentally assesses suppliers. The firm selects suppliers according to relevant environmental criteria, regularly evaluates the suppliers’ environmental performance according to the relevant environmental requirements, and controls the suppliers’ environmental performance [33]. The second is to provide environmental guidance, such as holding awareness seminars for suppliers, informing suppliers about the benefits of cleaner production methods and technologies, setting up environmental teams to visit a supplier’s plants and provide on-site guidance, and guiding suppliers in the establishment of their own environmental programs. The last involves green collaboration with suppliers; that is, the manufacturing company invites the suppliers to directly participate in their own environmental management activities. The two parties agree to long-term cooperation to understand each other’s responsibilities and capabilities in environmental management, jointly develop environmental goals and plans, improve their production processes, develop clean technologies and green products, reduce their use of materials and energy, reduce waste, and prevent pollution [34,35]. Chiou et al. (2011) further summarized supplier environmental assessment and supplier environmental guidance as greening the supplier. We followed this definition in previous studies, in which greening the supplier and green collaboration with suppliers were used as the two main dimensions of green supplier integration.

2.2. Proactive Environmental Strategy and Internal Green Integration

A proactive environmental strategy includes a set of environmental goals, visions, plans, and processes designed to exceed the minimum compliance with environmental regulations and to reduce negative environmental impacts [10]. From a natural resource viewpoint, a proactive environmental strategy can leverage its tangible and intangible resources to reduce environmental burdens, improve performance, and increase competitive advantage [7]. The SSP framework shows that the strategic needs of a firm are matched with its structure, and the resource integration activities of a firm are determined by its strategy [23]. Firms that are positive about environmental protection are more willing to consider environmental factors in their strategic planning, linking green development to their policies and goals [36] and taking various internal actions to reduce their adverse impacts on the environment. To become an industry leader, business managers incorporate environmental goals into their executive compensation awards and strengthen their environmental awareness. Environmental goals and performance responsibilities are simultaneously integrated into various functional models [29], which helps all employees to form a collective sense of the environment and compels them to seek ways to minimize the negative impacts on the environment in their daily operations [1]. For example, inter-departmental environmental information can be actively shared among different departments, and a cross-functional environmental management team can be jointly established to coordinate and solve environment-related problems in the procurement–production–transportation links. In addition, firms with a positive environmental management strategy establish a good environmental reputation by sending green signals, making is easier to attract relevant talent, to expand their environmental talent system, and to successfully ensure the implementation of internal green integration. Therefore, the following hypothesis is proposed:

Hypothesis 1 (H1):

A positive relationship exists between a firm’s proactive environmental strategies and its internal green integration.

2.3. Internal Green Integration and Supplier Green Integration

Firms that implement internal green integration in the supply chain context are more likely to require supply chain partners to adopt green practices [17]. Arimura et al. (2011) found that firms that have passed ISO14001 certification in Japan have a 40% higher chance of evaluating supplier environmental performance and a 50% higher chance of requiring suppliers to follow specific environmental practices [37]. There are two reasons for this. The first is risk prevention and control. When a firm’s suppliers produce environmental problems, consumers often require firms to be responsible for the non-green behavior of their upstream partners [13]. To avoid “chain liability” and obtain an environmental legitimacy status for the organization, firms with higher internal environmental integration have stronger motivation and willingness to manage suppliers, supervise and control them, and enhance the environmental sustainability of suppliers to reduce their own environment and reputational risks. The other reason is information sharing. Firms with a complete internal system can effectively integrate data and share information between different business units. When exchanging information with suppliers, it is easier to embed functional modules linked with external partners into the internal system, quickly and accurately obtain the supplier’s environmental data, and effectively identify and diagnose their possible environmental problems.

Internal green integration activities increase the likelihood of firms collaborating with external partners and absorbing the knowledge and technology from external partner environments [38]. For organizations with cross-functional integration activities, the internal communication and coordination mechanism is more mature, to some extent reflecting the common collaboration with external partners to establish synchronization process ability, which creates better communication with suppliers, so that they understand each other’s business process, and promotes supplier support of firm environment and understanding [39]. In addition, firms with high levels of internal green integration can fully demonstrate to suppliers the enormous advantages of environmental input, including meeting customer needs, increasing financial returns, and enhancing product competitiveness to transform suppliers from passive to active, proactively implementing green manufacturing and stimulating the willingness of suppliers and firms to cooperate in green activities [17,39].

Therefore, the following hypotheses are proposed:

Hypothesis 2a (H2a):

A positive relationship exists between internal green integration and greening the supplier.

Hypothesis 2b (H2b):

A positive relationship exists between internal green integration and environmental collaboration with the supplier.

2.4. Supplier Green Integration and Environmental Performance

As a risk management and control activity [34], greening the supplier helps firms achieve multiple goals, such as reducing energy consumption, saving money, protecting the ecological environment, and safeguarding their reputation. By monitoring suppliers’ waste and pollution levels, firms reduce their information asymmetry and the supplier’s opportunistic behavior in the environment [40]. This monitoring can reduce the proportion of high-risk suppliers with a supplier evaluation management system, supplier certification, selections, audits, performance management, and exit mechanisms. This relies on regular seminars with suppliers on environmental issues to provide environmental solutions to encourage suppliers to protect their entire production process [35]. Energy consumption and waste emissions can be reduced, and suppliers can be assisted with green transformations, thereby increasing their production and efficiency and improving the company’s environmental reputation.

