The Durability of One-Part Alkali-Activated Slag-Based Mortars in Different Environments

Abstract

1. Introduction

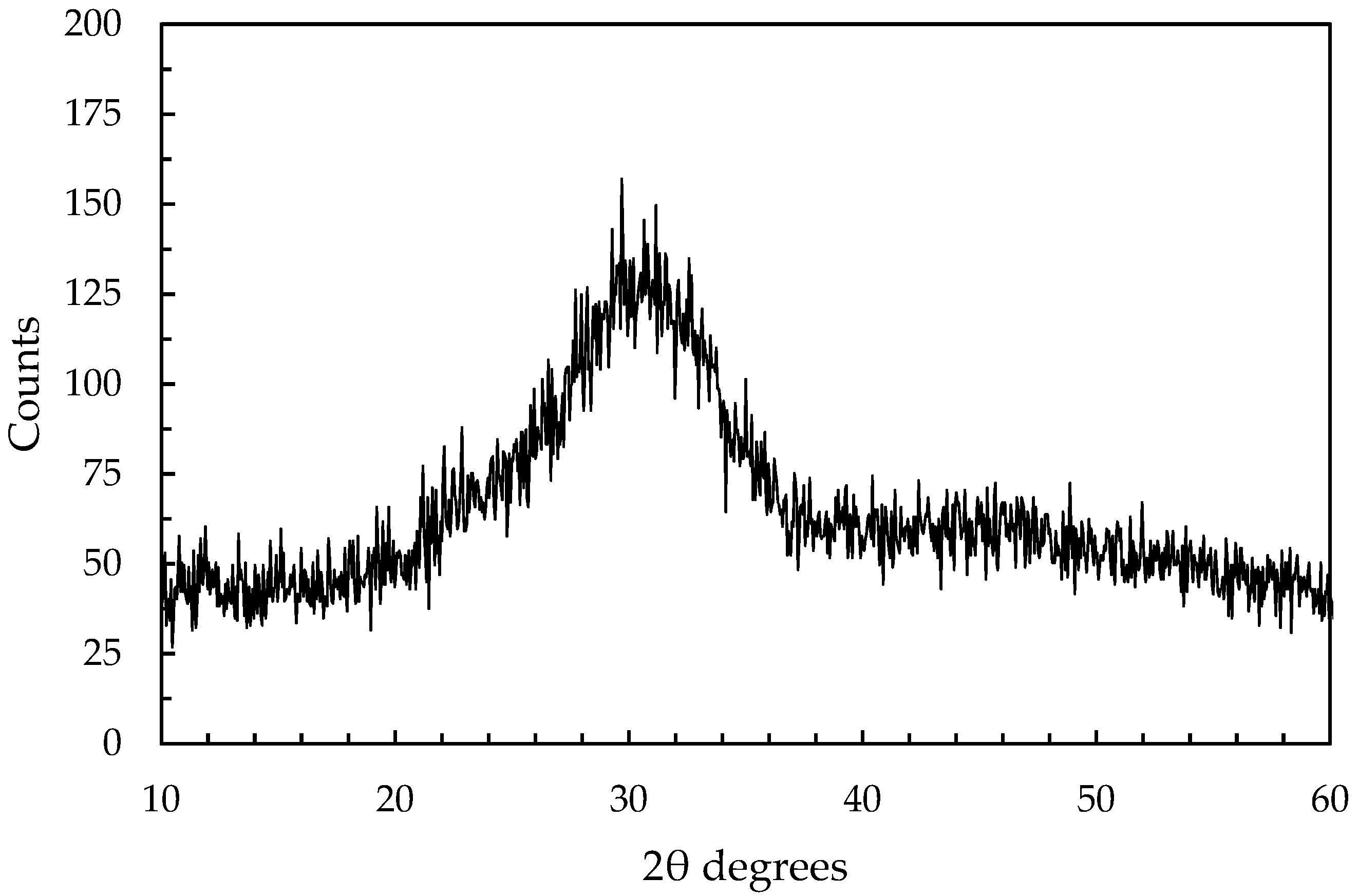

2. Materials

3. Mixture, Preparation and Samples Curing

- (i)

- GGBFS, alkali activator in solid form and tap water are placed into the steel bowl;

- (ii)

- The mixer starts at low speed (140 rpm for the revolving action, 62 rpm for the planetary action) for 30 s;

- (iii)

- The mixing proceeds at high speed (285 rpm for the revolving action, 125 rpm for the planetary action) for 60 s;

- (iv)

- The mixture rests for 90 s;

- (v)

- The mixer completes the procedure with further 60 s at high speed.

