Towards a Conceptual Development of Industry 4.0, Servitisation, and Circular Economy: A Systematic Literature Review

Abstract

:1. Introduction

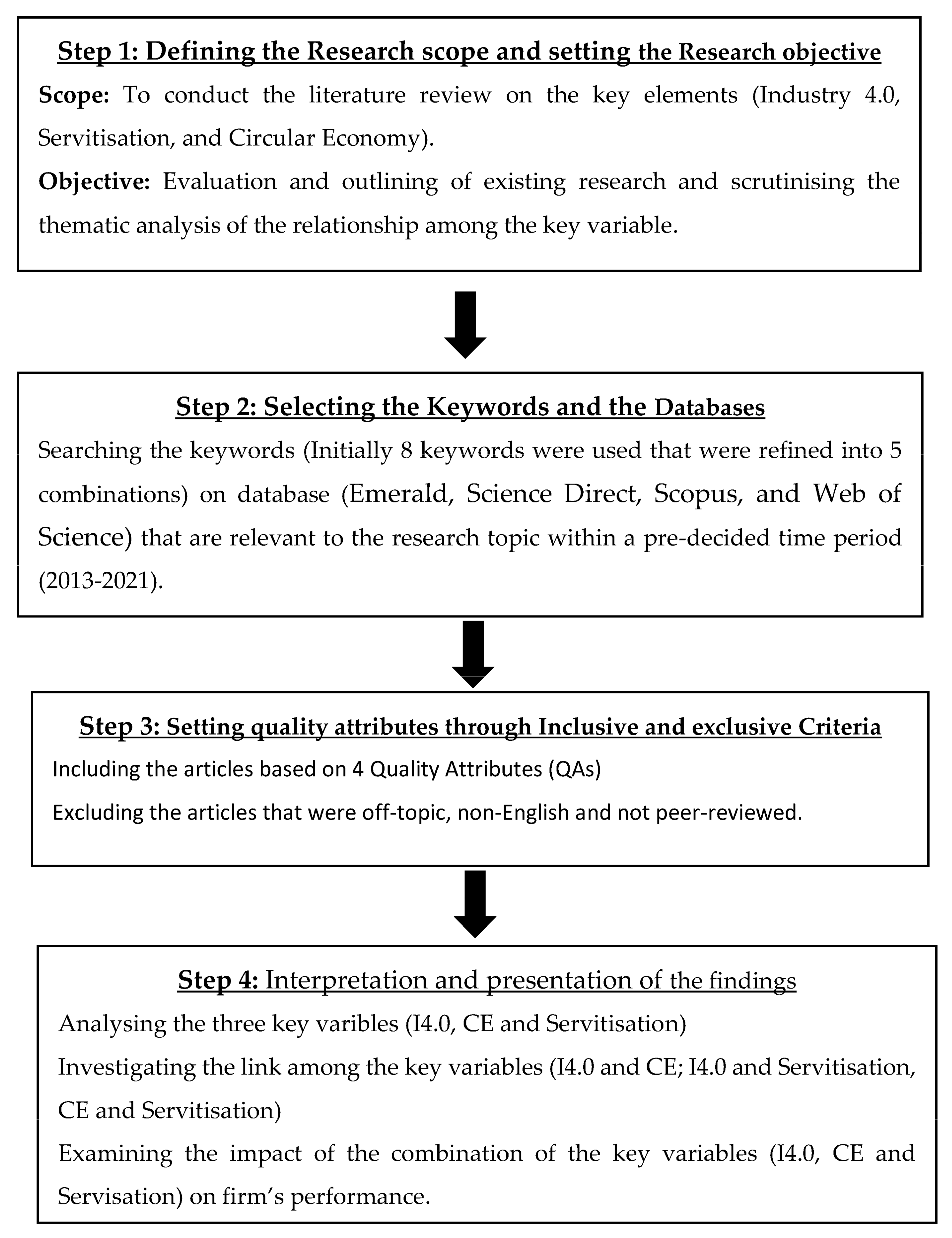

2. Research Methodology

2.1. Steps of Systematic Literature Review

- Empirical research papers in the business and management discipline.

- Multidisciplinary empirical papers on I4.0, CE, and servitisation, especially business and management discipline (including supply-chain management).

- Papers only selected from peer-reviewed scientific journals published in English.

- Non-academic papers such as white papers, industry magazine papers, and personal blogs were excluded.

- Articles with at least one keyword (I4.0 or/and servitisation or/and CE) in the title or abstract were selected to ensure relevance.

- Duplicates and papers published outside the specified period (from 2013 to the first quarter of 2021) were excluded.

- QA1: Do the selected papers discuss any I4.0 technologies or/and servitisation or/and CE or CEBM?

- QA2: Does the selected paper related to the key variables (I4.0, CE, and servitisation)?

- QA3: Does the selected paper discuss the relationship among the key variables (I4.0, CE, and servitisation)?

- QA4: Do the selected paper findings, results, and conclusion correspond to our research domain?

2.2. Methodology Process

2.2.1. Analysis Process

- Keyword analysis

- Descriptive analysis

- Methodology analysis

2.2.2. Keyword Analysis

2.2.3. Descriptive Analysis

2.2.4. Methodology Analysis

3. Results

3.1. Key Variables

3.1.1. Industry 4.0

3.1.2. Servitisation

3.1.3. Circular Economy

3.2. Relationship Among the Three Key Variables

3.2.1. Linking I4.0 and Servitisation

3.2.2. Linking I4.0 and CE

| I4.0 and CE References | Life-Cycle Management | Stakeholders Perspective | Business Model | Competitive Advantage | Value Chain | Supply-Chain Management | Strategy | Product Development/Design | Innovation | Reduce Waste | Resource Efficiency | Recycle | Recover | Reuse | Transformation |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [9] | x | x | x | x | |||||||||||

| [14] | x | x | |||||||||||||

| [16] | x | x | x | x | |||||||||||

| [36] | x | x | x | ||||||||||||

| [49] | x | x | |||||||||||||

| [52] | x | x | x | ||||||||||||

| [69] | x | x | x | x | |||||||||||

| [75] | x | ||||||||||||||

| [79] | x | x | |||||||||||||

| [111] | x | x | |||||||||||||

| [119] | x | x | x | x | x | x | x | x | |||||||

| [121] | x | x | x | ||||||||||||

| [122] | x | x | |||||||||||||

| [123] | x | ||||||||||||||

| [124] | x | x | x |

3.2.3. Linking Servitisation and CE

| Servitisation and CE References | Life-Cycle Management | Stakeholders Perspective | Business Model | Differentiation | Competitive Advantage | Value Chain | Supply-Chain Management | Strategy | Product Development | Innovation | Smart Services | Reduce Waste | Resource Efficiency | Smart Manufacturing |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [13] | x | x | x | x | ||||||||||