As the environment gradually becomes an important component of a firm’s supply chain strategy, upstream and downstream firms in the supply chain need to invest resources and time into understanding each other’s operations, exchanging technical information, and achieving environmental collaboration [41]. The theory of resource dependence holds that long-term performance gains can be obtained through the collaboration of interdependent supply chain firms [42]. Cooperation between supply chain members can promote improvements in environmental practices and pollution reduction [34]. In particular, environmental collaboration can allow manufacturing firms to access critical environmental resources (such as materials, standards, or technologies) [43,44]. Sharing expertise and ideas across organizational boundaries can help realize different strategies, jointly conduct environmental activities, develop environmental protection products, implement sustainable production processes, reduce costs for both parties, and create win–win results. Therefore, we propose the following hypotheses:

Hypothesis 3a (H3a):

A positive relationship exists between greening the supplier and environmental performance.

Hypothesis 3b (H3b):

A positive relationship exists between environmental collaboration with the supplier and environmental performance.

2.5. The Moderating Role of Relational Capability

Internal green integration provides an important internal environmental foundation for greening the supplier and for environmental collaboration with the supplier. However, how this internal environmental mechanism can be better used by upstream partners depends on the firm’s own relationship capabilities [19]. Relational capability is defined as a firm’s capability to create, manage, and leverage the overall structure of the relationships in its network over time [45]. This not only includes the capability of firms to create greater value, to identify the best partners, and to build and manage relationships [46], but also covers the ability to activate and fully use potential assets and resources in the network.

Firms implementing internal green integration often impose control activities, such as monitoring and assessment, on suppliers, ignoring the green will of suppliers; in return, suppliers tend to use opportunistic and greenwashing behavior. As a key element in sharing resources among supply chain partners, eliminating non-environmental behaviors, and implementing larger green activities, relationship capacity plays an active role in enhancing cooperation tendencies and increasing cooperation effectiveness [47]. If a firm can accurately identify the key suppliers in the network and can establish a good relationship with them to maintain close communication and interaction, increasing the suppliers’ recognition of green activities within the firm will be easier [48]. This will not only enhance the enthusiasm of the suppliers to accept an environmental audit from the core enterprise and improve the product and process flow to meet the environmental requirements of the core enterprise, but will also improve their understanding and implementation of environmental protection standards; provide environmental protection materials, products, or components for enterprises; and help to actively solve environmental problems in the supply chain with core enterprises. In conclusion, firms that have the ability to identify and maintain important relationships are more likely to instill their own environmental values into upstream suppliers and to increase the willingness of suppliers to work hard to achieve the focal firm’s environmental goals. Hence, we posit:

Hypothesis 4a (H4a):

Relational capability moderates the effect of internal green integration on greening the supplier.

Hypothesis 4b (H4b):

Relational capability moderates the effect of internal green integration on environmental collaboration with the supplier.

3. Research Method

3.1. Sample Selection

To validate the hypothetical model, a structured questionnaire was used to gather original firm data from Chinese manufacturing companies. We chose China’s manufacturing industry as the research object for a number of reasons. First, China is the world’s largest manufacturing base, with a large number of industries and a full range of types, which could help, to a certain extent, to ensure the universality of research conclusions. Secondly, in recent years, the Chinese government has attached considerable importance to environmental issues and has successively enacted a number of relevant environmental laws and regulations, such as “Renewable energy law of the People’s Republic of China”, “Measures for the administration of the restricted use of the hazardous substances contained in electrical and electronic products”, and “Law of the People’s Republic of China on promoting clean production”. In addition, many products of Chinese manufacturing firms are exported to North America and Europe; they are highly export-oriented and face strict environmental regulations, such as the Montreal Convention, Kyoto Protocol, ROHS (Restriction of Hazardous Substances), and WEEE (Waste Electrical and Electronic Equipment) Directive [49]. Faced with the strong institutional environment pressure at home and abroad, manufacturing companies urgently need to optimize the existing supply chain processes to provide products that meet the environmental needs of customers and achieve sustainable development. Third, the products of manufacturing firms are more complex, requiring close cooperation between upstream and downstream firms. Compared to other industries, supply chain integration activities are common.

3.2. Survey Instrument

To ensure the accuracy of the questionnaire, the preparation of the scale followed a rigorous procedure. First, we conducted a comprehensive study of the literature to find valid items. Secondly, a questionnaire was prepared and translated into Chinese by a professor of operational management with a background in overseas study. Subsequently, another operation management scholar translated Chinese back into English. We checked the translated English version against the original text to determine whether it accurately reflected the original intent of the item. Finally, before the large-scale survey, we conducted face-to-face discussions with the managers of 20 companies to modify the ambiguous statements in the questionnaire. The measurement items for proactive environmental strategy, internal green integration, greening the supplier, environmental collaboration with the supplier, environmental performance, and relational capability were mainly obtained from prior research (Appendix A). These items were scored using a five-point Likert scale, where 1 corresponded to ‘‘strongly disagree” and 5 to ‘‘strongly agree”. The six constructs were as follows:

Proactive environmental strategy (PES) was composed of five items drawn from Dai et al. (2017), which describe the proactive environmental strategy from the severity of the company’s current environmental regulations, the importance placed by corporate and management personnel on environmental issues, the environmental risk control of daily operations, and the status of environmental protection in the industry.