4. Experimental Methods

4.1. Fresh State and Elasto-Mechanical Properties

4.2. Freezing and Thawing Resistance

4.3. Calcium Chloride Resistance

4.4. Magnesium Sulphate Attack Resistance

5. Results and Discussion

5.1. Fresh State and Elasto-Mechanical Properties

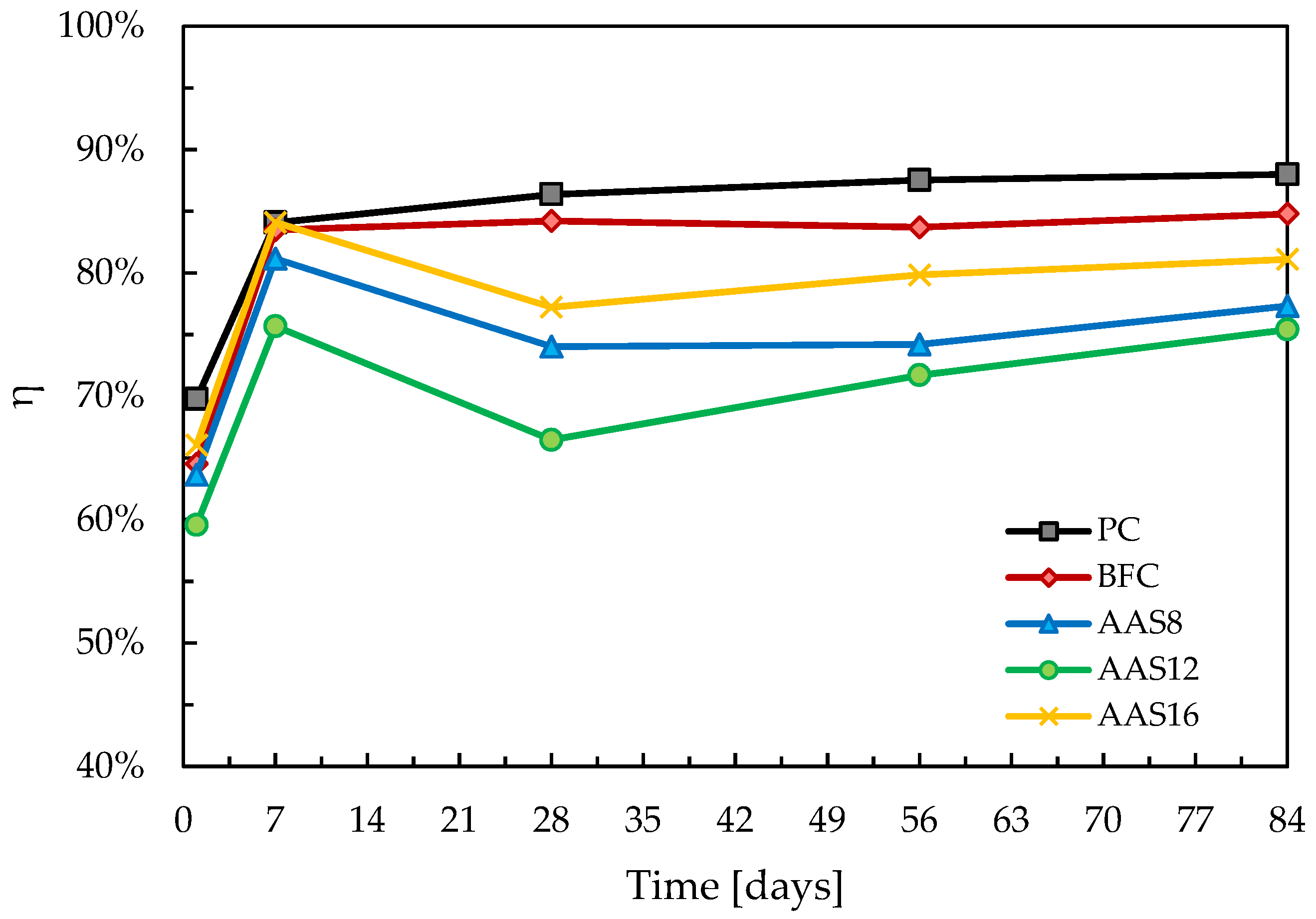

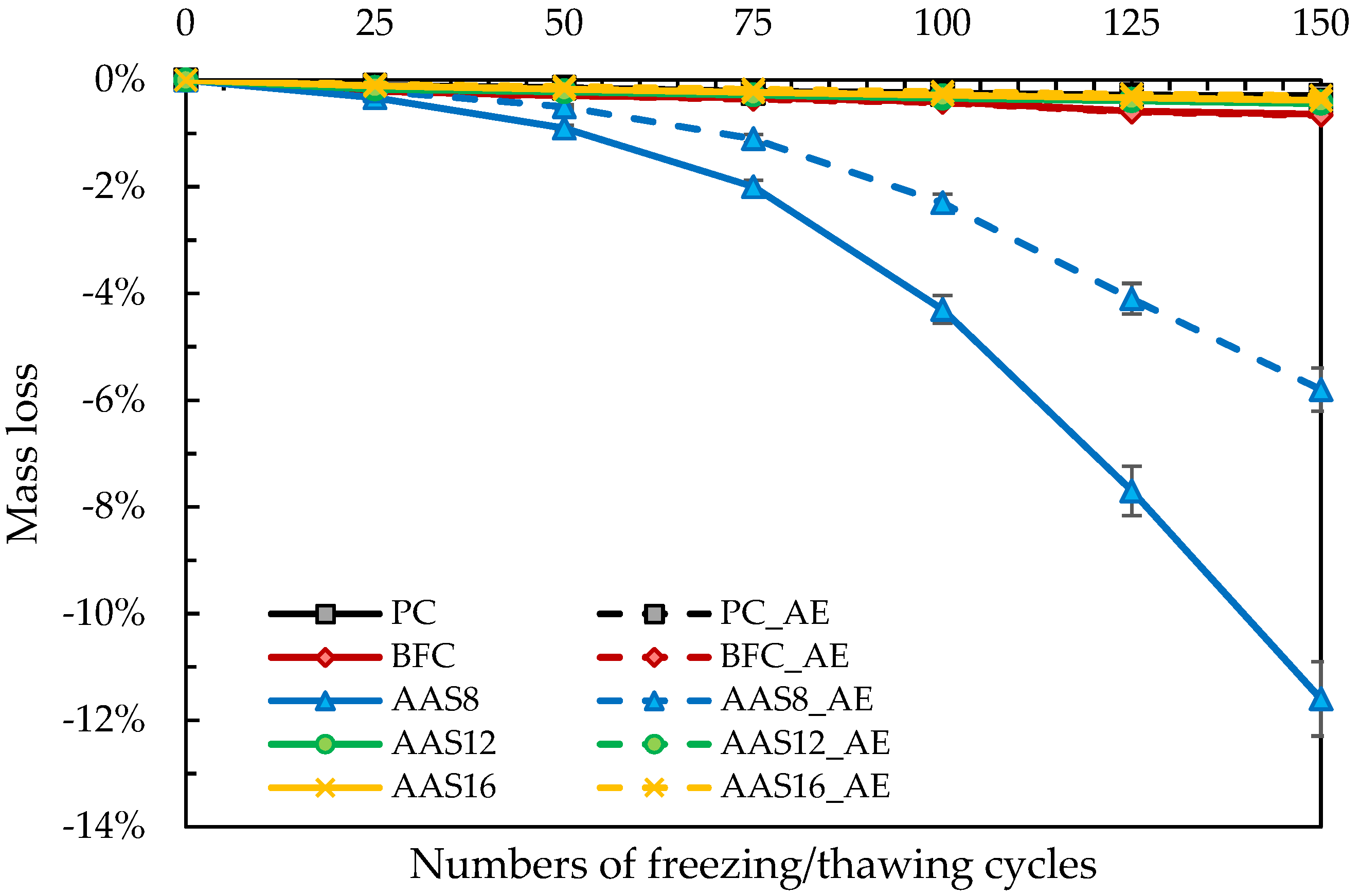

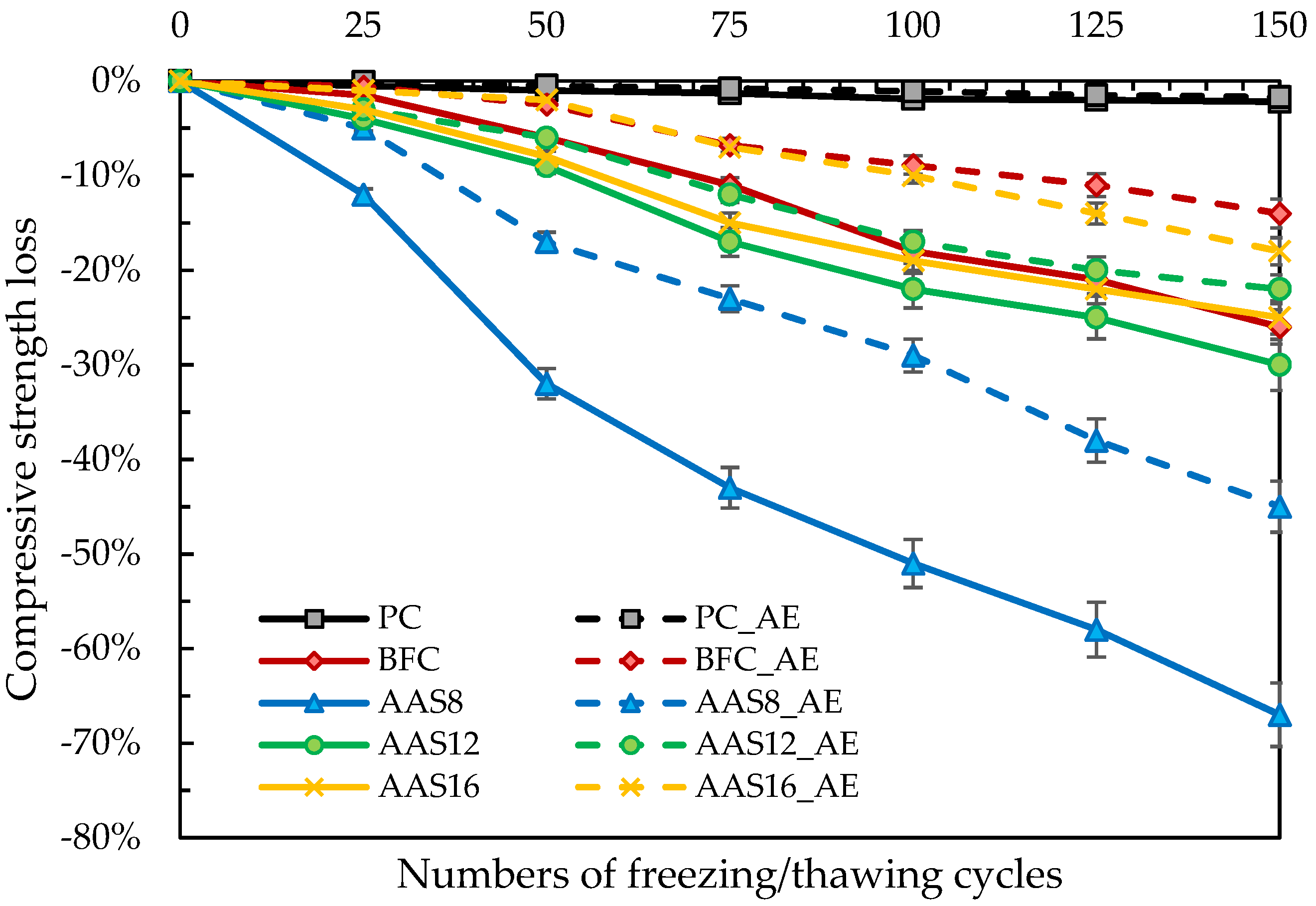

5.2. Freezing and Thawing Resistance

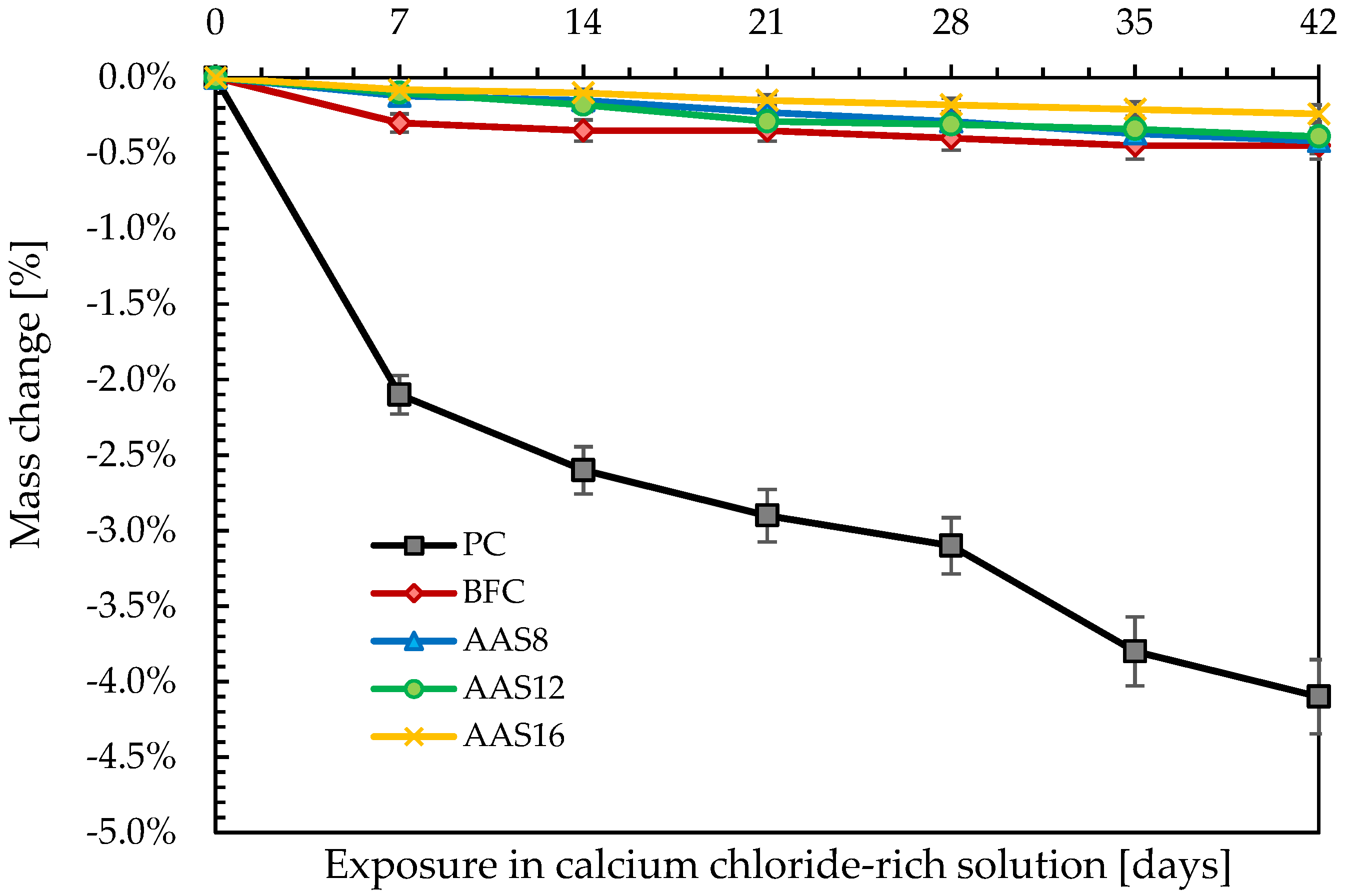

