1. Introduction

Along with the growth in industrial activity, environmental issues are rising. The demands of different stakeholders concerning these issues are also rising. Many studies indicate that manufacturing activities make a significant contribution to environmental degradation. Industrial manufacture causes an increase in carbon emissions by 36 percent and represents one-third of world energy consumption [

1]. The manufacturing sector also consumes a lot of materials and produces waste [

2]. Based on these findings, manufacturing industry waste is one of the sources of environmental damage. Various attempts have been made to mitigate the presence of waste.

Some of the efforts made include using waste to make it valuable. Nurmesniemi et al. investigated waste utilization at the Stora Enso Oyj Veitsiluoto Mills paper mill in Kemi, Northern Finland [

3]. This study suggested using green liquid waste from caustic processes to neutralize water acidity. The resulting solid waste is all burned in a fluidized bed boiler to produce energy.

Singh et al. [

4] examined the use of paper waste as a material for building bricks. The waste produced is Deinking Paper Mill Sludge (DPMS). The non-thermal brick developed is more heat resistant than conventional bricks and can be an alternative to traditional bricks. Other research on waste utilization occurs in the food industry. Food industry wastes originating from tropical fruits produce phenolic compounds [

5]. Based on these studies, the manufacturing industry’s waste still has the potential to be utilized. Many manufacturing industries have not realized the potential value that the waste produced has. The potential value possessed by the waste is known as Value Uncaptured (VU).

VU is a potential value that the company has not captured, even though it benefits the company [

6]. According to Yang M. et al. [

6], VU’s presence is detected throughout the beginning of life, middle of life and end of life (product life cycle). VU can take the form of waste heat (waste energy), overproduction, and lack of resources/input [

6]. The existence of VU in these forms shows that its manufacturing practices have not efficient. Meanwhile, the VU still has the potential to be a source of value for the company. Companies need to identify the existence of the VU.

Yang et al. [

6] studied VU in companies operating business models of the Product-Service System (PSS) in China, England, and America. In companies that adopt this business model, this study has established 26 VU sources. This study aims to change value uncaptured (VU) to value captured (VC) through the innovation of a Sustainable Business Model (SBM).

Several things need to be considered in the SBM innovation concept, namely business model innovation and SBM. The combination of these two concepts will produce new values and have a sustainable character.

Business model innovation generates new value through a process of capture, create, and deliver. Two essential concepts in a business model are value creation and value capture. Value creation is the process aimed at increasing value generation [

7]. Value capture is the process of obtaining profits from value creation and distributing these profits to the parties involved, such as providers, customers and partners [

8]. Meanwhile, Sjödin et al. [

9] put forward the idea of aligning value creation and value capture in the context of business model innovation. With this alignment, the value creation process is no longer provider-centric but also involves the consumer. This concept is in line with this study. This suitability can be seen from how this study conducts value creation with the tools used.

A sustainable business model (SBM) is a business model that contributes to sustainable development resulting in a competitive advantage due to the superior value offered to customers [

10]. Meanwhile, other studies have linked sustainability in business models with three sustainability pillars, economic, social, and environmental. SBM creates and embodies social and ecological values in addition to economic benefits [

11]. Value creation that considers environmental, social, economic pillars becomes organizational challenges to create competitiveness [

12]. Meanwhile, value creation can refer to various forms of social or economic value [

13]. One form of SBM that can be applied is the Circular Business Model (CBM).

In Closed Material Loops (CML), CBM is the premise of how organizations capture, create and deliver value [

14]. CML means that either as a bulk material, product, or component, the material may be used again [

14]. The Circular Economic (CE) definition is the reuse of materials, items or components. Thus, CBM is a business model implemented by CE implementing manufacturing firms. Several studies demonstrate the success stories of CBM implementation. This business model’s performance offers economic advantages in the form of savings valued at more than

$1 million [

15]. All stakeholders expect support from CBM’s application in the process of value creation. The Swedish men’s apparel company, Nudie Jeans, Dutch carpet company Desso, and French furniture company Steelcase, have introduced CBM [

16]. The empirical evidence of this success story will cause CBM adoption by manufacturing companies. Lewandowski suggests a discourse on evaluating the efficiency of CBM in the context of a fit between the Value Proposition (VP) and the Consumer Segment (CS) [

17]. This discourse is appropriate for the principle of Value Proposition Design (VPD) offered [

18].

