Modeling an Innovative Green Design Method for Sustainable Products

Abstract

1. Introduction

2. Related Works of Green Product Design

2.1. Definitions and Classifications of Green Products

2.2. Green DNAs

2.3. Green Design Methods

2.4. Green Modular and Product Disassembly for Sustainability

3. Methodology

3.1. Extension Theory and Method

3.2. Matter–Element Model

3.2.1. Extendibility of Matter–Element

3.2.2. Basic Matter–Element Transformation

3.2.3. Extension Set

3.3. Green DNAs

3.3.1. Green Technology

3.3.2. Green Material

3.3.3. Green Manufacture

3.4. Innovative Green Design Method

4. A Case Study

4.1. Green Air Purifier Design

- Antibacterial and antiviral function

- Filter PM2.5 and formaldehyde organic substances

- Show and warn about PM2.5 air quality

- Air purification efficiency up to 200 CADR

- Noise is less than 50 decibels

- Filter replacement reminder

- Easy to operate interface.

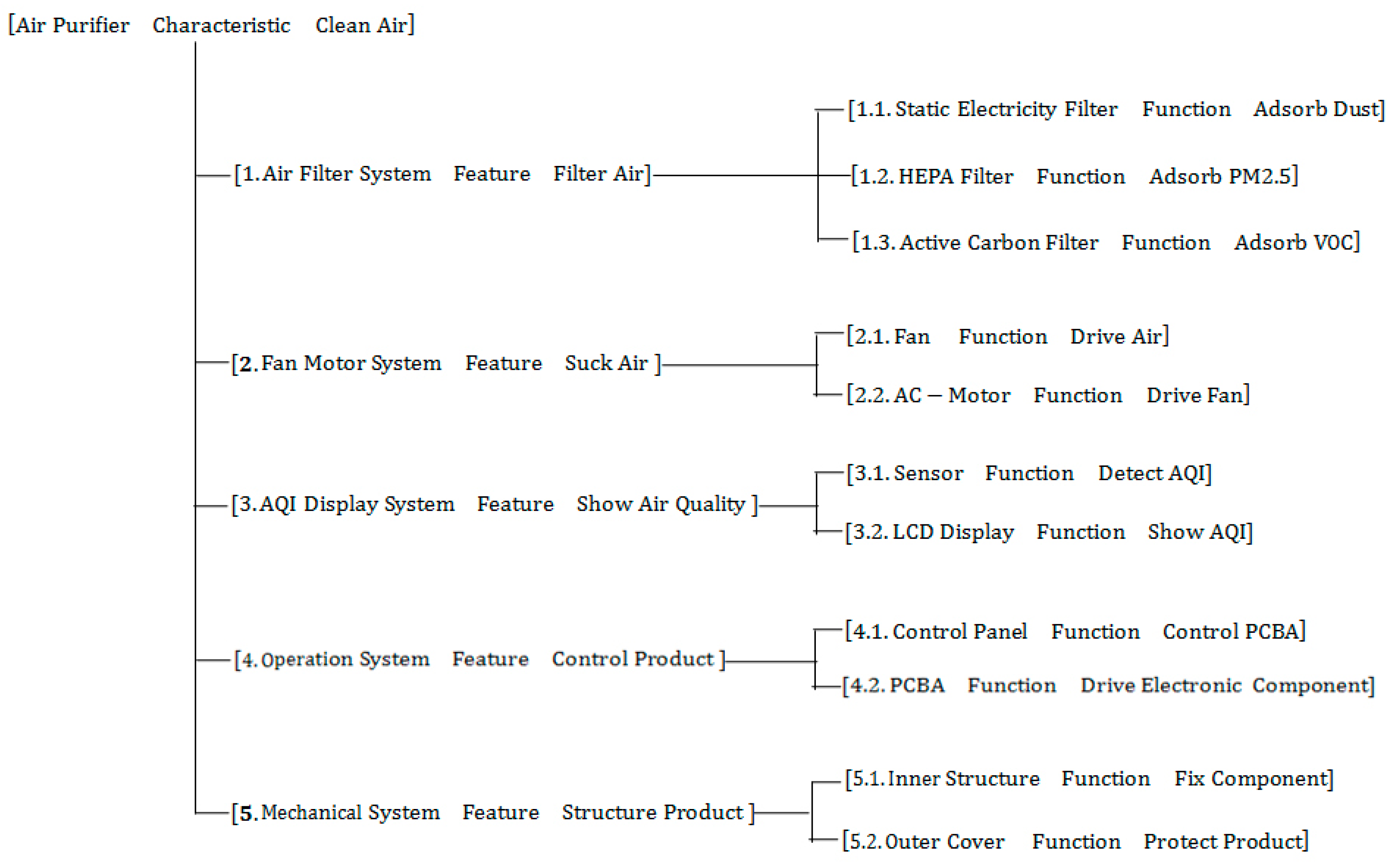

4.2. The Basic Matter–Element Model of the Air Purifier

4.3. The Transformation of the Matter–Element Model of the Air Purifier

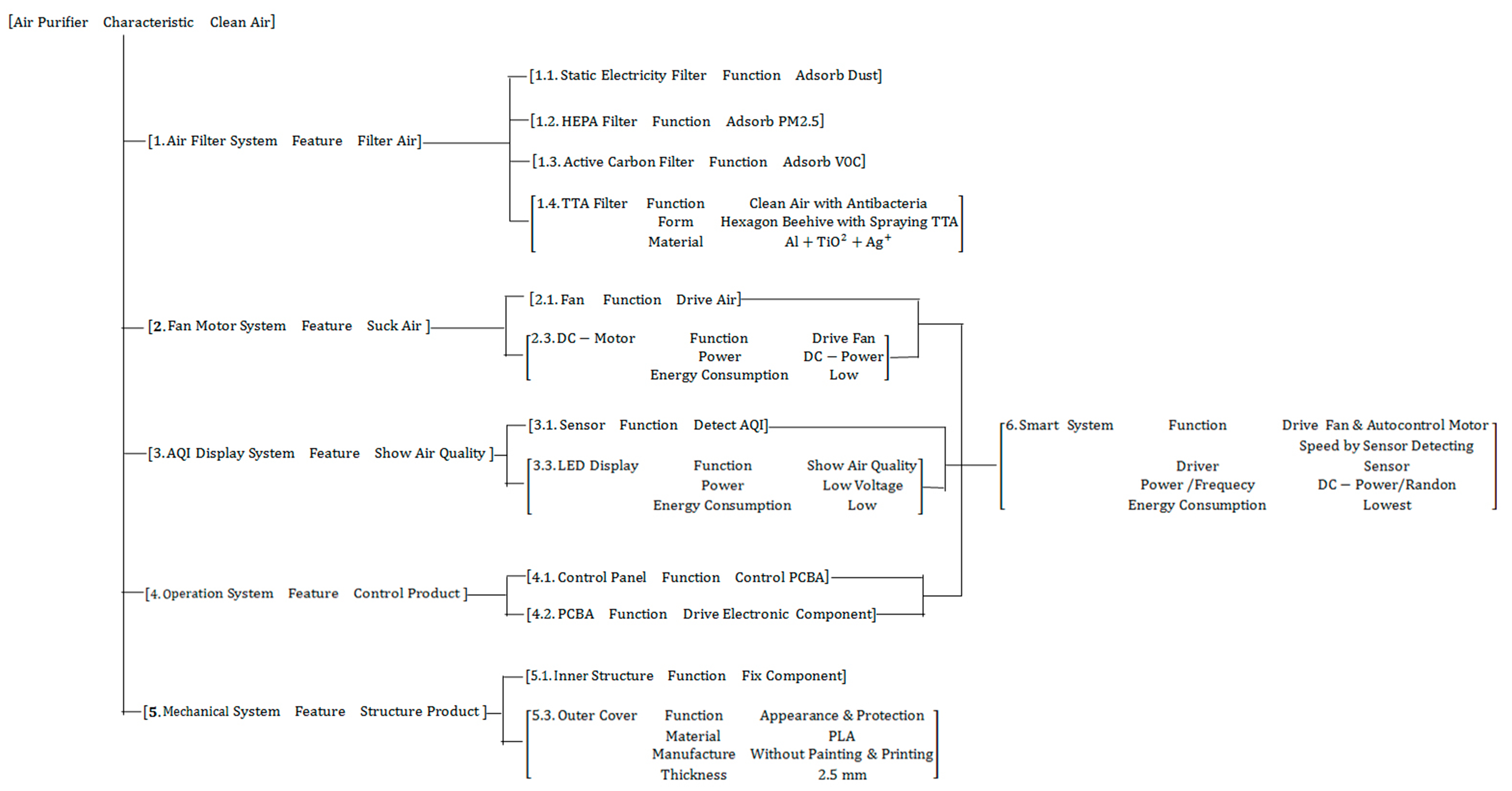

4.3.1. The Transformation of the Matter–Element Model of the Air Purifier System

4.3.2. The Transformation of the Matter–Element Model of the Fan Motor System

4.3.3. The Transformation of the Matter–Element Model of the Detecting and Warning System

4.3.4. The Transformation of the Matter–Element Model of the Appearance Cover System