5.3. Calcium Chloride Resistance

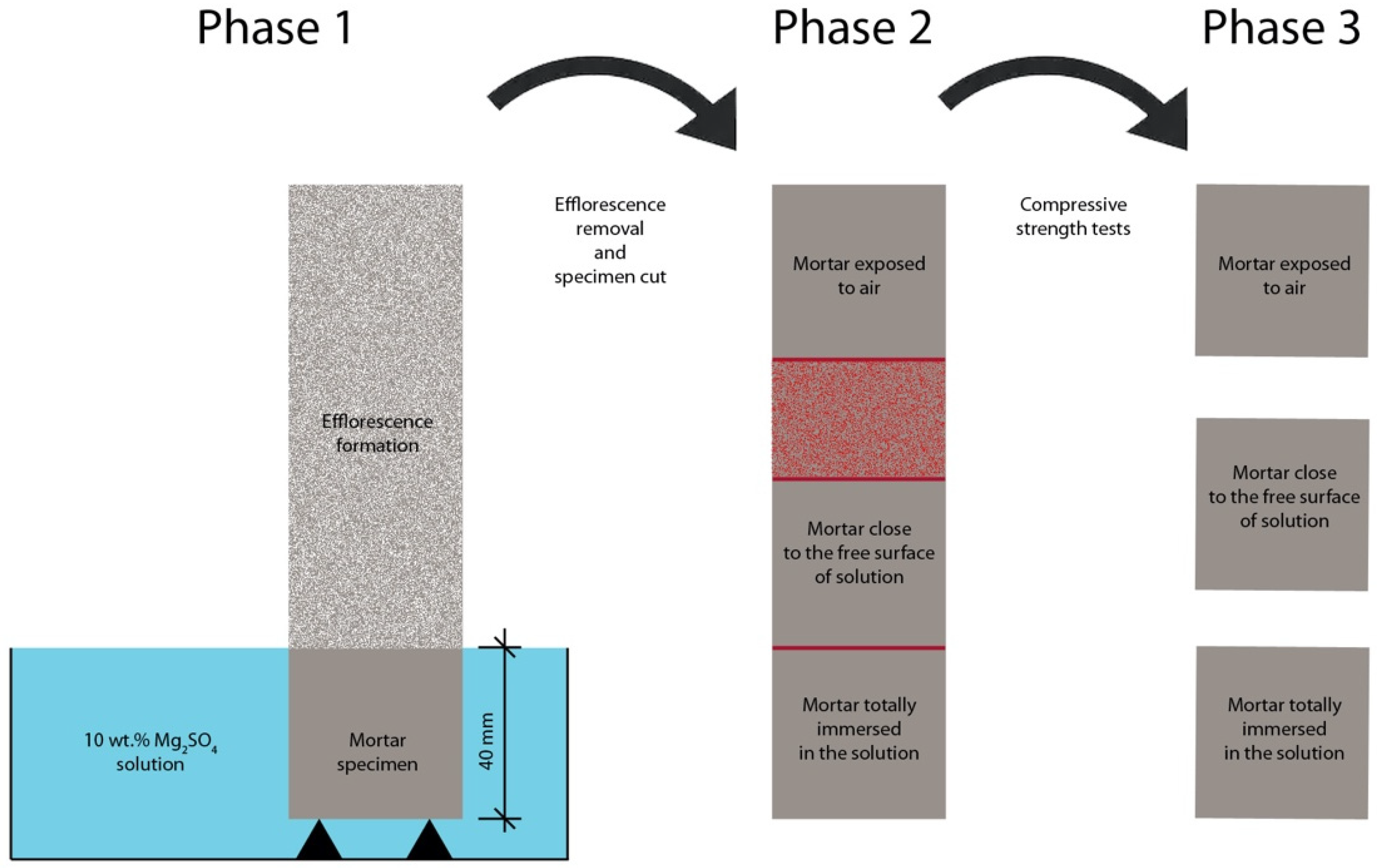

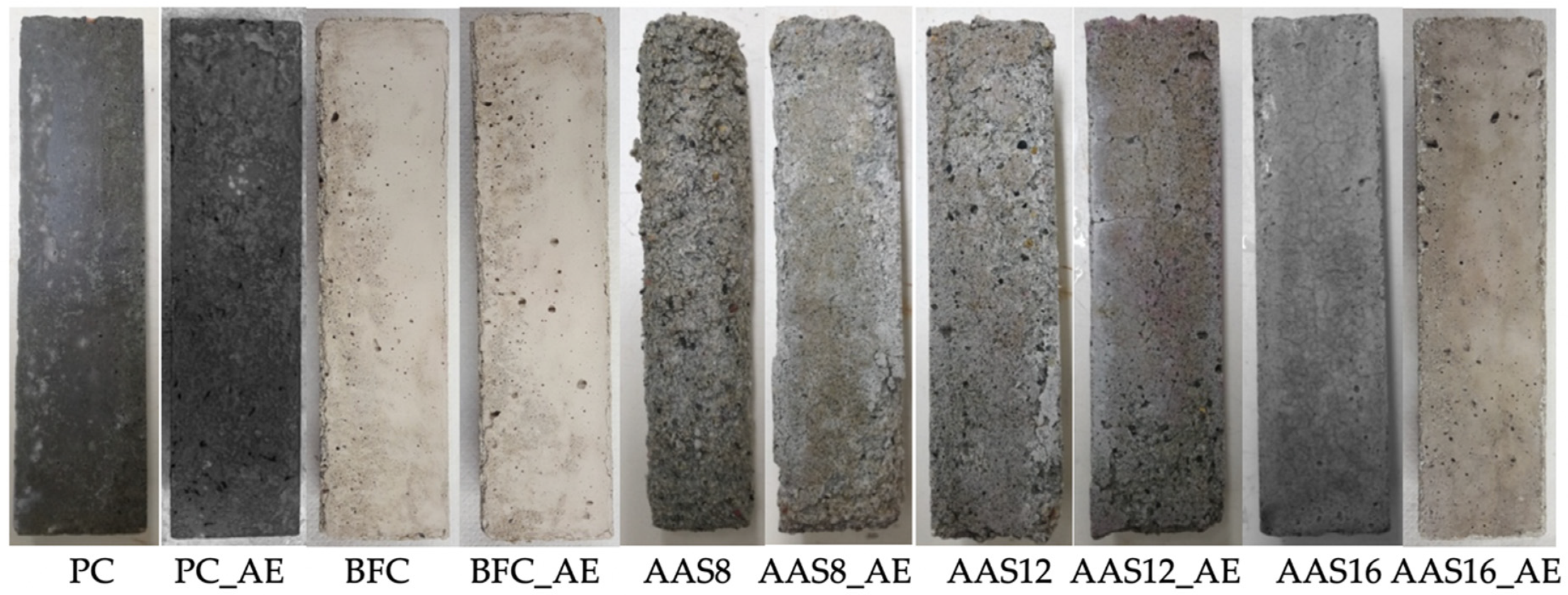

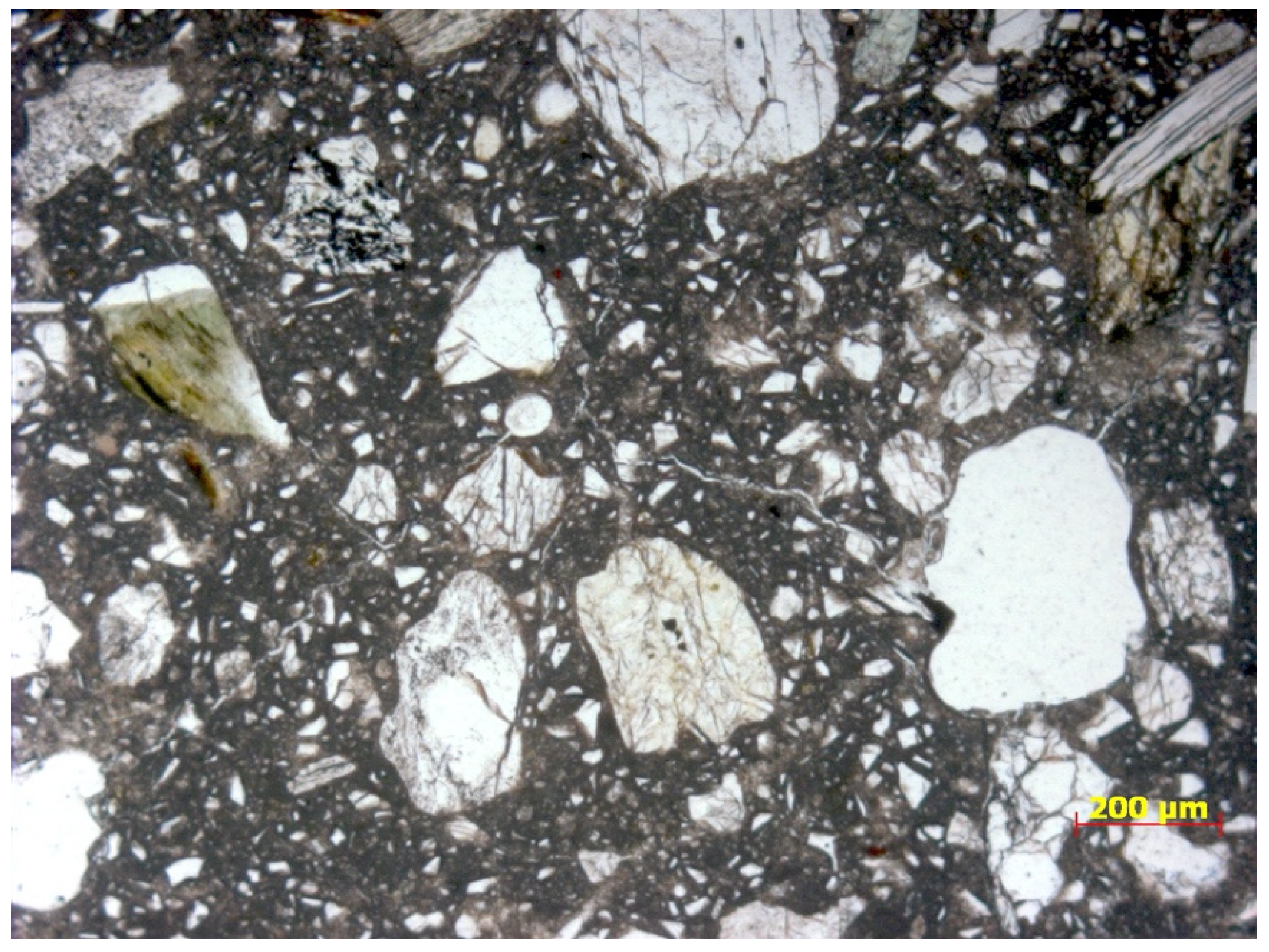

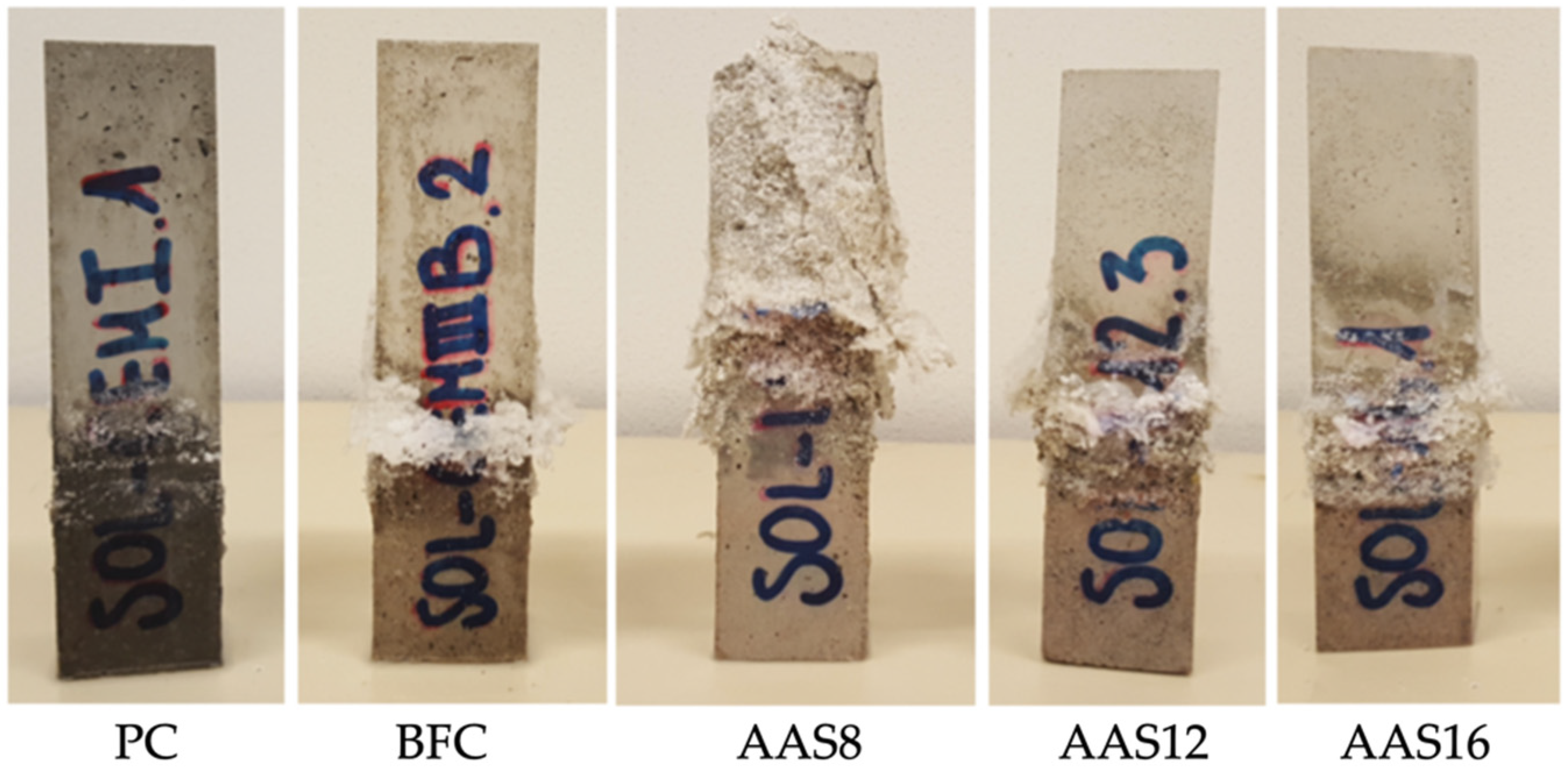

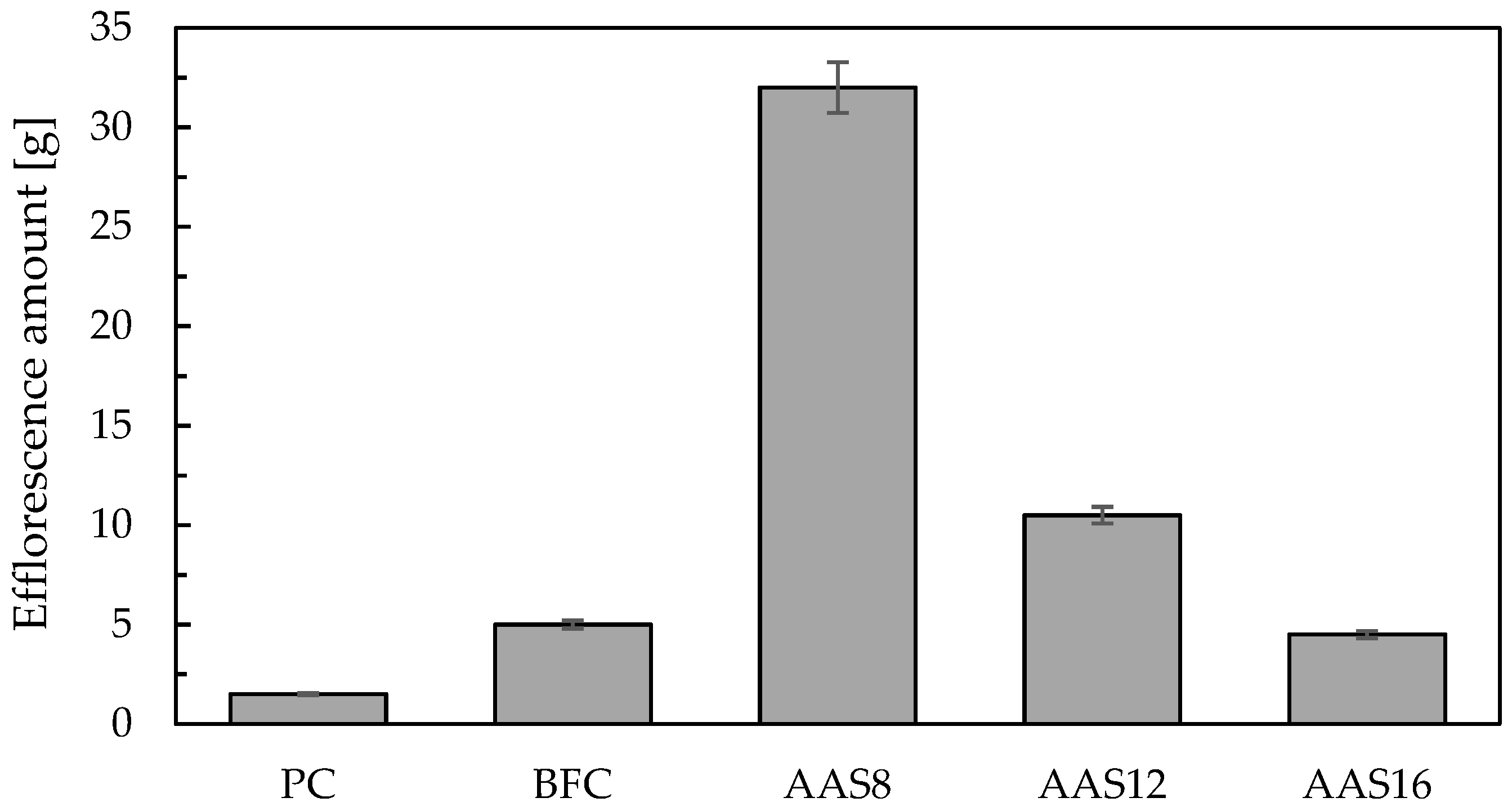

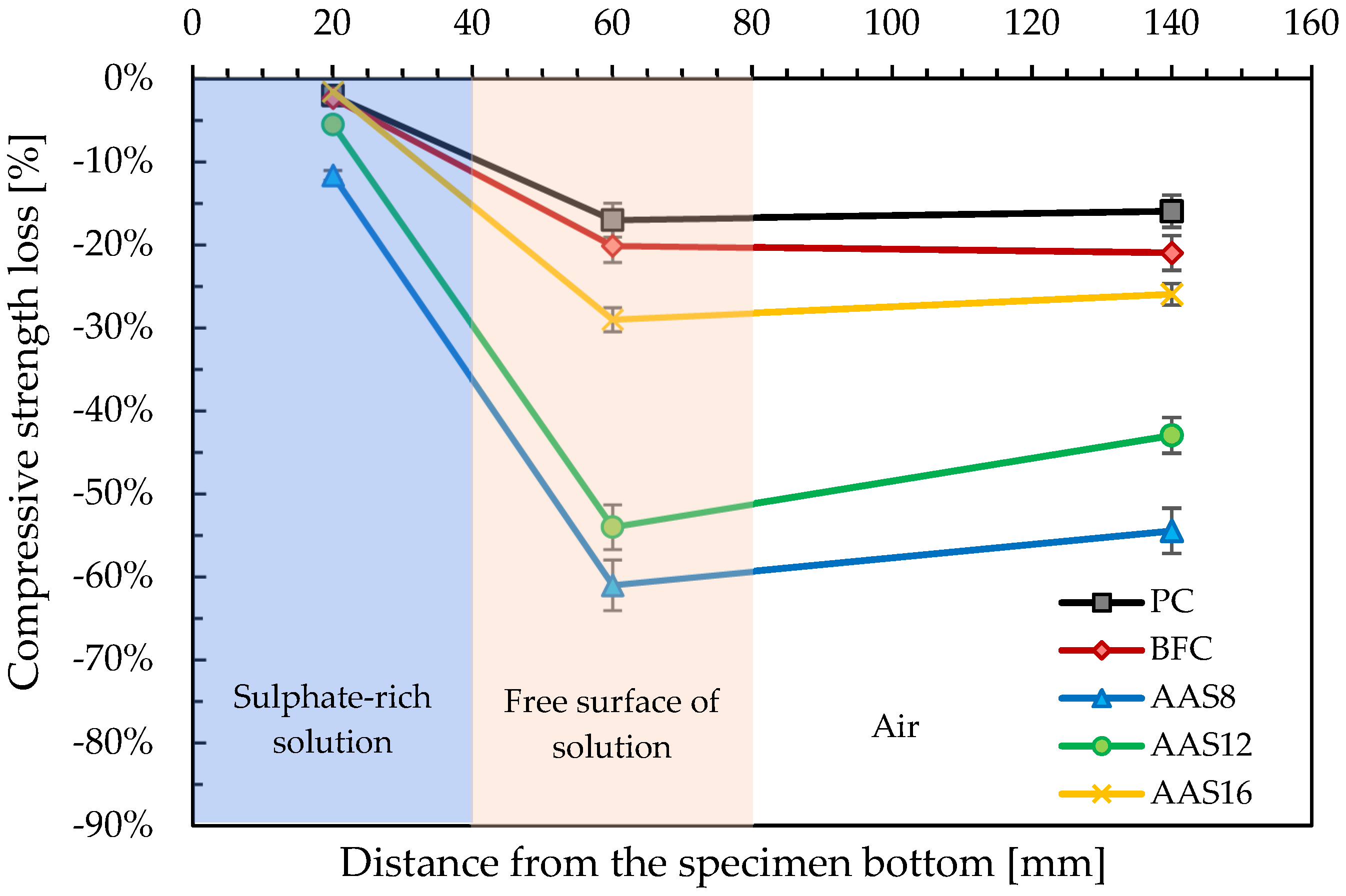

5.4. Magnesium Sulphate Attack Resistance

6. Conclusions

- The alkali content plays a crucial role both in elasto-mechanical properties and in durability performances of alkali-activated materials. In general, the higher the alkali content, the higher the strength and the resistance in severe conditions;

- High-alkali content AAS mortars evidenced a freeze–thaw resistance similar to that of BFC mortars but lower than that of PC—probably due to the different compactness of AAS matrix respect to Portland cement mortars at equal water content. On the contrary, AAS manufactured with low dosages of activators are characterized by a very limited resistance in cold environments;

- The use of AEA enhances the freezing and thawing resistance of alkali-activated slag-based mortars without any strong reduction in compressive strength;

- Similarly to BFC, alkali-activated mixtures are quasi-immune to expansive calcium oxychloride formation in presence of CaCl2-based deicing salts due to the negligible calcium hydroxide content;

- Alkali-activated slag-based mortars suffer from severe damages and high strength loss as a consequence of semi-immersion in 10 wt.% Mg2SO4 solution due to decalcification of C-S-H gel and gypsum formation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Coppola, L.; Coffetti, D.; Crotti, E.; Gazzaniga, G.; Pastore, T. An Empathetic Added Sustainability Index (EASI) for cementitious based construction materials. J. Clean. Prod. 2019, 220, 475–482. [Google Scholar] [CrossRef]

