Looking for Answers to Food Loss and Waste Management in Spain from a Holistic Nutritional and Economic Approach

Abstract

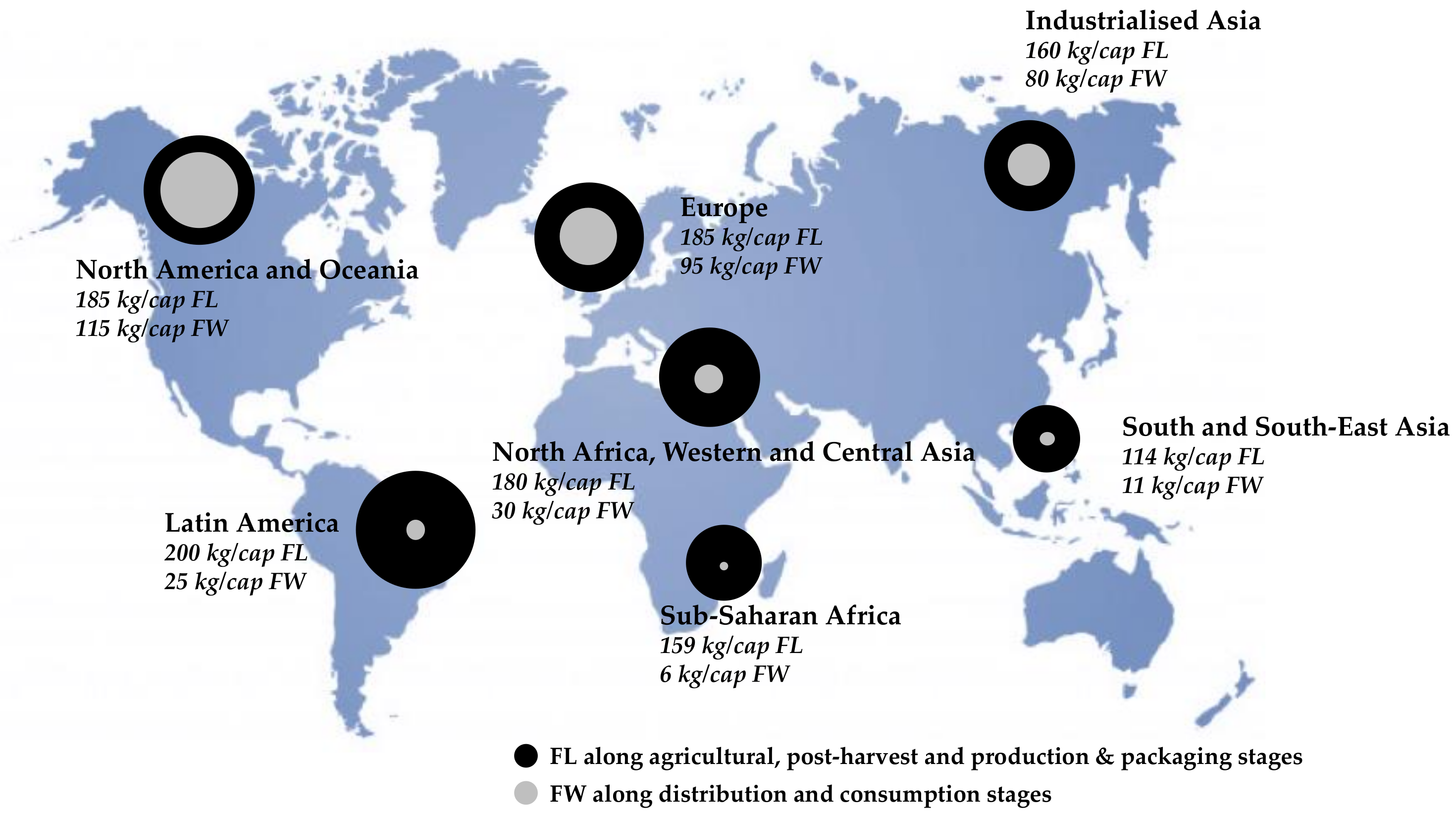

1. Introduction

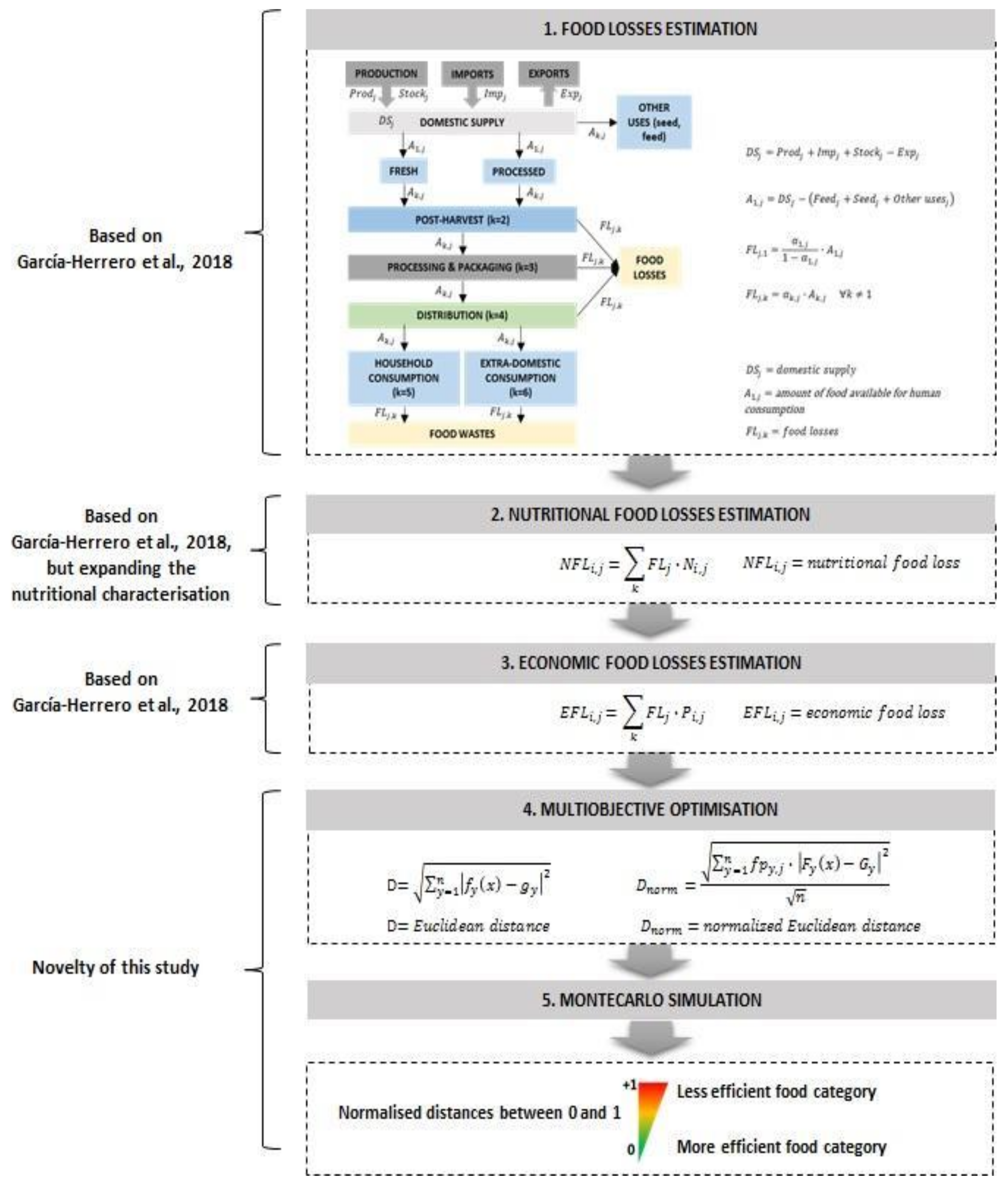

2. Methodology

3. Results

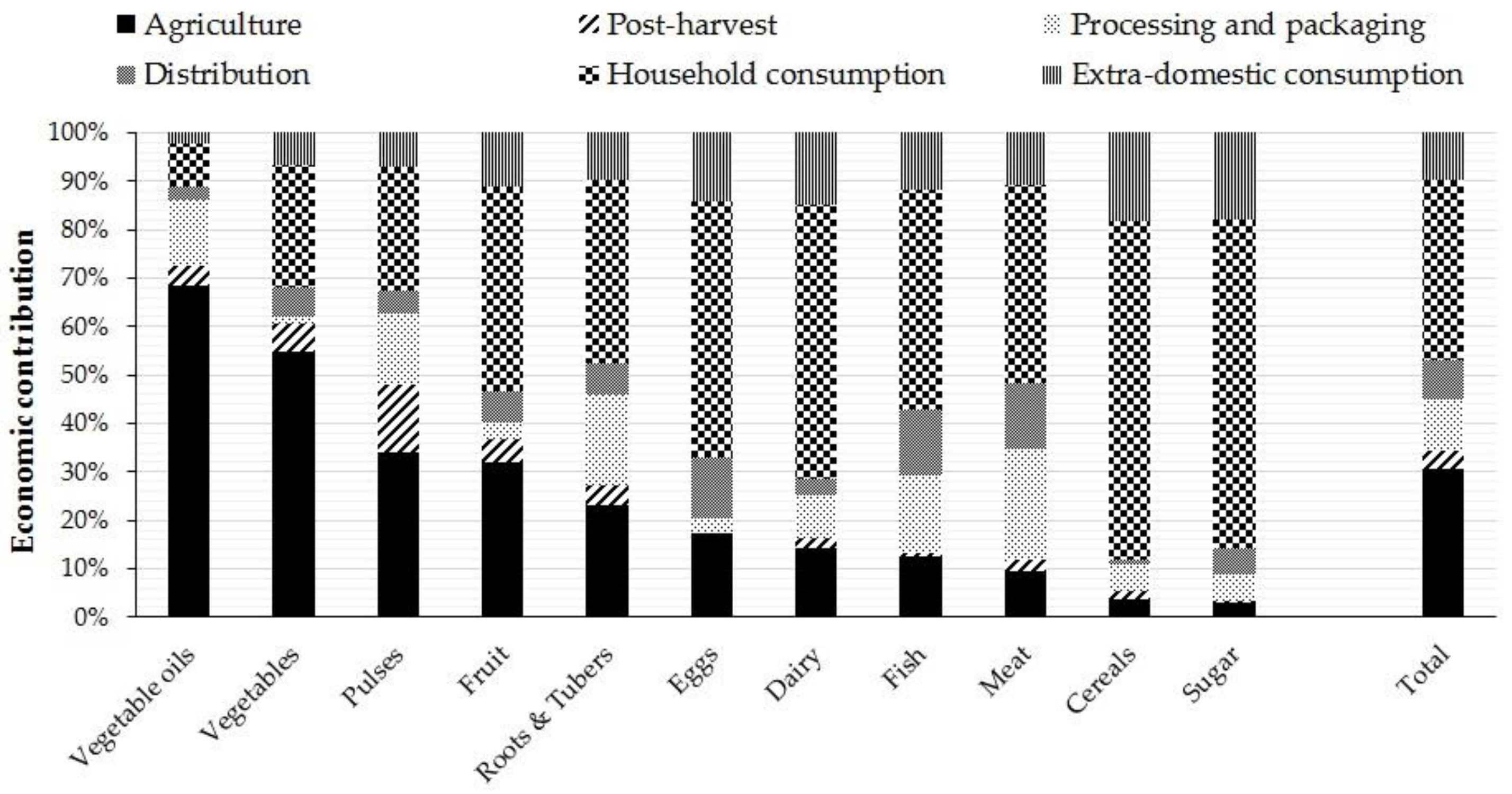

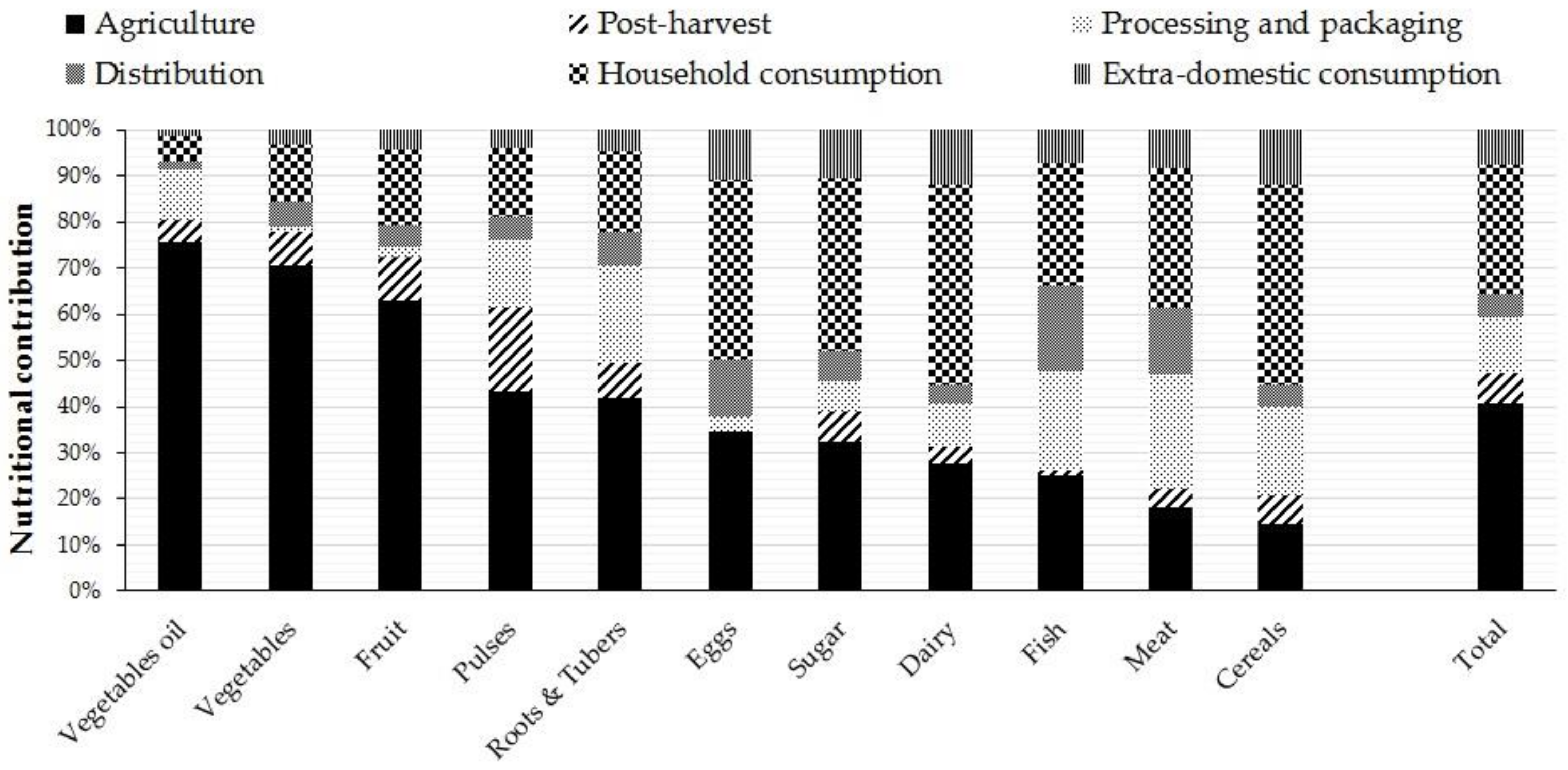

3.1. FLW Quantification in Mass, Economic, and Nutritional Terms

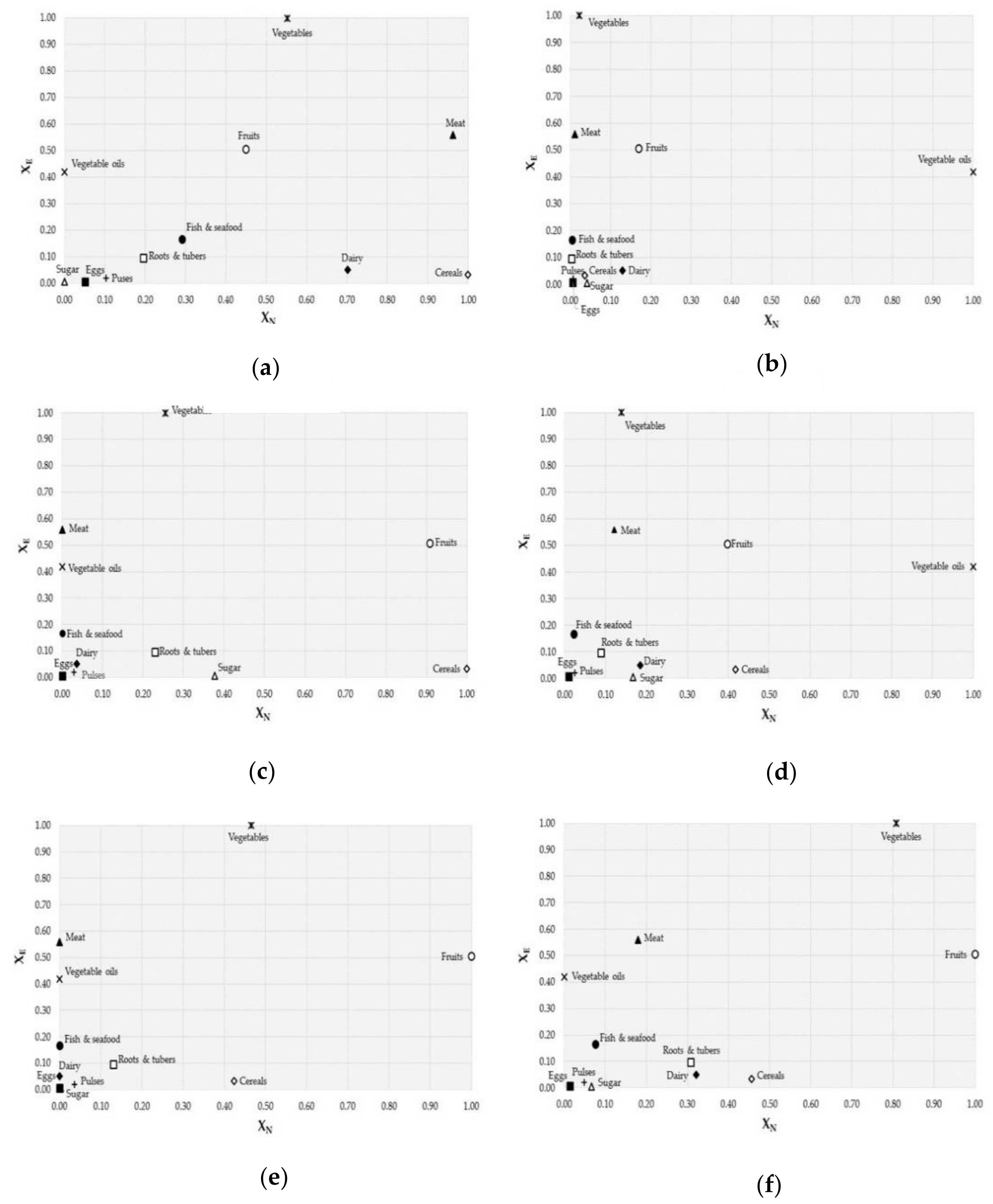

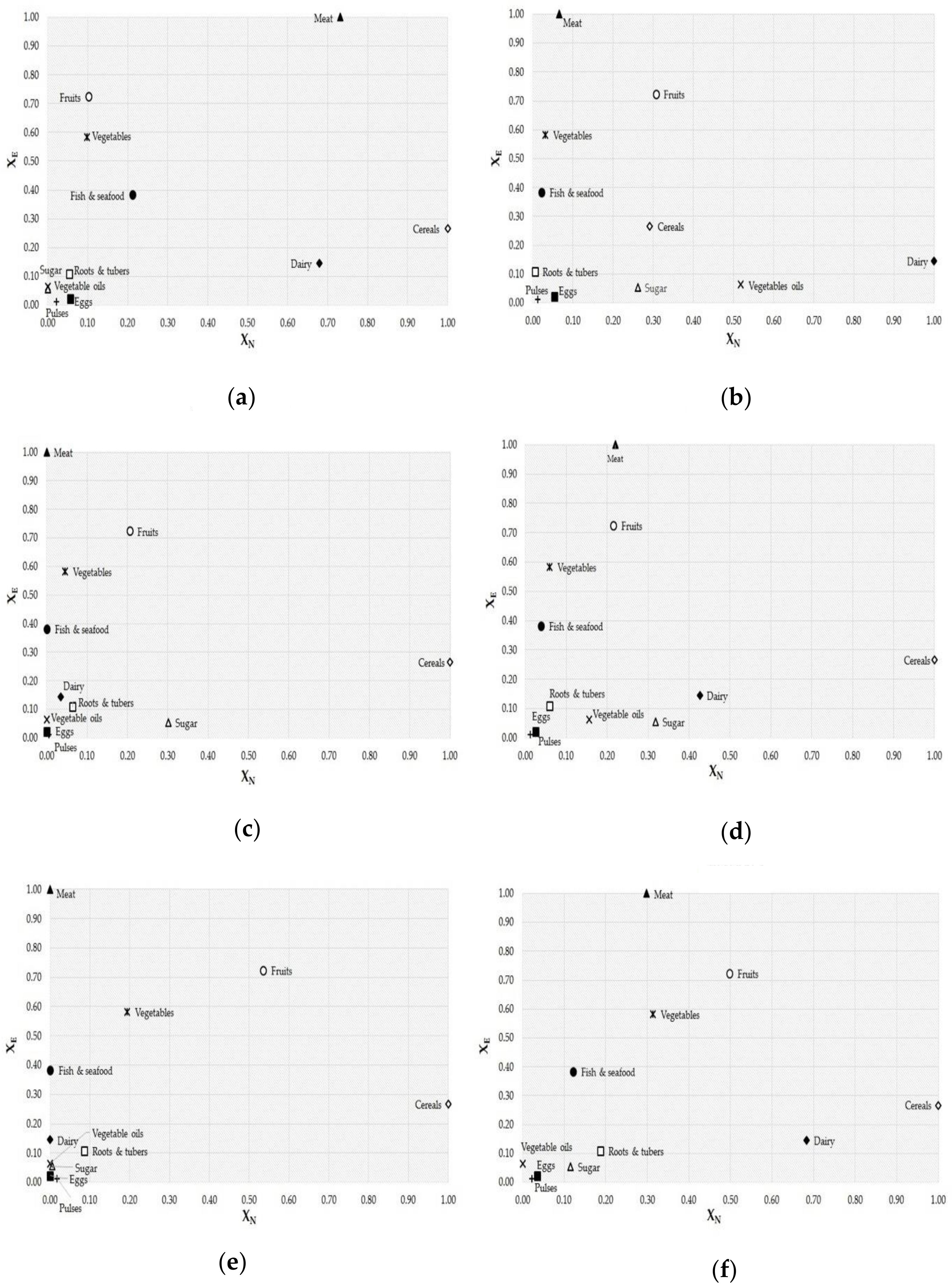

3.2. Multi-Objective Simulation Results

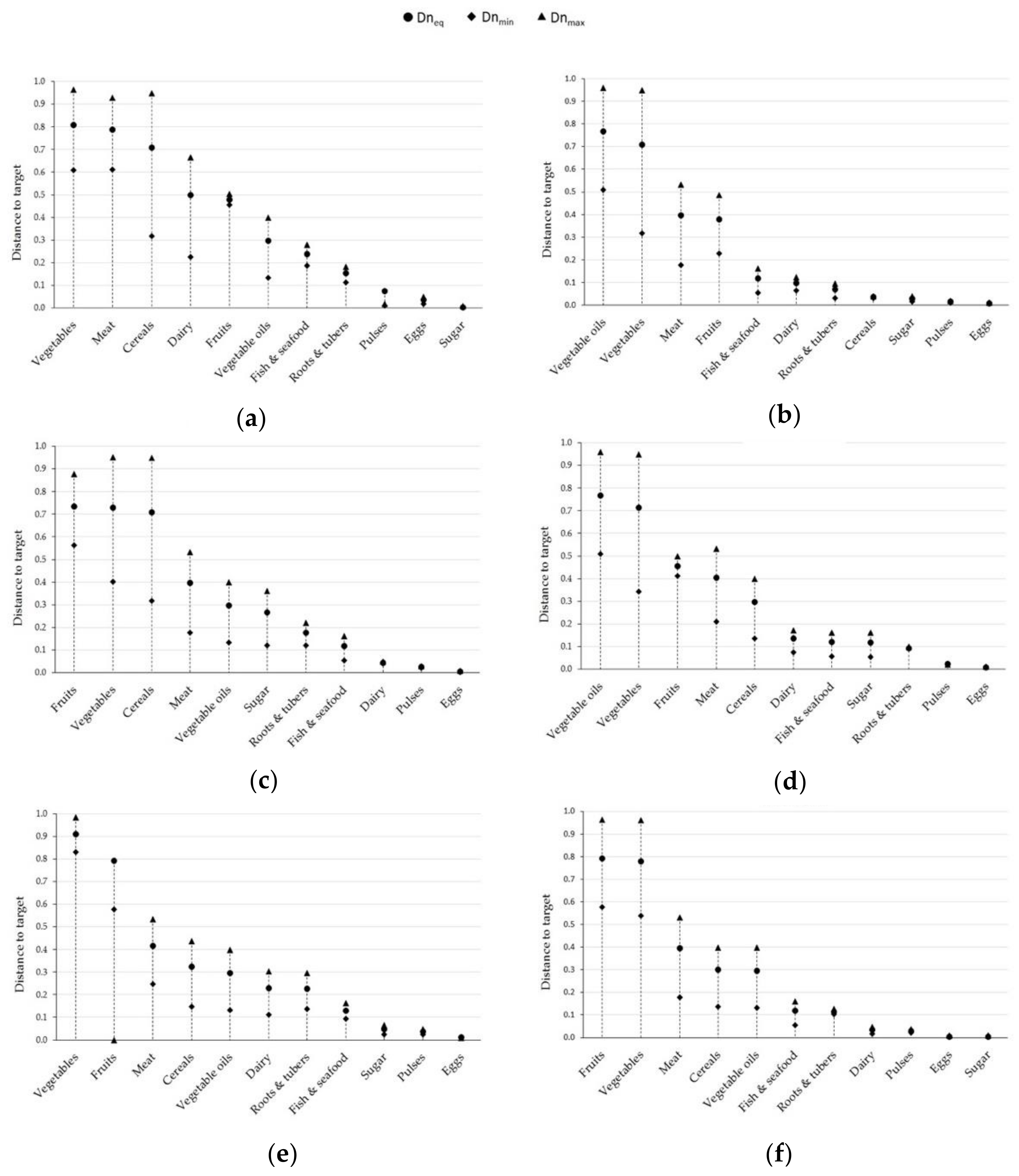

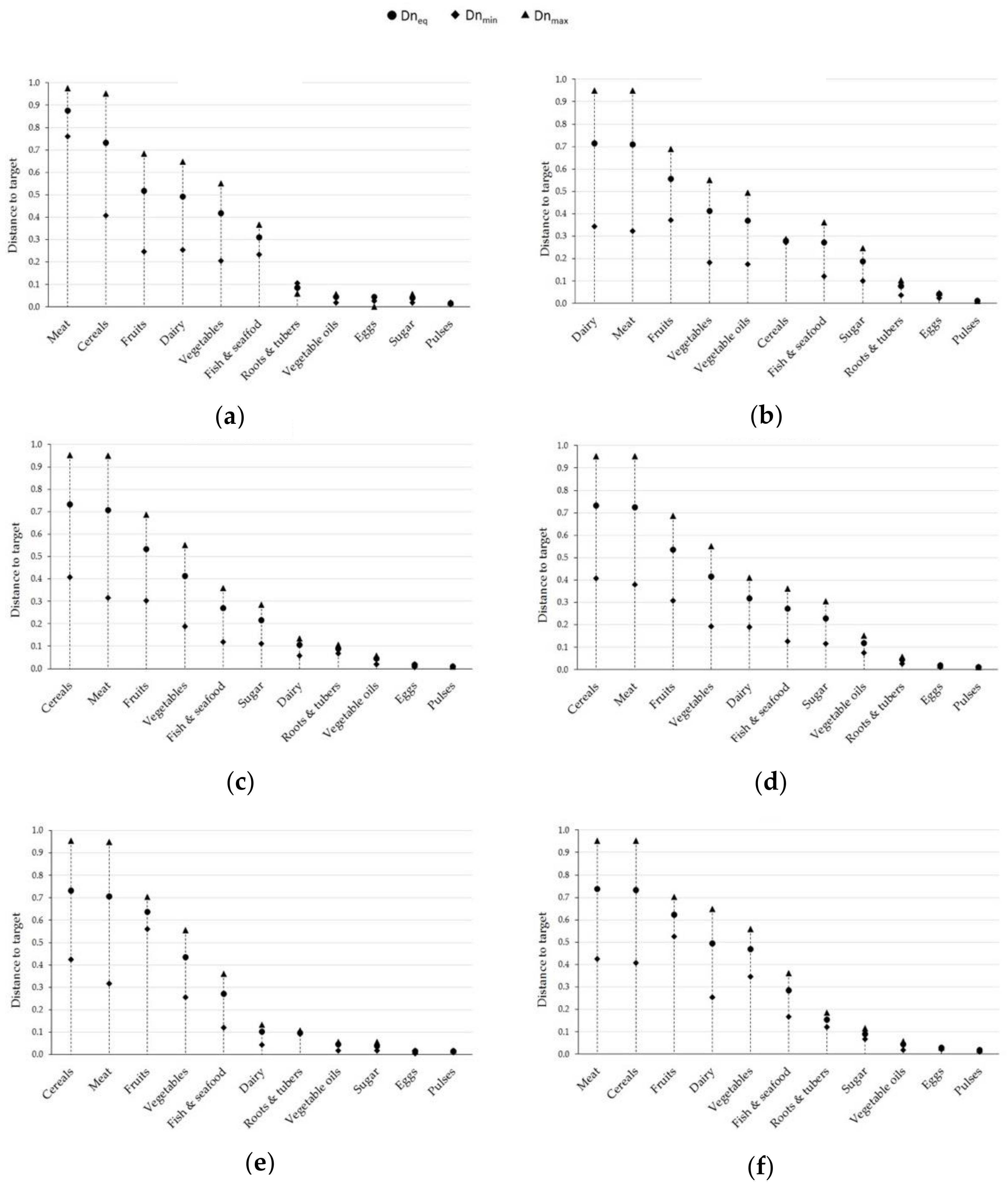

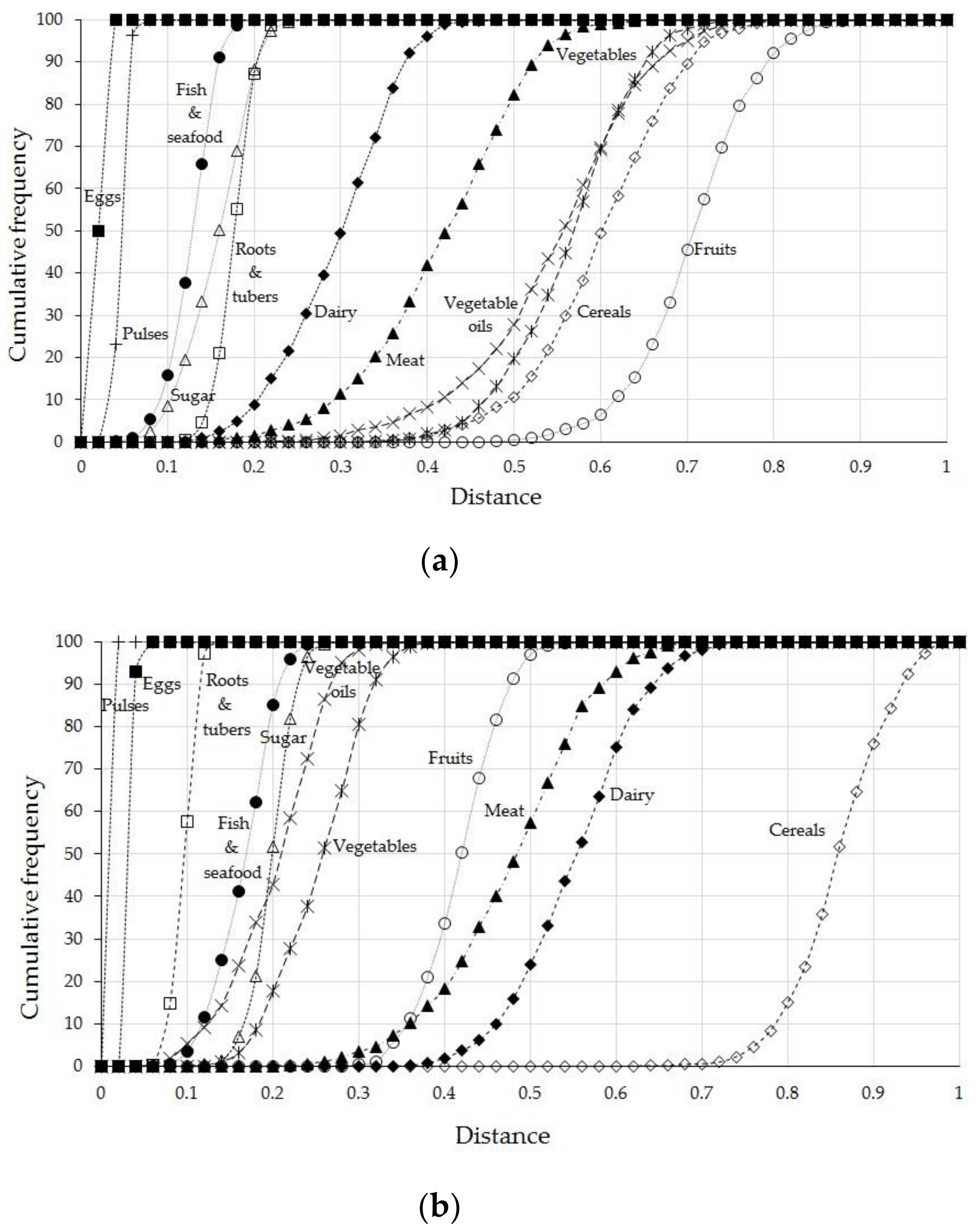

3.3. Monte Carlo Simulation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Category | Agriculture | Post-Harvest | Processing and Packaging | Distribution | Consumption | |||

|---|---|---|---|---|---|---|---|---|

| Milling | Processing | Fresh | Processing | Fresh | Processing | |||

| Cereals | 4.6 | 2 | 0.5 | 10 | 2 | 2 | 25 | 25 |

| Roots and tubers | 2.6 | 7 | 15 | 15 | 7 | 3 | 17 | 12 |

| Sugar | 20 | 5 | 2 | 2 | 10 | 2 | 19 | 15 |

