Towards Sustainable Soil Stabilization in Peatlands: Secondary Raw Materials as an Alternative

Abstract

:1. Introduction

2. Challenges in Peatland Stabilization

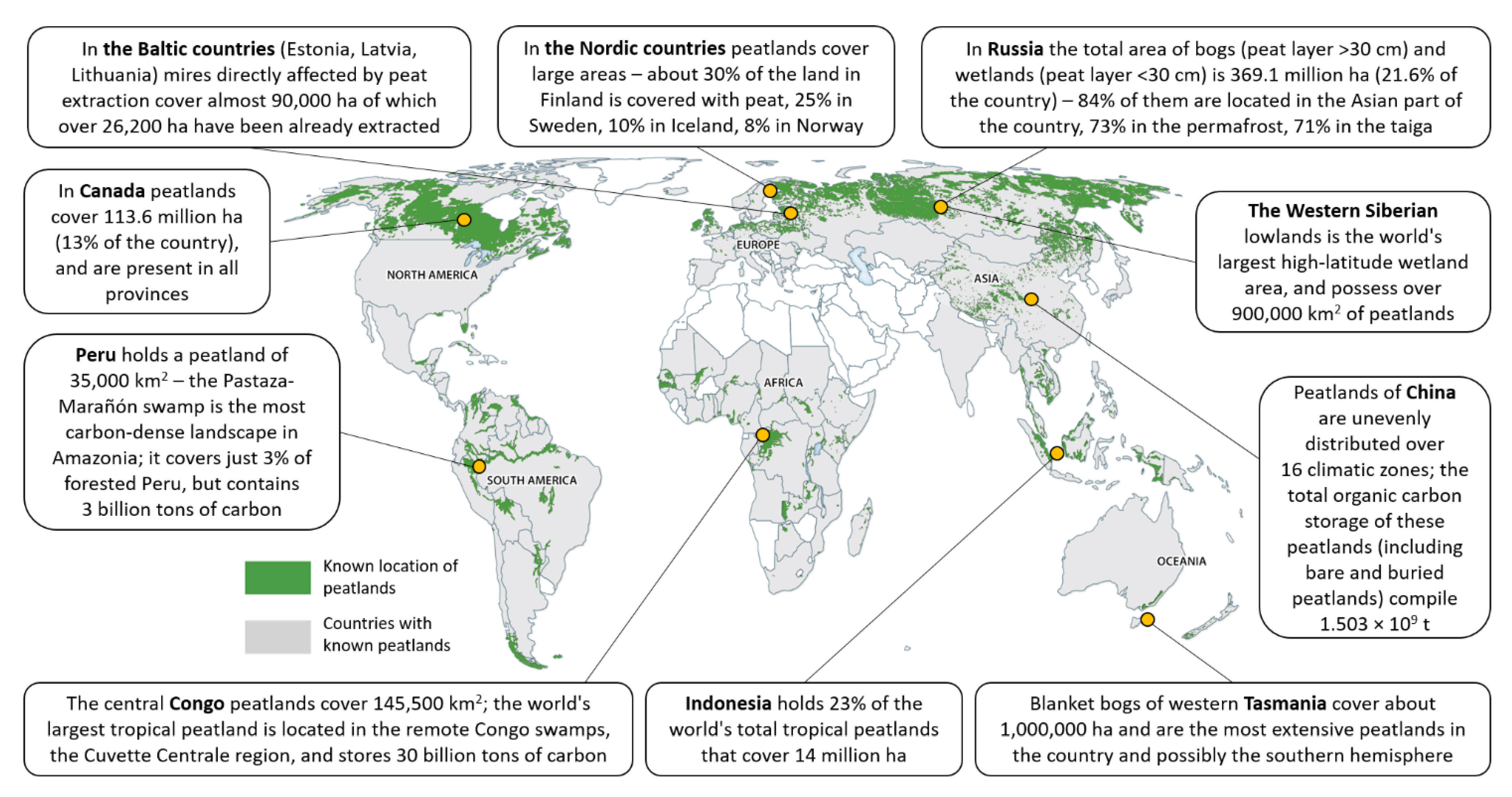

2.1. Demand for Stabilization

2.2. General Principles of Stabilization

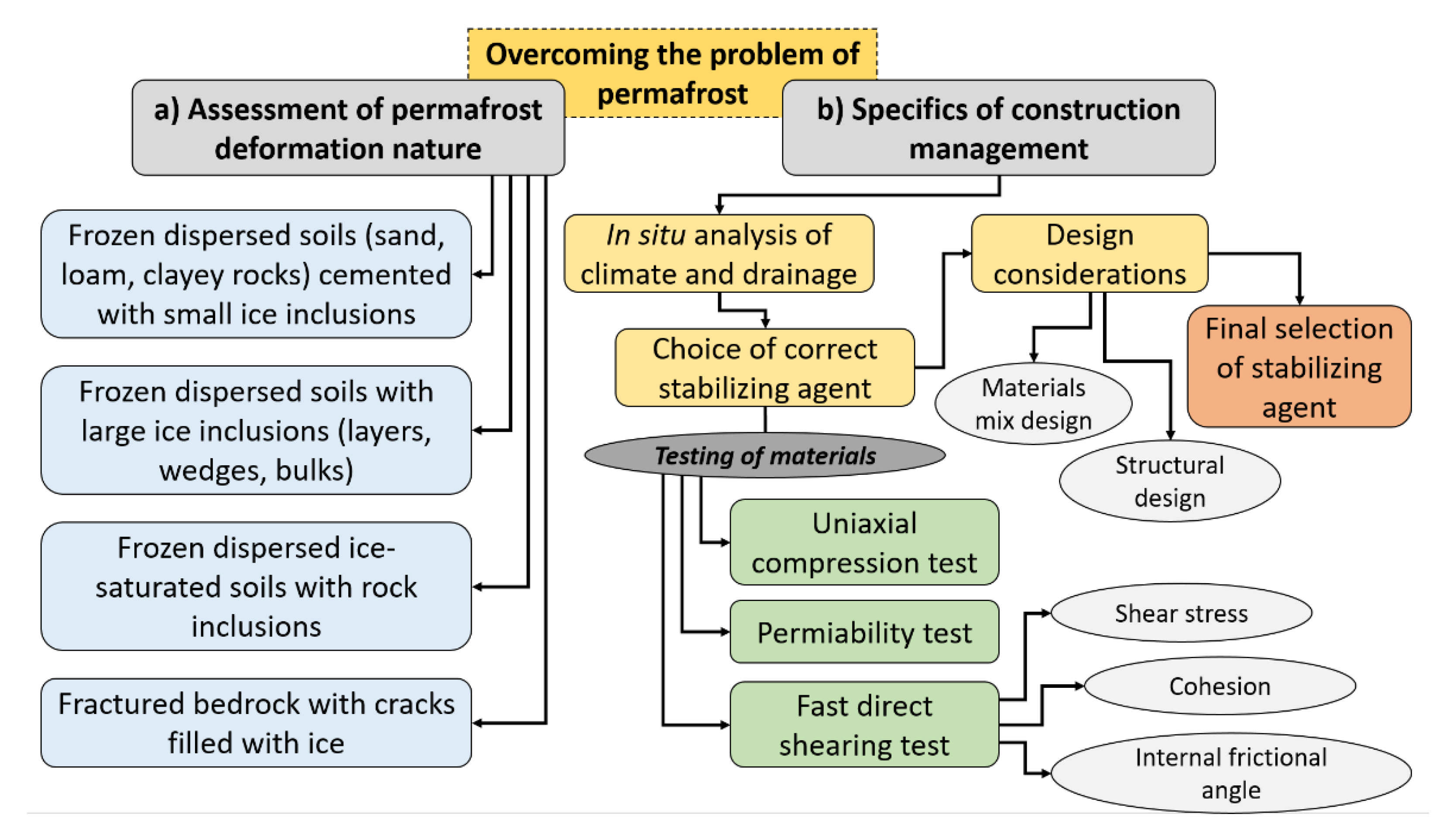

2.3. The Problem of Permafrost

2.4. Mass Stabilization as an Option

3. Applying a Circular Economy Approach in Material Choice for Stabilization

4. Peculiarities Regarding the Use of Certain Secondary Raw Materials

4.1. Solving the Problem of Oil Shale Waste

4.2. Applicability of Municipal Solid Waste Bottom Ashes in Weak Soil Stabilization

4.3. Perspectives of Fly Ashes from Power Industry for Forest Road Constructions

4.4. Application of Ashes from Other Industries in Peatland Stabilization

4.5. Geopolymer Composites from Thermally Treated Waste

4.6. Some Other Specific Materials Used in Peatland Soil Stabilization

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Type of material | Advantages | Disadvantages | Reference |

|---|---|---|---|

| 1. Conventional raw materials | |||

| 1.1. Primary raw materials (industrial products) | |||

| Cement | + Broad availability at market + Wide applicability | – Large amount needed results in high costs – Slow pozzolanic reaction – Brittle behavior (may be affected by seismic activities) – Relatively high carbon footprint – Affects occupational health safety | [35,211] |

| Lime | + The oldest material used for stabilization with broad availability + Wide applicability due to various states: quicklime, hydrated lime, or liquid lime | – Quarrying resource | [35,44] |

| 1.2. Conventional secondary raw materials | |||

| Fly ash of class C | + Self-cementing (pozzolanic) properties + Applicable as a component in the production of cement and cement clinker | – May induce environmental problems, mainly groundwater contamination, due to leaching of trace elements | [88,89,125,138,155,161,162,212] |

