Development and Application of Precast Concrete Double Wall System to Improve Productivity of Retaining Wall Construction

Abstract

1. Introduction

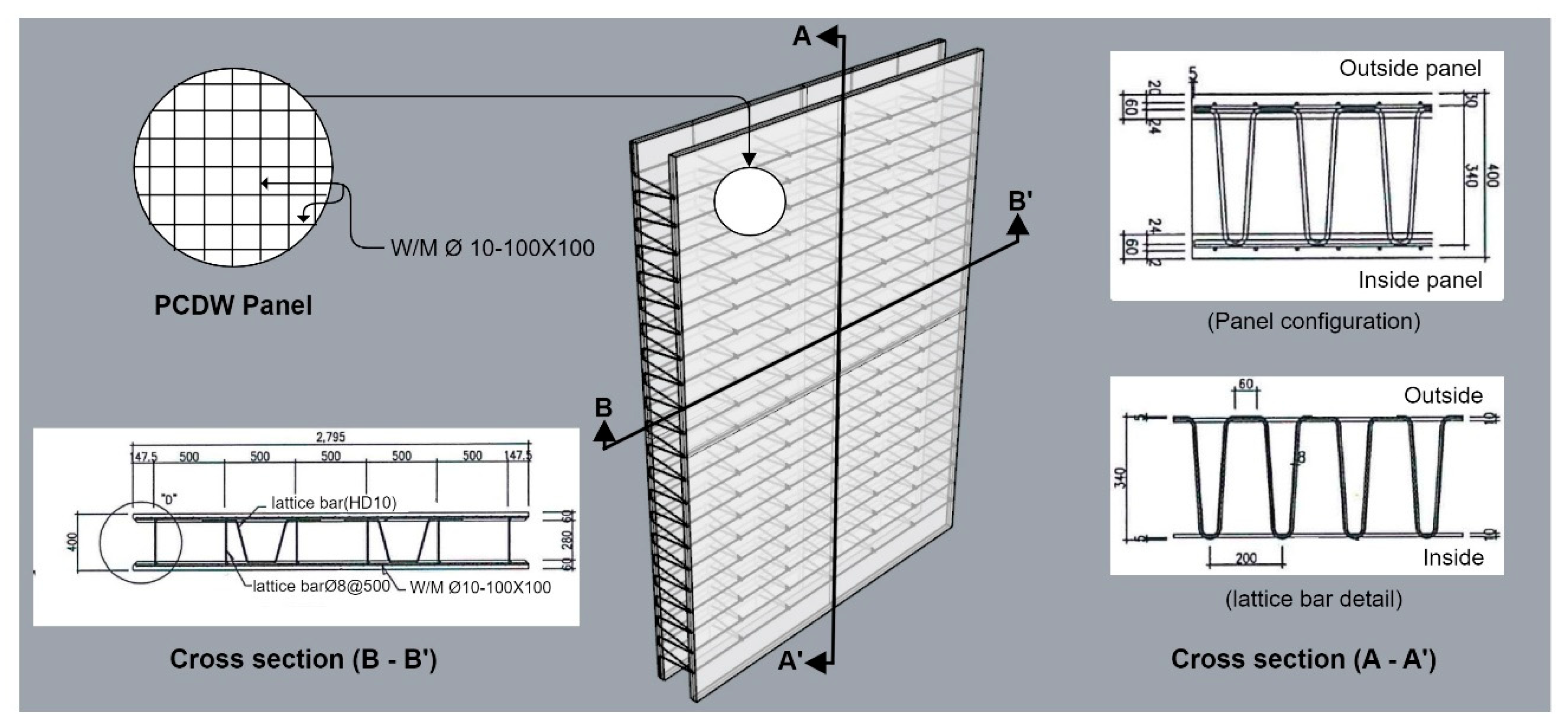

2. Development of Precast Concrete Double Wall System

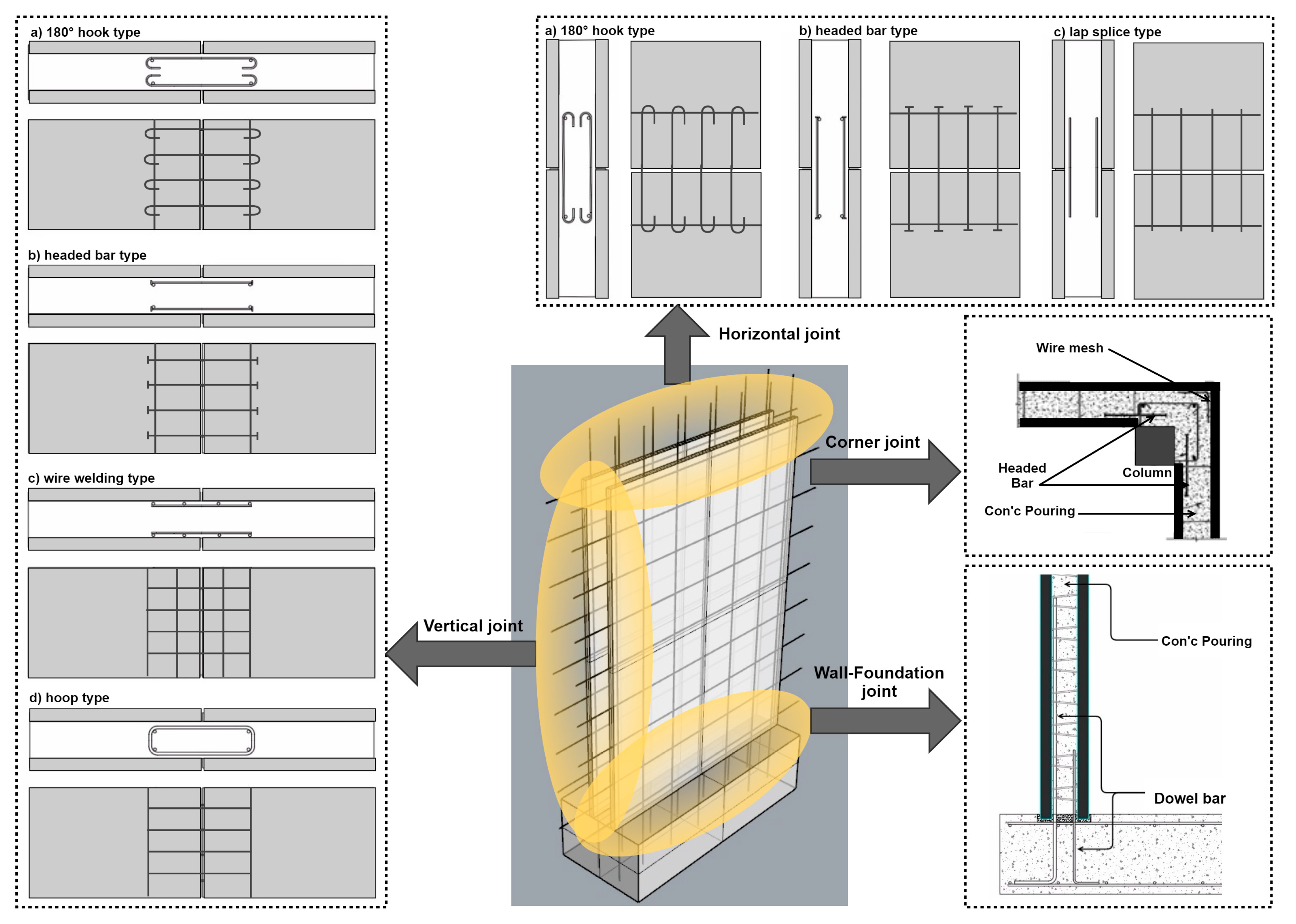

2.1. Securing the Integrity of PCDW Joints

2.2. PCDW Joint Configuration

2.3. Headed Bar Performance Evaluation

3. PCDW Design through the Examination of Lateral Pressure and Bending

3.1. PCDW Member Design

3.2. Examination of Lpressure and Bending

4. Field Application of the PCDW System

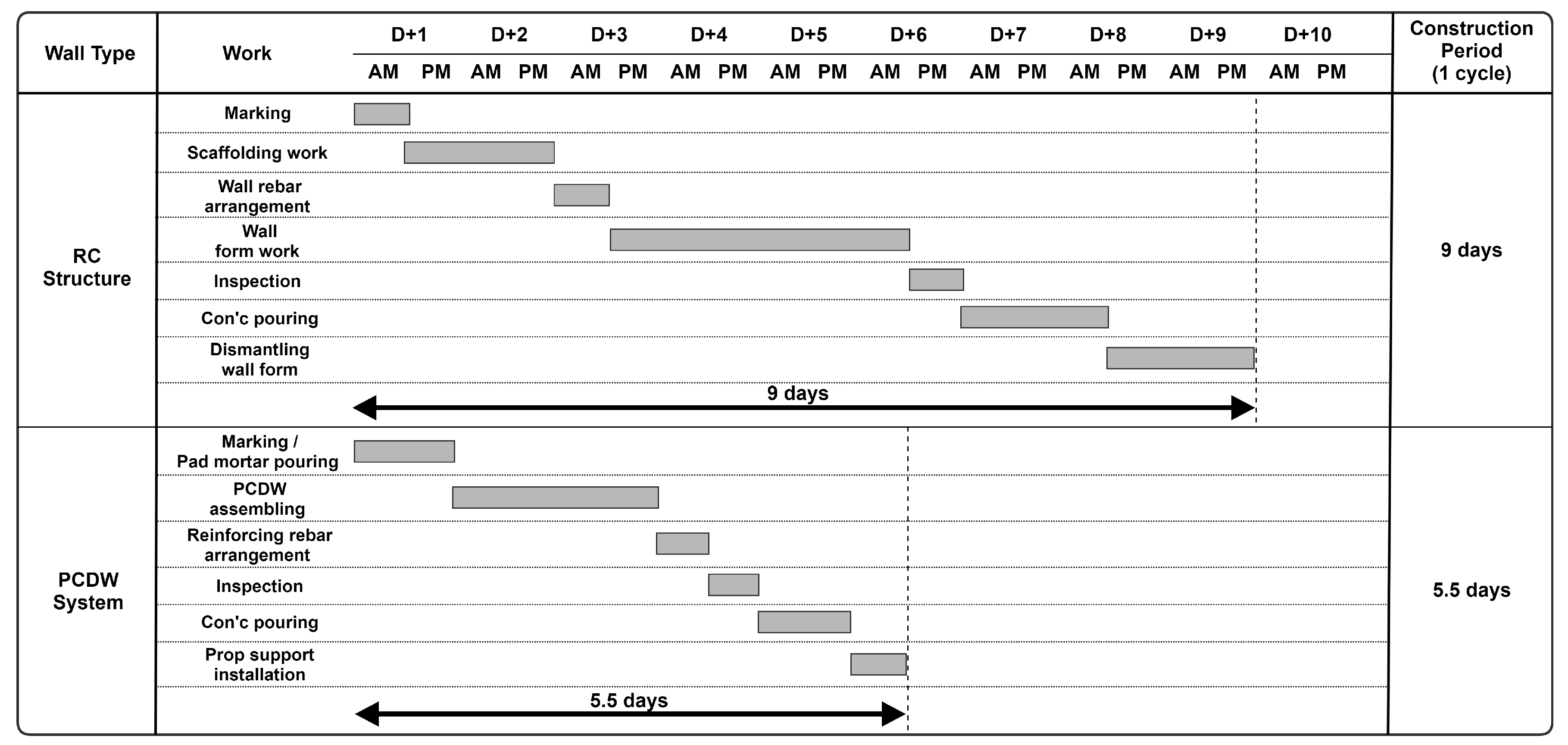

4.1. PCDW Construction Sequence

- Before the installation of PCDW, foundation rebars and the anchorage rebars of PCDW are placed and the recess metal lath for pad mortar pouring are installed at the top for accurate connection between PCDW and the foundation. In this case, the cover thickness of the upper part of the foundation must be approximately 50 mm.

- Two liner shims are installed on the floor per PCDW system. After examination of the liner shim level, pad mortar is applied in two rows and PCDW is installed on top of them.

- After the assembly of PCDW, its vertical state is examined using an inclinometer. Two or more prop supports are firmly installed to prevent any gaps or misalignment.

- After inspection of the assembly state, the reinforced state, and the installation of the other parts, concrete is poured in the PCDW void. Before concrete pouring, the inside is cleaned to remove foreign substances, and water is sprayed to keep the inside wet. In addition, compaction is performed using a rod-type vibrator or a form vibrator to prevent poor-compacted concrete, and then PCDW is assembled and prop supports are installed. After the assembly of the PCDW system, the assembly accuracy is inspected. Table 2 shows the inspection methods and the judgment criterion.

