Archaeometry and Analysis of Ceramic Materials from Ávila (Spain): Late-Vetton Evidence

Abstract

:1. Introduction

2. Materials and Methods

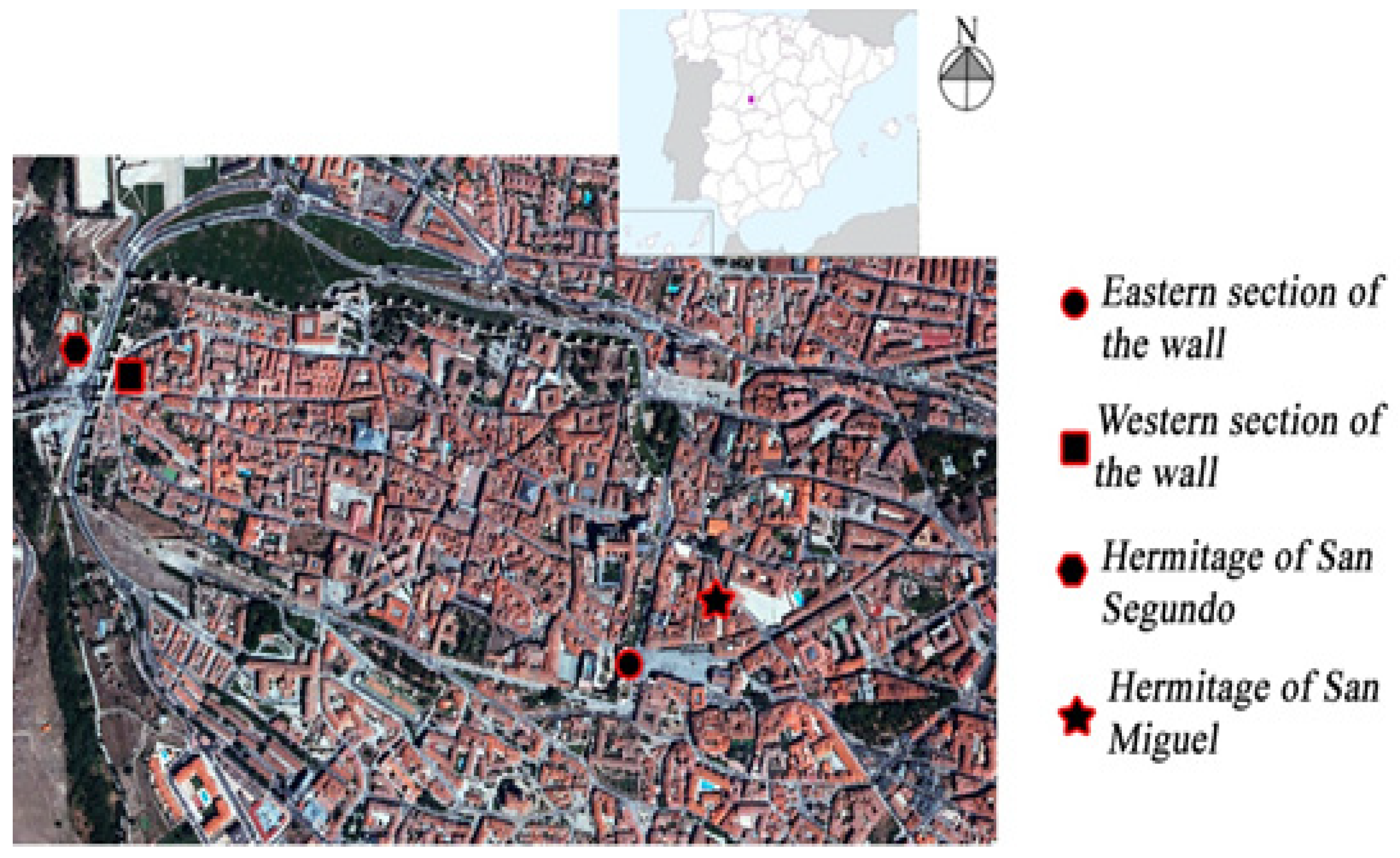

2.1. Materials

- -

- San Segundo Hermitage: This small hermitage is located outside the walls, next to the gate of the wall near the bridge over the Adaja River. A single fragment of high empire chronology comes from the excavation there.

- -

- San Miguel Hermitage: It is a hermitage that has now disappeared and was located in the current San Miguel Place. A single fragment of high empire chronology comes from this intervention.

