The Role of Urban Manufacturing for a Circular Economy in Cities

Abstract

:1. Introduction

- RQ1:Does urban manufacturing contribute to a circular economy in cities, and if so, how?

- RQ2:What are the drivers and barriers to circular urban manufacturing?

2. Background

2.1. Circular Economy in Cities

2.1.1. Circular Economy and Sustainability

2.1.2. Why Circular Cities?

2.1.3. Connecting Circular Cities with Urban Manufacturing

2.2. Urban Manufacturing

- Personal fabricators: hobbyists (sometimes referred to as “makers”) making products for personal use.

- Maker spaces: (examples of makerspaces/fab labs can be found on: http://fablab.org/, https://artdesignxchange.com/) workshops where makers share fabrication space, equipment, and ideas.

- Mini-factories: (examples of mini factories can be found on: https://make.works/, https://madeinnyc.org/, https://www.urbanmfg.org/) small- to medium-sized manufacturing companies that have less than ~20 employees.

- Traditional urban industry: large-scale manufacturers that have chosen to stay in the city instead of offshoring production.

Urban Manufacturing and Circular Economy in Cities

3. Materials and Methods

3.1. Literature Review on Life Cycle Assessments (LCAs) of Urban Manufacturing

- conducted a life-cycle assessment that provided empirical evidence for the total GHG emissions during the production and transportation process.

- made a comparison between the environmental impact of urban (or distributed) manufacturing and traditional centralized manufacturing.

3.2. Semi-Structured Interviews with Experts in Circular Economy and Urban Manufacturing

- What is your definition of circular cities?

- What is your definition of urban manufacturing?

- Could urban manufacturing be a driver for the circular economy?

- Could circular economy be a driver to urban manufacturing?

- Could urban manufacturing and circular economy be a barrier for each other?

- Should manufacturing be situated in cities?

- Where in cities should they be situated, and why?

- What kinds of manufacturing is / is not suitable for cities?

- In what condition should products be produced locally?

- How do you see the future of manufacturing in cities?

3.3. Literature Review of Drivers and Barriers to Circular Urban Manufacturing

Literature Search, Selection, and Coding Process

- Focused on listing out drivers and barriers for circular cities or urban manufacturing.

- Provided a general overview of drivers and barriers, rather than focuses on specific materials and products.

- Contained drivers and barriers that can be categorized as space, people, or flow related.

4. Results

4.1. Does Urban Manufacturing Contribute to a Circular Economy at the City Level?

4.1.1. Empirical Evidence for Environmental Impact of Urban Manufacturing

4.1.2. Caveats to the Circularity of Urban Manufacturing Found in Literature and Expert Interviews

- “In Belgium, there’s just a couple of metal treatment plants. So anytime a building is being totally renovated or rebuilt, all that steel that comes out gets taken to Antwerp or Ghent to be recycled” (Interviewee F).

- “It’s an issue of the product and the scale. If you have, let’s say, small lithium batteries, you need quite a lot of them to make it worth setting up a recycling plant. You could imagine that you only need one plant for the whole of the UK” (Interviewee C).

- “Large recycling processors want to have tons (of waste) coming in monthly, because they’re looking for a certain percentage of returns for their investors. I don’t think it’s economically viable for them to operate within a city” (Interviewee G).

- The business sources from local supply chains, and produces for a local consumer base.

- Transportation emissions of the product being manufactured contributes to a significant percentage of the total environmental impact of the product (for example, products produced from secondary raw materials will have much lower emissions associated with material extraction and processing).

- Local waste or secondary raw materials is used as a resource (this includes materials from both technical and biological cycles).

- There is a possibility of scaling up without moving out of the city.