VPD is a continuous process that generates a value proposition to fulfill customer desires [

18]. From the perspective of consumers and producers, VPD maps value. From a customer viewpoint, VPD maps value in terms of jobs, gains and pains. Meanwhile, producers map the inherent values of product/service, gain creators, and pain reliever. Many studies show the success stories of using VPD in solving corporate value mapping issues. Pokorná et al. [

19] established the factors of the business model that form the VP of customers of the agricultural sector. The research was able to classify jobs (supply of safe and fresh foods and emotions of pleasure to buy), gain creators (new and healthy food), and pains (higher prices and less comfortable opening hours). Baldassarre et al. [

20] merged the idea of sustainable business model innovation and user-driven innovation. A sustainable value proposition that takes all stakeholders into account is the outcome of this study. To respond to the sense of sustainability in a circular business model framework, VPD generates an environmental value proposition [

21]. The qualitative VPD model used in these studies is in the form of a mapping and a framework. As well as the steps that producers take to respond to these desires, these models often reflect customer preferences. These models are identical to the House of Quality (HOQ) concept.

HOQ is a matrix that defines the process of translating the customer’s needs and how to fulfill them [

22]. HOQ has so far been widely used as a method to link customer preferences with responses from producers. The HOQ matrix consists of client requirements (row—what) and design requirements (column—way). The HOQ approach is widely adopted to solve problems outside of product design. Many studies have implemented the HOQ approach for problem-solving in different fields. HOQ has been used to assess human errors in supply chain activities [

23]. HOQ is used to resolve risk reduction issues in the supply of tuna fish [

24]. In the meantime, Pulansari et al. [

25] used HOQ to evaluate the variables affecting company efficiency and consumer concerns. These studies usually used HOQ to solve problems (what) in a way (how).

This research model was developed based on previous studies on the recognition of the existence of VU [

6], sustainable business model innovation [

17], qualitative VPD methods [

18,

20,

21] and versatility in the use of HOQ [

23,

24,

25]. The goal of this study is to create a sustainable business model to turn VU into VC. This research utilizes an approach to sustainable business model innovation (CBM). VPD can become a reference in determining value from two perspectives (consumers and producers). HOQ is a tool in the VPD fitting process. The use of two instruments (VPD and HOQ) to strengthen previous studies’ shortcomings is the novelty of this study.

Using a combination of VPD and HOQ approaches, this study restricts the process of converting VU to VC. The problem-solving steps are approached in the order of VU—jobs (triggers)—gains—gain creators—VC. The sustainable business model approach connects VC with the elements of the three pillars of sustainability.

This research uses a case study in one of the furniture companies in Indonesia. This company is an online wholesaler, exporter and wholesale producer of handicrafts, Indonesian teak furniture. It has been in this business for more than 12 years in manufacturing, designing, developing, wholesaling, and exporting wooden furniture and rattan furniture. Ninety-five percent of the furniture products are for export needs. Even though this company is quite large, it still produces inefficiencies in its manufacturing and business practices. The existence of this inefficiency becomes an indicator of the presence of VU, which may not be realized. This model can be applied to the manufacturing industry in general. It is also possible to use this model in the service sector by looking at inefficient activities that indicate value uncaptured.

2. Research Methods

This study builds a sustainable business model based on the circular business model concept [

17]. Based on the idea of a business model, this study uses two kinds of input in the context of value. These inputs can come from two perspectives, namely consumers and producers. The information from the consumer’s and producer’s perspective can be detailed as follows:

Jobs explain what clients in their job or life are trying to get done [

18]. Jobs come from customers’ voices about the function of a product that current products have not fulfilled.

Gains define the outcomes and benefits that consumers want [

18]. Gains come from the voices of customers on the advantages they feel by using current goods.

Value Uncaptured (VU) is the potential value possible of becoming captured but not yet caught [

6]. VU comes from detecting inefficient production processes such as waste, defects in quality, and so forth.

Gain creators explain how producers create consumer gains [

18]. Gain creators are the reactions of producers to customers’ voices regarding their benefits by using current goods. By enhancing the method to create a better product or service, the producers will generate gain creators.