Internal green integration (IGI): Wong et al. (2015) comprehensively summarized five types of internal green integration activities, including integrating environmental objectives into enterprise strategies, integrating environmental objectives into management systems, and cross-functional cooperation for environmental management. Based on this, we designed five items to measure internal green integration.

Greening the supplier (GS): The measures of GS were based on Chiou et al. (2011). According to the definition of greening the supplier in this paper, it mainly includes two kinds of practice (monitoring and guidance) and consists of five items including supplier selection, training, and evaluation.

Environmental collaboration with the supplier (ECS): This construct is composed of five items, drawn from Gölgeci et al. (2019), including providing suppliers with design specifications containing environmental requirements, supporting and encouraging suppliers to try to save energy and improve efficiency, cooperating with suppliers to reduce their waste emissions, and cooperating with suppliers to conduct environmental product development and cleaner production.

Environmental performance (ES): ES was adapted from Large and Thomsen (2011) and is measured using five items: reducing waste, enhancing compliance, improving product recycling, improving reputation, and overall environmental performance [50].

Relational capability (RC): We drew upon the scale in Gölgeci et al. (2019), mainly from the establishment of a network, management of a network, and the use of network resources, for a total of 10 items to measure the relationship capability of firms.

Firm size: Large firms pay more attention to their environmental reputation due to public attention. They also have more resources than small- and medium-sized enterprises to invest in environmental protection activities [36]. Therefore, we considered firm size as the control variable. The number of employees, which was used to measure the firm size, was divided into four categories, 1 = less than 100 employees, 2 = 100–1000 employees, 3 = 1000–10,000 employees, 4 = more than 10,000 employees, in order to control for the potential impact.

3.3. Data Collection

The sample selection was based on an information database developed by the Public Environmental Research Center (IPE) for green procurement, green finance, and government environmental decision making. In this database, 500 companies were randomly selected as survey objects and included automobile, electrical and electronic, chemical, leather, and other industries. Paper mail was sent to each company, including a letter of introduction for the research project. To judge the actual situation of an enterprise as accurately as possible and improve the data accuracy, respondents needed to comprehensively understand supply chain management. After collecting data from September 2018 to January 2019 and March to May 2019, data from a total of 314 companies were collected, of which 62 were excluded due to incomplete information. The effective response rate was 50.4%.

The main characteristics of the sample firms are shown in Table 1. Among these sample firms, 29.0% had fewer than 100 employees, 32.1% had 100–1000 employees, and 38.9% had more than 1000 employees. Of the firms in the sample, 52.4% belonged to high pollution industries and 47.6% belonged to low pollution industries. In terms of company location, 29.8% of the firms were located in the northeastern part of China, 22.7% were located in southeastern China, the sample firms in the central region accounted for 16.7%, and the western firms accounted for 30.8%. The sample distribution was relatively uniform.

Table 1.

Characteristics of sample firms.

4. Analysis and Findings

4.1. Non-Response Bias and Common Method Bias

A t-test was used to test non-response bias in the study. By comparing the data, we found no significant difference between the early and late respondents in environmental proactive strategy, internal green integration, greening the supplier, environmental collaboration with the supplier, environmental performance, or relational capability. Thus, non-response bias was not a problem in this study.

Since both the independent and dependent variables were obtained from the same respondent, there is the potential for a common method bias (CMB). To reduce the possibility of this common method bias, all respondents were managers with extensive experience in supply chain management. To minimize the possibility of common method bias in the research design, we also used a Harman single-factor test and controlled for the effects of an unmeasured latent methods factor to test CMB. The result of the Harman single-factor test showed that six factors had eigenvalues above one. The cumulative explainable variance was 70.086%, of which the main factor only explained 33.701% of the variance (less than 40%), which is not the majority of total variance [48]. Another variable approach that was used involves adding a first-order factor with all of the measures as indicators to the researcher’s base model, controlling for the effects of an unmeasured latent methods factor [51] by comparing the base model with the common method factor to confirm whether there is a method bias problem. If the common method factor is added, the model fitting index becomes much better (the increase of CFI and TLI exceeds 0.1), which indicates that there is a serious common method bias problem [51,52,53]. The results show that, when adding common method factors, there are no significant differences between the two models in χ2/df, CFI, TLI, IFI, and RMESA (Table 2). Based on the above two methods, there was no common method bias problem in this study.

Table 2.

Controlling for effects of an unmeasured latent methods factor method.

4.2. Reliability and Validity

The reliability was mainly measured by Cronbach’s α (CA). As shown in Table 3, the CA values of environmental proactive strategy, internal green integration, greening the supplier, environmental collaboration with the supplier, environmental performance, or relational capability were all above 0.70. This indicates that the scale had high internal consistency. The convergence validity and discrimination validity of the scale were also tested. The composite reliability for each construct was above 0.80 (Table 3), and average variance extracted (AVE) was above 0.50 (Table 3). Discriminant validity was assessed by comparing the AVE for each construct with the square of the correlation between all possible pairs of constructs (Hair et al., 2010). In all cases, the AVE was greater than the square of the correlation between all possible pairs of constructs (Table 4). Overall, the results support convergence validity and discriminant validity among the constructs.

Table 3.

Convergent validity and reliability.

Table 4.

Descriptive statistics and discriminant validity.

