Abstract

The industry has entered on the Fourth Industrial Revolution, the so-called Industry 4.0, with global markets and strong competition, some traditional manufacturing firms are implementing new maintenance innovations and policies, based on digitalisation and data driven approach, but also based on servitisation. The implementation of these new equipment maintenance business models, could require new organisational approach at different levels. Different sorts of integration are arranged, in vertical with a flat structure of intelligent, flexible and autonomous units working integrated, in horizontal with a strong external and internal supply chain integration, and in transverse, with an integrated approach that link internal and external stakeholders. A new prescriptive maintenance business model for equipment exploiting digitalisation opportunities, including stakeholder relationship is proposed. Different perspectives such as organisational, innovation and sustainability have been adopted to discuss the implications of the proposal. The social value potentially gained as well as the alignment with the SDGs are discussed as well.

1. Introduction

Business models (BMs) have been described as frameworks by which firms create and captures value, including a unique activity and resource structure and an innovative customer value proposition besides a scheme for capturing value [1,2,3]. Although essentially generic, those instruments can be useful for business analysis. BMs offer a more nuanced view of customer demand, considering the context in which the customer is embedded, the differing needs of different customer groups, and the connection of the resources and capabilities of the firm and its network to satisfying these needs. This perspective is gaining momentum because of the adoption of the Industry 4.0 (I4.0) paradigm, with the development of the Internet of Things (IoT) and smart sensing technology [4].

The so called digitalisation in industry aims to connect products and services in an extended way, by shortening innovation cycles, and it takes form with different levels of engagement through the use of platforms [5]. Therefore, digitalisation offers an alternative view to the old dichotomy between product and service, allowing to discuss topics in management practice, theory, and demand for new concepts [6,7]. From another point of view digitalisation fosters a product-service continuum, where the combination of product and service delivers value in use when different actors become involved, i.e., a Product-Service System (PSS) [8].

The PSS approach has been applied to help industries mainly in production related environments, enabling their own smart product service ecosystems (SPSE) to enhance their integrated competitiveness and offer better customer experience [9]. Deeply, SPSE is defined as an Information and Communication Technologies (ICT) based dynamic ecological smart PSS network, which integrates customers, smart product service systems, smart service platform and product service suppliers for value co-creation and customers experience improvement, by means of smart interaction, mutual cooperation, resource sharing and optimal configuration [10].

However, the scientific literature related to BMs frameworks usually focus on value creation and value extraction, but less attention was paid to concepts such as value destroyed or transformed and value missed both, inside and outside of the agents’ ecosystem. Indeed, no enough attention was paid to smaller sectors, but able to significantly transform business because of the positive effects of digitalisation such as transparency, efficiency and sustainability. Such a sector is the smart maintenance of industrial assets, where research specifically considering the characteristics of digital BMs for maintenance services is lacking, as claimed by Passlick et al. [11].

The coming evolution of strategies in maintenance not only enhances the use of equipment health management systems, that have the potential to predict the remaining useful life of items of interest, but also allows identifying more than one alternative response to conflicts of interest in the conduction of operations by actors’ ecosystem [12]. In this engagement digitalisation helps to create assets that become aware of themselves and able to foresee their future operational status according to the estimated demand by using their own digital twins (DT) and the process DT implementations [13]. Therefore, the assets become aware of their damage function in time and they can estimate their maintenance needs, it is the prescriptive maintenance (PcrM) [14,15]. Coordination to accomplish preventive actions must be established between different actors, with the appropriate level of specialised knowledge.

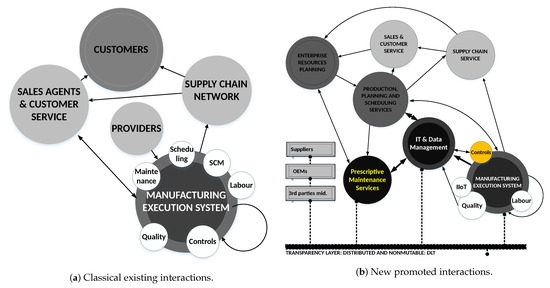

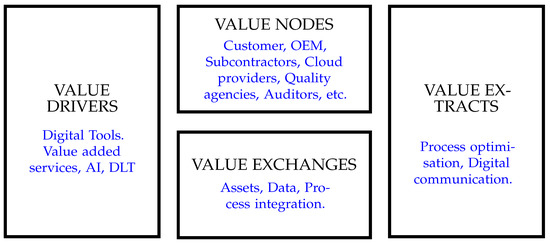

The business network based framework enlarges the value creation across the company borders (see Figure 1, as what it becomes relevant now is the SPSE and the way it can deliver value from different perspectives to each of the participants. For the owner, by making better decisions, considering maintenance and production under an integrative and formal perspective. For the OEM providers, because of they protect themselves against competitors because of the added value inside the network, and because of the focus is not just the equipment design, but the modelling capabilities. For third part service providers linked to service manufacturers, as they need to evolve in order to cover additional sensors and devices required for such models to become effective and they reinforce their position as supportive add-on for OEMs, in order to deliver high quality services. Finally, agencies and certification bodies, but also legal services can get benefit of what it was advised by having a look at the relevant DLT addresses, which will make workflow and smart contract based certifications cheaper, easier and less effort demanding than in the classical way.

Figure 1.

Relationship between agents.

Therefore, PcrM planning is an essential enabler of smart, transparent, and highly flexible production processes. As an enabler, it also promotes the BM at network level (SPSE), which extends and allows organisations to achieve benefits. Like biological ecosystems, firms within business ecosystems evolve symbiotically, that is, they co-evolve, through simultaneous collaboration and competition, co-creation and co-destruction value [16,17] through a long-term relationship and communication with each other [18].

Although existing literature argues that appropriate BMs are crucial to derive the benefits from digital technology economically, environmentally, and socially [19], it is relevant to highlight that recent works in this field Chen et al. [20] only consider the economic benefits from sustainable competitive advantage in the context of the digitalisation technologies, without considering the complex decision making process involved. Therefore, it is required to consider different principles affecting new formulations of BMs when PcrM is addressed, at least:

- Sustainability. According to the social role that organisations are requested to play as providers of good, services, respectful environmental behaviour and social wellness, Sustainable Business Model (SBM) requirements need to be considered.

- Innovation. The innovative dimension is rather intrinsic to the BM creation, therefore, consideration of Business Model Innovation (BMI) becomes natural.

- Organisational. PcrM requires to develop an ecosystem of agents cooperating in a long term engagement through different workflows, while they can involve either human or Artificial Intelligence (AI) based agents. Such dynamic ecosystem is deeply innovative, and it can have a significant impact over the institutional logic for most of the involved agents/organisations.

From the existing literature each of the above principles for BM creation have been extensively discussed Baima et al. [21], Tirabeni et al. [22], Foss and Saebi [23]. However, when considering both principles together, SBM and BMI the existing literature is limited and the fist review was produced by Geissdoerfer et al. [24], where rather generic definition was proposed. The next significant contribution comes from Bocken et al. [25] where it is stated that these BMs extend the emphasis on stakeholder relationships, moving from value creation for customers, suppliers or other business partners, to value creation with and for stakeholders. This engagement takes place in a value network to denote the possibility of mutual value exchanges [26]. In fact an ecosystem typically contains a high degree of inter-dependency among member firms and they normally benefit from the value creating members of the ecosystem [27].

The literature is even more scarce when considering SBM, BMI and Organisational design effects linked to the evolution of the digitalisation fostered ecosystems. Therefore, this paper raises the following research questions,

- When PcrM BMs are considered, which framework and perspectives for the analysis on the interaction inside the built ecosystem are meaningful?

- Which are the significant factors or elements allowing to transform data into value inside the ecosystem?

- When PcrM BMs are considered, what are the expected impacts in terms of innovation, sustainability, social effects, and organisational design for the involved agents?