4.2. Drivers and Barriers to Circular Urban Manufacturing

4.2.1. Drivers

4.2.2. Barriers

4.3. People/Flows

5. Discussion

5.1. Significance of Results, Further Research Directions

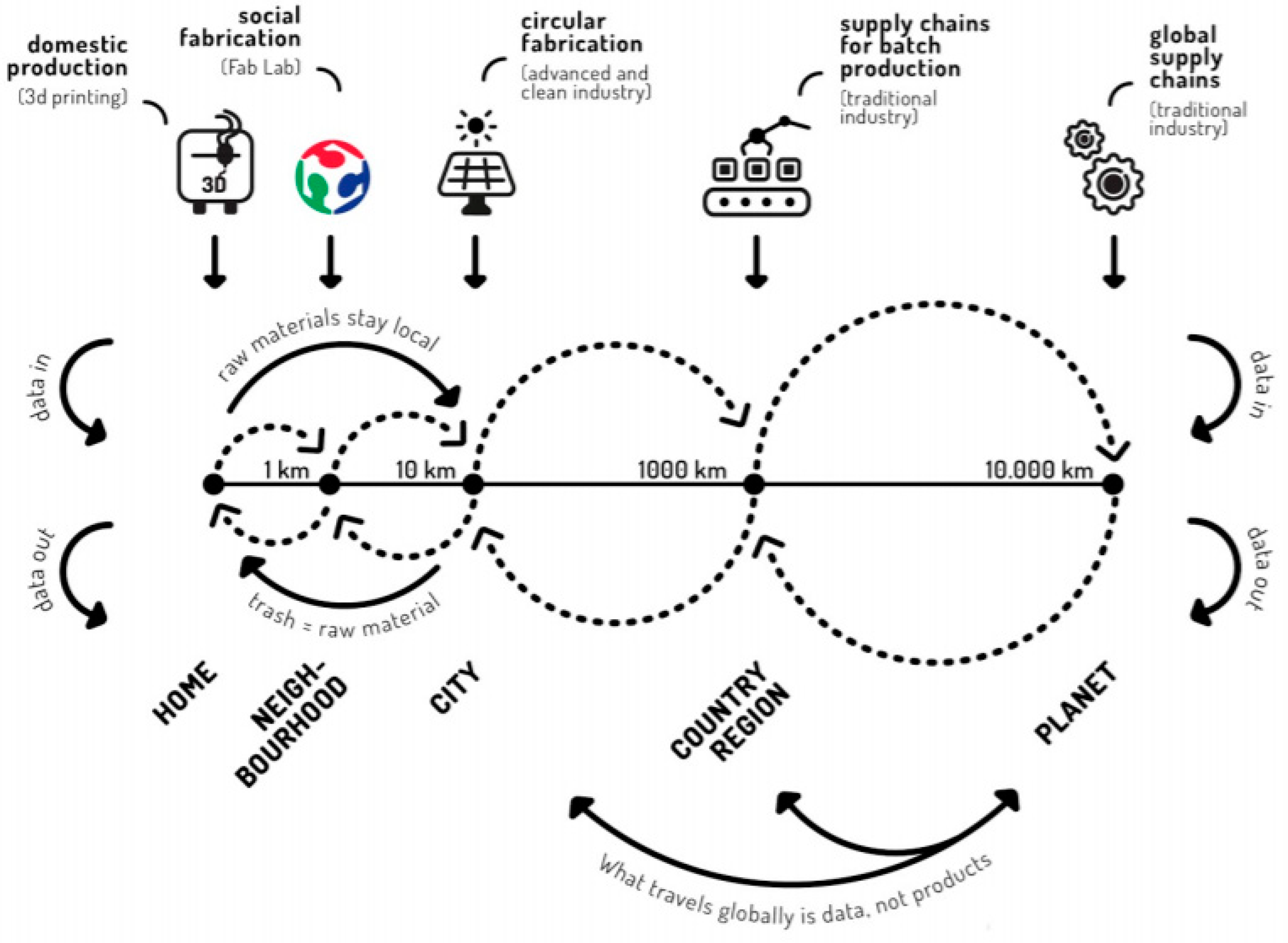

5.1.1. Geographical Scales of the Circular Economy

5.1.2. Locally Embedded Urban Manufacturers

5.1.3. Scale of Production and Environmental Impact

5.1.4. Industries Suitable for Circular Urban Manufacturing

5.2. Limitations of Methodology

5.2.1. Review of LCAs on Urban Manufacturing

5.2.2. Selection and Interviewing of Experts

6. Conclusions

6.1. Summary of Research

6.2. Theoretical and Practical Contributions

6.3. Further Research

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Camaren, P.; Swilling, M. Sustainable, Resource Efficient Cities-Making it Happen; UNEP: Nairobi, Kenya, 2012. [Google Scholar]

- European Commission. A new Circular Economy Action Plan for a Cleaner and More Competitive Europe; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Fratini, C.F.; Georg, S.; Jørgensen, M.S. Exploring circular economy imaginaries in European cities: A research agenda for the governance of urban sustainability transitions. J. Clean. Prod. 2019, 228, 974–989. [Google Scholar] [CrossRef]

- Diez, T. Fab City—The Mass Distribution of (Almost) Everything; IAAC: Barcelona, Spain, 2018. [Google Scholar]

- Cities of Making. Foundries of the Future; TU Delft Open: Delft, The Netherlands, 2020. [Google Scholar]

- Hirshberg, P.; Dougherty, D.; Kadanoff, M. Maker City: A Practical Guide to Reinvention in American Cities; Maker Media Inc.: North Sebastopol, CA, USA, 2016. [Google Scholar]

- Rappaport, N. Hybrid factory, Hybrid city. Built Environ. 2017, 43, 72–86. [Google Scholar] [CrossRef]

