The Effect of Vehicle and Road Conditions on Rollover of Commercial Heavy Vehicles during Cornering: A Simulation Approach

Abstract

1. Introduction

2. Materials and Methods

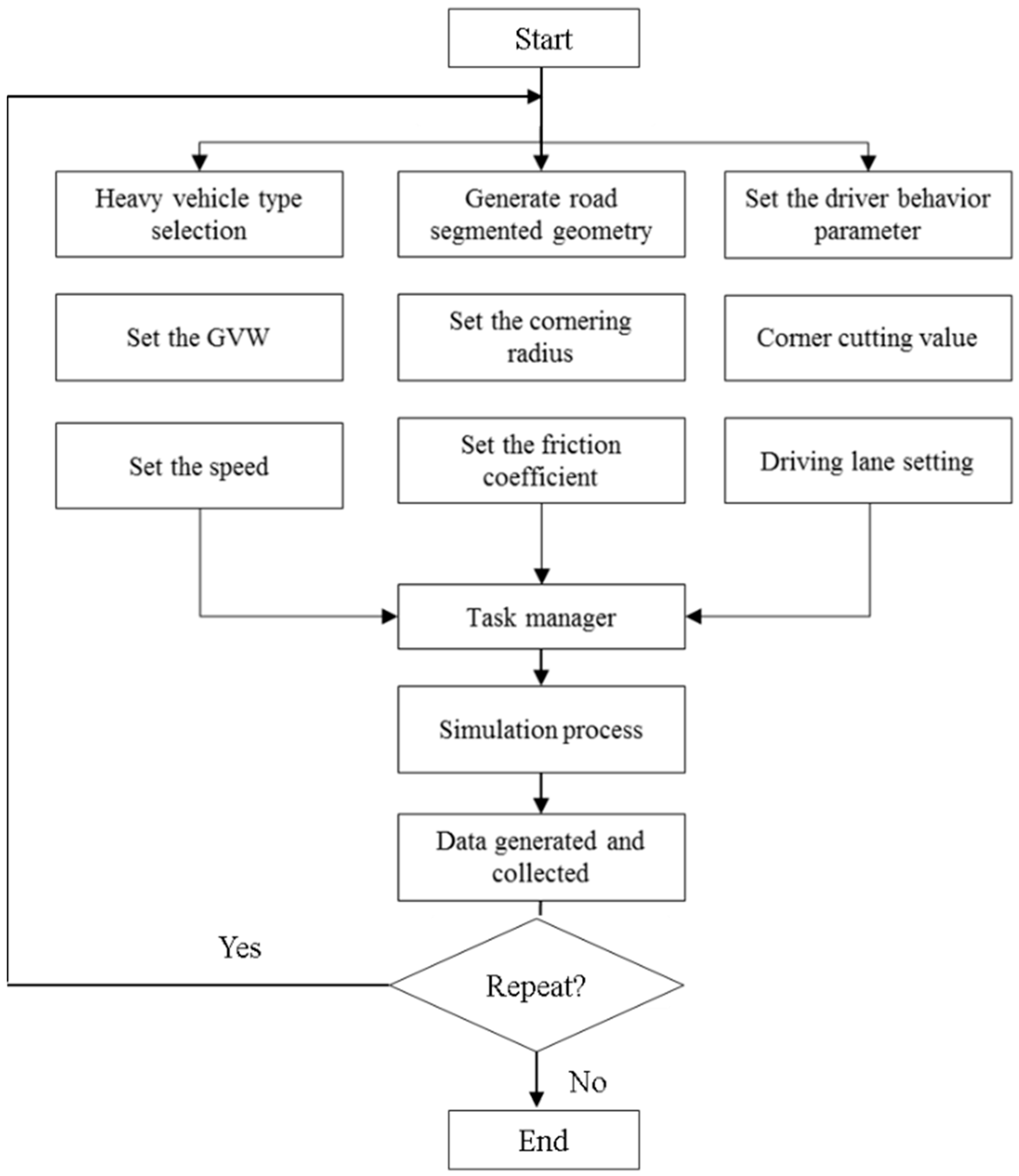