This model uses Value Proposition Design (VPD) and House of Quality (HOQ) methods. VPD is a guide in identifying jobs, gains, and gain creators. In the meantime, HOQ is a guide for fitting the client’s product specifications with the design requirements. The synthesis of these two approaches is the novelty of this model. Understanding of this model using a systems approach.

VU in this analysis comes from inefficiencies in the production process and the resulting waste. This business model will turn VU into VC. A sustainable business model (Circular Business Model—CBM) is used to solve this issue. The definition of sustainability here refers to all business activities that pay attention to sustainability’s three pillars (Profit People Planet—3P). VPD and HOQ are the methods used to implement CBM. VPD is used as a reference for identifying and mapping jobs, gains, and gain creators. The fitting process is the final stage of this method. In this study, the fitting process was carried out using the HOQ method. Because this study uses the value case, the researcher calls it the House of Value (HOV) for the fitting process in HOQ.

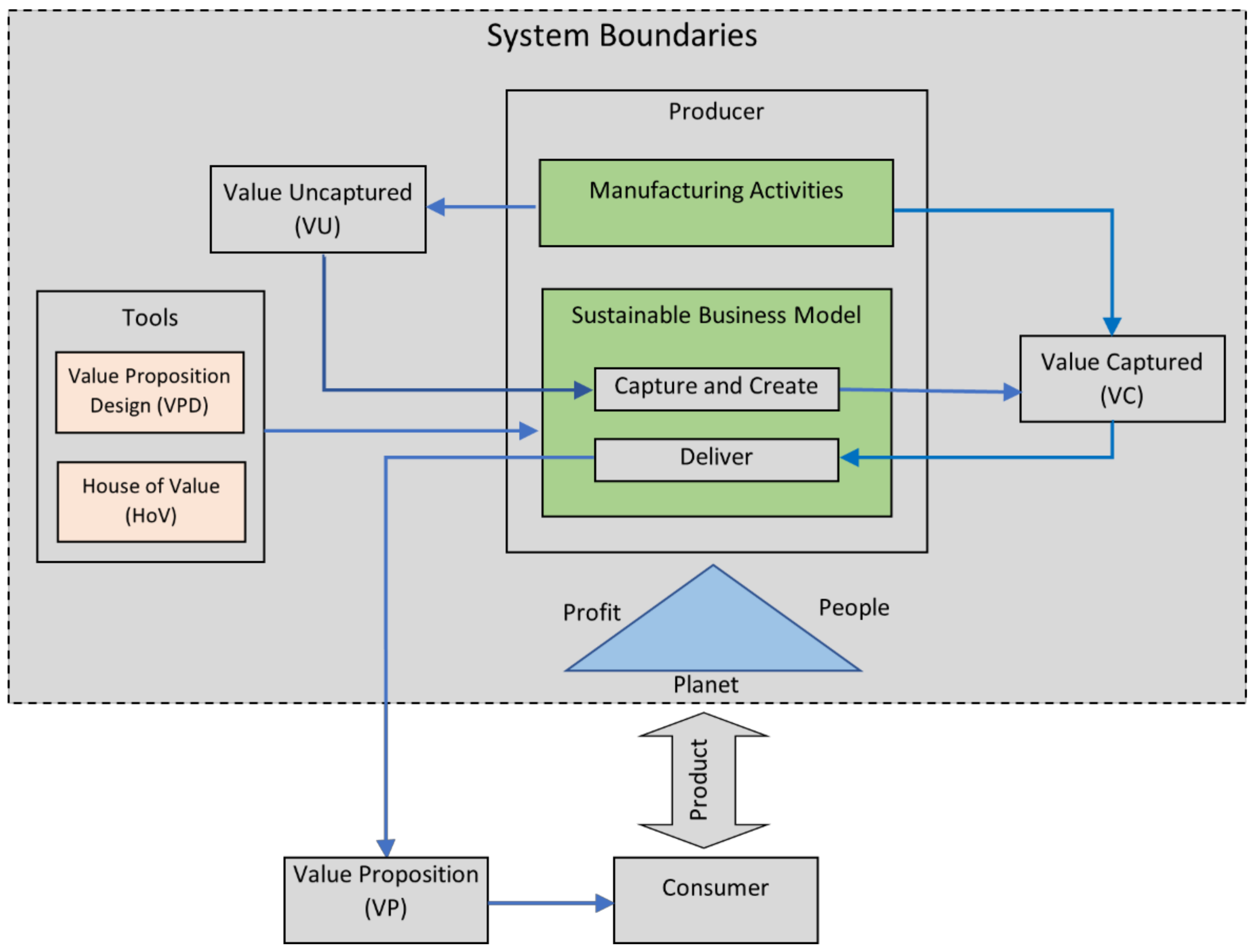

Figure 1 shows that manufacturing operations often render Value Uncaptured (VU) in addition to generating Value Captured (VC).