2.2. Methods

3. Results and Discussion

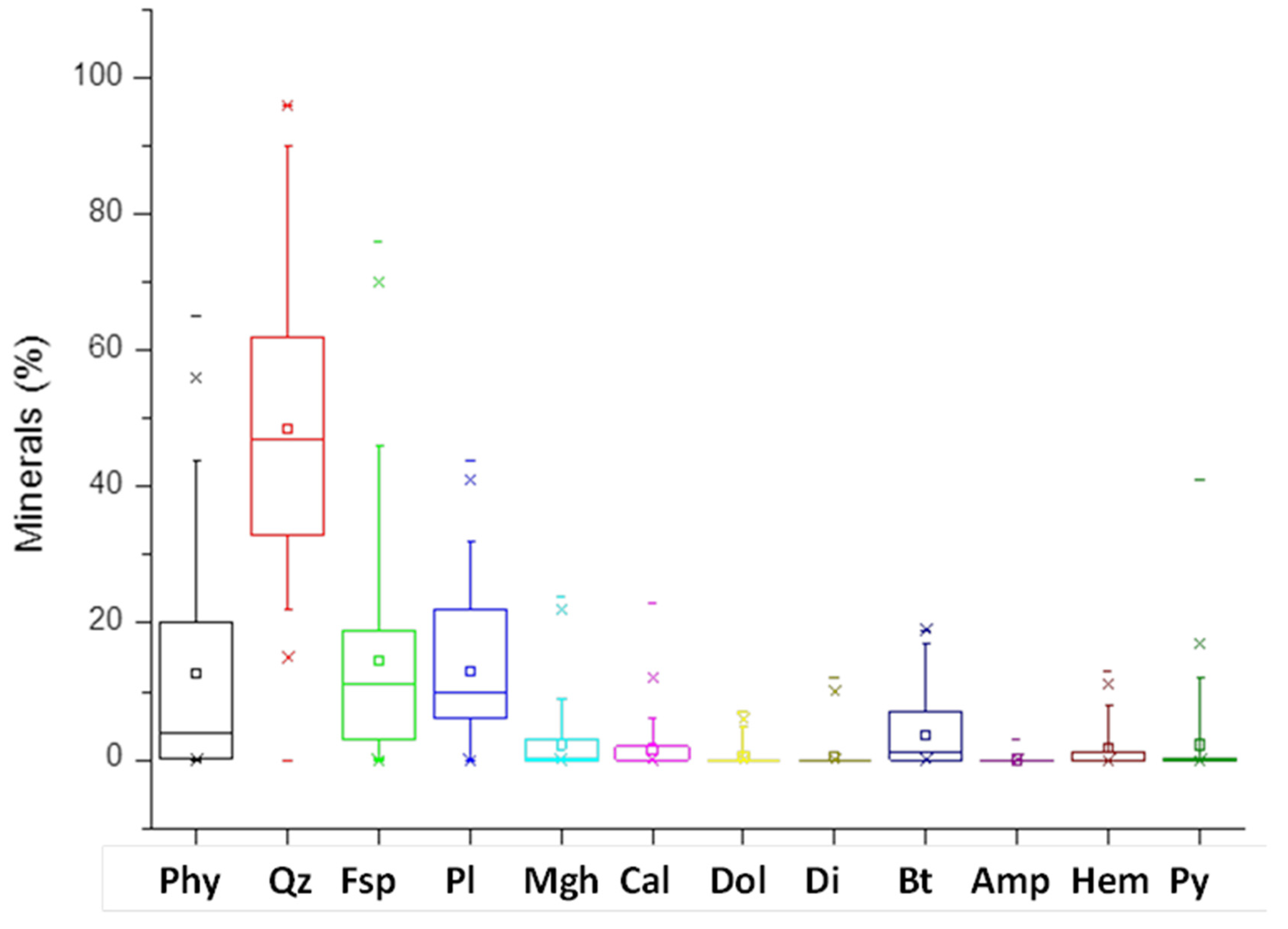

3.1. Mineralogical Analysis

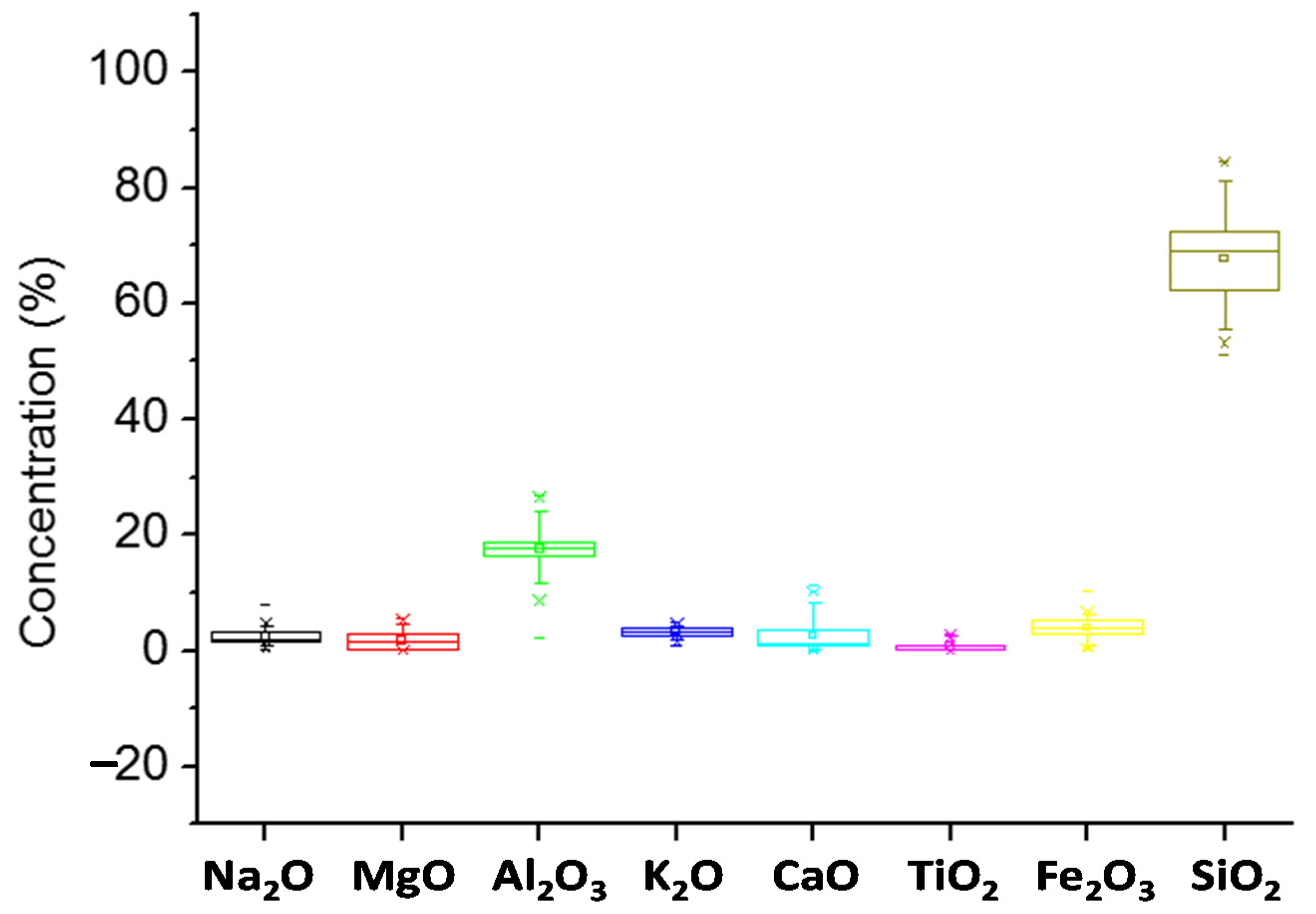

3.2. Chemical Analysis: Major and Trace Elements

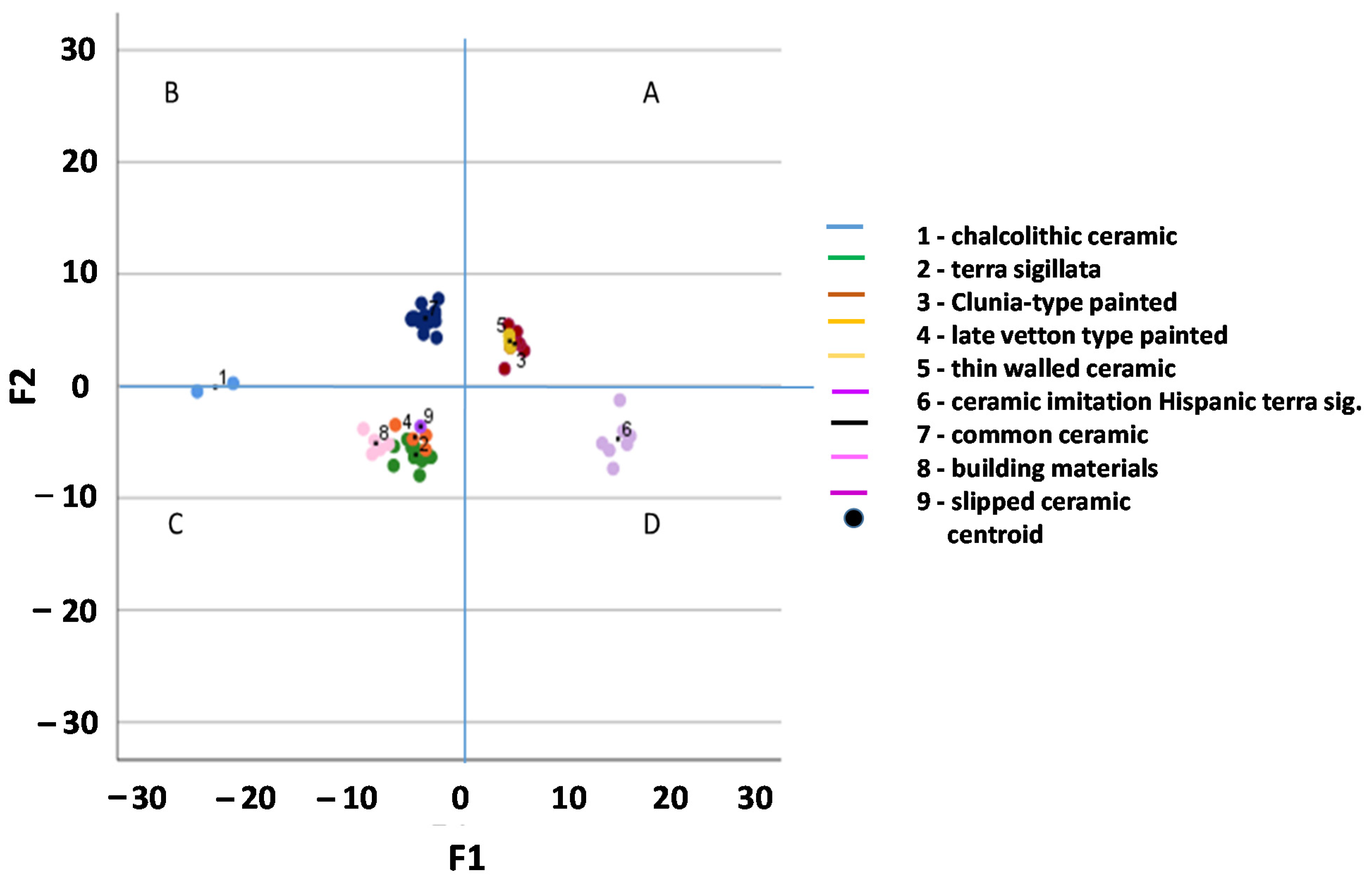

- -

- Group A: with samples of painted Clunia type and ceramics with thin walls. It is characterized by Li, Nb, Nd, Sb, Ho, and Er contents.

- -

- Group B: is represented by the samples of common ceramic pottery and Chalcolithic productions, characterized by similar Rb, Pr, Sm, Sb, Ho, and Er content.

- -

- Group C: includes samples of terra sigillata, late-Vetton-type painted ceramics, construction materials, and slipped ceramics, being the elements Rb, Pr, Sm, Pb, Se, and Tm, which group them.

- -

- Group D: ceramic imitation of Hispanic terra sigillata late burnished stamped, being Li, Nb, Nd, Pb, Se, and Tm content, those that separate them.