4.3. Hypothesis Tests

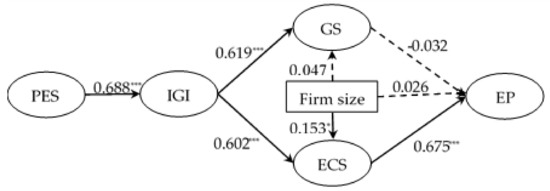

Considering the interaction between variables, a structural equation model can more intuitively and comprehensively reflect the influence path between variables than multiple regression analysis. Therefore, MPlus7.0 was used to verify the hypothesis model. The results of the path analysis of the main path model are shown in Figure 2 and Table 5. The four impact paths, proactivity environmental strategy → internal green integration, internal green integration → greening the supplier, internal green integration → environmental collaboration with the supplier, and environmental collaboration with the supplier→ environmental performance all reached the 0.001 significance level, and the standardized path coefficients were 0.688, 0.619, 0.602, and 0.675, respectively. H1, H2a, H2b, and H3b were all supported. Greening the supplier had no direct impact on environmental performance (p > 0.05), H3a was not tested. Firm size had a significant impact on environmental collaboration with the supplier (p < 0.05), but no significant impact on greening the supplier and environmental performance. All fit indices of the model met the corresponding criteria (χ2/df = 1.953, SRMR = 0.041, CFI = 0.939, TLI = 0.918, RMESA = 0.062).

Figure 2.

Original structural equation model.

Table 5.

Original model test.

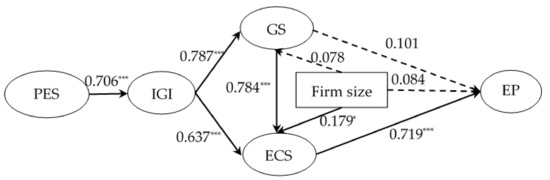

Our results are basically consistent with those reported by Simpson et al. (2007) and Gimenez and Tachizawa (2012) [54,55]. They found that manufacturer collaboration with suppliers helped improve their environmental performance, whereas monitoring the suppliers had no impact on environmental performance. Firms not only need to green the supplier but also need to further deepen their cooperation with suppliers on environmental issues. Focal firms develop environmental standards for suppliers; provide adequate guidance, advice, and assistance with the environment; and share environmental knowledge and skills with suppliers to help them establish an internal environmental management system. When suppliers successfully achieve green transformation, focal firms cooperate more closely with them, such as by inviting suppliers to participate in product development to solve environmental problems and improve their sustainability [36]. According to Gimenez and Tachizawa (2012) [55], we considered the mediating role of environmental collaboration with the supplier between greening the supplier and environmental performance. The modified model is shown in Figure 3. Most of our hypotheses were supported, except for H3b. In terms of control variables, we found that firm size had a positive and statistically significant relationship with environmental collaboration with the supplier. We also confirmed the significant effect of greening the supplier on environmental collaboration with the supplier (p < 0.001). The impact of greening the supplier on environmental performance was completely mediated by environmental collaboration, and greening the supplier indirectly influenced environmental performance through environmental collaboration. The model results are presented in Table 6.

Figure 3.

Improved structural equation model.

Table 6.

Improved model test.

MPlus7.0 was also used to construct the interaction item (Int) of relationship capability and internal green integration to test the moderating effect of relationship capability. As shown in Table 7, the model had a good fit (χ2/df = 1.748, SRMR = 0.029, CFI = 0.984, TLI = 0.952, RMESA = 0.039). The interaction item, Int, had a significant positive impact on greening the supplier (p < 0.001). Therefore, H4a was supported. The impact of the interaction term between IGI and RC was positive and significant (p < 0.05). Therefore, H4b was supported.

Table 7.

Moderating effect test.

5. Discussion and Conclusions

5.1. Main Findings

This paper had two main purposes. The first was to reveal how environmentally proactive firms can use green supply chain integration to improve their environmental performance. To achieve this goal, a strategy-structure-performance framework was introduced to explore the relationship between proactive environmental strategies, green supply chain integration, and environmental performance. The second was to explore the boundary conditions for internal green integration to promote the green integration of upstream suppliers. The results show that the successful combination of a proactive environmental strategy (strategy) and green supply chain integration (structure) can improve the organization’s environmental performance (performance), and that relationship cability plays a moderating role between internal green integration and green supplier integration. Specifically, (1) proactive environmental strategies improve environmental performance by promoting the implementation of green supply chain integration. (2) The internal green integration activities of a firm help to implement green integration for the upstream suppliers. Thus, internal green integration not only helps to green the supplier but also promotes environmental collaboration with the supplier. (3) Green supplier integration contributes to improving a firm’s environmental performance. Environmental collaboration with the supplier can directly improve environmental performance, but greening the supplier has no direct impact on environmental performance, as environmental performance needs to be improved indirectly through environmental collaboration with the supplier. (4) A good relationship capability helps focal firms extend their green ideas and practices to upstream suppliers. The relationship between internal green integration and greening the supplier is stronger when the relational capability is high, and the relationship between internal green integration and environmental collaboration with the supplier is stronger when their relational capabilities are high. These findings contribute to both the theory and practice in this field. We discuss these contributions in detail below.

5.2. Theoretical Contributions

Firstly, this study clarified the transmission mechanism of proactive environmental strategies to improve environmental performance. Most previous studies discussed whether proactive greening is worthwhile, but they were less concerned with the path of implementation between proactive environmental strategies and environmental performance. We explored how companies that respond to environmental issues with a positive attitude can implement green supply chain integration while being environmentally friendly. Firms that play a proactive role in the environment contribute to the effective integration and use of internal resources within the organization and implement, track, and monitor environmental management work across functional departments. Thus, promoting the implementation of the green integration of suppliers can improve environmental performance. In addition, these findings expand upon related research in the field of corporate proactive environmental strategies and green supply chain integration.

