Sustainable Additive Manufacturing: Mechanical Response of Polypropylene over Multiple Recycling Processes

Abstract

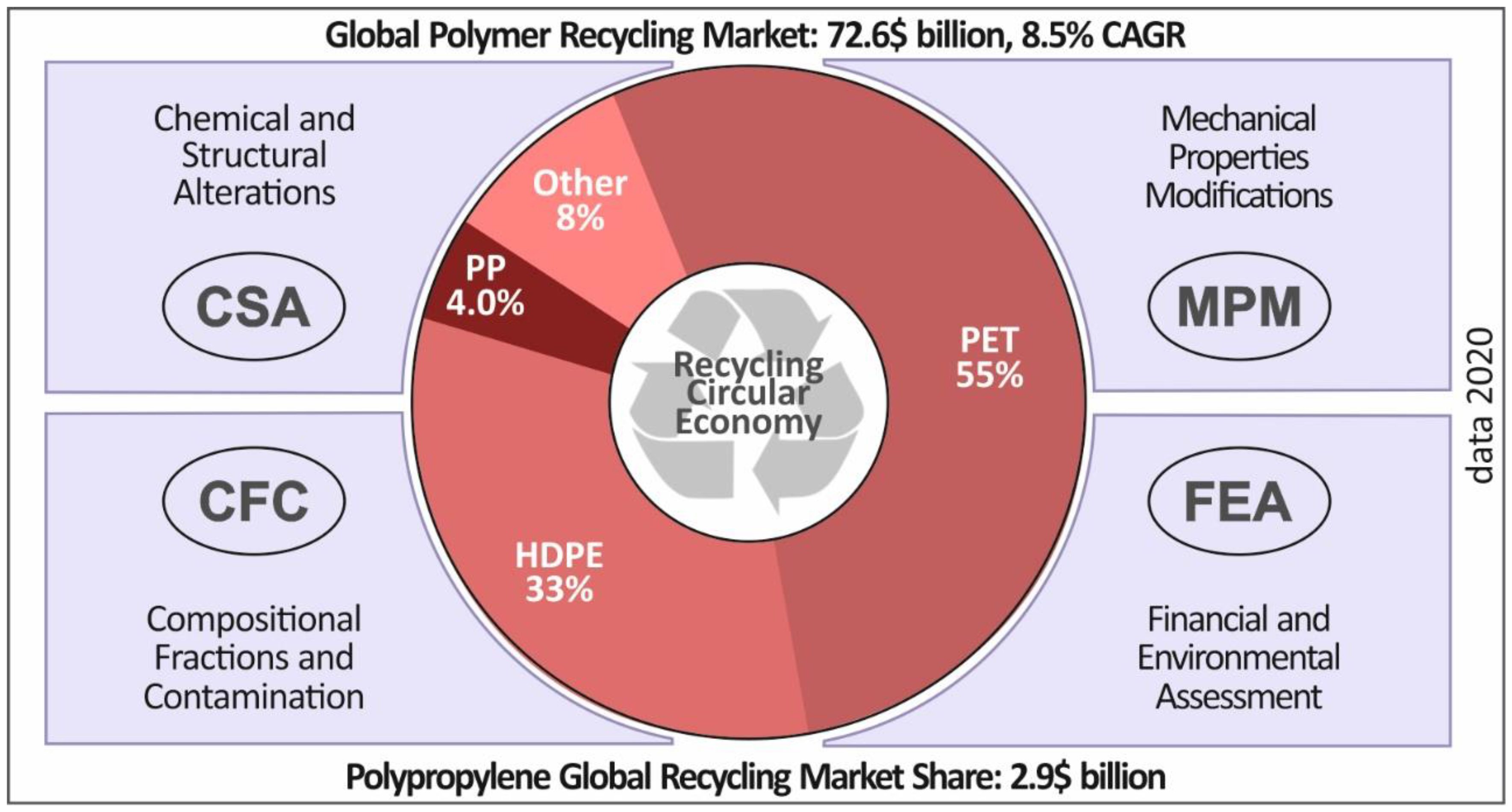

1. Introduction

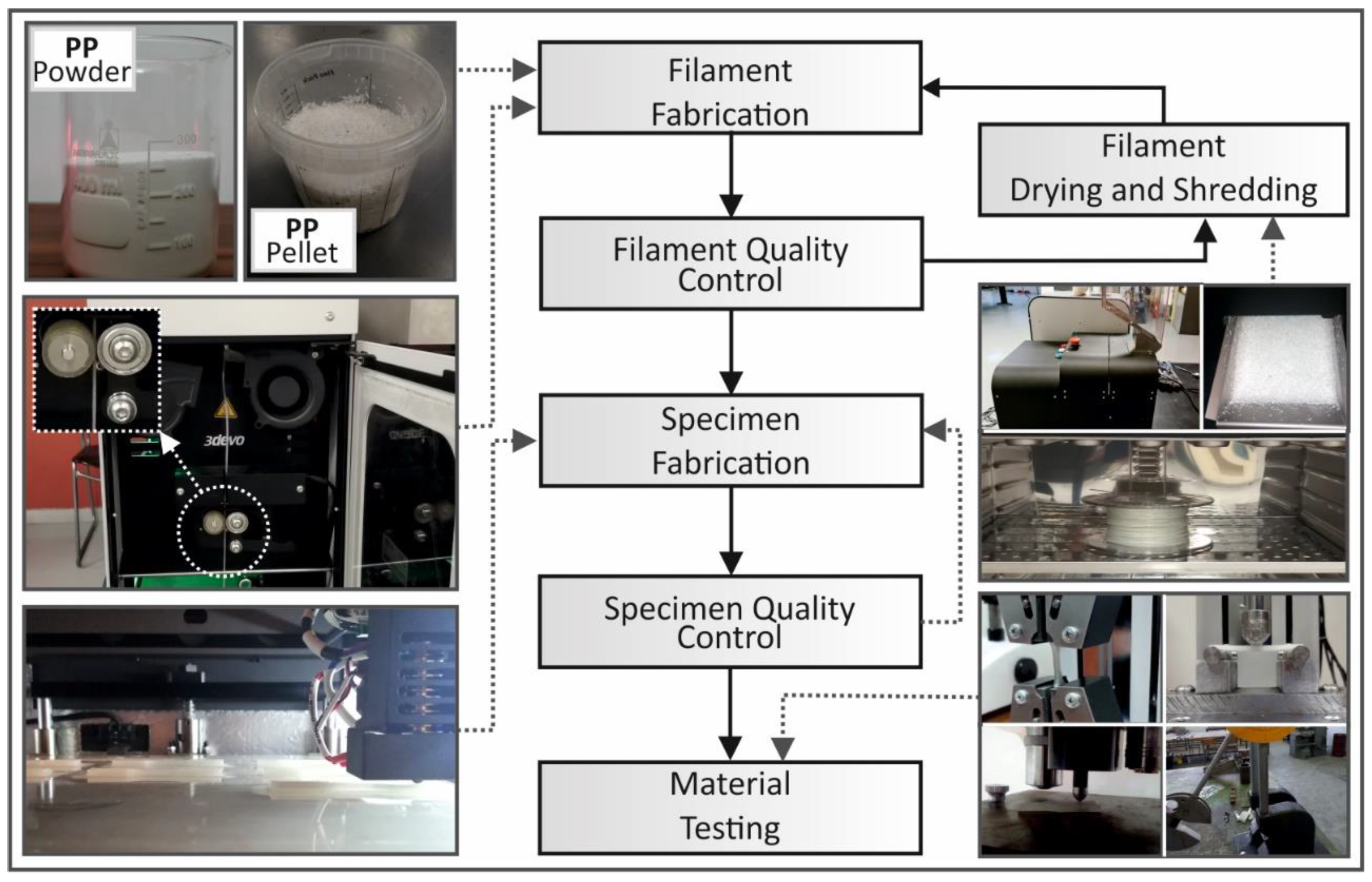

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Recycling Process

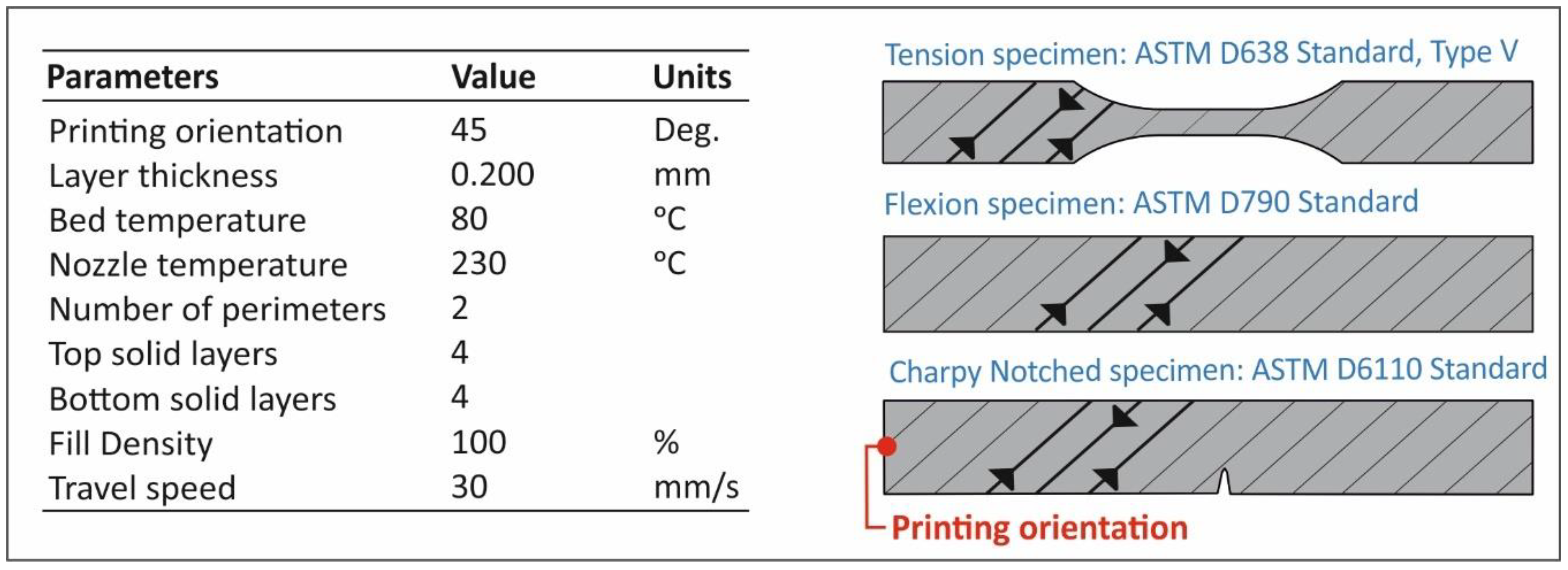

2.2.2. Tensile Specimens’ Fabrication and Testing

2.2.3. Flexion Specimens’ Fabrication and Testing

2.2.4. Impact Specimens’ Fabrication and Testing

2.2.5. Micro-Hardness Measurements

2.2.6. Thermal Analysis

2.2.7. Raman Spectroscopy

2.2.8. Morphological Characterization

3. Results

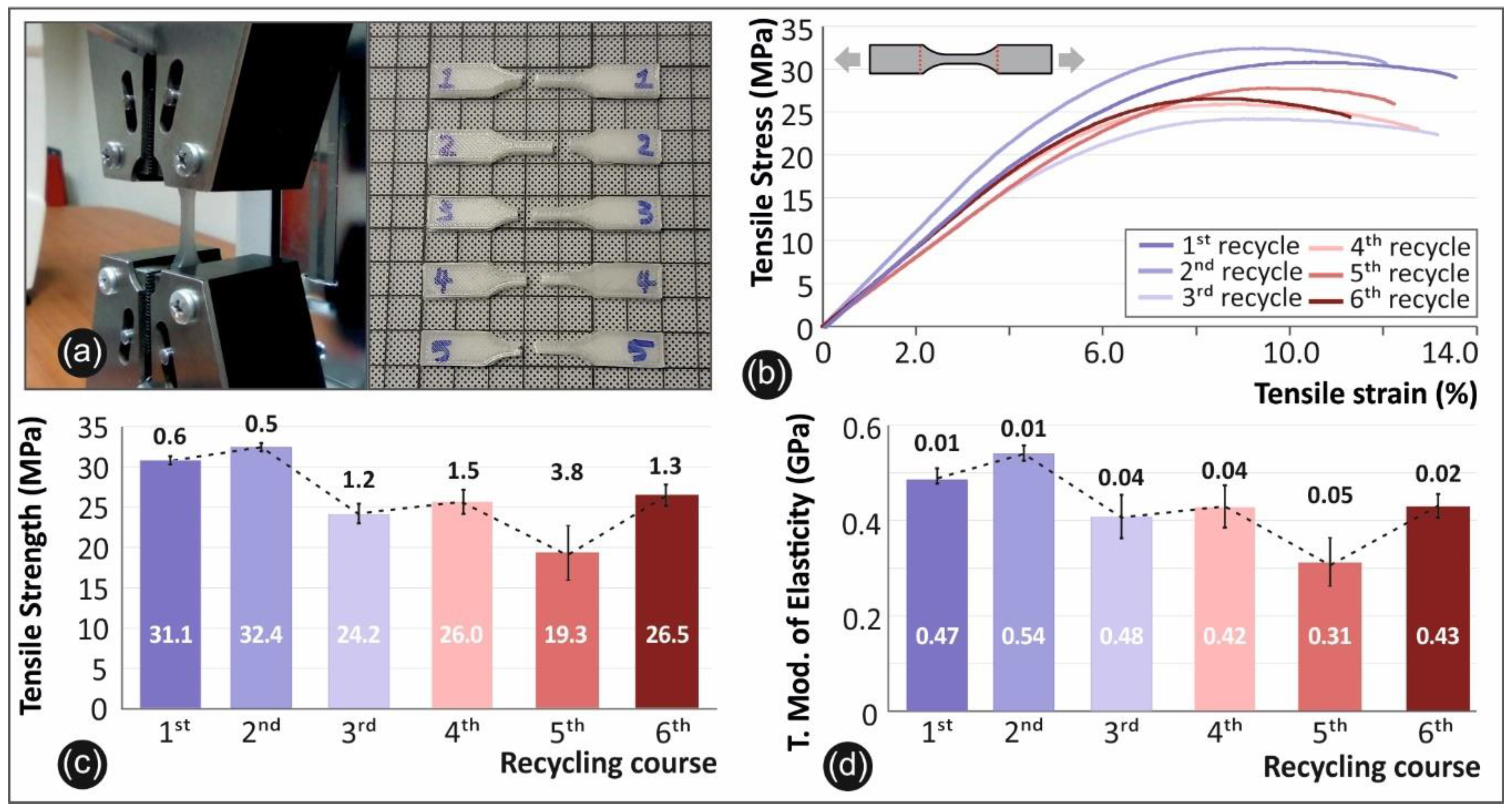

3.1. Tensile Test Results

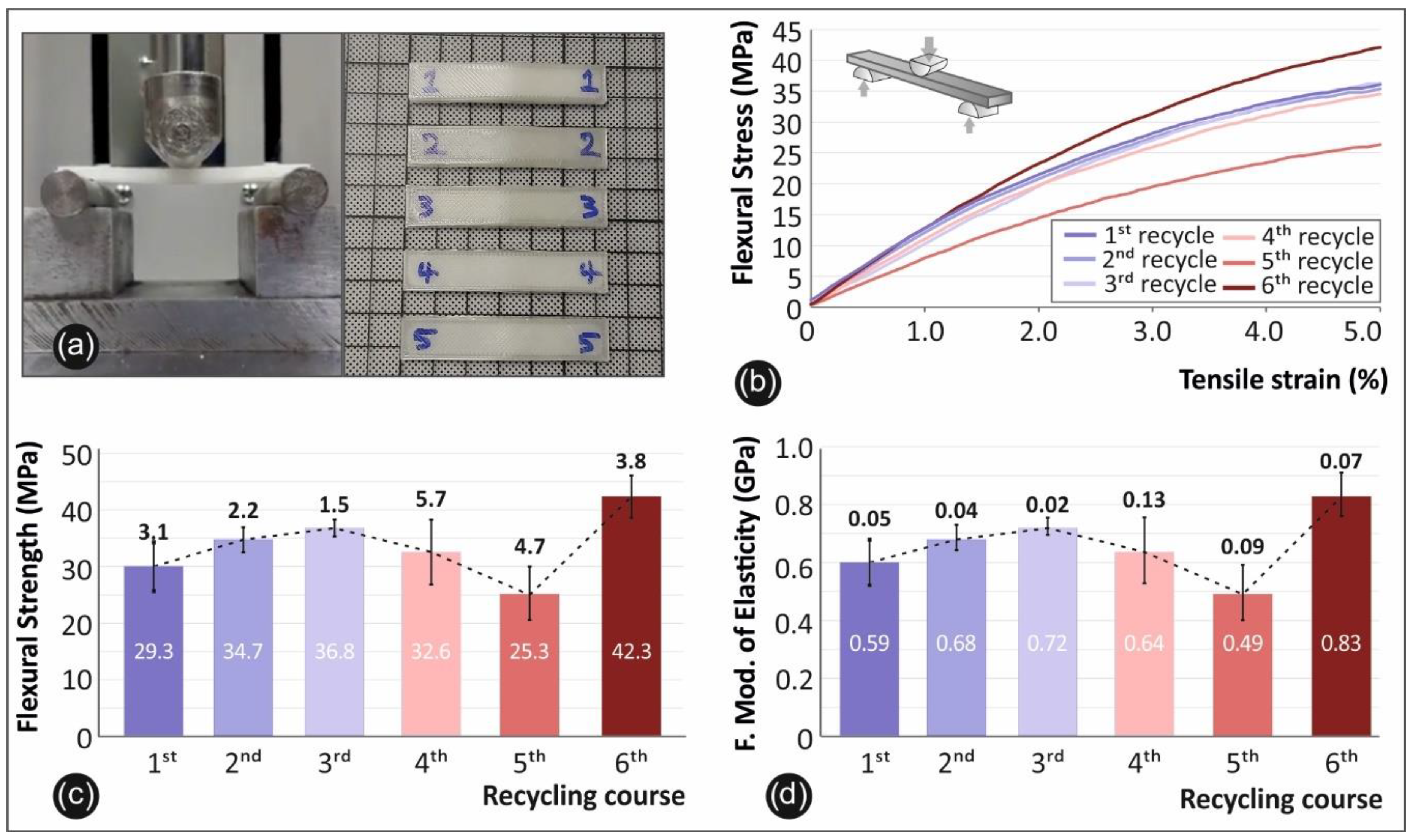

3.2. Flexural Test Results

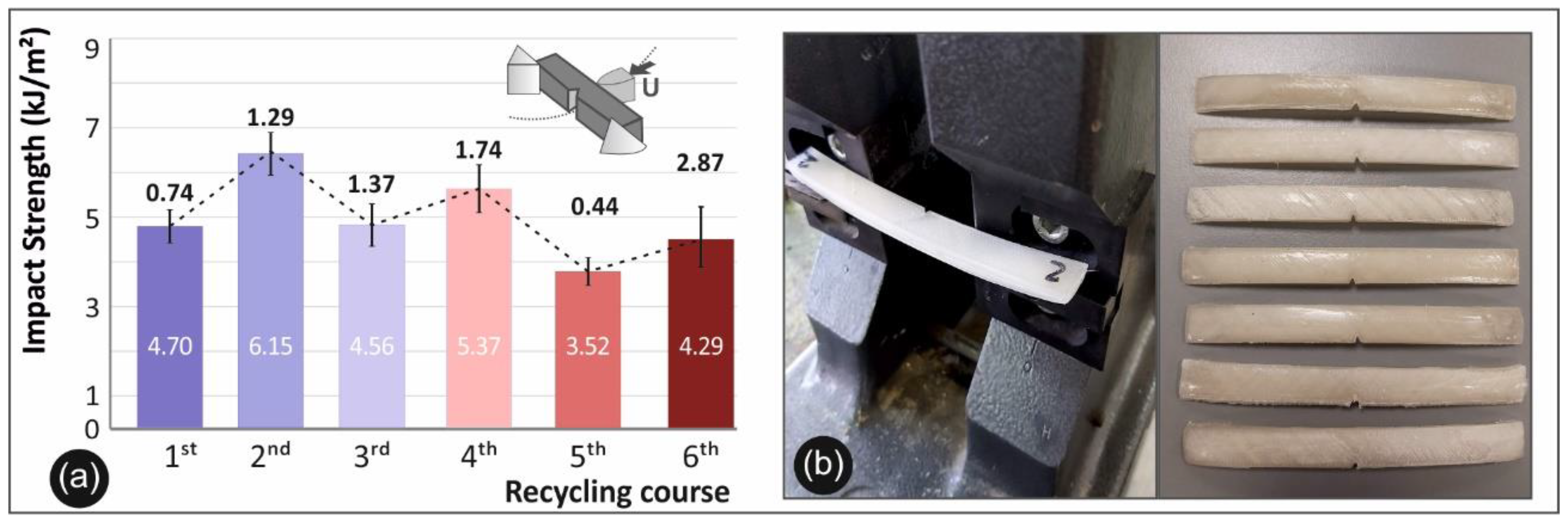

3.3. Impact Results