4.3.5. The New Matter–Element Model of the TTA Air Purifier

4.4. The Practical Product Design of the TTA Air Purifier

5. Results and Discussions

5.1. The Evaluation of Product Functions and Green Features

5.2. The Evaluation of the Green Design Method

6. Conclusions

Supplementary Materials

Supplementary File 1Funding

Conflicts of Interest

References

- Papanek, V.; Lazarus, E.L. Design for the Real World: Human Ecology and Social Change, 2nd ed; Academy Chicago Publishers: Chicago, IL, USA, 2005. [Google Scholar]

- Kurk, F.; Eagan, P. The value of adding design-for-the-environment to pollution prevention assistance options. J. Clean. Prod. 2008, 16, 722–726. [Google Scholar] [CrossRef]

- Gheorghe, R.; Ishii, K. Eco-design value alignment—Keys to success. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Seattle, WA, USA, 11–15 November 2007; Volume15, pp. 267–277. [Google Scholar]

- Tulacz, G.; Traynor, M. The top 100 green design firms. Eng. News Rec. 2008, 260, 116–118. [Google Scholar]

- Zhu, Q.; Sarkis, J. The moderating effects of institutional pressures on emergent green supply chain practices and performance. Int. J. Prod. Res. 2007, 45, 4333–4355. [Google Scholar] [CrossRef]

- Mahmoud-Jouini, S.B.; Midler, C.; Silberzahn, P. Contributions of design thinking to project management in an innovation context. Proj. Manag. J. 2016, 47, 144–156. [Google Scholar] [CrossRef]

- Brown, T. Design thinking. Harv. Bus. Rev. 2008, 86, 84–92. [Google Scholar]