| [40] | x | x | x | x | ||||||||||

| [55] | x | x | x | |||||||||||

| [58] | x | x | x | |||||||||||

| [60] | x | x | ||||||||||||

| [64] | x | x | x | x | ||||||||||

| [66] | x | x | x | x | ||||||||||

| [70] | x | x | x | x | x | |||||||||

| [77] | x | x | x | x | x | |||||||||

| [133] | x | x | ||||||||||||

| [87] | x | x | ||||||||||||

| [88] | x | x | ||||||||||||

| [134] | x | x | x | x | ||||||||||

| [129] | x | x | x | |||||||||||

| [132] | x | x | x |

3.3. Impact on the Firm’s Performance

- Operational Performance

- Financial Performance

3.3.1. Operational Performance

- Business Model

- Value Domain

- Supply Chain Management

3.3.2. Financial Performance

- Impact on Revenue stream

- Impact on Growth

- Impact on Profitability

| Impact on Firm’s Performance References | Main Variables Used in the Study | Financial Performance | Operational Performance | Legal/Regulatory Policies | Environmental Performance | Social Performance |

|---|---|---|---|---|---|---|

| [1] | Servitisation+I4.0 | x | x | |||

| [10] | Servitisation+I4.0 | x | x | |||

| [14] | CE+I4.0 | x | ||||

| [21] | CE+I4.0 | x | ||||

| [40] | Servitisation+I4.0+CE | x | x | |||

| [49] | Servitisation+I4.0 | x | ||||

| [52] | CE+I4.0 | x | ||||

| [61] | Servitisation+CE | x | x | |||

| [62] | Servitisation+I4.0 | x | ||||

| [65] | Servitisation+I4.0+CE | x | x | |||

| [77] | Servitisation+I4.0+CE | x | ||||

| [78] | CE+I4.0 | x | ||||

| [170] | CE+I4.0 | x | ||||

| [88] | Servitisation+CE | x | x | |||

| [122] | CE+I4.0 | x | x | |||

| [165] | CE+I4.0 | x | x | x | ||

| [139] | CE+I4.0 | x | x | x | ||

| [129] | Servitisation+CE | x | x | |||

| [171] | CE+I4.0 | x | x | |||

| [172] | CE+I4.0 | x |

4. Conclusions and Future Recommendations

- This SLR has offered a thorough review from the business and management context to provide a deeper insight into how well I4.0 supports CE and servitisation. Since I4.0, servitisation and CE have become the most debated topics [9] in the last decade. This study provides a comprehensive review of servitisation that led to a more circular supply chain [113] from the perspective of the firms and indicated what role I4.0 played in enabling this transformation [85,93,173].

- It is evident from the analysis presented in this study that majority of the authors agree that firms should systematically adopt I4.0 technologies as they support CE to create value through servitisation. However, there is still a lack of practical implications to validate theoretical knowledge [9,55,85,174]. Thus, more empirical evidence is required regarding the reconfiguration of the BM [12,56,104], principally in terms of capturing the value through innovation [58,65,98,107], setting the strategy based on circularity [80,101,133], offering smart-product through smart-services, and managing the supply-chain network [38,124].

- Businesses are frequently pushed to experiment with innovative BMs [56] to capture unique value propositions while curbing operational costs [10,14,15,109]. The trend from the analysis of this study reveals that most of the servitisation literature discusses this from a functional perspective (see Table 6) [14,56]. Servitisation is seen as a path that enhances the downstream opportunities by providing autonomous services to their customers [1,62]

- This study adds to current knowledge since it assesses that I4.0 can play in solidifying the sustainable global competitiveness of a firm [16] through servitisation [9,75]. Hence, there is a need for future researchers to investigate factors that will enable firms to take advantage of the opportunities which accompany I4.0 and project strategies to overcome the barriers associated with this transition [52,86,151].

- This study suggests that many uncertainties and risks occur during the transformation phase [1,55]. To eradicate these uncertainties, [119], we propose four methods that can transform these challenges into opportunities, i.e., the reconfiguration of the revenue model, external environment, customer relationship, and the optimising of cost structures. The journal papers used for this analysis are mostly literature reviews or case-studies. Thus, generalisation is challenging to achieve. Consequently, future researchers are instructed to conduct a longitudinal investigation using a mixed-method approach to run a detailed assessment of this venture’s financial, economic, and social aspects [12,40,44,106].

- The finding of this SLR indicates that the relationship between the key variables of this study is expected to impact firms’ performance [96] positively. Adopting I4.0 technologies to business and manufacturing models enables sustainability, energy, and resource efficiency while enhancing performance efficacy and offering smart products through smart services. This integration will eventually lead to a market shift [32,41,89] with enhanced management and production capability [12,64,71,157]. Therefore, perspective presented in this study can be used as a baseline by future researchers to investigate the hidden gems in this venture and explore innovative strategies from its integration. This paper presented the literature that focuses on large enterprises from developed countries using generic CE practices. Therefore, future research is recommended to investigate the impact of a specific I4.0 technology when firms adopt servitisation BMs surrounding an explicit CE practice.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rymaszewska, A.; Helo, P.; Gunasekaran, A. IoT powered servitization of manufacturing—An exploratory case study. Int. J. Prod. Econ. 2017, 192, 92–105. [Google Scholar] [CrossRef]

- Kohtamäki, M.; Parida, V.; Oghazi, P.; Gebauer, H.; Baines, T. Digital servitization business models in ecosystems: A theory of the firm. J. Bus. Res. 2019, 104, 380–392. [Google Scholar] [CrossRef]

- Majeed, A.; Zhang, Y.; Ren, S.; Lv, J.; Peng, T.; Waqar, S.; Yin, E. A big data-driven framework for sustainable and smart additive manufacturing. Robot. Comput. Integr. Manuf. 2021, 67, 102026. [Google Scholar] [CrossRef]

- Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. The role of digital technologies to overcome Circular Economy challenges in PSS Business Models: An exploratory case study. Procedia CIRP 2018, 73, 216–221. [Google Scholar] [CrossRef]

- Schröder, P.; Lemille, A.; Desmond, P. Making the circular economy work for human development. Resour. Conserv. Recycl. 2020, 156, 104686. [Google Scholar] [CrossRef]

- Kiel, D.; Arnold, C.; Voigt, K.-I. The influence of the Industrial Internet of Things on business models of established manufacturing companies—A business-level perspective. Technovation 2017, 68, 4–19. [Google Scholar] [CrossRef]

- Davies, I.A.; Doherty, B. Balancing a Hybrid Business Model: The Search for Equilibrium at Cafédirect. J. Bus. Ethics 2018, 157, 1043–1066. [Google Scholar] [CrossRef] [Green Version]

- Rosa, P.; Sassanelli, C.; Urbinati, A.; Chiaroni, D.; Terzi, S. Assessing relations between Circular Economy and Industry 4.0: A systematic literature review. Int. J. Prod. Res. 2019, 58, 1662–1687. [Google Scholar] [CrossRef] [Green Version]

- Shihundla, T.B.; Mpofu, K.; Adenuga, O.T. Integrating Product-Service Systems into the manufacturing industry: Industry 4.0 perspectives. Procedia CIRP 2019, 83, 8–13. [Google Scholar] [CrossRef]

