Artificial Intelligence Applications for Increasing Resource Efficiency in Manufacturing Companies—A Comprehensive Review

Abstract

:1. Introduction

2. Fundamentals of AI and Resource Efficiency

2.1. Definition of AI

2.2. Definition of Resource Efficiency

2.3. Link between AI and Resource Efficiency

3. Materials and Methods

3.1. Identification of AI Methods

3.2. Identification of Relevant Business Divisions

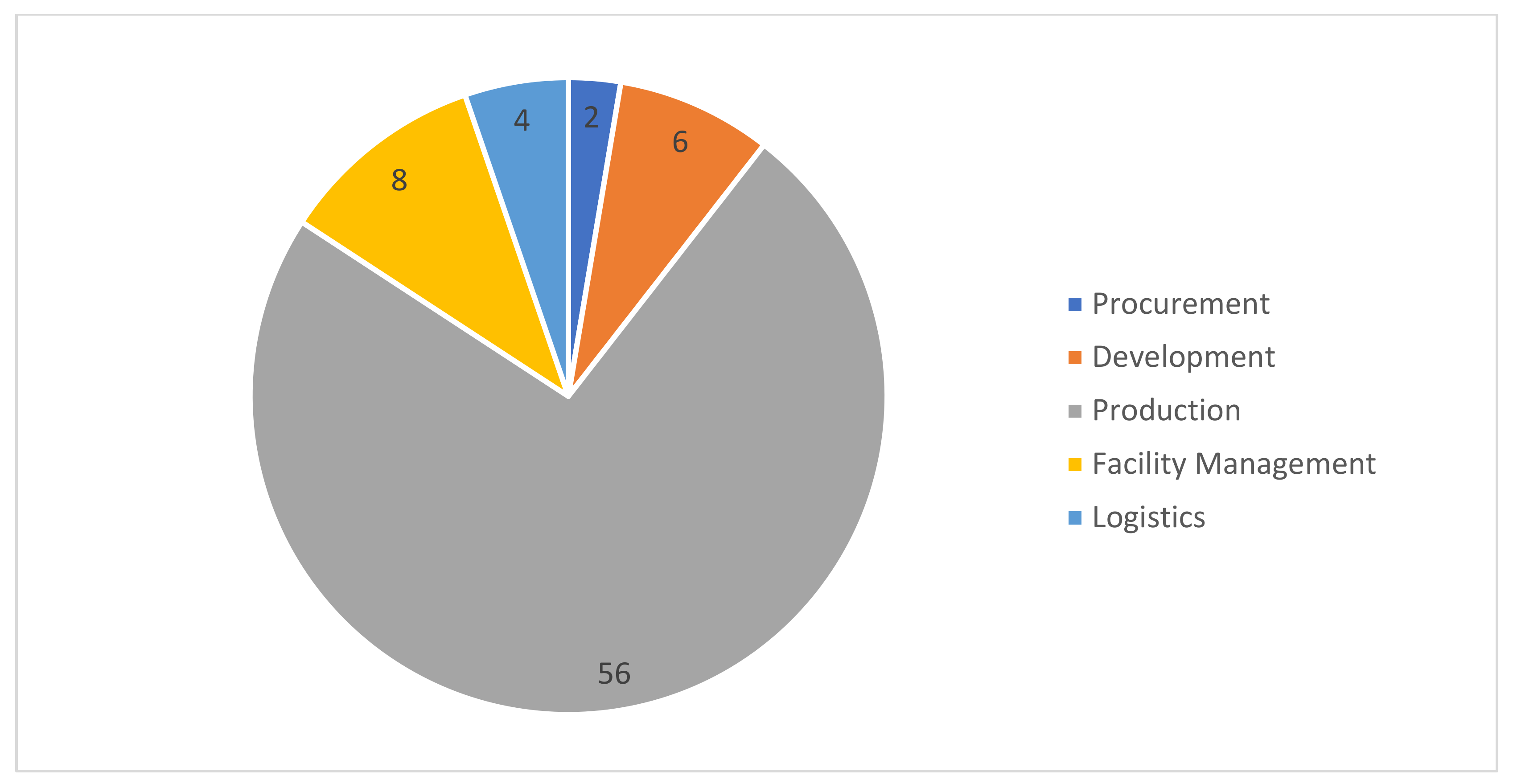

- -

- Procurement;

- -

- Product development;

- -

- Production planning and optimization;

- -

- Facility management;

- -

- Logistics (internal/external).

3.3. Identification of Relevant Resource Efficiency Terms

3.4. Literature Review according to the PRISMA Guidelines

3.5. Analysis of the Identified Literature

- -

- High influence, if a paper states an improvement in a resource efficiency aspect of 1% or more;

- -

- Potential influence, if the AI application is able to improve a resource efficiency aspect, e.g., by optimizing a process and decreasing product errors. However, no quantification of the improvement is given, or the improvement is below 1%;

- -

- None, if the AI application does not influence any of the resource efficiency aspects;

- -

- N/A, if not enough information is available to evaluate the potential influence.

