Experimental Study on the Performance Decay of Permeable Asphalt Mixture in Seasonally Frozen Regions under Freeze-Thaw Cycles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Gradation Design

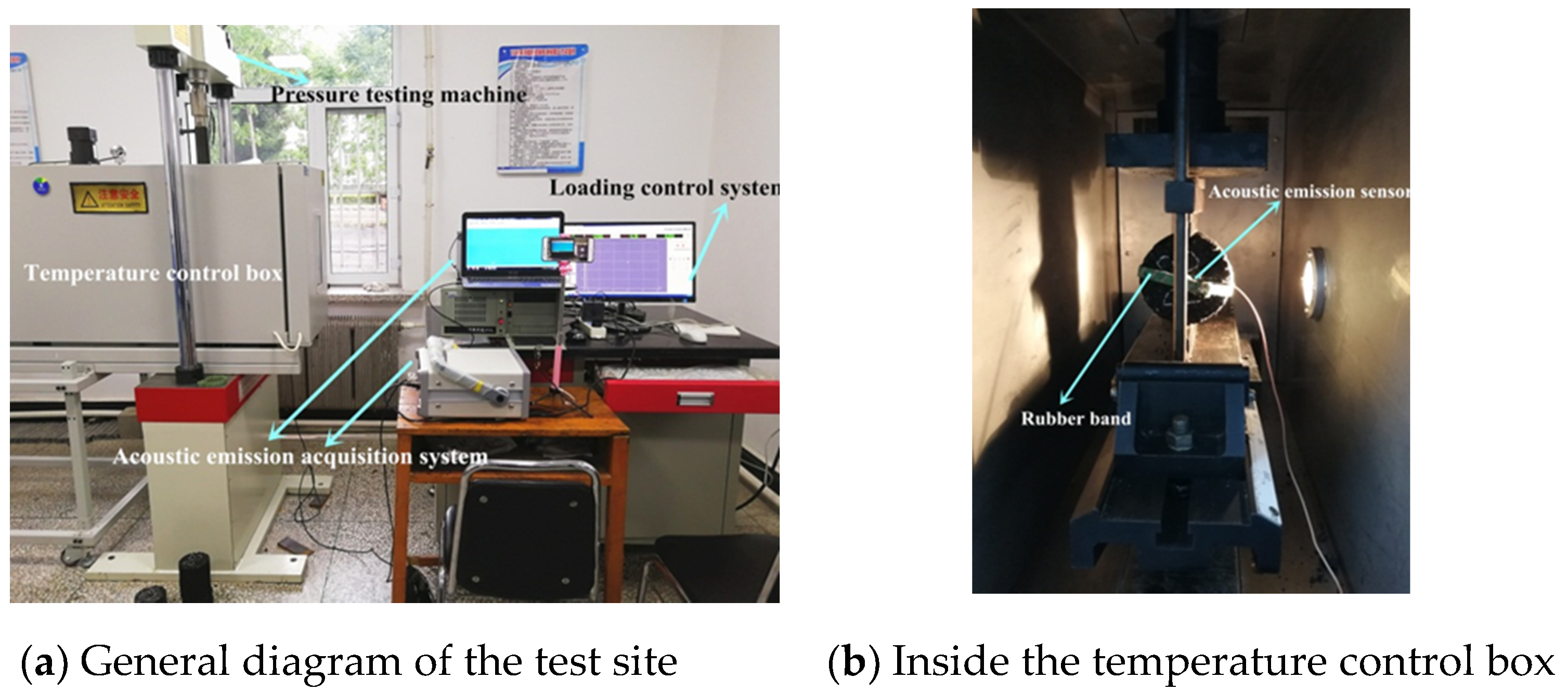

2.2. Experimental Methods

2.2.1. Freeze-Thaw Cycle

2.2.2. Low-Temperature Splitting Test

2.2.3. Indirect Tensile and Compression Test at Room Temperature

2.2.4. Cantabro Particle Loss Test

2.2.5. Dynamic Creep Test

3. Results and Discussion

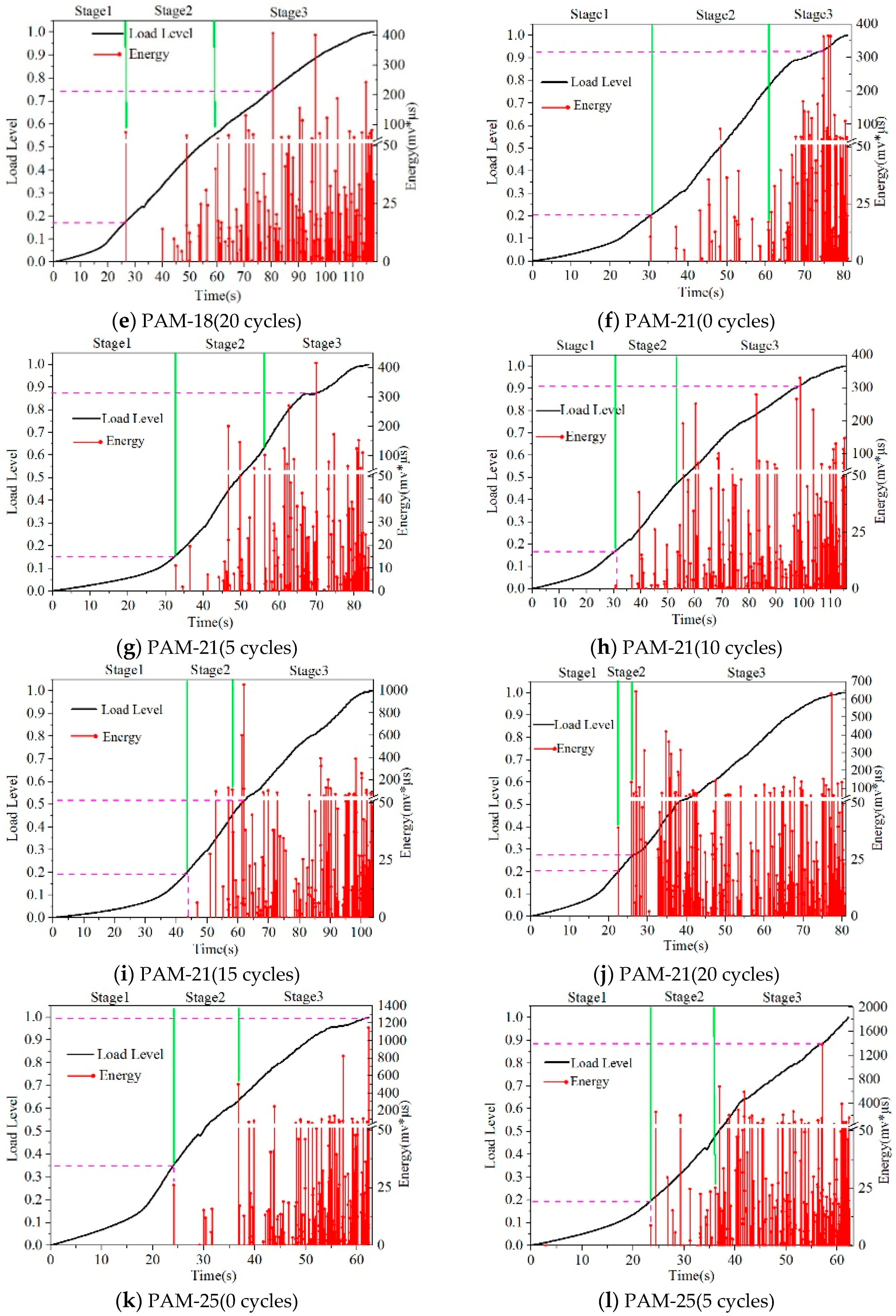

3.1. Low-Temperature Splitting Test

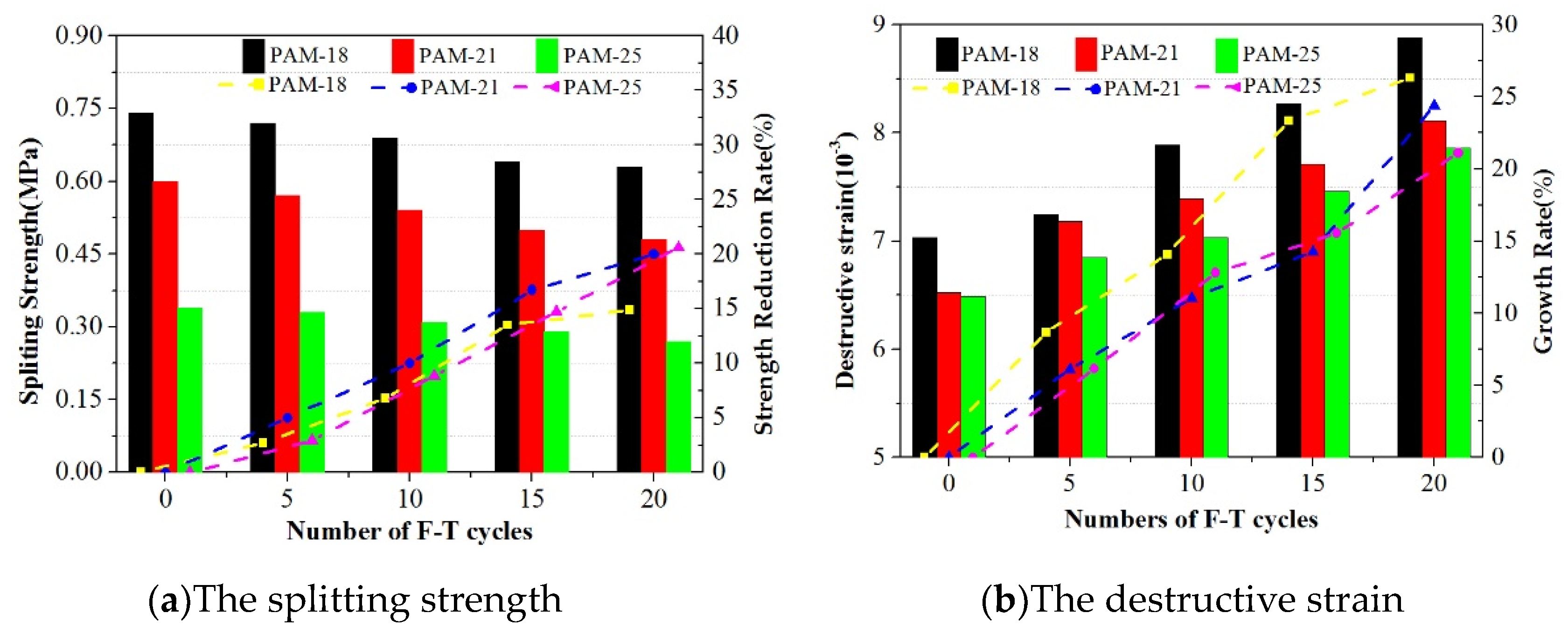

3.2. Indirect Tensile and Compression Experiments at Normal Temperature

3.2.1. Indirect Tensile Test

3.2.2. Compression Test

3.3. Cantabro Particle Loss Test