- Brown, T.; Katz, B. Change by design. J. Prod. Innov. Manag. 2011, 28, 381–383. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Bocken, N.M.; Hultink, E.J. Design thinking to enhance the sustainable business modelling process—A workshop based on a value mapping process. J. Clean. Prod. 2016, 135, 1218–1232. [Google Scholar] [CrossRef]

- Shapira, H.; Ketchie, A.; Nehe, M. The integration of design thinking and strategic sustainable development. J. Clean. Prod. 2017, 140, 277–287. [Google Scholar] [CrossRef]

- Cai, W. The extension set and non-compatible problem. Sci. Explor. 1983, 3, 83. (In Chinese) [Google Scholar]

- Gonzalez-Benito, J.; Gonzalez-Benito, O. Operations management practices linked to the adoption of ISO 14001: An empirical analysis of spanish manufacturers. Int. J. Prod. Econ. 2008, 113, 60–73. [Google Scholar] [CrossRef]

- Murillo-Luna, J.L.; Garcés-Ayerbe, C.; Rivera-Torres, P. Why do patterns of environmental response differ? A stakeholders’ pressure approach. Strateg. Manag. J. 2008, 29, 1225–1240. [Google Scholar] [CrossRef]

- Unruh, G.; Ettenson, R. Growing green. Harv. Bus. Rev. 2010, 88, 94–100. [Google Scholar]

- Rehfeld, K.M.; Rennings, K.; Ziegler, A. Integrated product policy and environmental product innovations: An empirical analysis. Ecol. Econ. 2007, 61, 91–100. [Google Scholar] [CrossRef]

- Albino, V.; Balice, A.; Dangelico, R.M. Environmental strategies and green product development: An overview on sustainability-driven companies. Bus. Strategy Environ. 2009, 18, 83–96. [Google Scholar] [CrossRef]