Secondly, this paper revealed the intrinsic relationship between internal green integration and green supplier integration. Regarding green supply chain integration, the existing research focuses on how internal green integration affects supplier and customer integrations [17,39], but we focused on how internal green integration drives suppliers’ green integration (including supplier greening and supplier collaboration). Our findings refine the relevant research on existing supply chain integration. As an effective method to achieve supplier integration, internal green integration activities show that companies have a strong sense of the environmental crisis and a high level of internal communication and coordination, which lays the foundation for promoting the green integration of suppliers.

Thirdly, this study distinguished the methods for greening the supplier and environmental collaboration with the supplier to improve environmental performance. The results show that supplier environmental cooperation has a direct and significant impact on environmental performance. However, supplier greening can only affect environmental performance through supplier environmental collaboration, which is consistent with the findings reported by Tachizawa et al. (2015) [42]. Relying on green activities with assessment and guidance as the main means cannot effectively achieve supplier transformation of enterprise environmental requirements into their own environmental needs. Some suppliers may also use deception to pass an evaluation [56]. Conversely, greening the supplier does not involve suppliers directly participating in the environmental management activities of firms, and so their environmental performance is limited. Therefore, to improve environmental performance, firms need to more deeply cooperate with suppliers in environmental protection and to implement green upgrades for suppliers instead of green packaging.

Fourthly, this paper explored the boundary conditions for the impact of internal green integration on green supplier integration. By introducing relationship capability as a context factor, we extend the understanding of the relationship mechanism between internal green integration and the supply chain partner green integration proposed by Yang (2018) [39]. Although the importance of relationship capabilities has long been known to academics and practitioners, their impacts on green supplier integration have not yet been proven. Our findings reveal that relationship capabilities can significantly enhance the impact of internal green integration on green supplier integration. The key resources needed for firm development exist within the enterprise and within the external partners. Green supplier integration not only requires the basic resources of internal environment integration, but also necessitates a focus on the cultivation of relationship capabilities to procure external complementary resources. In addition, if two partners form mutually beneficial relationships, they may have similar values and goals, further enhancing the positive impact of internal green integration on green supplier integration.

5.3. Managerial Implications

These research conclusions provide guidance to help business managers implement green supply chain integration activities. First, proactive environmental strategies can directly promote internal environmental integration activities. Therefore, firms should consider the environment when formulating development and competition strategies, which will help establish a perfect environmental management system, an environmental protection reward punishment system, and an environment and culture of environmental protection, thus enhancing employees’ environmental awareness. Secondly, firms not only need to select suppliers that meet their environmental standards (as well as regularly evaluate and train them), but also need to cooperate with suppliers in depth, including activities such as the joint development of environmental protection materials, thereby holistically reducing negative impacts on the environment. In addition, firms should regard environmental protection indicators as an important aspect of managerial performance evaluations. An environmental data sharing system should be established between departments to form a unified understanding of environmental protection. Based on this, environmental data should be shared with suppliers, who should be monitored, guided, and cooperated with. Finally, relationship capabilities can enhance the impact of internal green integration on suppliers’ green integration. This integration will aid in establishing good relationships with existing suppliers, especially considering the daily operations of suppliers, who often interact with suppliers through daily communications, regular meetings, and supplier training. By establishing a wide network, firms can identify potential key suppliers with advanced environmental technology or high levels of environmental governance and can establish links with them; firms can also further integrate the suppliers into their own supply networks, ultimately promoting the successful implementation of green supplier integration activities.

5.4. Limitations and Future Research

First, this study focused on how firms with proactive environmental strategies improve their environmental performance. We suggest that firms that conduct positive environmental actions may improve their environmental performance through a green supply chain integration mechanism. Some scholars have also investigated green supply chain management [15,48] using internal ecological capabilities, innovation capabilities, stakeholder integration capabilities [39,57], and other aspects to answer this question. In the future, we intend to further investigate whether other possible paths exist, and will explore the selection of corporate environmental performance improvement methods under different conditions to expand this research. Second, our conclusions indicate that the implementation of internal green integration helps suppliers to achieve green integration and to improve environmental performance. We also found that firm size has a significantly positive impact on a supplier’s environmental synergy, but has no significant relationship with greening the supplier. Therefore, we infer that firms of different sizes, industries, and regions may have different focuses when implementing green supply chain integration and may produce different environmental results due to differences in their economic levels, environmental regulations, industrial competitive intensity, and strength. Further research could include a comparative study based on factors such as firm size, industry, and location to bolster the results presented here. Third, to empirically test the suggested model, we surveyed 252 manufacturing companies in China, but differences exist between China and other developed manufacturing industries, such as those in Europe, North America, Japan, and Taiwan, in terms of their environmental regulations and consumer green awareness. Future studies should discuss whether our conclusions are applicable in other areas. A comparative study in this field between China and other areas could also be conducted. Fourth, we introduced the strategy–structure–performance framework into green supply chain integration. However, further research is needed to apply the SSP to solving more issues in the green supply chain.