2.1. Simulation Settings

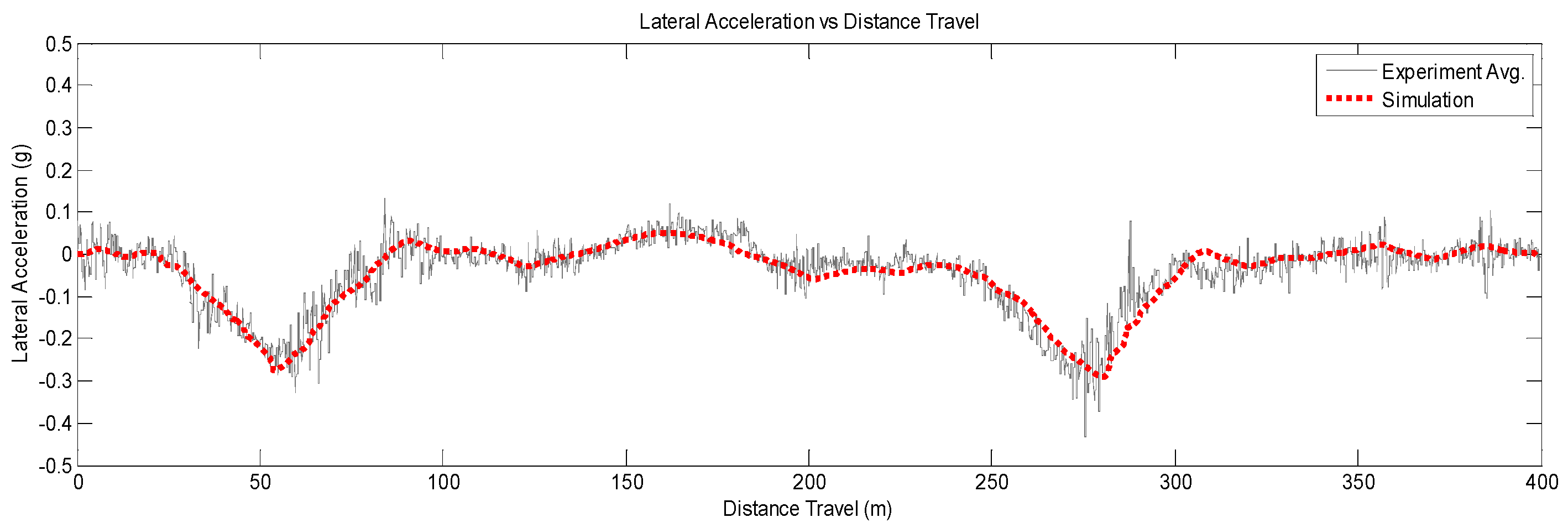

2.2. Post-Processing and Correlation Analysis

3. Results and Discussion

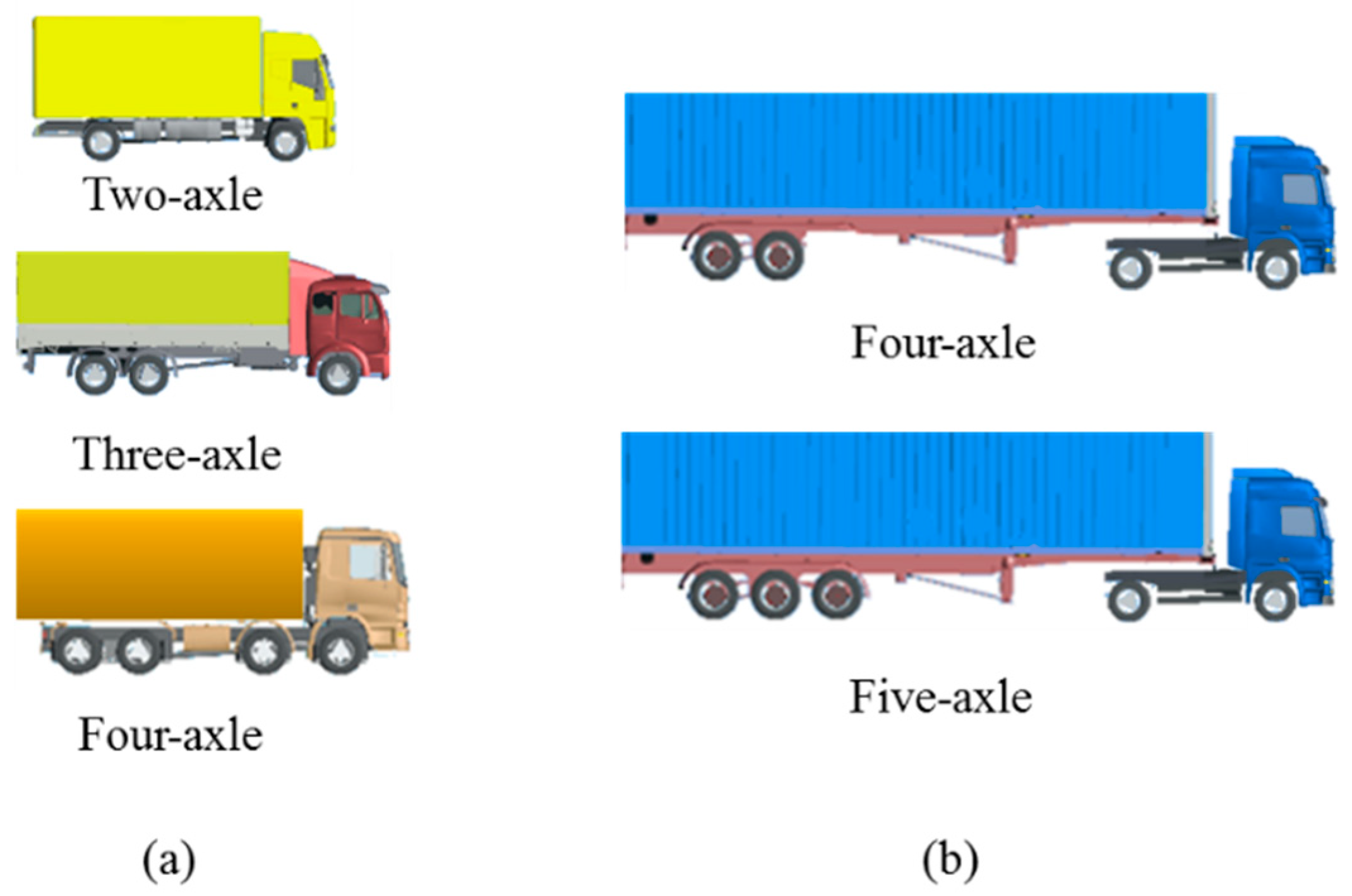

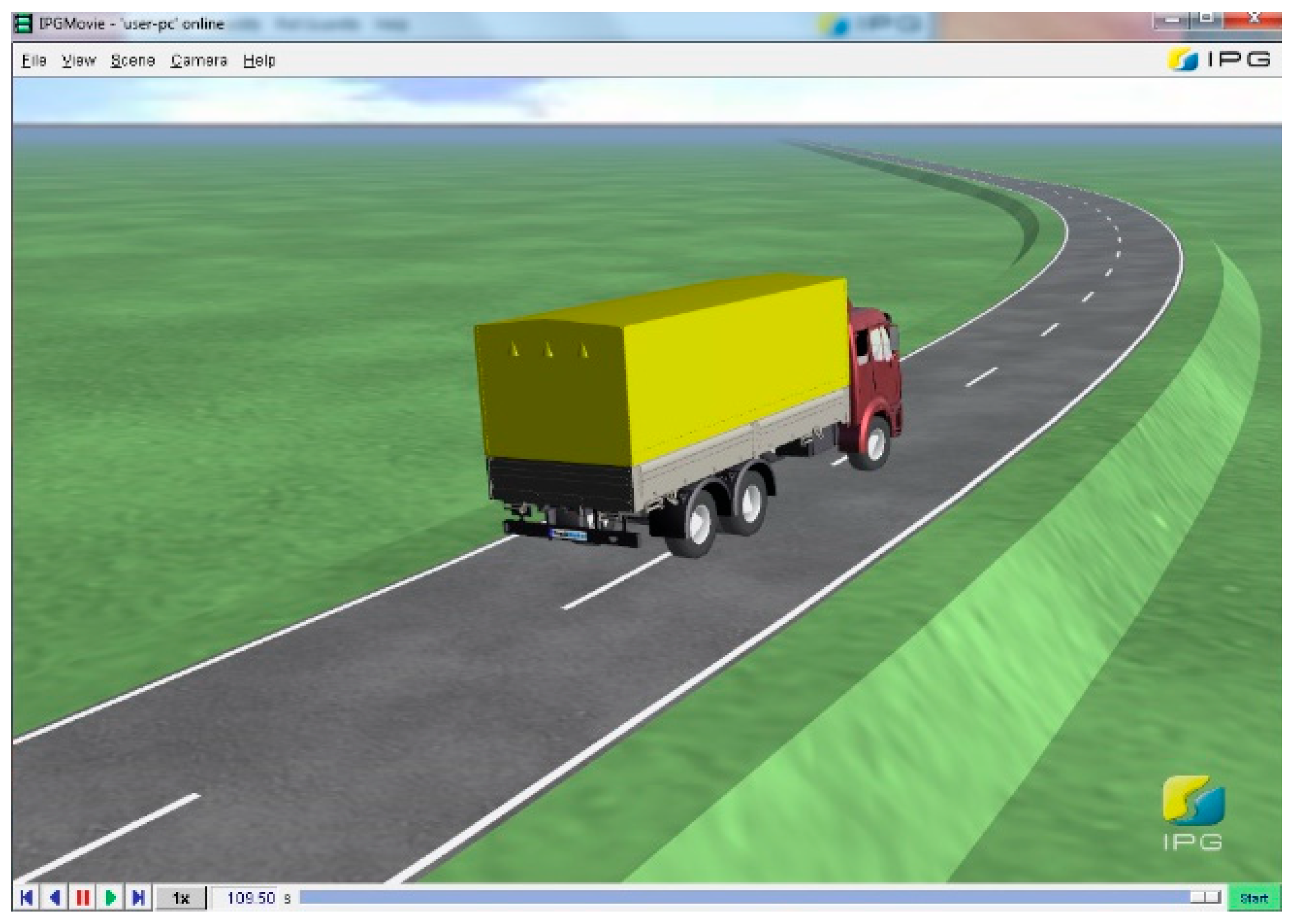