3.6. Identification of Typical Use Cases of AI Application Increasing Resource Efficiency

4. Results

5. Discussion

5.1. Analysis of the Identified Research Papers

5.2. Identification of Typical Use Cases of AI Application Increasing Resource Efficiency

- -

- -

- -

- -

6. Conclusions

6.1. Limitations

6.2. Theoretical and Practical Implications

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- IPCC. Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II, and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Miehe, R.; Waltersmann, L.; Sauer, A.; Bauernhansl, T. Sustainable production and the role of digital twins—Basic reflections and perspectives. J. Adv. Manuf. Process. 2021, 3. [Google Scholar] [CrossRef]

- Miehe, R. Methodik zur Quantifizierung der Nachhaltigen Wertschöpfung von Produktionssystemen an der Ökonomisch-Ökologischen Schnittstelle Anhand Ausgewählter Umweltprobleme. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2018. [Google Scholar]

- Jarass, L.J.; Obermair, G.M.; Voigt, W. Windenergie: Zuverlässige Integration in die Energieversorgung, 2nd ed.; Springer: Berlin, Germany, 2009. [Google Scholar]

- Sauer, A.; Bauernhansl, T. (Eds.) Energieeffizienz in Deutschland—Eine Metastudie: Analyse und Empfehlungen; Springer Vieweg: Berlin, Germany, 2016. [Google Scholar]

- DeMartini, M.; Evans, S.; Tonelli, F. Digitalization Technologies for Industrial Sustainability. Procedia Manuf. 2019, 33, 264–271. [Google Scholar] [CrossRef]

- Vinuesa, R.; Azizpour, H.; Leite, I.; Balaam, M.; Dignum, V.; Domisch, S.; Felländer, A.; Langhans, S.D.; Tegmark, M.; Nerini, F.F. The role of artificial intelligence in achieving the Sustainable Development Goals. Nat. Commun. 2020, 11, 233. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Di Vaio, A.; Palladino, R.; Hassan, R.; Escobar, O. Artificial intelligence and business models in the sustainable development goals perspective: A systematic literature review. J. Bus. Res. 2020, 121, 283–314. [Google Scholar] [CrossRef]

- Nishant, R.; Kennedy, M.; Corbett, J. Artificial intelligence for sustainability: Challenges, opportunities, and a research agenda. Int. J. Inf. Manag. 2020, 53, 102104. [Google Scholar] [CrossRef]

- Hatiboglu, B.; Schuler, S.; Bildstein, A.; Hämmerle, M. Einsatzfelder von Künstlicher Intelligenz im Produktionsumfeld. 2019. Available online: http://publica.fraunhofer.de/eprints/urn_nbn_de_0011-n-5491073.pdf (accessed on 1 April 2021).

- Nilsson, N.J. The Quest for Artificial Intelligence: A History of Ideas and Achievements; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Wang, P. On Defining Artificial Intelligence. J. Artif. Gen. Intell. 2019, 10, 1–37. [Google Scholar] [CrossRef] [Green Version]

- Kok, J.N.; Boers, E.J.; Kosters, W.A.; van der Putten, P. Artificial Intelligence: Definition, Trends, Techniques and Cases. In Encyclopedia of Life Support Systems (EOLSS); Developed under the Auspices of the UNESCO; EOLSS Publishers: Paris, France, 2009. [Google Scholar]

- Dobrev, D.A. Definition of Artificial Intelligence. Math. Balk. 2005, 19, 67–74. [Google Scholar]

- Iriondo, R. Machine Learning (ML) vs. Artificial Intelligence (AI)—Crucial Differences. 2018. Available online: https://pub.towardsai.net/differences-between-ai-and-machine-learning-and-why-it-matters-1255b182fc6 (accessed on 17 February 2021).

- Kavlakoglu, E. AI vs. Machine Learning vs. Deep Learning vs. Neural Networks: What’s the Difference? 2020. Available online: https://www.ibm.com/cloud/blog/ai-vs-machine-learning-vs-deep-learning-vs-neural-networks (accessed on 1 April 2021).

- Benaich, N.; Hogart, I. State of AI Report 2020. 2020. Available online: https://www.stateof.ai/ (accessed on 17 February 2021).

- VDMA Software und Digitalisierung. Quick Guide: Machine Learning im Maschinen- und Anlagenbau. 2018. Available online: https://sud.vdma.org/documents/15012668/26742261/!VDMA%20Quick%20Guide_Machine%20Learning_EN_1553781666349.pdf/47bd499f-087d-4650-0af6-a569d7825b0d (accessed on 17 February 2021).

- Sathya, R.; Abraham, A. Comparison of Supervised and Unsupervised Learning Algorithms for Pattern Classification. IJARAI 2013. [Google Scholar] [CrossRef] [Green Version]

- Haldorai, A.; Ramu, A.; Khan, S.A.R. Business Intelligence for Enterprise Internet of Things; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar]

- Mohri, M.; Rostamizadeh, A.; Talwalkar, A. Adaptive Computation and Machine Learning. In Foundations of Machine Learning, 2nd ed.; The MIT Press: Cambridge, MA, USA, 2018. [Google Scholar]

- Aulet, B. Startup mit System: In 24 Schritten zum Erfolgreichen Entrepreneur, 1st ed.; O’Reilly: Heidelberg, Germany, 2016. [Google Scholar]

- Kaelbling, L.P.; Littman, M.L.; Moore, A.W. Reinforcement Learning: A Survey. JAIR 1996, 4, 237–285. [Google Scholar] [CrossRef] [Green Version]

- VDI Zentrum Ressourceneffizienz GmbH (Ed.) Potenziale der Schwachen Künstlichen Intelligenz für die Betriebliche Ressourceneffizienz. 2021. Available online: https://www.ressource-deutschland.de/fileadmin/user_upload/downloads/studien/VDI-ZRE_Studie_KI-betriebliche-Ressourceneffizienz_Web_bf.pdf (accessed on 7 June 2021).

- VDI. Resource Efficiency—Methodical Principles and Strategies (4800). 2016. Available online: https://www.vdi.de/en/home/vdi-standards/details/vdi-4800-blatt-1-resource-efficiency-methodical-principles-and-strategies (accessed on 7 June 2021).

- VDI Zentrum Ressourceneffizienz GmbH. Ressourceneffizienz Durch Industrie 4.0—Potenziale für KMU des verarbeitenden Gewerbes. 2017. Available online: https://www.ressource-deutschland.de/fileadmin/Redaktion/Bilder/Newsroom/Studie_Ressourceneffizienz_durch_Industrie_4.0.pdf (accessed on 17 February 2021).

- Umweltbundesamt. Glossar zum Ressourcenschutz. 2012. Available online: https://www.umweltbundesamt.de/publikationen/glossar-ressourcenschutz (accessed on 15 April 2021).