To answer these research questions this paper promotes an integrative multi-view framework for the ecosystem, it analyses how different agent behaviours fit into the framework, including interactions and finally it discusses the significance of the adoption of such PcrM BM, from the aforementioned perspectives.

Providing such integrated PcrM BM has significant impact in both, the academic and the practical work. For the first one, it brings new glasses based on SBM, BMI and OD for the analysis of the ecosystem framing the agents’ relationships, and it allows to better understand value creation, value appropriation, value transformation, value loosing and value destroying effects, both inside and outside of the ecosystem. It allows to integrate the managerial and the technical perspective seamless but complementary. From the practical point of view, it can help agents to understand the power of each contribution and the value of the whole ecosystem. Therefore, it can help to better identify organisational inefficiencies that need to be overcame. It will also help to develop and implement effective KPIs aligning value transformation with the Sustainable Development Goals (SDGs) contingent on the specific role of each agent in the ecosystem. Finally but yet importantly, it can provide guidance to managers when addressing the opportunities for new SPSE based alternatives in different contexts.

After this introduction to motivate the research and to establish the goals, the next Section 2 will review relevant literature about SBMs and the convenience for their extension, as well as their impact into the organisational design dimension of affected organisations. The next Section 3 presents the adopted methodology to address the research questions and the creation of the PcrM BM. Later, in In Section 4 the relevant framework helping to describe the BMs, including its value proposition is introduced. The Section 5 promotes the discussion of the innovation, sustainability and organisational dimensions inherent to the proposed BMs. Finally, Section 6 presents the main conclusions for the performed research, discusses some limitations and propose future research lines.

2. Literature Review

Industry has entered in the Fourth Industrial Revolution, the so-call Industry 4.0 (I4.0). This digitalisation takes form with different levels of engagement through the use of platforms [5]. this has a direct impact on reducing the lead time associated with production processes. In these processes, the flow of information is just as important, if not more so, than the physical flow of products. One area affected by this paradigm shift is that of facility maintenance, where the goal is to improve the maintenance process, but also offers an opportunity for innovated BMs [28].

2.1. Prescriptive Maintenance and Shared Value

As it has been previously mentioned traditional maintenance is reactive-responding to failures in equipment or devices. This reactive approach of describing failures after they have occurred is the worst-case scenario for maintenance: reacting to failures in equipment or devices after the fact. Preventive maintenance empowers operators to perform continuous maintenance, looking to avoid critical situations, increasing its marginal cost. The next evolution in the maintenance strategy is linked to the predictive capabilities, then the Total Productive Maintenance (TPM) came into the scene, trying to simply minimising machine downtime and looking to improve the Overall Equipment Effectiveness (OEE) of the facility. This strategy was strongly popularised because of incorporating intelligent software into the connected devices (Things) the machines incorporate [7], thus providing machines with a sort of intelligence. Japanese management popularised this approach with the concept of JIDOKA or automation with a human touch [29].

In order to obtain reliable information about the production object, sensors are installed in different parts of the machine to monitor its operation in real time. The data that these sensors send must then be consequently structured and properly labelled. Then, data processing takes place, either in intelligence integrated in the sensors or in external intelligence that allows predicting the failure of the monitored spare parts of the machine. With this Porter and Millar [30] argue that information technology creates value by supporting differentiation strategies. The term “value” refers to the total value created in business transactions regardless of whether it is the firm, the customer or any other participant [31].

Previous studies on proactive maintenance process already recommended adopt proper management procedures in the area of maintenance and technical services as well, but they were only focused on OEM organisational structure. Until recently, information technology has not been consider relevant for maintenance staff, even thought they have highly technical and specialised tasks related to a broad range of technologies. There are a myriad of different technologies than can be seen as cooperating to foster new business development opportunities, such as Internet of Things (IoT), Industry 4.0, AI, automation, smart contracts, big data, the cloud, analytics, etc. [4].

Embedded sensors, software, controllers, connectivity, breakthroughs in networking, edge and fog computing, cloud technology, faster CPUs, cheaper memory, energy efficiency, and miniaturisation are all converging to create low-cost processing power and data storage everywhere and they became the key enabling technologies fuelling up the evolution in the paradigms [32,33,34]. As presented in Merluzzi and Brunetti [35] the “Reliability-Centered Maintenance” represents a systematic approach to evaluate a facility’s equipment and resources to best mate the two and result in a high degree of facility reliability and cost-effectiveness. This maintenance strategy, defined within a wider proposal for Smart-Plant Enabling Solutions, includes also the implementation of combined Condition and Process Monitoring using a common analysis platform.

In PcrM the digital twin knows about the status of the equipment and it will be able to foresee the degradation level based on future demand patterns. All these prediction must be communicated to the relevant stakeholders in an immutable way, because of further actions could be based on them.

To this end, digital twins and Distributed Ledger Technology (DLT) can bring an excellent solution [4]. The fast development of digital modelling tools also creates huge possibilities which facilities decision making within the design team and between clients, contractors and designers; and when the project is socially relevant, it could be open to other stakeholders like the public and the authorities or certification bodies [36]. Therefore, industries have the possibility to enhance their integrated competitiveness by offering extended digitalisation functions and giving a better customer experience. Initial proof of concept has been carried out [37].

From the maintenance BMs review, traditional reliability models were constructed using failure data. In recent decades, with increased product reliability, it has become difficult to obtain failure data within a feasible time period, but sensors make degradation data available during system operation. As a result, degradation models are taking the place of failure data-based reliability models. Degradation models can be either continuous or discrete. In a discrete degradation model, the system condition is divided into a finite number of states, which is usually characterised by a Markov or semi-Markov chain [38,39]. The disadvantage of Markov or semi-Markov models lies in the arbitrary classification of the system states and fails to fully characterise its degradation evolution. An interesting review of the capabilities of different techniques to estimate the degradation modelling can be found in [39].

The consideration of the integrated contribution from the degradation models as a transparent agent in the network of stakeholders as well as their development and improvement will require a deep transformation of business from providers, which requires not only new BMs, but also to consider the impact of it into their own organisational design. However, taking advantage of these new opportunities, it becomes clear that innovation capabilities are critical aspects, and it also will place under question the organisational design approach undertaken at OEM level, in order to increase the business sustainability.

Prescriptive maintenance, is primarily about shared value with customers through more services, and also with internal ecosystem stakeholders through service capabilities. But it is also “co-opetition” within the business environment, where companies simultaneously competing to capture value and cooperating to cocreate value [40].

Besides, value creation opportunities in PcrM ecosystem markets may result from the reconfiguration and integration of resources, capabilities, roles and relationships among the different ecosystem actors.

2.2. Business Model Innovation

BMs and more recently BMIs have become important concept to foster cross sector analysis of organisations from different perspectives, and there is a definitional convergence of the literature as creating value tools [2,41], although research on BM innovation induces the additional dimension of innovation and introduces new questions regarding the key elements of a firm’s BM and the architecture linking these elements [23].

Business model canvas (BMC) is a great tool for describing, analysing and designing BMs [42]. Osterwalder et al. [43] have recently published a customer-value canvas, which is an add-on to BMC. However, due to the innovation and sustainability principles we have adopted in our research and because of the ecosystem dimension needed to create value from the technology enablers, such BMC view needs to be enlarged to cover either the principles as well as the ecosystem aggregated dimension. For a better understanding Table 1) describes the most relevant concepts related BM frameworks and it shows interesting contribution from these different approaches: innovation, sustainable and networked to explain the current state of the art.

Table 1.

Principle Related Frameworks helping to assess new BMs proposals.

Koskela-Huotari et al. [39] define innovation as “a process of re-configuring the institutional structure in service ecosystems that unfolds through the efforts of multiple actors breaking, making and maintaining the institutionalised rules of resource integration”. Change in the institutional logic is then essential for innovation to become successful [44], although innovations strongly deviating from established institutional logic will have problems in breaking through. They will not be regarded as legitimate, will not be taken for granted and will not be supported by authorised power [45].