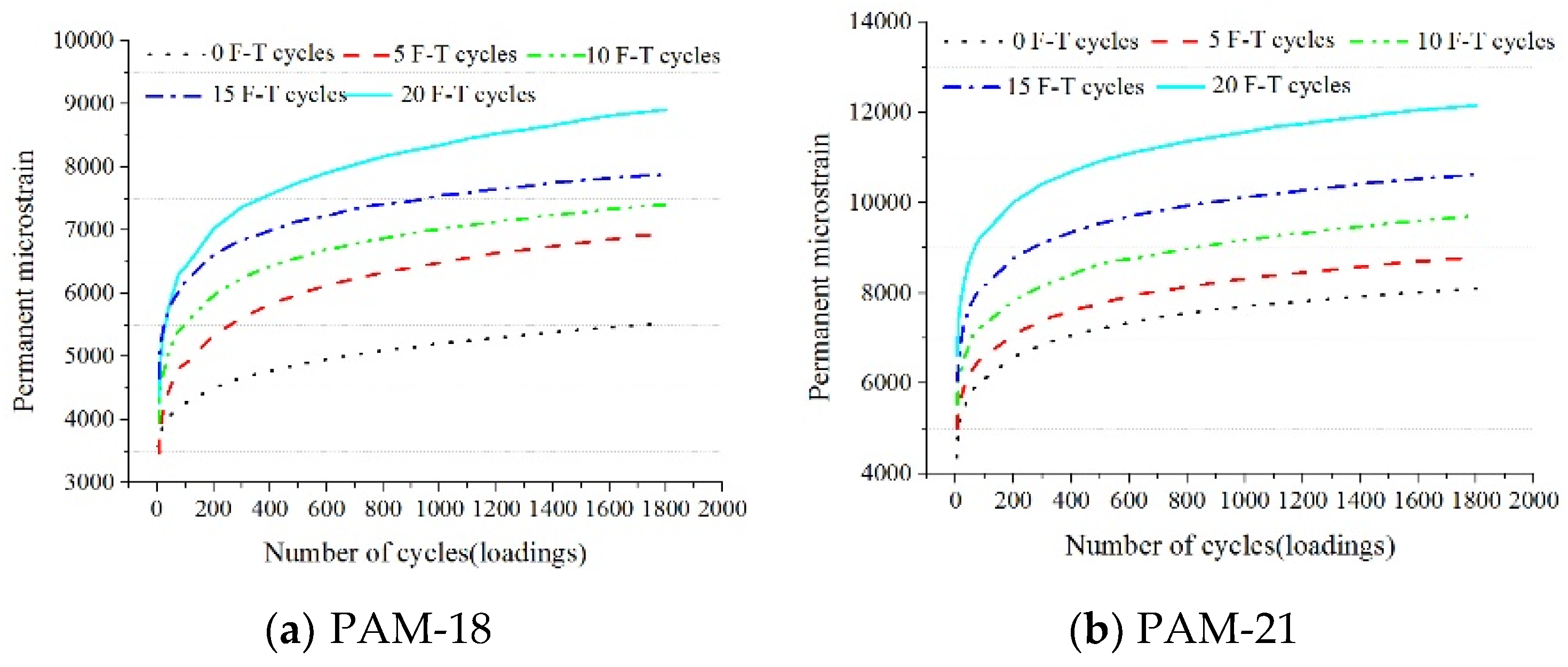

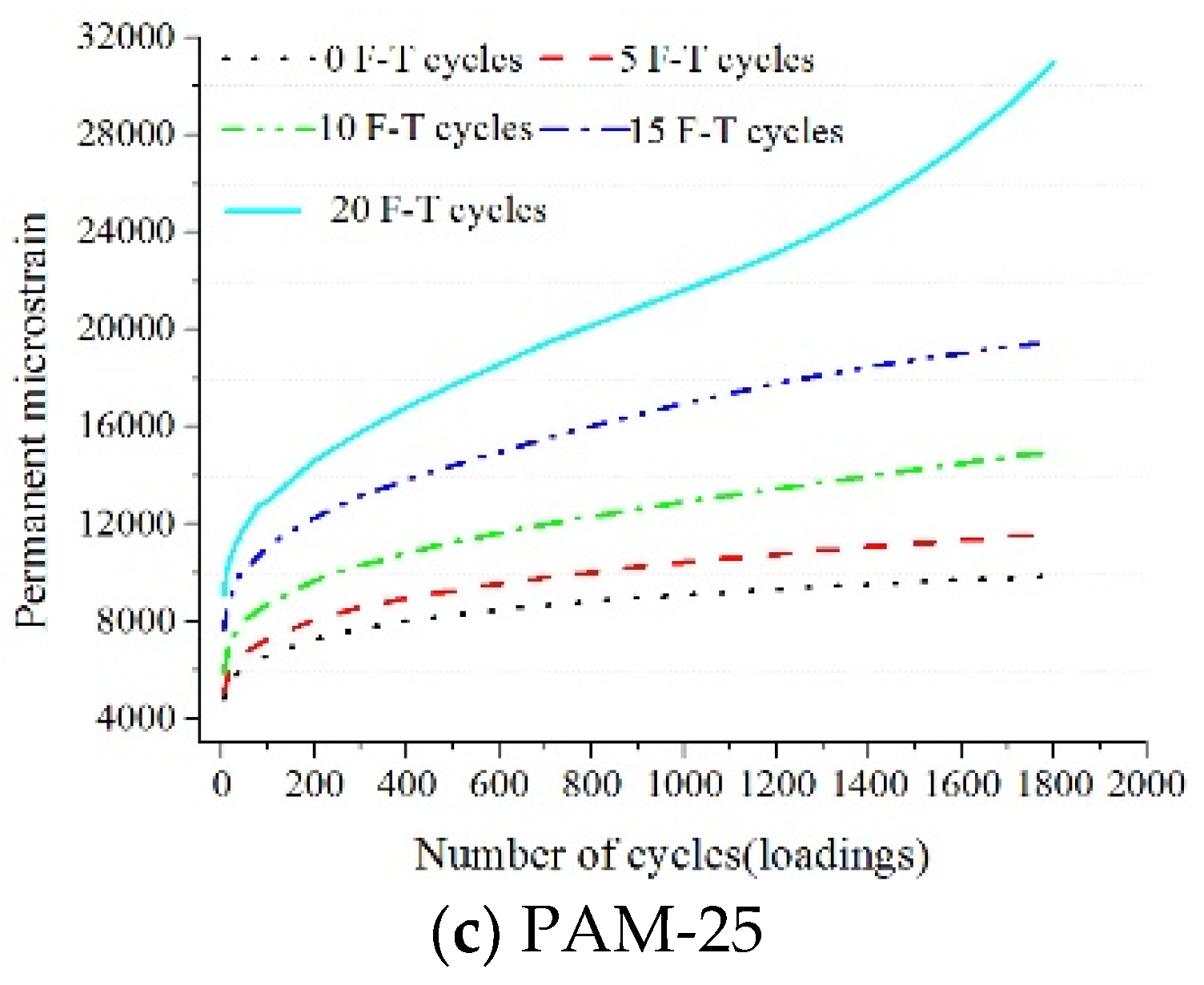

3.4. Dynamic Creep Test Results

4. Conclusions

- Acoustic emission parameters well reflect the stress characteristics of the specimens during the low-temperature splitting process. Under the effect of F-T cycles, the damage stage and destruction stage of the three groups of PAMs were advanced. The larger the proportion of coarse aggregate in the PAM, the greater the single energy released by the specimen during the destruction process.

- The indirect tensile strength of PAM decreases rapidly with the increase of air void and the number of F-T cycles. In contrast, the failure strain increases with the increase of F-T cycles. PAM-18 was the least affected by the F-T cycles. The results of compression experiments at normal temperature showed similar rules.