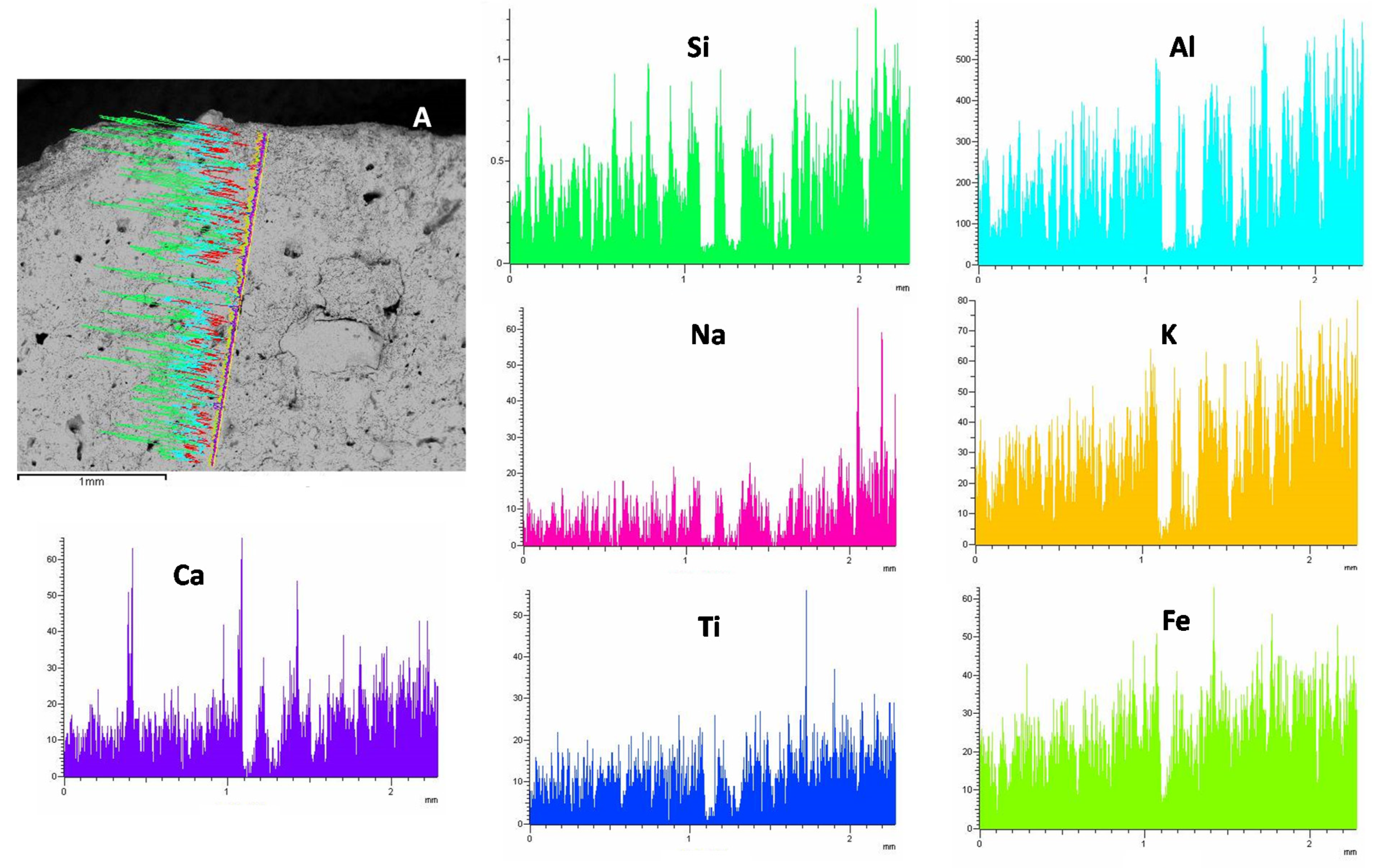

3.3. Linescan in the Late-Vetton Pottery

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Williams, D.F. An integrated archaeometric approach ceramic fabric recognition. A study on Late Roman amphora 1 from the eastern Mediterranean. In Late Roman Coarse Wares, Cooking, Wares and Amphorae in the Mediterranean: Archaeology and Archaeometry; Gurt i Esparraguera, J.M., Buxeda i Garrigós, J., Cau Ontiveros, M.A., Eds.; BAR International Series: London, UK, 2005; Volume 1340, pp. 613–624. [Google Scholar]

- Vigil de la Villa Mencía, R.; García Giménez, R. Cerámica y su caracterización. In La Ciencia y el Arte: Ciencias Experimentales y Conservación del Patrimonio Histórico; Antonio Molina, C., Carrión Martín, M.D., Jiménez Jiménez, J., Eds.; Instituto del Patrimonio Histórico Español: Madrid, Spain, 2008; pp. 223–233. [Google Scholar]

- Martinón-Torres, M.; Killick, D. Archaeological Theories and Archaeological Sciences. In The Oxford Handbook of Archaeological Theory; Oxford University Press: Oxford, UK, 2015; p. 32. [Google Scholar]

- García Heras, M.; Olaetxea, P. Métodos y análisis para la caracterización de cerámicas arqueológicas. Estado actual de la investigación en España. AEspA 1992, 65, 263–289. [Google Scholar] [CrossRef] [Green Version]

- Pérez Arantegui, J.; Aguarod Otal, C.; Lapuente Mercadal, M.P.; Feliz Ortega, M.J.; Pernot, M. Arqueometría y Caracterización de Materiales Arqueológicos; Cuadernos del Instituto Aragonés de Arqueología: Teruel, Spain, 1996; p. 100. [Google Scholar]

- Gliozzo, E. Ceramics investigation: Research questions and sampling criteria. Archaeol. Anthropol. Sci. 2020, 12, 202. [Google Scholar] [CrossRef]

- Maritan, L. Archaeo-ceramic 2.0: Investigating ancient ceramics using modern technological approaches. Archaeol. Anthropol. Sci. 2019, 11, 5085–5093. [Google Scholar] [CrossRef]

- Hradil, D.; Hradilová, J.; Holcová, K.; Bezdička, P. The use of pottery clay for canvas priming in Italian Baroque—An example of technology transfer. Appl. Clay Sci. 2018, 165, 135–147. [Google Scholar] [CrossRef]

- Giannossa, L.C.; Muntoni, I.M.; Laviano, R.; Mangone, A. Building a step-by-step result in archaeometry. Raw materials, provenance and production technology of Apulian Red Figure pottery. J. Cult. Herit. 2020, 43, 242–248. [Google Scholar] [CrossRef]

- Kordatzaki, G.; Kiriatzi, E.; Müller, N.S.; Voyatzis, M.; Romano, D.; Petrakis, S.; Forsén, J.; Nordquist, G.; Rodriguez-Alvarez, E.; Linn, S. A diachronic investigation of ‘local’ pottery production and supply at the sanctuary of Zeus, Mount Lykaion, Arcadia, Peloponnese. J. Archaeol. Sci. Rep. 2016, 7, 526–529. [Google Scholar] [CrossRef] [Green Version]

- Montana, G. Ceramic raw materials: How to recognize them and locate the supply basins—Mineralogy, petrography. Archaeol. Anthropol. Sci. 2020, 12, 175. [Google Scholar] [CrossRef]

- Hein, H.; Kilikoglou, V. Ceramic raw materials: How to recognize them and locate the supply basins: Chemistry. Archaeol. Anthropol. Sci. 2020, 12, 180. [Google Scholar] [CrossRef]

- Rathossi, C.; Tsolis-Katagas, P.; Katagas, C. Technology and composition of Roman pottery in north-western Peloponnese, Greece. Appl. Clay Sci. 2004, 24, 313–326. [Google Scholar] [CrossRef]

- Raad, D.R.; Makarewicz, C.A. Application of XRD and digital optical microscopy to investigate lapidary technologies in Pre-Pottery Neolithic societies. J. Archaeol. Sci. Rep. 2019, 23, 731–745. [Google Scholar] [CrossRef]

- Sanjurjo-Sánchez, J.; Montero Fenollós, J.L.; Barrientos, V.; Polymeris, G.S. Assessing the firing temperature of Uruk pottery in the Middle Euphrates Valley (Syria): Bevelled rim bowls. Microch. J. 2018, 142, 43–53. [Google Scholar] [CrossRef]

- Emmitt, J. Formation and function: Middle Holocene pottery from Kom W, Fayum, Egypt. Quat. Int. 2020, 555, 126–134. [Google Scholar] [CrossRef]