Although, BMI has been defined by many authors using different classification criteria, and an agreement has not been reached, there is a mainstream classification criterion for BMI. So it has to consider sources of value, innovation degree, market perception, innovation scope, and sources of competitive advantage [20]. However consistent, these criteria are not complete, and other aspects need to be taken into consideration, such as organisational resilience against changes and corporate diversification behaviour promoted by the innovation itself [23,24].

On the other hand, future sustainable business model innovation (SBMs) frameworks should identify the following principles [46]:

- Sustainable value should incorporate economic, social and environmental benefits,

- SBMs require a system of sustainable value flows among multiple stakeholders including the natural environment and society as primary stakeholders,

- SBMs require a value network with a new purpose, design and governance, conceptualized as value forms,

- SBMs require a systemic consideration of stakeholder interests and responsibilities for mutual value creation, and

- Internalizing externalities through PSS enables innovation towards SBMs.

All those criteria will support a consistent sustainable competitive advantage from a multidisciplinary approach for innovative BMs based on PSS, that has been no adopted by previous maintenance studies: customer and service centred BM, integrated and networked BM, and sustainable BM.

Parida et al. [19] points out that there are three main digitalisation functionalities have been identified that facilitate value-creating and value-capturing opportunities in a business-to-business setting. The first functionality is the collection of operational data through sensors. Second, connectivity enables the efficient sharing of data among digital units. Third, analytics is the ability to transform the data available into valuable insights and actionable directives.

As an example in the field of digitalisation Arnaiz et al. [28] analyses how advanced maintenance technologies are enabling the generation of new rental service oriented BMs, where product ownership is not transferred and the focus is on selling usage instead of time, promoting a shift from value in exchange to value in use when looking for customer needs satisfaction.

Chen et al. [20] described two types of Equipment Maintenance Business Models Innovation (EMBMI) in the digitalisation context, based on the functions of this equipment (monitoring, diagnosis, prediction, optimisation) and the gestalt of BMs (value proposition, value creation, value capture). Besides control and all levels of operations and operational planning must co-exist in the same environment, and collaborate, complementing each other without redundancies or competitive functions [47].

But PcrM BM may offer opportunities for sustainable ecosystem BMs. The future maintenance processes can dilute the borders to allow more open interfaces for value-adding components to a broad scope of stakeholders, society and natural environment [48] and the change (innovation) concerns the development of new value propositions, value creation, value capture mechanism, and value delivery networks [49,50]. The impact is not only for customers, who will be able to adopt decisions about production having the information about “what if” in terms of degradation for all those devices, since scope of value should include not just economic transactions but additional relationships, exchanges and interactions that take place among stakeholders and that can be represented by value flows [22].

PcrM business network delivers value from different perspectives to each of the participants. In the SPSE network focal organisations concept is raised, allowing to explore and assess together with stakeholders issues such as value created, fairness, efficiency and effectiveness. Like biological ecosystems business ecosystems are characterised by high complexity, interdependence, cooperation, competition, and coevolution [51]. An ecosystem member competes and collaborates with others within the ecosystem as well as with external actors [52]. Ecosystem members evolve symbiotically, that is, they coevolve through simultaneous collaboration and competition. Some authors refer to the same concept as business constellations [53,54,55], where there is a problem with the combination of participants with a new value proposition which should be clear to all of them and allows their own assessment from profitability (economic feasibility) and technological feasibility perspective [55]. From this perspective the needs for transparency derives rather straight forward, as the normative dimension acquires a fundamental role in explaining behaviours inside such networks. In this sense normative not only accounts for legal enforcement but also to get alignment with the SDGs.

2.3. Overview and Research Gap

Complex networks play an important role in describing these ecosystems, and we can understand it from the megascopic view. Especially in the move towards Industry 4.0, the importance can not be overstated. Other views can be found in distinct forms and at different organisational levels. In [56], three levels of organisational socio-technical complexity are defined as microscopic, mesoscopic, and macroscopic. The macroscopic level takes a bird’s-eye view on the organisation as a socio-technical system, because workers and technology form a complex network based on their interactions. On a lower layer, the mesoscopic level deals with single value streams and the resulting networks of material and information flows. The most atomic view is through the microscopic level. This has usually been the main target in research solving a specific technical step in the value stream [57]. In recent years it has also been used to examine the influence of diverse management systems on the brain of an operator [58,59].

The analysis of contributions from the literature (see Table 1) promotes different principle related frameworks helping to assess new BMs proposals. Indeed, it also shows interesting contribution from digitalisation and technical enablers to explain the dynamic behaviour of agents. However, they fail in providing a consistent perspective for the impact of some specific elements related to the prescriptive maintenance, such as the digital twins, the DLTs, at the BMs level. Even worse, as different perspectives need to be observed, such as the inter-firm ecosystem (megascopic view), but also the firm (macroscopic view), the intra-firm dependencies between organic units (mesoscopic view), as well as the more technical aspects related to the technology required to develop the prescriptive maintenance (microscopic view), the authors were not able to find in the literature a technology based SBM Innovation proposal being observed from all those levels.

3. Methodology

In this section the research design adopted to address the research questions is depicted. The research design for this paper is based on a hybrid strategy based in combining initiatives between literature analysis and action research [73,74,75]. This approach was chosen for two main reasons. Firstly, because it offers the opportunity to investigate processes in-depth and is widely accepted suitable for gaining an understanding of a multidimensional phenomenon [76]. Secondly, it allows for a stream of multiple sources of evidence through, for example, direct observations, interviews, and document search and analysis, which improves the overall quality of the study analysis and enables triangulation.

The systematic literature review helped the authors in identifying the main contributions regarding BM when high technological aspects are involved, and from there to identify the existing gaps. In addition it helped to analyse the existing contributions for BM when different relevant principles are considered. Main outcome from such activity have been presented in the previous section, and it provided additional guidance for the analysis of the created framework.

The action research approach allows the authors to use their practical experience in the technical areas, as well as some existing implementations addressing partially the expected functionalities to be able to configure the framework and analysis perspectives. By continuous iteration between experience, specific implementations and literature research, model refinement and properties highlighting were conducted.

When creation of the framework is addressed, different elements need to be considered all together [77], in a structured manner at the same time to construct a robust business strategy proposal taking into account the pros and reducing the cons of each strategic tool [78]:

- Business Model Canvas (BMC) [64],

- Technology Roadmap (TRM) [78], and

- Information and communication technologies (ICT) [6].

Although all those elements are relevant and provide valid starting point for addressing BM change, the main problem is that those dimensions are quite monolithic. However, there are some authors [79] that have proposed a specific method for addressing the BM creation. Such a method has been adapted in this work and now includes the following stages,

- Understand the BM. This stage requires to identify the BM from different angles, as well as the relevant factors. Then the core of the BM as well as reinforcing and balancing feedback loops can be defined.

- Identify Technology Influence. The central activity for this stage is to identify the key technological aspects for the BM. It also involves the analysis of the possibilities of the forthcoming changes, and finally, the stage requires to elaborate the value proposal.

- Assessment. In this stage all the value related aspects need to be analysed, but also relevant strengths and connections with key concepts must be described. In the present case this stage becomes particularly relevant as ecosystem interactions are essential in the BM proposal.

The outcome of selected method are presented as the key part of the Section 4. The connection between innovation, sustainability and organisational design with the existing BMs does not include the ecosystem perspective. Obviously, such a generic methodology needs to be adapted to the specificity derived from the intra-organisation usage, to the inter-organisational perspective, as it will manage the integrated perspective of different organisational units looking to enlarge the value stream.