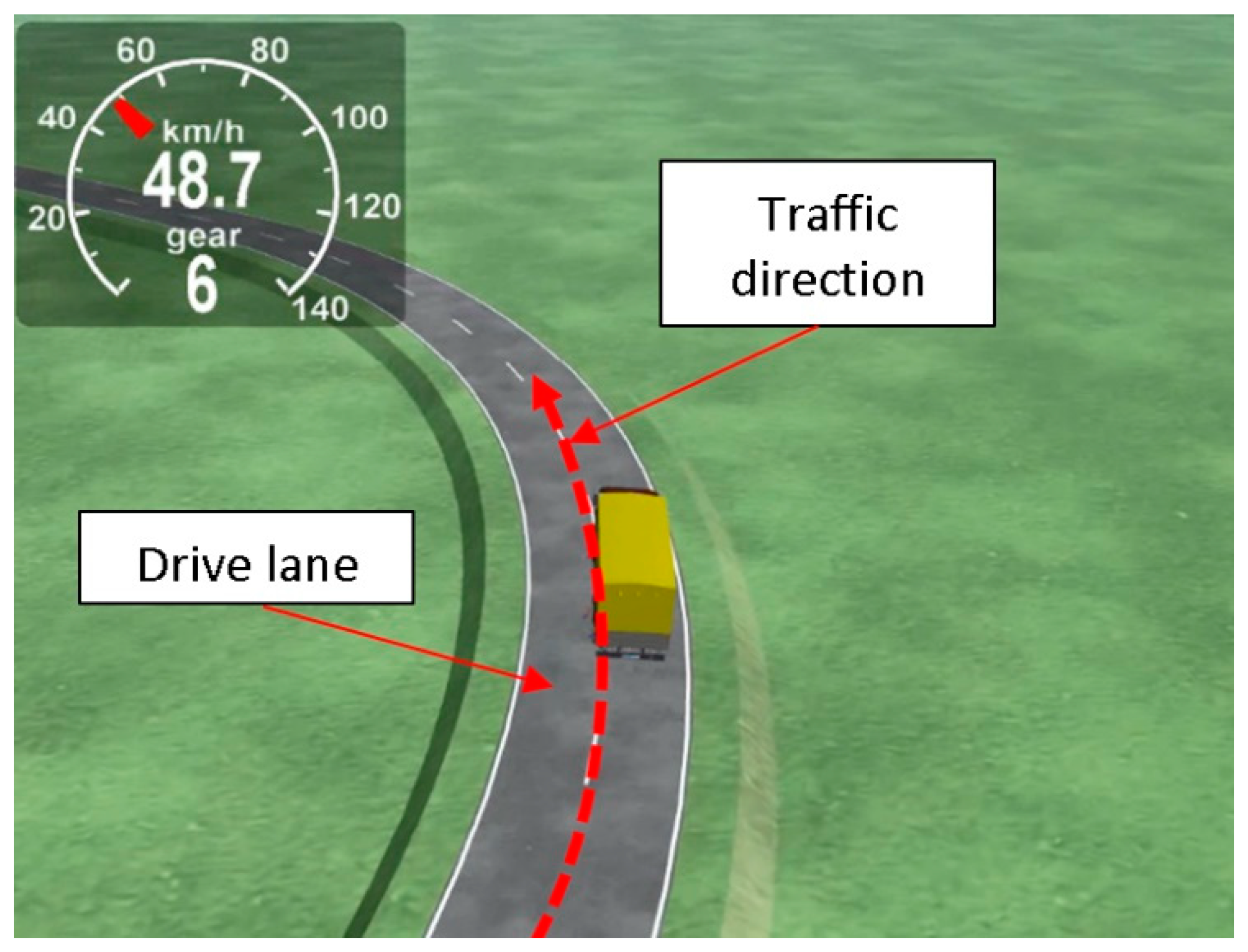

3.1. Simulation of Virtual Heavy Vehicle Models

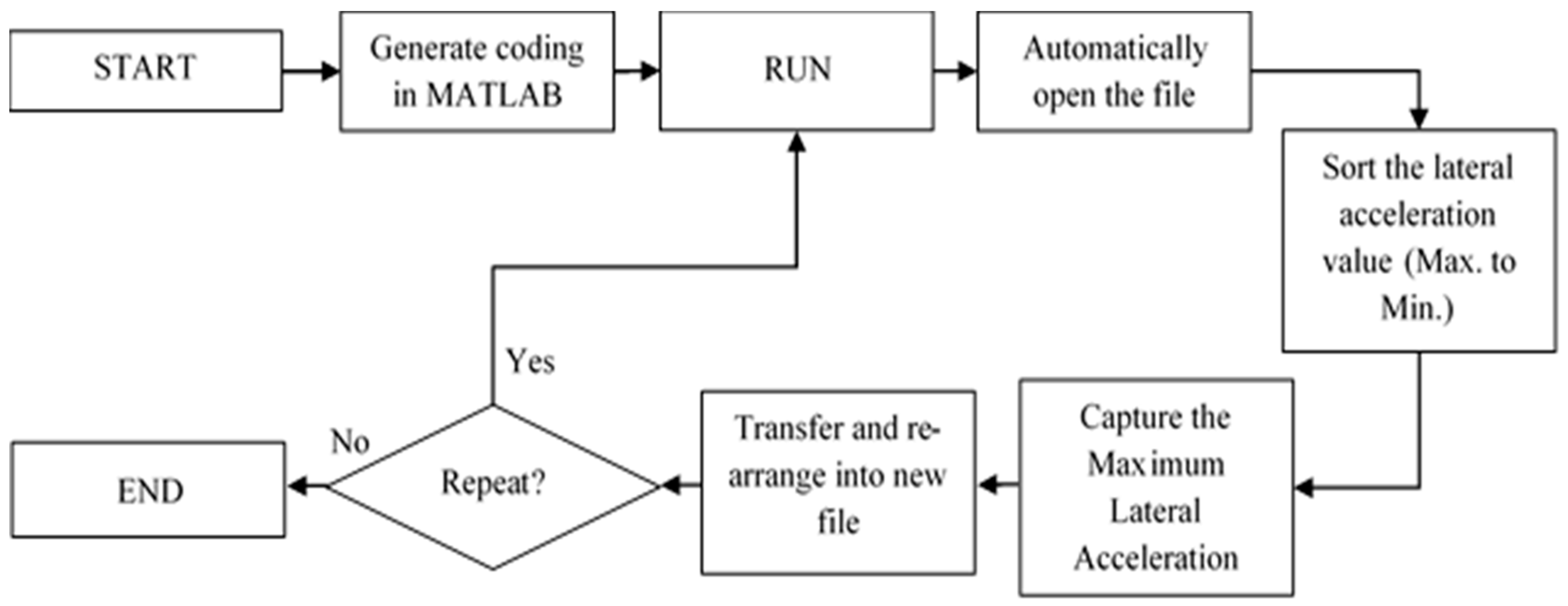

3.2. Data Screening and Processing

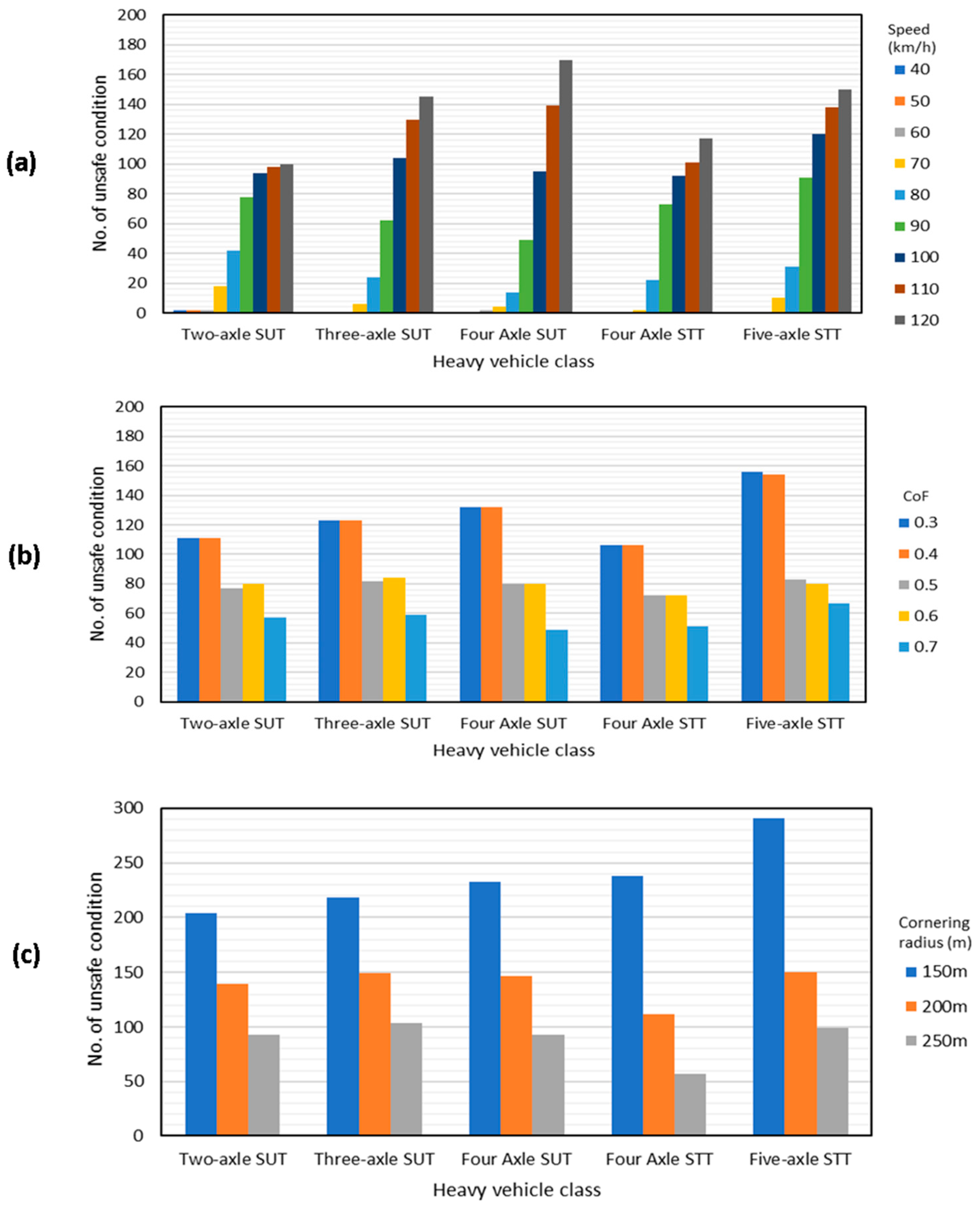

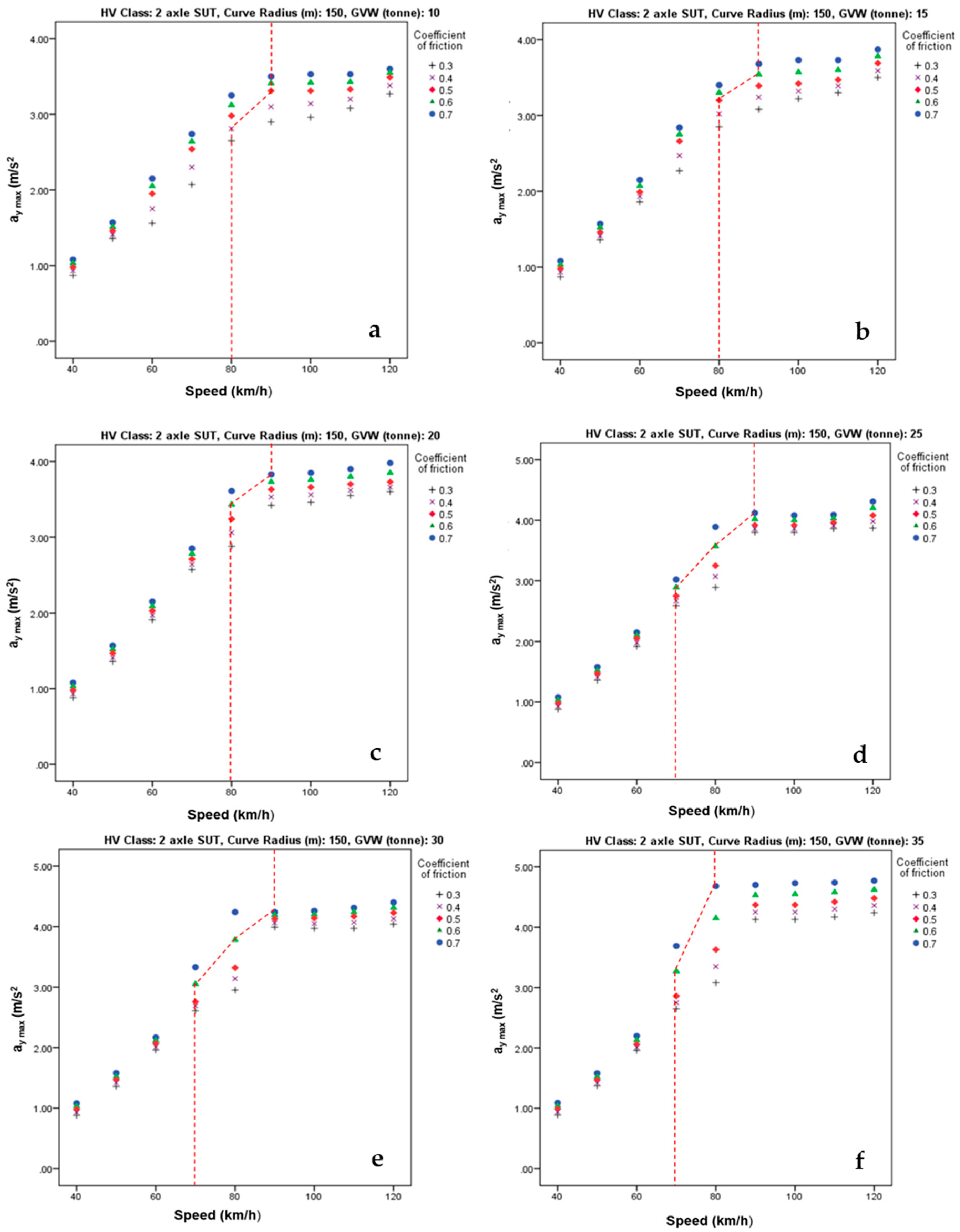