| 2. New choice of secondary raw materials | |||

| 2.1. Thermally treated waste products (ashes) | |||

| 2.1.1. Ashes from agricultural production | |||

| Bagasse ash | + Contains a significant amount of silica, thus, is considered as a sensible pozzolanic material with non-reactive behavior + Has a potential to be used in road subgrade stabilization | – Limited regional availability (in tropical areas only) | [213,214,215,216] |

| Rice husk ash | + Ensures improved sulfate resistance by stabilization of C-S-H and the refinement of pore structure embodied CO2 emission and energy consumption | – Not a self-cementitious material, if used in stabilization, needs the addition of a hydraulic binder such as lime – Limited regional availability (in tropical areas only) | [216,217,218] |

| 2.1.2. Ashes from energy production | |||

| Fly ash | + Improves compressive and shearing strength of soils + Applicable as a stabilizing agent due to its siliceous and calcareous character | – May contain hazardous compounds released by leachate | [128,155,156,159,160,161,162,164,165,166,167,172,219] |

| Fuel oil fly ash | + Applicable as a stabilizing amendment and for adding to mortars | – May contain hazardous compounds released by leachate | [220] |

| Coal ash | + Wide applicability, including use as a top layer on unpaved roads | – May induce environmental problems, mainly groundwater contamination, due to leaching of trace elements | [221] |

| Granulated blast furnace slag | + Applicable as a stabilizing agent due to siliceous and calcareous character | – Limited availability – Leaching control needed – Legislative gaps | [54,222,223,224] |

| Oil shale ash | + Applicable as a stabilizer/binder for road/railway construction in unstable or contaminated soils + Applicable to create low carbon solutions and as a replacement of cement | – Limited availability – Leaching control needed – Legislative gaps | [101,107,110,115,116,118,119,195,196] |

| Semi-coke | + Applicable as a stabilizer/binder for road/railway construction in unstable or contaminated soils | – By itself has a high toxicity level – Leaching control needed – Legislative gaps | [100,108,109,110,111,112,113] |

| Palm oil fuel ash (POFA) | + POFA-peat composites ensure increased CBR values by >20% in comparison to untreated peat | – Limited regional availability (in tropical areas only) | [185,186,187] |

| 2.1.3. Ashes from various manufacturing | |||

| Cement kiln dust or limestone ash (waste from cement and cement clinker production) | + Highly alkaline (contains 70% CaO and 30% undecomposed CaCO3), thus, applicable as a substitute for lime | – May contain hazardous compounds released by leachate – Harmful to the environment due to caustic nature | [44,212,225,226,227] |

| Sawdust ash (waste from woodworking) | + Mainly consists of silica, in the presence of moisture forms cementitious compounds + Improves strength and compressibility properties of soils + Due to low energy consumption and carbon footprint of activated fly ash, applicable as a replacement for cement | – By itself has a little cementitious value | [174,176,228] |

| Ashes from pulp and paper industry | + High moisture-holding capacity due to hydrophilic nature + Consists mainly of silica, aluminum oxide, and iron oxide, but it depends on wood species + Exhibits high acid-neutralizing capacity, thus, inducing a liming effect + Due to low energy consumption and carbon footprint, presence of reactive silicates and calcium carbonate, applicable as a replacement for cement | – High content of sulfates may affect the application | [171,173,177,178] |

| 2.1.4. Ashes from waste processing | |||

| Sewage sludge ash | + If used in combination with cement, improves the California Bearing Ration (CBR) values by up to 30 times in comparison to untreated soil | – Toxicity risks, including contamination with pharmaceuticals and their residues – Pharmaceutical pollutant risks | [180,183,184,229,230] |

| Municipal solid waste (MSW) incineration products (fly ash and bottom ash) | + Strengthens geotechnical parameters of soil in combination with a binder material + Bottom ash is applicable as an aggregate material | – May contain hazardous compounds released by leachate | [136,137,138,139,140,141,142] |

| 2.1.5. High carbon content pyrolysis products | |||

| Pyrogenic carbonaceous materials (PCM) and biochar | + Applicable for replacement of cement, but in small amount (<1%) or carbon sequestering admixture in cement + Useful for contaminated/polluted soils | – Variable composition and properties – Limited amount can be added – Mixing with other materials is needed | [231,232] |

| 2.2. Untreated waste and new products made from secondary raw materials | |||

| 2.2.1. Waste from municipal biological treatment (MBTs) rejected materials and landfills | |||

| Waste sludge, alum sludge | + Consists mainly of aluminum oxide (>30%), if used for soil stabilization, may significantly increase the CBR values + Has good pozzolanic properties + Small optimum amount (~8%) to be added | – Energy consumption, if drying is needed prior application | [34,209,210] |

| Fine fraction of landfilled waste | + Closing the loop of the material cycle in the circular economy + Methane degradation potential | – Toxicity problem – Non-homogenous material – Legislative gaps | [30,233,234,235,236,237] |

| 2.2.2. Waste form various industries | |||

| Lignosulfonates (waste from wood pulping industry | + Chemical and physical binding of soil particles + Smaller amount is needed than conventional materials resulting in cost-efficiency + Non-brittle behavior (unaffected by seismic activities) | – Limited availability | [5,35,202] |

| Natural plant fibers (agricultural waste) | + Easy accessible material + Large amounts available | – Non-homogenous material – Legislative gaps | [203,204,205,206] |

| 2.3. New products made from secondary raw materials | |||

| 2.3.1. Composite materials | |||

| Geopolymer composites | + Similar effect as using conventional materials + Smaller amount is needed than conventional materials (addition to soil 5–30% by weight) resulting in cost-efficiency | – Mixing with an alkaline activator is required | [87,89,90,91,92,96,175,178,195,198,199,201,222] |

References

- Joosten, H. Peatlands across the globe. In Peatland Restoration and Ecosystem Services: Science, Policy and Practice; Bonn, A., Allott, T., Evans, M., Joosten, H., Stoneman, R., Eds.; Cambridge University Press: Cambridge, UK, 2016; pp. 19–43. [Google Scholar] [CrossRef]

- Rebelo, A.J.; Morris, C.; Meire, P.; Esler, K.J. Ecosystem services provided by South African palmiet wetlands: A case for investment in strategic water source areas. Ecol. Indic. 2019, 101, 71–80. [Google Scholar] [CrossRef]

- Saaremäe, E.; Liira, M.; Poolakese, M.; Tamm, T. Removing phosphorus with Ca-Fe oxide granules—A possible wetlands filter material. Hydrol. Res. 2014, 45, 368–378. [Google Scholar] [CrossRef]

- Schumann, M.; Joosten, H. Global Peatland Restoration Manual; Greifswald University: Greifswald, Germany, 2008. [Google Scholar]

- Xu, J.; Morris, P.J.; Liu, J.; Holden, J. PEATMAP: Refining estimates of global peatland distribution based on a meta-analysis. CATENA 2018, 160, 134–140. [Google Scholar] [CrossRef] [Green Version]

- Lilleskov, E.; McCullough, K.; Hergoualc’h, K.; del Castillo Torres, D.; Chimner, R.; Murdiyarso, D.; Kolka, R.; Bourgeau-Chavez, L.; Hribljan, J.; del Aguila Pasquel, J.; et al. Is Indonesian peatland loss a cautionary tale for Peru? A two-country comparison of the magnitude and causes of tropical peatland degradation. Mitig. Adapt. Strateg. Glob. Chang. 2019, 24, 591–623. [Google Scholar] [CrossRef]

- GRID Arendal. Distribution of Global Peatlands. Available online: https://www.grida.no/resources/12546 (accessed on 17 February 2021).

- Driessen, P.; Deckers, J.; Spaargaren, O.; Nachtergaele, F. Lecture Notes on the Major Soils of the World; FAO: Rome, Italy, 2001. [Google Scholar]

- Climate Change Post. Forestry and Peatlands in Russia. Available online: https://www.climatechangepost.com/russia/forestry-and-peatlands/ (accessed on 17 February 2021).

- Climate Change Post. Forestry and Peatlands in Sweden. Available online: https://www.climatechangepost.com/sweden/forestry-and-peatlands/ (accessed on 17 February 2021).

- Dargie, G.C.; Lewis, S.L.; Lawson, I.T.; Mitchard, E.T.A.; Page, S.E.; Bocko, Y.E.; Ifo, S.A. Age, extent and carbon storage of the central Congo Basin peatland complex. Nature 2017, 542, 86–90. [Google Scholar] [CrossRef]

- Draper, F.C.; Roucoux, K.H.; Lawson, I.T.; Mitchard, E.T.A.; Honorio, C.E.N.; Lähteenoja, O.; Torre Montenegro, L.; Valderrama Sandoval, E.; Zaráte, R.; Baker, T.R. The distribution and amount of carbon in the largest peatland complex in Amazonia. Environ. Res. Lett. 2014, 9. [Google Scholar] [CrossRef]

- Karofeld, E.; Jarašius, L.; Priede, A.; Sendžikaitė, J. On the after-use and restoration of abandoned extracted peatlands in the Baltic countries. Restor. Ecol. 2016, 25, 293–300. [Google Scholar] [CrossRef]

- Kremenetski, K.V.; Velichko, A.A.; Borisova, O.K.; MacDonald, G.M.; Smith, L.C.; Frey, K.E.; Orlova, L.A. Peatlands of the Western Siberian lowlands: Current knowledge on zonation, carbon content and Late Quaternary history. Quat. Sci. Rev. 2003, 22, 703–723. [Google Scholar] [CrossRef]

- Liu, Z.; Ming, W.; Xuehui, M. Estimation of storage and density of organic carbon in peatlands of China. Chin. Geogr. Sci. 2012, 22, 637–646. [Google Scholar] [CrossRef]

- Peat and Peatlands. Peatland Distribution in Canada. Available online: https://peatmoss.com/what-is-peat-moss/peatland-distribution/ (accessed on 17 February 2021).