- Schroeder, P.; Anggraeni, K.; Weber, U. The Relevance of Circular Economy Practices to the Sustainable Development Goals. J. Ind. Ecol. 2019, 23, 77–95. [Google Scholar] [CrossRef] [Green Version]

- Kohtamäki, M.; Parida, V.; Patel, P.C.; Gebauer, H. The relationship between digitalization and servitization: The role of servitization in capturing the financial potential of digitalization. Technol. Forecast. Soc. Chang. 2020, 151, 119804. [Google Scholar] [CrossRef]

- Lightfoot, H.; Baines, T.S.; Smart, P. The servitization of manufacturing. Int. J. Oper. Prod. Manag. 2013, 33, 1408–1434. [Google Scholar] [CrossRef] [Green Version]

- Rehman, M.H.U.; Chang, V.; Batool, A.; Wah, T.Y. Big data reduction framework for value creation in sustainable enterprises. Int. J. Inf. Manag. 2016, 36, 917–928. [Google Scholar] [CrossRef] [Green Version]

- Dev, N.K.; Shankar, R.; Qaiser, F.H. Industry 4.0 and circular economy: Operational excellence for sustainable reverse supply chain performance. Resour. Conserv. Recycl. 2020, 153, 104583. [Google Scholar] [CrossRef]

- Weking, J.; Stöcker, M.; Kowalkiewicz, M.; Böhm, M.; Krcmar, H. Leveraging industry 4.0—A business model pattern framework. Int. J. Prod. Econ. 2020, 225, 107588. [Google Scholar] [CrossRef]

- Lieder, M.; Asif, F.M.A.; Rashid, A.; Mihelič, A.; Kotnik, S. Towards circular economy implementation in manufacturing systems using a multi-method simulation approach to link design and business strategy. Int. J. Adv. Manuf. Technol. 2017, 93, 1953–1970. [Google Scholar] [CrossRef] [Green Version]

- Santamaría, L.; Nieto, M.J.; Miles, I. Service innovation in manufacturing firms: Evidence from Spain. Technovation 2012, 32, 144–155. [Google Scholar] [CrossRef] [Green Version]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A Glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Stock, T.; Obenaus, M.; Kunz, S.; Kohl, H. Industry 4.0 as enabler for a sustainable development: A qualitative assessment of its ecological and social potential. Process. Saf. Environ. Prot. 2018, 118, 254–267. [Google Scholar] [CrossRef]

- Neely, A. Exploring the financial consequences of the servitization of manufacturing. Oper. Manag. Res. 2008, 1, 103–118. [Google Scholar] [CrossRef] [Green Version]

- Romero, D.; Rossi, M. Towards Circular Lean Product-Service Systems. Procedia CIRP 2017, 64, 13–18. [Google Scholar] [CrossRef] [Green Version]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Kunisch, S.; Menz, M.; Bartunek, J.M.; Cardinal, L.B.; Denyer, D. Feature Topic at Organizational Research Methods. Organ. Res. Methods 2018, 21, 519–523. [Google Scholar] [CrossRef] [Green Version]

- Kitchenham, B.; Brereton, O.P.; Budgen, D.; Turner, M.; Bailey, J.; Linkman, S. Systematic literature reviews in software engineering—A systematic literature review. Inf. Softw. Technol. 2009, 51, 7–15. [Google Scholar] [CrossRef]

- Fisch, C.; Block, J. Six tips for your (systematic) literature review in business and management research. Manag. Rev. Q. 2018, 68, 103–106. [Google Scholar] [CrossRef] [Green Version]

- Okorie, O.; Salonitis, K.; Charnley, F.; Moreno, M.; Turner, C.; Tiwari, A. Digitisation and the Circular Economy: A Review of Current Research and Future Trends. Energies 2018, 11, 3009. [Google Scholar] [CrossRef] [Green Version]

- Anastasiades, K.; Blom, J.; Buyle, M.; Audenaert, A. Translating the circular economy to bridge construction: Lessons learnt from a critical literature review. Renew. Sustain. Energy Rev. 2020, 117, 109522. [Google Scholar] [CrossRef]

- Agrawal, V.; Atasu, A.; Ülkü, S. Leasing, Modularity, and the Circular Economy. Manag. Sci. 2021. [Google Scholar] [CrossRef]

- Demirkan, H.; Bess, C.; Spohrer, J.; Rayes, A.; Allen, D.; Moghaddam, Y. Innovations with smart service systems: Analytics, big data, cognitive assistance, and the internet of everything. Commun. Assoc. Inf. Syst. 2015, 37, 35. [Google Scholar] [CrossRef]

- Mourtzis, D.; Zervas, E.; Boli, N.; Pittaro, P. A cloud-based resource planning tool for the production and installation of industrial product service systems (IPSS). Int. J. Adv. Manuf. Technol. 2020, 106, 4945–4963. [Google Scholar] [CrossRef]

- Camacho-Otero, J.; Boks, C.; Pettersen, I.N. Consumption in the Circular Economy: A Literature Review. Sustainability 2018, 10, 2758. [Google Scholar] [CrossRef] [Green Version]

- Frank, A.G.; Mendes, G.; Ayala, N.F.; Ghezzi, A. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technol. Forecast. Soc. Chang. 2019, 141, 341–351. [Google Scholar] [CrossRef]

- Matthyssens, P. Reconceptualizing value innovation for Industry 4.0 and the Industrial Internet of Things. J. Bus. Ind. Mark. 2019, 34, 1203–1209. [Google Scholar] [CrossRef]

- Beier, G.; Niehoff, S.; Xue, B. More Sustainability in Industry through Industrial Internet of Things? Appl. Sci. 2018, 8, 219. [Google Scholar] [CrossRef]

- Bag, S.; Pretorius, J.H.C. Relationships between industry 4.0, sustainable manufacturing and circular economy: Proposal of a research framework. Int. J. Organ. Anal. 2020. [Google Scholar] [CrossRef]

- Sony, M. Design of cyber physical system architecture for industry 4.0 through lean six sigma: Conceptual foundations and research issues. Prod. Manuf. Res. 2020, 8, 158–181. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; Fiorini, P.D.C.; Wong, C.W.; Jugend, D.; Jabbour, A.B.L.D.S.; Seles, B.M.R.P.; Pinheiro, M.A.P.; da Silva, H.M.R. First-mover firms in the transition towards the sharing economy in metallic natural resource-intensive industries: Implications for the circular economy and emerging industry 4.0 technologies. Resour. Policy 2020, 66, 101596. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. A review of Internet of Things (IoT) embedded sustainable supply chain for industry 4.0 requirements. Comput. Ind. Eng. 2019, 127, 925–953. [Google Scholar] [CrossRef]

- Martín, M.G.; Álvarez, A.P.; Ordieres-Meré, J.; Villalba-Díez, J.; Morales-Alonso, G. New Business Models from Prescriptive Maintenance Strategies Aligned with Sustainable Development Goals. Sustainability 2021, 13, 216. [Google Scholar] [CrossRef]

- Stock, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar] [CrossRef] [Green Version]