| Oils | 26.2 | 2.19 | 5 | 5 | 1 | 1 | 4 | 4 |

| Vegetables | 27.6 | 4 | 2 | 2 | 10 | 2 | 19 | 15 |

| Fruit | 20.7 | 4 | 2 | 2 | 10 | 2 | 19 | 15 |

| Pulses | 4.6 | 2 | 5 | 5 | 1 | 1 | 4 | 4 |

| Meat | 3.1 | 0.7 | 6.3 | 6.3 | 4 | 4 | 11 | 11 |

| Fish and seafood | 9.4 | 0.5 | 6 | 6 | 9 | 5 | 11 | 10 |

| Milk | 3.5 | 0.5 | 1.2 | 1.2 | 0.5 | 0.5 | 7 | 7 |

| Eggs | 4 | 0 | 0.5 | 0.5 | 2 | 2 | 8 | 8 |

| Proteins (%) | Fats (%) | Carbohydrates (%) | Fiber (%) | Minerals (%) | Energy (kcal) | |

|---|---|---|---|---|---|---|

| Cereals | 13.00 | 3.57 | 68.46 | 8.72 | 0.91 | 363 |

| Roots and tubers | 1.85 | 0.19 | 11.48 | 1.96 | 0.45 | 56 |

| Sugar | 0.00 | 12.14 | 78.14 | 0.16 | 0.40 | 439 |

| Oils | 0.00 | 99.97 | 0.00 | 0.00 | 0.00 | 888 |

| Vegetables | 1.12 | 0.34 | 2.74 | 1.50 | 0.25 | 19 |

| Fruit | 0.90 | 2.56 | 9.60 | 3.18 | 0.31 | 70 |

| Pulses | 20.90 | 11.73 | 31.71 | 11.33 | 1.53 | 326 |

| Meat | 19.94 | 1.70 | 0.00 | 0.00 | 0.57 | 167 |

| Fish and seafood | 17.96 | 1.70 | 0.22 | 0.00 | 0.72 | 89 |

| Milk | 12.03 | 16.68 | 3.30 | 0.00 | 0.85 | 211 |

| Eggs | 12.50 | 11.10 | 0.00 | 0.00 | 0.54 | 150 |