4.2. Analysis of the Effect of PCDW System Application

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kim, S.Y.; Lee, B.S.; Park, K.Y.; Lee, S.B.; Yoon, Y.H. Foreign parking structures and practical using method of PC system for the domestic underground parking structures. Mag. Korea Concr. Inst. 2008, 20, 34–40. [Google Scholar] [CrossRef]

- Hwang, J.H. Development of Integrated Management Process for Precast Concrete Construction Method based on BIM. Master’s Thesis, School of Urban Science, University of Seoul, Seoul, Korea, 2019. [Google Scholar]

- Qin, Y.; Shu, G.P.; Zhou, G.G.; Han, J.H. Compressive behavior of double skin composite wall with different plate thicknesses. J. Constr. Steel Res. 2017, 157, 297–313. [Google Scholar] [CrossRef]

- Chai, S.; Guo, T.; Chen, Z.; Jun, Y. Monitoring and simulation of long-term performance of precast concrete segmental box girders with dry joints. J. Bridge Eng. 2019, 24, 04019043. [Google Scholar] [CrossRef]

- Park, J.H.; Choi, J.W.; Jang, Y.J.; Park, S.K.; Hong, S.N. An experimental and analytical study on the deflection behavior of precast concrete beams with joints. Appl. Sci. 2017, 7, 1198. [Google Scholar] [CrossRef]

- Chen, S.; Feng, K.; Lu, W. A Simulation-Based optimisation for contractors in precast concrete projects. In 10th Nordic Conference on Construction Economics and Organization; Emerald Publishing Limited: Bingley, UK, 2019; Volume 2, pp. 137–145. [Google Scholar] [CrossRef]

- Zhai, X.; Reed, R.; Mills, A. Factors impeding the offsite production of housing construction in China: An investigation of current practice. Constr. Manag. Econ. 2014, 32, 40–52. [Google Scholar] [CrossRef]

- Ahmad, S.; Soetanto, R.; Goodier, C.I. Lean approach in precast concrete component production. Built Environ. Proj. Asset Manag. 2019, 9, 457–470. [Google Scholar] [CrossRef]

- Kang, T.S. Precast concrete construction of SAMPYO engineering & construction LTD, R&D institute. Mag. Korea Concr. Inst. 2019, 25, 46–49. [Google Scholar]

- Kim, S.Y.; Yoon, Y.H.; Park, K.Y.; Lee, B.S.; PC Council. A Research for Practical Using Method of PC Structural System for the Underground Parking Garage in an Apartment Housing Site. Korea National Housing Corporation Housing & Urban Research Institute. 2006. Available online: https://dl.nanet.go.kr/SearchDetailView.do?cn=MONO1200827476 (accessed on 9 April 2020).

- Kim, H.D.; Lee, S.S.; Park, K.S.; Bae, K.W. A study on plant certification program for precast concrete products. KSMI 2014, 18, 131–138. [Google Scholar] [CrossRef][Green Version]

- Augusto, T.; Mounir, K.; Melo, A.M. A cost optimization-based design of precast concrete floors using genetic algorithms. Autom. Constr. 2012, 22, 348–356. [Google Scholar] [CrossRef]

- Castilho, V.C.; Lima, M.C.V. Comparative costs of the production, transport and assembly stages of prestressed precast slabs using genetic algorithms. IJOCE 2012, 2, 407–422. [Google Scholar]

- Ko, C.H. Material transshipment for precast fabrication. J. Constr. Eng. Manag. 2013, 19, 335–347. [Google Scholar] [CrossRef]

- Sacks, R.; Eastman, C.M.; Lee, G. Parametric 3D modeling in building construction with examples from precast concrete. Autom. Constr. 2004, 13, 291–312. [Google Scholar] [CrossRef]

- Suh, J.I.; Park, H.G.; Hwang, H.J.; Im, J.H.; Kim, Y.N. Development of PC double wall for staircase construction. J. Korea Inst. Build. Constr. 2014, 14, 571–581. [Google Scholar] [CrossRef][Green Version]

- Ji, K.H.; Choi, B.J. Improvement of Underground Wall Design and Construction Safety Using Mega Double Wall Construction Method. J. Korean Soc. Hazard Mitig. 2019, 19, 1–12. [Google Scholar] [CrossRef]

- Park, K.M. A Study on the Production and Construction of Precast Concrete Walls. Master’s Thesis, Kyonggi University, Suwon, Korea, 2017. [Google Scholar]

- Oh, S.Y.; Hong, S.Y.; Park, K.M. A study on the site work of precast concrete double composite wall. Proc. Korea Concr. Inst. 2017, 29, 407–408. [Google Scholar]

- Yang, H.M.; Han, S.J.; Lee, S.H.; Choi, S.H.; Chung, J.H.; Kim, K.S. Out of plane behavior of double composite PC walls. Proc. Korea Concr. Inst. 2018, 30, 149–150. [Google Scholar]