- Pemberton, M. Australian peatlands: A brief consideration of their origin, distribution, natural values and threats. J. R. Soc. West Aust. 2005, 88, 81–89. [Google Scholar]

- Warren, M.; Hergoualc’h, K.; Kauffman, J.B.; Murdiyarso, D.; Kolka, R. An appraisal of Indonesia’s immense peat carbon stock using national peatland maps: Uncertainties and potential losses from conversion. Carbon Balance Manag. 2017, 12, 12. [Google Scholar] [CrossRef]

- Johansen, M.D.; Aker, P.; Klanderud, K.; Olsen, S.L.; Skrindo, A.B. Restoration of peatland by spontaneous revegetation after road construction. Appl. Veg. Sci. 2017, 20, 631–640. [Google Scholar] [CrossRef]

- Jardine, R.J. Geotechnics, energy and climate change: The 56th Rankine Lecture. Geotechnique 2020, 70, 3–59. [Google Scholar] [CrossRef] [Green Version]

- Mahmood, A.A.; Hussain, M.K.; Mohamad, S.N.A. Use of palm oil fuel ash (POFA) stabilized Sarawak peat composite for road subbase. Mater. Today Proc. 2020, 20, 505–511. [Google Scholar] [CrossRef]

- Paul, A.; Hussain, M. Geotechnical properties and microstructural characteristics of Northeast Indian peats. Mires Peat 2019, 24, 7. [Google Scholar] [CrossRef]

- Sladen, W.E.; Wolfe, S.A.; Morse, P.D. Evaluation of threshold freezing conditions for winter road construction over discontinuous permafrost peatlands, subarctic Canada. Cold Reg. Sci. Technol. 2020, 170, 102930. [Google Scholar] [CrossRef]

- Pehme, K.-M.; Burlakovs, J.; Kriipsalu, M.; Pilecka, J.; Grinfelde, I.; Tamm, T.; Jani, Y.; Hogland, W. Urban hydrology research fundamentals for waste management practices. Res. Rural Dev. 2019, 1, 160–167. [Google Scholar] [CrossRef]

- Purmalis, O.; Grinfelde, I.; Valujeva, V.; Burlakovs, J. The abandoned block-cut peat extraction field influence on the natural raised bog hydrological regime. Res. Rural Dev. 2016, 1, 236–241. [Google Scholar]

- Patton, A.I.; Rathburn, S.L.; Capps, D.M. Landslide response to climate change in permafrost regions. Geomorphology 2019, 340, 116–128. [Google Scholar] [CrossRef]

- Gomes Correia, A.; Winter, M.G.; Puppala, A.J. A review of sustainable approaches in transport infrastructure geotechnics. Transp. Geotech. 2016, 7, 21–28. [Google Scholar] [CrossRef] [Green Version]

- European Commission. Environment, Green Growth, Raw Materials. Available online: https://ec.europa.eu/environment/green-growth/raw-materials/index_en.htm (accessed on 17 February 2021).

- Murray, A.; Skene, K.; Haynes, K. The circular economy: An interdisciplinary exploration of the concept and application in a global context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef] [Green Version]

- Pehme, K.-M.; Kriipsalu, M. Full-scale project: From landfill to recreational area. Detritus 2018, 1, 174–179. [Google Scholar] [CrossRef]

- Urbinati, A.; Chiaroni, D.; Chiesa, V. Towards a new taxonomy of circular economy business models. J. Clean. Prod. 2017, 168, 487–498. [Google Scholar] [CrossRef]

- Mhatre, P.; Panchal, R.; Singh, A.; Bibyan, S. A systematic literature review on the circular economy initiatives in the European Union. Sustain. Prod. Consum. 2021, 26. [Google Scholar] [CrossRef]

- Deboucha, S.; Hashim, R.; Alwi, A. Engineering properties of stabilized tropical peat soils. Electron. J. Geotech. Eng. 2008, 13, 0843. [Google Scholar]

- Aamir, M.; Mahmood, A.; Nisar, A.; Farid, A.; Khan, T.A.; Abbas, A.; Ismaeel, M.; Shah, S.A.R.; Waseem, M. Performance evaluation of sustainable soil stabilization process using waste materials. Processes 2019, 7, 378. [Google Scholar] [CrossRef] [Green Version]

- Zahri, A.M.; Zainorabidin, A. An overview of traditional and non traditional stabilizer for soft soil. IOP Conf. Ser. Mater. Sci. 2019, 527. [Google Scholar] [CrossRef] [Green Version]

- Boylan, N.; Jennings, P.; Long, M. Peat slope failure in Ireland. Q. J. Eng. Geol. Hydrogeol. 2008, 41, 93–108. [Google Scholar] [CrossRef] [Green Version]

- Song, M.; Lin, S.; Takahashi, F. Coal fly ash amendment to mitigate soil water evaporation in arid/semi-arid area: An approach using simple drying focusing on sieve size and temperature. Resour. Conserv. Recycl. 2020, 156, 104726. [Google Scholar] [CrossRef]

- Vardanega, P.J.; Hickey, C.L.; Lau, K.; Sarzier, H.D.L.; Couturier, C.M.; Martin, G. Investigation of the Atterberg limits and undrained fall-cone shear strength variation with water content of some peat soils. Int. J. Pavement Res. Technol. 2019, 12, 131–138. [Google Scholar] [CrossRef] [Green Version]

- O’Kelly, B.C.; Pichan, S.P. Effects of decomposition on the compressibility of fibrous peat—A review. Geomech. Geoengin. 2013, 8, 286–296. [Google Scholar] [CrossRef]

- Nie, L.; Lv, Y.; Li, M. Influence of organic content and degree of decomposition on the engineering properties of a peat soil in NE China. Q. J. Eng. Geol. Hydrogeol. 2012, 45, 435–446. [Google Scholar] [CrossRef]

- Rahgozar, M.A.; Saberian, M. Geotechnical properties of peat stabilized with shredded waste tyre chips. Mires Peat 2016, 18, 3. [Google Scholar] [CrossRef]

- Wang, J.; Li, M.; Wang, Z.; Shen, L. The benefits of using manufactured sand with cement for peat stabilisation: An experimental investigation of physico-chemical and mechanical properties of stabilised peat. Bull. Eng. Geol. Environ. 2020, 79, 4441–4460. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, S.; Li, J.; Huang, X.; Li, C.; Wu, J. Engineering and mineralogical properties of stabilized expansive soil compositing lime and natural pozzolans. Constr. Build. Mater. 2018, 187, 1031–1038. [Google Scholar] [CrossRef]

- Okagbue, C.O.; Yakubu, J.A. Limestone ash waste as a substitute for lime in soil improvement for engineering construction. Bull. Eng. Geol. Environ. 2000, 58, 107–113. [Google Scholar] [CrossRef]

- Al-Rawas, A.A.; Hago, A.W.; Al-Sarmi, H. Effect of lime, cement and Sarooj (artificial pozzolan) on the swelling potential of an expansive soil from Oman Build. Environment 2005, 40, 681–687. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Olgun, C.G.; Firoozi, A.A.; Baghini, M.S. Fundamentals of soil stabilization. Int. J. Geoengin. 2017, 8, 26. [Google Scholar] [CrossRef] [Green Version]

- MolaAbasi, H.; Semsani, S.B.; Saberian, M.; Khajeh, A.; Li, J.; Harandi, M. Evaluation of the long-term performance of stabilized sandy soil using binary mixtures: A micro- and macro-level approach. J. Clean. Prod. 2020, 267. [Google Scholar] [CrossRef]

- Senneca, O.; Cortese, L.; Di Martino, R.; Fabbricino, M.; Ferraro, A.; Race, M.; Scopino, A. Mechanisms affecting the delayed efficiency of cement based stabilization/solidification processes. J. Clean. Prod. 2020, 261. [Google Scholar] [CrossRef]

- Scope, C.; Vogel, M.; Guenther, E. Greener, cheaper, or more sustainable: Reviewing sustainability assessments of maintenance strategies of concrete structures. Sustain. Prod. Consum. 2021, 26, 838–858. [Google Scholar] [CrossRef]

- Abdrakhimov, V.Z.; Ilyina, T.A. Ispoljzovaniye zoloshlakovogo materiala v proizvodstve poristogo zapolnitelya sposobstvuyet razvitiyu “zelenoy” ekonomiki i transportno-logicheskoy infrastruktury/The use of ash and slag material in the production of porous aggregate contributes to the development of a “green” economics and transport-logistics infrastructure. Ugol’ Russ. Coal J. 2019, 11, 59–63. [Google Scholar] [CrossRef]

- Thom, N.; Dawson, A. Sustainable road design: Promoting recycling and non-conventional materials. Sustainability 2019, 11, 6106. [Google Scholar] [CrossRef] [Green Version]

- Bordoloi, S.; Garg, A.; Sekharan, S. A review of physio-biochemical properties of natural fibers and their application in soil reinforcement. Adv. Civil Eng. Mater. 2017, 6, 323–359. [Google Scholar] [CrossRef]

- Celik, E.; Nalbantoglu, Z. Effects of ground granulated blastfurnace slag (GGBS) on the swelling properties of lime-stabilized sulfate-bearing soils. Eng. Geol. 2013, 163, 20–25. [Google Scholar] [CrossRef]

- Sharma, A.K.; Sivapullaiah, P.V. Ground granulated blast furnace slag amended fly ash as an expansive soil stabilizer. Soils Found. 2016, 56, 205–212. [Google Scholar] [CrossRef]