- Tietenberg, T.; Lewis, L. Environmental and Natural Resource Economics, 11th ed.; Routledge: New York, NY, USA, 2018. [Google Scholar]

- Saiga, K.; Ullah, A.S.; Kubo, A.; Tashi, A. Sustainable Reverse Engineering Process. Procedia CIRP 2021, 98, 517–522. [Google Scholar] [CrossRef]

- Ullah, A.S. What is knowledge in Industry 4.0? Eng. Rep. 2020, 2. [Google Scholar] [CrossRef]

- Corea, F. AI Knowledge Map: How to Classify AI Technologies. In An Introduction to Data: Everything You Need to Know about AI, Big Data and Data Science; Corea, F., Ed.; Springer: Cham, Switzerland, 2019; Volume 50, pp. 25–29. [Google Scholar]

- Draper, N.R.; Smith, H. Applied Regression Analysis: Includes Disk, 3rd ed.; A Wiley-Interscience Publication; Wiley: New York, NY, USA, 1998. [Google Scholar]

- Bethea, R.M.; Duran, B.S.; Boullion, T.L. Statistical Methods for Engineers and Scientists, 2nd ed.; Dekker: New York, NY, USA, 1985; Volume 57. [Google Scholar]

- Wu, X.; Kumar, V.; Quinlan, J.R.; Ghosh, J.; Yang, Q.; Motoda, H.; McLachlan, G.J.; Ng, A.; Liu, B.; Yu, P.S.; et al. Top 10 algorithms in data mining. Knowl. Inf. Syst. 2008, 14, 1–37. [Google Scholar] [CrossRef] [Green Version]

- Allison, P.D. Logistic Regression Using SAS, 2nd ed.; SAS Institute: Cary, NC, USA, 2012. [Google Scholar]

- Domingos, P.; Pazzani, M. On the Optimality of the Simple Bayesian Classifier under Zero-One Loss. Mach. Learn. 1997, 29, 103–130. [Google Scholar] [CrossRef]

- Cortes, C.; Vapnik, V. Support-Vector Networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- Liu, F.T.; Ting, K.M.; Zhou, Z.-H. Isolation Forest. In Proceedings of the 2008 Eighth IEEE International Conference on Data Mining, Pisa, Italy, 15–19 December 2008; IEEE: New York, NY, USA, 2008; pp. 413–422. [Google Scholar]

- Breunig, M.M.; Kriegel, H.-P.; Ng, R.T.; Sanders, J. LOF: Identifying density-based local outliers. In Proceedings of the 2000 ACM SIGMOD International Conference on Management of Data—SIGMOD ’00, Dallas, TX, USA, 15–18 May 2000; Dunham, M., Naughton, J.F., Chen, W., Koudas, N., Eds.; ACM Press: New York, NY, USA, 2000; pp. 93–104. [Google Scholar]

- O’Shea, K.; Nash, R. An Introduction to Convolutional Neural Networks. arXiv 2015, arXiv:1511.08458. [Google Scholar]

- Geyer, C.J. Practical Markov Chain Monte Carlo. Stat. Sci. 1992, 7, 473–483. [Google Scholar] [CrossRef]

- Bishop, C.M. Pattern Recognition and Machine Learning, Corrected at 8th printing 2009; Information Science and Statistics; Springer: New York, NY, USA, 2009. [Google Scholar]

- Schuster, M.; Paliwal, K. Bidirectional recurrent neural networks. IEEE Trans. Signal Process. 1997, 45, 2673–2681. [Google Scholar] [CrossRef] [Green Version]

- Vaswani, A.; Shazeer, N.; Parmar, N.; Uszkoreit, J.; Jones, L.; Gomez, A.; Kaiser, L.; Polosukhin, I. Attention Is All You Need. arXiv 2017, arXiv:1706.03762. [Google Scholar]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef]

- Johnson, S.C. Hierarchical clustering schemes. Psychometrika 1967, 32, 241–254. [Google Scholar] [CrossRef]

- Kanungo, T.; Mount, D.; Netanyahu, N.; Piatko, C.; Silverman, R.; Wu, A. An efficient k-means clustering algorithm: Analysis and implementation. IEEE Trans. Pattern Anal. Mach. Intell. 2002, 24, 881–892. [Google Scholar] [CrossRef]

- Jolliffe, I.T.; Cadima, J. Principal component analysis: A review and recent developments. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2016, 374, 20150202. [Google Scholar] [CrossRef]

- Fan, J.; Wang, Z.; Xie, Y.; Yang, Z. A Theoretical Analysis of Deep Q-Learning. arXiv 2019, arXiv:1901.00137. [Google Scholar]

- Van Hasselt, H. Double Q-Learning. In Proceedings of the 23rd International Conference on Neural Information Processing Systems, Vancouver, BC, Canada, 6 December 2009; Curran Associates Inc.: Red Hook, NY, USA, 2010; Volume 2, pp. 2613–2621. [Google Scholar]

- Porter, M.E. Competitive Advantage: Creating and Sustaining Superior Performance; First Free Press Edition; Free Press: New York, NY, USA, 1998. [Google Scholar]

- Rentz, O.; Fröhling, M.; Nebel, F.; Schultmann, F.; Engels, B. Integrierter Umweltschutz in der Metallerzeugung: Simulationsgestützte Operative Produktionsplanung zur Optimierung Metallurgischer Abfallverwertungsprozesse. Schlussbericht des Forschungsvorhabens; KIT Scientific Publishing: Karlsruhe, Germany, 2006. [Google Scholar]

- Irrek, W.; Barthel, C. Abschlussbericht des AP14 “Ökodesign-Richtlinie”: Materialeffizienz und Ressourcenschonung; Wuppertal-Institut für Klima, Umwelt, Energie: Wuppertal, Germany, 2010. [Google Scholar]