- Bag, S.; Gupta, S.; Luo, Z. Examining the role of logistics 4.0 enabled dynamic capabilities on firm performance. Int. J. Logist. Manag. 2020, 31, 607–628. [Google Scholar] [CrossRef]

- Rajput, S.; Singh, S.P. Industry 4.0—Challenges to implement circular economy. Benchmarking Int. J. 2021, 28, 1717–1739. [Google Scholar] [CrossRef]

- Wang, G.; Gunasekaran, A.; Ngai, E.W.; Papadopoulos, T. Big data analytics in logistics and supply chain management: Certain investigations for research and applications. Int. J. Prod. Econ. 2016, 176, 98–110. [Google Scholar] [CrossRef]

- Chang, W.; Ellinger, A.E.; Kim, K.K.; Franke, G.R. Supply chain integration and firm financial performance: A meta-analysis of positional advantage mediation and moderating factors. Eur. Manag. J. 2016, 34, 282–295. [Google Scholar] [CrossRef]

- Pinheiro, M.A.P.; Seles, B.M.R.P.; Fiorini, P.D.C.; Jugend, D.; Jabbour, A.B.L.D.S.; Da Silva, H.M.R.; Latan, H. The role of new product development in underpinning the circular economy. A systematic review and integrative framework. Manag. Decis. 2019, 57, 840–862. [Google Scholar] [CrossRef]

- Abdel-Basst, M.; Mohamed, R.; Elhoseny, M. A novel framework to evaluate innovation value proposition for smart product–service systems. Environ. Technol. Innov. 2020, 20, 101036. [Google Scholar] [CrossRef]

- Peker, Y.K.; Rodriguez, X.; Ericsson, J.; Lee, S.J.; Perez, A.J. A Cost Analysis of Internet of Things Sensor Data Storage on Blockchain via Smart Contracts. Electronics 2020, 9, 244. [Google Scholar] [CrossRef] [Green Version]

- Osterrieder, P.; Budde, L.; Friedli, T. The smart factory as a key construct of industry 4.0: A systematic literature review. Int. J. Prod. Econ. 2020, 221, 107476. [Google Scholar] [CrossRef]

- Bag, S.; Gupta, S.; Kumar, S. Industry 4.0 adoption and 10R advance manufacturing capabilities for sustainable development. Int. J. Prod. Econ. 2021, 231, 107844. [Google Scholar] [CrossRef]

- Li, A.Q.; Found, P. Towards sustainability: PSS, digital technology and value co-creation. In Proceedings of the 9th CIRP IPSS Conference: Circular Perspectives on PSS, Copenhagen, Denmark, 19–21 June 2017; pp. 79–84. [Google Scholar]

- Tukker, A. Product services for a resource-efficient and circular economy—A review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Reim, W.; Parida, V.; Sjödin, D.R. Risk management for product-service system operation. Int. J. Oper. Prod. Manag. 2016, 36, 665–686. [Google Scholar] [CrossRef]

- Adel, R.; Wiesner, S.A. Conceptual approach for value driven performance in servitising companies. Int. J. Serv. Oper. Manag. 2015, 21, 504–531. [Google Scholar] [CrossRef]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic Capabilities and Strategic Management. Strateg. Manag. J. 1998, 18, 509–533. [Google Scholar] [CrossRef]

- Witell, L.; Snyder, H.; Gustafsson, A.; Fombelle, P.; Kristensson, P. Defining service innovation: A review and synthesis. J. Bus. Res. 2016, 69, 2863–2872. [Google Scholar] [CrossRef] [Green Version]

- Pakurár, M.; Haddad, H.; Nagy, J.; Popp, J.; Oláh, J. The Service Quality Dimensions that Affect Customer Satisfaction in the Jordanian Banking Sector. Sustainability 2019, 11, 1113. [Google Scholar] [CrossRef] [Green Version]

- Mathieu, V. Product services: From a service supporting the product to a service supporting the client. J. Bus. Ind. Mark. 2001, 16, 39–61. [Google Scholar] [CrossRef]

- Kühl, C.; Bourlakis, M.; Aktas, E.; Skipworth, H. How does servitisation affect supply chain circularity?—A systematic literature review. J. Enterp. Inf. Manag. 2019, 33, 703–728. [Google Scholar] [CrossRef] [Green Version]

- Leite, A.F.D.M.; Canciglieri, M.B.; Goh, Y.M.; Monfared, R.P.; Loures, E.D.F.R.; Canciglieri, O. Current Issues in the Flexibilization of Smart Product-Service Systems and their Impacts in Industry 4.0. Procedia Manuf. 2020, 51, 1153–1157. [Google Scholar] [CrossRef]

- Frederiksen, T.; Pieroni, M.P.P.; Pigosso, D.; McAloone, T. Strategic Development of Product-Service Systems (PSS) through Archetype Assessment. Sustainability 2021, 13, 2592. [Google Scholar] [CrossRef]

- Bustinza, O.F.; Gomes, E.; Vendrell-Herrero, F.; Baines, T. Product-service innovation and performance: The role of collaborative partnerships and R&D intensity. R&D Manag. 2019, 49, 33–45. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z.; Chen, C.-H.; Zheng, P. A data-driven reversible framework for achieving Sustainable Smart product-service systems. J. Clean. Prod. 2021, 279, 123618. [Google Scholar] [CrossRef]

- Reim, W.; Sjödin, D.R.; Parida, V. Servitization of global service network actors—A contingency framework for matching challenges and strategies in service transition. J. Bus. Res. 2019, 104, 461–471. [Google Scholar] [CrossRef]

- Ghisetti, C.; Montresor, S. On the adoption of circular economy practices by small and medium-size enterprises (SMEs): Does “financing-as-usual” still matter? J. Evol. Econ. 2019, 30, 559–586. [Google Scholar] [CrossRef]

- Rossi, J.; Bianchini, A.; Guarnieri, P. Circular Economy Model Enhanced by Intelligent Assets from Industry 4.0: The Proposition of an Innovative Tool to Analyze Case Studies. Sustainability 2020, 12, 7147. [Google Scholar] [CrossRef]

- Esmaeilian, B.; Sarkis, J.; Lewis, K.; Behdad, S. Blockchain for the future of sustainable supply chain management in Industry 4.0. Resour. Conserv. Recycl. 2020, 163, 105064. [Google Scholar] [CrossRef]

- Kristensen, H.S.; Remmen, A. A framework for sustainable value propositions in product-service systems. J. Clean. Prod. 2019, 223, 25–35. [Google Scholar] [CrossRef]

- Copani, G.; Behnam, S. Remanufacturing with upgrade PSS for new sustainable business models. CIRP J. Manuf. Sci. Technol. 2020, 29, 245–256. [Google Scholar] [CrossRef]

- Jabbour, A.B.L.D.S.; Ndubisi, N.O.; Seles, B.M.R.P. Sustainable development in Asian manufacturing SMEs: Progress and directions. Int. J. Prod. Econ. 2020, 225, 107567. [Google Scholar] [CrossRef]