Indeed, it is also needed to consider the technological perspective, both technology influence and ICT, in particular the valuable active role of DT as fostering the transparent multi-criterion decision making processes, as is had not being yet considered. Therefore, the authors have decided to address the BM by elaborating an integrated framework, covering such aspects, and linking all the relevant agents and their interactions according to the value management aspects, but indeed enabling the analysis from the different levels of observation. The last stage is presented in the last part of the Section 4 and in the Section 5, when the analysis of strengths and connections is required.

4. Business Model Creation

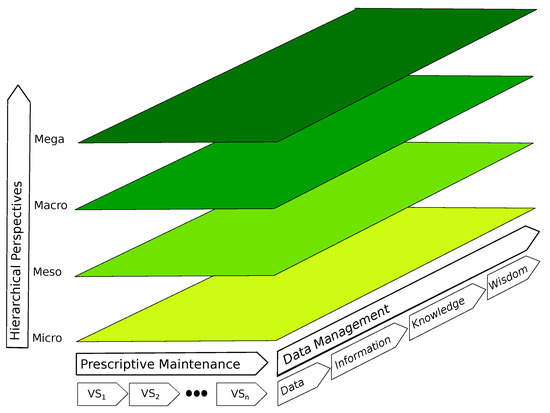

This paper presents a value proposition based on prescriptive maintenance as a fundamental part of strategically achieving sustainable organisational objectives, linked to a digital transformation of the business essence, enabled by SPSE. We have based our work on the initial hypothesis that the flow of information is the key to understanding business value creation. In this new sustainable prescriptive maintenance BMs, we have represented this information flow in four layers of aggregated complexity (see Figure 2). This allows us to represent the flow of value that is produced by translating information into knowledge in a way that is accessible to the interested reader. PcrM, as a fundamental element integrated within an Industry 4.0 framework as presented in this BM, allows a better use of industrial resources since it reduces the downtime of productive processes, allows planning maintenance activities and anticipates system failures before they occur, but also increases the production quality because of the permanent awareness of their status.

Figure 2.

BM Framework.

Within the framework, along the value stream, the main two dimensions to be clarified are: the hierarchical layers of analysis and the data management.

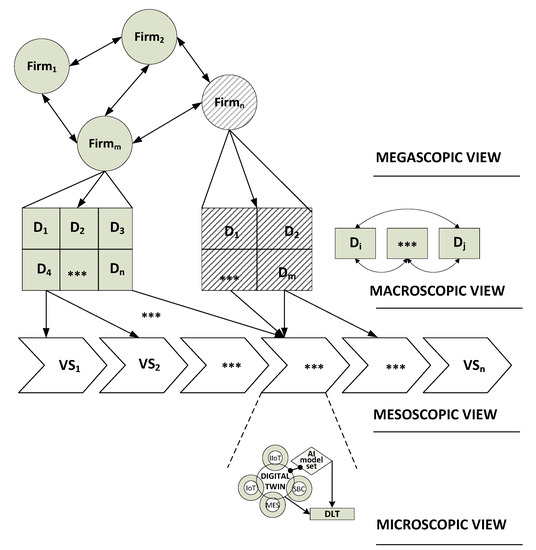

The first dimension describe the hierarchical layers of analysis. As already presented in the Literature Review such layers of presentation are the mega, macro, meso and microscopic views (see Figure 3).

Figure 3.

Different scales of observation to be considered, where ellipses mean repetition for the previous concept, such as next Value Stream or next Department.

The megascopic view represents the same relationship that it was already presented in Figure 1b. However, the macroscopic view focuses on the company level view, where aspects like governance, organisational design, etc. matters. The mesoscopic view gets a closer view to the product or the service under consideration (in our case the prescriptive maintenance of assets being used as services). In this case, the Value Stream (VS) perspective was adopted, where it becomes clear that every step into the VS can be provided by different operational units, single or in cooperation, and where different organisations have explicit cooperation in connected value stream steps. Finally but yet importantly, the microscopic view has the perspective over the finest layer where the prescriptive maintenance related technology, where the different IoT elements but also the Digital Twin (DT) and the AI based models allows to forecast the expected degradation where different usage conditions are under consideration. It is important, as already introduced in the Section 2, to emphasise the networked distribution of information from the models and from the digital twin, providing extra trust level because of the increased traceability of actions and decisions it helps to create.

Following the second dimension of the model, the factors to be focused on the transformation of data into information, of information into knowledge and knowledge into wisdom.

- Systematic data acquisition: In this phase, data collection is ensured by placing smart sensors on the network nodes. At the different hierarchical levels this presents different challenges that must be dealt with in different ways.

- Information: To allow proper data processing into information, the structure in which the data is located is as important as the data itself. The topology in which the data is found will largely determine the methods needed to convert this information into actionable knowledge. That is why this BM proposes standardisation processes for these structures.

- Knowledge:

- Data processing. The data are processed to be transformed into knowledge. This treatment takes place by means of AI algorithms on distributed platforms to ensure its robustness and reliability.

- Business Analytics. Data analysis is performed in semi- or fully supervised processes by experts. However, the trend shown by Industry 4.0 is to delegate more and more processes to unsupervised algorithms based on Big Data and technologies such as Deep Learning.

- Value:

- Decision making. Depending on the strategic objectives of the organisation, corresponding decisions will be made. For this purpose, the management must have an adequate management system that supports the BM.

- Operationalisation. The implementation of the decisions taken, carries with it an implicit commitment by the management that allows not only the achievement of objectives, but also that these are sustainable over time.

In the area of prescriptive maintenance, in line with the definition of the BM given in Section 1, this framework makes it possible to create and capture value by offering a structure of activities along the value stream that make it possible to organise the available resources and put them at the service of the intended strategic sustainability objectives.

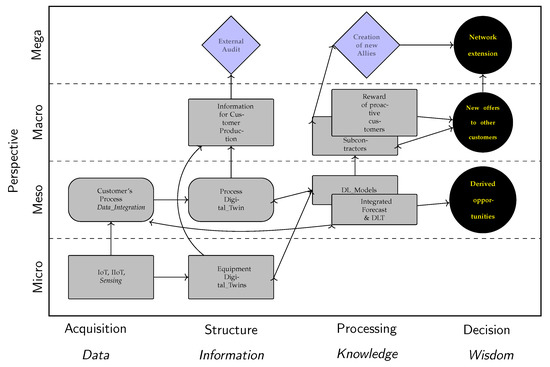

In the following paragraphs we will proceed to describe Figure 4 in detail. On the vertical axis we depict the hierarchical levels: as we move from left to right the level of aggregation increases. On the horizontal axis we represent the phases of information management that allow the acquisition and structuring of information so that it is processed into knowledge that becomes value for the client through informed and actionable decision-making. Moving along these two axes, and always based on the definition of the value drivers that determine the different customers of prescriptive maintenance, both internal and external, we will represent the different steps of the value creation process.

Figure 4.

Explanation of the business model for one stakeholder (The OEM of product being servitised).

At a micro level, we start with a sensory structure based on the IoT or IIoT, which on one hand generates relevant information for modelling Digital–Twin equipment, and on the other hand allows an integration of customer processes at a meso level. The digital twin at asset level is essential to develop degradation models allowing to explore different operational scenarios. Depending on them service details will be shared through DLT transactions with other network partners. Customer data is required to develop consistently such degradation models, based on the Digital–Twins (DTs) (product and process.)

Customer will realise the convenience of structuring its process data by generating a DT model at meso level of the process. This information structured at meso level on one hand will be processed into knowledge when degradation status becomes estimated and shared to different stakeholders through DLT. On the other hand it will be aggregated into information for the internal production customer at a macro level. Based on such information coming from the process but also from the different DTs representing different involved assets it will be possible either ask independent third parts to assess the quality of the information, which provides trust to the network, or allow the customer to optimise the process based on the process data, or to increase its intrinsic security. This innovation can be handled at customer node, either at meso or macro levels.