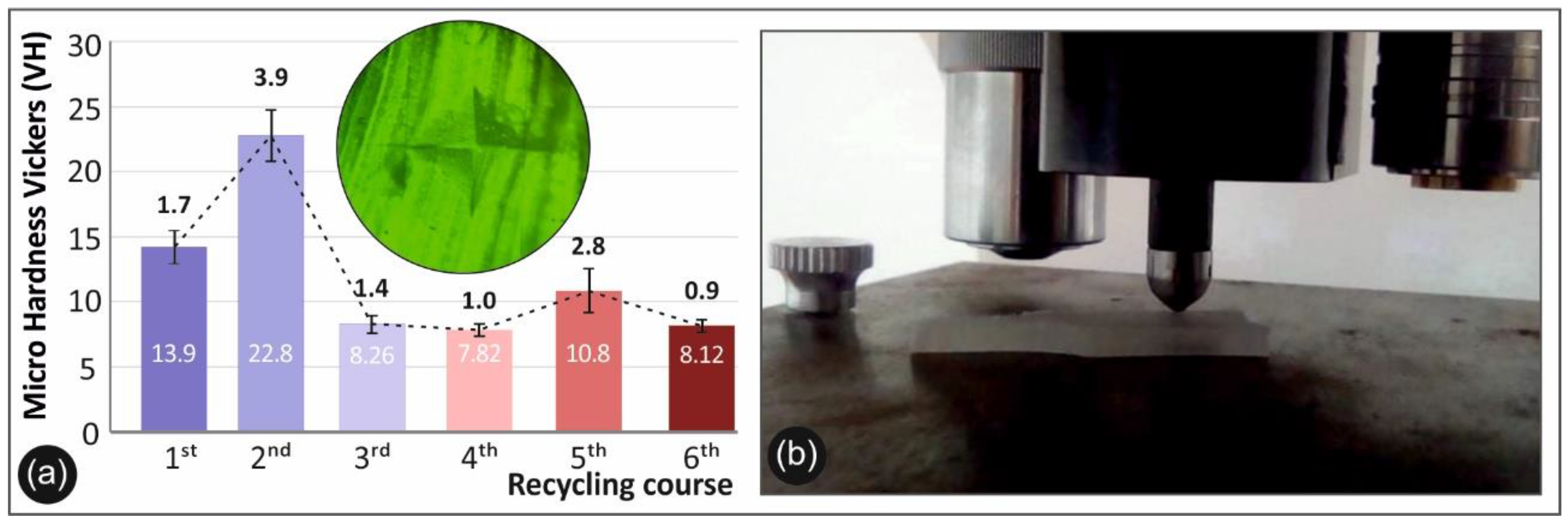

3.4. Microhardness Results

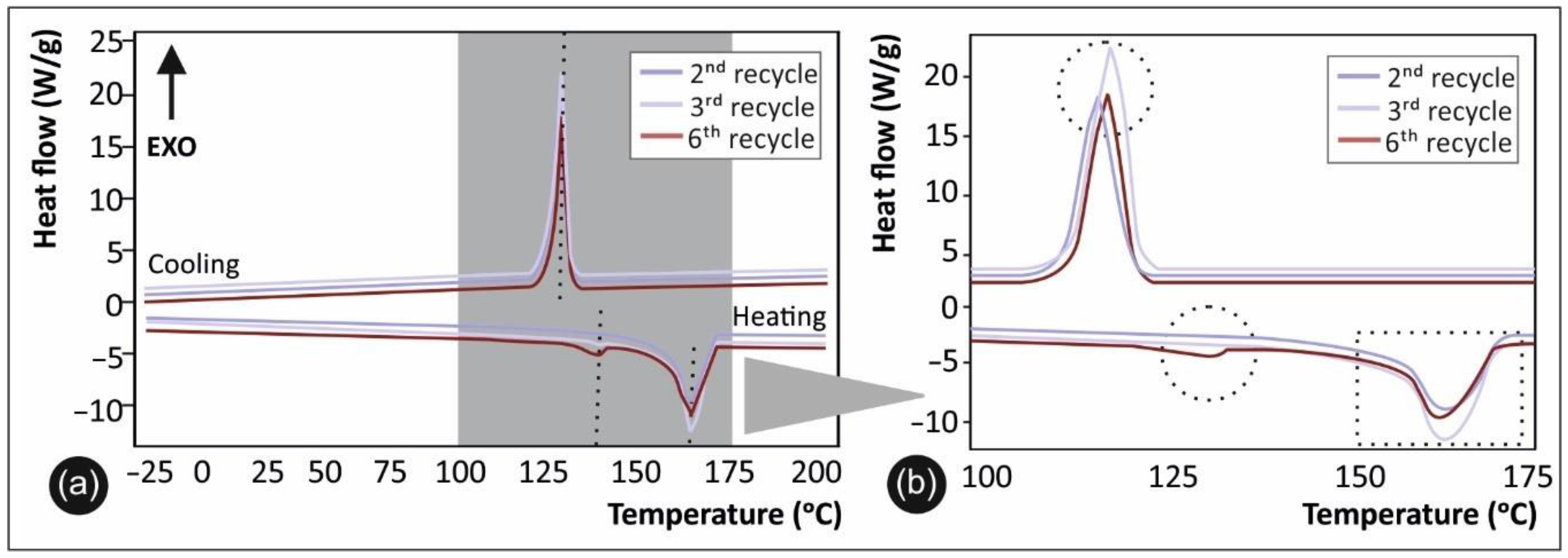

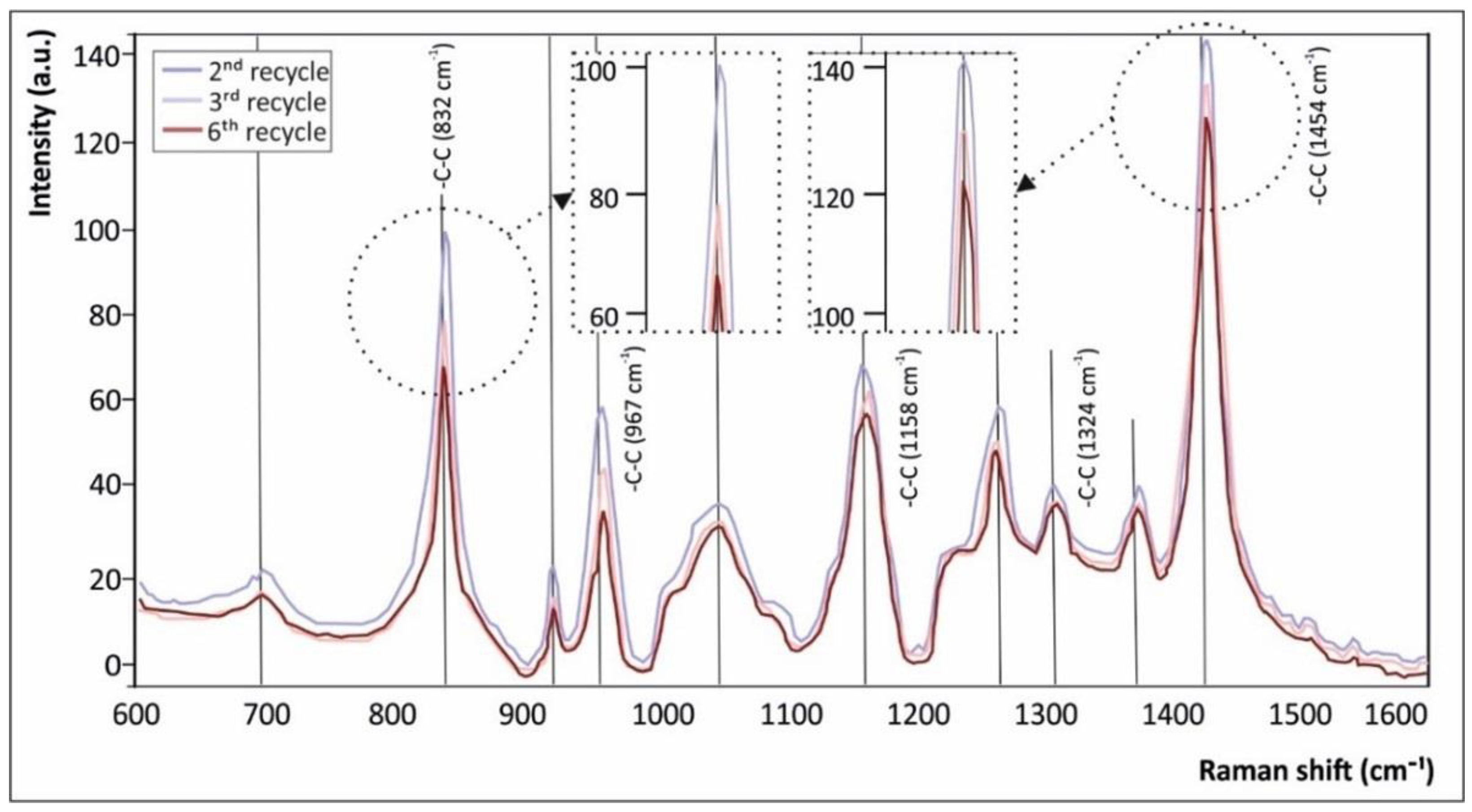

3.5. Thermal Analysis and Raman Spectroscopy Results

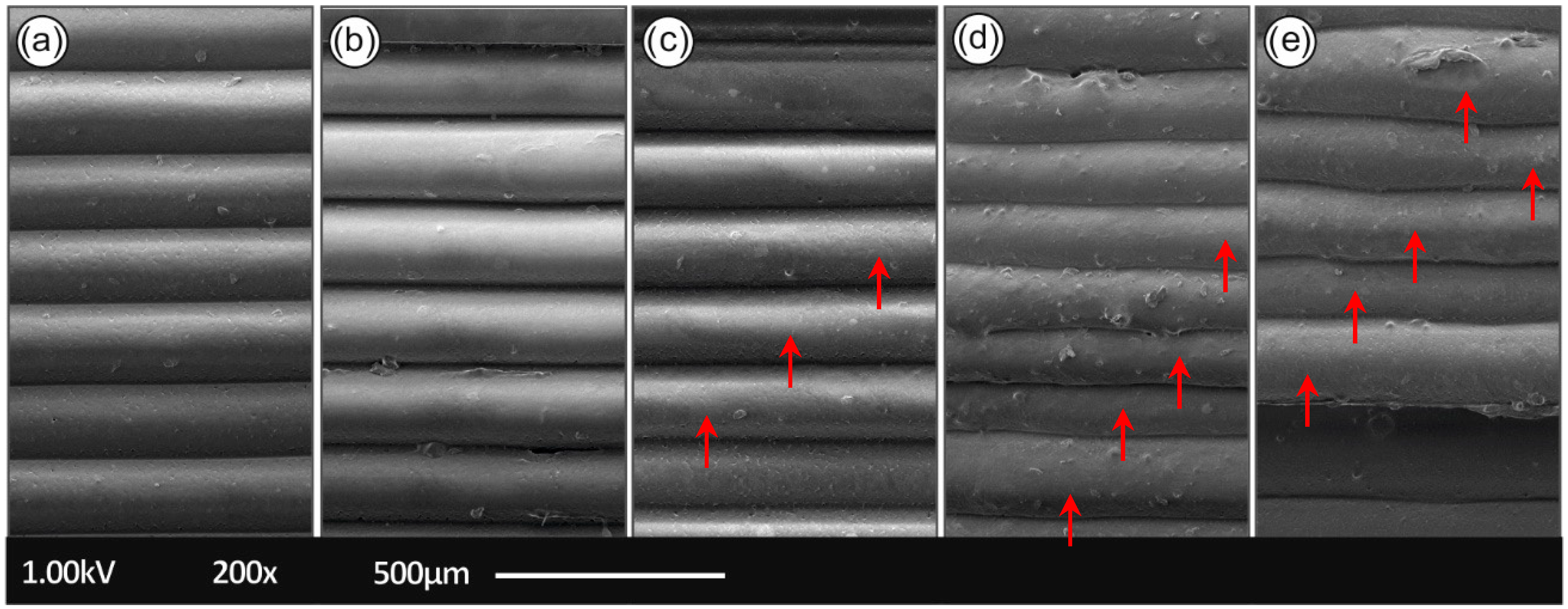

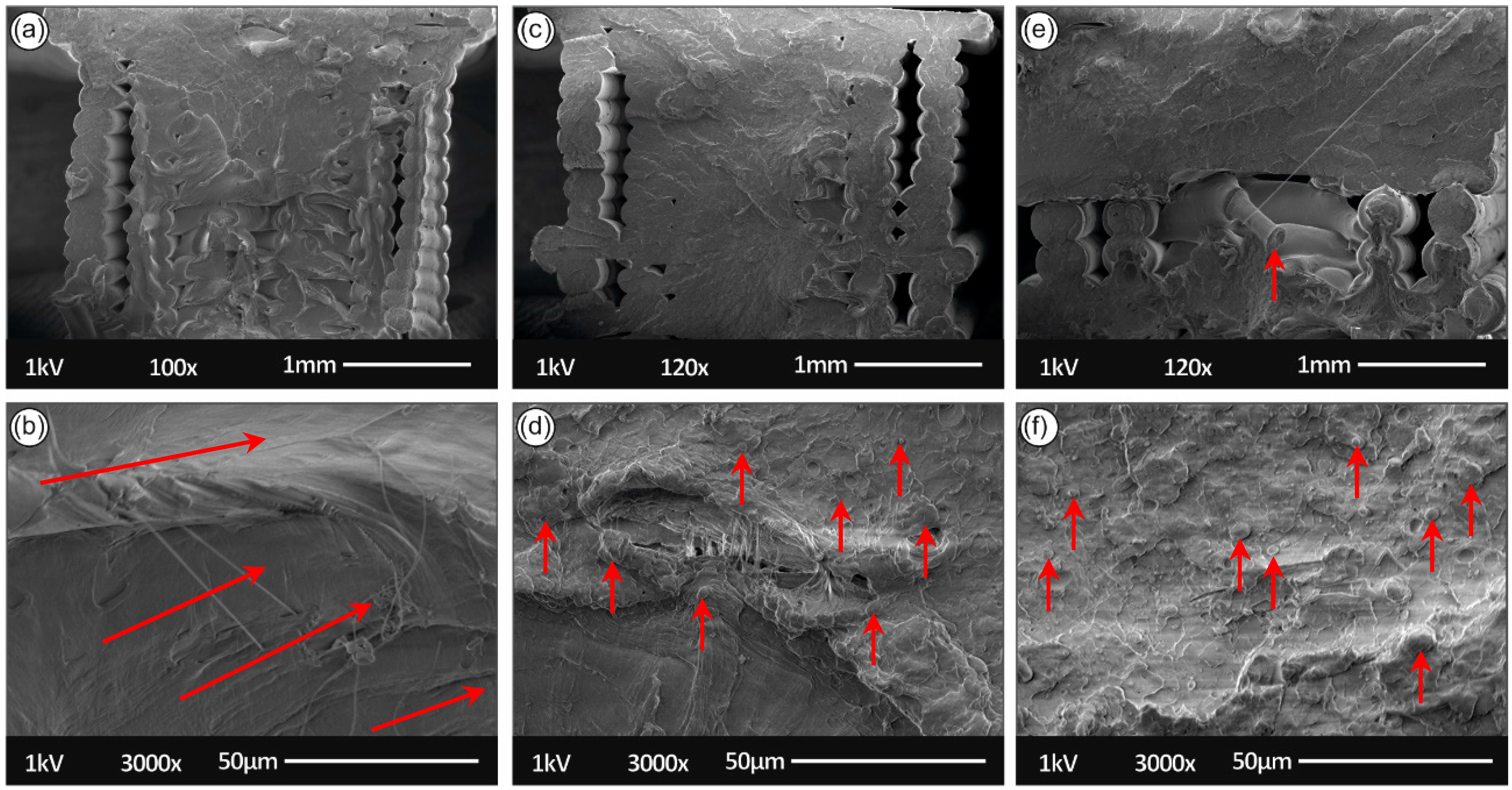

3.6. Morphological Characterization Results

4. Discussion

4.1. Mechanical Properties

4.2. Thermal Analysis Investigations

4.3. Raman Spectroscopic Analysis

4.4. AM. Samples’ Side Surface Morphology and Microstructure

4.5. Fractography Microstructure Investigations

5. Conclusions

- Thermal stress has a negative effect on tensile properties of PP material when it comes to AM applications.

- Flexural behavior of PP under repeated thermal reprocessing and used in AM processes seems to be improved.

