A Simulation Model of Construction Projects Executed in Random Conditions with the Overlapping Construction Works

Abstract

1. Introduction

2. Materials and Methods

2.1. Literature Review

2.2. Simulation Model

- δij1 = {0, 1} and takes the value 1 in the event when, within the time limit t on the unit i, only the process j is realized; 0 in other cases;

- δij2 = {0, 1} and takes the value 1 in the event when, within the time limit t on the unit i, the process j and (j + 1) are realized simultaneously; 0 in other cases;

- δij3 = {0, 1} and takes the value 1 in the event when, within the time limit t on the unit i, the process j and (j − 1) are realized simultaneously; 0 in other cases;

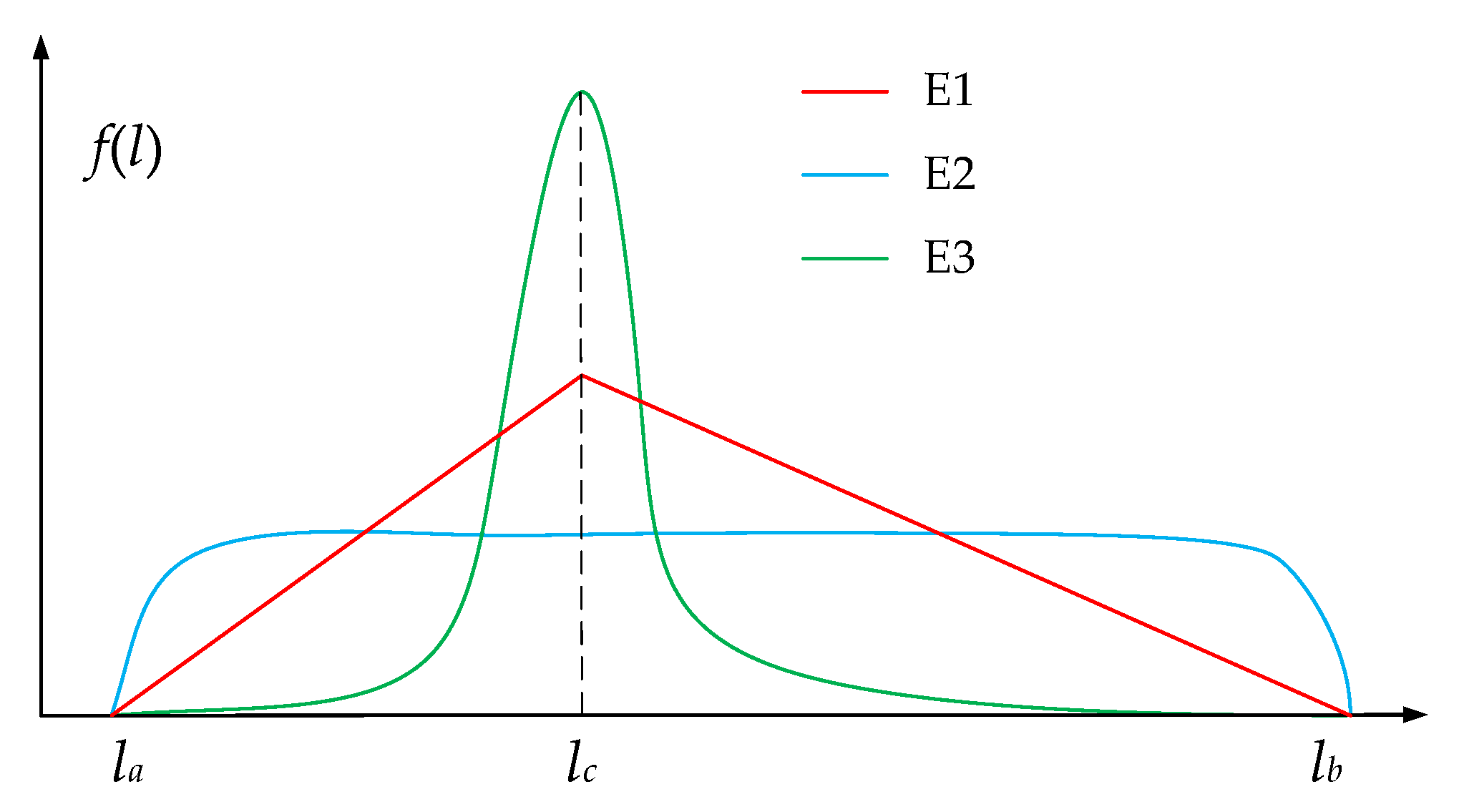

- lijt1, lijt2, lijt3—random numbers according to the probability distribution of daily efficiency appropriate for the variant of the process overlap Li1, Li2, Li3 taking into account overlap processes.