DLT distributed information from models and DTs, integrated at the meso level will be used to provide relevant information to subcontractors at the macro level. At both meso and macro levels, this information will be used to create business opportunities and create value at different stakeholder nodes. All those new opportunities requires deeply analysis for the value transformed, to determine the proper compensations between agents. This is the case for instance between the OEM and the customer, as its process information becomes essential to determine the degradation models.

The new opportunities allow creation of new strategic alliances at the mega level and the extension of the value creation network. These actions determine the way in which value is created through resources, processes, activities and capacities.

Attending now at the third stage of the adopted methodology, the action plan needs to consider different phases. The Table 2 provides an additional perspective in the three phases of the life cycle -breaking existing institutional rules, making institutional new rules and mantaining a large part of the existing institutional rules -, regarding effects on both, decision making and organisational structures, as it summarises the actions to be developed both at meso and micro levels for the re-configurations of the structure coordinating value co-creation practices [39].

Table 2.

Patterns of making, breaking and maintaining institutionalised rules at micro and meso levels.

When the forth stage of the methodology is considered, and in particular, the identification of the value creation, a conceptual approach of the value relationship for the ecosystem network is proposed (see Figure 5). Where the term value refers to the total value created in business transactions, regardless of whether it is the OEM, the customer or any other participant within the ecosystem. Its ontology borrows concepts from business literature, such as actors, relationships and flows [31].

Figure 5.

Value relationship for the network.

Value drivers in prescriptive maintenance, create new competitive advantages and a sustainable differentiation strategy and organisation within the ecosystem. Porter and Millar [30] argue that information technology creates value by supporting differentiation strategies. Technology per se has no inherent value [80] but an enabler of the ecosystem BM. DTs, AI or DLT can bring new solutions and value added services that can integrate people, business processes and assets and are delivered as service [81]. Such integration of resources intrinsically pursues the optimisation through time, which enhance efficiency, both locally at nodes and globally at network level. At organisational level, smart organisations do no rely on knowledge production, but focus on knowledge integration instead. Knowledge integration becomes a key part of management systems. This also means that value transformation (destroy and creation), will be promoted. At firm level there is a growing need to develop abilities to act in changing non-linear situations due to the complexity related to utilisation and developing digitalisation inside and across organisations [82]. Sharing of knowledge and beliefs in business opportunities in the network help in building of trust, and legitimacy for specific nodes, which increases its resilience [83].

Value nodes in prescriptive maintenance, include the relationships between different ecosystem actors which have the opportunity to both create and appropriate value [16] from the reconfiguration and integration of resources, capabilities, roles and relationships. It can sponsor potential collaboration points for stakeholder’s BMs by identifying the complementarities and non-complementarities of the BMs. While complementarities help strengthen future collaboration, non-complementarities help to address and reduce the possibility of direct future competition. Examples of such value-creating processes in prescriptive maintenance ecosystem are Smart PSS development, strategic and operational decision-making, alliance formation, knowledge creation, or capabilities transfer. The locus of value creation is the network rather than the firms.

Value exchange reflects the way in which resources are integrated into value creation and is based on the different value propositions. In prescriptive maintenance, value exchange is primarily about value co-creation with customers through more services, and also value-creation with internal ecosystem stakeholders through service capabilities. But it is also co-petition within the business environment, where companies simultaneously competing to capture value and cooperating to co-create value [40]. Although, negative value could emerge depending on their alignment or misalignment between ecosystem actors, and co-destruction value can occur [16]. In terms of Schumpeter’s model of creative destruction, firm and industry boundaries span, involving new exchange mechanisms and unique transaction methods, and foster new forms of collaborations among firms.

Value extracts in prescriptive maintenance, reflect the value created, economical and no economical, for ecosystem. Value is created and delivered in the interaction between ecosystem actors. The actually generated and achieved value is stakeholder specific [84] and its connections are value proposition based [85]. In this sense, prescriptive maintenance firm acts as a holistic system, dynamically integrating maintenance activities and production scheduling and operations to increase the life of production assets and to reduce total industrial costs. A relevant value proposition not only to its customers but also to interested parties beyond. On one hand, primary added value is created using the technology on a micro-functional level, but the value extract could be reduced if the required skills and knowledge are insufficiently available. On the other hand, when a customer shares its data with a prescriptive maintenance firm in exchange receives the service of smart PPS, and other ecosystem actors can apply this customer-generated data to optimise their own product or processes. Then, they could further increase the generated value at meso-tactical and macro-strategic level, but they may stop participating in the value co-creation process if it is not fulfilling their value expectations. As a result, no more value is exchanged [86].

In the following Table 3, we will proceed to describe these concepts in detail for two specific ecosystem actors, the prescriptive maintenance firm (OEM) and its customer from the value proposition and from different scales of observation:

Table 3.

Explanation of value relationship between Prescriptive maintenance firm and its customer.

- Mega, the development of capabilities looking for understanding how actors within the ecosystem are making money or could make money,

- Macro, the role of data or how the data is processed for creating value of existing products, at the same time enabling other services,

- Meso, path to profit or how information asymmetry reduced and sustainable cost efficiency developed by transforming operating models,

- Micro, from push to pull or how to address real time and emerging needs in a predictive manner.

The comprehensive perspective provided by the promoted framework means creating a new market logic. Instead of finding solutions to existing problems, it focuses on strategy driven by market-creating logic, moving companies’ products to servitisation through digitalisation. This paradigm was discussed in the strategy “from the red ocean to the blue ocean” [87], where the terms red and blue oceans to denote the market universe. Red oceans are all the industries in existence today, the known market space, where industry boundaries are defined and companies try to outperform their rivals to grab a greater share of the existing market. Blue oceans denote all the industries not in existence today, the unknown market space, unexplored and untainted by competition. Like the blue ocean, the foreseen expansion is vast, deep and powerful in terms of opportunity and profitable growth.

It is important to remember that digitalisation of processes is in its infancy, therefore it is expected that for the SBMI networks, its dynamic evolution will bring increased performance and network growth, and because of the specialisation, space for new agents and evolution of technologies and incremental optimisation will increase the performance. The hidden aspect will be the complexity increases.

5. Discussion

In this section the latest step of the forth stage of the methodology is discussed. Therefore, the proposed business model framework brings significant impacts on different dimensions, such as the innovative context but also pays attention to the environmental performance. As the innovation is the critical dimension promoted by the new perspective of prescriptive maintenance and it affects the whole network of actors, it is suggested to discuss the organisational effects of the transformations being implemented according to the proposed BM, at the organisational design of the actor institutional logic.

Innovation as an institutional change process creates opportunities for new organisational structure both through the de-institutionalisation of the existing norms and practices likely to be associated with the arrival of new beliefs and practices [88] and or the theorising and the legitimisation of changes in prevailing norms and practices by existing or new actors [89].

5.1. Innovative Content

Innovation, as an institutional change for businesses, is perceived contingent to multi-actor efforts where new and existing actors are joining forces and creating new resource in order to foster novel and fruitful forms of cooperation [90]. It can be seen in this context as service ecosystem transformation enabled by digital transformation, and it is primarily about value co-creation between new stakeholders through additional services, and also value-creation with the already existing stakeholders through service capabilities. Therefore, it can be done in novel and useful ways by:

- Including new actors in service ecosystem: This way is one of the most powerful ways for innovation, not only by adding customers but also technology providers among others. Within service ecosystems, actors cannot avoid the institutional arrangements guiding their behaviour even when innovating [91]. However, it is possible to redefine parts of “how things are done” by adding diversity to the institutionalised rules.In order to visualise main conceptual differences between classical strategies and prescriptive maintenance, Figure 1a was introduced. Major differences arise because of the technical IT management component, requested to deal with real time data coming from the production processes, including events, and in cooperation with the Deep Learning based modelling and the Digital Twin technologies, but also working as a hub by enabling other functions to benefit from such datasets, such as system to system information through DLT solutions.This entire paradigm relies on the value for different applications of data collected from the production system both, product related as well as process related. It can provide context for equipment related data allowing to describe the degradation in the quality of service.Prescriptive maintenance scenario clearly will require a considerable standardisation effort to harmonise [92]

- (i)

- communication protocols as well as configuration management,

- (ii)

- modelling methodologies,

- (iii)

- big data architecture, tools, and applications with different kind of technical platforms (local, cloud, private, public, virtualised, etc.) as well as

- (iv)

- different tools to feed-in the collected data in streaming way.