| Food Category | Origin | Wholesale Market | Consumption |

|---|---|---|---|

| Cereals | 0.17 | 0.17 | 1.03 |

| Roots and tubers | 0.31 | 0.48 | 1.20 |

| Sugar | 0.04 | 0.37 | 0.81 |

| Oils | 2.09 | 2.95 | 3.82 |

| Vegetables | 0.79 | 1.19 | 2.09 |

| Fruit | 0.38 | 1.05 | 1.95 |

| Pulses | 1.57 | 2.01 | 3.46 |

| Meat | 3.23 | 5.76 | 8.29 |

| Fish and seafood | 3.36 | 4.90 | 11.27 |

| Milk | 0.29 | 0.51 | 0.73 |

| Eggs (dozen) | 0.63 | 1.03 | 1.44 |

| Study | Year | Assessment | Goal | Scope | Main Results |

|---|---|---|---|---|---|

| Quested and Johnson [39] | 2009 | CO2 eq./t waste | Household food and drink waste. | United Kingdom | 4.5 t CO2 eq./t waste. |

| Hall et al. [36] | 2009 | Nutritional loss and freshwater consumption of food waste. | Energy content of nationwide food waste. | United States | Food waste generation: more than 1400 kcal per person per day, more than one quarter of the total freshwater consumption and 300 million barrels of oil per year. |

| Cuéllar & Webber [54] | 2010 | Embodied energy loss (EEL). | Sustainability of meat based and plant-based diets. | United States | Highest EEL of food waste: dairy products and vegetables. |

