Timeliness Harvesting Loss of Rice in Cold Region under Different Mechanical Harvesting Methods

Abstract

:1. Introduction

2. Materials and Methods

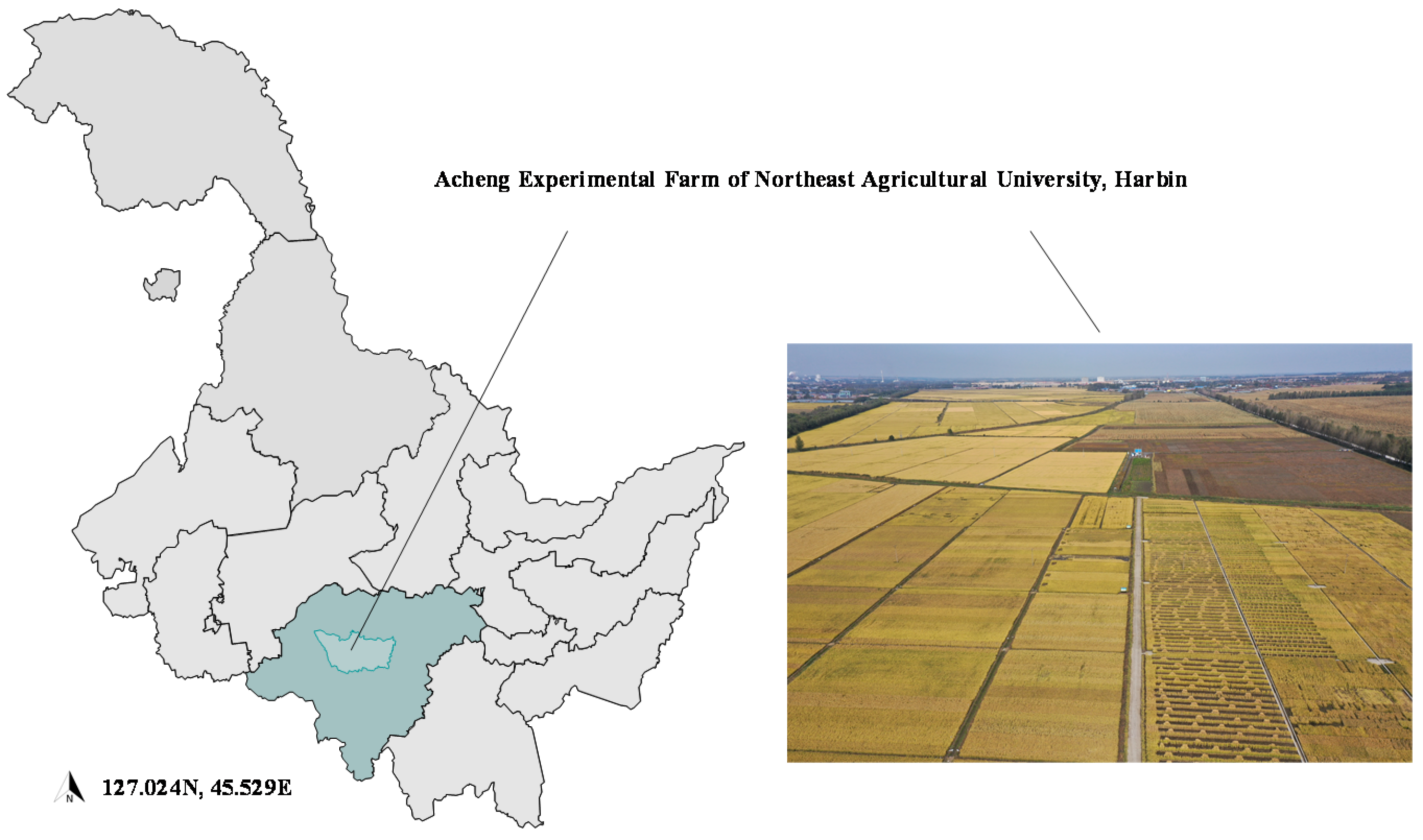

2.1. Study Site

2.2. Test Sample and Field Management

2.3. Harvesting Instruments and the Parameters Setting

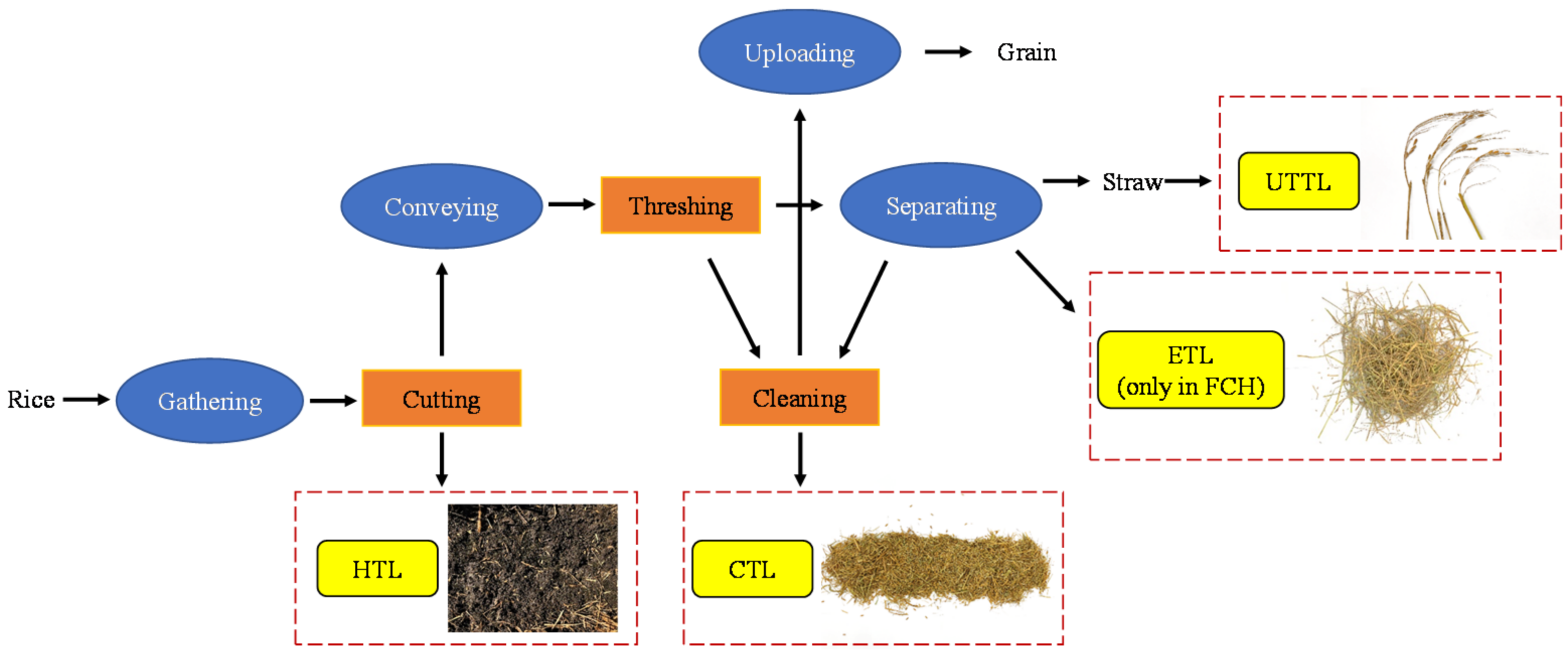

2.4. Experimental Design and Sampling Processes

2.5. Statistical Analysis

3. Results

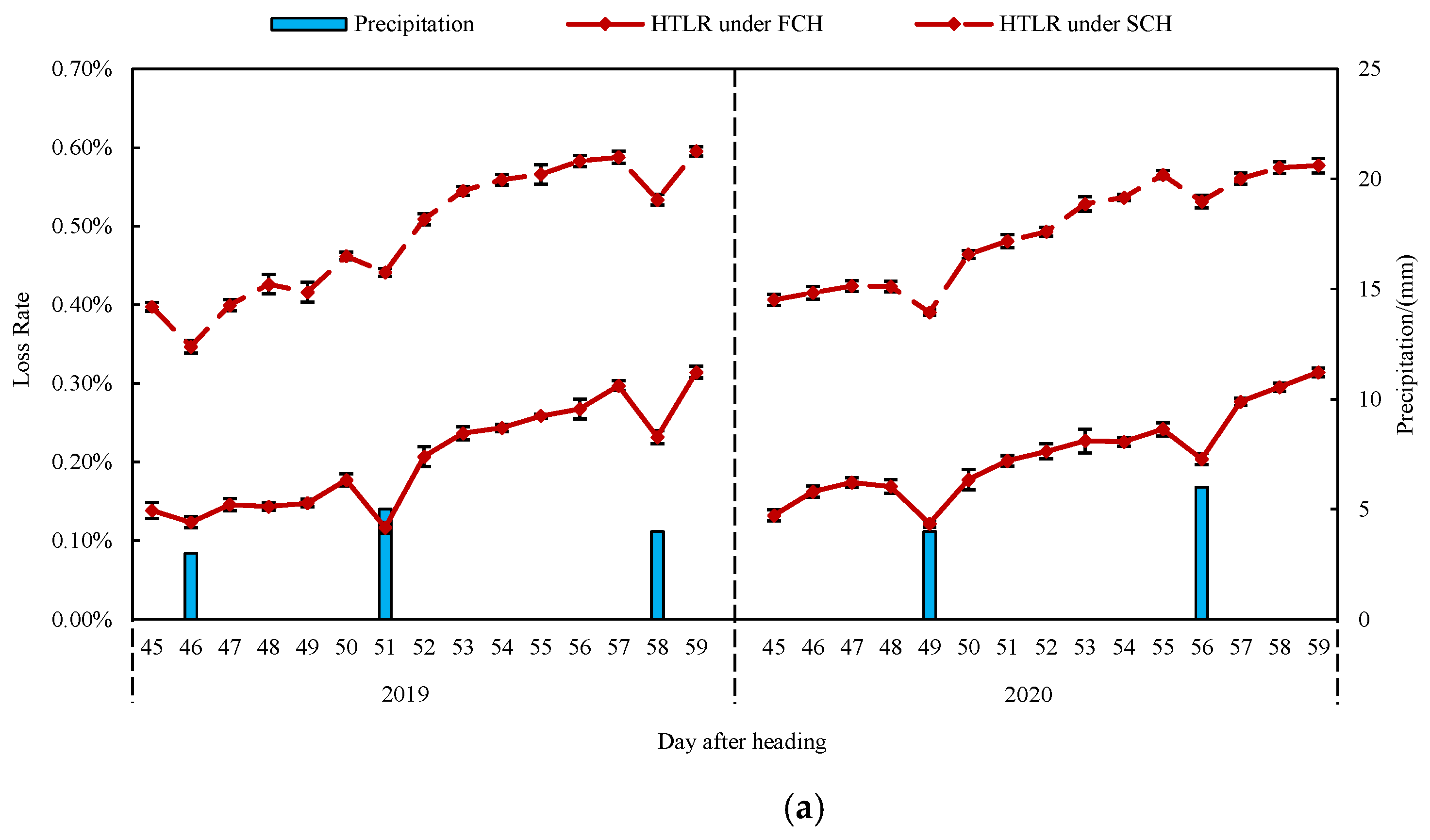

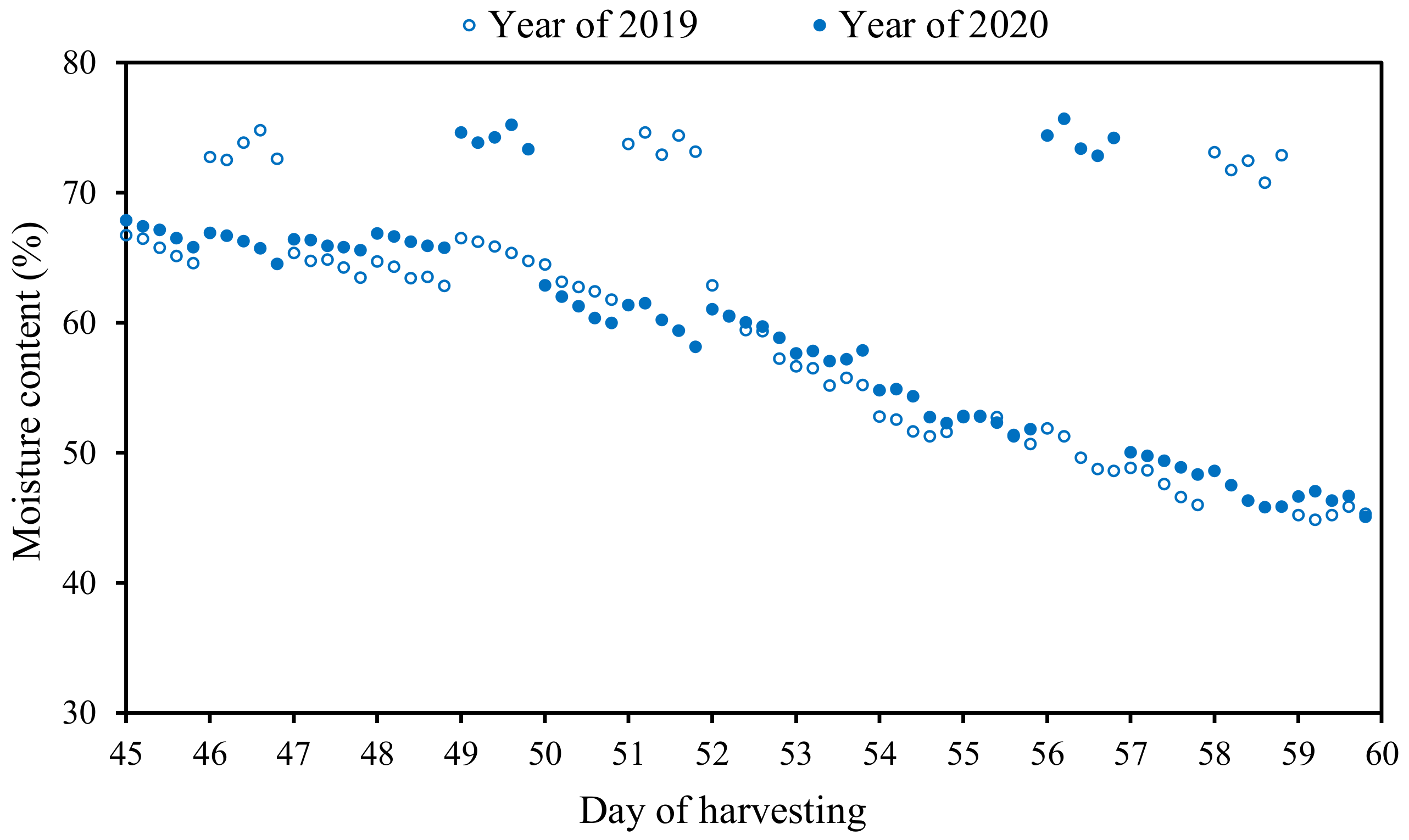

3.1. Variation of the GDMTLR Based on Different Mechanical Harvesting Methods

3.2. Variation of the MTL Based on Different Mechanical Harvesting Methods

3.3. Variation of the Timeliness Harvest Loss and the Differences in the Proportion of Each Loss

3.4. The Effect of Harvest Date on Yield under Different Combine Harvesting Methods