- Kashani, A.; Provis, J.L.; Qiao, G.G.; van Deventer, J.S.J. The interrelationship between surface chemistry and rheology in alkali activated slag paste. Constr. Build. Mater. 2014, 65, 583–591. [Google Scholar] [CrossRef]

- Palacios, M.; Banfill, P.F.; Puertas, F. Marta Palacios and Francisca Puertas, Rheology and Setting of Alkali-Activated Slag Pastes and Mortars: Effect of Organic Admixture. Mater. J. 2008, 105, 140. [Google Scholar] [CrossRef]

- Palacios, M.; Houst, Y.F.; Bowen, P.; Puertas, F. Adsorption of superplasticizer admixtures on alkali-activated slag pastes. Cem. Concr. Res. 2009, 39, 670–677. [Google Scholar] [CrossRef]

- Bassani, M.; Tefa, L.; Coppola, B.; Palmero, P. Alkali-activation of aggregate fines from construction and demolition waste: Valorisation in view of road pavement subbase applications. J. Clean. Prod. 2019, 234, 71–84. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E.; Dell’Aversano, R.; Gazzaniga, G. The influence of heat and steam curing on the properties of one-part fly ash/slag alkali activated materials: Preliminary results. AIP Conf. Proc. 2019, 2196, 020038. [Google Scholar] [CrossRef]

- Bondar, D.; Ma, Q.; Soutsos, M.; Basheer, M.; Provis, J.L.; Nanukuttan, S. Alkali activated slag concretes designed for a desired slump, strength and chloride diffusivity. Constr. Build. Mater. 2018, 190, 191–199. [Google Scholar] [CrossRef]

- Long, W.-J.; Wei, J.-J.; Gu, Y.-C.; Xing, F. Research on dynamic mechanical properties of alkali activated slag concrete under temperature-loads coupling effects. Constr. Build. Mater. 2017, 154, 687–696. [Google Scholar] [CrossRef]

- Angulo-Ramírez, D.E.; de Gutiérrez, R.M.; Puertas, F. Alkali-activated Portland blast-furnace slag cement: Mechanical properties and hydration. Constr. Build. Mater. 2017, 140, 119–128. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E. One-Part Alkali-Activated Slag Cement for Conservation of Existing Structures. ACI Spec. Publ. 2018, 330, 107–122. [Google Scholar]

- Giosuè, C.; Mobili, A.; di Perna, C.; Tittarelli, F. Performance of lightweight cement-based and alkali-activated mortars exposed to high-temperature. Constr. Build. Mater. 2019, 220, 565–576. [Google Scholar] [CrossRef]

- Bernal, S.; Nicolas, R.S.; Provis, J.; van Deventer, J.S.J. Alkali-activated slag cements produced with a blended sodium carbonate / sodium silicate activator. Adv. Cem. Res. 2015, 28, 262–273. [Google Scholar] [CrossRef]

- Shi, C.; Krivenko, P.V.; Roy, D.M. Alkali-Activated Cements and Concretes; Taylor & Francis: Boca Raton, FL, USA, 2006. [Google Scholar]

- Aydin, S.; Baradan, B. Effect of activator type and content on properties of alkali-activated slag mortars. Compos. Part B Eng. 2014, 57, 166–172. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.G.; Cheng, Y.B. Sulfate attack on alkali-activated slag concrete. Cem. Concr. Res. 2002, 32, 211–216. [Google Scholar] [CrossRef]

- Komljenovic, M.; Bascarevic, Z.; Marjanovic, N.; Nikolic, V. External sulfate attack on alkali-activated slag. Constr. Build. Mater. 2013, 49, 31–39. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Longman: London, UK, 1995. [Google Scholar]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; Hamdan, S.; van Deventer, J.S.J. Microstructural changes in alkali activated fly ash/slag geopolymers with sulfate exposure. Mater. Struct. Constr. 2013, 46, 361–373. [Google Scholar] [CrossRef]

- Shi, C. Strength, pore structure and permeability of alkali-activated slag mortars. Cem. Concr. Res. 1996, 26, 1789–1799. [Google Scholar] [CrossRef]

- Fu, Y.; Cai, L.; Yonggen, W. Freeze-thaw cycle test and damage mechanics models of alkali-activated slag concrete. Constr. Build. Mater. 2011, 25, 3144–3148. [Google Scholar] [CrossRef]

- Cai, L.; Wang, H.; Fu, Y. Freeze-thaw resistance of alkali-slag concrete based on response surface methodology. Constr. Build. Mater. 2013, 49, 70–76. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. One-part alkali-activated materials: A review. Cem. Concr. Res. 2018, 103, 21–34. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E.; Marini, A.; Passoni, C.; Pastore, T. Lightweight cement-free alkali-activated slag plaster for the structural retrofit and energy upgrading of poor quality masonry walls. Cem. Concr. Compos. 2019, 104, 103341. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E. Pre-packed alkali activated cement-free mortars for repair of existing masonry buildings and concrete structures. Constr. Build. Mater. 2018, 173, 111–117. [Google Scholar] [CrossRef]

- Wang, S.-D.; Scrivener, K.L. Hydration products of alkali activated slag cement. Cem. Concr. Res. 1995, 25, 561–571. [Google Scholar] [CrossRef]

- Wang, S.-D.; Scrivener, K.L.; Pratt, P.L. Factors affecting the strength of alkali-activated slag. Cem. Concr. Res. 1994, 24, 1033–1043. [Google Scholar] [CrossRef]

- Allahverdi, A.; Kani, E.N.; Esmaeilpoor, S. Effects of Silica Modulus and Alkali Concentration on Activation of Blast-Furnace Slag. Iran. J. Mater. Sci. Eng. 2008, 5, 32–35. [Google Scholar]

- Bayuaji, R.; Yasin, A.K.; Susanto, T.E.; Darmawan, M.S.; Darmawan, S. A review in geopolymer binder with dry mixing method (geopolymer cement). AIP Conf. Proc. 2017, 1887, 20042. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E.; Candamano, S.; Crea, F.; Gazzaniga, G.; Pastore, T. The combined use of admixtures for shrinkage reduction in one-part alkali activated slag-based mortars and pastes. Constr. Build. Mater. 2020, 248, 118682. [Google Scholar] [CrossRef]

- Qiao, C.; Suraneni, P.; Weiss, J. Phase diagram and volume change of the Ca(OH)2-CaCl2-H2O system for varying Ca(OH)2/CaCl2 molar ratios. J. Mater. Civ. Eng. 2018, 30. [Google Scholar] [CrossRef]

- Coffetti, D. Alternative Binders as Milestone of 3R Strategy for Sustainable Construction Materials. Ph.D. Thesis, University of Bergamo, Dalmine (BG), Italy, 2019. [Google Scholar] [CrossRef]

- Ye, H.; Cartwright, C.; Rajabipour, F.; Radlińska, A. Understanding the drying shrinkage performance of alkali-activated slag mortars. Cem. Concr. Compos. 2017, 76, 13–24. [Google Scholar] [CrossRef]

- Ye, H.; Radlińska, A. Shrinkage mechanisms of alkali-activated slag. Cem. Concr. Res. 2016, 88, 126–135. [Google Scholar] [CrossRef]