- Kim, J.S.; Jung, J.W.; Lee, K.H.; Ahn, J.M. Recent domestic precast concrete slab technologies. Mag. Korea Concr. Inst. 2004, 16, 16–19. [Google Scholar] [CrossRef]

- Seo, S.Y.; Yoon, S.J.; Lee, W.J. Evaluation of structural performance the hollow PC column joint subjected to cyclic lateral load. J. Korea Concr. Inst. 2008, 20, 335–343. [Google Scholar] [CrossRef]

- Roh, H.S.; Hashlamon, I.H. Hysteretic model and seismic response of partial precast concrete piers with cast-in-place for base and outside of hollow cross section. Proc. Korea Concr. Inst. 2016, 28, 123–124. Available online: http://www.riss.kr/link?id=A101902151 (accessed on 9 April 2020).

- Kim, T.H.; Kang, H.T. Seismic performance assessment of hollow circular reinforced concrete bridge columns with confinement steel. J. Earthq. Eng. Soc. Korea 2012, 16, 13–25. [Google Scholar] [CrossRef]

| Basic Data of Specimen | fck (MPa) | fy (MPa) | hef (mm) | D (mm) | A (mm) | Additional Information |

|---|---|---|---|---|---|---|

| 44.7 | 516 | 210 | 30 | 127 | ||

| (kN) | Yield strength of the headed bar | |||||

| (kN) | Rupture Strength of the headed bar | |||||

| (kN) | Concrete Cone Breakout | |||||

| specimen-1 | 73.3 | (kN) | yield and fracture | |||

| specimen-2 | 73.6 | (kN) | yield and fracture | |||

| specimen-3 | 77.6 | (kN) | yield and fracture | |||

| specimen-4 | 68.2 | (kN) | yield and fracture | |||

| specimen-5 | 76.1 | (kN) | yield and fracture | |||

| specimen-6 | 74.9 | (kN) | yield and fracture | |||

| specimen-7 | 73.6 | (kN) | yield and fracture | |||

| specimen-8 | 71.4 | (kN) | yield and fracture | |||

| specimen-9 | 70.7 | (kN) | yield and fracture | |||

| specimen-10 | 78.7 | (kN) | yield and fracture | |||

| Overall average | 73.8 | (kN) | ||||

| Standard deviation | 3.2 | (kN) | ||||

| Coefficient of variation | 4.3 | (%) | ||||

| Category | Test Method | Frequency | Judgment Criterion | |

|---|---|---|---|---|

| PCDW system | Installation position | The difference from the reference line marked on the floor is measured using a steel ruler | After assembly | ±5 mm or less |

| Inclination | Measured using a plumb or a slope scale | |||

| Ceiling height | Measured using a level | |||

| Category | RC | PCDW | Remark |

|---|---|---|---|

| Construction cost | 100% | 99% | 1% reduction |

| Construction/ safety | - Formwork for concrete pouring requires a considerable amount of time - Work safety must be examined for pouring | - Site work can be simplified without formwork - Construction safety can be secured without external scaffold and temporary facilities | |

| Construction period | 100% | 60% | 40% reduction |

| Quality | - Quality significantly varies depending on the type and condition of formwork | - Factory production ensures excellent quality | |

| Others | - No lifting equipment required - Easy connection to the bottom wall rebars - Labor-intensive structure, lack of skilled workers - Highly difficult formwork | - Eco-friendly because of on-site waste reduction - Member size limited by the transport and lifting conditions - Constructible regardless of the climate - Increased durability due to steam curing |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Lee, D.-E.; Kim, Y.; Kim, S. Development and Application of Precast Concrete Double Wall System to Improve Productivity of Retaining Wall Construction. Sustainability 2020, 12, 3454. https://doi.org/10.3390/su12083454

Kim S, Lee D-E, Kim Y, Kim S. Development and Application of Precast Concrete Double Wall System to Improve Productivity of Retaining Wall Construction. Sustainability. 2020; 12(8):3454. https://doi.org/10.3390/su12083454

Chicago/Turabian StyleKim, Seungho, Dong-Eun Lee, Yonggu Kim, and Sangyong Kim. 2020. "Development and Application of Precast Concrete Double Wall System to Improve Productivity of Retaining Wall Construction" Sustainability 12, no. 8: 3454. https://doi.org/10.3390/su12083454

APA StyleKim, S., Lee, D.-E., Kim, Y., & Kim, S. (2020). Development and Application of Precast Concrete Double Wall System to Improve Productivity of Retaining Wall Construction. Sustainability, 12(8), 3454. https://doi.org/10.3390/su12083454