| Gustavsson et al. [7] | 2011 | Weight of food losses and waste. | Differences between countries. | Global | Direct relation between higher amounts of food waste and the industrialization level of the country. |

| Berners-Lee et al. [55] | 2012 | Greenhouse gas (GHG) emissions. | Impacts of realistic dietary choices. | Supermarket chain—northwest of England | Highest GHG emissions of food waste: fresh fruit, vegetables, and salads. |

| Kummu et al. [33] | 2012 | Weight of food losses and waste and its nutritional energy loss. | Food supply losses and the resources used to produce them. | Global | Around one quarter of the produced food supply (614 kcal/capita/day) is lost (enough food for one billion extra people). |

| Rutten [41] | 2013 | Economic loss. | Comparison of different countries. | Global | Food losses and waste in industrialized and developing countries: US$ 680 and US$ 310 billion. |

| Vázquez-Rowe et al. [56] | 2014 | Edible protein energy return on investment (ep-EROI). | Ratio between energy inputs and energy provided. | Seafood products in Galicia (Spain) | Highest ep-EROI: Small pelagic species. |

| Vittuari et al. [57] | 2016 | EEL. | Assessment of the food supply chain. | Italy | Highest EEL of food waste: meat, milk and fish. |

| Spiker et al. [35] | 2017 | Nutritional loss. | Nutrient loss and comparison to gaps in dietary intake. | Retail and consumer levels in the United States | Food wasted: 1217 kcal, 33 g protein, 5.9 g dietary fiber, 1.7 μg vitamin D, 286 mg calcium, and 880 mg potassium per capita per day. |

| Eriksson and Spångberg [58] | 2017 | Carbon footprint and energy use. | Impacts of different food waste management options. | Fresh fruit and vegetables from supermarkets in Växjö (Sweden) | Reduction in GHG emissions and primary energy use by changes to more favorable options in the waste hierarchy. |

| García-Herrero et al. [3] | 2018 | Weight of food losses and waste and its nutritional and economic loss. | Development of the nutritional food losses footprint index. | Spain | Lowest efficiency: vegetables, fruits and meat. Main FW generation: consumption and agricultural production stages. |