- Yadu, L.; Tripati, R.K. Effects of granulated blast furnace slag in the engineering behavior of stabilized soft soil. Procedia Eng. 2013, 51, 125–131. [Google Scholar] [CrossRef] [Green Version]

- Ossowski, R.; Gwizdała, K. Mechanical properties of a dike formed from a soil-ash composite. Procedia Eng. 2017, 172, 816–822. [Google Scholar] [CrossRef]

- Sikora, Z.; Ossowski, R. Geotechnical aspects of dike construction using soil-ash composites. Procedia Eng. 2013, 57, 1029–1035. [Google Scholar] [CrossRef] [Green Version]

- Forsman, J.; Korkiala-Tanttu, L.; Piispanen, P. Mass stabilization as a ground improvement method for soft peaty. In Peat; Topcuoğlu, B., Turan, M., Eds.; IntechOpen: London, UK, 2018. [Google Scholar]

- Nelson, F.E.; Anisimov, O.A.; Shiklomanov, N.I. Subsidence risk from thawing permafrost. Nature 2001, 410, 889–890. [Google Scholar] [CrossRef]

- Yakubovich, A.; Trofimenko, Y.; Pospelov, P. Principles of developing a procedure to assess consequences of natural and climatic changes for transportation infrastructure facilities in permafrost regions. Transp. Res. Proc. 2018, 36, 810–816. [Google Scholar] [CrossRef]

- Yu, F.; Qi, J.; Yao, X.; Liu, Y. Degradation process of permafrost underneath embankments along Qinghai-Tibet Highway: An engineering view. Cold Reg. Sci. Technol. 2013, 85, 150–156. [Google Scholar] [CrossRef]

- Yang, Z.J.; Zhang, F.; Na, X.; Yu, H. Thaw settlement and mechanical properties of admixture-stabilized frozen soil. J. Cold Reg. Eng. 2020, 34, 04020005. [Google Scholar] [CrossRef]

- Ashpiz, E.S. The problems of the railway subgrade construction in the subarctic part of the Russian cryolithozone and the ways of their solution. In Transportation Soil Engineering in Cold Regions; Petriaev, A., Konon, A., Eds.; Springer: Singapore, 2020; Volume 49, pp. 295–302. [Google Scholar] [CrossRef]

- Bogomolova, N.; Bryn, M.; Nikitchin, A.; Kolos, A.; Romanov, A. The study of railway embankment deformations in cold regions. In Transportation Soil Engineering in Cold Regions; Petriaev, A., Konon, A., Eds.; Springer: Singapore, 2020; Volume 50, pp. 223–229. [Google Scholar] [CrossRef]

- Harun, S.F.B.; Zainorabidin, A.B.; Talib, M.K.A. A study on the unconfined compressive strength (UCS) of peat stabilization admixed with ceramic dust. TEST Eng. Manag. 2020, 83, 6471–6477. [Google Scholar]

- Hou, X.; Chen, J.; Jin, H.; Rui, P.; Zhao, J.; Mei, Q. Thermal characteristics of cast-in-place pile foundations in warm permafrost at Beiluhe on interior Qinghai-Tibet Plateau: Field observations and numerical simulations. Soils Found. 2020, 60, 90–102. [Google Scholar] [CrossRef]

- Heikkilä, R.; Kivimäki, T.; Puolitaival, K. Latent potentials of automation for deep stabilization machines and working processes. In Proceedings of the 27th ISARC International Symposium on Automation and Robotics in Construction, Bratislava, Slovakia, 25–27 June 2010; pp. 6–72. [Google Scholar] [CrossRef]

- Havukainen, J.; Piispanen, A.; Leppänen, M. Stabilisation of tributyltin-sediment in a harbour in Helsinki. Ground Improv. 2011, 164, 139–150. [Google Scholar] [CrossRef]

- Holm, G.; Svedberg, B.; Rogbeck, Y.; Lundberg, K.; Larsson, L.; Blazauskas, N.; Sapota, G. Stabilized sediments in port constructions—Important considerations and key experiences. In Proceedings of the of 16th European Conference on Soil Mechanics and Geotechnical Engineering, Edinburgh, Scotland, 13–17 September 2015; pp. 1291–1296. [Google Scholar]

- Corrêa-Silva, M.; Miranda, T.; Rouainia, M.; Araújo, N.; Glendinning, S.; Cristelo, N. Geomechanical behaviour of a soft soil stabilised with alkali-activated blast-furnace slags. J. Clean. Prod. 2020, 267. [Google Scholar] [CrossRef]

- Vanhanen, H.; Dahl, O.; Joensuu, S. Utilization of wood ash as a road construction material—Sustainable use of wood ashes. In ISWA BEACON 2nd International Conference on Final Sinks—Sinks a Vital Element of Modern Waste Management; Aalto ARTS Books: Espoo, Finland, 2013; pp. 83–89. [Google Scholar]

- Forsman, J.; Jyrävä, H.; Lahtinen, P.; Niemelin, T.; Hyvönen, I. Mass Stabilization Manual; ALLU Stamix Oy: Helsinki, Finland, 2015. [Google Scholar]

- Kotta, J.; Herkül, K.; Jaagus, J.; Kaasik, A.; Raudsepp, U.; Alari, V.; Arula, T.; Haberman, J.; Järvet, A.; Kangur, K.; et al. Linking atmospheric, terrestrial and aquatic environments: Regime shifts in the Estonian climate over the past 50 years. PLoS ONE 2018, 13, e0209568. [Google Scholar] [CrossRef]

- Mahedi, M.; Cetin, B.; White, D.J. Cement, lime, and fly ashes in stabilizing expansive soils: Performance evaluation and comparison. J. Mater. Civil Eng. 2020, 32, 04020177. [Google Scholar] [CrossRef]

- Turchin, V.; Yudina, L.; Ivanova, T.; Zhilkina, T.; Sychugove, S.; Mackevicius, R.; Danutė, S. Efficiency of using construction machines when strengthening foundation soils. IOP C Ser. Earth Environ. 2017, 90, 012205. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim; Herius, A.; Fikri, J.; Ramadhinata, M.S.; Maryani. Stabilization of peat soils using Petrasoil with cement viewed from CBR value and free compressive strength value of soils. J. Phys. Conf. Ser. 2020, 1500, 012069. [Google Scholar] [CrossRef]

- Havukainen, J.; Leppänen, M.; Piispanen, A. Mass stabilization—A method for the reuse of TBT-contaminated sediments as a part of the harbour field in Helsinki, Finland. In Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering, Alexandria, Egypt, 5–9 October 2009; pp. 2284–2287. [Google Scholar] [CrossRef]

- Åhnberg, H. Strength of Stabilized Soils—A Laboratory Report on Clays and Organic Soils Stabilized with Different Types of Binders. Ph.D. Thesis, Lund University, Lund, Sweden, 2006. [Google Scholar]

- Pan, D.; Li, L.; Tian, X.; Wu, Y.; Cheng, N.; Yu, H. A review on lead slag generation, characteristics, and utilization. Resour. Conserv. Recycl. 2019, 146, 140–155. [Google Scholar] [CrossRef]

- Tomasevic, D.; Dalmacija, M.; Prica, M.; Dalmacija, B.; Kerkez, D.; Becelic-Tomin, M.; Roncevic, S. Use of fly ash for remediation of metals polluted sediment—Green remediation. Chemosphere 2013, 92, 1490–1497. [Google Scholar] [CrossRef]

- Coenen, L.; Moodysson, J.; Martin, H. Path renewal in old industrial regions: Possibilities and limitations for regional innovation policy. Reg. Stud. 2015, 49, 850–865. [Google Scholar] [CrossRef]

- European Parliament. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives. OJEU 2008, L312, 3–30. [Google Scholar]

- Lederer, J.; Syc, M.; Biganzoli, L.; Bogush, A.; Bontempi, E.; Braga, R.; Costa, G.; Funari, V.; Grosso, M.; Hyks, J.; et al. Recovery Technologies for Waste Incineration Residues; Report; COST Action MINEA: Wien, Austria, 2018. [Google Scholar]

- Eyo, E.U.; Ng’ambi, S.; Abbey, S.J. Performance of clay stabilized by cementitious materials and inclusion of zeolite/alkaline metals-based additive. Transp. Geotech. 2020, 23. [Google Scholar] [CrossRef]

- Dantas, T.E.T.; de-Souza, E.D.; Destro, I.R.; Hammes, G.; Rodriguez, C.M.T.; Soares, S.R. How the combination of Circular Economy and Industry 4.0 can contribute towards achieving the Sustainable Development Goals. Sustain. Prod. Consum. 2021, 26, 213–227. [Google Scholar] [CrossRef]

- Yin, K.; Ahamed, A.; Lisak, G. Environmental perspectives of recycling various combustion ashes in cement production—A review. Waste Manag. 2018, 78, 401–416. [Google Scholar] [CrossRef]

- Provis, J.L.; Bernal, S.A. Geopolymers and related alkali-activated materials. Ann. Rev. Mater. Res. 2014, 44, 299–327. [Google Scholar] [CrossRef]

- Guo, X.; Shi, H.; Chen, L.; Dick, W.A. Alkali-activated complex binders from class C fly ash and Ca-containing admixtures. J. Hazard. Mater. 2010, 173, 480–486. [Google Scholar] [CrossRef]

- Guo, X.; Shi, H.; Dick, W.A. Compressive strength and microstructural characteristics of class C fly ash geopolymer. Cem. Concr. Comp. 2010, 32, 142–147. [Google Scholar] [CrossRef]