Author Contributions

S.L. designed the conceptual model, J.Q. carried out all research plan design and writing, H.C. carried out questionnaire survey and participated in data analysis, S.W. participated in model discussions and article review. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by a grant from the National Natural Science Foundation of China (No.71872148) and Science and Technology Program of Xi’an China (201805072RK3SF6(8)).

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Measurement scales.

Table A1.

Measurement scales.

| Proactive environmental strategy (PES) | |

| PES1 | Our firm always attempt to go beyond basic compliance with laws and regulations on environmental issues |

| PES2 | The top managers in our company give environmental issues a high priority |

| PES3 | Our firm leads our industry on environmental issues |

| PES4 | Our firm effectively manages the environmental risks that affect our business |

| PES5 | Our corporate management give high priority to environmental issues |

| Internal green integration (IGI) | |

| IGI1 | Our firm integrates environmental goals and responsibilities into business strategies |

| IGI2 | Our firm links environmental responsibility with executive compensation rewards |

| IGI3 | Our firm integrates environmental responsibility and objectives into various functional management systems (e.g., finance, human resource, manufacturing) |

| IGI4 | Our firm encourages employees in different departments to share opinions, information, or resources on environmental issues |

| IGI5 | Our firm encourages cross-functional communication, coordination, and collaboration to reduce environmental impacts and to achieve environmental goal collectively |

| Greening the supplier (GS) | |

| GS1 | Our firm selects suppliers by environmental criteria |

| GS2 | Our firm requires and assists suppliers in obtaining a third-party certification of environmental management system (EMS) |

| GS3 | Our firm provides environmental awareness seminars and training for suppliers |

| GS4 | Our firm provides environmental technical advice to suppliers and contractors in order to help suppliers meet environmental criteria. |

| GS5 | Our firm sends in-house auditors to appraise the environmental performance of suppliers. |

| Environmental collaboration with the supplier (ECS) | |

| ECS1 | Our firm provides its suppliers with design specifications that include environmental requirements for purchased items |

| ECS2 | Our firm encourages its suppliers to develop new source reduction strategies |

| ECS3 | Our firm cooperates with its suppliers to improve their waste reduction initiatives |

| ECS4 | Our firm works with its suppliers for environmental product development and cleaner production |

| ECS5 | Our firm collaborates with its suppliers to acquire materials, parts and/or services that support its environmental goals |

| Environmental performance (EP) | |

| EP1 | Our firm has achieved a reduction in pollution and waste |

| EP2 | Our firm has improved compliance with environmental laws |

| EP3 | Our firm has increased the level of recycling |

| EP4 | Our firm has preserved the environment |

| EP5 | Our firm has improved the environmental reputation of our company |

| Relational capability (RC) | |

| RC1 | Our firm can easily overcome difficulties in initiating business relationships with potential suppliers and customers |

| RC2 | Our firm is able to easily attract other firms to conduct business with us |

| RC3 | Our firm is good at evaluating and selecting firms before establishing a business relationship |

| RC4 | Our firm can comfortably establish business relationships with potential customers and suppliers |

| RC5 | Our firm can effectively manage a diverse set of business relationships in its network |

| RC6 | Our firm can easily overcome potential conflicts and problems when doing business with its supply chain partners |

| RC7 | Our firm is successful in communicating and collaborating with its supply chain partners |

| RC8 | Our firm is always able to acquire value from its supply chain relationships |

| RC9 | Our firm is successful at leveraging potential benefits from its suppliers |

| RC10 | Our firm often utilizes ideas and inputs from its supply chain partners to become more innovative and successful |

References

- Zhang, S.; Wang, Z.; Zhao, X. Effects of proactive environmental strategy on environmental performance: Mediation and moderation analyses. J. Clean. Prod. 2019, 235, 1438–1449. [Google Scholar] [CrossRef]

- Alt, E.; Díez-de-Castro, E.P.; Lloréns-Montes, F.J. Linking employee stakeholders to environmental performance: The role of proactive environmental strategies and shared vision. J. Bus. Ethics 2015, 128, 167–181. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, J.; Chi, N. The antecedents and performance consequences of proactive environmental strategy: A meta-analytic review of national contingency. Manag. Organ. Rev. 2015, 11, 521–557. [Google Scholar] [CrossRef]

- Walker, K.; Ni, N.; Huo, W. Is the red dragon green? An examination of the antecedents and consequences of environmental proactivity in China. J. Bus. Ethics 2014, 125, 27–43. [Google Scholar] [CrossRef]

- Darnall, N.; Henriques, I.; Sadorsky, P. Adopting proactive environmental strategy: The influence of stakeholders and firm size. J. Manag. Stud. 2010, 47, 1072–1094. [Google Scholar] [CrossRef]

- Yang, D.; Jiang, W.; Zhao, W. Proactive environmental strategy, innovation capability, and stakeholder integration capability: A mediation analysis. Bus. Strategy Environ. 2019, 28, 1534–1547. [Google Scholar] [CrossRef]

- Dai, J.; Cantor, D.E.; Montabon, F.L. Examining corporate environmental proactivity and operational performance: A strategy-structure-capabilities-performance perspective within a green context. Int. J. Prod. Econ. 2017, 193, 272–280. [Google Scholar] [CrossRef]

- Li, S.; Jayaraman, V.; Paulraj, A.; Shang, K. Proactive environmental strategies and performance: Role of green supply chain processes and green product design in the Chinese high-tech industry. Int. J. Prod. Res. 2016, 54, 2136–2151. [Google Scholar] [CrossRef]