- Chung, Y.; Tsai, C. The effect of green design activities on new product strategies and performance: An empirical study among high-tech companies. Int. J. Manag. 2007, 24, 276–288. [Google Scholar]

- Berchicci, L.; Bodewes, W. Bridging environmental issues with new product development. Bus. Strategy Environ. 2005, 14, 272–285. [Google Scholar] [CrossRef]

- Miller, J.; Szekely, F. What is green? Eur. Manag. J. 1995, 13, 322–333. [Google Scholar] [CrossRef]

- McDonagh, P.; Prothero, A. Green Management: A Reader; The Dryden Press, Harcourt Brace & Company Limited: London, UK, 1996. [Google Scholar]

- Roy, R.; Wield, D.; Gardiner, J.P.; Potter, S. Innovative Product Development; The Open University: Milton Keynes, UK, 1996. [Google Scholar]

- Chen, C. Design for the environment: A quality-based model for green product development. Manag. Sci. 2001, 47, 250–263. [Google Scholar] [CrossRef]

- Commission of the European Communities, Green Paper on Integrated Product Policy. 2001. Available online: http://eur-lex.europa.eu/LexUriServ/site/en/com/2001/com2001_0068en01.pdf (accessed on 10 November 2019).

- Dangelico, R.M.; Pontrandolfo, P. From green product definitions and classifications to the Green Option Matrix. J. Clean. Product. 2010, 18, 1608–1628. [Google Scholar] [CrossRef]

- Pujari, D. Eco-innovation and new product development: Understanding the influences on market performance. Technovation 2006, 26, 76–85. [Google Scholar] [CrossRef]

- Baumann, H.; Boons, F.; Bragd, A. Mapping the green product development field: Engineering, policy and business perspectives. J. Clean. Prod. 2002, 10, 409–425. [Google Scholar] [CrossRef]

- Ottman, J.A.; Stafford, E.R.; Hartman, C.L. Green marketing myopia. Environment 2006, 48, 22–36. [Google Scholar]

- Shrivastava, P. Environmental technologies and competitive advantage. Strateg. Manag. J. 1995, 16, 183–200. [Google Scholar] [CrossRef]

- Kaebernick, H.; Soriano, V. An Approach to Simplified Environmental Assessment by Classification of Products. In Proceedings of the Seventh CIRP International Conference on Life Cycle Engineering, Tokyo, Japan, 27–29 November 2000. [Google Scholar]

- Dewberry, E.; Goggin, P. Spaceship Ecodesign. Co-Design 1996, 5/6, 12–17. [Google Scholar]

- Calza, F.; Parmentola, A.; Tutore, I. Types of green innovations: Ways of implementation in a non-green industry. Sustainability 2017, 9, 1301. [Google Scholar] [CrossRef]

- Ferrer, J.B.; Negny, S.; Robles, G.C.; Le Lann, J.M. Eco-innovative design method for process engineering. Comput. Chem. Eng. 2012, 45, 137–151. [Google Scholar] [CrossRef]

- Bocken, N.; Allwood, J.; Willey, A.; King, J. Development of an eco-ideation tool to identify stepwise greenhouse gas emissions reduction options for consumer goods. J. Clean. Product. 2011, 19, 1279–1287. [Google Scholar] [CrossRef]

- Eastwood, M.D.; Haapala, K.R. A unit process model based methodology to assist product sustainability assessment during design for manufacturing. J. Clean. Prod. 2015, 108, 54–64. [Google Scholar] [CrossRef]

- Livotov, P. Sustainable european collaboration in the field of knowledge-based innovation and inventive problem solving with TRIZ, 1866-4180. J. Eur. Triz Assoc. 2017, 1–3. [Google Scholar]

- Russo, D.; Serafini, M.; Rizzi, C. Is TRIZ an Ecodesign Method? In Sustainable Design and Manufacturing 2016. SDM 2016. Smart Innovation, Systems and Technologies; Setchi, R., Howlett, R., Liu, Y., Theobald, P., Eds.; Springer: Cham, Germany, 2016; Volume 52. [Google Scholar]

- Mann, D. Systematic Sustainable Innovation, Sustainable Innovation 03: Creating sustainable products, services and product-service-system, Towards Sustainable Product Design. In Proceedings of the 8th International Conference, Stockholm, Sweden, 27–28 October 2003. [Google Scholar]