| Abbade [37] | 2018 | Nutritional loss. | Rate of loss for the main food groups in the world. | Global | The rate of loss remains constant or slightly growing. The amount of food losses would be enough to feed 940 million adult individuals. |

| Scherhaufer et al. [38] | 2018 | Environmental impacts of food waste. | CO2 eq./t waste. | Europe | 1.9 t CO2 eq./t waste. |

| Laso et al. [44] | 2018 | Energetic and environmentally efficiency. | Assessment of the efficiency of agri-food system. | Spain | An average energy saving of approximately 70% is estimated in order to be efficient. |

| García-Herrero et al. [9] | 2019 | Nutritional and economic food losses and waste. | Development of a nutritional cost footprint indicator combining nutritional and economic variables. | Spain | Highest nutritional and economic food waste: agricultural production and fruits and vegetables. |

| Hoehn et al. [59] | 2019 | EEL and food energy loss. | Energy return on investment—circular economy index. | Spain | Highest energy loss: cereals, meat, fish and seafood and vegetables. Lowest energy loss: vegetarian diet. |

| Vázquez-Rowe et al. [10] | 2019 | Nutritional cost footprint. | Assessment of the nutritional and economic efficiency of food loss and waste. | Spain | Less efficiency: vegetables and fruits Main FW generation: agricultural production and consumption. |

| Aldaco et al. [43] | 2020 | Climate, economic, and nutritional impacts assessment. | Impacts of food loss and waste. | COVID-19 outbreak in Spain | Highest loss rates: fruits and vegetables. Highest nutritional loss: animal fats, snacks, pastries, and sweets. Highest economic loss: red meat, cereals, fruits, and vegetables. Highest GHG emissions: red meat. |

| Chen et al. [60] | 2020 | Nutritional and environmental losses. | Nutritional and environmental footprint in food waste. | 151 countries | Highest mass loss: vegetables, cereals, and fruits. Highest nutritional loss: cereals, fruits, vegetables, and meat. Highest environmental impacts: cereals, fruits, and vegetables. |

| Wohner et al. [61] | 2020 | Environmental and economic assessment. | Impacts of food-packaging systems with a focus on food waste. | Austria | Higher food waste resulted in higher environmental impacts but also higher value added to the economy. |

References

- Esposito, B.; Sessa, M.R.; Sica, D.; Malandrino, O. Towards Circular Economy in the Agri-Food Sector. A Systematic Literature Review. Sustainability 2020, 12, 7401. [Google Scholar] [CrossRef]

- Bahadur, K.; Haque, I.; Legwegoh, A.; Fraser, E. Strategies to Reduce Food Loss in the Global South. Sustainability 2016, 8, 595. [Google Scholar] [CrossRef]

- García-Herrero, I.; Hoehn, D.; Margallo, M.; Laso, J.; Bala, A.; Batlle-Baver, L.; Fullana, P.; Vazquez-Rowe, I.; González, M.J.; Sarabia, C.; et al. On the estimation of potential food waste reduction to support sustainability. Food Policy 2018, 80, 24–38. [Google Scholar] [CrossRef]

- Parfitt, J.; Barthel, M.; Macnaughton, S. Food waste within food supply chains: Quantification and potential for change to 2050. Philos. Trans. R. Soc. Lond. B Biol. Sci. 2010, 365, 3065–3081. [Google Scholar] [CrossRef] [PubMed]

- Chauhan, Y. Food waste Management with Technological Platforms: Evidence from Indian Food Supply Chains. Sustainability 2020, 12, 8162. [Google Scholar] [CrossRef]

- FAO. Global Food Losses and Wastes—Scope, Causes and Prevention; FAO: Rome, Italy, 2012; ISBN 978-92-5-307205-7. [Google Scholar]

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; Emanuelsson, A. The Methodology of the FAO Study: “Global Food Losses and Food Waste Exent, Causes and Prevention”-FAO 2011; FAO: Rome, Italy, 2013; p. 857. ISSN 0436-2071. [Google Scholar]

- FAO. The State of Food Security and Nutrition in the World. Report. 2019. Available online: https://reliefweb.int/sites/reliefweb.int/files/resources/ca5162es.pdf (accessed on 19 October 2020).

- García-Herrero, I.; Margallo, M.; Laso, J.; Batlle-Bayer, L.; Bala, A.; Fullana, P.; Vazquez-Rowe, I.; González, M.J.; Amo, F.; Durá, M.J.; et al. Nutritional data management of food losses and waste under a life cycle approach: The case study of the Spanish agri-food system. J. Food Compos. Anal. 2019, 82, 103223. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Laso, J.; Margallo, M.; García, I.; Hoehn, D.; Amo-Setién, F.; Bala, A.; Abajas, R.; Sarabia, C.; Durá, M.J.; et al. Food loss and waste metrics: A proposed nutritional cost footprint linking linear programming and life cycle assessment. Int. J. Life Cycle Assess. 2019, 25, 1197–1209. [Google Scholar] [CrossRef]

- FAO. Food Losses and Wastage in the Context of Sustainable Food Systems. Report of the High-Level Panel of Experts on Food Security and Nutrition. 2014. Available online: http://www.fao.org/3/a-i3901s.pdf (accessed on 19 October 2020).

- FAO. Food Wastage Footprint. Impacts on Natural Resources. Summary Report. 2013. Available online: http://www.fao.org/3/i3347e/i3347e.pdf (accessed on 20 October 2020).

- FAO. Toolkit: Reducing the Food Wastage Footprint. Report. 2013. Available online: http://www.fao.org/3/i3342e/i3342e.pdf (accessed on 19 October 2020).

- FUSIONS. Recommendations and Guidelines for a Common European Food Waste Policy Framework. Report. 2016. Available online: https://www.eu-fusions.org/phocadownload/Publications/D3.5%20recommendations%20and%20guidelines%20food%20waste%20policy%20FINAL.pdf (accessed on 20 October 2020).

- Zorpas, A.A.; Lasaridi, K. Measuring waste prevention. Waste Manag. 2013, 33, 1047–1056. [Google Scholar] [CrossRef]

- Lasaridi, K.; Chroni, C.; Zorpas, A.A.; Abeliotis, K. Waste Prevention. Sustain. Solid Waste Manag. 2016, 53–93. [Google Scholar] [CrossRef]

- Zorpas, A.A.; Lasaridi, K.; Pociovalisteanu, D.M.; Loizia, P. Monitoring and evaluation of prevention activities regarding household organics waste from insular communities. J. Clean. Prod. 2018, 172, 3567–3577. [Google Scholar] [CrossRef]

- Zorpas, A.A. Strategy development in the framework of waste management. Sci. Total Environ. 2020, 137088. [Google Scholar] [CrossRef] [PubMed]

- European Parliament. Report on How to Avoid Food Wastage: Strategies for a More Efficient Food Chain in the EU. Report. 2011. Available online: https://www.europarl.europa.eu/sides/getDoc.do?pubRef=-//EP//NONSGML+REPORT+A7-2011-0430+0+DOC+PDF+V0//EN (accessed on 27 October 2020).

- European Commission. Regions Closing the Circle: An EU Action Plan for the Circular Economy. Report from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee. 2015. Available online: https://data.consilium.europa.eu/doc/document/ST-14972-2015-INIT/es/pdf (accessed on 20 October 2020).

- European Commission. EU Platform on Food Losses and Food Waste. Report from the European Commission. 2020. Available online: https://ec.europa.eu/food/safety/food_waste/eu_actions/eu-platform_en#:~:text=The%20EU%20and%20the%20EU,food%20production%20and%20supply%20chains (accessed on 23 October 2020).

- FUSIONS. Estimates of European Food Waste Levels. Report. 2016. Available online: http://www.eu-fusions.org/phocadownload/Publications/Estimates%20of%20European%20food%20waste%20levels.pdf (accessed on 20 October 2020).

- REFRESH. Resource Efficient Food and Drink for the Entire Supply Chain. Report from European Union. 2015. Available online: https://eu-refresh.org/comienza-el-nuevo-proyecto-de-la-ue-para-reducir-el-desperdicio-alimentario-en-toda-europa (accessed on 21 October 2020).

- European Commission. Preparatory Study on Food Waste across EU 27. Technical Report from the European Commission. 2011. Available online: https://ec.europa.eu/environment/eussd/pdf/bio_foodwaste_report.pdf (accessed on 20 October 2020).