- Khalifeh, M.; Saasen, A.; Vralstad, T.; Hodne, H. Potential utilization of class C fly ash-based geopolymer in oil well cementing operations. Cem. Concr. Comp. 2014, 53, 10–17. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Fly ash-based geopolymers: The relationship between composition, pore structure and efflorescence. Cem. Concr. Res. 2014, 64, 30–41. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, H.; Zhu, Y.; Reid, A.; Provis, J.L.; Bullen, F. Using fly ash to partially substitute metakaolin in geopolymer synthesis. Appl. Clay Sci. 2014, 88–89, 194–201. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rodriguez, E.D.; Kirchheim, A.P.; Provis, J.L. Management and valorisation of wastes through use in producing alkali-activated cement materials. J. Chem. Technol. Biotechnol. 2016, 91, 2365–2388. [Google Scholar] [CrossRef]

- Paaver, P.; Paiste, P.; Liira, M.; Kirsimäe, K. Alkali activation of Estonian ca-rich oil shale ashes: A synthesis. Oil Shale 2019, 36, 214–225. [Google Scholar] [CrossRef]

- Provis, J.L.; Palomo, A.; Shi, C.J. Advances in understanding alkali-activated materials. Cem. Concr. Res. 2015, 78, 110–125. [Google Scholar] [CrossRef]

- Duxson, P.; Fernandez-Jimenez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Bachmann, M.; Ilp, R.; Kilk, K.; Kopti, M.; Leies, E.; Loorents, K.; Metusala, T.; Nõgene, M.; Sipelgas, K.; Sirkel, E.; et al. Kukersite and Mudstone. The Story of Our Energy; Eesti Energia AS: Tallin, Estonia, 2014. [Google Scholar]

- Aaloe, A.; Bauert, H.; Soesoo, A. Kukersite Oil Shale; MTÜ GEOGuide Baltoscandia: Tallinn, Estonia, 2007. [Google Scholar]

- Ots, A. Oil Shale Fuel Combustion: Properties. Power Plants. Boiler’s Design. Firig. Mineral Matter Behavior and Fouling. Heat Transfer. Corrosion and Wear; Tallinna Raamatutrükikoda: Tallinn, Estonia, 2006. [Google Scholar]

- Loo, L.; Maaten, B.; Konist, A.; Siirde, A.; Neshumayev, D.; Pihu, T. Carbon dioxide emission factors for oxy-fuel CFBC and aqueous carbonation of the Ca-rich oil shale ash. Energy Procedia 2017, 128, 144–149. [Google Scholar] [CrossRef]

- Bityukova, L.; Motlep, R.; Kirsimae, K. Composition of oil shale ashes from pulverized firing and circulating fluidized-bed boiler in Narva thermal power plants, Estonia. Oil Shale 2010, 27, 339–353. [Google Scholar] [CrossRef] [Green Version]

- Siirde, A.; Eldermann, M.; Rohumaa, P.; Gusca, J. Analysis of greenhouse gas emissions from Estonian oil shale based energy production processes. Life cycle energy analysis perspective. Oil Shale 2013, 30, 268–282. [Google Scholar] [CrossRef] [Green Version]

- EASAC. A Study on the EU Oil Shale Industry—Viewed in the Light of the Estonian Experience; EASAC: Halle, Germany, 2007. [Google Scholar]

- Kõiv, M.; Liira, M.; Mander, U.; Mõtlep, R.; Vohla, C.; Kirsimäe, K. Phosphorus removal using Ca-rich hydrated oil shale ash as filter material – The effect of different phosphorus loadings and wastewater compositions. Water Res. 2010, 44, 5232–5239. [Google Scholar] [CrossRef] [PubMed]

- Kõiv, M.; Ostonen, I.; Vohla, C.; Mõtlep, R.; Liira, M.; Lõhmus, K.; Kirsimäe, K.; Mander, Ü. Reuse potential of phosphorus-rich filter materials from subsurface flow wastewater treatment filters for forest soil amendment. Hydrobiologia 2012, 692, 145–156. [Google Scholar] [CrossRef]

- Liira, M.; Kõiv, M.; Mander, U.; Mõtlep, R.; Vohla, C.; Kirsimät, K. Active filtration of phosphorus on Ca-rich hydrated oil shale ash: Does longer retention time improve the process? Environ. Sci. Technol. 2009, 43, 3809–3814. [Google Scholar] [CrossRef] [PubMed]

- Mõtlep, R.; Sild, T.; Puura, E.; Kirsimäe, K. Composition, diagenetic transformation and alkalinity potential of oil shale ash sediments. J. Hazard. Mater. 2010, 184, 567–573. [Google Scholar] [CrossRef]

- Pihu, T.; Arro, H.; Prikk, A.; Rootamm, R.; Konist, A.; Kirsimäe, K.; Liira, M.; Mõtlep, R. Oil shale CFBC ash cementation properties in ash fields. Fuel 2012, 93, 172–180. [Google Scholar] [CrossRef]

- Paiste, P.; Liira, M.; Heinmaa, I.; Vahur, S.; Kirsimäe, K. Alkali activated construction materials: Assessing the alternative use for oil shale processing solid wastes. Constr. Build. Mater. 2016, 122, 458–464. [Google Scholar] [CrossRef]

- Pihu, T.; Konist, A.; Puura, E.; Liira, M.; Kirsimäe, K. Properties and environmental impact of oil shale ash landfills. Oil Shale 2019, 36, 257–270. [Google Scholar] [CrossRef]

- Talviste, P.; Sedman, A.; Mõtlep, R.; Kirsimäe, K. Self-cementing properties of oil shale solid heat carrier retorting residue. Waste Manag. Res. 2013, 31, 641–647. [Google Scholar] [CrossRef]

- Liira, M.; Kirsimäe, K.; Kuusik, R.; Mõtlep, R. Transformation of calcareous oil-shale circulation fluidized bed combustion boiler ashes under wet conditions. Fuel 2009, 88, 712–718. [Google Scholar] [CrossRef]

- Paiste, P.; Külaviir, M.; Paaver, P.; Heinmaa, I.; Vahur, S.; Kirsimäe, K. Beneficiation of oil shale processing waste: Secondary binder phases in alkali activated composites. Waste Biomass Valor. 2019, 10, 1407–1417. [Google Scholar] [CrossRef]

- Tcvetkov, P.S. The history, present status and future prospects of the Russian fuel peat industry. Mires Peat 2017, 19, 14. [Google Scholar] [CrossRef]

- Liiv, J.; Teppand, T.; Rikmann, E.; Tenno, T. Novel ecosustainable peat and oil shale ash-based 3D-printable composite material. SM&T 2018, 17, e00067. [Google Scholar] [CrossRef]

- Reinik, J.; Irha, N.; Koroljova, A.; Meriste, T. Use of oil shale ash in road construction: Results of follow-up environmental monitoring. Environ. Monit. Assess. 2018, 190, 59. [Google Scholar] [CrossRef]

- Tamm, T.; Nõges, T.; Järvet, A.; Bouraoui, F. Contributions of DOC from surface and groundflow into Lake Võrtsjärv (Estonia). In European Large Lakes. Ecosystem Changes and Their Ecological and Socioeconomic Impacts; Nõges, T., Eckmann, R., Kangur, K., Nõges, P., Reinart, A., Roll, G., Simola, H., Viljanen, M., Eds.; Springer: Dordrecht, The Netherlands, 2007; pp. 213–220. [Google Scholar] [CrossRef]

- Adamson, J.; Irha, N.; Adamson, K.; Steinnes, E.; Kirso, U. Effect of oil shale ash application on leaching behavior of arable soils: An experimental study. Oil Shale 2010, 27, 250–257. [Google Scholar] [CrossRef] [Green Version]

- Raado, L.-M.; Kuusik, R.; Hain, T.; Uibu, M.; Somelar, P. Oil shale ash based stone formation-hydration, hardening dynamics and phase transformations. Oil Shale 2014, 31, 91–101. [Google Scholar] [CrossRef] [Green Version]

- Reinik, J.; Irha, N.; Steinnes, E.; Urb, G.; Jefimova, J.; Piirisalu, E.; Loosaar, J. Changes in trace element contents in ashes of oil shale fueled PF and CFB boilers during operation. Fuel Process. Technol. 2013, 115, 174–181. [Google Scholar] [CrossRef]

- Reinik, J.; Irha, N.; Steinnes, E.; Piirisalu, E.; Aruoja, V.; Schultz, E.; Leppänen, M. Characterization of water extracts of oil shale retorting residues from gaseous and solid heat carrier processes. Fuel Process. Technol. 2015, 131, 443–451. [Google Scholar] [CrossRef]

- Sauve, S.; Hendershot, W.; Allen, H.E. Solid-solution partitioning of metals in contaminated soils: Dependence on pH, total metal burden, and organic matter. Environ. Sci. Technol. 2000, 34, 1125–1131. [Google Scholar] [CrossRef]

- Reinik, J.; Irha, N.; Steinnes, E.; Urb, G.; Jefimova, J.; Piirisalu, E. Release of 22 elements from bottom and fly ash samples of oil shale fueled PF and CFB boilers by a two cycle standard leaching test. Fuel Process. Technol. 2014, 124, 147–154. [Google Scholar] [CrossRef]

- Twardowska, I.; Allen, H.E.; Kettrup, A.F.; Lacy, W.J. Solid Waste: Assessment, Monitoring and Remediation; Elsevier: Amsterdam, The Netherlands, 2004; Volume 4. [Google Scholar]