- The air void is the main factor that affects the cohesiveness between aggregate and asphalt. The larger the air void, the larger the Cantabro particle loss of the specimen, and the greater the adverse effect of the freeze-thaw cycle on the adhesion of the aggregate to the asphalt. When the air void reached 25%, the Cantabro particle loss rate of the specimen was far greater than the 15% in the specifications, regardless of whether it suffered the F-T cycles or not.

- Both the air void and F-T cycles are important factors affecting the high-temperature viscoelastic properties of PAM. As the air void and the number of F-T cycles increased, the creep strain slope of the three groups of PAMs gradually increased and the creep stiffness gradually decreased. When the air void is greater than 21%, the adverse effects of F-T cycles become apparent.

- For seasonal frozen regions that are often subjected to F-T cycles, the air void of PAM should be minimized while ensuring drainage performance. It is recommended to keep the air void to 21% or less to avoid early damage to the pavement.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cobbinah, P.B.; Kosoe, E.A.; Diawuo, F. Environmental planning crisis in urban Ghana: Local responses to nature’s call. Sci. Total. Environ. 2020, 701, 134898. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Chen, S.S.; Lau, A.Y.T.; Tsang, D.C.W.; Mohanty, S.K.; Bhatnagar, A.; Rinklebe, J.; Lin, K.Y.A.; Ok, Y.S. Waste-derived compost and biochar amendments for stormwater treatment in bioretention column: Co-transport of metals and colloids. J. Hazard. Mater. 2020, 383, 121243. [Google Scholar] [CrossRef] [PubMed]

- Ye, Q.; Han, Y.; Zhang, S.; Gao, Q.; Zhang, W.; Chen, H.; Gong, S.; Shi, S.Q.; Xia, C.; Li, J. Bioinspired and biomineralized magnesium oxychloride cement with enhanced compressive strength and water resistance. J. Hazard. Mater. 2020, 383, 121099. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.Q.; Sun, G.Q.; Zhu, X.Y.; Xiao, F.P.; Dai, Z.W.; Liu, F.L. Electrical characteristics of conductive ultrathin bonded wearing course for active deicing and snow melting. Int. J. Pavement. Eng. 2019, 20, 1299–1308. [Google Scholar] [CrossRef]