- Mapama. Desperdicio Alimentario en los Hogares Españoles. Available online: https://www.mapa.gob.es/es/prensa/200922informedesperdicioalimentario_tcm30-543937.pdf (accessed on 3 December 2020).

- Mena, C.; Adenso-Diaz, B.; Yurrt, O. The causes of food waste in the supplier-retailer interface: Evidences from the UK and Spain. Resour. Conserv. Recycl. 2020, 55, 648–658. [Google Scholar] [CrossRef]

- AECOC. Manufacturers and Distributors Association. Food Is Not Wasted. 2012. Available online: https://www.alimentacionsindesperdicio.com/ (accessed on 20 October 2020).

- Mapama. “More Food, Less Waste” strategy. In Programme for the Reduction of Food Losses and Waste and the Evaluation of Discarded Food; Report from the Ministry of Agriculture, Food and Environment; Ministry of Agriculture, Food and Environment: Madrid, Spain, 2013. Available online: http://www.besana.es/sites/default/files/estrategia_mas_alimento.pdf (accessed on 23 October 2020).

- Mapama. Las pérdidas y el Desperdicio Alimentario Generado por la Producción Agrícola en España. Resumen Ejecutivo. Ministerio de Agricultura, Pesca y Alimentación, 2014. Available online: https://menosdesperdicio.es/sites/default/files/documentos/relacionados/resumen_perdidas_desperdicioagricolas_2014.pdf (accessed on 26 October 2020).

- BOE. Law 8/2019. Waste and Contaminated Soil of the Balearic Islands; Consolidated Legislation; Government of Spain: Madrid, Spain, 2019.

- Xunta. Draft Bill of the Law of Waste and Contaminated Soils of Galicia. Explanation of Reasons. 2020. Available online: https://ficheiros-web.xunta.gal/transparencia/normativa-tramitacion/cmatv/CMATV_anteproxecto_lei_residuos_soloscontam_2019_cas.pdf (accessed on 20 October 2020).

- BOE. Law 3/2020. 11th of March on the Prevention of Food Losses and Wastage. Off. J. General. Catalunya 2020. [Google Scholar]

- Kummu, M.; de Moel, H.; Porkka, M.; Siebert, S.; Varis, O.; Ward, P.J. Lost food, wasted resources: Global food supply chain losses and their impacts on freshwater, cropland, and fertiliser use. Sci. Total Environ. 2012, 438, 477–489. [Google Scholar] [CrossRef] [PubMed]

- Buzby, J.C.; Wells, H.F.; Hyman, J. The estimated amount, value, and calories of postharvest food losses at the retail and consumer levels in the United States. In Food Loss in the United States: Selected Analyses; Report for United States Department of Agriculture; United States Department of Agriculture: Washington, DC, USA, 2014. Available online: https://www.ers.usda.gov/webdocs/publications/43833/43680_eib121.pdf?v=2822.4 (accessed on 27 October 2020).

- Spiker, M.L.; Hiza, H.A.B.; Siddiqi, S.M.; Neff, R.A. Wasted Food, Wasted Nutrients: Nutrient Loss from Wasted Food in the United States and Comparison to Gaps in Dietary Intake. J. Acad. Nutr. 2017, 117, 1031–1040. [Google Scholar] [CrossRef]

- Hall, K.D.; Guo, J.; Dore, M.; Chow, C.C. The progressive increase of food waste in America and its environmental impact. PLoS ONE 2009, 4, e7940. [Google Scholar] [CrossRef] [PubMed]

- Abbade, E.B. Estimating the nutritional loss and the feeding potential derived from food losses worldwide. World Dev. 2018, 134, 105038. [Google Scholar] [CrossRef]

- Scherhaufer, S.; Moates, G.; Hartikainen, H.; Waldron, K.; Obersteiner, G. Environmental impacts of food waste in Europe. Waste Manag. 2018, 77, 98–113. [Google Scholar] [CrossRef]

- Quested, T.; Johnson, H. Household Food and Drink Waste in the UK. Report from WRAP (Material Change for a Better Environment). 2009. Available online: https://www.wrap.org.uk/sites/files/wrap/Household_food_and_drink_waste_in_the_UK_-_report.pdf (accessed on 20 October 2020).

- Gruber, L.M.; Brandstetter, C.P.; Bos, U.; Lindner, J.P.; Albrech, S. LCA study of unconsumed food and the influence of consumer behavior. Int. J. Life Cycle Assess. 2015, 21, 773–784. [Google Scholar] [CrossRef]

- Rutten, M.M. What economic theory tells us about the impacts of reducing food losses and/or waste: Implications for research, policy, and practice. Agric. Food Secur. 2013, 2, 13. [Google Scholar] [CrossRef]

- Stenmarck, A.; Jensen, C.; Quested, T.; Moates, G.; Buksti, M.; Cseh, B.; Juul, S.; Parry, A.; Politano, A.; Redlingshofer, B.; et al. Estimates of European Food Waste Levels. Report from EU Fusions. 2016. Available online: https://research.wur.nl/en/publications/estimates-of-european-food-waste-levels (accessed on 28 October 2020).

- Aldaco, R.; Hoehn, D.; Laso, J.; Margallo, M.; Ruiz-Salmón, J.; Cristobal, J.; Kahhat, R.; Villanueva-Rey, P.; Bala, A.; Batlle-Bayer, L.; et al. Food waste management during the COVID-19 outbreak: A holistic climate, economic and nutritional approach. Sci. Total Environ. 2020, 742, 140524. [Google Scholar] [CrossRef] [PubMed]

- Laso, J.; Hoehn, D.; Margallo, M.; García-Herrero, I.; Batlle-Bayer, L.; Bala, A.; Fullana-i-Palmer, P.; Vázquez-Rowe, I.; Irabien, A.; Aldaco, R. Assessing Energy and Environmental Efficiency of the Spanish Agri-Food System Using the LCA/DEA Methodology. Energies 2018, 11, 3395. [Google Scholar] [CrossRef]

- FAO. FAO Food Balance Sheets: A Handbook; Report; Food and Agriculture Organization of the United Nations: Rome, Italy, 2001; Available online: http://www.fao.org/3/a-x9892e.pdf (accessed on 20 October 2020).

- Bedca. Base de Datos Española de Composición de Alimentos. 2007. Available online: http://www.bedca.net/bdpub/index.php (accessed on 20 October 2020).

- Abejón, R.; Vazquez-Rowe, I.; Bala, A.; Fullana, P.; Margallo, M.; Aldaco, R. Application of the “Distance to target” Approach to the Multiobjective Optimization of nutritional and economic costs due to food loss and waste. Comput. Aided Chem. Eng. 2020, 48, 24–27. [Google Scholar] [CrossRef]

- Limleamthong, P.; Guillen-Gosálbez, G. Rigorous analysis of Pareto fronts in sustainability studies based on bilevel optimization: Application to the redesign of the UK electricity mix. J. Clean. Prod. 2017, 164, 1602–1613. [Google Scholar] [CrossRef]

- Fichthorn, K.A.; Weinberg, W.H. Theoretical foundations of dynamical Monte Carlo simulations. J. Chem. Phys. 1991, 95, 1090–1096. [Google Scholar] [CrossRef]

- GAMS. GAMS Development Corporation: General Algebraic Modeling System. 2017. Available online: https://www.gams.com/ (accessed on 23 October 2020).

- RPCV. Red Peruana de Ciclo de Vida y Ecología Industrial. Calculadora para la Huella Ambiental del Café Peruano. Available online: https://red.pucp.edu.pe/ciclodevida/proyecto/calculadora-la-huella-ambiental-del-cafe-peruano/ (accessed on 2 January 2020).

- Vázquez-Rowe, I.; Villanueva-Rey, P.; Moreira, M.T.; Feijoo, G. Opportunities and challenges of implementing life cycle assessment in seafood certification: A case study for Spain. Int. J. Life Cycle Assess. 2016, 21, 451–464. [Google Scholar] [CrossRef]

- Mapama. Precios Origen-Mayorista. Available online: https://www.mapa.gob.es/es/alimentacion/servicios/observatorio-de-precios-de-los-alimentos/default2.aspx (accessed on 23 October 2020).