- Wolf-Powers, L.; Doussard, M.; Schrock, G.; Heying, C.; Eisenburger, M.; Marotta, S. The Maker Movement and Urban Economic Development. J. Am. Plan. Assoc. 2017, 83, 365–376. [Google Scholar] [CrossRef]

- Brundtland Commission. Our Common Future; Oxford University Press: Oxford, UK, 1987. [Google Scholar]

- Braungart, M.; McDonough, W. Cradle to Cradle: Remaking the Way We Make Things; Ferrar, Straus and Giroux: New York, NY, USA, 2002. [Google Scholar]

- Stahel, W.R. The Performance Economy: Business Models for the Functional Service Economy. In Handbook of Performability Engineering; Springer: London, UK, 2008; pp. 127–138. [Google Scholar]

- Jelinski, L.W.; Graedel, T.E.; Laudise, R.A.; McCall, D.W.; Patel, C.K.N. Industrial ecology: Concepts and approaches. Proc. Natl. Acad. Sci. USA 1992, 89, 793–797. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Elkington, J. The triple bottom line. In Environmental Management: Readings and Cases; SAGE Publications Inc.: Thousand Oaks, CA, USA, 1997. [Google Scholar]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef] [Green Version]

- Prendeville, S.; Cherim, E.; Bocken, N. Circular Cities: Mapping Six Cities in Transition. Environ. Innov. Soc. Transit. 2018, 26, 171–194. [Google Scholar] [CrossRef] [Green Version]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef] [Green Version]

- Rashid, A.; Asif, F.M.A.; Krajnik, P.; Nicolescu, C.M. Resource conservative manufacturing: An essential change in business and technology paradigm for sustainable manufacturing. J. Clean. Prod. 2013, 57, 166–177. [Google Scholar] [CrossRef]

- Bakker, C.; den Hollander, M.; van Hinte, E. Products That Last: Product Design for Circular Business Models; Laurence King Publishing: London, UK, 2019. [Google Scholar]

- Allwood, J.; Cullen, J.M.; Carruth, M.A.; Cooper, D.R. Sustainable Materials: With Both Eyes Open; UIT Cambridge Ltd.: Cambridge, UK, 2012. [Google Scholar]