- Jiang, L.; Wang, L.C.; Wang, S.Y. A novel solar reflective coating with functional gradient multilayer structure for cooling asphalt pavements. Constr. Build. Mater. 2019, 210, 13–21. [Google Scholar] [CrossRef]

- Lu, G.Y.; Renken, L.; Li, T.S.; Wang, D.W.; Li, H.; Oeser, M. Experimental study on the polyurethane-bound pervious mixtures in the application of permeable pavements. Constr. Build. Mater. 2019, 202, 838–850. [Google Scholar] [CrossRef]

- Tang, T.C.; Anupam, K.; Kasbergen, C.; Scarpas, A.; Erkens, S. A finite element study of rain intensity on skid resistance for permeable asphalt concrete mixes. Constr. Build. Mater. 2019, 220, 464–475. [Google Scholar] [CrossRef]

- Liu, Z.M.; Luo, S.; Quan, X.; Wei, X.H.; Yang, X.; Li, Q. Laboratory evaluation of performance of porous ultra-thin overlay. Constr. Build. Mater. 2019, 204, 28–40. [Google Scholar] [CrossRef]

- Khaki, A.M.; Forouhid, A.E.; Zare, M. Comparison of the noise level and the skid resistance of asphalt pavement mixtures on road surface. J. Meas. Eng. 2015, 3, 71–76. [Google Scholar]

- Hu, K. Key Technology of Research of Efficient Separation of Construction & Demolition Waste in Pavement Engineering. Ph.D. Thesis, Chang’an University, Xi’an, China, 2017. [Google Scholar]

- Zhang, L. Design and Performance of Experimental Research of Hot Recycled Asphalt Mixture. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2014. [Google Scholar]

- Zarrinkamar, B.T.; Modarres, A. Optimizing the asphalt pavement cold in-place recycling process containing waste pozzolans based on economic-environmental-technical criteria. J. Clean. Prod. 2020, 242, 11. [Google Scholar] [CrossRef]

- Yan, K.Z.; Li, L.L.; Zheng, K.G.; Ge, D.D. Research on properties of bitumen mortar containing municipal solid waste incineration fly ash. Constr. Build. Mater. 2019, 218, 657–666. [Google Scholar] [CrossRef]

- Cheng, Y.C.; Wang, W.S.; Tan, G.J.; Shi, C.L. Assessing High- and Low-Temperature Properties of Asphalt Pavements Incorporating Waste Oil Shale as an Alternative Material in Jilin Province, China. Sustainability 2018, 10, 2179. [Google Scholar] [CrossRef]

- Liu, W.; Li, H.; Zhu, H.; Xu, P. Properties of a Steel Slag-Permeable Asphalt Mixture and the Reaction of the Steel Slag-Asphalt Interface. Materials 2019, 12, 3603. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.N.; Li, P.; Nian, T.F.; Zhang, G.H.; He, T.; Wei, X.Y. Evaluation of asphalt and asphalt mixtures’ water stability method under multiple F-T cycles. Constr. Build. Mater. 2019, 228, 15. [Google Scholar] [CrossRef]

- Guo, Q.L.; Li, G.Y.; Gao, Y.; Wang, K.Y.; Dong, Z.Z.; Liu, F.C.; Zhu, H. Experimental investigation on bonding property of asphalt-aggregate interface under the actions of salt immersion and F-T cycles. Constr. Build. Mater. 2019, 206, 590–599. [Google Scholar] [CrossRef]

- Wang, W.S.; Cheng, Y.C.; Ma, G.R.; Tan, G.J.; Sun, X.; Yang, S.T. Further Investigation on Damage Model of Eco-Friendly Basalt Fiber Modified Asphalt Mixture under F-T cycles. J. Appl. Sci. 2019, 9, 60. [Google Scholar] [CrossRef]

- TehSek, Y.; Meor, O.H. Asphalt mixture workability and effects of long-term conditioning methods on moisture damage susceptibility and performance of warm mix asphalt. Constr. Build. Mater. 2019, 207, 316–328. [Google Scholar]