- Increase the simulation clock by 1 day: t = t + 1;

- Check if there are processes not yet realized. If yes, move to step 3. If not, move to step 8;

- Find the earliest process possible to realize due to date t according to the sequence relation—remember it as (r, s);

- If there are no processes to be realized by the date t, go to step 1;

- Check if Prs,t = 0. If yes, remember the starting date for this process;

- Check whether, on the date t, process r on unit s is performed independently or whether it is a subsequent of the (r − 1) process carried out on the date t or a predecessor of (r + 1). Select according to the assumed distributions of the value of the daily amount of works Prs,t. If process r is a successor to (r − 1) and condition 2 is not unfulfilled, reduce the daily output of that process. Increase the amount of realized works up to day t according to Equation (1). Remember that the process (r, s) was implemented on the date t;

- Check if Prs,t ≥ Prs,p. If yes, remember the end date of this process;

- Move to step 2;

- End of the simulation run. Remember the end date of the last process, which is also the end date of the project.

3. Results

- The duration of the project realization is crucial for the contractor, and they are ready to incur additional costs caused by extending the work of the working crews; hence, w1 = 0.9 and w2 = 0.1 (1st set of weights);

- The directive deadline of the project is distant, and the contractor aims to reduce the costs of the crews work; hence, w1 = 0.1 and w2 = 0.9 (2nd set of weights);

- Intermediate solution: weights equal to 0.6 and 0.4 (3rd set of weights).

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- PMI Standards Committee. A Guide to the Project Management Body of Knowledge; Project Management Institute: Worcester, MA, USA, 2000. [Google Scholar]

- Demeulemeester, E.L.; Herroelen, W. Project Scheduling: A Research Handbook; International Series in Operations Research & Management Science; Springer: New York, NY, USA, 2002; ISBN 978-1-4020-7051-8. [Google Scholar]

- Hajdu, M. Network Scheduling Techniques for Construction Project Management; Nonconvex Optimization and Its Applications; Springer: New York, NY, USA, 1997; ISBN 978-0-7923-4309-7. [Google Scholar]

- Tomczak, M.; Jaśkowski, P. New Approach to Improve General Contractor Crew’s Work Continuity in Repetitive Construction Projects. J. Constr. Eng. Manag. 2020, 146, 04020043. [Google Scholar] [CrossRef]

- Hosny, A.; Nik-Bakht, M.; Moselhi, O. Workspace Planning in Construction: Non-Deterministic Factors. Autom. Constr. 2020, 116, 103222. [Google Scholar] [CrossRef]

- Tomczak, M. Modeling of the Harmonization Method for Executing a Multi-Unit Construction Project. Open Eng. 2019, 9, 282–291. [Google Scholar] [CrossRef]

- Rzepecki, Ł.; Jaśkowski, P. Application of Game Theory against Nature in Supporting Bid Pricing in Construction. Symmetry 2021, 13, 132. [Google Scholar] [CrossRef]

- Kim, K. Generalized Resource-Constrained Critical Path Method to Improve Sustainability in Construction Project Scheduling. Sustainability 2020, 12, 8918. [Google Scholar] [CrossRef]

- Yu, M.; Zhu, F.; Yang, X.; Wang, L.; Sun, X. Integrating Sustainability into Construction Engineering Projects: Perspective of Sustainable Project Planning. Sustainability 2018, 10, 784. [Google Scholar] [CrossRef]

- Jaśkowski, P.; Biruk, S. Minimizing the Duration of Repetitive Construction Processes with Work Continuity Constraints. Computation 2019, 7, 14. [Google Scholar] [CrossRef]

- Biruk, S.; Rzepecki, L. Scheduling Repetitive Construction Processes Using the Learning-Forgetting Theory. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 112039. [Google Scholar] [CrossRef]