- Bartusch, H.; Fernández Alcalde, A.M.; Fröhling, M.; Schultmann, F.; Schwaderer, F. Erhöhung der Energie- und Ressourceneffizienz und Reduzierung der Treibhausgasemissionen in der Eisen-, Stahl- und Zinkindustrie (ERESTRE); KIT Scientific Publishing: Karlsruhe, Germany, 2012. [Google Scholar]

- Hofbauer, E.; Rogner, W.; Gruber, K. Untersuchung über Energiesparende Maßnahmen in der Wärmeintensiven Industrie; Energiepolitische Schriftenreihe; Springer: Vienna, Austria, 1983; Volume 4. [Google Scholar]

- Gebbe, C.; Klemm, F.; Zhai, S.; Reinhart, G. Estimating Machine Power Consumptions through Aggregated Measurements and Machine Data Acquisition. Appl. Mech. Mater. 2014, 655, 61–66. [Google Scholar] [CrossRef]

- Wehle, H.-D.; Dietel, M. Industrie 4.0—Lösung zur Optimierung von Instandhaltungsprozessen. Inform. Spektrum 2015, 38, 211–216. [Google Scholar] [CrossRef]

- Youssef, S.; Zimmer, C.; Szielasko, K.; Suri, Z.K.; Schütze, A. Vergleich Subjektiver und Automatisierter Merkmalsextraktion Sowie Einsatz Maschineller Lernalgorithmen zur Mikromagnetischen Materialcharakterisierung. In Tagungsband 20. GMA/ITG-Fachtagung Sensoren und Messsysteme 2019; VDI/VDE-Gesellschaft, Ed.; AMA Service GmbH: Wunstorf, Germany, 2019; pp. 347–354. [Google Scholar]

- Adamczak, S.; Wrzochal, M.; Durakbasa, N. Evaluation of a non-contact method for measuring vibration of rolling bearings in industrial conditions. Mechanik 2020, 93, 8–11. [Google Scholar] [CrossRef]

- Kuhlmann, T.; Sauer, A. Design and assessment of energetic agility measures in factories based on multivariate linear regression. Procedia CIRP 2019, 80, 162–167. [Google Scholar] [CrossRef]

- Johnson, R.; Yang, F.; Ankenman, B.; Nelson, B. Nonlinear Regression Fits for Simulated Cycle Time vs. Throughput Curves for Semicondutor Manufacturing. In Proceedings of the 2004 Winter Simulation Conference, Washington, DC, USA, 5–8 December 2004; Volume 2, pp. 867–871. [Google Scholar]

- Wohlgemuth, C. Entwurf und Galvanotechnische Fertigung Metallischer Trennmembranen für Mediengetrennte Piezo-Resistive Drucksensoren. Ph.D. Thesis, Technical University of Darmstadt, Darmstadt, Germany, 2008. [Google Scholar]

- Flick, D.; Ji, L.; Dehning, P.; Thiede, S.; Herrmann, C. Energy Efficiency Evaluation of Manufacturing Systems by Considering Relevant Influencing Factors. Procedia CIRP 2017, 63, 586–591. [Google Scholar] [CrossRef]

- Ghaedi, M.; Hossainpour, M.; Ansari, A.; Habibi, M.; Asghari, A. Least square-support vector (LS-SVM) method for modeling of methylene blue dye adsorption using copper oxide loaded on activated carbon: Kinetic and isotherm study. J. Ind. Eng. Chem. 2014, 20, 1641–1649. [Google Scholar] [CrossRef]

- Evans, L.; Lohse, N.; Summers, M. A fuzzy-decision-tree approach for manufacturing technology selection exploiting experience-based information. Expert Syst. Appl. 2013, 40, 6412–6426. [Google Scholar] [CrossRef]

- Ronowicz, J.; Thommes, M.; Kleinebudde, P.; Krysiński, J. A data mining approach to optimize pellets manufacturing process based on a decision tree algorithm. Eur. J. Pharm. Sci. 2015, 73, 44–48. [Google Scholar] [CrossRef]

- Hsu, C.-H.; Wang, M.-J.J. Using decision tree-based data mining to establish a sizing system for the manufacture of garments. Int. J. Adv. Manuf. Technol. 2005, 26, 669–674. [Google Scholar] [CrossRef]

- Antosz, K.; Paśko, Ł.; Gola, A. The Use of Artificial Intelligence Methods to Assess the Effectiveness of Lean Maintenance Concept Implementation in Manufacturing Enterprises. Appl. Sci. 2020, 10, 7922. [Google Scholar] [CrossRef]

- Yan, J.; Lee, J. Degradation Assessment and Fault Modes Classification Using Logistic Regression. J. Manuf. Sci. Eng. 2005, 127, 912–914. [Google Scholar] [CrossRef]

- Li, H.; Wang, Y.; Zhao, P.; Zhang, X.; Zhou, P. Cutting tool operational reliability prediction based on acoustic emission and logistic regression model. J. Intell. Manuf. 2015, 26, 923–931. [Google Scholar] [CrossRef]

- Schmid, M. Kognitive Prozesssteuerung zur Steigerung der Ressourceneffizienz in der Druckindustrie. Ph.D. Thesis, Technische Universität München, München, Germany, 2017. [Google Scholar]

- Yan, J.; Koc, M.; Lee, J. A prognostic algorithm for machine performance assessment and its application. Prod. Plan. Control. 2004, 15, 796–801. [Google Scholar] [CrossRef]

- Doreswamy, H.K.S. Performance Evaluation of Predictive Classifiers for Knowledge Discovery from Engineering Materials Data Sets. arXiv 2012, arXiv:1209.2501. [Google Scholar]

- Adam, A.; Chew, L.C.; Shapiai, M.I.; Jau, L.W.; Ibrahim, Z.; Khalid, M. A Hybrid Artificial Neural Network-Naive Bayes for solving imbalanced dataset problems in semiconductor manufacturing test process. In Proceedings of the 2011 11th International Conference on Hybrid Intelligent Systems (HIS), Malaxxa, Malaysia, 5–8 December 2011; pp. 133–138. [Google Scholar]