Figure 2 provides a more detailed combined use of these methods (a,b,c).

2.1. The Process of Obtaining Value Uncaptured (VU)

Researchers made observations on the company’s manufacturing practices to get VU. Yang et al. [

6] provides a reference to the presence of VU during the product life cycle. The company’s interviews resulted in three VUs, namely the size (dimension) of the product does not match what the consumer needs (

VU # 1), quality does not match consumer expectations (

VU # 2), and the remaining material (pieces of rattan) which have economic value (

VU # 3).

The measurement of the weight of VU uses a pairwise comparison process. The criteria used in this study are Value Missed (VM), Value Surplus (VS), and Value Absence (VA) [

6]. Value missed is a value that exists and is required but is not exploited. Value surplus is a value that exists but is not required. Value absence is a value that is needed but does not exist.

Figure 3 presents a decision hierarchy for determining the weight of the relative importance of VU.

Table 1 explains the measurement scale (1, 3, 5, 7, and 9). For each VU, this study generates a weight of relative importance, namely

W #

VU1,

W #

VU2, …,

W #

VUn. The design of calculating the relative weight of value uncaptured follows the following steps (1) making a pairwise comparison matrix between criteria (2) making a pairwise comparison matrix between alternatives.

Using a measurement scale (

Table 1), a questionnaire was distributed to the producers. The results of the questionnaire are presented in

Table 2 and

Table 3.

Appendix A shows the complete calculation of the relative weight of value uncaptured. The pairwise comparison method produces the relative weights of value uncaptured

W_

VU1,

W_

VU2, and

W_

VU3. These values will be used in calculating the relative weights of jobs at a later stage.

2.2. The Process of Obtaining Information about Jobs from Consumers (Customers)

Osterwalder et al. [

18] defined the basic notion of jobs. Meanwhile, Vaida et al. [

26] described jobs that furniture customers want with a smart furniture concept approach. This description is in line with the concept suggested by [

18]. This study uses the following jobs based on these two concepts: furniture products that are easy to clean (

Jb # 1), products that cause the appearance of the house (indoor and outdoor) to be tidier (

Jb # 2), decorative handicraft products (

Jb # 3), and eco-friendly craft products (

Jb # 4). Each job includes some gains, as shown in

Table A14.

To obtain the value

, the relationship between VU and jobs is determined.

Figure 4 illustrates the relationship between VU and jobs. The

value follows the measurement scale of 1 = slightly strong, 3 = moderate, and 9 = strong. A questionnaire was distributed to the producers using the Google Forms application.

Table 4 shows the results of the questionnaire. The results of scoring the relationship between value uncaptured and jobs (

) being the input of the HOV matrix (

Figure 5).

Job selection uses the criteria that have the greatest relative weight. The relative weight measurement of jobs uses the HOV method (

Figure 5).

The calculation of the absolute and relative weights of jobs uses Equations (1) and (2).

= weight of relative importance of VU i.

= Absolute importance of jobs j

= Relative importance of jobs j

Sum = the horizontal summation of the weight of the absolute importance of the job

The study yields the relative weights of jobs RI_Jb1, RI_Jb2, …, RI_Jbn. Jobs that have the largest relative weight are selected as inputs at a later stage.

2.3. The Process of Obtaining Gains from Consumers (Customers)

This research uses Osterwalder et al. [

18] as a conceptual approach and Vaida et al. [

26] as a practical approach to interpreting gains. Gains demonstrated the benefits that customers feel after using existing goods. Gains also reflect the expected benefits of the product.

This analysis uses gains relating to specific jobs based on the chosen jobs (

Figure 5). The relative gains weight calculation utilizing the basis of a consumer questionnaire’s results through the Google Forms application. The distribution of questionnaires to 30 respondents was sufficient to represent the sample in this study. Respondents are taken from regular customers (not only consumers) from the company so that the data gains obtained can be accounted for its validity.