- Brass, M.; Gregory, I. The chronological and social implications of the pottery from Jebel Moya (south-central Sudan). J. Archaeol. Sci. Rep. 2021, 35, 102677. [Google Scholar]

- Borgers, B.; Tol, G.; de Haas, T. Reconstructing production technology and distribution, using thin section petrography: A pilot study of Roman pottery production in the Pontine region, Central Italy. J. Archaeol. Sci. Rep. 2018, 21, 1064–1072. [Google Scholar] [CrossRef]

- Maritan, L.; Vidale, M.; Mazzoli, C.; Leonardi, G.; Facchi, A. From clays to pots: Chaînes opératoires and technical options at a burnt Late Iron Age potter’s workshop (north-eastern Italy). Archaeol. Anthropol. Sci. 2019, 11, 2049–2058. [Google Scholar] [CrossRef]

- Eramo, G. Ceramic technology: How to recognize clay processing. Archaeol. Anthropol. Sci. 2020, 12, 164. [Google Scholar] [CrossRef]

- Thér, R. Ceramic technology: How to reconstruct and describe pottery-forming practices. Archaeol. Anthropol. Sci. 2020, 12, 172. [Google Scholar] [CrossRef]

- Gliozzo, E. Ceramic technology. How to reconstruct the firing process. Archaeol. Anthropol. Sci. 2020, 12, 260. [Google Scholar] [CrossRef]

- Kozatsas, J.; Kotsakis, K.; Sagris, D.; David, K. Inside out: Assessing pottery forming techniques with micro-CT scanning. An example from Middle Neolithic Thessaly. J. Archaeol. Sci. 2018, 100, 102–119. [Google Scholar] [CrossRef]

- Bayazit, M.; Adsan, M.; Genç, E. Application of spectroscopic, microscopic and thermal techniques in archaeometric investigation of painted pottery from Kuriki (Turkey). Ceram. Int. 2020, 46, 3695–3707. [Google Scholar] [CrossRef]

- Michałowski, A.; Niedzielski, P.; Kozak, L.; Teska, M.; Jakubowski, K.; Żółkiewski, M. Archaeometrical studies of prehistoric pottery using portable ED-XRF. Measurement 2020, 159, 107758. [Google Scholar] [CrossRef]

- Papageorgiou, I. Ceramic investigation. How to perform statistical analyses. Archaeol. Anthropol. Sci. 2020, 12, 210. [Google Scholar] [CrossRef]

- Hein, A.; Tsolakidou, A.; Iliopoulos, I.; Mommsen, H.; Buxeda i Garrigos, J.; Montana, G.; Kilikoglou, V. Standarisation of Elemental analytical techniques applied to provenance studies of archaeological ceramics: An inter laboratory calibration study. Analyst 2002, 127, 542–553. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- García-Giménez, R.; Vigil de la Villa, R.; Petit Domínguez, M.D.; Rucandio, M.I. Application of chemical, physical and chemometric analytical techniques to the study of ancient ceramic oil lamps. Talanta 2006, 68, 1236–1246. [Google Scholar] [CrossRef] [PubMed]

- Berrocal Rangel, L.; García Giménez, R.; Ruano, L.; Vigil de la Villa, R. Vitrified Walls in the Iron Age of Western Iberia: New Research from an Archaeometric Perspective. Eur. J. Archaeol. 2019, 22, 185–209. [Google Scholar] [CrossRef]

- Mariné Isidro, M. La época romana. In Historia de Ávila, I Prehistoria, e Historia Antigua; Mariné Isidro, M., Ed.; Caja de Ahorros de Ávila, Diputación de Ávila, Institución Gran Duque de Alba: Ávila, Spain, 1998; pp. 281–338. [Google Scholar]

- Rodríguez Almeida, E. Ávila Romana. Notas Para La Arqueología, La Topografía y La Epigrafía Romanas De La Ciudad y Su Territorio, 2nd ed.; Caja de Ávila: Ávila, Spain, 2003. [Google Scholar]

- Ruiz Entrecanales, R.; Cabrera González, B. Arqueología en la muralla de Ávila: Últimas aportaciones. Cuadernos de Arquitectura y Fortificación 2017, 4, 9–46. [Google Scholar]

- Ariño Gil, E.; Dahí Elena, S. Contextos cerámicos de la Antigüedad tardía y la Alta Edad Media en la provincia de Salamanca (España). In SFECAG, Actes du Congrès de L`Escala-Empúries; L`Escala; SFECAG: Marsella, France, 2008; pp. 265–276. [Google Scholar]

- Pérez de Dios, V.; de Soto García, M.R. La producciones cerámicas de El Cortinal de San Juan (Salvatierra de Tormes, Salamanca) como ejemplo de transición entre la época tardorromana y visigoda. Gallaecia 2015, 34, 159–174. [Google Scholar]

- García Giménez, R.; de la Villa, R.V.; Recio de la Rosa, P.; Petit Domínguez, M.D.; Rucandio, M.I. Analytical and multivariate study of roman age architectural terracotta from northeast of Spain. Talanta 2005, 65, 861–868. [Google Scholar] [CrossRef] [PubMed]

- Lassinantti Gualtieri, M.; Romagnoli, M.; Miselli, P.; Cannio, M.; Gualtieri, A.F. Full quantitative phase analysis of hydrated lime using the Rietveld method. Cem. Concr. Res. 2012, 42, 1273–1279. [Google Scholar] [CrossRef]

- Baxter, M.J. Mathematics, statistics and archaeometry: The past 50 years or so. Archaeometry 2008, 50, 968–982. [Google Scholar] [CrossRef]

- Fermo, P.; Delnevo, E.; Lasagni, M.; Polla, S.; de Vos, M. Application of chemical and chemometric analytical techniques to the study of ancient ceramics from Dougga (Tunisia). Microchem. J. 2008, 88, 150–159. [Google Scholar] [CrossRef]

- Padeletti, G.; Fermo, P. A scientific approach to the attribution problem of renaissance ceramic productions based on chemical and mineralogical markers. Appl. Phys. A Mat. Sci. Proc. 2010, 100, 771–784. [Google Scholar] [CrossRef]

- Petit-Domínguez, M.D.; de Soto, I.S.; García, R.; da Silva, M.P.; Rucandio, I. Analytical information on the composition of Roman Glass from Braga (Portugal). Quat. Inter. 2013, 308–309, 140–147. [Google Scholar] [CrossRef]