- Bocken, N.M.P.; Short, S.W.; Rana, P.; Evans, S. A literature and practice review to develop sustainable business model archetypes. J. Clean. Prod. 2014, 65, 42–56. [Google Scholar] [CrossRef] [Green Version]

- Allwood, J.M. Squaring the Circular Economy: The Role of Recycling within a Hierarchy of Material Management Strategies. In Handbook of Recycling: State-of-the-art for Practitioners, Analysts, and Scientists; Elsevier Inc.: Amsterdam, The Netherlands, 2014; pp. 445–477. [Google Scholar]

- Loorbach, D.; Shiroyama, H. The Challenge of Sustainable Urban Development and Transforming Cities. In Governance of Urban Sustainability Transitions; Springer: Tokyo, Japan, 2016; pp. 3–12. [Google Scholar]

- Li, J. Wastes could be resources and cities could be mines. Waste Manag. Res. 2015, 33, 301–302. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Circle Economy. Circular Amsterdam—A Vision and Action Agenmda for the City and Metropolitan Area; TNO: Delft, The Netherlands, 2016. [Google Scholar]

- Circularity City. Circularity City: Shaping Our Urban Future; Circularity City: Copenhagen, Denmark, 2018. [Google Scholar]

- Gemeente Amsterdam. Amsterdam Circular 2020–2025 Strategy; Municipality of Amsterdam: Amsterdam, The Netherlands, 2020; pp. 1–30. [Google Scholar]

- Gravagnuolo, A.; Angrisano, M.; Girard, L.F. Circular economy strategies in eight historic port cities: Criteria and indicators towards a circular city assessment framework. Sustainability 2019, 11, 3512. [Google Scholar] [CrossRef] [Green Version]

- Remøy, H.; Wandl, A.; Ceric, D.; van Timmeren, A. Facilitating Circular Economy in Urban Planning. Urban Plan. 2019, 4, 1–4. [Google Scholar] [CrossRef]

- Williams, J. Circular cities: Challenges to implementing looping actions. Sustainability 2019, 11, 423. [Google Scholar] [CrossRef] [Green Version]

- Ferm, J.; Jones, E. Mixed-use ‘regeneration’ of employment land in the post-industrial city: Challenges and realities in London. Eur. Plan. Stud. 2016, 24, 1913–1936. [Google Scholar] [CrossRef]

- Williams, J. Circular cities. Urban Stud. 2019, 56, 2746–2762. [Google Scholar] [CrossRef]

- Mulrow, J.S.; Derrible, S.; Ashton, W.S.; Chopra, S.S. Industrial Symbiosis at the Facility Scale. J. Ind. Ecol. 2017, 21, 559–571. [Google Scholar] [CrossRef]

- Rosado, L.; Kalmykova, Y. Combining Industrial Symbiosis with Sustainable Supply Chain Management for the Development of Urban Communities. IEEE Eng. Manag. Rev. 2019, 47, 103–114. [Google Scholar] [CrossRef] [Green Version]

- Cappellaro, F.; Cutaia, L.; Innella, C.; Meloni, C.; Pentassuglia, R.; Porretto, V. Investigating circular economy urban practices in Centocelle, Rome district. Environ. Eng. Manag. J. 2019, 18, 2145–2153. [Google Scholar]

- Joshi, C.; Seay, J.; Banadda, N. A perspective on a locally managed decentralized circular economy for waste plastic in developing countries. Environ. Prog. Sustain. Energy 2019, 38, 3–11. [Google Scholar] [CrossRef] [Green Version]

- Kampelmann, S. Wood works: How local value chains based on urban forests contribute to place-based circular economy. Urban Geogr. 2020, 41, 911–914. [Google Scholar] [CrossRef]

- De Oliveira, F.R.; França, S.L.B.; Rangel, L.A.D. Challenges and opportunities in a circular economy for a local productive arrangement of furniture in Brazil. Resour. Conserv. Recycl. 2018, 135, 202–209. [Google Scholar] [CrossRef]