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ileleji, K.E.; Shrestha, R.; Sarr, I.; Diop, P.; Ketiem, P.; de Groote, H. Others Field testing of a multipurpose solar dryer for small farmholders. In Proceedings of the 1st All Africa Post Harvest Congress & Exhibition, Reducing Food Losses and Waste: Sustainable Solutions for Africa, Nairobi, Kenya, 28–31 March 2017; pp. 45–48. [Google Scholar]

- MOA (Ministry of Agriculture, China). Annual Rice Production in China. 2020. Available online: https://data.stats.gov.cn/easyquery.htm?cn=C01 (accessed on 5 April 2021).

- Chandegara, D.V.; Joshi, D.; Yadavendra, J.P. Effect of harvesting time on yield and milling quality of upland rice. J. Agric. Eng. 1999, 36, 33–40. [Google Scholar]

- Najafi, B.; Dastgerduei, S.T. Optimization of Machinery Use on Farms with Emphasis on Timeliness Costs. J. Agric. Sci. Technol. 2015, 17, 533–541. [Google Scholar]

- Hossain, M.; Bhuiya, M.; Ahmed, M.; Mian, M. Effect of Harvesting Time on the Milling and Physicochemical Properties of Aromatic Rice. Thai. J. Agric. Sci. 2009, 42, 91–96. [Google Scholar]

- Ali, A.; Majid, A.; Sagar, M.A. Milling recovery of Basmati as affected by threshing methods and crop harvesting time. Pak. J. Agric. Res. 1990, 11, 7–12. [Google Scholar]

- Khir, R.; Atungulu, G.; Chao, P.M.D.; Pan, Z. Influence of Harvester and Weather Conditions on Field Loss and Milling Quality of Rough Rice. J. Agric. Biol. Eng. 2017, 10, 216–223. [Google Scholar]

- Teasdale, J.; Devine, T.; Mosjidis, J.; Bellinder, R.; Beste, C. Growth and Development of Hairy Vetch Cultivars in the Northeastern United States as Influenced by Planting and Harvesting Date. Agron. J. 2004, 96, 1266–1271. [Google Scholar] [CrossRef]

- Yoshida, S. Fundamentals of Rice Crop Science; International Rice Research Institute: Los Baños, Laguna, Philippines, 1981; p. 269. [Google Scholar]

- Surek, H.; Aydin, H.; Negis, M.; Kushu, H. Determining the suitable rice harvesting time in Erdine. Cah. Options Méditerranéennes 2003, 15, 29–31. [Google Scholar]

- Vishnu, K.; Kannan, E.; Kumar, P. Assessment of Pre and Post Harvest Losses of Rice and Red Gram in Karnataka; Agricultural Development and Rural Transformation Centre, Institute for Social and Economic Change: Bangalore, India, 2016. [Google Scholar]

- Tavasoli, A. Investigation on the Effect of Speed and Reel Type Indexes of Combine on Losses While Reaping Wheat through Design and Developing Reel Speed Control Mechanism; Tarbiat Modares University: Maharashtra, Iran, 2002. [Google Scholar]

- Zhenwei, L.; Li, Y.; Xu, L.; Zhao, Z.; Tang, Z. Optimum design of an array structure for the grain loss sensor to upgrade its resolution for harvesting rice in a combine harvester. Biosyst. Eng. 2017, 157, 24–34. [Google Scholar] [CrossRef]