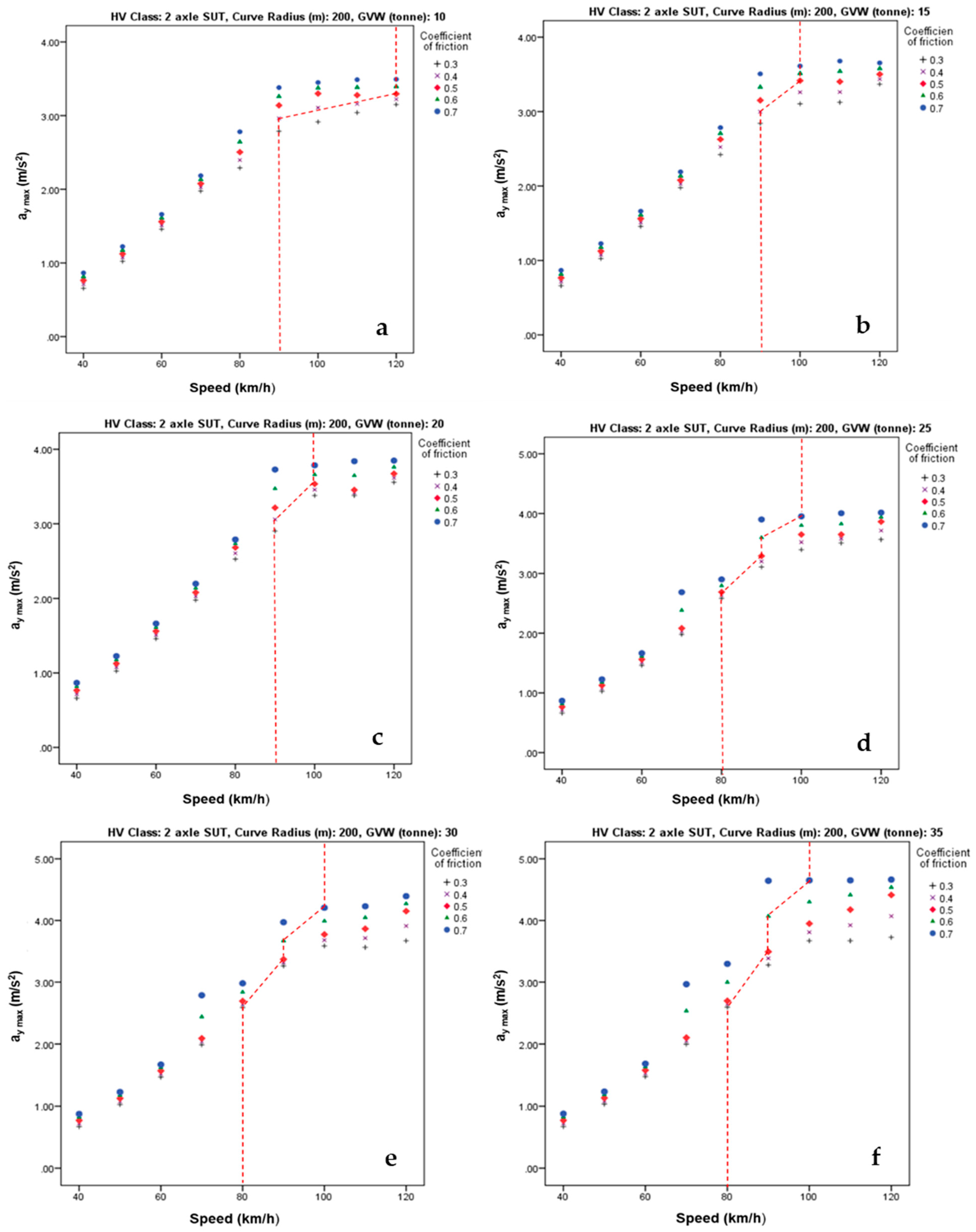

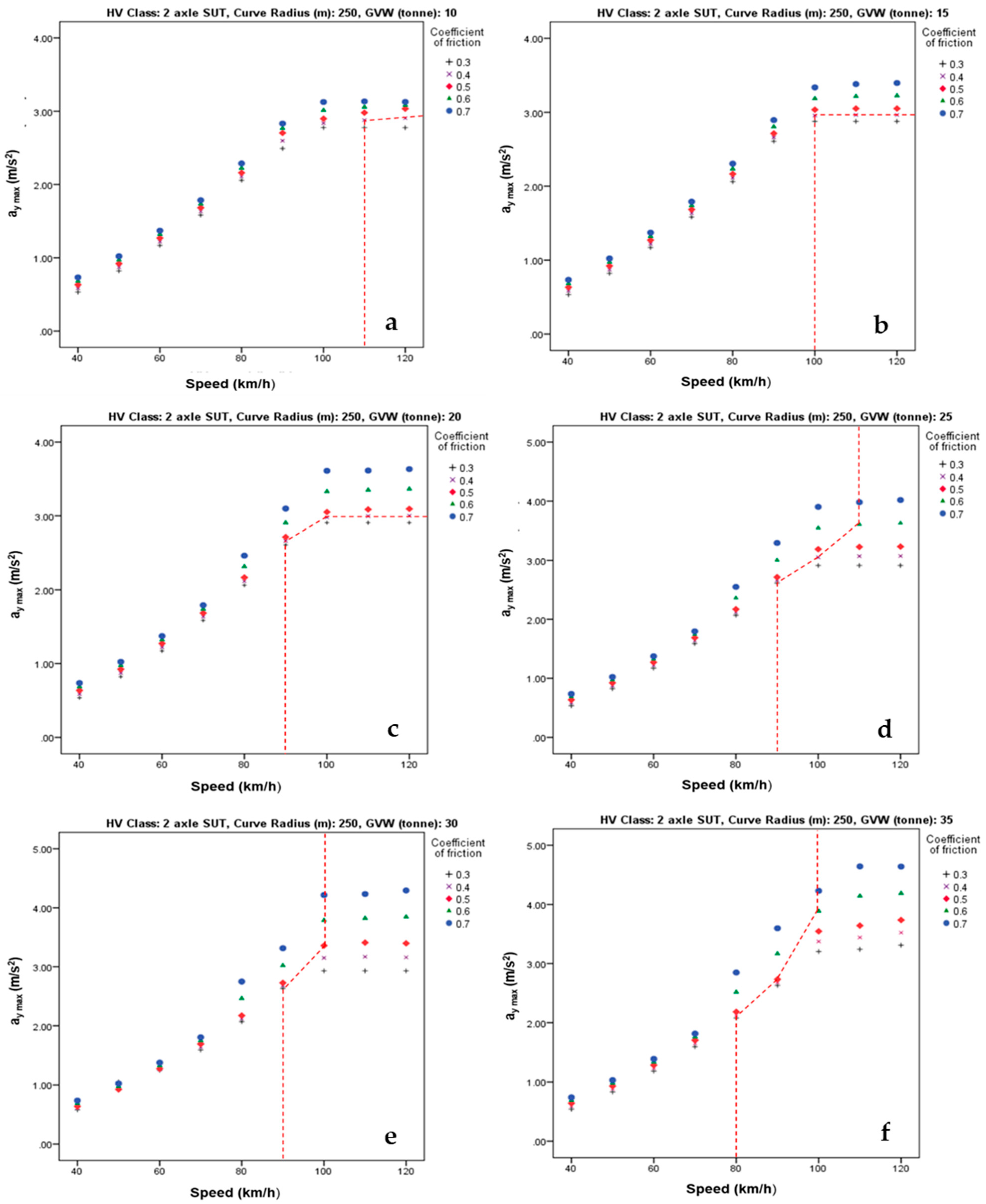

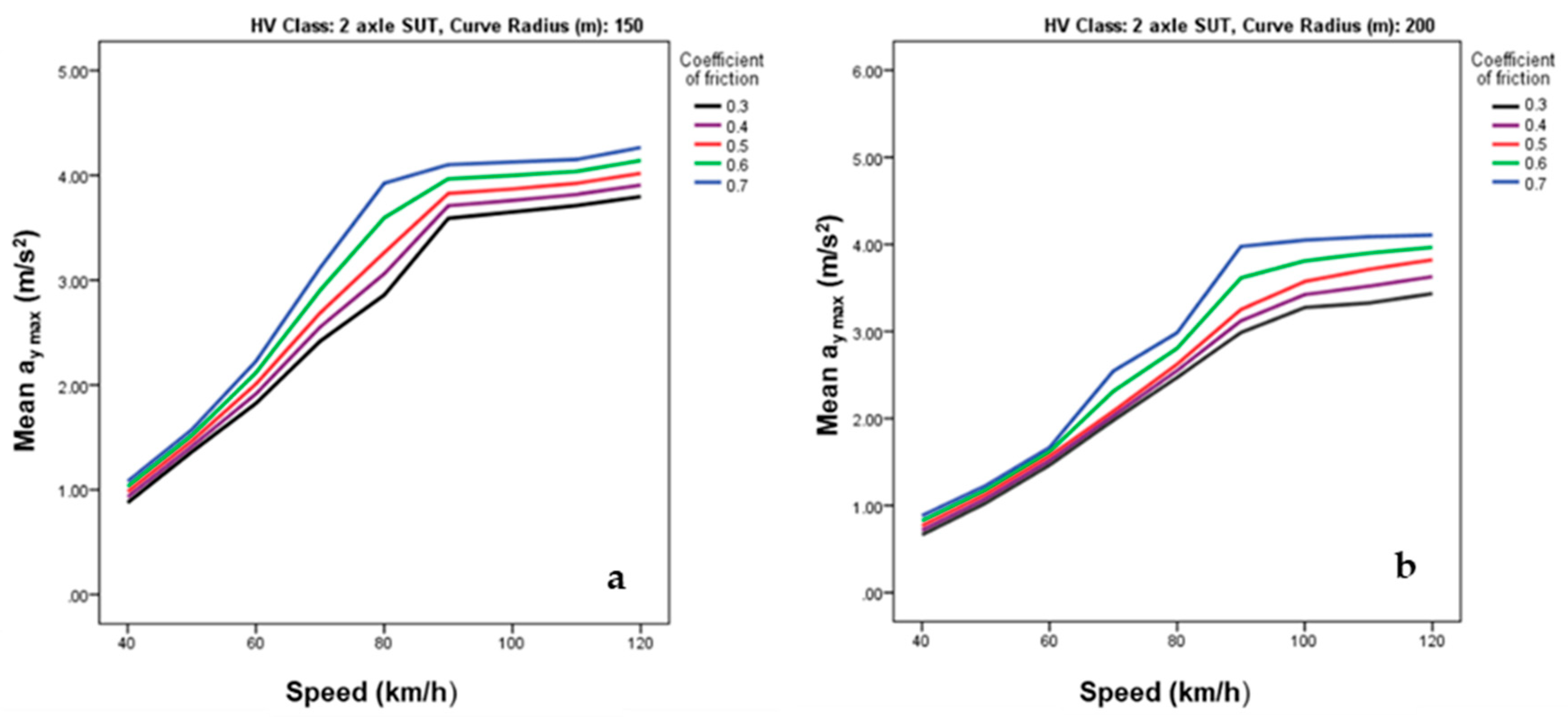

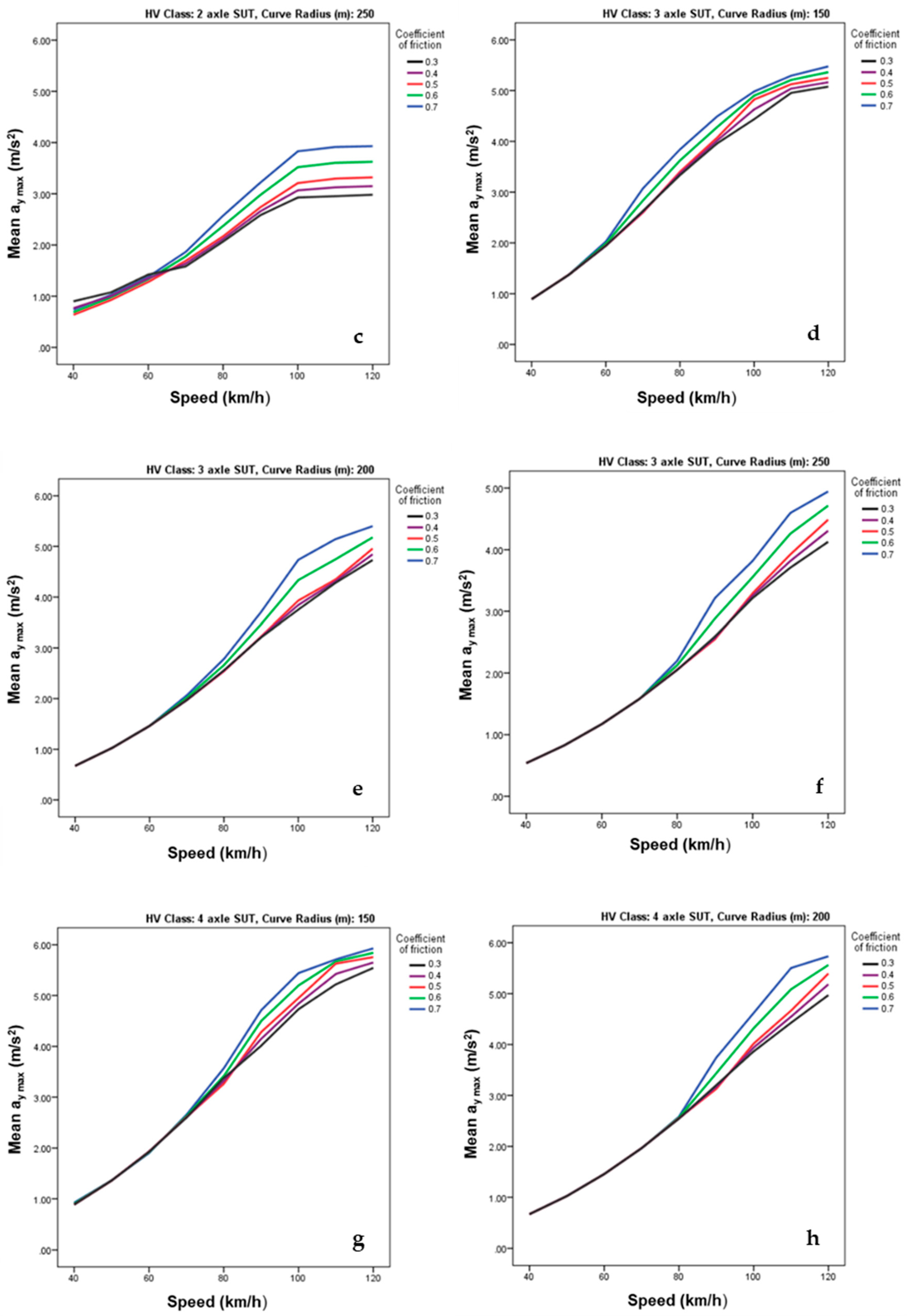

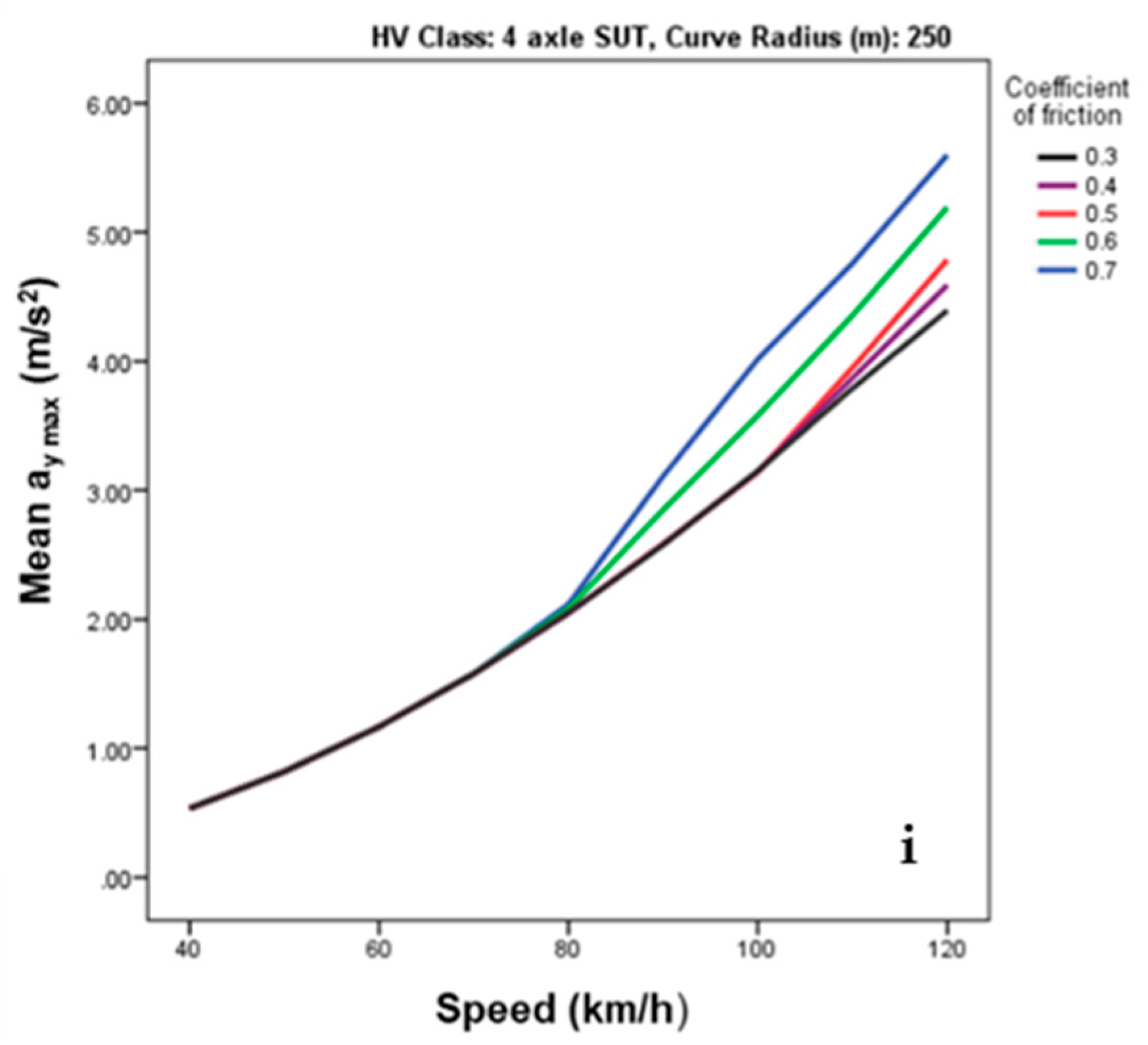