- Cetin, B.; Aydilek, A.H.; Li, L. Experimental and numerical analysis of metal leaching from fly ash-amended highway bases. Waste Manag. 2012, 32, 965–978. [Google Scholar] [CrossRef]

- Ding, A.; Fu, J.; Sheng, G.; Liu, P.; Carpenter, P.J. Effects of oil shale waste disposal on soil and water quality: Hydrogeochemical aspects. Chem. Speciat. Bioavailab. 2003, 14, 79–86. [Google Scholar] [CrossRef]

- Kabata-Pendias, A. Soil-plant transfer of trace elements—An environmental issue. Geoderma 2004, 122, 143–149. [Google Scholar] [CrossRef]

- Oburger, E.; Jäger, A.; Pasch, A.; Stampfer, K.; Wenzel, W.W. Environmental impact assessment of wood ash utilization in forest road construction and maintenance—A field study. Sci. Total Environ. 2016, 544, 711–721. [Google Scholar] [CrossRef]

- Zou, C.; Yang, Z.; Cui, J.; Zhu, R.; Hou, L.; Tao, S.; Yuan, X.; Wu, S.; Lin, S.; Wan, L.; et al. Formation mechanism, geological characteristics and development strategy of nonmarine shale oil in China. Petrol. Explor. Dev. 2013, 40, 15–27. [Google Scholar] [CrossRef]

- Raave, H.; Kapak, S.; Orupold, K. Phytotoxicity of oil shale semi-coke and its aqueous extracts: A study by seed germination bioassay. Oil Shale 2007, 24, 59–71. [Google Scholar]

- Vallner, L.; Gavrilova, O.; Vilu, R. Environmental risks and problems of the optimal management of an oil shale semi-coke and ash landfill in Kohtla-Järve, Estonia. Sci. Total Environ. 2015, 15, 400–415. [Google Scholar] [CrossRef]

- Tan, G.; Zhu, Z.; Gong, Y.; Shi, C.; Liu, Z. Performance evaluation of cement-stabilized oil shale semicoke as base or subbase course construction material. Adv. Mater. Sci. Eng. 2018, 2018. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Sun, X.; Jia, C.; Qin, H.; Wang, Q. Analysis of mineral composition of oil shale semicoke and its cocombustion performance with cornstalks. Trans. Chin. Soc. Agr. Eng. 2016, 32, 226–231. [Google Scholar] [CrossRef]

- Wang, Q.; Xuan, Y.; Liu, H.; Li, X.; Chi, M. Gaseous emission and thermal analysis during co-combustion of oil shale semi-coke and sawdust using TG-FTIR. Oil Shale 2015, 32, 356–372. [Google Scholar] [CrossRef] [Green Version]

- US EPA. Advancing Sustainable Materials Management: 2015 Fact Sheet; US EPA: Washington, DC, USA, 2018.

- Intrakamhaeng, V.; Clavier, K.A.; Roessler, J.G.; Townsend, T.G. Limitations of the toxicity characteristic leaching procedure for providing a conservative estimate of landfilled municipal solid waste incineration ash leaching. J. Air Waste Manag. Assoc. 2019, 69, 623–632. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Clavier, K.A.; Spreadbury, C.; Townsend, T.G. Limitations of the TCLP fluid determination step for hazardous waste characterization of US municipal waste incineration ash. Waste Manag. 2019, 87, 590–596. [Google Scholar] [CrossRef] [PubMed]

- Colonna, P.; Berloco, N.; Ranieri, V.; Shuler, S.T. Application of bottom ash for pavement binder course. Procedia Soc. Behav. Sci. 2012, 53, 962–972. [Google Scholar] [CrossRef] [Green Version]

- Lynn, C.J.; Ghataora, G.S.; Dhir Obe, R.K. Municipal incinerated bottom ash (MIBA) characteristics and potential for use in road pavements. Int. J. Pavement Res. Technol. 2017, 10, 185–201. [Google Scholar] [CrossRef]

- Sarmiento, L.M.; Clavier, K.A.; Paris, J.M.; Ferraro, C.C.; Townsend, T.G. Critical examination of recycled municipal solid waste incineration ash as a mineral source for portland cement manufacture—A case study. Resour. Conserv. Recycl. 2019, 148, 1–10. [Google Scholar] [CrossRef]

- Schafer, M.L.; Clavier, K.A.; Townsend, T.G.; Ferraro, C.C.; Paris, J.M.; Watts, B.E. Use of coal fly ash or glass pozzolan as a mitigation tool for alkali-silica reactivity in cement mortars amended with recycled municipal solid waste incinerator bottom ash. Waste Biomass Valor. 2019, 10, 2733–2744. [Google Scholar] [CrossRef]

- Tang, P.; Florea, M.V.A.; Spiesz, P.; Brouwers, H.J.H. Characteristics and application potential of municipal solid waste incineration (MSWI) bottom ashes from two waste-to-energy plants. Constr. Build. Mater. 2015, 83, 77–94. [Google Scholar] [CrossRef]

- Van der Wegen, G.; Hofstra, U.; Speerstra, J. Upgraded MSWI bottom ash as aggregate in concrete. Waste Biomass Valor. 2013, 4, 737–743. [Google Scholar] [CrossRef]

- Huang, C.M.; Yang, W.F.; Ma, H.W.; Song, Y.R. The potential of recycling and reusing municipal solid waste incinerator ash in Taiwan. Waste Manag. 2006, 26, 979–987. [Google Scholar] [CrossRef]

- Oehmig, W.N.; Roessler, J.G.; Blaisi, N.I.; Townsend, T.G. Contemporary practices and findings essential to the development of effective MSWI ash reuse policy in the United States. Environ. Sci. Policy 2015, 51, 304–312. [Google Scholar] [CrossRef]

- Blasenbauer, D.; Huber, F.; Lederer, J.; Quina, M.J.; Blanc-Biscarat, D.; Bogush, A.; Bontempi, E.; Blondeau, J.; Chimenos, J.M.; Dahlbo, H.; et al. Legal situation and current practice of waste incineration bottom ash utilisation in Europe. Waste Manag. 2020, 102, 868–883. [Google Scholar] [CrossRef]

- Clavier, K.A.; Watts, B.; Liu, Y.; Ferraro, C.C.; Townsend, T.G. Risk and performance assessment of cement made using municipal solid waste incinerator bottom ash as a cement kiln feed. Resour. Conserv. Recycl. 2019, 146, 270–279. [Google Scholar] [CrossRef]

- Xie, R.; Xu, Y.; Huang, M.; Zhu, H.; Chu, F. Assessment of municipal solid waste incineration bottom ash as a potential road material. Road Mater. Pavement Des. 2017, 18, 992–998. [Google Scholar] [CrossRef]

- Carpenter, A.C.; Gardner, K.H.; Fopiano, J.; Benson, C.H.; Edil, T.B. Life cycle based risk assessment of recycled materials in roadway construction. Waste Manag. 2007, 27, 1458–1464. [Google Scholar] [CrossRef]

- Norgate, T.; Haque, N. Energy and greenhouse gas impacts of mining and mineral processing operations. J. Clean. Prod. 2010, 18, 266–274. [Google Scholar] [CrossRef]

- Lynn, C.J.; Ghataora, G.S.; Dhir, R.K. Environmental impacts of MIBA in geotechnics and road applications. Environ. Geotech. 2018, 5, 31–55. [Google Scholar] [CrossRef]

- Burlakovs, J.; Arina, D.; Rudovica, V.; Klavins, M. Leaching of heavy metals from soils stabilized with portland cement and municipal solid waste incineration bottom ash. Res. Rural Dev. 2013, 2, 101–106. [Google Scholar]

- Roessler, J.G.; Townsend, T.G.; Ferraro, C.C. Use of leaching tests to quantify trace element release from waste to energy bottom ash amended pavements. J. Hazard. Mater. 2015, 300, 830–837. [Google Scholar] [CrossRef]

- Schafer, M.L.; Clavier, K.A.; Townsend, T.G.; Kari, R.; Worobel, R.F. Assessment of the total content and leaching behavior of blends of incinerator bottom ash and natural aggregates in view of their utilization as road base construction material. Waste Manag. 2019, 98, 92–101. [Google Scholar] [CrossRef]

- Emilsson, S. International Handbook: From Extraction of Forest Fuels to Ash Recycling; Technical Report; Swedish Forest Agency: Karlstad, Sweden, 2006. [Google Scholar]

- Lindroos, A.-J.; Ryhti, K.; Kaakkurivaara, T.; Uusitalo, J.; Helmisaari, H.-S. Leaching of heavy metals and barium from forest roads reinforced with fly ash. Silva Fenn. 2019, 53, 10088. [Google Scholar] [CrossRef]

- Moilanen, M.; Silverberg, K.; Hökkä, H.; Issakainen, J. Wood ash as a fertilizer on drained mires—Growth and foliar nutrients of Scots pine. Can. J. For. Res. 2005, 35, 2734–2742. [Google Scholar] [CrossRef]

- Patterson, S.J.; Acharya, S.N.; Thomas, J.E.; Bertschi, A.B.; Rothwell, R.L. Barley biomass and grain yield and canola seed yield response to land application of wood ash. Agron. J. 2004, 96, 971–977. [Google Scholar] [CrossRef] [Green Version]

- Pesonen, J.; Yliniemi, J.; Kuokkanen, T.; Ohenoja, K.; Illikainen, M. Îmbunătăţirea procesului de întărire a cenuşii rezultate la arderea în pat fluidizat a turbei şi lemnului prin adăugarea de activator alcalin şi ciment portland/Improving the hardening of fly ash from fluidized-bed combustion of peat and wood with the addition of alkaline activator and Portland cement. Rev. Rom. Mat. 2016, 46, 82–88. [Google Scholar]