- Zareei, S.; Abdollahpour, S.; Moghaddam, M.; Sahrayan, H. Optimum setting of combine header for wheat harvesting using Taguchi method. Res. Crop. 2012, 13, 1142–1146. [Google Scholar]

- Alatürk, F.; Gökkuș, A.; Kaya, S.; Akar, C.; Kiran, B.; Kirmizigül, E. Others A study on the feasibility of double production (seed and hay) in triticale with different height and number of harvestings. COMU J. Agric. Fac. 2018, 6, 235–241. [Google Scholar]

- Tihanov, G. A grain harvester performance according to unloading time and modes. Agric. Sci. Technol. 2019, 11, 59–62. [Google Scholar] [CrossRef]

- Tang, Z.; Li, Y.; Cheng, C. Development of multi-functional combine harvester with grain harvesting and straw baling. Span. J. Agric. Res. 2017, 15, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Adisa, A.F.; Ndirika, V.I.O.; Yiljep, Y.D.; Mohammed, U.S. Others Determination of optimum critical operating parameters of stripping rice harvester in a rural area. In Proceedings of the CIGR-AgEng Conference, Aarhus, Denmark, 26–29 June 2016; pp. 1–10. [Google Scholar]

- Bunna, S.O.M.; Sereyvuth, H.; Somaly, Y.I.M.; Ngoy, N.; Mengsry, L.; Chea, S.; Makara, O.; Mitchell, J.; Fukai, S.H.U. Head Rice Yield of Crops Harvested by Combine and Hand at Different Ripening Times in Cambodia. Exp. Agric. 2018, 55, 1–11. [Google Scholar] [CrossRef]

- Alizadeh, M.R.; Allameh, A. Evaluating rice losses in various harvesting practices. Int. Res. J. Appl. Basic Sci. 2013, 4, 894–901. [Google Scholar]

- Dumitru, O.; Iorga, S.; Vladut, N.-V.; Bracacescu, C. Food Losses in Primary Cereal Production. A Review. INMATEH Agric. Eng. 2020, 12, 133–146. [Google Scholar] [CrossRef]

- National Agricultural High-Tech Center. Technical Specification for Production of High Quality and High Yield Rice in Cold Regions; Construction of Sanjiang Administration: Sanjiang, China, 2015. [Google Scholar]

- National Standards of the People’s Republic of China NY/T 995-2006. Operation Quality of Combined Grain Harvester; China Standard Publishing House: Beijing, China, 2006. [Google Scholar]

- National Standards of the People’s Republic of China NY/T 995-2006. Test Method for Combine Harvesters; China Standard Publishing House: Beijing, China, 2008. [Google Scholar]

- Siebenmorgen, T.; Andrews, S.; Vories, E.; Loewer, D. Comparison of Combine Grain Loss Measurement Techniques. Appl. Eng. Agric. 1994, 10. [Google Scholar] [CrossRef] [Green Version]

- Oh-e, I.; Saitoh, K.; Kuroda, T. Effects of High Temperature on Growth, Yield and Dry-Matter Production of Rice Grown in the Paddy Field. Plant Prod. Sci. 2007, 10, 412–422. [Google Scholar] [CrossRef]

- Mesterházy, Á.; Oláh, J.; Popp, J. Losses in the Grain Supply Chain: Causes and Solutions. Sustainability 2020, 12, 2342. [Google Scholar] [CrossRef] [Green Version]

- Sinclair, T.R.; Bai, Q. Analysis of high wheat yields in Northwest China. Agric. Syst. 1997, 53, 373–385. [Google Scholar] [CrossRef]

- Kwon, Y.-W.; Shin, J.-C. A Study on the Changes in Grain Weight, Moisture Content, Shattering Force, Milling Ratio and Apparant Physical Quality of Rice with Harvesting Time. Korean J. Crop Sci. 1980, 25. [Google Scholar]

- Yazdpour, H.; Shahri, M.; Soleymani, A.; Shahrajabian, M.H. Effects of harvesting time and harvesting height on grain yield and agronomical characters in rice ratoon (Oryza sativa L.). J. Food Agric. Environ. 2012, 10, 438–440. [Google Scholar]

- Kumar, R.; Sarawgi, A.K.; Ramos, C.; Amarante, S.T.; Ismail, A.M.; Wade, L.J. Partitioning of dry matter during drought stress in rainfed lowland rice. Field Crops Res. 2006, 96, 455–465. [Google Scholar] [CrossRef]

- Yang, J. Grain and Dry Matter Yields and Partitioning of Assimilates in Japonica/Indica Hybrid Rice. Crop Sci. 2002, 42, 766–772. [Google Scholar] [CrossRef]