- Kozlenkova, I.V.; Samaha, S.A.; Palmatier, R.W. Resource-based theory in marketing. J. Acad. Mark. Sci. 2014, 42, 1–21. [Google Scholar] [CrossRef]

- Spanos, Y.E.; Lioukas, S. An examination into the causal logic of rent generation: Contrasting Porter’s competitive strategy framework and the resource-based perspective. Strat. Manag. J. 2001, 22, 907–934. [Google Scholar] [CrossRef]

- Chuang, S.-H.; Lin, H.-N. Co-creating e-service innovations: Theory, practice, and impact on firm performance. Int. J. Inf. Manag. 2015, 35, 277–291. [Google Scholar] [CrossRef]

- Zancul, E.D.S.; Takey, S.M.; Barquet, A.P.B.; Kuwabara, L.H.; Miguel, P.A.C.; Rozenfeld, H. Business process support for IoT based product-service systems (PSS). Bus. Process. Manag. J. 2016, 22. [Google Scholar] [CrossRef]

- Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. Exploring How Usage-Focused Business Models Enable Circular Economy through Digital Technologies. Sustainability 2018, 10, 639. [Google Scholar] [CrossRef] [Green Version]

- Bal, A.; Badurdeen, F. A Business Model to Implement Closed-loop Material Flow in IoT-enabled Environments. Procedia Manuf. 2019, 38, 1284–1291. [Google Scholar] [CrossRef]

- Seddon, J.J.; Currie, W.L. A model for unpacking big data analytics in high-frequency trading. J. Bus. Res. 2017, 70, 300–307. [Google Scholar] [CrossRef]

- Tavares-Lehmann, A.T.; Varum, C. Industry 4.0 and Sustainability: A Bibliometric Literature Review. Sustainability 2021, 13, 3493. [Google Scholar] [CrossRef]

- Tuttokmaǧi, Ö.; Kaygusuz, A. Smart Grids and Industry 4.0. In 2018 International Conference on Artificial Intelligence and Data Processing (IDAP); IEEE: New York, NY, USA, 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Michelini, G.; Moraes, R.N.; Cunha, R.N.; Costa, J.M.; Ometto, A.R. From Linear to Circular Economy: PSS Conducting the Transition. Procedia CIRP 2017, 64, 2–6. [Google Scholar] [CrossRef]

- Lyons, A.C.; Um, J.; Sharifi, H. Product variety, customisation and business process performance: A mixed-methods approach to understanding their relationships. Int. J. Prod. Econ. 2020, 221, 107469. [Google Scholar] [CrossRef]

- Sousa-Zomer, T.; Miguel, P.C. Product-service Systems as a Promising Approach to Sustainability: Exploring the Sustainable Aspects of a PSS in Brazil. Procedia CIRP 2015, 30, 138–143. [Google Scholar] [CrossRef]

- Machado, C.G.; Winroth, M.P.; Da Silva, E.H.D.R. Sustainable manufacturing in Industry 4.0: An emerging research agenda. Int. J. Prod. Res. 2020, 58, 1462–1484. [Google Scholar] [CrossRef]

- Lin, K.C.; Shyu, J.Z.; Ding, K. A Cross-Strait Comparison of Innovation Policy under Industry 4.0 and Sustainability Development Transition. Sustainability 2017, 9, 786. [Google Scholar] [CrossRef]

- Ozkan-Ozen, Y.D.; Kazancoglu, Y.; Mangla, S.K. Synchronized Barriers for Circular Supply Chains In Industry 3.5/Industry 4.0 Transition For Sustainable Resource Management. Resour. Conserv. Recycl. 2020, 161, 104986. [Google Scholar] [CrossRef]

- Hernandez, R.J. Sustainable Product-Service Systems and Circular Economies. Sustainability 2019, 11, 5383. [Google Scholar] [CrossRef] [Green Version]

- Ramsheva, Y.; Moalem, R.; Milios, L. Realizing a Circular Concrete Industry in Denmark through an Integrated Product, Service and System Perspective. Sustainability 2020, 12, 9423. [Google Scholar] [CrossRef]

- D’Agostin, A.; de Medeiros, J.F.; Vidor, G.; Zulpo, M.; Moretto, C.F. Drivers and barriers for the adoption of use-oriented product-service systems: A study with young consumers in medium and small cities. Sustain. Prod. Consum. 2020, 21, 92–103. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef] [Green Version]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Sajjad, A.; Eweje, G.; Tappin, D. Sustainable Supply Chain Management: Motivators and Barriers. Bus. Strateg. Environ. 2015, 24, 643–655. [Google Scholar] [CrossRef]

- Gangi, F.; Daniele, L.M.; Varrone, N. How do corporate environmental policy and corporate reputation affect risk-adjusted financial performance? Bus. Strat. Environ. 2020, 29, 1975–1991. [Google Scholar] [CrossRef]

- Côrte-Real, N.; Ruivo, P.; Oliveira, T.; Popovič, A. Unlocking the drivers of big data analytics value in firms. J. Bus. Res. 2019, 97, 160–173. [Google Scholar] [CrossRef]

- Shrivastava, M.; Tamvada, J.P. Which green matters for whom? Greening and firm performance across age and size distribution of firms. Small Bus. Econ. 2017, 52, 951–968. [Google Scholar] [CrossRef] [Green Version]

- Da Costa Fernandes, S.; Martins, L.D.; Campese, C.; Rozenfeld, H. Representing the Value Proposition of Product-Service Systems (PSS) in a Value-Based Perspective. In Proceedings of the Design Society: International Conference on Engineering Design; Cambridge University Press: Cambridge, UK, 2019; pp. 3091–3100. [Google Scholar] [CrossRef] [Green Version]

- Giner, B.; Merello, P.; Pardo, F. Assessing the impact of operating lease capitalization with dynamic Monte Carlo simulation. J. Bus. Res. 2019, 101, 836–845. [Google Scholar] [CrossRef]

- Rangkuti, M.M. The Effect Of Intellectual Capital And Financial Performance on Firm Value With Return on Investment as a Modeling Variable In The Mining Industry Listed On Indonesia Stock Exchange. Int. J. Public Budg. Account. Financ. 2020, 2, 1–11. [Google Scholar]

- Scheel, C.; Aguiñaga, E.; Bello, B. Decoupling Economic Development from the Consumption of Finite Resources Using Circular Economy. A Model for Developing Countries. Sustainability 2020, 12, 1291. [Google Scholar] [CrossRef] [Green Version]

- Demirel, P.; Danisman, G.O. Eco-innovation and firm growth in the circular economy: Evidence from European small- and medium-sized enterprises. Bus. Strat. Environ. 2019, 28, 1608–1618. [Google Scholar] [CrossRef]

- Sehnem, S.; Vazquez-Brust, D.; Pereira, S.C.F.; Campos, L.M. Circular economy: Benefits, impacts and overlapping. Supply Chain Manag. Int. J. 2019, 24, 784–804. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Govindan, K.; Cheng, T.; Mishra, N.; Shukla, N. Big data analytics and application for logistics and supply chain management. Transp. Res. Part E Logist. Transp. Rev. 2018, 114, 343–349. [Google Scholar] [CrossRef]