In some specific sectors, like maintenance of services in buildings, the management of the decision making can also be integrated through the existing standards like BIM, which plays the role of MES system and changes both the ways of working and the business structure [36]. In this case, stakeholders carry out their work on one share platform which creates enormous possibilities that allow controlled decisions to be made within the design team and among clients, contractors and designers. In this particular application the Digital Twin is the natural contributor for integrating BIM with sensors and service data, where DLT becomes central keeping the different decision makers updated. Furthermore, when the social relevance of the project is significant, these digital and virtual models can be opened to the public and to the authorities. - Redefining roles of actors in service ecosystems: In addition to adding new actors, institutional reconfiguration in service ecosystems often also manifest themselves as redefined roles of both the existing and new actors [93]. Prescriptive maintenance promotes changes on the role of the customer from a traditional passive to a more engaged and active learner and doer.As the customer acquires additional perspective on the production because of the knowledge gain from the deployed technology. It can help to evolve their role into a more active one. Instead of rehearsing or forwarding new solutions, they now participate in idea generation actively. The redefinition of roles affects also to other existing agents, such as the OEMs, now expaning their activities to develop advanced digital twins for their products, and having additional requirements for computational and communication capabilities. Indeed, new agents are invited to join the network to externally assess contractual requirements and to provide different digital based added value services.Besides, at the plant level it is particularly relevant the Maintenance function, which moves itself from being a supporting concept for the Manufacturing Execution System into an active component able to see the systems as probabilistic exposed to failures. Therefore, it will care, not only of technical procedures and their management but also of analyzing their remaining life. Because of this, it will be possible to cooperate with production planning by estimating potential damage impacts on different subsystems because of the use of different production parameter. This higher integration between system components at mesoscopic level will benefit the performance of the agent at macroscopic level.

- Reframing resources in service ecosystems: In service ecosystems, institutional arrangements act as sense-making frames for the ’resourceness’ of potential resources [39]. In other words, when partially conflicting institutional arrangements coexist, they can provide actors with alternative frames of sense-making and enable the combinatory emergence of new instances of ’resourceness’.It is argued that, the more the value of the PSS moves from the physical product to the performance, the greater the benefit is, but also the more radical is the change required to companies [94]. Now the products are owned by the manufacturers, keeping the responsibility of them along life cycle, and they are operated by customers as a service.The existing challenge is the trust, sharing critical information with third-party can be difficult [92]. Although new technologies such as DLT can help to find a solution to minimise some of the associate risks, as access to the customer IT systems are not required.One relevant aspect of prescriptive maintenance is that in order to look for failure causes, traditional approaches are focused on considering human oriented feature selection and related criteria. Cognitive system engineering techniques provide an opportunity to even utilise people acting as soft sensors. Fusing data from humans with that from electronic sensors [4,95] is another key concept in this approach.In addition, prescriptive maintenance shows that innovation becomes a process of reconfiguring the institutional structure of service ecosystem, which also results in reframed resources, and requires investments on other capabilities as well [28,96]:

- (i)

- designer system which can faster innovation, introducing improvements on user experience repairing and to upgrading components with improved technologies that can be installed on existing or future machines. Product developer is now aware of operating conditions.

- (ii)

- financial system which have to manage a new perspective over the cost and revenues arising during the product lifecycle, moving to a new frame of long-term service contract at a predetermined price. Stable and continuous cash flows from customer to manufacturer over the product lifecycle, of a smaller entity compared to product sales.

- (iii)

- commercial system which would to avoid product-cost competition to capture market shares and to growth profits by building new sources of sustainable advantage.Smart Product-Service Ecosystems as a relational, long-term process.

Obviously the process for reframing the resources reaches all the agents in the network, and it has a dynamic effect and network will continue to increase in size to cope with the increasing complexity, bringing each actor behaviour more efficient along the innovation path.

5.2. Organisational Design

The presented framework enable extended relationships including different level of interactions among different stakeholders, but also through different workflows, where agents in those workflows can be either human or AI based agents. They also can include sophisticated communication channels, such as DLT, integrated REST based web services, etc. From both, the technical and managerial point of view such approaches can be understood as deeply innovating, and having a wide impact in the institutional logic of most of the organisations.

The innovations strongly deviating from established institutional logic will have problems in breaking through; not only because of business logic changes based on flows of information rather than on materials, but also because of changes in core competences. In particular, the introduced business model can have remarkable impacts that can be observed from the different layers of the hierarchical perspective,

- at the mega level, systems become interdependent across firm boundaries, and performance is disembodied from ownership of assets. Actors that support innovation therefore are both constrained and enabled in their actions by the structure of innovations and have to challenge the dominant institutional logic, as it is essential for its success. However institutional change is often beyond the capacity of individual actors and requires joint activities by a wide group of them on the basis of mutual interests [97,98].

- at the macro-level is not only the articulation of the newly framed problem, governance, but also in a way that is likely to resonate with the interests of firms ecosystem actors, legitimacy, which implies the creation of more complex governance practices around trust and cooperation within the firm ecosystem [31,99].

- at the micro and meso level relates to the organisational structures design and decision making procedures [100]. New equipment prescriptive maintenance innovation requires actors that contribute to the innovation process in a wide variety of ways (for instance through knowledge development of advanced forecasting models, fostering the continuous learning procedures not only internally but also for the technology, standardisation of procedures, etc.). Such contributions can include an integrative framework for the business value of the unit and the facility as a whole and use of the innovation with a dynamic cooperation between prescriptive maintenance tasks and production activities in a more integrated way (see Table 2).

5.3. Sustainable Development Goals

As it has already mention in the literature review, PrcM, is primarily about shared value with customers and also with internal ecosystem stakeholders through service capabilities. The digitalisation and servitisation as key enablers bring the potential to create innovative interactions. Prescriptive Maintenance needs for the reconfiguration and integration of resources, capabilities, roles and relationships among the different ecosystem actors; utilising this organisational resources and capabilities to create social and environmental benefits becomes a Sustainable Business Model.

Into the new ways of value transformation in SBMI -thus integrating the environmental and social value-, delivery and capture value, value co-creation and value destroyed have been analysed. However, a deeper study in this section is not considered, since the focus is on the integration with the SDG. Environmental value is created when the organisation generates more environmental benefits than impacts. There are several approaches to estimate environmental impacts, as for example Life Cycle Assessment. Incorporating Life Cycle perspective has prompted the redefinition of the maintenance role. As a tool for measuring environmental impacts using different types of indicators over the full life cycle of a product or service (eco-system quality, CO2 emissions, resource depletion, etc.) sets new information into the management for decision making for planning and executing maintenance activities. All indicators should be incorporated into the Data Management and scaled to the dimensional perspective.

In terms of environmental value, PcrM transforms by big data analytics the product/service life extension; it is an enabling system to sustain the equipment/machinery throughout its life cycle. Through extended resources and activities there is space for an organisation to explore the environmental benefits:

- Maximise material efficiency: Preservation of raw materials by predicting machinery operational capacities; also by enhancing ecological footprint; and, by decreasing spare parts since they are replaced only when needed rather than on a fixed schedule.

- Optimises energy efficiency: Preservation of energy by integration of resources optimisation through time, closing resource loops through reuse, re-manufacturing, and recycling; lower the environmental impact corresponding to greenhouse gas emissions due to the energy saving by integrating operation with maintenance activities.