- Evans, L. Crop Physiology: Some Case Histories; Evans, L.T., Ed.; Cambridge University Press: New York, NY, USA, 1978. [Google Scholar]

- Ali, M.Y.; Hossain, S.M.A.; Ahmed, S.M.; Gaffer, M.A. Effect of harvesting time on seed and seed quality of transplant aman rice varieties. Bangladesh J. Crop Sci. 2000, 11, 31–37. [Google Scholar]

- Xihong, D.; Rong, X.; GuanngCai, L. Drymatter Production and Photosynetic Characters as Related to Kernel Plumpness in Hybrid Rice. J. Southwest Agric. Univ. 1993, 5, 433–437. [Google Scholar]

- Ying, J.; Peng, S.; He, Q.; Yang, H.; Yang, C.; Visperas, R.; Cassman, K. Comparison of high-yield rice in tropical and subtropical environments: I. Determinants of grain and dry matter yields. Field Crops Res. 1998, 57, 71–84. [Google Scholar] [CrossRef]

- Tian, Z.; Li, J.; He, X.; Jia, X.; Yang, F.; Wang, Z. Grain Yield, Dry Weight and Phosphorus Accumulation and Translocation in Two Rice (Oryza sativa L.) Varieties as Affected by Salt-Alkali and Phosphorus. Sustainability 2017, 9, 1461. [Google Scholar] [CrossRef] [Green Version]

- Zhiming, W.; Pengmin, L.; Ni, C. Study on distribution spectrum of grain connection force and differential-speed threshing device for combine harvester. J. Zhejiang Univ. 2017, 43, 120–127. [Google Scholar]

- Helmy, M.; Fouda, T.; Derbala, A.; Kassem, H. Developing the transmission system of the combine cutting device for harvesting rice crop. Sci. Pap. 2010, 27, 79. [Google Scholar] [CrossRef]

- Maertens, K.; Ramon, H.; De Baerdemaeker, J. Online Monitoring System for Separation Processes in Combine Harvesters; Automation Technology for Off-Road Equipment Conference: Leuven, Belgium, 2002. [Google Scholar]

- Yao, H.; Chen, X.; Yang, J.; Li, J.; Hong, J.; Hu, Y.; Mao, X. Effects and Mechanisms of Phosphate Activation in Paddy Soil by Phosphorus Activators. Sustainability 2020, 12, 3917. [Google Scholar] [CrossRef]

- Yaoming, L.; Zheng, M.; Lizhang, X. Tribological characteristics of adhesive materials on cleaning sieve of rape combine harvester. Trans. Chin. Soc. Agric. Mach. 2010, 41, 54–57. [Google Scholar] [CrossRef]

- Chao, C.; Jun, F.; Zhi, C.; Luquan, R. Effect of vibration parameters of vibrating screen for harvester on adhesion characteristics of threshed mixtures with different moistures. Trans. Chin. Soc. Agric. Eng. 2019, 35, 29–36. [Google Scholar]

- Boz, H.; Gercekaslan, K.E.; Karaoglu, M.M.; Kotancilar, H.I.G. Differences in some physical and chemical properties of wheat grains from different parts within the spike. Turk. J. Agric. For. 2012, 36, 309–316. [Google Scholar]

- Yaoming, L.; Lizhang, X.; Xilong, S. Analysis of factors affecting performance of petiolate seeds in threshing. Trans. Chin. Soc. Agric. Eng. 2007, 23, 131–134. [Google Scholar]

- Zheng, M.; Yaoming, L.; Lizhang, X. Wetting property of rapeseed (Brassica napus L.) stalk surface. Trans. Chin. Soc. Agric. Mach. 2014, 45, 98–103. [Google Scholar]

- Risius, H.; Prochnow, A.; Ammon, C.; Mellmann, J.; Hoffmann, T. Appropriateness of on-combine moisture measurement for the management of harvesting and postharvest operations and capacity planning in grain harvest. Biosyst. Eng. 2017, 156, 120–135. [Google Scholar] [CrossRef]

- MOA (Ministry of Agriculture, China). Production Price Index of Agricultural Products. 2020. Available online: https://data.stats.gov.cn/easyquery.htm?cn=C01 (accessed on 28 March 2021).