- Petit-Domínguez, M.D.; Giménez, R.G.; de Soto, I.S.; Rucandio, I. Chemical and statistical analysis of Roman glass from several north western Iberian archaeological sites. Medit. Archaeol. Archaeo 2014, 14, 221–235. [Google Scholar]

- de Soto, I.S.; Giménez, R.G.; de Soto, M.R. Roman ceramic pieces from central Spain: Visual, textural, chemical, mineralogical and statistical analysis. Medit. Archaeol. Archaeo 2016, 16, 237–248. [Google Scholar]

- Pérez de Dios, V.; De Soto García, M.R.; De Soto García, I.S.; García Giménez, R. Archaeometric Study of Roman Tesserae from Salamanca (Spain). Archaeology and Geochemical Analysis. Interdiscip. Archaeol. Nat. Sci. Archaeol. 2018, IX, 31–42. [Google Scholar] [CrossRef]

- Fisher, R.A. The Use of Multiple Measurements in Taxonomic Problems. An. Eugen. 1936, 7, 179–188. [Google Scholar] [CrossRef]

- Fisher, R.A. The Precision of Discriminant Functions. An. Eugen. 2011, 10, 422–429. [Google Scholar] [CrossRef] [Green Version]

- Orrù, M.; Grillo, O.; Lovicu, G.; Venora, G.; Bacchetta, G. Morphological characterisation of Vitis vinifera L. seeds by image analysis and comparison with archaeological remains. Veg. Hist. Archaeob. 2013, 22, 231–242. [Google Scholar] [CrossRef]

- Mapa Geológico de España 1:50000. Ávila de los Caballeros; Hoja 531; Instituto Geológico y Minero de España (IGME): Madrid, Spain, 2008.

- de Soto García, I.S.; de Soto García, M.R.; García Giménez, R. Mineralogical analysis of mortars in the Walls of Ávila (Spain) and its surroundings. Minerals 2019, 9, 381. [Google Scholar] [CrossRef] [Green Version]

- Vigil de la Villa, R.; Frías, M.; Sánchez de Rojas, M.I.; Vegas, I.; García, R. Mineralogical and morphological changes of calcined paper sludge at different temperatures and retention in furnace. Appl. Clay Sci. 2007, 36, 279–286. [Google Scholar] [CrossRef]

- Sherikar, B.N.; Sahoo, B.; Umarji, A.M. One-step synthesis of diopside (CaMgSi2O6) ceramic powder by solution combustion method. Adv. Powder Technol. 2020, 31, 3492–3499. [Google Scholar] [CrossRef]

| Sample | Tipology | Münsell Color |

| MU-OR-01 | Hispanic terra sigillata | 10 YR 6/6 light red |

| MU-OR-02 | Clunia-type indigenous painted pottery | 7.5 YR 7/4 pink |

| MU-OR-03 | Hispanic terra sigillata | 10 YR 6/6 light red |

| MU-OR-04 | Hispanic terra sigillata | 10 YR 6/8 light red |

| MU-OR-05 | Late-Vetton painted pottery | 7.5 R 7/4 pink |

| MU-OR-06 | Shiny Hispanic terra sigillata | 10 YR 7/6 yellow |

| MU-OR-07 | Late-Vetton painted pottery | 5 YR 7/8 reddish yellow |

| MU-OR-08 | Late-Vetton painted pottery | 10 YR 7/6 yellow |

| MU-OR-09 | Hispanic terra sigillata | 10 R 6/6 light red |

| MU-OR-10 | Fine-walled pottery | 5 YR 6/2 pinkish gray |

| MU-OR-11 | Fine-walled pottery | 5 YR 6/2 pinkish gray |

| MU-OR-12 | Shiny Hispanic terra sigillata | 5 YR 7/2 pink |

| MU-OR-13 | Hispanic terra sigillata | 10 R 6/6 light red |

| MU-OR-14 | Hispanic terra sigillata | 10 R 6/6 light red |

| MU-OR-15 | Fine-walled pottery | 2.5 YR 6/4 reddish brown |

| MU-OR-16 | Late Hispanic terra sigillata | 10 R 6/6 light red |

| MU-OR-17 | Hispanic terra sigillata | 10 R 6/6 light red |

| MU-OR-18 | Late-Vetton painted pottery | 2.5 YR 6/8 light red |

| MU-OR-19 | Chalcolithic pottery | 5 YR 5/2 reddish gray |

| MU-OR-20 | Ceramic imitation of Hispanic terra sigillata, late burnished stamped | 10 YR 6/2 light brownish gray |

| MU-OR-21 | Slipped ceramic | 5 YR 7/6 pink |

| MU-OR-22 | Clunia-type indigenous painted pottery | 5 YR 8/2 pinkish white |

| MU-OR-23 | Shiny Hispanic terra sigillata | 5 YR 7/6 reddish yellow |

| MU-OR-24 | Hispanic terra sigillata | 2.5 YR 6/6 light red |

| MU-OC-01 | Clunia-type indigenous painted pottery | 5 YR 7/1 light gray |

| MU-OC-02 | Clunia-type indigenous painted pottery | 5 YR 5/1 gray |

| MU-OC-03 | Shiny Hispanic terra sigillata | 5 YR 5/1 gray |

| MU-OC-04 | Hispanic terra sigillata | 5 YR 6/4 light reddish brown |

| MU-OC-05 | Clunia-type indigenous painted pottery | 10 R 6/6 light red |

| MU-OC-06 | Clunia-type indigenous painted pottery | 10 R 6/6 light red |

| MU-OC-07 | Construction material. Clay ball | 2.5 YR 6/8 light red |

| MU-OC-08 | Construction material. Clay ball | 5 YR 5/2 reddish gray |

| MU-OC-09 | Common Ceramic | 10 YR 6/2 light brownish gray |

| MU-OC-10 | Common Ceramic | 5 YR 8/4 pink |

| MU-OC-11 | Common Ceramic | 5 YR 8/4 pink |

| MU-OC-12 | Common Ceramic | 5 YR 6/4 light reddish brown |

| MU-OC-13 | Common Ceramic | 5 YR 7/4 pink |

| MU-OR-25 | Common Ceramic | 5 YR 6/2 pinkish gray |

| MU-OC-26 | Common Ceramic | 5 YR 5/1 gray |

| MU-OR-26 | Common Ceramic | 5 YR 8/4 pink |

| MU-OC-27 | Common Ceramic | 5 YR 8/4 pink |

| MU-OR-27 | Common Ceramic | 5 YR 6/4 light reddish brown |

| MU-OC-28 | Construction material. Plane tile, tegula | 5 YR 7/4 pink |

| MU-OR-28 | Chalcolithic pottery. Hemispherical bowl | 5 YR 6/2 pinkish gray |

| MU-OC-29 | Common Ceramic | 5 YR 5/1 gray |

| ESS01 | Clunia-type indigenous painted pottery | 5 YR 5/1 gray |

| ESM01 | Clunia-type indigenous painted pottery | 5 YR 6/4 light reddish brown |