- Risku-Norja, H.; Hietala, R.; Virtanen, H.; Ketomäki, H.; Helenius, J. Localisation of primary food production in Finland: Production potential and environmental impacts of food consumption patterns. Agric. Food Sci. 2008, 17, 127–145. [Google Scholar] [CrossRef] [Green Version]

- Säumel, I.; Reddy, S.E.; Wachtel, T. Edible city solutions-one step further to foster social resilience through enhanced socio-cultural ecosystem services in cities. Sustainability 2019, 11, 972. [Google Scholar] [CrossRef] [Green Version]

- Boeri, A.; Gaspari, J.; Gianfrate, V.; Longo, D.; Boulanger, S.O.M. Circular city: A methodological approach for sustainable districts and communities. In WIT Transactions on the Built Environment; WIT Press: Southhampton, UK, 2019; Volume 183, pp. 73–82. [Google Scholar]

- Campbell-Johnston, K.; Cate, J.T.; Elfering-Petrovic, M.; Gupta, J. City level circular transitions: Barriers and limits in Amsterdam, Utrecht and The Hague. J. Clean. Prod. 2019, 235, 1232–1239. [Google Scholar] [CrossRef]

- Chang, I.C.C.; Sheppard, E. China’s Eco-Cities as Variegated Urban Sustainability: Dongtan Eco-City and Chongming Eco-Island. J. Urban Technol. 2013, 20, 57–75. [Google Scholar] [CrossRef]

- De Jong, M.; Wang, D.; Yu, C. Exploring the Relevance of the Eco-City Concept in China: The Case of Shenzhen Sino-Dutch Low Carbon City. J. Urban Technol. 2013, 20, 95–113. [Google Scholar] [CrossRef]

- Geng, Y.; Tsuyoshi, F.; Chen, X. Evaluation of innovative municipal solid waste management through urban symbiosis: A case study of Kawasaki. J. Clean. Prod. 2010, 18, 993–1000. [Google Scholar] [CrossRef]

- Vergragt, P.J.; Dendler, L.; de Jong, M.; Matus, K. Transitions to sustainable consumption and production in cities. J. Clean. Prod. 2016, 134, 1–12. [Google Scholar] [CrossRef]

- Doussard, M.; Schrock, G.; Wolf-Powers, L.; Eisenburger, M.; Marotta, S. Manufacturing without the firm: Challenges for the maker movement in three U.S. cities. Environ. Plan. A 2018, 50, 651–670. [Google Scholar] [CrossRef]

- Hatuka, T.; Ben-Joseph, E.; Peterson, S.M. Facing forward: Trends and Challenges in the development of industry in cities. Built Environ. 2017, 43, 145–155. [Google Scholar] [CrossRef]

- Unterfrauner, E.; Voigt, C.; Schrammel, M.; Menichinelli, M. The Maker Movement and the Disruption of the Producer-Consumer Relation. In Proceedings of the International Conference on Internet Science, Thessaloniki, Greece, 22–24 November 2017; pp. 113–125. [Google Scholar]

- Sassen, S. Cities today: A new frontier for major developments. Ann. Am. Acad. Pol. Soc. Sci. 2009, 626, 53–71. [Google Scholar] [CrossRef]

- Schrock, G.; Wolf-Powers, L. Opportunities and risks of localised industrial policy: The case of ‘maker-entrepreneurial ecosystems’ in the USA. Camb. J. Reg. Econ. Soc. 2019, 12, 369–384. [Google Scholar] [CrossRef]

- Diez, T. Personal Fabrication: Fab Labs as Platforms for Citizen-Based Innovation, from Microcontrollers to Cities. Nexus Netw. J. 2012, 14, 457–468. [Google Scholar] [CrossRef]

- Kohtala, C. Addressing sustainability in research on distributed production: An integrated literature review. J. Clean. Prod. 2015, 106, 654–668. [Google Scholar] [CrossRef] [Green Version]