- Rizos, V.; Behrens, A.; Van Der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Flamos, A.; Rinaldi, R.; Papadelis, S.; Hirschnitz-Garbers, M.; et al. Implementation of Circular Economy Business Models by Small and Medium-Sized Enterprises (SMEs): Barriers and Enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef] [Green Version]

- Ormazabal, M.; Prieto-Sandoval, V.; Puga-Leal, R.; Jaca, C. Circular Economy in Spanish SMEs: Challenges and opportunities. J. Clean. Prod. 2018, 185, 157–167. [Google Scholar] [CrossRef]

- Nakata, C.; Bahadir, S.C. Spotlight on design: Strengthening innovation for more product and service sales. J. Bus. Strat. 2020, 42, 83–90. [Google Scholar] [CrossRef]

- Day, S. Drivers and Barriers to Product-Service System Consumer Adoption in a Fashion Subscription Case. Ph.D. Thesis, University of Warwick, Coventry, UK, 2019. [Google Scholar]

- Bag, S.; Telukdarie, A.; Pretorius, J.; Gupta, S. Industry 4.0 and supply chain sustainability: Framework and future research directions. Benchmarking Int. J. 2018. [Google Scholar] [CrossRef]

- D’Amato, D.; Veijonaho, S.; Toppinen, A. Towards sustainability? Forest-based circular bioeconomy business models in Finnish SMEs. For. Policy Econ. 2020, 110, 101848. [Google Scholar] [CrossRef]

- Smeets, R. Circular Revenue Models in the Civil and Non-Residential Building Sector. An Investigation of Existing Barriers and the Influence of Product’s Functional Lifecycle on Their Adoption. Master’s Thesis, Utrecht University, Utrecht, The Netherlands, 2019. [Google Scholar]

- Tseng, M.-L.; Chiu, A.S.; Liu, G.; Jantaralolica, T. Circular economy enables sustainable consumption and production in multi-level supply chain system. Resour. Conserv. Recycl. 2020, 154, 104601. [Google Scholar] [CrossRef]

- Werning, J.P.; Spinler, S. Transition to circular economy on firm level: Barrier identification and prioritization along the value chain. J. Clean. Prod. 2020, 245, 118609. [Google Scholar] [CrossRef]

- Widmer, T. Assessing the Strengths and Limitations of Business Model Frameworks for Product Service Systems in the Circular Economy: Why Canvas and Co. Are Not Enough. Master’s Thesis, Stockholm University, Stockholm, Sweden, 2016. [Google Scholar] [CrossRef]

- Boer, D.; Segarra, M.; Fernández, A.I.; Vallès, M.; Mateu, C.; Cabeza, L.F. Approach for the analysis of TES technologies aiming towards a circular economy: Case study of building-like cubicles. Renew. Energy 2020, 150, 589–597. [Google Scholar] [CrossRef]

- Lüdeke-Freund, F.; Gold, S.; Bocken, N.M.P. A Review and Typology of Circular Economy Business Model Patterns. J. Ind. Ecol. 2018, 23, 36–61. [Google Scholar] [CrossRef] [Green Version]

- Oghazi, P.; Mostaghel, R. Circular Business Model Challenges and Lessons Learned—An Industrial Perspective. Sustainability 2018, 10, 739. [Google Scholar] [CrossRef] [Green Version]

- Agyemang, M.; Kusi-Sarpong, S.; Khan, S.A.; Mani, V.; Rehman, S.T.; Kusi-Sarpong, H. Drivers and barriers to circular economy implementation. Manag. Decis. 2019, 57, 971–994. [Google Scholar] [CrossRef]

- Heyes, G.; Sharmina, M.; Mendoza, J.M.F.; Schmid, A.G.; Azapagic, A. Developing and implementing circular economy business models in service-oriented technology companies. J. Clean. Prod. 2018, 177, 621–632. [Google Scholar] [CrossRef]

- Bag, S.; Gupta, S.; Kumar, S.; Sivarajah, U. Role of technological dimensions of green supply chain management practices on firm performance. J. Enterp. Inf. Manag. 2020, 34, 1–27. [Google Scholar] [CrossRef]

- Li, Y.; Dai, J.; Cui, L. The impact of digital technologies on economic and environmental performance in the context of industry 4.0: A moderated mediation model. Int. J. Prod. Econ. 2020, 229, 107777. [Google Scholar] [CrossRef]

- Gupta, S.; Chen, H.; Hazen, B.T.; Kaur, S.; Gonzalez, E.D.R.S. Circular economy and big data analytics: A stakeholder perspective. Technol. Forecast. Soc. Chang. 2019, 144, 466–474. [Google Scholar] [CrossRef]

- Ostermann, C.M.; Nascimento, L.D.S.; Da Silva, A.R. Business Model Innovation for Circular Economy: A Fashion Industry Perspective. In Proceedings of the XXI ENGEMA Conference, Sao Paolo, Brasil, 4–6 December 2019. [Google Scholar]

- Hongwei, Z.; Stuart, M.E.; Yang, L.W.; Richard, W.Y. Computing Handbook: Information Systems and Information Technology, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Piccarozzi, M.; Aquilani, B.; Gatti, C. Industry 4.0 in Management Studies: A Systematic Literature Review. Sustainability 2018, 10, 3821. [Google Scholar] [CrossRef] [Green Version]

- Ogbuke, N.J.; Yusuf, Y.Y.; Dharma, K.; Mercangoz, B.A. Big data supply chain analytics: Ethical, privacy and security challenges posed to business, industries and society. Prod. Plan. Control. 2020, 1–15. [Google Scholar] [CrossRef]

- Kjaer, L.L.; Pigosso, D.C.A.; Niero, M.; Bech, N.M.; McAloone, T.C. Product/Service-Systems for a Circular Economy: The Route to Decoupling Economic Growth from Resource Consumption? J. Ind. Ecol. 2019, 23, 22–35. [Google Scholar] [CrossRef] [Green Version]

- Pal, R.; Shen, B.; Sandberg, E. Circular fashion supply chain management: Exploring impediments and prescribing future research agenda. J. Fash. Mark. Manag. Int. J. 2019, 23, 298–307. [Google Scholar] [CrossRef]

- Ik, M.; Azeez, A.A. Organisational Green Behavioural Change: The Role of Change Management. Int. J. Entrep. Knowl. 2020, 8, 34–48. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; Jabbour, A.B.L.D.S.; Sarkis, J.; Filho, M.G. Unlocking the circular economy through new business models based on large-scale data: An integrative framework and research agenda. Technol. Forecast. Soc. Chang. 2019, 144, 546–552. [Google Scholar] [CrossRef]

- Kohtamäki, M.; Partanen, J. Co-creating value from knowledge-intensive business services in manufacturing firms: The moderating role of relationship learning in supplier–customer interactions. J. Bus. Res. 2016, 69, 2498–2506. [Google Scholar] [CrossRef]