| MU-OC-22 | Ceramic imitation of Hispanic terra sigillata, late burnished stamped | 5 YR 7/1 light gray |

| MU-OC-23 | Common Ceramic | 5 YR 5/1 gray |

| MU-OC-24 | Common Ceramic | 5 YR 5/1 gray |

| MU-OC-25 | Construction materialCurved tile | 5 YR 6/4 light reddish brown |

| MU-OC-26 | Construction material. Plane tile, tegula | 10 R 6/8 light red |

| MU-OC-27 | Ceramic imitation of Hispanic terra sigillata, late burnished stamped | 5 YR 5/1 gray |

| MU-OC-28 | Ceramic imitation of Hispanica terra sigillata, late burnished stamped | 5 YR 6/1 gray |

| MU-OC-29 | Common Ceramic | 5 YR 5/2 reddish gray |

| MU-OC-30 | Common Ceramic | 5 YR 5/4 reddish brown |

| MU-OC-31 | Shiny Hispanic terra sigillata | 5 YR 7/1 light gray |

| MU-OC-32 | Clunia-type indigenous painted pottery | 5 YR 8/4 pink |

| MU-OC-33 | Clunia-type indigenous painted pottery | 5 YR 8/4 pink |

| MU-OC-34 | Common Ceramic | 5 YR 6/4 ligh reddish brown |

| MU-OC-35 | Common Ceramic | 5 YR 7/4 pink |

| MU-OC-36 | Common Ceramic | 5 YR 6/2 pinkish gray |

| MU-OC-37 | Ceramic imitation of Hispanic terra sigillata, late burnished stamped | 5 YR 5/1 gray |

| MU-OC-38 | Common Ceramic | 5 YR 4/1 dark gray |

| MU-OC-39 | Common Ceramic | 5 YR 4/1 dark gray |

| MU-OR-30 | Ceramic imitation of Hispanica terra sigillata, late burnished stamped | 5 YR 6/2 pinkish gray |

| MU-OR-31 | Ceramic imitation of Hispanica terra sigillata, late burnished stamped | 5 YR 5/1 gray |

| Li | Be | B | P | S | Sc | V | Cr | Mn | Co | Ni | Cu | Zn | Ga | Ge | As | Se | Rb | Sr | Y | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X | 45.4 | 2.7 | 92.8 | 206.3 | 1306.2 | 5.0 | 37.6 | 30.4 | 199.9 | 5.6 | 20.6 | 51.2 | 57.6 | 17.3 | 1.1 | 6.8 | 1.6 | 79.5 | 157.7 | 11.9 |

| M | 108.0 | 10.0 | 710.0 | 1402.0 | 5500.0 | 18.0 | 79.0 | 85.0 | 595.0 | 17.0 | 50.0 | 1113.0 | 315.0 | 39.0 | 5.0 | 32.0 | 18.0 | 270.0 | 3450.0 | 60.0 |

| m | 5.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 1.0 | 2.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 3.0 | 16.0 | 0.0 |

| Zr | Nb | Mo | Ag | Cd | In | Sn | Sb | Cs | Ba | La | Ce | Pr | Nd | Sm | Eu | Gd | Tb | Dy | Ho | |

| X | 42.2 | 8.7 | 0.4 | 1.0 | 0.2 | 0.1 | 27.9 | 0.9 | 4.3 | 365.4 | 22.8 | 46.6 | 5.5 | 21.3 | 4.1 | 0.6 | 3.3 | 0.4 | 2.4 | 0.4 |

| M | 112.0 | 21.0 | 5.0 | 13.0 | 3.0 | 9.0 | 1425.0 | 19.0 | 22.0 | 1851.0 | 70.0 | 176.0 | 19.0 | 76.0 | 14.0 | 2.0 | 12.0 | 2.0 | 9.0 | 2.0 |

| m | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 50.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Er | Tm | Yb | Hf | Lu | Ta | W | Re | Os | Ir | Tl | Hg | Au | Pb | Bi | Th | U | Pt | |||

| X | 1.1 | 0.0 | 0.9 | 1.7 | 0.0 | 2.2 | 11.0 | 0.0 | 0.0 | 0.0 | 0.4 | 0.0 | 0.3 | 31.7 | 0.2 | 7.4 | 2.0 | 0.0 | ||

| M | 5.0 | 1.0 | 4.0 | 12.0 | 1.0 | 6.0 | 51.0 | 0.0 | 0.0 | 0.0 | 1.0 | 0.0 | 12.0 | 731.0 | 1.0 | 27.0 | 12.0 | 0.0 | ||

| m | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Function | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| Li | 15.378 | 0.715 | −2.352 | 4.793 | −1.837 | −1.390 | 0.012 | 0.436 |