Table 5 summarizes the results of the questionnaire and the calculation of the gains’ relative weight. The scores used in this analysis were 1 = not significant, 2 = less important, 3 = very important, 4 = important, and 5 = quite important. Equation (4) is used to calculate the weight of relative gains. This research results in the relative weight gain of

W_

Gn1,

W_

Gn2, …,

W_

Gnn. This relative weight is used as input for calculating the relative weight of the gain creators.

2.4. The Process of Obtaining Gain Creators from the Company (Producer)

Conceptually, the notion of GC fits the definition proposed by [

18]. The company responds to the gains from consumers in the form of gain creators (GC). Researchers conducted interviews with company owners to get a response to consumer’s gains. The GCs used in this study were

GC # 1,

GC # 2,

GC # 3,

GC # 4,

GC # 5.

The relative weight of gain creators (

RI_

GC) is provided by fitting the gains with the gain creators (

Figure 6). It is determined using the following steps:

- (1)

Calculation of absolute weight (absolute importance) of gain creators—Equation (5)

W_Gni is the weight of gains i (the result of the pairwise comparison).

= the relationship score of Gains i and Gain Creators j

- (2)

Calculation of the relative weight (relative importance) of gain creators—Equation (6)

This research resulted in n relative weight gain creators , , …, . All gain creators would point to a value, namely Value Captured (VC), with different relative weights.

2.5. The Process of Obtaining the Company’s Value Captured (VC)

The company realizes gain creators in the form of Value Captured (VC). VC is attached to the design of the company’s product. This research resulted in some VCs: VC # 1, VC # 2, VC # 3, VC # 4, and VC # 5.

The

value follows the measurement scale of 1 = slightly strong, 3 = moderate and 9 = strong. A questionnaire was distributed to the producers using the Google Forms application. The results of the questionnaire can be seen in

Table 6. The results of scoring the relationship between value uncaptured and jobs (

) being the input of the HOV matrix (

Figure 7). The results of scoring the relationship between the value uncaptured and jobs (

) were the input of the HOV matrix (

Figure 7). The absolute importance weight of each VC (

AI_VCj) is calculated using Equation (7). The VC’s relative weight (

RI_VCj) is determined using Equation (8).

- (1)

Calculation of Value Captured absolute importance weight

states the relationship score between Gain Creators i and value Captured j

- (2)

Calculation of Value Captured relative importance weight.

2.6. The Process of Linking the Concept of Sustainability to the Resulting VC

As this takes account of the demands of different stakeholders, it is essential to raise sustainability concerns. In this study the values captured were linked with the three sustainability pillars using the concept provided by Toivonen [

27] and Shuaib et al. [

28]. Shuaib et al. [

28] identifies the components of the three sustainability pillars. In the meantime, Hapuwatte et al. [

29] provides a guide as a model for calculating the Sustainable Value Captured (SVC).

Figure 8 describes the elements of the three pillars of sustainability. Meanwhile,

Table 7 shows a framework for measuring VCs and aspects of the three sustainability pillars relationship. The relationship scores in

Table 7 being the input of

Table 8 as a design for measuring Sustainable Value Captured (SVC).

The Equations (9)–(12) shows matrix calculation description from

Table 7.

- (1)

Economy Pillar:

Weighted value calculation at Sub Index Level—Equation (9):

= the weighted value of VC i on the economic pillar.

= weight for the economic pillar on cluster j

= the relationship between VC

j and the economic pillars of cluster

i (see

Table 6)

- (2)

Society Pillar

Weighted value calculation at Sub Index Level—Equation (8):

= the weighted value of VC i on society pillar

= weight for the social pillar on cluster j

= the relationship between VC

j and the social pillars of cluster

i (see

Table 6).

- (3)

Environmental Pillar

Weighted value calculation at Sub Index Level—Equation (9):

= the weighted value of VC i on the environmental pillar

= weight for the environmental pillar on cluster j

= the relationship between VC

j and the environmental pillars of cluster

i (see

Table 6)

- (4)

Calculation of the final value of VC with the index of sustainability—Equation (10):

= the final value of VC i

= the weight of the sustainability index j = 0.33

= the value of VC i on the sustainability index j

The study uses a case study at furniture company X.