- Wang, S.; Miller, A.; Llamazos, E.; Fonseca, F.; Baxter, L. Biomass fly ash in concrete: Mixture proportioning and mechanical properties. Fuel 2008, 87, 365–371. [Google Scholar] [CrossRef]

- Edil, T.B.; Benson, C.H. Demonstration of Ash Utilization in Low Volume Roads; Final Report; Minnesota Department of Transportation: Saint Paul, MN, USA, 2007. [Google Scholar]

- Lahtinen, P. Fly Ash Mixtures as Flexible Structural Materials for Low-Volume Roads; Report; Finnish Road Administration: Helsinki, Finland, 2001. [Google Scholar]

- Vincevica-Gaile, Z.; Stankevica, K.; Irtiseva, K.; Shishkin, A.; Obuka, V.; Celma, S.; Ozolins, J.; Klavins, M. Granulation of fly ash and biochar with organic lake sediments—A way to sustainable utilization of waste from bioenergy production. Biomass Bioenerg. 2019, 125, 23–33. [Google Scholar] [CrossRef]

- Kaakkurivaara, T. Innovative Methods for Measuring and Improving the Bearing Capacity of Forest Roads. Academic Dissertation, Finnish Society of Forest Science, Helsinki, Finland, 2018. [Google Scholar] [CrossRef]

- Kaakkurivaara, T.; Kolisoja, P.; Uusitalo, J.; Vuorimies, N. Fly ash in forest road rehabilitation. Croat. J. For. Eng. 2016, 37, 119–130. [Google Scholar]

- Bohrn, G.; Stampfer, K. Untreated wood ash as a structural stabilizing material in forest roads. Croat. J. For. Eng. 2014, 35, 81–88. [Google Scholar]

- Kaakkurivaara, T.; Korpunen, H. Increased fly ash utilization—Value addition through forest road reconstruction. Can. J. Civ. Eng. 2017, 44, 223–231. [Google Scholar] [CrossRef]

- Nordmark, D.; Vestin, J.; Lagerkvist, A.; Lind, B.B.; Arm, M.; Hallgren, P. Geochemical behavior of a gravel road upgraded with wood fly ash. J. Environ. Eng. 2014, 140, 05014002. [Google Scholar] [CrossRef]

- Huotari, N. Tuhkan Käyttö Metsälannoitteena/Use of Ash as Forest Fertilizer; METLA: Helsinki, Finland, 2012. [Google Scholar]

- Korpijärvi, K.; Mroueh, U.-M.; Merta, E.; Laine-Ylijoki, J.; Kivikoski, H.; Järvelä, E.; Wahlström, M.; Mäkelä, E. Energiantuotannon tuhkien jalostaminen maarakennuskäyttöön/Processing of Fly Ash for Earth Construction; Report; VTT Technical Research Centre of Finland: Helsinki, Finland, 2009. [Google Scholar]

- Cherian, C.; Siddiqua, S. Pulp and paper mill fly ash: A review. Sustainability 2019, 11, 4394. [Google Scholar] [CrossRef] [Green Version]

- Ondová, M.; Števulová, N. Slovak Fly Ash as Cement Substitution in the Concrete Road Pavements; LAMBERT Academic Publishing: Kosice, Slovakia, 2013. [Google Scholar]

- Zhou, H.; Smith, D.W.; Sego, D.C. Characterization and use of pulp mill fly ash and lime by-products as road construction amendments. Can. J. Civ. Eng. 2000, 27, 581–593. [Google Scholar] [CrossRef]

- James, J. Strength benefits of saw dust/wood ash amendment in stabilization of an expansive soil. Rev. Fac. Ing. 2019, 28, 44–61. [Google Scholar] [CrossRef] [Green Version]

- Murmu, A.L.; Dhole, N.; Patel, A. Stabilization of black cotton soil for subgrade application using fly ash geopolymer. Road Mater. Pavement Des. 2020, 21, 867–885. [Google Scholar] [CrossRef]

- Šķēls, P.; Bondars, K.; Plonis, R.; Haritonovs, V.; Paeglītis, A. Usage of wood fly ash in stabilization of unbound pavement layers and soils. In Proceedings of the 13th Baltic Sea Geotechnical Conference—Historical Experience and Challenges of Geotechnical Problems in Baltic Sea Region, Vilnius, Lithuania, 22–24 September 2016; pp. 122–125. [Google Scholar] [CrossRef] [Green Version]

- Rios, S.; Cristelo, N.; Miranda, T.; Araújo, N.; Oliviera, J.; Lucas, E. Increasing the reaction kinetics of alkali activated fly ash for stabilisation of a silty sand pavement sub-base. Road Mater. Pavement Des. 2018, 19, 201–222. [Google Scholar] [CrossRef] [Green Version]

- Slim, G.I.; Morales, M.; Alrumaidhin, L.; Bridgman, P.; Gloor, J.; Hoff, S.T.; Odem, W.I. Optimization of polymer-amended fly ash and paper pulp millings mixture for alternative landfill liner. Procedia Eng. 2016, 145, 312–318. [Google Scholar] [CrossRef] [Green Version]

- Vaníček, I.; Jirásko, D.; Vaníček, M. Transportation and environmental geotechnics. Procedia Eng. 2017, 189, 118–125. [Google Scholar] [CrossRef]

- Lynn, C.J.; Dhir, R.K.; Ghataora, G.S. Environmental impacts of sewage sludge ash in construction: Leaching assessment. Resour. Conserv. Recycl. 2018, 136, 306–314. [Google Scholar] [CrossRef]

- Ma, W.; Meng, F.; Qiu, D.; Tang, Y. Co-stabilization of Pb/Cu/Zn by beneficial utilization of sewage sludge incineration ash: Effects of heavy metal type and content. Resour. Conserv. Recycl. 2020, 156. [Google Scholar] [CrossRef]

- Lynn, C.J.; Dhir, R.K.; Ghataora, G.S.; West, R.P. Sewage sludge ash characteristics and potential for use in concrete. Constr. Build. Mater. 2015, 98, 767–779. [Google Scholar] [CrossRef] [Green Version]

- Sato, Y.; Oyamada, T.; Hanehara, S. Applicability of sewage sludge ash (SSA) for paving materials: A study on using SSA as filler for asphalt mixture and base course material. In Proceedings of the 3rd International Conference on Sustainable Construction Materials and Technologies (SCMT3), Kyoto, Japan, 18–21 August 2013; p. e283. [Google Scholar]

- Sato, Y.; Oyamada, T.; Hanehara, S.; Sasaki, T. The characteristics of ash of sewage sludge (SSA) in Iwate prefecture and application of SSA for asphalt mixture. J. MMIJ 2012, 128, 519–525. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, J.; Abdul Rahman, A.S.; Mohd Ali, M.R.; Abd. Rahman, K.F. Peat soil treatment using POFA. In Proceedings of the 2011 IEEE Colloquium on Humanities, Science and Engineering Research (CHUSER 2011), Penang, Malaysia, 5–6 December 2011; pp. 66–70. [CrossRef]

- Mohamed, A.R.; Lee, K.T.; Noor, N.M.; Zainudin, N.F. Oil palm ash/Ca (OH)2/CaSO4 absorbent for flue gas desulfurization. Chem. Eng. Technol. 2005, 28, 939–945. [Google Scholar] [CrossRef]

- Hussin, M.W.; Ismail, M.A.; Budiea, A.; Muthusamy, K. Durability of high strength concrete containing palm oil fuel ash of different fineness. Malays. J. Civ. Eng. 2009, 21, 180–194. [Google Scholar]

- Hussin, M.W.; Muthusamy, K.; Zakaria, F. Effect of mixing constituent toward engineering properties of POFA cement-based aerated concrete. J. Mater. Civ. Eng. 2010, 22, 287. [Google Scholar] [CrossRef]

- Muthusamy, K.; Azzimah, N.A. Exploratory study of palm oil fuel ash as partial cement replacement in oil palm shell lightweight aggregate concrete. Res. J. Appl. Sci. Eng. Technol. 2014, 2, 150–152. [Google Scholar] [CrossRef]

- Aris, S.M.; Muthusamy, K.; Uzer, A.; Ahmad, S.W. Properties of palm oil fuel ash cement sand brick containing pulverized cockle shell as partial sand replacement. IOP C Ser. Earth Environ. 2018, 140, 012145. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Saeting, T.; Jaturapitakkul, C.; Kiattikomol, K.; Siripanichgorn, A. Use of waste ash from palm oil industry in concrete. Waste Manag. 2007, 27, 81–88. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Mahmud, H.; Jumaat, M.Z. Enhancement and prediction of modulus of elasticity of palm kernel shell concrete. Mater. Des. 2011, 32, 2143–2148. [Google Scholar] [CrossRef]

- Ismail, M.; Yusuf, T.O.; Noruzman, A.H.; Hassan, I. Early strength characteristics of palm oil fuel ash and metakaolin blended geopolymer mortar. Adv. Mat. Res. 2013, 690–693, 1045–1048. [Google Scholar] [CrossRef]

- Huseien, G.F.; Ismail, M.; Tahir, M.M.; Mirza, J.; Khalid, N.H.A.; Asaad, M.A.; Husein, A.A.; Sarbini, N.N. Synergism between palm oil fuel ash and slag: Production of environmental-friendly alkali activated mortars with enhanced properties. Constr. Build. Mater. 2018, 170, 235–244. [Google Scholar] [CrossRef]

- Haddad, R.H.; Ashteyat, A.M.; Lababneh, Z.K. Producing geopolymer composites using oil shale ash. Struct. Concr. 2018, 20, 225–235. [Google Scholar] [CrossRef] [Green Version]