| Be | −12.204 | 2.890 | 2.174 | −4.694 | 2.009 | 1.298 | 1.114 | −1.119 |

| B | 4.030 | 0.853 | −0.589 | 0.277 | 1.150 | 0.280 | 0.410 | −0.151 |

| P | 7.091 | 4.088 | −2.143 | 0.474 | 1.168 | −1.095 | −0.015 | 1.243 |

| S | 2.452 | 3.073 | 0.316 | −1.186 | 0.633 | −0.466 | 0.144 | 0.979 |

| Sc | 14.432 | −6.562 | 4.372 | 3.201 | −0.540 | 0.502 | −0.533 | −1.464 |

| V | −4.792 | −0.152 | −1.517 | −2.004 | −7.801 | 0.717 | 1.633 | 1.154 |

| Cr | −11.717 | 0.282 | −0.254 | −2.601 | 0.518 | 0.291 | −0.044 | 2.078 |

| Mn | −3.074 | −1.357 | 1.986 | 0.610 | 3.484 | 0.817 | 0.135 | −2.085 |

| Co | −5.478 | 0.292 | −0.218 | −1.138 | 0.899 | 0.502 | 0.365 | 0.830 |

| Ni | −2.171 | 0.185 | −0.587 | −0.829 | 0.565 | −1.501 | −1.783 | −0.945 |

| Cu | 0,815 | −0.866 | −1.495 | −0.699 | −1.789 | 0.589 | 0.862 | 1.072 |

| Zn | 0.429 | 1.362 | −0.799 | 1.010 | 2.794 | −0.340 | −0.130 | −0.753 |

| Ga | 4.572 | −4.681 | 0.208 | 5.369 | −2.307 | −0.957 | −2.422 | 3.245 |

| Ge | 11.692 | −1.094 | −0.240 | 2.074 | 1.700 | −0.355 | 0.406 | −0.277 |

| As | −2.956 | 1.104 | −3.242 | 1.174 | 1.001 | −0.612 | −0.027 | 0.416 |

| Se | −3.461 | −1.487 | 1.844 | −2.861 | 0.736 | 0.252 | −0.690 | −0.493 |

| Rb | −16.686 | −1.915 | 0.609 | −5.174 | −2.480 | 0.186 | −0.265 | −0.633 |

| Sr | 2.184 | −0.601 | 2.021 | −0.274 | −0.358 | 1.523 | −0.700 | −0.628 |

| Y | 1.441 | −0.682 | 2.261 | 2.007 | 0.028 | −0.241 | −0.840 | −0.681 |

| Zr | −3.741 | −1.792 | 2.371 | 2.438 | −2.027 | 0.380 | −0.060 | −1.135 |

| Nb | 14.436 | −3.902 | 2.696 | 0.569 | 5.509 | −0.365 | −1.054 | −2.671 |

| Mo | −3.775 | −0.491 | 0.030 | 0.758 | 1.437 | 0.304 | 0.275 | −0.231 |

| Ag | −0.744 | 2.743 | −0.998 | 0.090 | 1.219 | 1.040 | 0.225 | −0.579 |

| Cd | −2.967 | −0.116 | 1.110 | 0.422 | −0.857 | 0.336 | 0.371 | −0.800 |

| In | −2.572 | 0.777 | 0.087 | −0.122 | 1.040 | −0.347 | −0.151 | 0.326 |

| Sn | 9.688 | 4.166 | −0.594 | −5.894 | 1.491 | 0.261 | 6.664 | 2.865 |

| Sb | 5.440 | 5.564 | 4.602 | 2.871 | −0.741 | 0.009 | −0.684 | −6.307 |

| Te | 1.746 | 1.422 | 0.113 | 0.877 | −0.047 | 0.051 | −0.063 | −0.253 |

| Cs | 10.432 | 1.834 | −1.879 | 2.773 | 1.889 | −0.413 | 0.755 | 1.280 |

| Ba | −1.410 | −0.172 | −0.692 | −1.237 | 3.271 | 0.637 | 1.257 | −0.118 |

| La | −7.354 | 5.292 | −0.785 | −5.497 | −0.582 | 0.024 | 0.923 | −1.325 |

| Ce | 4.720 | 1.729 | −1.799 | −10.744 | −0.060 | −1.070 | −1.167 | 3.154 |

| Pr | −13.842 | 1.151 | −10.280 | 13.785 | 7.707 | −1.075 | 1.414 | 5.122 |

| Nd | 14.406 | 1.246 | 16.053 | 4.830 | −3.116 | 3.746 | 1.643 | −6.271 |

| Sm | −12.738 | −4.365 | −2.555 | 1.776 | −2.812 | −2.159 | −3.626 | 0.037 |

| Eu | −4.172 | 0.138 | −1.582 | −1.471 | 0.389 | −0.446 | −0.059 | 0.650 |

| Gd | 15.748 | −1.575 | 3.022 | −9.195 | −7.839 | 2.897 | 3.395 | −4.250 |

| Tb | 1.117 | −2.662 | 0.678 | −0.891 | −1.978 | 1.163 | 1.007 | −0.116 |

| Dy | −4.806 | −1.322 | −5.086 | −1.034 | 6.844 | −1.956 | −1.655 | 0.715 |

| Ho | 5.630 | 4.846 | −1.248 | −1.261 | 1.761 | −1.790 | −1.327 | 1.012 |

| Er | −9.774 | 4.816 | 1.389 | 0.957 | 0.200 | 1.038 | 0.819 | 1.022 |

| Tm | 5.534 | −5.939 | 2.545 | 3.956 | −0.333 | −0.599 | −1.938 | −0.432 |

| Yb | 1.043 | 1.475 | −1.847 | 1.602 | −2.115 | −0.198 | 0.401 | 1.666 |

| Hf | −0.171 | 3.398 | −0.313 | −1.254 | 0.096 | 0.461 | 0.851 | 0.536 |

| Lu | 5.279 | 1.261 | 0.304 | 0.032 | 0.528 | −0.567 | 0.352 | 0.216 |

| Ta | −10806 | 4.202 | −2.936 | −2.959 | −2.822 | 0.579 | 0.949 | 1.546 |

| Tl | 2.249 | 2.399 | 0.551 | 0.489 | 0.323 | −0.464 | −0.410 | −0.296 |

| Pb | −10.708 | −10.826 | −4.147 | 4.423 | −3.260 | −0.141 | −5.505 | 4.296 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Soto García, I.S.; de Soto García, M.d.l.R.; González, B.C.; Giménez, R.G. Archaeometry and Analysis of Ceramic Materials from Ávila (Spain): Late-Vetton Evidence. Sustainability 2021, 13, 5910. https://doi.org/10.3390/su13115910

de Soto García IS, de Soto García MdlR, González BC, Giménez RG. Archaeometry and Analysis of Ceramic Materials from Ávila (Spain): Late-Vetton Evidence. Sustainability. 2021; 13(11):5910. https://doi.org/10.3390/su13115910

Chicago/Turabian Stylede Soto García, Isabel Sonsoles, María de los Reyes de Soto García, Blas Cabrera González, and Rosario García Giménez. 2021. "Archaeometry and Analysis of Ceramic Materials from Ávila (Spain): Late-Vetton Evidence" Sustainability 13, no. 11: 5910. https://doi.org/10.3390/su13115910