- Ferreira, L.; Borenstein, D. A fuzzy-Bayesian model for supplier selection. Expert Syst. Appl. 2012, 39, 7834–7844. [Google Scholar] [CrossRef]

- Prasetiyo, B.; Alamsyah; Muslim, M.A. Analysis of building energy efficiency dataset using naive bayes classification classifier. J. Physics: Conf. Ser. 2019, 1321, 032016. [Google Scholar] [CrossRef] [Green Version]

- Decker, M. Entwicklung Eines Ganzheitlichen Prognosemodells zur Kompensation von Varianzen in Prozessfolgen Mittels Support Vektor Maschinen. IPA-IAO-Forschung und Praxis. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2008. Volume 469. [Google Scholar]

- Freitag, M.; Kück, M.; Alla, A.A. Potenziale von Data Science in Produktion und Logistik: Teil 2: Vorgehensweise zur Datenanalyse und Anwendungsbeispiele. Ind. 4.0 Manag. 2015, 31, 40–46. [Google Scholar]

- Zendehboudi, A.; Baseer, M.; Saidur, R. Application of support vector machine models for forecasting solar and wind energy resources: A review. J. Clean. Prod. 2018, 199, 272–285. [Google Scholar] [CrossRef]

- Wanner, J.; Herm, L.-V.; Hartel, D.; Janiesch, C. Verwendung binärer Datenwerte für eine KI-gestützte Instandhaltung 4.0. HMD 2019, 56, 1268–1281. [Google Scholar] [CrossRef]

- Deng, F.; Guo, S.; Zhou, R.; Chen, J. Sensor Multifault Diagnosis with Improved Support Vector Machines. IEEE Trans. Autom. Sci. Eng. 2017, 14, 1053–1063. [Google Scholar] [CrossRef]

- Pai, P.-F.; Wu, T.-M.; Lin, K.-P.; Yang, S. Diagnosing Faulty Products in TFT-LCD Manufacturing Processes by Support Vector Machines with Principal Components Analysis. In Proceedings of the 2009 WRI Global Congress on Intelligent Systems: GCIS 2009, Xiamen, China, 19–21 May 2009; Zhou, S.-M., Ed.; IEEE: Piscataway, NJ, USA; pp. 413–417.

- Zhang, J.; Wang, P.; Yan, R.; Gao, R.X. Long short-term memory for machine remaining life prediction. J. Manuf. Syst. 2018, 48, 78–86. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhu, H.; Wu, J.; Shao, X. Machine Health Monitoring Using Adaptive Kernel Spectral Clustering and Deep Long Short-Term Memory Recurrent Neural Networks. IEEE Trans. Ind. Inform. 2019, 15, 987–997. [Google Scholar] [CrossRef]

- Yu, C.-M.; Chien, C.-F.; Kuo, C.-J. Exploit the Value of Production Data to Discover Opportunities for Saving Power Consumption of Production Tools. IEEE Trans. Semicond. Manuf. 2017, 30, 345–350. [Google Scholar] [CrossRef]

- Susto, G.A.; Beghi, A.; McLoone, S. Anomaly detection through on-line isolation Forest: An application to plasma etching. In Proceedings of the 2017 28th Annual SEMI Advanced Semiconductor Manufacturing Conference (ASMC), Saratoga Springs, NY, USA, 15–18 May 2017; pp. 89–94. [Google Scholar]

- Weimer, D.; Scholz-Reiter, B.; Shpitalni, M. Design of deep convolutional neural network architectures for automated feature extraction in industrial inspection. CIRP Ann. 2016, 65, 417–420. [Google Scholar] [CrossRef]

- Bechtsis, D.; Tsolakis, N.; Vlachos, D.; Iakovou, E. Sustainable supply chain management in the digitalisation era: The impact of Automated Guided Vehicles. J. Clean. Prod. 2017, 142, 3970–3984. [Google Scholar] [CrossRef] [Green Version]

- Scime, L.; Beuth, J. A multi-scale convolutional neural network for autonomous anomaly detection and classification in a laser powder bed fusion additive manufacturing process. Addit. Manuf. 2018, 24, 273–286. [Google Scholar] [CrossRef]

- Willenbacher, M.; Wohlgemuth, V. Einsatzmöglichkeiten von Methoden der Künstlichen Intelligenz zur Optimierung von Stoff- und Energieströmen und prototypische Umsetzung auf der Basis von Stoffstromnetzen. In Nachhaltige Betriebliche Umweltinformationssysteme; Arndt, H.-K., Marx Gómez, J., Wohlgemuth, V., et al., Eds.; Springer Fachmedien: Wiesbaden, Germany, 2018; pp. 97–108. [Google Scholar]

- Choi, I.; Kim, H. An On-Device Deep Learning Approach to Battery Saving on Industrial Mobile Terminals. Sensors 2020, 20, 4044. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Li, W.; Lu, X.; Wang, S. Fog computing and convolutional neural network enabled prognosis for machining process optimization. J. Manuf. Syst. 2019, 52, 32–42. [Google Scholar] [CrossRef]

- Lee, S.Y.; Tama, B.A.; Moon, S.J.; Lee, S. Steel Surface Defect Diagnostics Using Deep Convolutional Neural Network and Class Activation Map. Appl. Sci. 2019, 9, 5449. [Google Scholar] [CrossRef] [Green Version]