- Cuéllar, A.D.; Webber, M.E. Wasted Food, Wasted Energy: The Embedded Energy in Food Waste in the United States. Environ. Sci. Technol. 2010, 44, 6464–6469. [Google Scholar] [CrossRef]

- Berners-Lee, M.; Hoolohan, C.; Cammack, H.; Hewitt, C.N. The relative greenhouse gas impacts of realistic dietary choices. Energy Policy 2012, 43, 184–190. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Villanueva-Rey, P.; Moreira, M.T.; Feijoo, G. Edible Protein Energy Return on Investment Ratio (ep-EROI) for Spanish Seafood Products. AMBIO 2014, 43, 381–394. [Google Scholar] [CrossRef]

- Vittuari, M.; de Menna, F.; Pagani, M. The Hidden Burden of Food Waste: The Double Energy Waste in Italy. Energies 2016, 9, 660. [Google Scholar] [CrossRef]

- Eriksson, M.; Spångberg, J. Carbon footprint and energy use of food waste management options for fresh fruit and vegetables from supermarkets. J. Waste Manag. 2017, 60, 786–799. [Google Scholar] [CrossRef] [PubMed]

- Hoehn, D.; Margallo, M.; Laso, J.; García-Herrero, I.; Bala, A.; Fullana-i-Palmer, P.; Irabien, A.; Aldaco, R. Energy embedded in food loss management and in the production of uneaten food: Seeking a sustainable pathway. Energies 2019, 12, 767. [Google Scholar] [CrossRef]

- Chen, C.; Chaudhary, A.; Mathys, A. Nutritional and environmental losses embedded in global food waste. Resour. Conserv. Recycl. 2020, 160, 104912. [Google Scholar] [CrossRef]

- Wohner, B.; Gabriel, V.H.; Krenn, B.; Krauter, V.; Tacker, M. Environmental and economic assessment of food-packaging systems with a focus on food waste. Case study on tomato ketchup. Sci. Total Environ. 2020, 738, 139846. [Google Scholar] [CrossRef] [PubMed]

| Food Category | Proteins | Carbohydrates | Fats | Kcal | Minerals | Fiber |

|---|---|---|---|---|---|---|

| Cereals | ||||||

| Roots and tubers | X | |||||

| Sugar | X X | |||||

| Vegetable oils | X X | |||||

| Vegetables | ||||||

| Fruits | ||||||

| Pulses | X | X | X | X X | X | X |

| Meat | ||||||

| Fish | ||||||

| Milk and other dairy products | ||||||

| Eggs | X X | X | X | X | X X |

| Food Category | XE | XN | Dn eq. | Dn Min | Dn Max | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Proteins | Fats | Carbohydrates | Minerals | Fiber | Kcal | |||||

| Fruits | 0.51 | 0.45 | 0.17 | 0.91 | 1.00 | 1.00 | 0.40 | 0.70 | 0.42 | 0.91 |

| Cereals | 0.03 | 1.00 | 0.04 | 1.00 | 0.46 | 0.42 | 0.42 | 0.61 | 0.25 | 0.72 |

| Vegetables | 1.00 | 0.55 | 0.02 | 0.26 | 0.81 | 0.46 | 0.14 | 0.57 | 0.32 | 0.83 |

| Vegetable oils | 0.42 | 0.00 | 1.00 | 0.00 | 0.00 | 0.00 | 1.00 | 0.56 | 0.30 | 0.89 |

| Meat | 0.56 | 0.96 | 0.01 | 0.00 | 0.18 | 0.00 | 0.12 | 0.43 | 0.23 | 0.71 |

| Milk and other dairy products | 0.05 | 0.70 | 0.13 | 0.04 | 0.32 | 0.00 | 0.18 | 0.30 | 0.17 | 0.50 |

| Roots and tubers | 0.10 | 0.19 | 0.00 | 0.23 | 0.31 | 0.13 | 0.09 | 0.18 | 0.11 | 0.25 |

| Sugar | 0.01 | 0.00 | 0.04 | 0.38 | 0.07 | 0.00 | 0.17 | 0.16 | 0.09 | 0.27 |

| Fish | 0.17 | 0.29 | 0.00 | 0.00 | 0.08 | 0.00 | 0.02 | 0.13 | 0.07 | 0.21 |

| Pulses | 0.02 | 0.10 | 0.01 | 0.03 | 0.05 | 0.04 | 0.02 | 0.05 | 0.03 | 0.07 |

| Eggs | 0.01 | 0.05 | 0.01 | 0.00 | 0.01 | 0.00 | 0.01 | 0.02 | 0.01 | 0.03 |

| Food Category | XE | XN | Dn eq. | Dn Min | Dn Max | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Proteins | Fats | Carbohydrates | Minerals | Fiber | Kcal | |||||

| Fruits | 0.27 | 1.00 | 0.29 | 1.00 | 1.00 | 1.00 | 1.00 | 0.86 | 0.45 | 0.94 |

| Cereals | 0.14 | 0.68 | 1.00 | 0.04 | 0.68 | 0.00 | 0.43 | 0.55 | 0.30 | 0.79 |

| Vegetables | 1.00 | 0.73 | 0.07 | 0.00 | 0.30 | 0.00 | 0.22 | 0.49 | 0.27 | 0.79 |

| Vegetable oils | 0.72 | 0.10 | 0.31 | 0.21 | 0.50 | 0.54 | 0.22 | 0.42 | 0.27 | 0.59 |

| Meat | 0.58 | 0.10 | 0.03 | 0.05 | 0.31 | 0.19 | 0.06 | 0.26 | 0.15 | 0.42 |

| Milk and other dairy products | 0.06 | 0.00 | 0.52 | 0.00 | 0.00 | 0.00 | 0.16 | 0.21 | 0.11 | 0.35 |

| Roots and tubers | 0.06 | 0.00 | 0.26 | 0.30 | 0.12 | 0.00 | 0.32 | 0.20 | 0.11 | 0.28 |

| Sugar | 0.38 | 0.21 | 0.02 | 0.00 | 0.12 | 0.00 | 0.04 | 0.17 | 0.09 | 0.28 |

| Fish | 0.11 | 0.05 | 0.01 | 0.06 | 0.19 | 0.09 | 0.06 | 0.10 | 0.06 | 0.14 |

| Pulses | 0.02 | 0.06 | 0.05 | 0.00 | 0.03 | 0.00 | 0.02 | 0.03 | 0.02 | 0.05 |

| Eggs | 0.01 | 0.02 | 0.01 | 0.01 | 0.02 | 0.02 | 0.01 | 0.02 | 0.01 | 0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Laso, J.; Campos, C.; Fernández-Ríos, A.; Hoehn, D.; del Río, A.; Ruiz-Salmón, I.; Cristobal, J.; Quiñones, A.; Amo-Setién, F.J.; del Carmen Ortego, M.; et al. Looking for Answers to Food Loss and Waste Management in Spain from a Holistic Nutritional and Economic Approach. Sustainability 2021, 13, 125. https://doi.org/10.3390/su13010125

Laso J, Campos C, Fernández-Ríos A, Hoehn D, del Río A, Ruiz-Salmón I, Cristobal J, Quiñones A, Amo-Setién FJ, del Carmen Ortego M, et al. Looking for Answers to Food Loss and Waste Management in Spain from a Holistic Nutritional and Economic Approach. Sustainability. 2021; 13(1):125. https://doi.org/10.3390/su13010125

Chicago/Turabian StyleLaso, Jara, Cristina Campos, Ana Fernández-Ríos, Daniel Hoehn, Andrea del Río, Israel Ruiz-Salmón, Jorge Cristobal, Ainoa Quiñones, Francisco José Amo-Setién, María del Carmen Ortego, and et al. 2021. "Looking for Answers to Food Loss and Waste Management in Spain from a Holistic Nutritional and Economic Approach" Sustainability 13, no. 1: 125. https://doi.org/10.3390/su13010125

APA StyleLaso, J., Campos, C., Fernández-Ríos, A., Hoehn, D., del Río, A., Ruiz-Salmón, I., Cristobal, J., Quiñones, A., Amo-Setién, F. J., del Carmen Ortego, M., Tezanos, S., Abajas, R., Bala, A., Fullana-i-Palmer, P., Puig, R., Margallo, M., Aldaco, R., & Abejón, R. (2021). Looking for Answers to Food Loss and Waste Management in Spain from a Holistic Nutritional and Economic Approach. Sustainability, 13(1), 125. https://doi.org/10.3390/su13010125