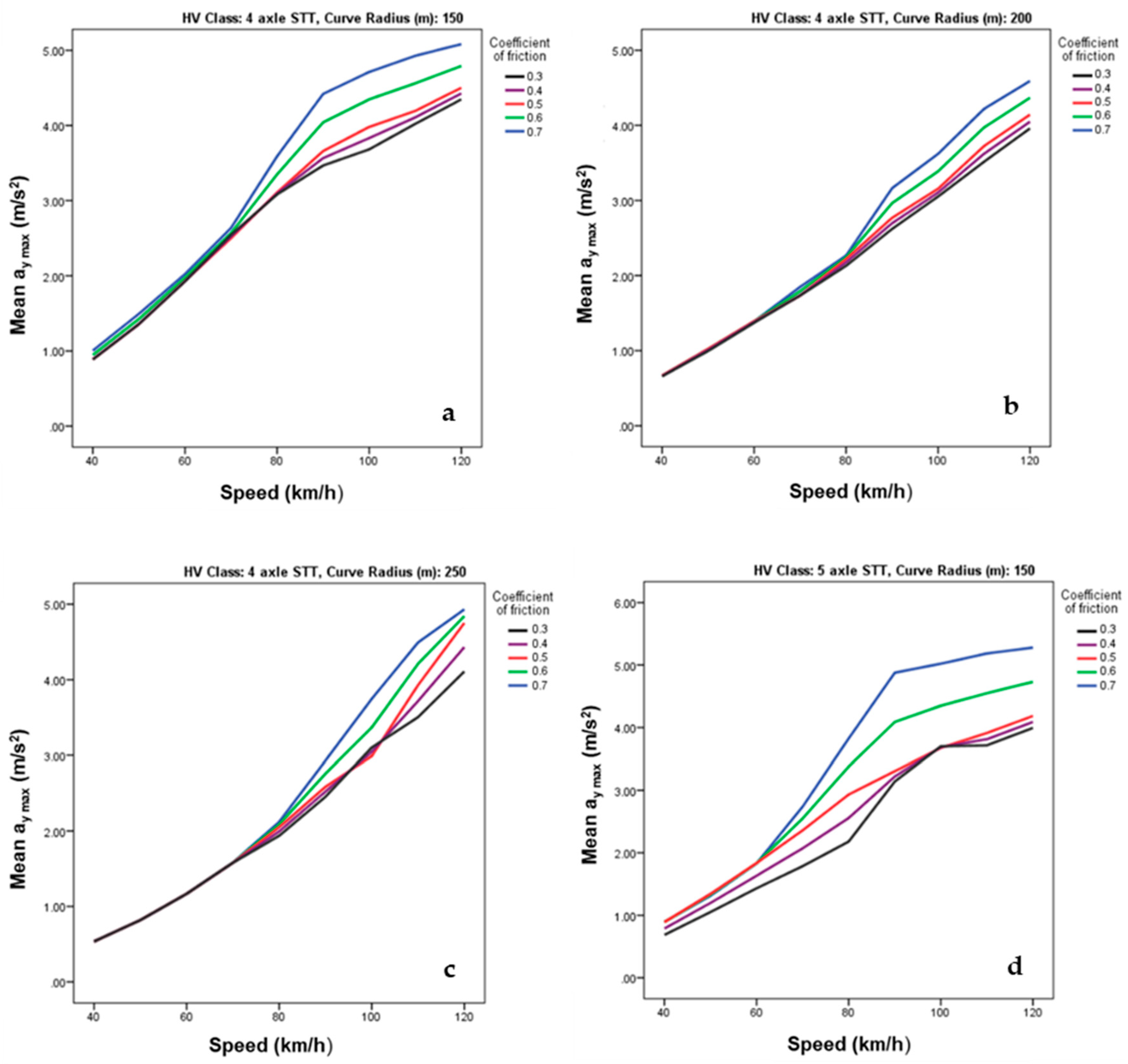

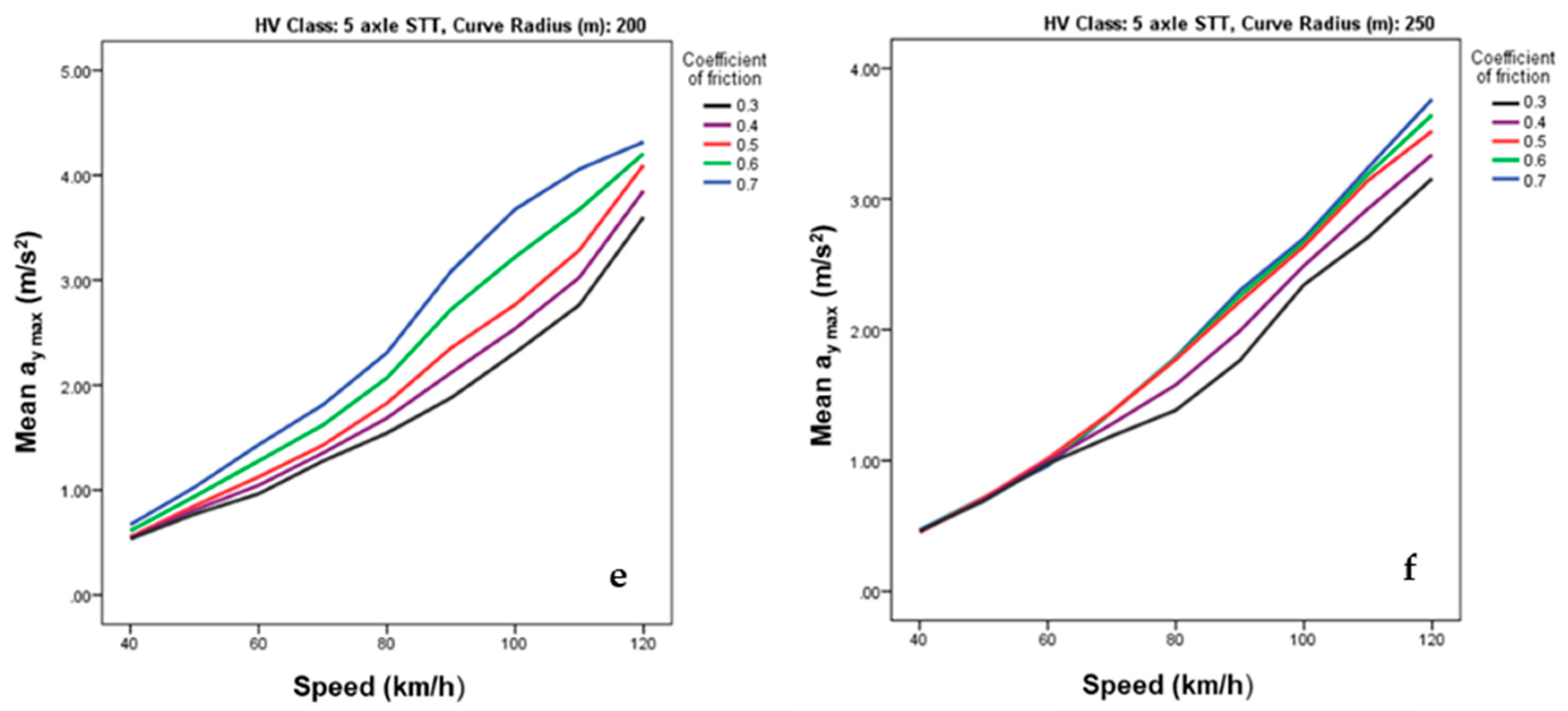

3.3. Analysis of Simulation Results

3.4. Correlation Analysis

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Malaysian Automotive Association. Sales and Production Statistics; Malaysian Automotive Association: Selangor, Malaysia, 2020. [Google Scholar]

- Ministry of Transport Malaysia. Transport Statistics Malaysia 2018; Ministry of Transport Malaysia: Putrajaya, Malaysia, 2019.