- Lee, S.Y.; Rhee S, K. The change in corporate environmental strategies: A longitudinal empirical study. Manag. Decis. 2007, 45, 196–216. [Google Scholar] [CrossRef]

- Ates, M.A.; Bloemhof, J.; van Raaij, E.M.; Wynstra, F. Proactive environmental strategy in a supply chain context: The mediating role of investments. Int. J. Prod. Res. 2012, 50, 1079–1095. [Google Scholar] [CrossRef]

- Margerum, R.D.; Born, S.M. A co-ordination diagnostic for improving integrated environmental management. J. Environ. Plan. Manag. 2000, 43, 5–21. [Google Scholar] [CrossRef]

- Cantor, D.E.; Morrow, P.C.; Montabon, F. Engagement in environmental behaviors among supply chain management employees: An organizational support theoretical perspective. J. Supply Chain Manag. 2012, 48, 33–51. [Google Scholar] [CrossRef]

- Hartmann, J.; Moeller, S. Chain liability in multitier supply chains? Responsibility attributions for unsustainable supplier behavior. J. Oper. Manag. 2014, 32, 281–294. [Google Scholar] [CrossRef]

- Blome, C.; Hollos, D.; Paulraj, A. Green procurement and green supplier development: Antecedents and effects on supplier performance. Int. J. Prod. Res. 2014, 52, 32–49. [Google Scholar] [CrossRef]

- Chan, R.Y.K.; He, H.; Chan, H.K.; Wang, W.Y.C. Environmental orientation and corporate performance: The mediation mechanism of green supply chain management and moderating effect of competitive intensity. Ind. Market. Manag. 2012, 41, 621–630. [Google Scholar] [CrossRef]

- Mariadoss, B.J.; Chi, T.; Tansuhaj, P.; Pomirleanu, N. Influences of firm orientations on sustainable supply chain management. J. Bus. Res. 2016, 69, 3406–3414. [Google Scholar] [CrossRef]

- Dai, J.; Cantor, D.E.; Montabon, F.L. How environmental management competitive pressure affects a focal firm’s environmental innovation activities: A green supply chain perspective. J. Bus. Logist. 2015, 36, 242–259. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. The moderating effects of institutional pressures on emergent green supply chain practices and performance. Int. J. Prod. Res. 2007, 45, 4333–4355. [Google Scholar] [CrossRef]

- Gölgeci, I.; Gligor, D.M.; Tatoglu, E.; Arda, O.A. A relational view of environmental performance: What role do environmental collaboration and cross-functional alignment play? J. Bus. Res. 2019, 96, 35–46. [Google Scholar] [CrossRef]

- Grinyer, P.H.; Yasai-Ardekani, M.; Al-Bazzaz, S. Strategy, structure, the environment, and financial performance in 48 United Kingdom companies. Acad. Manag. J. 1980, 23, 193–220. [Google Scholar] [CrossRef]

- Habib, M.M.; Victo, R.B. Strategy, structure, and performance of US manufacturing and service MNCs: A comparative analysis. Strateg. Manag. J. 1991, 12, 589–606. [Google Scholar] [CrossRef]

- Clifford Defee, C.; Stank, T.P. Applying the strategy-structure-performance paradigm to the supply chain environment. Int. J. Logist. Manag. 2005, 16, 28–50. [Google Scholar] [CrossRef]

- Chen, H.; Daugherty, P.J.; Landry, T.D. Supply chain process integration: A theoretical framework. J. Bus. Logist. 2009, 30, 27–46. [Google Scholar] [CrossRef]

- Spillan, J.E.; McGinnis, M.A.; Kara, A.; Yi, L.G. A comparison of the effect of logistic strategy and logistics integration on firm competitiveness in the USA and China. Int. J. Logist. Manag. 2013, 24, 153–179. [Google Scholar] [CrossRef]

- Chen, H.; Daugherty, P.J.; Roath, A.S. Defining and operationalizing supply chain process integration. J. Bus. Logist. 2009, 30, 63–84. [Google Scholar] [CrossRef]

- Wook Kim, S. The effect of supply chain integration on the alignment between corporate competitive capability and supply chain operational capability. Int. J. Oper. Prod. Manag. 2006, 26, 1084–1107. [Google Scholar] [CrossRef]

- Agan, Y. Impact of operations, marketing, and information technology capabilities on supply chain integration. J. Econ. Soc. Res. 2011, 13, 27–58. [Google Scholar] [CrossRef]

- Bowen, F.E.; Cousins, P.D.; Lamming, R.C.; Farukt, C.A. The role of supply management capabilities in green supply. Prod. Oper. Manag. 2001, 10, 174–189. [Google Scholar] [CrossRef]

- Wong, C.Y.; Wong, C.W.Y.; Boon-Itt, S. Integrating environmental management into supply chains: A systematic literature review and theoretical framework. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 43–68. [Google Scholar] [CrossRef]

- Lo, S.M.; Zhang, S.; Wang, Z.; Zhao, X. The impact of relationship quality and supplier development on green supply chain integration: A mediation and moderation analysis. J. Clean. Prod. 2018, 202, 524–535. [Google Scholar] [CrossRef]

- Yu, W.; Chavez, R.; Feng, M.; Wiengarten, F. Integrated green supply chain management and operational performance. Supply Chain Manag. Int. J. 2014, 19, 683–696. [Google Scholar] [CrossRef]