- Millard, J.; Sorivelle, M.N.; Deljanin, S.; Unterfrauner, E.; Voigt, C. Is the maker movement contributing to sustainability? Sustainability 2018, 10, 2212. [Google Scholar] [CrossRef] [Green Version]

- Unterfrauner, E.; Voigt, C. Makers’ ambitions to do socially valuable things. Des. J. 2017, 20, S3317–S3325. [Google Scholar] [CrossRef] [Green Version]

- Diez, T. Fab City Whitepaper: Locally Productive, Globally Connected Self-Sufficient Cities; Fab City: Barcelona, Spain, 2011. [Google Scholar]

- Hennelly, P.A.; Srai, S.; Graham, G.; Meriton, R.; Kumar, M.; Srai, J.S. Do makerspaces represent scalable production models of community-based redistributed manufacturing? Prod. Plan. Control 2019, 30. [Google Scholar] [CrossRef]

- Kohtala, C.; Sampsa, H. Anticipated environmental sustainability of personal fabrication. J. Clean. Prod. 2015, 99, 333–344. [Google Scholar] [CrossRef] [Green Version]

- Prendeville, S.; Hartung, G.; Purvis, E.; Brass, C.; Hall, A. Makespaces: From Redistributed Manufacturing to a Circular Economy. In Sustainable Design and Manufacturing; Springer: New York, NY, USA, 2016. [Google Scholar]

- Russell, M.; Gianoli, A.; Grafakos, S. Getting the ball rolling: An exploration of the drivers and barriers towards the implementation of bottom-up circular economy initiatives in Amsterdam and Rotterdam. J. Environ. Plan. Manag. 2019, 63, 1903–1926. [Google Scholar] [CrossRef]

- Tjallingii, S. Ecopolis: Strategies for Ecologically Sound Urban Development; Backhuys: Leiden, The Netherlands, 1995. [Google Scholar]

- IPCC. Global Warming of 1.5 °C. In An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change; IPCC: Geneva, Switzerland, 2018. [Google Scholar]

- Benis, K.; Ferrão, P. Potential mitigation of the environmental impacts of food systems through urban and peri-urban agriculture (UPA)—A life cycle assessment approach. J. Clean. Prod. 2017, 140, 784–795. [Google Scholar] [CrossRef]

- Russell, S.N.N.; Allwood, J.M.M. Environmental evaluation of localising production as a strategy for sustainable development: A case study of two consumer goods in Jamaica. J. Clean. Prod. 2008, 16, 1327–1338. [Google Scholar] [CrossRef]

- Hall, G.; Rothwell, A.; Grant, T.; Isaacs, B.; Ford, L.; Dixon, J.; Kirk, M.; Friel, S. Potential environmental and population health impacts of local urban food systems under climate change: A life cycle analysis case study of lettuce and chicken. Agric. Food Secur. 2014, 3, 6. [Google Scholar] [CrossRef] [Green Version]

- Kreiger, M.; Pearce, J.M. Environmental life cycle analysis of distributed three-dimensional printing and conventional manufacturing of polymer products. ACS Sustain. Chem. Eng. 2013, 1, 1511–1519. [Google Scholar] [CrossRef]

- Almena, A.; Lopez-Quiroga, E.; Fryer, P.J.J.; Bakalis, S. Towards the decentralisation of food manufacture: Effect of scale production on economics, carbon footprint and energy demand. Energy Procedia 2019, 161, 182–189. [Google Scholar] [CrossRef]

- Kreidenweis, U.; Lautenbach, S.; Koellner, T. Regional or global? The question of low-emission food sourcing addressed with spatial optimization modelling. Environ. Model. Softw. 2016, 82, 128–141. [Google Scholar] [CrossRef]

- Srai, J.S.; Kumar, M.; Graham, G.; Phillips, W.; Tooze, J.; Ford, S.; Beecher, P.; Raj, B.; Gregory, M.; Tiwari, M.K.; et al. Distributed manufacturing: Scope, challenges and opportunities. Int. J. Prod. Res. 2016, 54, 6917–6935. [Google Scholar] [CrossRef]