4. Discussion

Some studies supporting this research include the following: [

18,

21,

22,

28,

29]. Osterwalder et al. [

18] pointed out that VU is an issue for manufacturing companies that need to be solved and proposed an idea of a sustainable business model to solve the VU problem. Meanwhile, Manninen et al. [

21] use the Circular Business Model (CBM) in closed material loops for material reuse. The definition of [

18] for the VU issue is relevant to this business model. Thus, solving this problem can use the CBM method. In the meantime, Franceschini [

22] demonstrates how CBM output can be measured by adjusting Value Proposition (VP) with Customer Segment (CS). This output measurement can be done using the Value Proposition Design (VPD) tool. This VPD operation generates VC. In the meantime, Shuaib et al. and Hapuwatte et al. [

28,

29] are the basis of the interaction between VC values and sustainability issues.

Study [

9] introduced Outcome-Based Business Models to be applied in companies. The model proposes the simultaneous application of the concepts of value creation and value capture. By using this model, the company is expected to achieve a competitive advantage. This condition is indicated by the value attached to the product, which results from value creation involving producers and consumers. This study is in line with [

9], where the company includes consumers in the value creation process to convert VU into VC. This consumer involvement can be seen when using the value proposition design (VPD) and the house of value tools.

This study’s output is a VC that meets the economic, social, and environmental requirements (SVC). Here are the steps for calculating the SVC value:

Three VUs resulting from this study are shown in

Table 8. Consumers’ changing needs are the reason for the emergence of

VU # 1. Often, existing products are not supported by these alterations. The reason for

VU # 2 existence is increased customer standards for product quality. There were several complaints about product quality, such as untidy rattan matting. The presence of

VU # 3 is related to the waste generated by the company. The number of rattan pieces found in the company being proof of the

VU # 3 existence. At a later stage, these three VUs will be linked to consumer jobs.

Table 10 shows the types of jobs based on the interview results. This study chose

Jb # 4 to be followed up based on the highest relative importance weight (

Table 11). Buyers are increasingly concerned with the importance and advantages of environmentally friendly furniture products. Another explanation for this is that, in part, the furniture produced is for the export market. Foreign consumers are more concerned with furniture items that take eco-friendly features into account.

The resulting gains would support the jobs currently chosen. The gains identified are shown in

Table 12. To fulfill the jobs that its consumers want, the firm must respond to these five gains. In general, studies attribute these gains to healthy furniture products for consumers. The safety of this furniture is inseparable from using the materials and components that make up the product. The value of durability refers to the use of materials that consider aspects of sustainability and dematerialization. Such market response is based on increasing awareness among consumers of environmentally friendly furniture products.

The manufacturer responds to five gains with five gain creators (

Table 14). The manufacturers do process improvement and the use of auxiliary health-safe materials. Process improvements include water-based paint finishing. Usage of health-safe additional materials by using bio-varnish as a replacement for solvent-based paint. This paint has a low content of volatile organic compounds (VOC). Besides being health-safe, it is not flammable either.

Five Value Captured (VC) resulted from the interviews (

Table 16). All VCs generated relate to the features of superior products from an environmental perspective. This perspective makes sense since the aim of the company is to raise exports. Countries are importing furniture and demanding environmentally friendly products. Ultimately, the fulfillment of these demands will be a competitive advantage for the company. However, to be competitive, the company must pay attention to two other aspects (economic and social). The step taken by the company is to link VC with the concept of sustainability.

A requirement that the company must fulfill is the issue of sustainability. The benefits that companies get from meeting this issue are in the form of increased competitiveness. A Sustainable Value Captured (SVC) that met the requirements for sustainability resulted from this study. The study selects eco-friendly products (VC # 3) based on their highest SVC value. Many factors and reasons for choosing VC # 3 include (1) the company’s intention to increase exports of its furniture products to several American and European countries; (2) the demand for worldwide furniture products tends to grow, and (3) the potential for waste (rattan pieces) to be transformed into valuable handicraft products.

It might be possible to undertake future research to develop this study. Future research encompasses:

The determination of VC from the side of the pains faced by consumers.

The application of this model is for companies engaged in foods and beverages.

The application of this model is for companies in the service sector.