- Lu, Y.; Zhao, C.; Xu, L.; Shen, L. Dual Institutional Pressures, Sustainable Supply Chain Practice and Performance Outcome. Sustainability 2018, 10, 3247. [Google Scholar] [CrossRef]

- Rao, P. Greening the supply chain: A new initiative in South East Asia. Int. J. Oper. Prod. Manag. 2002, 22, 632–655. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Environmental management and manufacturing performance: The role of collaboration in the supply chain. Int. J. Prod. Econ. 2008, 111, 299–315. [Google Scholar] [CrossRef]

- Chiou, T.Y.; Chan, H.K.; Lettice, F.; Chung, H.S. The influence of greening the suppliers and green innovation on environmental performance and competitive advantage in Taiwan. Trans. Res. Part E Logist. Transp. Rev. 2011, 47, 822–836. [Google Scholar] [CrossRef]

- Danese, P.; Lion, A.; Vinelli, A. Drivers and enablers of supplier sustainability practices: A survey-based analysis. Int. J. Prod. Res. 2019, 57, 2034–2056. [Google Scholar] [CrossRef]

- Arimura, T.H.; Darnall, N.; Katayama, H. Is ISO 14001 a gateway to more advanced voluntary action? The case of green supply chain management. J. Environ. Econ. Manag. 2011, 61, 170–182. [Google Scholar] [CrossRef]

- Zhao, X.; Huo, B.; Selen, W.; Yeung, J.H.Y. The impact of internal integration and relationship commitment on external integration. J. Oper. Manag. 2011, 29, 17–32. [Google Scholar] [CrossRef]

- Yang, C.S. An analysis of institutional pressures, green supply chain management, and green performance in the container shipping context. Transp. Res. Part D Transp. Environ. 2018, 61, 246–260. [Google Scholar] [CrossRef]

- Zhang, T. How Do Information Technology Resources Facilitate Relational and Contractual Governance in Green Supply Chain Management? Sustainability 2019, 11, 3663. [Google Scholar] [CrossRef]

- Song, Y.; Feng, T.; Jiang, W. The influence of green external integration on firm performance: Does firm size matter? Sustainability 2017, 9, 1328. [Google Scholar] [CrossRef]

- Tachizawa, E.M.; Gimenez, C.; Sierra, V. Green supply chain management approaches: Drivers and performance implications. Int. J. Oper. Prod. Manag. 2015, 35, 1546–1566. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q.; Lai, K. An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Oelze, N. Sustainable supply chain management implementation–enablers and barriers in the textile industry. Sustainability 2017, 9, 1435. [Google Scholar] [CrossRef]

- Capaldo, A. Network structure and innovation: The leveraging of a dual network as a distinctive relational capability. Strateg. Manag. J. 2007, 28, 585–608. [Google Scholar] [CrossRef]

- Wang, G.; Dou, W.; Zhu, W.; Zhou, N. The effects of firm capabilities on external collaboration and performance: The moderating role of market turbulence. J. Bus. Res. 2015, 68, 1928–1936. [Google Scholar] [CrossRef]

- Schillebeeckx, S.J.D.; Chaturvedi, S.; George, G.; King, Z. What do I want? The effects of individual aspiration and relational capability on collaboration preferences. Strateg. Manag. J. 2016, 37, 1493–1506. [Google Scholar] [CrossRef]

- Yu, Y.; Huo, B. The impact of environmental orientation on supplier green management and financial performance: The moderating role of relational capital. J. Clean. Prod. 2019, 211, 628–639. [Google Scholar] [CrossRef]

- Chen, Y.S.; Chang, C.H.; Wu, F.S. Origins of green innovations: The differences between proactive and reactive green innovations. Manag. Decis. 2012, 50, 368–398. [Google Scholar] [CrossRef]

- Large, R.O.; Thomsen, C.G. Drivers of green supply management performance: Evidence from Germany. J. Purch. Supply Manag. 2011, 17, 176–184. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.Y.; Podsakoff, N.P. Common method biases in behavioral research: A critical review of the literature and recommended remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef] [PubMed]

- Williams, L.J.; McGonagle, A.K. Four research designs and a comprehensive analysis strategy for investigating common method variance with self-report measures using latent variables. J. Bus. Psychol. 2016, 31, 339–359. [Google Scholar] [CrossRef]

- Wen, Z.L.; Huang, B.B.; Tang, D.D. Preliminary work for modeling questionnaire data. J. Psychol. Sci. 2018, 41, 204–210. [Google Scholar] [CrossRef]

- Simpson, D.; Power, D.; Samson, D. Greening the automotive supply chain: A relationship perspective. Int. J. Oper. Prod. Manag. 2007, 27, 28–48. [Google Scholar] [CrossRef]

- Gimenez, C.; Tachizawa, E.M. Extending sustainability to suppliers: A systematic literature review. Supply Chain Manag. Int. J. 2012, 17, 531–543. [Google Scholar] [CrossRef]

- Wilhelm, M.M.; Blome, C.; Bhakoo, V.; Paulraj, A. Sustainability in multi-tier supply chains: Understanding the double agency role of the first-tier supplier. J. Oper. Manag. 2016, 41, 42–60. [Google Scholar] [CrossRef]

- Gabler, C.B.; Richey, R.G., Jr.; Rapp, A. Developing an eco-capability through environmental orientation and organizational innovativeness. Ind. Market. Manag. 2015, 45, 151–161. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).