- Wu, Y.H.; Ho, C.C. Integration of green quality function deployment and fuzzy theory: A case study on green mobile phone design. J. Clean. Prod. 2015, 108, 271–280. [Google Scholar] [CrossRef]

- Thankia, S.; Govindanb, K.; Thakkarc, J. An investigation on lean-green implementation practices in Indian SMEs using analytical hierarchy process (AHP) approach. J. Clean. Prod. 2016, 135, 284–298. [Google Scholar] [CrossRef]

- Chen, J.L.; Liu, C.C. An eco-innovative design approach incorporating the TRIZ method without contradiction analysis. J. Sustain. Prod. Des. 2001, 1, 263–272. [Google Scholar] [CrossRef]

- Chen, J.L.; Liu, C.C. Green innovation design of products by TRIZ inventive principles and green evolution rules. In Proceedings of the 2002 International CIRP Design Seminar, Hong Kong, 16–18 May 2002. [Google Scholar]

- Chang, H.T.; Chen, J.L. An Eco-Innovative Design Method Based on Design around Approach. In Proceedings of the Third International Symposium on Environmentally Conscious Design and Inverse Manufacturing, Ecodesign03, Tokyo, Japan, 8–11 December 2003. [Google Scholar]

- Altshuller, G.S. 40 Principles: TRIZ Keys to Technical Innovation; Shulyak, L., Rodman, S., Eds.; Technical Innovation Center: Worcester, MA, USA, 1997. [Google Scholar]

- Altshuller, G.S. Creativity as an Exact Science:The Theory of the Solution Inventive Problems; Gordon and Breach Science Publishing: New York, NY, USA, 1984. [Google Scholar]

- Ishii, K. Product Modularity: A Key Concept in Life-Cycle Design. In Second Annual Symposium on Frontiers of Engineering; National Academy Press: Washington, DC, USA, 1997; pp. 17–24. [Google Scholar]

- Huang, H.H.; Liu, Z.F.; Wang, S.W.; Liu, G.F.; Guo, W.X. Research on methodology of modular design for recycling. Trans. Chin. Soc. Agric. Mach. 2006, 37, 144–149. [Google Scholar]

- Gu, P.; Sosale, S. Product modularization for life cycle engineering. Robot. Comput. Integr. Manuf. 1999, 15, 387–401. [Google Scholar] [CrossRef]

- Umeda, Y.; Fukushige, S.; Tonoike, K.; Kondoh, S. Product modularity for life cycle design. CIRP Ann. Manuf. Technol. 2008, 57, 13–16. [Google Scholar] [CrossRef]

- Tseng, H.E.; Chang, C.C.; Li, J.D. Modular design to support green lifecycle engineering. Expert Syst. Appl. 2008, 34, 2524–2537. [Google Scholar] [CrossRef]

- Smith, S.; Yen, C.C. Green product design through product modularization using atomic theory. Robot. Comput. Integr. Manuf. 2010, 26, 790–798. [Google Scholar] [CrossRef]

- Yi, J.; Ji, B.; Guan, Y.; Dong, J.; Li, C. Research on evaluation methodologies of product life cycle engineering design (LCED) and development of its tools International. J. Comput. Integr. Manuf. 2008, 21, 923–942. [Google Scholar]

- Pnueli, Y.; Zussman, E. Evaluating the end-of-life value of a product and improving it by redesign. Int. J. Prod. Res. 1997, 35, 921–942. [Google Scholar] [CrossRef]

- Seo, K.; Park, J.; Jang, D.; Wallace, D. Approximate estimation of the product life cycle cost using artificial neural networks in conceptual design. Int. J. Adv. Manuf. Technol. 2002, 19, 461–471. [Google Scholar] [CrossRef]

- Xanthopoulos, A.; Iakovou, E. On the optimal design of the disassembly and recovery processes. Waste Manag. 2009, 29, 1702–1711. [Google Scholar] [CrossRef] [PubMed]

- Aguinaga, I.; Borro, D.; Matey, L. Parallel RRT-based path planning for selective disassembly planning. Int. J. Adv. Manuf. Technol. 2008, 36, 1221–1233. [Google Scholar] [CrossRef]