- Freeman, R.; McMahon, C.; Godfrey, P. Design of an Integrated Assessment of Re-Distributed Manufacturing for the Sustainable, Resilient City; Springer: New York, NY, USA, 2016; Volume 52. [Google Scholar]

- Freeman, R.; McMahon, C.; Godfrey, P. An exploration of the potential for re-distributed manufacturing to contribute to a sustainable, resilient city. Int. J. Sustain. Eng. 2017, 10, 260–271. [Google Scholar] [CrossRef] [Green Version]

- Leigh, N.G.; Hoelzel, N.Z. Smart growth’s blind side: Sustainable cities need productive urban industrial land. J. Am. Plan. Assoc. 2012, 78, 87–103. [Google Scholar] [CrossRef]

- Burggräf, P.; Dannapfel, M.; Uelpenich, J.; Kasalo, M. Urban factories: Industry insights and empirical evidence within manufacturing companies in German-speaking countries. Procedia Manuf. 2019, 28, 83–89. [Google Scholar] [CrossRef]

- Amenta, L.; van Timmeren, A. Beyond wastescapes: Towards circular landscapes. addressing the spatial dimension of circularity through the regeneration of wastescapes. Sustainability 2018, 10, 4740. [Google Scholar] [CrossRef] [Green Version]

- Lyons, D.; Rice, M.; Wachal, R. Circuits of scrap: Closed loop industrial ecosystems and the geography of us international recyclable material flows 1995–2005. Geogr. J. 2009, 175, 286–300. [Google Scholar] [CrossRef]

- Lyons, D.I. A spatial analysis of loop closing among recycling, remanufacturing, and waste treatment firms in Texas. J. Ind. Ecol. 2007, 11, 43–54. [Google Scholar] [CrossRef]

- Park, J.Y.; Gupta, C. Evaluating localism in the management of post-consumer plastic bottles in Honolulu, Hawai’i: Perspectives from industrial ecology and political ecology. J. Environ. Manag. 2015, 154, 299–306. [Google Scholar] [CrossRef]

- Velenturf, A.P.M.; Jensen, P.D. Promoting Industrial Symbiosis: Using the Concept of Proximity to Explore Social Network Development. J. Ind. Ecol. 2016, 20, 700–709. [Google Scholar] [CrossRef] [Green Version]

- Petit-Boix, A.; Leipold, S. Circular economy in cities: Reviewing how environmental research aligns with local practices. J. Clean. Prod. 2018, 195, 1270–1281. [Google Scholar] [CrossRef]

| Interviewee | Country | Affiliation | Role | Date |

|---|---|---|---|---|

| A | United States of America | Yale University | Academic on urban planning, urban planning history, urban manufacturing | 7 February 2020 |

| B | United States of America | City University of New York | Academic on urban economic planning, urban manufacturing, the maker movement | 12 February 2020 |

| C | United Kingdom | University College London | Academic on circular economy, energy | 3 April 2020 |

| D | Spain | Institute for Advanced Architecture of Catalonia | Academic and practitioner on urban manufacturing, urbanism, the maker movement, fab.city co-founder | 9 April 2020 |

| E | United States of America | Urban Manufacturing Alliance | Practitioner on urban manufacturing network building | 10 April 2020 |

| F | Belgium | Université libre de Bruxelles | Academic on urban manufacturing, urban planning | 21 April 2020 |

| G | United States of America | UPcyclers Network | Practitioner on circular economy, policy and business models for recycling and reuse | 26 May 2020 |

| H | United States of America | Square Nail Consulting | Practitioner on circular economy, building product reuse | 3 June 2020 |