- Radziszewska-Zielina, E.; Sroka, B. Priority Scheduling in the Planning of Multiple-Structure Construction Projects. Arch. Civ. Eng. 2017, 63, 21–33. [Google Scholar] [CrossRef][Green Version]

- Apollo, M.; Grzyl, B.; Jakubowicz, P. Risk of Delays in Implementation of Building Investment in Urban Conditions in the Aspect of Historical Background of Its Location. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 112054. [Google Scholar] [CrossRef]

- Laufer, A.; Shapira, A.; Goren, I. Implementing an Integrative Approach to Project Schedule Compression. Eng. Constr. Archit. Manag. 1998, 5, 82–92. [Google Scholar] [CrossRef]

- Biruk, S.; Jaskowski, P. Scheduling Linear Construction Projects with Constraints on Resource Availability. Arch. Civ. Eng. 2017, 63, 3–15. [Google Scholar] [CrossRef]

- Arık, O.A. Credibility Based Chance Constrained Programming for Project Scheduling with Fuzzy Activity Durations. Int. J. Optim. Control Theor. Appl. 2019, 9, 208–215. [Google Scholar] [CrossRef]

- Biruk, S.; Rzepecki, Ł. Simulation Model for Resource-Constrained Construction Project. Open Eng. 2019, 9, 37. [Google Scholar] [CrossRef]

- Sahu, K.; Sahu, M. Cost & Time and Also Minimum Project Duration Using Alternative Method. Int. Rev. Appl. Eng. Res. 2014, 4, 403–412. [Google Scholar]

- Georges, N.; Semaan, N.; Rizk, J. Crash: An Automated Tool for Schedule Crashing. Int. J. Sci. 2007, 3, 374–394. [Google Scholar]

- Anysz, H.; Krzemiński, M. Cost Approach to the Flow-Shop Construction Scheduling. E3S Web Conf. 2019, 110, 02048. [Google Scholar] [CrossRef]

- Moselhi, O. Schedule Compression Using the Direct Stiffness Method. Can. J. Civ. Eng. 2011, 20, 65–72. [Google Scholar] [CrossRef]

- Radziszewska-Zielina, E.; Sroka, B. Planning Repetitive Construction Projects Considering Technological Constraints. Open Eng. 2018, 8, 500–505. [Google Scholar] [CrossRef]

- O’Regan, N.; Ghobadian, A.; Sims, M. Fast Tracking Innovation in Manufacturing SMEs. Technovation 2006, 26, 251–261. [Google Scholar] [CrossRef]

- Bissiri, Y.; Dunbar, S. Resource Allocation Model for a Fast-Tracked Project. In Proceedings of the Second International Conference on Intelligent Processing and Manufacturing of Materials, IPMM’99 (Cat. No.99EX296), Honolulu, HI, USA, 10–15 July 1999; Volume 1, pp. 635–640. [Google Scholar]

- Ng, T.; Cheung, S.O.; Kumaraswamy, M.M.; Choy, K.K.M. Selection of Activities to Be Crashed for Mitigating Construction Delays. HKIE Trans. 2004, 11, 42–47. [Google Scholar] [CrossRef]

- Biruk, S.; Jaśkowski, P. Selection of the Optimal Actions for Crashing Processes Duration to Increase the Robustness of Construction Schedules. Appl. Sci. 2020, 10, 8028. [Google Scholar] [CrossRef]

- Tomczak, M.; Jaśkowski, P. Crashing Construction Project Schedules by Relocating Resources. IEEE Access 2020, 8, 224522–224531. [Google Scholar] [CrossRef]

- Goldratt, E.M. Critical Chain: A Business Novel; Routledge: London, UK, 2017; ISBN 978-1-351-21896-2. [Google Scholar]

- Deacon, H.; Lingen, E. van der The Use of the Critical Path and Critical Chain Methods in the South African Construction Industry. Acta Structilia 2015, 22, 73–95. [Google Scholar]

- Herroelen, W.; Leus, R. On the Merits and Pitfalls of Critical Chain Scheduling. J. Oper. Manag. 2001, 19, 559–577. [Google Scholar] [CrossRef]