- Impact strength and microhardness show a rather neutral behavior under first six (6) thermal recycling processes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barnes, J. Out of sight, out of mind: Plastic waste exports, psychological distance and consumer plastic purchasing. Glob. Environ. Change 2019, 58, 101943. [Google Scholar] [CrossRef]

- Bijaisoradat, O.; Luttapreecha, M.; Manuspiya, H. Eco composites with synergistic combinations of natural rubber latex and wood flour toughened recycled HDPE. Mater. Today Commun. 2020, 25, 101483. [Google Scholar] [CrossRef]

- Luedtke, J.; Gaugler, M.; Grigsby, J.; Krause, A. Understanding the development of interfacial bonding within PLA/wood-based thermoplastic sandwich composites. Ind. Crop. Prod. 2019, 127, 129–134. [Google Scholar] [CrossRef]

- Plastics—The Facts 2019 An Analysis of European Plastics Production, Demand and Waste Data 2019 23th April 2020. Available online: https://www.plasticseurope.org/application/files/1115/7236/4388/FINAL_web_version_Plastics_the_facts2019_14102019.pdf (accessed on 25 November 2020).

- Technavio. Global Recycled Plastics Market 2018–2022 (IRTNTR21968); Infiniti Research Limited: Toronto, ON, Canada, 2019. [Google Scholar]

- Diegel, O. 10.02 Additive Manufacturing. In Comprehensive Materials Processing; Hashmi, S., Batalha, G.F., van Tyne, C.J., Yilbas, B., Eds.; Elsevier: Oxford, UK, 2014; pp. 3–18. [Google Scholar]

- Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Vairis, A.; Kechagias, J. Sustainable additive manufacturing: Mechanical response of acrylonitrile-butadiene-styrene over multiple recycling processes. Sustainability 2020, 12, 3568. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Liebscher, M.; Tzounis, L. Mechanical properties of 3D-printed acrylonitrile-butadiene-styrene TiO2 and ATO nanocomposites. Polymers 2020, 12, 1589. [Google Scholar] [CrossRef] [PubMed]

- Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Kenanakis, G.; Romanitan, C.; Tutunaru, O.; Suchea, M.; Kechagias, J. The mechanical and physical properties of 3D-Printed materials composed of ABS-ZnO nanocomposites and ABS-ZnO microcomposites. Micromachines 2020, 11, 615. [Google Scholar] [CrossRef]

- Spoerk, M.; Arbeiter, F.; Raguž, I.; Holzer, C.; Gonzalez-Gutierrez, J. Mechanical recyclability of polypropylene composites produced by material extrusion-based additive manufacturing. Polymers 2019, 11, 1318. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S. Recycling of Thermoplastic Wastes: A Route of Waste to Wealth via Three-Dimensional Printing; Elsevier Ltd.: Oxford, UK, 2020; ISBN 9780128203521. [Google Scholar]

- Spina, R.; Cavalcante, B. Preliminary analysis of extruded PP filaments for FFF. Procedia Manuf. 2020, 47, 915–919. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Reinicke, T. On the environmental impacts of 3D printing technology. Appl. Mater. Today 2020, 20, 100689. [Google Scholar] [CrossRef]

- Grigorescu, R.M.; Ghioca, P.; Iancu, L.; David, M.E.; Andrei, E.R.; Filipescu, M.I.; Ion, R.M.; Vuluga, Z.; Anghel, I.; Sofran, I.E.; et al. Development of thermoplastic composites based on recycled polypropylene and waste printed circuit boards. Waste Manag. 2020, 118, 391–401. [Google Scholar] [CrossRef]

- Othman, M.H. Recycled Polypropylene-Nanoclay Composites—Mechanical Properties; Elsevier Ltd.: Oxford, UK, 2020; ISBN 9780128035818. [Google Scholar]

- Rokbi, M.; Khaldoune, A.; Sanjay, M.R.; Senthamaraikannan, P.; Ati, A.; Siengchin, S. Effect of processing parameters on tensile properties of recycled polypropylene based composites reinforced with jute fabrics. Int. J. Light. Mater. Manuf. 2020, 3, 144–149. [Google Scholar] [CrossRef]

- Stoof, D.; Pickering, K. Sustainable composite fused deposition modelling filament using recycled pre-consumer polypropylene. Compos. Part B Eng. 2018, 135, 110–118. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- An Lin, T.; Lin, J.H.; Bao, L. Polypropylene/thermoplastic polyurethane blends: Mechanical characterizations, recyclability and sustainable development of thermoplastic materials. J. Mater. Res. Technol. 2020, 9, 5304–5312. [Google Scholar] [CrossRef]