Social value is gained when the organisations generate more social benefits than impacts while they contribute and incorporate innovation, responsibility and sustainability into the core of their activities through value co-creation both in the company and along the ecosystem [101,102]. Social sustainability of maintenance processes involves wider social benefits that can be derived from delivering high quality maintenance services. There is not consensus about the indicators to be considered; some examples would be integration societal culture, transparency consultation, personal development, fair competition, working hours, cultural heritage, health and safety,... All indicators should be incorporated into the Data Management and scaled to the dimensional perspective (from micro to mega).

In terms of social value, PcrM changes the actors and their relationship; actors in the network share value and develop long term value from mutually beneficial relationships at different level of interactions (horizontal and vertical flow in the BM framework). The new organisational design for the actors gives an space to explore the social benefits:

- Improves worker safety: Reduction of accidents and risky works for operators by lowering incidents with assets by predicting incidents before they escalate.

- Improves working conditions: Additional Information on machine ergonomics and incidents (by virtual reality for example) to maximise people’s health and safety, satisfaction from work.

- Improves working environment: Opportunities for new service providers, specially smaller and technological oriented, not dependent of a specific localisations.

- New educational model and culture: Articulate connections between new behaviours and corporate success; create new social norms and shared values consistent with new approach.

The United Nations’ 2015 Sustainable Development Goals (SDGs), provide a globally accepted framework for sustainability. However, the usability of the 17 goals and the large number of subgoals can represent barriers to the required assessment. To assess sustainability within innovation processes being developed inside the network, stakeholders’ needs and objectives must be defined. They will depend on each actor in the network, co-creation approach results in a winning strategy to exploit knowledge, above all in an ecosystem context, and in this process, both stakeholder groups should be included [103]:

- (i)

- actively involved groups (e.g., employees and users with individual interests such as well-being and satisfaction) as well as

- (ii)

- passively involved or “affected” groups (e.g., administrative stakeholders or future generations with collective interests such as ecological concerns).

Although the outcome will be agent dependent and contingent on their position in the network in charge of develop added value to its members, to have common tools helping in the individual assessment processes can be seen as a significant contribution [104].

The proposed BM for prescriptive maintenance has direct implication with different SDGs, such as,

- (i)

- G8: Decent work and Economic growth,

- (ii)

- G9: Industry, Innovation and infrastructure and

- (ii)

- G11: Sustainable communities.

but also to some others in an indirect way, such as,

- (i)

- G3: Good health and Well-being, as better work conditions are being promoted, where digitalisation can promote learning procedures at work.

- (ii)

- G4: Quality Education, as the all the technology involved can illustrate case studies highlighting advanced techniques. It will promote convenient skills for the future,

- (iii)

- G5: Gender equality, as higher level skills will be needed in the continuous innovation process, and where they can be obtained from different people, and

- (iv)

- G10: Reduced Inequality, where neutral technology can also help people suffering disabilities.

Indeed, fostering the network empowerment due to explicit highlight of the contribution to the SDGs will require governance improvements at actor level, and in many cases they will require changes in the existing institutional logic of agents, which also recommends to discuss the BM from the organisational Design perspective for the different agents in the network.

In consequence, new prescriptive maintenance enables new innovation patterns capable of bringing new institutional logic at different levels. Although not all the institutional levels are necessarily at risk at the same time [105]. Changes in institutional arrangements can be initiated at and institutionalised within different scopes and grade [39].

6. Conclusions

This paper formalised new opportunities enabling advanced servitisation business transformations, fostered by the digitalisation of processes and operations in the field of prescriptive maintenance, where AI and DT technologies allow equipment to become aware of their functional status and they become capable of predicting the evolution of their degradation. Based on these new capabilities, creation of new value proposals from an aggregation of agents in the context of SPSE becomes possible. Such integrated networks have common characteristics, such as their digital engagement, their innovation orientation, and their sustainability dimension. From this context, the paper configure a generalised BM proposal, considering that the network of agents are dynamic and it can be observed from different perspectives, from the process perspective, and from the data management approach. It also considers advanced communication capabilities through the DLT, in particular between services of different agents, where non mutability allow authorised third parties to assess them, providing additional trust to the network participants.

Different aspects such as value drivers, value co-creation, value exchange, value extraction, and value transformation have been identified between network nodes. Indeed, value destroy is identified at different agents either because of concentration in core competences, but also because of failing in attempt to fully exploit the potentialities offered by the technology.

Based on the proposed innovative and sustainable BM, a discussion regarding main innovative and sustainable attributes is developed. In particular, impacts according to the UN SDs are analysed, while it is recognised that an agent focused analysis must be carried out according to the specific impacts is needed, in such a way that measuring of changes and achievements can be implemented. Further than those aspects, the impact into the agent organisations motivated by the evolution of the network and the potential misalignment against the institutional logic is explored. It shows how these types of innovation push to deeply transform their organisational design serving their institutional dimension. However, additional research is needed contingent to other transformation drivers, looking to produce higher level of understanding.

Although the ecosystem was generalised from an specific case, the proposed BM can be further applied in many different contexts where digitalisation allows such business transformations. As the ecosystem is now better identified, the BM proposal can help to different stakeholders in understanding new opportunities to enlarge their participation or to extend the new tools to other businesses.

From the research point of view, the paper contributes by offering to scholars a new framework and four different perspectives of analysis. Indeed, it details relevant factors to transform data into value inside the ecosystem and finally it discusses the proposed BM impacts from different management dimensions. The research field allow us to think how to estimate performance gains for the whole network, based on their topological properties. Such research line will be carried out in the future, in particular when additional aspects such as complexity, but also legitimacy are considered.

Author Contributions

Conceptualisation, A.P.Á., M.G.M., J.V.-D. and J.O.-M.; methodology, J.O.-M. and M.G.M.; Model creation, J.V.-D. and M.G.M.; validation, J.V.-D. and M.G.M.; formal analysis, G.M.-A. and A.P.Á. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partially funded by the Spanish Agencia Estatal de Investigacion, through the research project with code RTI2018-094614-B-I00 into the “Programa Estatal de I+D+i Orientada a los Retos de la Sociedad”.

Acknowledgments

The authors want to thank the EU RFCS research program for the contribution to this research through the grant with ID 793505 (WISEST project), mainly due to the industrial cases provided.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AI | Artificial Intelligence |

| BMs | Business Models |

| BMC | Business Model Canvas |

| BMI | Business Model Innovation |

| CBM | Condition Based Monitoring |

| CPU | Central Process Unit |

| DLT | Distributed Ledger Technologies |

| EBM | Ecosystem Business Models |

| EMBMI | Equipment Maintenance Business Model Innovation |

| ICT | Information and Communication Technologies |

| IoT | Internet of Things |

| IIoT | Industrial Internet of Things |

| OD | Organisational Design |

| OEE | Overall Equipment Effectiveness |

| OEM | Original Equipment Manufacturer |

| PcrM | Prescriptive maintenance |

| PSS | Product-Service System |

| TPM | Total Productive Maintenace |

| TRM | Teechnology Roadmap |

| SM | Smart Maintenace |

| SBM | Sustainable Business Model |

| SBMI | Sustainable Business Model Innovation |

| SPSE | Smart Product Service Ecosystem |

References

- Casadesus-Masanell, R.; Ricart, J. From Strategy to Business Models and onto Tactics. Long Range Plan. 2010, 43, 195–215. [Google Scholar] [CrossRef]

- Teece, D. Business Models, Business Strategy and Innovation. Long Range Plan. 2010, 43, 172–194. [Google Scholar] [CrossRef]

- Lemus-Aguilar, I.; Morales-Alonso, G.; Ramirez-Portilla, A.; Hidalgo, A. Sustainable Business Models through the Lens of Organizational Design: A Systematic Literature Review. Sustainability 2019, 11, 5379. [Google Scholar] [CrossRef]

- Sun, S.; Zheng, X.; Villalba-Díez, J.; Ordieres-Meré, J. Data Handling in Industry 4.0: Interoperability Based on Distributed Ledger Technology. Sensors 2020, 20, 3046. [Google Scholar] [CrossRef]