- Zhang, Q.L.; Huang, Z.Y. Investigation of the micro-characteristics of asphalt mastics under dry-wet and F-T cycles in a coastal salt environment. Materials 2019, 12, 2627. [Google Scholar] [CrossRef]

- You, L.Y.; You, Z.P.; Dai, Q.L.; Xie, X.F.; Washko, S.; Gao, J.F. Investigation of adhesion and interface bond strength for pavements underlying chip-seal: Effect of asphalt-aggregate combinations and F-T cycles on chip-seal. Constr. Build. Mater. 2019, 203, 322–330. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Ahn, J.; Lee, J.; Kim, J.H. Dynamic Modulus of Porous Asphalt and the Effect of Moisture Conditioning. Materials 2019, 12, 1230. [Google Scholar] [CrossRef]

- Ji, J.; Yao, H.; Yuan, Z.K.; Suo, Z.; Xu, Y.; Li, P.F.; You, Z.P. Moisture susceptibility of warm mix asphalt (WMA) with an organic wax additive based on X-ray computed tomography (CT) technology. Adv. Mater. Sci. Eng. 2019, 2019, 1–12. [Google Scholar] [CrossRef]

- Badeli, S.; Carter, A.; Dore, G. Effect of laboratory compaction on the viscoelastic characteristics of an asphalt mix before and after rapid F-T cycles. Cold. Reg. Sci. Technol. 2018, 146, 98–109. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical Specification for Permeable Asphalt Pavement; Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2012. (In Chinese)

- Cheng, Y.C.; Chai, C.; Liang, C.Y.; Chen, Y. Mechanical performance of warm-mixed porous asphalt mixture with steel slag and crumb-rubber-SBS modified bitumen for seasonal frozen regions. Materials 2019, 12, 857. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.C.; Chai, C.; Zhang, Y.W.; Chen, Y.; Zhu, B. A new eco-friendly porous asphalt mixture modified by crumb rubber and basalt fiber. Sustainability 2019, 11, 5754. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; Ministry of Transport of the People’s Republic of China: Beijing, China, 2011. (In Chinese)

- Jiao, Y.B.; Liu, S.Q.; Fu, L.X.; Shan, W.C. Fracture monitoring of SBS and crumb rubber modified porous asphalt mixtures under compression and splitting testing using acoustic emission technique. J. Mater. Civ. Eng. 2019, 31, 12. [Google Scholar] [CrossRef]

- Jiao, Y.B.; Fu, L.X.; Shan, W.C.; Liu, S.Q. Damage fracture characterization of pervious asphalt considering temperature effect based on acoustic emission parameters. Eng. Fract. Mech. 2019, 210, 147–159. [Google Scholar] [CrossRef]

- The British Standards Institution. BS EN 12697-25, Bituminous Mixtures—Test Methods for Hot Mix Asphalt Part 25: Cyclic Compression Test; BSI Standard: London, UK, 2013. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chai, C.; Cheng, Y.-C.; Zhang, Y.; Chen, Y.; Zhu, B. Experimental Study on the Performance Decay of Permeable Asphalt Mixture in Seasonally Frozen Regions under Freeze-Thaw Cycles. Sustainability 2020, 12, 2966. https://doi.org/10.3390/su12072966

Chai C, Cheng Y-C, Zhang Y, Chen Y, Zhu B. Experimental Study on the Performance Decay of Permeable Asphalt Mixture in Seasonally Frozen Regions under Freeze-Thaw Cycles. Sustainability. 2020; 12(7):2966. https://doi.org/10.3390/su12072966

Chicago/Turabian StyleChai, Chao, Yong-Chun Cheng, Yuwei Zhang, Yu Chen, and Bing Zhu. 2020. "Experimental Study on the Performance Decay of Permeable Asphalt Mixture in Seasonally Frozen Regions under Freeze-Thaw Cycles" Sustainability 12, no. 7: 2966. https://doi.org/10.3390/su12072966

APA StyleChai, C., Cheng, Y.-C., Zhang, Y., Chen, Y., & Zhu, B. (2020). Experimental Study on the Performance Decay of Permeable Asphalt Mixture in Seasonally Frozen Regions under Freeze-Thaw Cycles. Sustainability, 12(7), 2966. https://doi.org/10.3390/su12072966