- Karim, M.R.; Saifizul, A.; Yamanaka, H.; Sharizli, A.; Ramli, R. An Investigation on Safety Performance Assessment of Close-Following Behavior of Heavy Vehicle Using Empirical-Simulation Technique. J. Transp. Technol. 2014, 4, 22–30. [Google Scholar] [CrossRef][Green Version]

- Radja, G.A. National Automotive Sampling System–Crashworthiness Data System 2015. In Analytical User’s Manual; National Highway Traffic Safety Administration: Washington, DC, USA, 2016. [Google Scholar]

- Hinch, J.; Shadle, S.; Klein, T.M. NHTSA’s rollover rulemaking program-results of testing and analysis. SAE Trans. 1992, 101, 677–690. [Google Scholar] [CrossRef]

- Hamidun, R.; Hoong, A.P.W.; Roslan, A.; Shabadin, A.; Jamil, H. Characteristics of heavy goods vehicles (HGV) accidents in Malaysia. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 10th Malaysian Road Conference and Exhibition 2018, Selangor, Malaysia, 29–31 October 2018; IOP Publishing: Bristol, UK, 2019; Volume 512, p. 012021. [Google Scholar]

- Buddhavarapu, P.; Banerjee, A.; Prozzi, J.A. Influence of pavement Condition on Horizontal Curve Safety. Accid. Anal. Prev. 2013, 52, 9–18. [Google Scholar] [CrossRef] [PubMed]

- Sharizli, A.A.; Rahizar, R.; Karim, M.R.; Saifizul, A. New Method for Distance-based Close Following Safety Indicator. Traffic Inj. Prev. 2015, 16, 190–195. [Google Scholar] [CrossRef] [PubMed]

- Goldman, R.W.; El-Gindy, M.; Kulakowski, B.T. Rollover dynamics of road vehicles: Literature survey. Int. J. Heavy Veh. Syst. 2001, 8, 103–141. [Google Scholar] [CrossRef]

- Hyun, D.; Langari, R. Modeling to Predict Rollover Threat of Tractor-Semitrailers. Veh. Syst. Dyn. 2003, 39, 401–414. [Google Scholar] [CrossRef]

- Winkler, C.; Ervin, R. Rollover of Heavy Commercial Vehicles. In University of Michigan Transportation Research Institute Research Review; University of Michigan Transportation Research Institute: Ann Arbor, MI, USA, 2000; Volume 31. [Google Scholar]

- Garrott, W.R.; Howe, J.G.; Forkenbrock, G. Results from NHTSA’s Experimental Examination of Selected Maneuvers that may Induce On-Road Untripped, Light Vehicle Rollover. SAE Tech. Pap. Ser. 2001, 12, 21–39. [Google Scholar] [CrossRef]

- Tokunaga, R.A.; Asano, M.; Munehiro, K.; Hagiwara, T.; Kunugiza, K.; Kagaya, S. Effects of curve designs and road conditions on driver’s curve sharpness judgment and driving behavior. J. East. Asia Soc. Transp. Stud. 2005, 6, 3536–3550. [Google Scholar]

- Bambach, M.; Grzebieta, R.; McIntosh, A.; Mattos, G. Cervical and thoracic spine injury from interactions with vehicle roofs in pure rollover crashes. Accid. Anal. Prev. 2013, 50, 34–43. [Google Scholar] [CrossRef]

- Sun, Y.; Chen, W.; Zhang, Y.; Chen, L. Modeling and Simulation of Heavy Truck with Works. In Proceedings of the 8th International Modelica Conference, Dresden, Germany, 20–22 March 2011; Linköping University Electronic Press: Linköping, Sweden, 2011; Volume 63, pp. 725–729. [Google Scholar]

- Ahmad, F.; Mazlan, S.; Zamzuri, H.; Jamaluddin, H.; Hudha, K.; Short, M. Modelling and Validation of the Vehicle Longitudinal Model. Int. J. Automot. Mech. Eng. 2014, 10, 2042–2056. [Google Scholar] [CrossRef]

- Dong, X.; Jiang, Y.; Zhong, Z.; Zeng, W. Rollover threshold investigation of a heavy-duty vehicle during cornering based on multi-body dynamics. Adv. Mech. Eng. 2018, 10, 1687814018789505. [Google Scholar] [CrossRef]

- Takahashi, T.; Hada, M.; Oyama, K.; Sakai, H. New Model of Tire Overturning Moment Characteristics and Analysis of Their Influence on Vehicle Rollover Behavior. Veh. Syst. Dyn. 2004, 42, 109–118. [Google Scholar] [CrossRef]

- Fukushima, T.; Shitamichi, M.; Nishikata, O.; Mori, M.; Hatano, K.; Torigaki, T.; Nishi, M.; Miyachi, T. A Study of the Ditch Fall-over Test Method Using Numerical Simulation. SAE Int. J. Passeng. Cars Mech. Syst. 2012, 5, 76–88. [Google Scholar] [CrossRef]

- Han, I.; Rho, K. Characteristic analysis of vehicle rollover accidents: Rollover scenarios and prediction/warning. Int. J. Automot. Technol. 2017, 18, 451–461. [Google Scholar] [CrossRef]

- Ertlmeier, R.; Faisst, H.; Spannaus, P.; Brandmeier, T. Model-Based Soil Trip Rollover Prediction Using Driving Dynamics. In Sustainable Automotive Technologies 2012; Springer: Berlin/Heidelberg, Germany, 2012; pp. 363–372. [Google Scholar]

- Shi, Y.; Nusholtz, G.S. Simple Models for Analysis of Curb- and Soil-trip Rollover Events. SAE Tech. Pap. Ser. 2006, 653–668. [Google Scholar] [CrossRef]

- Elassad, Z.E.A.; Mousannif, H.; Al Moatassime, H. Class imbalanced crash prediction based on real time traffic and weather data: A driving simulator study. Traffic Inj. Prev. 2020, 21, 201–208. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Zhang, Y.; Cheng, K. Exploring the Impact of Climate and Extreme Weather on Fatal Traffic Accidents. Sustainability 2021, 13, 390. [Google Scholar] [CrossRef]

- Ikhsan, N.; Saifizul, A.; Ramli, R. Experimental validation of vehicle dynamic characteristics of a virtual heavy vehicle model. J. Mech. Eng. 2017, 4, 131–143. [Google Scholar]

- Jabatan Keselamatan Jalan Raya Malaysia. Road Safety Plan Malaysia 2014–2020; Jabatan Keselamatan Jalan Raya: Putrajaya, Malaysia, 2014.

- Saifizul, A.; Yamanaka, H.; Karim, M.R. Empirical analysis of gross vehicle weight and free flow speed and consideration on its relation with differential speed limit. Accid. Anal. Prev. 2011, 43, 1068–1073. [Google Scholar] [CrossRef]

- Aziza, R.S.R.A.; Karim, M.R.; Saifizul, A.; Yamanaka, H. The effect of gross vehicle weight on platoon speed and size characteristics on two-lane road. In Proceedings of the International Conference on Innovative Trends in Multidisciplinary Academic Research, Istanbul, Turkey, 20–21 October 2014. [Google Scholar]

- Kordani, A.A.; Rahmani, O.; Nasiri, A.S.A.; Boroomandrad, S.M. Effect of Adverse Weather Conditions on Vehicle Braking Distance of Highways. Civ. Eng. J. 2018, 4, 46. [Google Scholar] [CrossRef]

- Green, S.D. Prevent Heavy Truck Rollover. In Traffic Safety (Chicago); National Safety Council: Itasca, IL, USA, 2002; Volume 2. [Google Scholar]

- McKnight, A.J.; Bahouth, G.T. Analysis of Large Truck Rollover Crashes. Traffic Inj. Prev. 2009, 10, 421–426. [Google Scholar] [CrossRef]

- Karim, M.R.; Saifizul, A.; Yamanaka, H.; Ramli, R. Degree of vehicle overloading and its implication on road safety in developing countries. J. Civ. Environ. Res. 2013, 3, 20–31. [Google Scholar]

- Elischer, M.; Prem, H. Stability of Over–Height Low-Density Freight Vehicles and its Prediction. In Proceedings of the 5th International Symposium on Heavy Vehicle Weights and Dimensions, Queensland, Australia, 29 March–2 April 1998. [Google Scholar]

- Jones, E.R.; Childers, R.L. Contemporary College Physics; McGraw Hill: New York, NY, USA, 2001. [Google Scholar]

- Yang, J.-D.; Chen, Y.-K.; Shi, Q.; Li, Y.-M.; Wang, F.-C.; Zhu, L. Variable Speed Limits on Circular Curved Road Sections under Various Weather Conditions. In Proceedings of the 15th COTA International Conference of Transportation Professionals, Beijing, China, 25–27 July 2015; pp. 3242–3253. [Google Scholar] [CrossRef]

- Permanent International Association of Road Congress. Road Safety Manual: Recommendations from the World Road Association; Route2 Market: Boston, MA, USA, 2003. [Google Scholar]

- Olofsson, M.; Pettersson, J. Parameterization and Validation of Road and Driver Behavior Models for CarMaker Simulations and Transmission HIL-Rig. Master’s Thesis, Chalmers University of Technology, Goteborg, Sweden, 2015. [Google Scholar]