- Kara, S.; Pornprasitpol, P.; Kaebernick, H. Selective disassembly sequencing: A methodology for the disassembly of end-of-life products. Ann. CIRP 2006, 55, 37–40. [Google Scholar] [CrossRef]

- Shyamsundar, N.; Gadh, R. Selective disassembly of virtual prototypes, Proceedings of the IEEE International Conference on Systems, Man and Cybernetics. Inf. Intell. Syst. 1996, 4, 3159–3164. [Google Scholar]

- Cai, W. Matter-Element Analysis; Guangdong Higher Education Publishers: Guangzhou, China, 1987. (In Chinese) [Google Scholar]

- Cai, W. Matter-Element Models and Their Application; Science and Technology Documentation Publishers: Beijing, China, 1994. (In Chinese) [Google Scholar]

- Cai, W. Introduction of Extenics. Syst. Eng. Theory Pract. 1998, 18, 76. (In Chinese) [Google Scholar]

- Cai, W.; Yang, C.; Lin, W. Methods of Extension Engineering; Science Press: Beijing, China, 1997. (In Chinese) [Google Scholar]

- Wang, W.L.; Zhao, Y.W. Research extension decision of mechanical intelligent CAD system. Syst. Eng. Theory Pract. 1998, 18, 114–117. (In Chinese) [Google Scholar]

- Ye, J. Application of extension theory in misfire fault diagnosis of gasoline engines. Expert Syst. Appl. 2009, 36, 1217–1221. [Google Scholar] [CrossRef]

- SGS Report Query Website. 2019. Available online: https://twap.sgs.com/sgssip/Report_Query.aspx (accessed on 20 December 2019).

- Kennet, M.; Heinemann, V. Green Economics: Setting the scene. Aims, context, and philosophical underpinning of the distinctive new solutions offered by Green Economics. J. Green Econ. 2006, 1, 68–102. [Google Scholar] [CrossRef]

- Akao, Y. Quality Function Deployment: Integrating Customer Requirements into Product Design; Productivity Press: Cambridge, MA, USA, 1990. [Google Scholar]

| Test Item | Unit | Control Test | Experiment Test | Elimination Ratio (%) |

|---|---|---|---|---|

| Fine Suspended Particulates (PM2.5) | ug/m3 | 1140 | <1 | >99.9 |

| Total Bacteria Counts | CFU/m3 | 4005 | <6 | >99.9 |

| Formaldehyde | ppm | 0.857 | <0.001 | >99.9 |

| Items | Test Results (Specifications) | Verification |

|---|---|---|

| Rate of air clean | Over 300 CADR (200 CADR) | PASS |

| Clean function | 1. PM 2.5 elimination ratio: >99.9% 2. Bacteria elimination ratio: >99.9% 3. Formaldehyde elimination ratio: >99.9% | PASS (SGS Reports) |

| Detecting function | Auto detect PM2.5 and display the data | PASS |

| Warming function | Auto warn PM2.5: show AQI by different color | PASS |

| Air volume | Three modes: low/medium/high | PASS |

| Timer function | Three modes: 1 h/4 h/8 h | PASS |

| Noise | Under 40 decibel (50 decibel) | PASS |

| Power consumption | Under 65 watt/h (150 watt/h) | PASS |

| Outer cover thickness | 2.5 mm (3 mm) | PASS |

| Item | Feasibility | Efficiency | Design Solution Generation |

|---|---|---|---|

| Proposed Method | ○ | ○ | X |

| QFD Method | ○ | △ | X |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ko, Y.-T. Modeling an Innovative Green Design Method for Sustainable Products. Sustainability 2020, 12, 3351. https://doi.org/10.3390/su12083351

Ko Y-T. Modeling an Innovative Green Design Method for Sustainable Products. Sustainability. 2020; 12(8):3351. https://doi.org/10.3390/su12083351

Chicago/Turabian StyleKo, Yao-Tsung. 2020. "Modeling an Innovative Green Design Method for Sustainable Products" Sustainability 12, no. 8: 3351. https://doi.org/10.3390/su12083351

APA StyleKo, Y.-T. (2020). Modeling an Innovative Green Design Method for Sustainable Products. Sustainability, 12(8), 3351. https://doi.org/10.3390/su12083351