- Shahrajabian, F.; Behfarnia, K. The effects of nano particles on freeze and thaw resistance of alkali-activated slag concrete. Constr. Build. Mater. 2018, 176, 172–178. [Google Scholar] [CrossRef]

- Galan, I.; Perron, L.; Glasser, F.P. Impact of chloride-rich environments on cement paste mineralogy. Cem. Concr. Res. 2015, 68, 174–183. [Google Scholar] [CrossRef]

- Myers, R.J.; Bernal, S.A.; Provis, J.L. Phase diagrams for alkali-activated slag binders. Cem. Concr. Res. 2017, 95, 30–38. [Google Scholar] [CrossRef]

- Myers, R.J.; Lothenbach, B.; Bernal, S.A.; Provis, J.L. Thermodynamic modelling of alkali-activated slag cements. Appl. Geochem. 2015, 61, 233–247. [Google Scholar] [CrossRef]

| Component wt.% | Spec. Mass [kg/dm3] | Spec. Surface [m2/kg] | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CaO | Al2O3 | SiO2 | Fe2O3 | SO3 | TiO2 | K2O | MgO | Others | |||

| PC | 63.7 | 5.2 | 19.1 | 3.5 | 2.9 | 0.3 | 0.6 | 1.1 | 3.6 | 3.0 | 350 |

| BFC | 47.7 | 6.3 | 32.9 | 2.5 | 3.1 | 1.8 | 0.4 | 4.8 | 0.5 | 3.0 | 410 |

| GGBFS | 45.8 | 10.0 | 32.8 | 1.5 | 0.2 | 2.0 | 0.5 | 6.4 | 0.8 | 3.1 | 345 |

| Aggregate Size [mm] | Specific Mass [kg/dm3] | Water Absorption s.s.d. [wt.%] | Dosage [wt.% vs Total Aggregates] |

|---|---|---|---|

| 0.00/0.25 | 2.41 | 1.20 | 25 |

| 0.25/0.50 | 2.70 | 0.76 | 30 |

| 0.50/1.00 | 2.58 | 0.77 | 25 |

| 1.00/1.50 | 2.63 | 0.93 | 10 |

| 1.50/2.50 | 2.62 | 1.02 | 10 |

| Composition [g] | PC PC_AE | BFC BFC_AE | AAS8 AAS8_AE | AAS12 AAS12_AE | AAS16 AAS16_AE |

|---|---|---|---|---|---|

| PC | 450 | ||||

| BFC | 450 | ||||

| GGBFS | 450 | 450 | 450 | ||

| Activators | 36 | 54 | 72 | ||

| Aggregates | 1350 | 1350 | 1350 | 1350 | 1350 |

| Water | 225 | 225 | 225 | 225 | 225 |

| Superplasticizer | 2.25 | 2.25 | |||

| Air entraining agent | 0 | 0 | 0 | 0 | 0 |

| 0.140 | 0.125 | 0.225 | 0.200 | 0.160 | |

| Water/binder | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 |

| Aggregates/binder | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 |

| PC | BFC | AAS8 | AAS12 | AAS16 | ||

|---|---|---|---|---|---|---|

| Workability [mm] | 150 | 160 | 165 | 180 | 190 | |

| Entrapped air [%] | 5.0 | 5.2 | 4.7 | 4.5 | 4.0 | |

| Specific mass at fresh state [kg/m3] | 2140 | 2140 | 2150 | 2150 | 2165 | |

| Specific mass at hardened state [kg/m3] | 2110 | 2100 | 2010 | 2090 | 2120 | |

| Flexural strength [MPa] | 1 day | 4.9 | 3.0 | 0.3 | 2.5 | 2.7 |

| 7 days | 6.8 | 4.3 | 2.1 | 2.7 | 3.0 | |

| 28 days | 9.1 | 6.7 | 2.7 | 3.1 | 3.4 | |

| 56 days | 9.2 | 6.8 | 2.7 | 3.2 | 3.4 | |

| 84 days | 9.3 | 7.0 | 2.9 | 3.8 | 3.5 | |

| Compressive strength [MPa] | 1 day | 27.8 | 12.4 | 1.1 | 9.4 | 10.9 |

| 7 days | 46.5 | 31.5 | 15.4 | 25.5 | 30.2 | |

| 28 days | 47.7 | 43.1 | 18.1 | 34.0 | 39.1 | |

| 56 days | 48.1 | 44.2 | 19.0 | 35.0 | 40.2 | |

| 84 days | 48.3 | 44.7 | 19.4 | 35.8 | 41.3 | |

| 28-day elastic modulus [GPa] | 32.8 | 30.2 | 20.9 | 24.9 | 27.9 | |

| PC_AE | BFC_AE | AAS8_AE | AAS12_AE | AAS16_AE | ||

|---|---|---|---|---|---|---|

| Workability [mm] | 180 | 185 | 210 | 220 | 220 | |

| Entrapped air [%] | 11.0 | 11.0 | 10.5 | 10.0 | 11.0 | |

| Specific mass at fresh state [kg/m3] | 2000 | 2010 | 2020 | 2020 | 2010 | |

| Specific mass at hardened state [kg/m3] | 1950 | 1950 | 1970 | 1980 | 1980 | |

| Flexural strength [MPa] | 1 day | 3.2 | 1.9 | 0.2 | 1.8 | 1.9 |

| 7 days | 5.7 | 3.1 | 1.2 | 2.1 | 2.5 | |

| 28 days | 7.8 | 5.0 | 1.8 | 2.5 | 2.9 | |

| 56 days | 8.0 | 5.2 | 2.0 | 2.9 | 3.0 | |

| 84 days | 8.0 | 5.8 | 2.1 | 3.0 | 3.2 | |

| Compressive strength [MPa] | 1 day | 19.4 | 8.0 | 0.8 | 5.6 | 7.2 |

| 7 days | 39.1 | 26.3 | 12.5 | 19.3 | 25.4 | |

| 28 days | 41.2 | 36.3 | 13.4 | 22.6 | 30.2 | |

| 56 days | 42.1 | 37.0 | 14.1 | 25.1 | 32.1 | |

| 84 days | 42.5 | 37.9 | 15.0 | 27.0 | 33.5 | |

| 28-day elastic modulus [GPa] | 28.1 | 27.0 | 17.9 | 21.6 | 25.9 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coppola, L.; Coffetti, D.; Crotti, E.; Gazzaniga, G.; Pastore, T. The Durability of One-Part Alkali-Activated Slag-Based Mortars in Different Environments. Sustainability 2020, 12, 3561. https://doi.org/10.3390/su12093561

Coppola L, Coffetti D, Crotti E, Gazzaniga G, Pastore T. The Durability of One-Part Alkali-Activated Slag-Based Mortars in Different Environments. Sustainability. 2020; 12(9):3561. https://doi.org/10.3390/su12093561

Chicago/Turabian StyleCoppola, Luigi, Denny Coffetti, Elena Crotti, Gabriele Gazzaniga, and Tommaso Pastore. 2020. "The Durability of One-Part Alkali-Activated Slag-Based Mortars in Different Environments" Sustainability 12, no. 9: 3561. https://doi.org/10.3390/su12093561

APA StyleCoppola, L., Coffetti, D., Crotti, E., Gazzaniga, G., & Pastore, T. (2020). The Durability of One-Part Alkali-Activated Slag-Based Mortars in Different Environments. Sustainability, 12(9), 3561. https://doi.org/10.3390/su12093561