- Yang, Q.; Lu, T.; Yao, T.; Zhang, B. The Impact of Uncertainty and Ambiguity Related to Iteration and Overlapping on Schedule of Product Development Projects. Int. J. Proj. Manag. 2014, 32, 827–837. [Google Scholar] [CrossRef]

- Koyuncu, E.; Erol, R. PSO Based Approach for Scheduling NPD Projects Including Overlapping Process. Comput. Ind. Eng. 2015, 85, 316–327. [Google Scholar] [CrossRef]

- Wang, J.; Lin, Y.-I. An Overlapping Process Model to Assess Schedule Risk for New Product Development. Comput. Ind. Eng. 2009, 57, 460–474. [Google Scholar] [CrossRef]

- Roemer, T.A.; Ahmadi, R. Concurrent Crashing and Overlapping in Product Development. Oper. Res. 2004, 52, 606–622. [Google Scholar] [CrossRef]

- Hau Yee, S.; Murata, T. Risk Assessment of New Product Development Process with Concurrent Engineering Based on Stochastic Network Model. Int. J. Mech. Prod. Eng. 2019, 7, 133–139. [Google Scholar]

- Gerk, J.E.V.; Qassim, R.Y. Project Acceleration via Activity Crashing, Overlapping, and Substitution. IEEE Trans. Eng. Manag. 2008, 55, 590–601. [Google Scholar] [CrossRef]

- Terwiesch, C.; Loch, C.H. Measuring the Effectiveness of Overlapping Development Activities. Manag. Sci. 1999, 45, 455–465. [Google Scholar] [CrossRef]

- Meier, C.; Yassine, A.A.; Browning, T.R.; Walter, U. Optimizing Time–Cost Trade-Offs in Product Development Projects with a Multi-Objective Evolutionary Algorithm. Res. Eng. Des. 2016, 27, 347–366. [Google Scholar] [CrossRef]

- Ballesteros-Pérez, P. Modelling the Boundaries of Project Fast-Tracking. Autom. Constr. 2017, 84, 231–241. [Google Scholar] [CrossRef]

- Dehghan, R.; Ruwnapura, J.Y. Model of Trade-Off between Overlapping and Rework of Design Activities. J. Constr. Eng. Manag. 2014, 140, 04013043. [Google Scholar] [CrossRef]

- Hossain, M.A.; Chua, D.K.H. Overlapping Design and Construction Activities and an Optimization Approach to Minimize Rework. Int. J. Proj. Manag. 2014, 32, 983–994. [Google Scholar] [CrossRef]

- Pena-Mora, F.; Park, M. Dynamic Planning for Fast-Tracking Building Construction Projects. J. Constr. Eng. Manag. 2001, 127, 445–456. [Google Scholar] [CrossRef]

- Berthaut, F.; Grèze, L.; Pellerin, R.; Perrier, N.; Hajji, A. Optimal Resource-Constraint Project Scheduling with Overlapping Modes. In Proceedings of the International Conference on Industrial Engineering and Systems Management IESM’11, Metz, France, 25–27 May 2011; pp. 299–308. [Google Scholar]

- Bogus, S.M.; Diekmann, J.E.; Molenaar, K.R.; Harper, C.; Patil, S.; Lee, J.S. Simulation of Overlapping Design Activities in Concurrent Engineering. J. Constr. Eng. Manag. 2011, 137, 950–957. [Google Scholar] [CrossRef]

- Cho, S.-H.; Eppinger, S.D. A Simulation-Based Process Model for Managing Complex Design Projects. IEEE Trans. Eng. Manag. 2005, 52, 316–328. [Google Scholar] [CrossRef]

- Srour, I.M.; Abdul-Malak, M.-A.U.; Yassine, A.A.; Ramadan, M. A Methodology for Scheduling Overlapped Design Activities Based on Dependency Information. Autom. Constr. 2013, 29, 1–11. [Google Scholar] [CrossRef]

- Hossain, M.A.; Chua, D.K.H.; Liu, Z. Optimizing Concurrent Execution of Design Activities with Minimum Redesign. J. Comput. Civ. Eng. 2012, 26, 409–420. [Google Scholar] [CrossRef]