- Cui, W.; Zhang, Y.; Zhang, X.; Li, L.; Liou, F. Metal Additive Manufacturing Parts Inspection Using Convolutional Neural Network. Appl. Sci. 2020, 10, 545. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Ota, K.; Dong, M. Deep Learning for Smart Industry: Efficient Manufacture Inspection System with Fog Computing. IEEE Trans. Ind. Inform. 2018, 14, 4665–4673. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Li, H.; Qi, C. An adaptive mode convolutional neural network based on bar-shaped structures and its operation modeling to complex industrial processes. Chemom. Intell. Lab. Syst. 2020, 199, 103932. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Wu, Z.; Li, H.; Christofides, P.D. Operational trend prediction and classification for chemical processes: A novel convolutional neural network method based on symbolic hierarchical clustering. Chem. Eng. Sci. 2020, 225, 115796. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Q.; Xu, W.; Liu, Z.; Zhou, Z.; Chen, J. Deep Learning-based Human Motion Prediction Considering Context Awareness for Human-Robot Collaboration in Manufacturing. Procedia CIRP 2019, 83, 272–278. [Google Scholar] [CrossRef]

- Zhang, C.; Ji, W. Edge Computing Enabled Production Anomalies Detection and Energy-Efficient Production Decision Approach for Discrete Manufacturing Workshops. IEEE Access 2020, 8, 158197–158207. [Google Scholar] [CrossRef]

- Reger, A.; Oette, C.; Aires, A.P.; Steinhilper, R. Pattern recognition in load profiles of electric drives in manufacturing plants. In Proceedings of the 2015 5th International Electric Drives Production Conference (EDPC 2015), Nuremberg, Germany, 15–16 September 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1–10. [Google Scholar]

- Abedi, S.; Mousakhani, M.; Hamidi, N. Using Markov Chain to Analyze Production Lines Systems with Layout Constraints. J. Optim. Ind. Eng. 2010, 3, 15–23. [Google Scholar]

- Jónás, T.; Kalló, N.; Tóth, Z.E. Application of Markov Chains for Modeling and Managing Industrial Electronic Repair Processes. Period. Polytech. Soc. Manag. Sci. 2014, 22, 87–98. [Google Scholar] [CrossRef] [Green Version]

- Xu, W.; Cao, L. Energy efficiency analysis of machine tools with periodic maintenance. Int. J. Prod. Res. 2014, 52, 5273–5285. [Google Scholar] [CrossRef]

- Tsiliyannis, C.A. Markov chain modeling and forecasting of product returns in remanufacturing based on stock mean-age. Eur. J. Oper. Res. 2018, 271, 474–489. [Google Scholar] [CrossRef]

- Chin, R.T. Automated visual inspection techniques and applications: A bibliography. Pattern Recognit. 1982, 15, 343–357. [Google Scholar] [CrossRef]

- Bhagat, P. Pattern Recognition in Industry, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Dong, B.; Andrews, B. Sensor-based occupancy behavioral pattern recognition for energy and comfort management in intelligent buildings. In Proceedings of the Eleventh International IBPSA Conference, Glasgow, Scotland, 27–30 July 2009. [Google Scholar]

- O’Driscoll, E.; Kelly, K.; Cusack, D.O.; O’Donnell, G. Characterising the Energy Consumption of Machine Tool Actuator Components Using Pattern Recognition. Procedia CIRP 2013, 12, 127–132. [Google Scholar] [CrossRef]

- Wang, Y.; Velswamy, K.; Huang, B. A Long-Short Term Memory Recurrent Neural Network Based Reinforcement Learning Controller for Office Heating Ventilation and Air Conditioning Systems. Processes 2017, 5, 46. [Google Scholar] [CrossRef] [Green Version]

- Meyes, R.; Donauer, J.; Schmeing, A.; Meisen, T. A Recurrent Neural Network Architecture for Failure Prediction in Deep Drawing Sensory Time Series Data. Procedia Manuf. 2019, 34, 789–797. [Google Scholar] [CrossRef]

- Selver, M.A.; Akay, O.; Alim, F.; Bardakçı, S.; Ölmez, M. An automated industrial conveyor belt system using image processing and hierarchical clustering for classifying marble slabs. Robot. Comput. Manuf. 2011, 27, 164–176. [Google Scholar] [CrossRef]

- Kain, S. Charakterisierung von Mittels 3D-Druck Verarbeiteten Biogenen Holz-Filamenten unter Anwendung der Raman-Spektroskopie; Fachhochschule Salzburg: Salzburg, Austria, 2018. [Google Scholar]

- Yiakopoulos, C.; Gryllias, K.; Antoniadis, I. Rolling element bearing fault detection in industrial environments based on a K-means clustering approach. Expert Syst. Appl. 2011, 38, 2888–2911. [Google Scholar] [CrossRef]

- Park, G.Y.; Kim, H.; Jeong, H.W.; Youn, H.Y. A Novel Cluster Head Selection Method based on K-Means Algorithm for Energy Efficient Wireless Sensor Network. In Proceedings of the 2013 27th International Conference on Advanced Information Networking and Applications Workshops, Barcelona, Spain, 25–28 March 2013; pp. 910–915. [Google Scholar]

- Moll, P.; Schäfer, A.; Coutandin, S.; Fleischer, J. Method for the Investigation of Mold Filling in the Fiber Injection Molding Process Based on Image Processing. Procedia CIRP 2019, 86, 156–161. [Google Scholar] [CrossRef]

- Gould, O.; Simeone, A.; Colwill, J.; Woolley, E.; Willey, R.; Rahimifard, S. Optimized Assembly Design for Resource Efficient Production in a Multiproduct Manufacturing System. Procedia CIRP 2017, 62, 523–528. [Google Scholar] [CrossRef] [Green Version]

- Kanyama, M.; Nyirenda, C.; Temaneh Nyah, C. Anomaly Detection in Smart Water Metering Networks. In Proceedings of the 5th International Workshop on Advanced Computational Intelligence and Intelligent Informatics, 2017; School of Automation, Beijing Institute of Technology: Beijing, China, 2017. [Google Scholar]