- Nastasiea, M.; Mironeasa, C. Key Performance Indicators in Small and Medium Sized Enterprises. Total Qual. Manag. 2015, 1, 46–53. [Google Scholar]

- Hartley, K.; van Santen, R.; Kirchherr, J. Policies for transitioning towards a circular economy: Expectations from the European Union (EU). Resour. Conserv. Recycl. 2020, 155, 104634. [Google Scholar] [CrossRef]

- Velte, P.; Stawinoga, M.; Lueg, R. Carbon performance and disclosure: A systematic review of governance-related determinants and financial consequences. J. Clean. Prod. 2020, 254, 120063. [Google Scholar] [CrossRef]

- Van Stijn, A.; Gruis, V. Towards a circular built environment. Smart Sustain. Built Environ. 2020, 9, 635–653. [Google Scholar] [CrossRef]

- Ciano, M.P.; Dallasega, P.; Orzes, G.; Rossi, T. One-to-one relationships between Industry 4.0 technologies and Lean Production techniques: A multiple case study. Int. J. Prod. Res. 2021, 59, 1386–1410. [Google Scholar] [CrossRef]

- Di Nardo, M.; Clericuzio, M.; Murino, T.; Sepe, C. An Economic Order Quantity Stochastic Dynamic Optimization Model in a Logistic 4.0 Environment. Sustainability 2020, 12, 4075. [Google Scholar] [CrossRef]

- Danilova, J.; Grant, D.B.; Menachof, D. Investigating SME Participation in the UK Offshore Wind Supply Chain. In 2016 Annual Logistics Research Network (LRN) Conference; CILT UK-The Chartered Institute of Logistics and Transport in the UK: Corby, UK, 2008. [Google Scholar]

- Raja, J.Z.; Frandsena, T.; Kowalkowskibc, C.; Jarmatza, M. Learning to discover value: Value-based pricing and selling capabilities for services and solutions. J. Bus. Res. 2020, 114, 142–159. [Google Scholar] [CrossRef]

- Turunen, T.; Finne, M. The organisational environment’s impact on the servitization of manufacturers. Eur. Manag. J. 2014, 32, 603–615. [Google Scholar] [CrossRef]

- Cainelli, G.; D’Amato, A.; Mazzanti, M. Resource efficient eco-innovations for a circular economy: Evidence from EU firms. Res. Policy 2020, 49, 103827. [Google Scholar] [CrossRef]

- Schenkl, S.A.; Sauer, R.M.; Mörtl, M. A Technology-centered Framework for Product-service Systems. Procedia CIRP 2014, 16, 295–300. [Google Scholar] [CrossRef] [Green Version]

- Bag, S.; Yadav, G.; Dhamija, P.; Kataria, K.K. Key resources for industry 4.0 adoption and its effect on sustainable production and circular economy: An empirical study. J. Clean. Prod. 2021, 281, 125233. [Google Scholar] [CrossRef]

- De Man, J.C.; Strandhagen, J.O. An Industry 4.0 Research Agenda for Sustainable Business Models. Procedia CIRP 2017, 63, 721–726. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Murino, T. Layout and Material Flow Optimization in Digital Factory. Int. J. Simul. Model. 2016, 15, 223–235. [Google Scholar] [CrossRef]

- Pero, M.; Moretto, A.; Bottani, E.; Bigliardi, B. Environmental Collaboration for Sustainability in the Construction Industry: An Exploratory Study in Italy. Sustainability 2017, 9, 125. [Google Scholar] [CrossRef] [Green Version]

- Wang, N.; Ren, S.; Liu, Y.; Yang, M.; Wang, J.; Huisingh, D. An active preventive maintenance approach of complex equipment based on a novel product-service system operation mode. J. Clean. Prod. 2020, 277, 123365. [Google Scholar] [CrossRef]

- Damonte, L.T.; Woodside, A.G. Are lodging revenue cycles leading indicators for shifts in financial well-being? J. Bus. Res. 2021, 129, 465–473. [Google Scholar] [CrossRef]

- Chowdhury, S.; Haftor, D.; Pashkevich, N. Smart Product-Service Systems (Smart PSS) in Industrial Firms: A Literature Review. Procedia CIRP 2018, 73, 26–31. [Google Scholar] [CrossRef]

- Zucchella, A.; Previtali, P. Circular business models for sustainable development: A “waste is food” restorative ecosystem. Bus. Strateg. Environ. 2019, 28, 274–285. [Google Scholar] [CrossRef]

- De Giovanni, P. When feature-based production capabilities challenge operations. Int. J. Oper. Prod. Manag. 2019, 40, 221–242. [Google Scholar] [CrossRef]

- Chen, Z.; Lu, M.; Ming, X.; Zhang, X.; Zhou, T. Explore and evaluate innovative value propositions for smart product service system: A novel graphics-based rough-fuzzy DEMATEL method. J. Clean. Prod. 2020, 243, 118672. [Google Scholar] [CrossRef]

- Ünal, E.; Urbinati, A.; Chiaroni, D. Managerial practices for designing circular economy business models. J. Manuf. Technol. Manag. 2019, 30, 561–589. [Google Scholar] [CrossRef]

- Lee, C.M.J.; Che-Ha, N.; Alwi, S.F.S. Service customer orientation and social sustainability: The case of small medium enterprises. J. Bus. Res. 2021, 122, 751–760. [Google Scholar] [CrossRef]

- Linder, M.; Sarasini, S.; van Loon, P. A Metric for Quantifying Product-Level Circularity. J. Ind. Ecol. 2017, 21, 545–558. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Luo, X.; Kwong, C.K.; Tang, J.; Yu, Y. Return and refund policy for product and core service bundling in the dual-channel supply chain. Int. Trans. Oper. Res. 2017, 26, 223–247. [Google Scholar] [CrossRef]

- Rossi, E.; Bertassini, A.C.; Ferreira, C.D.S.; Amaral, W.A.N.D.; Ometto, A.R. Circular economy indicators for organizations considering sustainability and business models: Plastic, textile and electro-electronic cases. J. Clean. Prod. 2020, 247, 119137. [Google Scholar] [CrossRef]

- Tebaldi, L.; Bigliardi, B.; Bottani, E. Sustainable Supply Chain and Innovation: A Review of the Recent Literature. Sustainability 2018, 10, 3946. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Y.; Azam, S.M.F.; Tham, J. Factors Influencing Enterprise Performance of Small and Medium Size Enterprises (Smes) in Malaysia. Eur. J. Manag. Mark. Stud. 2019, 4, 112–127. [Google Scholar] [CrossRef]

- Brown, R.; Lee, N. Strapped for cash? Funding for UK high growth SMEs since the global financial crisis. J. Bus. Res. 2019, 99, 37–45. [Google Scholar] [CrossRef]

- Dvouletý, O.; Srhoj, S.; Pantea, S. Public SME grants and firm performance in European Union: A systematic review of empirical evidence. Small Bus. Econ. 2020, 57, 1–21. [Google Scholar] [CrossRef]

- Goyal, R. The Question of Economic Choices-Startups: Service Sector vs. Product Sector. Available online: https://economictimes.indiatimes.com/tech/startups/piyush-goyal-asks-indian-investors-to-mentor-support-startups-in-bimstec-region/articleshow/80283699.cms (accessed on 10 December 2020).