- Elsharabasy, M.M. Total Grain Losses, Energy and Cost Requirements for Harvesting Rice Crop Mechanically in Delta Egypt. Misr J. Agric. Eng. 2007, 24, 1–7. [Google Scholar]

- Rodriguez-Verde, I.; Regueiro, L.; Carballa, M.; Hospido, A.; Lema, J. Combining Operational Parameters and Environmental Burdens When Assessing Agrowaste Anaerobic Co-Digestion; Biogas Science: Viena, Austria, 2014. [Google Scholar]

- Hegazy, R. Determination of Harvesting Losses, Field Capacity and Energy Consumption for Different Rice Combine Harvesters. Misr J. Agric. Eng. 2015, 32, 19–40. [Google Scholar] [CrossRef]

- El-sharabasy, M. Construction and Manufacture a Self-propelled Machine Suits for Cutting Some Grain Crops to Minimize Losses and Maximize Efficiency; Zagazig Journal of Agricultural Engineering: Damietta, Egypt, 2021. [Google Scholar]

- Stefanoni, W.; Latterini, F.; Ruiz, J.; Bergonzoli, S.; Palmieri, N.; Pari, L. Assessing the Camelina (Camelina sativa (L.) Crantz) Seed Harvesting Using a Combine Harvester: A Case-Study on the Assessment of Work Performance and Seed Loss. Sustainability 2020, 13, 195. [Google Scholar] [CrossRef]

| Type of the Soil | PH Value | Organic Matter (%) | Alkaline Nitrogen (mg/kg) | Available Phosphorus (mg/kg) | Available Potassium (mg/kg) |

|---|---|---|---|---|---|

| Black paddy soil | 6.74 | 5.21 | 110.8 | 16.1 | 82.1 |

| Cultivars | Number of Plants/hm2 | Number of Spikes per Plant | Number of Grains per Spike | Seed Setting Rate (%) | Thousand Grain Weight (g) |

|---|---|---|---|---|---|

| LG | 2.56 × 105 | 14 | 91 | 93 | 28.01 |

| Combine Harvesting Method | Model | Header Width (mm) | Minimum Ground Clearance (mm) | Theoretical Operation Speed (km/h) | Head Cutter Form |

|---|---|---|---|---|---|

| SCH | 4LBZ-150 | 1400 | 100 | 0–5.4 | Standard type II |

| FCH | 4LZ-4 | 2000 | 120 | 0–6.0 | Standard type II |

| Harvesting Method | Harvest Period | ||

|---|---|---|---|

| 45 DAH to 50 DAH | 51 DAH to 54 DAH | 55 DAH to 59 DAH | |

| FCH | GDMTLR > ETLR > UTTLR > CTLR > HTLR | CTLR > UTTLR > ETLR > HTLR > GDMTLR | GDMTLR > CTLR > UTTLR > ETLR > HTLR |

| SCH | GDMTLR > CTLR > UTTLR > HTLR | CTLR > HTLR > UTTLR > GDMTLR | GDMTLR > CTLR > HTLR > UTTLR |

| DAH | Year of Harvesting | Harvesting Method | GDMLR/(%) | MTL/(%) | MHY/(kg/hm2) | DAH | Year of Harvesting | Harvesting Method | GDMLR/(%) | MTL/(%) | MHY/(kg/hm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 45 | 2019 | FCH | 3.53 | 1.80 | 8904.5 ± 15.0 e | 53 | 2019 | FCH | 0.21 | 1.53 | 9232.8 ± 19.0 ab |

| SCH | 3.22 | 1.58 | 8982.9 ± 48.8 de | SCH | 0.22 | 1.65 | 9258.8 ± 21.7 ab | ||||

| 2020 | FCH | 3.19 | 1.78 | 8942.6 ± 20.3 e | 2020 | FCH | 0.08 | 1.58 | 9264.4 ± 23.8 ab | ||

| SCH | 3.07 | 1.60 | 8988.4 ± 52.2 de | SCH | 0.31 | 1.65 | 9245.1 ± 27.3 ab | ||||

| 46 | 2019 | FCH | 3.01 | 1.94 | 8920.8 ± 37.7 e | 54 | 2019 | FCH | 0.57 | 1.52 | 9211.1 ± 25.5 bc |

| SCH | 2.86 | 1.56 | 8956.5 ± 27.3 e | SCH | 0.44 | 1.67 | 9253.1 ± 32.3 ab | ||||

| 2020 | FCH | 2.77 | 1.78 | 8980.2 ± 17.4 de | 2020 | FCH | 0.37 | 1.62 | 9221.5 ± 13.8 b | ||

| SCH | 2.85 | 1.50 | 9010.0 ± 21.3 de | SCH | 0.48 | 1.64 | 9224.7 ± 23.6 b | ||||

| 47 | 2019 | FCH | 2.30 | 1.71 | 9022.5 ± 14.7 de | 55 | 2019 | FCH | 0.79 | 1.49 | 9181.8 ± 16.2 bc |

| SCH | 2.34 | 1.48 | 9070.5 ± 11.3 cd | SCH | 0.63 | 1.70 | 9234.6 ± 20.4 ab | ||||

| 2020 | FCH | 2.46 | 1.80 | 9011.5 ± 25.8 de | 2020 | FCH | 1.20 | 1.53 | 9166.2 ± 21.8 bc | ||