- Lane, S.; Martin, E.B.; Morris, A.J.; Gower, P. Application of exponentially weighted principal component analysis for the monitoring of a polymer film manufacturing process. Trans. Inst. Meas. Control. 2003, 25, 17–35. [Google Scholar] [CrossRef]

- Jagadish; Ray, A. Optimization of process parameters of green electrical discharge machining using principal component analysis (PCA). Int. J. Adv. Manuf. Technol. 2016, 87, 1299–1311. [Google Scholar] [CrossRef]

- Yang, Y.; Juntao, L.; Lingling, P. Multi-robot path planning based on a deep reinforcement learning DQN algorithm. CAAI Trans. Intell. Technol. 2020, 5, 177–183. [Google Scholar] [CrossRef]

- Lütje, A.; Willenbacher, M.; Engelmann, M.; Kunisch, C.; Wohlgemuth, V. Exploring the System Dynamics of Industrial Symbiosis (IS) with Machine Learning (ML) Techniques—A Framework for a Hybrid-Approach. In Advances and New Trends in Environmental Informatics; Springer International Publishing: Cham, Switzerland, 2020; pp. 117–130. [Google Scholar]

- Yan, H.-S.; Li, W.-C. A scheduling procedure for a flow shop-like knowledgeable manufacturing cell with self-evolutionary features. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 2296–2306. [Google Scholar] [CrossRef]

- Shah, H.; Gopal, M. A fuzzy decision tree-based robust Markov game controller for robot manipulators. IJAAC 2010, 4, 417. [Google Scholar] [CrossRef]

- Johansson, M.; Thollander, P. A review of barriers to and driving forces for improved energy efficiency in Swedish industry—Recommendations for successful in-house energy management. Renew. Sustain. Energy Rev. 2018, 82, 618–628. [Google Scholar] [CrossRef]

- Jones, N. How to stop data centres from gobbling up the world’s electricity. Nature 2018, 561, 163–166. [Google Scholar] [CrossRef]

- Shehabi, A.; Smith, S.; Sartor, D.; Brown, R.; Herrlin, M.; Koomey, J.; Masanet, E.; Horner, N.; Azevedo, I.; Lintner, W. United States Data Center Energy Usage Report; 2016. Available online: https://eta-publications.lbl.gov/sites/default/files/lbnl-1005775_v2.pdf (accessed on 1 April 2021).

- Murugesan, S. Harnessing Green IT: Principles and Practices. IT Prof. 2008, 10, 24–33. [Google Scholar] [CrossRef]

- Schwartz, R.; Dodge, J.; Smith, N.A.; Etzioni, O. Green AI. arXiv 2019, arXiv:1907.10597. [Google Scholar] [CrossRef]

| Cluster | Task | Method |

|---|---|---|

| Supervised learning | Trend analysis | Linear regression |

| Non-linear regression | ||

| Classification | Decision trees | |

| Logistic regression | ||

| Naive Bayes classification | ||

| Support Vector Machines (SVM) | ||

| Anomaly detection | Isolation Forest | |

| Local Outlier Factor | ||

| Image recognition | Convolutional neural networks (CNN) | |

| Modeling, language processing | Markov chain | |

| Pattern recognition | ||

| Recurrent neural networks (RNN) | ||

| Transformer | ||

| Long short-term memory (LSTM) | ||

| Unsupervised learning | Clustering | Hierarchical clustering |

| K-means | ||

| Dimension reduction | Principal Component Analysis (PCA) | |

| Reinforcement learning | Learning tasks | State–action–reward–state–action (SARSA) |

| Deep Q-Network (DQN) | ||

| Double Deep Q Network (DDQN) | ||

| Q-Learning |

| Business Divison | Ressource Efficiency + GHG | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| AI Tasks | AI Methods | Source | Procurement | Development | Production | Facility Mgmt. | Logistics | Energy | Material | Water | GHGEemissions |

| Trend analysis | Linear regression | Rentz et al. (2006) | x | none | pot. | none | none | ||||

| Irrek and Barthel 2010) | x | pot. | none | none | pot. | ||||||

| Bartusch et al. (2012) | x | pot. | pot. | none | none | ||||||

| Hofbauer et al. (1983) | x | pot. | none | none | pot. | ||||||

| Gebbe et al. (2014) | x | pot. | none | none | pot. | ||||||

| Wehle and Dietel (2015) | x | pot. | pot. | pot. | pot. | ||||||

| Youssef et al. (2019) | x | pot. | pot. | none | pot. | ||||||

| Adamczak et al. (2020) | x | pot. | pot. | none | pot. | ||||||

| Kuhlmann and Sauer (2019) | x | x | pot. | none | none | pot. | |||||

| Non-linear regression | Johnson et al. (2004) | x | x | pot. | none | N/A | pot. | ||||

| Wohlgemuth (2008) | x | none | pot. | none | none | ||||||

| Trend analysis; dimension reduction | Linear regression; PCA | Flick et al. (2017) | x | pot. | none | none | pot. | ||||

| Trend analysis; dimension reduction | Linear regression; SVM; PCA | Ghaedi et al. (2014) | x | none | pot. | none | none | ||||

| Classification | Decision trees | Evans et al. (2013) | x | pot. | pot. | pot. | pot. | ||||

| Ronowicz et al. (2015) | x | pot. | pot. | none | pot. | ||||||

| Hsu and Wang (2005) | x | x | pot. | pot. | none | pot. | |||||

| Antosz et al. (2020) | x | pot. | pot. | pot. | pot. | ||||||

| Logistic regression | Yan and Lee (2005) | x | pot. | pot. | none | pot. | |||||

| Li et al. (2015) | x | pot. | pot. | none | pot. | ||||||

| Schmid (2017) | x | pot. | pot. | pot. | pot. | ||||||

| Yan et al. (2004) | x | pot. | pot. | none | pot. | ||||||

| Naive Bayes classification; decision trees | Doreswamy (2012) | x | pot. | pot. | none | pot. | |||||