- Souza Rosa, C.H.S.; Mothé, M.G.; Vieira Marques, M.F.; Mothé, C.G.; Monteiro, S.N. Steam-exploded fibers of almond tree leaves as reinforcement of novel recycled polypropylene composites. J. Mater. Res. Technol. 2020, 9, 11791–11800. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Core, B. 3D Printing 2019–2029 Technology and Market Analysis; IDTechEx: Cambridge, UK, 2019. [Google Scholar]

- Jin, M.; Neuber, C.; Schmidt, H.W. Tailoring polypropylene for extrusion-based additive manufacturing. Addit. Manuf. 2020, 33, 101101. [Google Scholar] [CrossRef]

- Fischer, J. Handbook of Molded Part Shrinkage and Warpage; William Andrew: Oxford, UK, 2012. [Google Scholar]

- Saxena, P.; Stavropoulos, P.; Kechagias, J.; Salonitis, K. Sustainability Assessment for Manufacturing Operations. Energies 2020, 13, 2730. [Google Scholar] [CrossRef]

- Salonitis, K.; Stavropoulos, P. On the Integration of the CAx Systems Towards Sustainable Production. Procedia CIRP 2013, 9, 115–120. [Google Scholar] [CrossRef]

- Guo, X.; Lin, Z.; Wang, Y.; He, Z.; Wang, M.; Jin, G. In-Line Monitoring the Degradation of Polypropylene under Multiple Extrusions Based on Raman Spectroscopy. Polymers 2019, 11, 1698. [Google Scholar] [CrossRef]

- González-González, V.A.; Neira-Velázquez, G.; Angulo-Sánchez, J.L. Polypropylene chain scissions and molecular weight changes in multiple extrusion. Polym. Degrad. Stab. 1998, 60, 33–42. [Google Scholar] [CrossRef]

- da Costa, H.M.; Ramos, V.D.; de Oliveira, M.G. Degradation of polypropylene (PP) during multiple extrusions: Thermal analysis, mechanical properties and analysis of variance. Polym. Test. 2007, 26, 676–684. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Liebscher, M.; Tzounis, L. Three-Dimensional Printed Antimicrobial Objects of Polylactic Acid (PLA)-Silver Nanoparticle Nanocomposite Filaments Produced by an In-Situ Reduction Reactive Melt Mixing Process. Biomimetics 2020, 5, 42. [Google Scholar] [CrossRef] [PubMed]

- Tzounis, L.; Hegde, M.; Liebscher, M.; Dingemans, T.; Pötschke, P.; Paipetis, A.S.; Zafeiropoulos, N.E.; Stamm, M. All-aromatic SWCNT-Polyetherimide nanocomposites for thermal energy harvesting applications. Compos. Sci. Technol. 2018, 156, 158–165. [Google Scholar] [CrossRef]

- Gee, D.R.; Melia, T.P. Thermal properties of melt and solution crystallized isotactic polypropylene. Die Makromol. Chem. 1970, 132, 195–201. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Bikiaris, D.N.; Chrissafis, K. Effect of crystalline structure of polypropylene random copolymers on mechanical properties and thermal degradation kinetics. Thermochim. Acta 2012, 543, 288–294. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Chrissafis, K.; Bikiaris, D.N. β-Nucleated Polypropylene: Processing, Properties and Nanocomposites. Polym. Rev. 2015, 55, 596–629. [Google Scholar] [CrossRef]

- Wang, L.; Yang, M.-B. Unusual hierarchical distribution of β-crystals and improved mechanical properties of injection-molded bars of isotactic polypropylene. Rsc Adv. 2014, 4, 25135–25147. [Google Scholar] [CrossRef]

- Tzounis, L.; Gärtner, T.; Liebscher, M.; Pötschke, P.; Stamm, M.; Voit, B.; Heinrich, G. Influence of a cyclic butylene terephthalate oligomer on the processability and thermoelectric properties of polycarbonate/MWCNT nanocomposites. Polymer 2014, 55, 5381–5388. [Google Scholar] [CrossRef]

- Tzounis, L.; Petousis, M.; Grammatikos, S.; Vidakis, N. 3D Printed Thermoelectric Polyurethane/Multiwalled Carbon Nanotube Nanocomposites: A Novel Approach towards the Fabrication of Flexible and Stretchable Organic Thermoelectrics. Materials 2020, 13, 2879. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vidakis, N.; Petousis, M.; Tzounis, L.; Maniadi, A.; Velidakis, E.; Mountakis, N.; Papageorgiou, D.; Liebscher, M.; Mechtcherine, V. Sustainable Additive Manufacturing: Mechanical Response of Polypropylene over Multiple Recycling Processes. Sustainability 2021, 13, 159. https://doi.org/10.3390/su13010159

Vidakis N, Petousis M, Tzounis L, Maniadi A, Velidakis E, Mountakis N, Papageorgiou D, Liebscher M, Mechtcherine V. Sustainable Additive Manufacturing: Mechanical Response of Polypropylene over Multiple Recycling Processes. Sustainability. 2021; 13(1):159. https://doi.org/10.3390/su13010159

Chicago/Turabian StyleVidakis, Nectarios, Markos Petousis, Lazaros Tzounis, Athena Maniadi, Emmanouil Velidakis, Nicolaos Mountakis, Dimitrios Papageorgiou, Marco Liebscher, and Viktor Mechtcherine. 2021. "Sustainable Additive Manufacturing: Mechanical Response of Polypropylene over Multiple Recycling Processes" Sustainability 13, no. 1: 159. https://doi.org/10.3390/su13010159

APA StyleVidakis, N., Petousis, M., Tzounis, L., Maniadi, A., Velidakis, E., Mountakis, N., Papageorgiou, D., Liebscher, M., & Mechtcherine, V. (2021). Sustainable Additive Manufacturing: Mechanical Response of Polypropylene over Multiple Recycling Processes. Sustainability, 13(1), 159. https://doi.org/10.3390/su13010159