- Ranjbari, M.; Morales-Alonso, G.; Carrasco-Gallego, R. Conceptualizing the sharing economy through presenting a comprehensive framework. Sustainability 2018, 10, 2336. [Google Scholar] [CrossRef]

- Frank, A.G.; Mendes, G.H.; Ayala, N.F.; Ghezzi, A. Strategy And The Internet. Harv. Bus. Rev. 2001, 79, 62–78. [Google Scholar] [CrossRef]

- Fusko, M.; Rakyta, M.; Krajcovic, M.; Dulina, L.; Gaso, M.; Grznar, P. Basics of designing maintenance processes in industry 4.0. MM Sci. J. 2018, 3, 2252–2259. [Google Scholar] [CrossRef]

- Leseure, M.; Hudson-Smith, M.; Martinez, V.; Bastl, M.; Kingston, J.; Evans, S. Challenges in transforming manufacturing organisations into product-service providers. J. Manuf. Technol. Manag. 2010, 21, 449–469. [Google Scholar]

- Zheng, M.; Ming, X.; Wang, L.; Yin, D.; Zhang, X. Status review and future perspectives on the framework of Smart Product Service Ecosystem. Procedia CIRP 2017, 64, 181–186. [Google Scholar] [CrossRef]

- Yin, D.; Ming, X.; Zhang, X. Sustainable and Smart Product Innovation Ecosystem: An integrative status review and future perspectives. J. Clean. Prod. 2020, 274, 123005. [Google Scholar] [CrossRef]

- Passlick, J.; Dreyer, S.; Olivotti, D.; Grutzner, L.; Eilers, D.; Breitner, M.H. Predictive maintenance as an internet of things enabled business model: A taxonomy. Electron. Mark. 2020, 1–21. [Google Scholar] [CrossRef]

- Marques, H.; Giacotto, A. Prescriptive Maintenance: Building Alternative Plans for Smart Operations. In Proceedings of the 10th Aerospace Technology Congress, Stockholm, Sweden, 8–9 October 2019; Linköping University Electronic Press: Stockholm, Sweden, 2019; pp. 231–236. [Google Scholar] [CrossRef]

- Fera, M.; Greco, A.; Caterino, M.; Gerbino, S.; Caputo, F.; Macchiaroli, R.; D’Amato, E. Towards Digital Twin Implementation for Assessing Production Line Performance and Balancing. Sensors 2019, 20, 97. [Google Scholar] [CrossRef] [PubMed]

- Matyas, K.; Nemeth, T.; Kovacs, K.; Glawar, R. A procedural approach for realizing prescriptive maintenance planning in manufacturing industries. CIRP Ann. 2017, 66, 461–464. [Google Scholar] [CrossRef]

- Nemeth, T.; Ansari, F.; Sihn, W.; Haslhofer, B.; Schindler, A. PriMa-X: A reference model for realizing prescriptive maintenance and assessing its maturity enhanced by machine learning. Procedia CIRP 2018, 72, 1039–1044. [Google Scholar] [CrossRef]

- Li, M.; Tuunanen, T. Actors’ Dynamic Value Co-creation and Co-destruction Behavior in Service Systems: A Structured Literature Review. In Proceedings of the 53rd Hawaii International Conference on System Science, Hawaii, Maui, 7–10 January 2020; pp. 1–10. [Google Scholar] [CrossRef]

- Nenonen, S.; Storbacka, K. Business model design: Conceptualizing networked value co-creation. Int. J. Qual. Serv. Sci. 2010, 2, 43–59. [Google Scholar] [CrossRef]

- Mourtzis, D.; Doukas, M.; Fotia, S. Classification and Mapping of PSS Evaluation Approaches. IFAC PapersOnLine 2016, 49, 1555–1560. [Google Scholar] [CrossRef]

- Parida, V.; Sjodin, D.; Reim, W. Reviewing Literature on Digitalization, Business Model Innovation, and Sustainable Industry: Past Achievements and Future Promises. Sustainability 2019, 11, 391. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, R.; Wu, D. Equipment Maintenance Business Model Innovation for Sustainable Competitive Advantage in the Digitalization Context: Connotation, Types, and Measuring. Sustainability 2018, 10, 3970. [Google Scholar] [CrossRef]

- Baima, G.; Forliano, C.; Santoro, G.; Vrontis, D. Intellectual capital and business model: A systematic literature review to explore their linkages. Intellect. Cap. Bus. Model 2020, 1469–1930. [Google Scholar] [CrossRef]

- Tirabeni, L.; De Bernardi, P.; Forliano, C.; Franco, M. How can organisations and business models lead to a more sustainable society? A framework from a systematic review of the industry 4.0. Sustainability 2019, 11, 6363. [Google Scholar] [CrossRef]

- Foss, N.J.; Saebi, T. Fifteen Years of Research on Business Model Innovation: How Far Have We Come, and Where Should We Go? J. Manag. 2017, 43, 200–227. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Vladimirova, D.; Evans, S. Sustainable business model innovation: A review. J. Clean. Prod. 2018, 198, 401–416. [Google Scholar] [CrossRef]

- Bocken, N.; Boons, F.; Baldassarre, B. Sustainable business model experimentation by understanding ecologies of business models. J. Clean. Prod. 2019, 208, 1498–1512. [Google Scholar] [CrossRef]

- Velter, M.; Bitzer, V.; Bocken, N.; Kemp, R. Sustainable business model innovation: The role of boundary work for multi-stakeholder alignment. J. Clean. Prod. 2020, 247, 119497. [Google Scholar] [CrossRef]

- Jansson, N.; Ahokangas, P.; Iivari, M.; Perala-Heape, M.; Salo, S. The competitive advantage of an ecosystemic business model: The case of OuluHealth. Interdiscip. Stud. J. 2014, 3, 282. [Google Scholar]

- Arnaiz, A.; Léger, J.B.; Aguirregomezkorta, A.; Fernandez, S.; Revilla, O.; Peysson, F. Advanced maintenance as enabler for service oriented business models (BM)-An application in forklift trucks. IFAC-PapersOnLine 2016, 49, 144–149. [Google Scholar] [CrossRef]

- Hirano, H. JIT Implementation Manual: The Complete Guide to Just-in-Time Manufacturing, (6-Volume Set); CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Porter, M.E.; Millar, V.E. How information gives you competitive advantage. Harv. Bus. Rev. 1985, 63, 149–160. [Google Scholar]

- Amit, R.; Zott, C. Value creation in e-business. Strateg. Manag. J. 2001, 22, 493–520. [Google Scholar] [CrossRef]

- Garramiola, F.; Poza, J.; Madina, P.; del Olmo, J.; Ugalde, G. A Hybrid Sensor Fault Diagnosis for Maintenance in Railway Traction Drives. Sensors 2020, 20, 962. [Google Scholar] [CrossRef]

- Lee, H.; Lee, B. The Development of a State-Aware Equipment Maintenance Application Using Sensor Data Ranking Techniques. Sensors 2020, 20, 3038. [Google Scholar] [CrossRef]

- Moleda, M.; Momot, A.; Mrozek, D. Predictive Maintenance of Boiler Feed Water Pumps Using SCADA Data. Sensors 2020, 20, 571. [Google Scholar] [CrossRef] [PubMed]

- Merluzzi, A.; Brunetti, G. Metals industry: Road to digitalization. In Proceedings of the 2017 40th International Convention on Information and Communication Technology, Electronics and Microelectronics (MIPRO), Opatija, Croatia, 22–26 May 2017; pp. 967–973. [Google Scholar]

- Hautala, K.; Jarvenpaa, M.E.; Pulkkinen, P. Digitalization transforms the construction sector throughout asset’s life-cycle from design to operation and maintenance. Stahlbau 2017, 86, 340–345. [Google Scholar] [CrossRef]