| SCH | 2.19 | 1.51 | 9066.1 ± 19.1 cd | SCH | 0.95 | 1.68 | 9187.1 ± 21.2 bc | ||||

| 48 | 2019 | FCH | 1.78 | 1.60 | 9079.5 ± 24.0 cd | 56 | 2019 | FCH | 0.95 | 1.47 | 9160.6 ± 13.7 bc |

| SCH | 1.60 | 1.48 | 9135.5 ± 18.4 c | SCH | 1.25 | 1.74 | 9175.4 ± 44.3 bc | ||||

| 2020 | FCH | 1.76 | 1.79 | 9080.8 ± 21.5 cd | 2020 | FCH | 1.71 | 1.80 | 9045.3 ± 39.8 d | ||

| SCH | 1.66 | 1.52 | 9109.0 ± 26.6 cd | SCH | 1.24 | 1.67 | 9100.5 ± 24.2 cd | ||||

| 49 | 2019 | FCH | 1.31 | 1.54 | 9136.6 ± 20.8 c | 57 | 2019 | FCH | 1.33 | 1.43 | 9118.3 ± 21.4 cd |

| SCH | 1.06 | 1.45 | 9191.0 ± 23.5 bc | SCH | 1.43 | 1.74 | 9153.9 ± 28.1 bc | ||||

| 2020 | FCH | 1.24 | 1.95 | 9080.0 ± 23.6 cd | 2020 | FCH | 2.13 | 1.54 | 9062.3 ± 25.9 cd | ||

| SCH | 1.44 | 1.53 | 9091.7 ± 13.2 cd | SCH | 1.89 | 1.67 | 9097.0 ± 22.7 cd | ||||

| 50 | 2019 | FCH | 0.56 | 1.51 | 9191.8 ± 32.3 b | 58 | 2019 | FCH | 1.55 | 1.76 | 9061.9 ± 23.6 cd |

| SCH | 0.83 | 1.52 | 9221.9 ± 30.0 b | SCH | 1.58 | 1.72 | 9086.0 ± 24.6 cd | ||||

| 2020 | FCH | 0.86 | 1.69 | 9182.2 ± 27.2 bc | 2020 | FCH | 2.36 | 1.69 | 9043.7 ± 22.6 d | ||

| SCH | 1.01 | 1.55 | 9193.8 ± 21.4 bc | SCH | 2.03 | 1.99 | 9076.5 ± 32.7 cd | ||||

| 51 | 2019 | FCH | 0.09 | 1.87 | 9192.5 ± 25.0 bc | 59 | 2019 | FCH | 1.82 | 1.46 | 9084.3 ± 19.8 cd |

| SCH | 0.26 | 1.62 | 9195.8 ± 28.0 bc | SCH | 1.84 | 1.80 | 9108.9 ± 43.6 cd | ||||

| 2020 | FCH | 0.47 | 1.62 | 9215.2 ± 20.1 b | 2020 | FCH | 2.65 | 1.58 | 9018.1 ± 30.1 de | ||

| SCH | 0.07 | 1.66 | 9256.1 ± 30.6 ab | SCH | 2.34 | 1.69 | 9051.4 ± 30.1 d | ||||

| 52 | 2019 | FCH | 0.00 | 1.50 | 9275.5 ± 11.7 ab | ||||||

| SCH | 0.00 | 1.62 | 9303.1 ± 60.4 a | ||||||||

| 2020 | FCH | 0.00 | 1.59 | 9283.1 ± 14.0 ab | |||||||

| SCH | 0.00 | 1.63 | 9291.4 ± 23.6 ab |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Sun, X.; Xu, Y.; Zhou, W.; Tang, H.; Wang, Q. Timeliness Harvesting Loss of Rice in Cold Region under Different Mechanical Harvesting Methods. Sustainability 2021, 13, 6345. https://doi.org/10.3390/su13116345

Wang J, Sun X, Xu Y, Zhou W, Tang H, Wang Q. Timeliness Harvesting Loss of Rice in Cold Region under Different Mechanical Harvesting Methods. Sustainability. 2021; 13(11):6345. https://doi.org/10.3390/su13116345

Chicago/Turabian StyleWang, Jinwu, Xiaobo Sun, Yanan Xu, Wenqi Zhou, Han Tang, and Qi Wang. 2021. "Timeliness Harvesting Loss of Rice in Cold Region under Different Mechanical Harvesting Methods" Sustainability 13, no. 11: 6345. https://doi.org/10.3390/su13116345

APA StyleWang, J., Sun, X., Xu, Y., Zhou, W., Tang, H., & Wang, Q. (2021). Timeliness Harvesting Loss of Rice in Cold Region under Different Mechanical Harvesting Methods. Sustainability, 13(11), 6345. https://doi.org/10.3390/su13116345