- Li, H.; Zhao, Y.; Wang, H.; Lin, F. Design of an improved predictive LTR for rollover warning systems. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 3779–3791. [Google Scholar] [CrossRef]

- Tsourapas, V.; Piyabongkarn, D.; Williams, A.C.; Rajamani, R. New method of identifying real-time Predictive Lateral load Transfer Ratio for rollover prevention systems. In Proceedings of the 2009 American Control Conference, Saint Louis, MO, USA, 10–12 June 2009; pp. 439–444. [Google Scholar]

- Eboli, L.; Mazzulla, G.; Pungillo, G. Combining speed and acceleration to define car users’ safe or unsafe driving behaviour. Transp. Res. Part C Emerg. Technol. 2016, 68, 113–125. [Google Scholar] [CrossRef]

- Farmer, C.M.; Lund, A.K. Rollover risk of cars and light trucks after accounting for driver and environmental factors. Accid. Anal. Prev. 2002, 34, 163–173. [Google Scholar] [CrossRef]

- Reymond, G.; Kemeny, A.; Droulez, J.; Berthoz, A. Role of Lateral Acceleration in Curve Driving: Driver Model and Experiments on a Real Vehicle and a Driving Simulator. Hum. Factors J. Hum. Factors Ergon. Soc. 2001, 43, 483–495. [Google Scholar] [CrossRef] [PubMed]

- Ryu, Y.I.; Kang, D.O.; Heo, S.J.; In, J.H. Rollover mitigation for a heavy commercial vehicle. Int. J. Automot. Technol. 2010, 11, 283–287. [Google Scholar] [CrossRef]

| Output | RMSE | MAE | R |

|---|---|---|---|

| Lateral acceleration | 0.0445 | 0.0325 | 0.7797 |

| Category | Heavy Vehicle Characteristics | Environment and Road Factor | Other Parameters |

|---|---|---|---|

| Details | Heavy vehicle class | Cornering radius | Corner cutting value |

| Heavy vehicle speed | Road friction | Driver behavior | |

| Gross vehicle weight (GVW) | Super-elevation | Selected drive lane |

| Type | No of Axles | Max GVW in kg * | Speed (km/h) |

|---|---|---|---|

| SUT | 2 | 35,000 | Varied starting from 40 km/h to 120 km/h (with intervals of 10 km/h) |

| 3 | 57,000 | ||

| 4 | 71,000 | ||

| STT | 4 | 71,000 | |

| 5 | 86,000 |

| Input/Variables | Output/Dependent Value | Test Result | ||

|---|---|---|---|---|

| Heavy Vehicle Type | GVW (kg) | Speed (km/h) | Maximum Lateral Acceleration (ms−2) | |

| 2-axle SUT | 10,000 | 40 | 0.87 | Pass |

| 50 | 1.36 | Pass | ||

| 60 | 1.56 | Pass | ||

| 70 | 2.07 | Pass | ||

| 80 | 2.65 | Failed | ||

| 90 | 2.90 | Failed | ||

| 100 | 2.96 | Failed | ||

| 110 | 3.08 | Failed | ||

| 120 | 3.27 | Failed | ||

| 15,000 | 40 | 0.87 | Pass | |

| 50 | 1.36 | Pass | ||

| 60 | 1.86 | Pass | ||

| 70 | 2.27 | Pass | ||

| 80 | 2.85 | Failed | ||

| 90 | 3.08 | Failed | ||

| 100 | 3.22 | Failed | ||

| 110 | 3.30 | Failed | ||

| 120 | 3.50 | Failed | ||

| Vehicle Class | Frequency | Safe Condition | Unsafe Condition | Total no. of Simulations |

|---|---|---|---|---|

| Two-axle SUT | No. of sim. | 644 | 436 | 1080 |

| % | 60% | 40% | 100% | |

| Three-axle SUT | No. of sim. | 1014 | 471 | 1485 |

| % | 68% | 32% | 100% | |

| Four-axle SUT | No. of sim. | 1282 | 473 | 1755 |

| % | 73% | 27% | 100% | |

| Four-axle STT | No. of sim. | 1348 | 407 | 1755 |

| % | 77% | 23% | 100% | |

| Five-axle STT | No. of sim. | 1620 | 540 | 2160 |

| % | 75% | 25% | 100% |

| Vehicle Class | Frequency | Tripped Rollover | Un-Tripped Rollover | Total no. and Percentage of Unsafe Conditions |

|---|---|---|---|---|

| Two-axle SUT | No. of sim. | 285 | 151 | 436 |

| % | 65% | 35% | 100% | |

| Three-axle SUT | No. of sim. | 294 | 177 | 471 |

| % | 62% | 38% | 100% | |

| Four-axle SUT | No. of sim. | 325 | 148 | 473 |

| % | 69% | 31% | 100% | |

| Four-axle STT | No. of sim. | 315 | 92 | 407 |

| % | 77% | 23% | 100% | |

| Five-axle STT | No. of sim. | 387 | 153 | 540 |

| % | 72% | 28% | 100% |

| No | GVW (kg) | Speed (km/h) | Coe. of Friction | Cornering Radius (m) | Maximum Lateral Acceleration (m/s2) |

|---|---|---|---|---|---|

| 1 | 10,000 | 40 | 0.3 | 150 | 0.872 |

| 2 | 15,000 | 0.874 | |||

| 3 | 20,000 | 0.880 | |||

| 4 | 25,000 | 0.881 | |||

| 5 | 30,000 | 0.883 | |||

| 6 | 35,000 | 0.892 | |||

| Mean maximum lateral acceleration = 0.880 (plotted in graph) |

| Correlations | ||||||

|---|---|---|---|---|---|---|

| Max. Lateral Acceleration (m/s2) | HV Speed (km/h) | GVW (Tonne) | Coefficient of Friction | Curve Radius (m) | ||

| Max. Lateral Acceleration (m/s2) | Pearson Correlation | 1 | ||||

| Sig. (2-tailed) | ||||||

| N | 1080 | |||||

| HV speed (km/h) | Pearson Correlation | 0.873 | 1 | |||

| Sig. (2-tailed) | 0.000 | |||||

| N | 1080 | 1080 | ||||

| GVW (tonne) | Pearson Correlation | 0.352 | 0.000 | 1 | ||

| Sig. (2-tailed) | 0.000 | 1.000 | ||||

| N | 1080 | 1080 | 1080 | |||

| Coefficient of friction | Pearson Correlation | −0.346 | 0.000 | 0.000 | 1 | |

| Sig. (2-tailed) | 0.000 | 1.000 | 1.000 | |||

| N | 1080 | 1080 | 1080 | 1080 | ||

| Curve Radius (m) | Pearson Correlation | −0.214 | 0.000 | 0.000 | 0.000 | 1 |

| Sig. (2-tailed) | 0.000 | 1.000 | 1.000 | 1.000 | ||

| N | 1080 | 1080 | 1080 | 1080 | 1080 | |

| Correlations | ||||||

|---|---|---|---|---|---|---|

| Max. Lateral Acceleration (m/s2) | HV Speed (km/h) | GVW (Tonne) | Coefficient of Friction | Curve Radius (m) | ||

| Max. Lateral Acceleration (m/s2) | Pearson Correlation | 1 | ||||

| Sig. (2-tailed) | ||||||

| N | 8235 | |||||

| HV speed (km/h) | Pearson Correlation | 0.853 | 1 | |||

| Sig. (2-tailed) | 0.000 | |||||

| N | 8235 | 8235 | ||||

| GVW (tonne) | Pearson Correlation | 0.373 | 0.000 | 1 | ||

| Sig. (2-tailed) | 0.000 | 1.000 | ||||

| N | 8235 | 8235 | 8235 | |||

| Coefficient of friction | Pearson Correlation | −0.341 | 0.000 | 0.000 | 1 | |

| Sig. (2-tailed) | 0.000 | 1.000 | 1.000 | |||

| N | 8235 | 8235 | 8235 | 8235 | ||

| Curve Radius (m) | Pearson Correlation | −0.214 | 0.000 | 0.000 | 0.000 | 1 |

| Sig. (2-tailed) | 0.000 | 1.000 | 1.000 | 1.000 | ||

| N | 8235 | 8235 | 8235 | 8235 | 8235 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ikhsan, N.; Saifizul, A.; Ramli, R. The Effect of Vehicle and Road Conditions on Rollover of Commercial Heavy Vehicles during Cornering: A Simulation Approach. Sustainability 2021, 13, 6337. https://doi.org/10.3390/su13116337

Ikhsan N, Saifizul A, Ramli R. The Effect of Vehicle and Road Conditions on Rollover of Commercial Heavy Vehicles during Cornering: A Simulation Approach. Sustainability. 2021; 13(11):6337. https://doi.org/10.3390/su13116337

Chicago/Turabian StyleIkhsan, Nurzaki, Ahmad Saifizul, and Rahizar Ramli. 2021. "The Effect of Vehicle and Road Conditions on Rollover of Commercial Heavy Vehicles during Cornering: A Simulation Approach" Sustainability 13, no. 11: 6337. https://doi.org/10.3390/su13116337

APA StyleIkhsan, N., Saifizul, A., & Ramli, R. (2021). The Effect of Vehicle and Road Conditions on Rollover of Commercial Heavy Vehicles during Cornering: A Simulation Approach. Sustainability, 13(11), 6337. https://doi.org/10.3390/su13116337