| Naive Bayes classification | Adam et al. (2011) | x | pot. | pot. | none | pot. | |||||

| Ferreira and Borenstein (2012) | x | none | none | none | pot. | ||||||

| Prasetiyo et al. (2019) | x | pot. | N/A | N/A | N/A | ||||||

| SVM | Decker (2008) | x | x | x | x | x | pot. | pot. | none | pot. | |

| Freitag et al. (2015) | x | none | pot. | none | none | ||||||

| Zendehboudi et al. (2018) | x | pot. | none | none | pot. | ||||||

| Wanner et al. (2019) | x | pot. | pot. | pot. | pot. | ||||||

| Deng et al. (2017) | x | pot. | pot. | none | pot. | ||||||

| Golkarnarenji et al. (2019) | x | high | pot. | none | high | ||||||

| Classification; dimension reduction | SVM; PCA | Pai et al. (2009) | x | pot. | pot. | none | pot. | ||||

| Classification; modeling, language processing | Naive Bayes classification; LSTM | Zhang et al. (2018) | x | pot. | none | none | pot. | ||||

| RNN; LSTM | Cheng et al. (2019) | x | pot. | pot. | none | pot. | |||||

| SVM; RNN | Yu et al. (2017) | x | high | none | none | high | |||||

| Anomaly detection | Isolation forest | Susto et al. (2017) | x | pot. | pot. | N/A | pot. | ||||

| Image recognition | CNN | Weimer et al. (2016) | x | pot. | pot. | none | pot. | ||||

| Bechtsis et al. (2017) | x | x | pot. | pot. | none | pot. | |||||

| Scime and Beuth (2018) | x | pot. | pot. | N/A | pot. | ||||||

| Willenbacher et al. (2017) | x | pot. | pot. | pot. | pot. | ||||||

| Choi and Kim (2020) | x | high | none | none | pot. | ||||||

| Liang et al. (2019) | x | high | none | none | high | ||||||

| Lee et al. (2019) | x | pot. | pot. | none | pot. | ||||||

| Cui et al. (2020) | x | none | pot. | none | none | ||||||

| Li et al. (2018) | x | none | pot. | none | none | ||||||

| Wang et al. (2020 a) | x | pot. | pot. | pot. | pot. | ||||||

| Image recognition; clustering | CNN; hierarchical clustering | Wang et al. (2020 b) | x | pot. | pot. | pot. | pot. | ||||

| Image recognition; modeling, language processing | CNN; LSTM | Liu et al. (2019) | x | pot. | none | none | pot. | ||||

| Modeling, language processing | LSTM | Zhang and Ji (2020) | high | pot. | none | high | |||||

| Markov chain; pattern recognition | Reger et al. (2015) | x | pot. | none | none | pot. | |||||

| Markov chain | Abedi et al. (2010) | x | pot. | none | none | pot. | |||||

| Jónás et al. (2014) | x | pot. | pot. | none | pot. | ||||||

| Xu and Cao (2014) | x | pot. | none | none | pot. | ||||||

| Tsiliyannis (2018) | x | pot. | pot. | none | pot. | ||||||

| Pattern recognition | Chin (1982) | x | pot. | pot. | none | pot. | |||||

| Bhagat (2005) | x | pot. | none | pot. | high | ||||||

| Dong and Burton (2009) | x | high | none | pot. | high | ||||||

| O’Driscoll et al. (2013) | x | pot. | none | none | pot. | ||||||

| RNN; LSTM | Wang et al. (2017) | x | pot. | none | none | pot. | |||||

| RNN | Meyes et al. (2019) | x | pot. | pot. | none | pot. | |||||

| Clustering | Hierarchical clustering | Alper Selver et al. (2011) | x | none | pot. | none | none | ||||

| Kain (2018) | x | x | none | pot. | none | none | |||||

| K-means | Yiakopoulos et al. (2011) | x | pot. | pot. | none | pot. | |||||

| Park et al. (2013) | x | pot. | none | none | none | ||||||

| Moll et al. (2019) | x | pot. | pot. | N/A | N/A | ||||||

| Gould et al. (2017) | x | pot. | pot. | pot. | pot. | ||||||

| Clustering; anomaly detection | K-means; Local Outlier Factor | Kanyama et al. (2017) | x | none | none | pot. | none | ||||

| Dimension reduction | PCA | Lane et al. (2003) | x | pot. | pot. | none | pot. | ||||

| Dimension reduction; classification | PCA; linear regression | Jagadish and Ray (2016) | x | pot. | pot. | N/A | pot. | ||||

| Learning tasks | Q-learning | Yang et al. (2020) | x | pot. | none | none | pot. | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Waltersmann, L.; Kiemel, S.; Stuhlsatz, J.; Sauer, A.; Miehe, R. Artificial Intelligence Applications for Increasing Resource Efficiency in Manufacturing Companies—A Comprehensive Review. Sustainability 2021, 13, 6689. https://doi.org/10.3390/su13126689

Waltersmann L, Kiemel S, Stuhlsatz J, Sauer A, Miehe R. Artificial Intelligence Applications for Increasing Resource Efficiency in Manufacturing Companies—A Comprehensive Review. Sustainability. 2021; 13(12):6689. https://doi.org/10.3390/su13126689

Chicago/Turabian StyleWaltersmann, Lara, Steffen Kiemel, Julian Stuhlsatz, Alexander Sauer, and Robert Miehe. 2021. "Artificial Intelligence Applications for Increasing Resource Efficiency in Manufacturing Companies—A Comprehensive Review" Sustainability 13, no. 12: 6689. https://doi.org/10.3390/su13126689

APA StyleWaltersmann, L., Kiemel, S., Stuhlsatz, J., Sauer, A., & Miehe, R. (2021). Artificial Intelligence Applications for Increasing Resource Efficiency in Manufacturing Companies—A Comprehensive Review. Sustainability, 13(12), 6689. https://doi.org/10.3390/su13126689