| Topic | Search Terms | # Results |

|---|---|---|

| Drivers and barriers for circular cities and urban manufacturing | TITLE-ABS-KEY (“circular economy” OR “industrial symbiosis” AND “makerspace” OR “urban industry” OR “local industry” OR “distributed industry” OR “urban manufacturing” OR “distributed manufacturing” OR “local manufacturing” OR “urban production” OR “local production” OR “distributed production” AND “urban” OR “city” AND “driver” OR “opportunity” OR “barrier” OR “challenge”) | 4 |

| Drivers and barriers for circular cities | TITLE-ABS-KEY (“circular economy” OR “industrial symbiosis” AND “urban” OR “city” AND “driver” OR “opportunity” OR “barrier” OR “challenge”) | 270 |

| Drivers and barriers for urban manufacturing | TITLE-ABS-KEY (“makerspace” OR “urban industry” OR “local industry” OR “distributed industry” OR “urban manufacturing” OR “distributed manufacturing” OR “local manufacturing” OR “urban production” OR “local production” OR “distributed production” AND “urban” OR “city” AND “driver” OR “opportunity” OR “barrier” OR “challenge”) | 184 |

| Drivers for Circular Urban Manufacturing | ||

|---|---|---|

| Space | People | Flows |

| Push factors | ||

| Manufacturing is cleaner, quieter, and smaller, allowing manufacturing to move back into the city Potential for place-making | Potential for reshoring manufacturing Independence from global supply chain Democratized manufacturing Faster prototyping and product development | Potential for turning local waste to a local resource Potential lower transportation emissions Repair, recycle, upcycle culture in the maker movement |

| Pull factors | ||

| Cheap real estate in smaller declining towns Availability of industrial land Space providing stakeholders for makers | Disturbances to the linear global supply chains Access to support networks Existing consumer market for circular urban manufacturing | Availability of waste (municipal waste, industrial waste, waste not worth shipping to other countries) |

| Barriers for Circular Urban Manufacturing | ||

|---|---|---|

| Space | People | Flows |

| Outdated land-use and zoning regulations Lack of space for circular infrastructure (such as storage, reuse, recycling) Lack of affordable space for urban manufacturers | Lack of knowledge required to scale up business Limited access to larger production networks Limited access to venture capital -circular and manufacturing businesses are seen as high-risk investments | Scaling up production leads to sourcing from offshore networks Circular urban manufacturers limited to working with high-value or niche products, which reduces total volume of waste converted into resources Limited availability of quality recycled material from local sources |

| High-Value | Small | Design-Driven | Customized | Essential | Technology Driven | Niche | Short Life-Times | Perishable | Heavy | |

|---|---|---|---|---|---|---|---|---|---|---|

| C&D 1 | x | x | x | x | x | x | ||||

| Fashion | x | x | x | x | x | x | ||||

| Healthcare | x | x | x | x | x | x | ||||

| Food | x | x | x | x | x | |||||

| Electronics | x | x | x | x | x | |||||

| Diamonds | x | x | x | x | ||||||

| Furniture | x | x | x | |||||||

| Plastic | x | x |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsui, T.; Peck, D.; Geldermans, B.; van Timmeren, A. The Role of Urban Manufacturing for a Circular Economy in Cities. Sustainability 2021, 13, 23. https://doi.org/10.3390/su13010023

Tsui T, Peck D, Geldermans B, van Timmeren A. The Role of Urban Manufacturing for a Circular Economy in Cities. Sustainability. 2021; 13(1):23. https://doi.org/10.3390/su13010023

Chicago/Turabian StyleTsui, Tanya, David Peck, Bob Geldermans, and Arjan van Timmeren. 2021. "The Role of Urban Manufacturing for a Circular Economy in Cities" Sustainability 13, no. 1: 23. https://doi.org/10.3390/su13010023

APA StyleTsui, T., Peck, D., Geldermans, B., & van Timmeren, A. (2021). The Role of Urban Manufacturing for a Circular Economy in Cities. Sustainability, 13(1), 23. https://doi.org/10.3390/su13010023