- Lim, T.-K.; Yi, C.-Y.; Lee, D.-E.; Arditi, D. Concurrent Construction Scheduling Simulation Algorithm. Comput. Aided Civ. Infrastruct. Eng. 2014, 29, 449–463. [Google Scholar] [CrossRef]

| Unit j | Process i | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| 1 | 400 | 800 | 900 | 1200 | 500 |

| 2 | 500 | 600 | 1000 | 1000 | 400 |

| 3 | 350 | 720 | 800 | 900 | 600 |

| 4 | 600 | 900 | 750 | 700 | 450 |

| 5 | 550 | 1000 | 850 | 900 | 300 |

| Process i | Simultaneity of Works on Units | |

|---|---|---|

| 1 | Only 1 | (34, 47, 39) |

| Process 1 (predecessor) and 2 (successor) simultaneously | (30, 40, 33) | |

| 2 | Only 2 | (50, 70, 55) |

| Process 1 (predecessor) and 2 (successor) simultaneously | (37, 61, 46) | |

| Process 2 (predecessor) and 3 (successor) simultaneously | (43, 67, 52) | |

| 3 | Only 3 | (88, 118, 94) |

| Process 2 (predecessor) and 3 (successor) simultaneously | (65, 98, 77) | |

| Process 3 (predecessor) and 4 (successor) simultaneously | (75, 107, 88) | |

| 4 | Only 4 | (63, 97, 80) |

| Process 3 (predecessor) and 4 (successor) simultaneously | (52, 80, 60) | |

| Process 4 (predecessor) and 5 (successor) simultaneously | (58, 90, 68) | |

| 5 | Only 5 | (25, 36, 30) |

| Process 4 (predecessor) and 5 (successor) simultaneously | (18, 30, 24) |

| Variant m | Reserve D | Project Duration (Days) | Process Duration Ti [Days] | ||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |||

| 1 | 0.4 | 107.434 | 64.617 | 77.767 | 72.588 | 74.931 | 79.893 |

| 2 | 0.5 | 108.968 | 63.759 | 76.422 | 70.780 | 73.889 | 78.990 |

| 3 | 0.6 | 111.715 | 63.441 | 75.158 | 68.613 | 72.014 | 78.146 |

| 4 | 0.7 | 114.748 | 63.124 | 74.066 | 67.084 | 70.380 | 77.622 |

| 5 | 0.8 | 117.871 | 62.868 | 73.195 | 65.300 | 69.026 | 77.323 |

| 6 | 0.9 | 121.260 | 62.537 | 72.337 | 64.232 | 67.529 | 76.849 |

| 7 | 1.0 | 124.746 | 62.268 | 71.729 | 63.604 | 67.091 | 76.644 |

| Variant m | Reserve D | Type of Distribution | ||

|---|---|---|---|---|

| E1 | E2 | E3 | ||

| 1 | 0.4 | 107.434 | 106.543 | 109.000 |

| 2 | 0.5 | 108.968 | 107.965 | 110.000 |

| 3 | 0.6 | 111.715 | 110.791 | 113.000 |

| 4 | 0.7 | 114.748 | 113.709 | 116.000 |

| 5 | 0.8 | 117.871 | 116.789 | 119.000 |

| 6 | 0.9 | 121.260 | 120.189 | 122.000 |

| 7 | 1.0 | 124.746 | 123.590 | 126.000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biruk, S.; Rzepecki, Ł. A Simulation Model of Construction Projects Executed in Random Conditions with the Overlapping Construction Works. Sustainability 2021, 13, 5795. https://doi.org/10.3390/su13115795

Biruk S, Rzepecki Ł. A Simulation Model of Construction Projects Executed in Random Conditions with the Overlapping Construction Works. Sustainability. 2021; 13(11):5795. https://doi.org/10.3390/su13115795

Chicago/Turabian StyleBiruk, Sławomir, and Łukasz Rzepecki. 2021. "A Simulation Model of Construction Projects Executed in Random Conditions with the Overlapping Construction Works" Sustainability 13, no. 11: 5795. https://doi.org/10.3390/su13115795

APA StyleBiruk, S., & Rzepecki, Ł. (2021). A Simulation Model of Construction Projects Executed in Random Conditions with the Overlapping Construction Works. Sustainability, 13(11), 5795. https://doi.org/10.3390/su13115795