- Tykkyläinen, S. Why social enterprises pursue growth? Analysis of threats and opportunities. Soc. Enterp. J. 2019, 15, 376–396. [Google Scholar] [CrossRef]

- Howard, M.; Caldwell, N.; Smith, L.; Maull, R.; Ng, I.C. Servitization and operations management: A service dominant-logic approach. Int. J. Oper. Prod. Manag. 2014, 34, 242–269. [Google Scholar] [CrossRef]

- Gupta, S.; Zeithaml, V. Customer Metrics and Their Impact on Financial Performance. Mark. Sci. 2006, 25, 718–739. [Google Scholar] [CrossRef] [Green Version]

- Sousa-Zomer, T.T.; Magalhães, L.; Zancul, E.; Cauchick-Miguel, P.A. Exploring the challenges for circular business implementation in manufacturing companies: An empirical investigation of a pay-per-use service provider. Resour. Conserv. Recycl. 2018, 135, 3–13. [Google Scholar] [CrossRef]

- Ejsmont, K.; Gladysz, B.; Corti, D.; Castaño, F.; Mohammed, W.M.; Lastra, J.L.M. Towards ’Lean Industry 4.0’—Current trends and future perspectives. Cogent Bus. Manag. 2020, 7, 1781995. [Google Scholar] [CrossRef]

- Bag, S.; Wood, L.C.; Mangla, S.K.; Luthra, S. Procurement 4.0 and its implications on business process performance in a circular economy. Resour. Conserv. Recycl. 2020, 152, 104502. [Google Scholar] [CrossRef]

- Ivanov, D.; Tang, C.S.; Dolgui, A.; Battini, D.; Das, A. Researchers’ perspectives on Industry 4.0: Multi-disciplinary analysis and opportunities for operations management. Int. J. Prod. Res. 2021, 59, 2055–2078. [Google Scholar] [CrossRef]

- Cherry, C.E.; Pidgeon, N.F. Why Is Ownership an Issue? Exploring Factors That Determine Public Acceptance of Product-Service Systems. Sustainability 2018, 10, 2289. [Google Scholar] [CrossRef] [Green Version]

- Matschewsky, J. Effective and Efficient Design and Provision of Product-Service Systems: Challenges, Opportunities, and Solutions. Ph.D. Thesis, Linköping University, Linköping, Sweden, 2019. [Google Scholar]

- Ibarra, D.; Ganzarain, J.; Igartua, J.I. Business model innovation through Industry 4.0: A review. Procedia Manuf. 2018, 22, 4–10. [Google Scholar] [CrossRef]

- Yang, M.; Smart, P.; Kumar, M.; Jolly, M.; Evans, S. Product-service systems business models for circular supply chains. Prod. Plan. Control 2018, 29, 498–508. [Google Scholar] [CrossRef] [Green Version]

- Planellas, M.; Muni, A. Business Model Canvas. Strateg. Decis. 2019, 128–131. [Google Scholar] [CrossRef]

- Sassanelli, C.; Seregni, M.; Hankammer, S.; Cerri, D.; Terzi, S. The role of internet of things (IoT) technologies for individualisation and service quality of a PSS. In 21st Summer School Francesco Turco 2016; AIDI-Italian Association of Industrial Operations Professors: Milano, Italy, 2016; pp. 36–41. [Google Scholar]

- Centobelli, P.; Cerchione, R.; Singh, R. The impact of leanness and innovativeness on environmental and financial performance: Insights from Indian SMEs. Int. J. Prod. Econ. 2019, 212, 111–124. [Google Scholar] [CrossRef]

| Scopus | Web of Science | Science Direct | Emerald | Total | |

|---|---|---|---|---|---|

| Step 1: Keywords Industry 4.0, servitisation, and circular economy. | 2069 | 1205 | 699 | 327 | 4301 |

| Step 2: Theme Managerial approach: literature related to business models, supply chains, or firm’s value chains. | 798 | 403 | 549 | 215 | 1965 |

| Step 3: Incl. and Excl. Criteria Off-topic, non-peer-reviewed, non-English, duplicate. | 86 | 78 | 39 | 23 | 226 |

| Step 4: Selected Papers Finalized paper for review | 49 | 32 | 46 | 12 | 139 |

| Author | Definition |

|---|---|

| Tim Baines [13] | “Servitisation is the concept of manufacturers offering services tightly coupled to their products”. |

| Andy Neely [22] | “The innovation of organisations’ capabilities and processes to better create mutual value through a shift from selling products to selling PSSs”. |

| Bart van Looy [62] | “A trend in which manufacturing firms adopt more and more service components in their offerings”. |

| I4.0 and Servitisation References | Life-Cycle Management | Stakeholders Perspective | Business Model | Differentiation | Competitive Advantage | Value Chain | Supply-Chain Management | Organisation Structure | Strategy | Product Design | Innovation | Smart Services | Resource Efficiency | Transformation | Smart/Lean Manufacturing |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [1] | x | x | x | ||||||||||||

| [9] | x | x | x | ||||||||||||

| [49] | x | x | x | ||||||||||||

| [62] | x | x | |||||||||||||

| [69] | x | x | x | x | |||||||||||

| [70] | x | x | x | x | |||||||||||

| [78] | x | x | |||||||||||||

| [84] | x | x | x | x | x | ||||||||||

| [85] | x | x | x | ||||||||||||

| [86] | x | ||||||||||||||

| [87] | x | x | x | x | |||||||||||

| [88] | x | x | x |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atif, S.; Ahmed, S.; Wasim, M.; Zeb, B.; Pervez, Z.; Quinn, L. Towards a Conceptual Development of Industry 4.0, Servitisation, and Circular Economy: A Systematic Literature Review. Sustainability 2021, 13, 6501. https://doi.org/10.3390/su13116501

Atif S, Ahmed S, Wasim M, Zeb B, Pervez Z, Quinn L. Towards a Conceptual Development of Industry 4.0, Servitisation, and Circular Economy: A Systematic Literature Review. Sustainability. 2021; 13(11):6501. https://doi.org/10.3390/su13116501

Chicago/Turabian StyleAtif, Sehrish, Shehzad Ahmed, Muhammad Wasim, Bassam Zeb, Zeeshan Pervez, and Lorraine Quinn. 2021. "Towards a Conceptual Development of Industry 4.0, Servitisation, and Circular Economy: A Systematic Literature Review" Sustainability 13, no. 11: 6501. https://doi.org/10.3390/su13116501

APA StyleAtif, S., Ahmed, S., Wasim, M., Zeb, B., Pervez, Z., & Quinn, L. (2021). Towards a Conceptual Development of Industry 4.0, Servitisation, and Circular Economy: A Systematic Literature Review. Sustainability, 13(11), 6501. https://doi.org/10.3390/su13116501