- Ashteyat, A.; Haddad, R.H.; Yamin, M.M. Production of self-compacting concrete using Jordanian oil shale ash. Jordan J. Civ. Eng. 2012, 6, 202–214. [Google Scholar]

- Azzam, M.O.J.; Al-Ghazawi, Z.; Al-Otoom, A. Incorporation of Jordanian oil shale in hot mix asphalt. J. Clean. Prod. 2016, 112, 2259–2277. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; van Deventer, J.S.J. Solid reactant-based geopolymers from rice hull ash and sodium aluminate. Waste Biomass Valor. 2017, 8, 2131–2140. [Google Scholar] [CrossRef]

- Tchakouté, H.K.; Rüscher, C.H.; Kong, S.; Kamseu, E.; Leonelli, C. Thermal behavior of metakaolin-based geopolymer cements using sodium waterglass from rice husk ash and waste glass as alternative activators. Waste Biomass Valor. 2017, 8, 573–584. [Google Scholar] [CrossRef]

- Yliniemi, J.; Tiainen, M.; Illikainen, M. Microstructure and physical properties of lightweight aggregates produced by alkali activation-high shear granulation of FBC recovered fuel-biofuel fly ash. Waste Biomass Valor. 2016, 7, 1235–1244. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; van Deventer, J.S.J. Characterisation of one-part geopolymer binders made from fly ash. Waste Biomass Valor. 2017, 8, 225–233. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, Y.-L.; Liu, S.-Y. Application of biomass by-product lignin stabilized soils as sustainable Geomaterials: A review. Sci. Total Environ. 2020, 728, 138830. [Google Scholar] [CrossRef]

- Gowthaman, S.; Nakashima, K.; Kawasaki, S. A state-of-the-art review on soil reinforcement technology using natural plant fiber materials: Past findings, present trends and future directions. Materials 2018, 11, 553. [Google Scholar] [CrossRef] [Green Version]

- Sato, A.; Kawasaki, S.; Hata, T.; Hayashi, T. Possibility for solidification of peaty soil by using microbes. Int. J. GEOMATE 2016, 10, 2071–2076. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Bhattacharyya, R.; Mondal, M.M. Potential applications of open weave jute geotextile (soil saver) in meeting geotechnical difficulties. Procedia Eng. 2017, 200, 200–205. [Google Scholar] [CrossRef]

- Sharma, V.; Vinayak, H.K.; Marwaha, B.M. Enhancing compressive strength of soil using natural fibers. Constr. Build. Mater. 2015, 93, 943–949. [Google Scholar] [CrossRef]

- Dassanayake, K.B.; Jayasinghe, G.Y.; Surapaneni, A.; Hetherington, C. A review on alum sludge reuse with special reference to agricultural applications and future challenges. Waste Manag. 2015, 38, 321–335. [Google Scholar] [CrossRef] [PubMed]

- Kyncl, M.; Číhalová, Š.; Juroková, M.; Langarová, S. Unieszkodliwianie i zagospodarowanie osadów z uzdatniania wody/Disposal and reuse of the water processing sludge. Inz. Miner. 2012, 2, 11–20. [Google Scholar]

- Owaid, H.M.; Hamid, R.; Taha, M.R. Influence of thermally activated alum sludge ash on the engineering properties of multiple-blended binders concretes. Constr. Build. Mater. 2014, 61, 216–229. [Google Scholar] [CrossRef]

- Millar, N.; McLaughlin, E.; Börger, T. The circular economy: Swings and roundabouts? Ecol. Econ. 2019, 158, 11–19. [Google Scholar] [CrossRef] [Green Version]

- Basha, E.; Hashim, R.; Mahmud, H.; Muntohar, A. Stabilization of residual soil with rice husk ash and cement. Constr. Build. Mater. 2005, 19, 448–453. [Google Scholar] [CrossRef] [Green Version]

- Al-Homidy, A.A.; Dahim, M.H.; El Aal, A.K.A. Improvement of geotechnical properties of sabkha soil utilizing cement kiln dust. J. Rock Mech. Geotech. Eng. 2017, 9, 749–760. [Google Scholar] [CrossRef]

- Hasan, H.; Dang, L.; Khabbaz, H.; Fatahi, B.; Terzaghi, S. Remediation of expansive soils using agricultural waste bagasse ash. Procedia Eng. 2016, 143, 1368–1375. [Google Scholar] [CrossRef] [Green Version]

- Jamsawang, P.; Poorahong, H.; Yoobanpot, N.; Songpiriyakij, S.; Jongpradist, P. Improvement of soft clay with cement and bagasse ash waste. Constr. Build. Mater. 2017, 154, 61–71. [Google Scholar] [CrossRef]

- Seleiman, M.F.; Kheir, A.M. Saline soil properties, quality and productivity of wheat grown with bagasse ash and thiourea in different climatic zones. Chemosphere 2018, 193, 538–546. [Google Scholar] [CrossRef]

- Yadav, A.K.; Gaurav, K.; Kishor, R.; Suman, S. Stabilization of alluvial soil for subgrade using rice husk ash, sugarcane bagasse ash and cow dung ash for rural roads. Int. J. Pavement Res. Technol. 2018, 10, 254–261. [Google Scholar] [CrossRef]

- Hu, L.; He, Z.; Zhang, S. Sustainable use of rice husk ash in cement-based materials: Environmental evaluation and performance improvement. J. Clean. Prod. 2020, 264, 121744. [Google Scholar] [CrossRef]

- Muntohar, A.S. Utilization of uncontrolled burnt rice husk ash in soil improvement. Dimens. Tek. Sipil 2002, 4, 100–105. [Google Scholar]

- Keramatikerman, M.; Chegenizadeh, A.; Nikraz, H.; Sabbar, A.S. Effect of flyash on liquefaction behaviour of sand-bentonite mixture. Soils Found. 2018, 58, 1288–1296. [Google Scholar] [CrossRef]

- Al-Malack, M.H.; Abdullah, G.M.; Al-Amoudi, O.S.B.; Bukhari, A.A. Stabilization of indigenous Saudi Arabian soils using fuel oil flyash. J. King Saud Univ. Eng. Sci. 2016, 28, 165–173. [Google Scholar] [CrossRef] [Green Version]

- Rifa’i, A.; Yasufuku, N.; Tsuji, K. Characterization and effective utilization of coal ash as soil stabilization on road application. In Proceedings of the International Symposium on Ground Improvement Technologies and Case Histories (ISGI’09), Singapore, 9–12 December 2009; pp. 469–474. [Google Scholar] [CrossRef]

- Phummiphan, I.; Horpibulsuk, S.; Rachan, R.; Arulrajah, A.; Shen, S.-L.; Chindaprasirt, P. High calcium fly ash geopolymer stabilized lateritic soil and granulated blast furnace slag blends as a pavement base material. J. Hazard. Mater. 2018, 341, 257–267. [Google Scholar] [CrossRef]

- Sharma, A.K.; Sivapullaiah, P. Improvement of strength of expansive soil with waste granulated blast furnace slag. In State of the Art and Practice in Geotechnical Engineering, Proceedings of the GeoCongress 2012, Oakland, USA, 25–29 March 2012; American Society of Civil Engineers: New York, NY, USA, 2012; pp. 3920–3928. [Google Scholar] [CrossRef]

- Türkmen, I. Influence of different curing conditions on the physical and mechanical properties of concretes with admixtures of silica fume and blast furnace slag. Mater. Lett. 2003, 57, 4560–4569. [Google Scholar] [CrossRef]

- Mosa, A.M.; Taher, A.H.; Al-Jaberi, L.A. Improvement of poor subgrade soils using cement kiln dust. Case Stud. Constr. Mater. 2017, 7, 138–143. [Google Scholar] [CrossRef]

- Sezer, A.; Inan, G.; Yılmaz, H.R.; Ramyar, K. Utilization of a very high lime fly ash for improvement of Izmir clay. Build. Environ. 2006, 41, 150–155. [Google Scholar] [CrossRef]

- Solanki, P.; Khoury, N.; Zaman, M. Engineering behavior and microstructure of soil stabilized with cement kiln dust. In Proceedings of the Geo-Denver 2007—New Peaks in Geotechnics: Soil Improvement, Denver, CO, USA, 18–21 February 2007. [Google Scholar]

- Karim, H.; Al-Recubay, M.; Nsaif, M. Stabilization of soft clayey soil with sawdust ashes. MATEC Web Conf. 2018, 162, 01006. [Google Scholar] [CrossRef] [Green Version]

- Camotti Bastos, M.; Soubrand, M.; Le Guet, T.; Le Floch, É.; Joussein, E.; Baudu, M.; Casellas, M. Occurrence, fate and environmental risk assessment of pharmaceutical compounds in soils amended with organic wastes. Geoderma 2020, 375. [Google Scholar] [CrossRef]

- Hazrati, S.; Farahbakhsh, M.; Heydarpoor, G.; Besalatpour, A.A. Mitigation in availability and toxicity of multi-metal contaminated soil by combining soil washing and organic amendments stabilization. Ecotoxicol. Environ. Saf. 2020, 201. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Novel biochar-concrete composites: Manufacturing, characterization and evaluation of the mechanical properties. Sci. Total Environ. 2018, 616–617, 408–416. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Low, C.J. Use of biochar as carbon sequestering additive in cement mortar. Cem. Concr. Comp. 2018, 87, 110–129. [Google Scholar] [CrossRef]

- Burlakovs, J.; Kaczala, F.; Vincevica-Gaile, Z.; Rudovica, V.; Orupõld, K.; Stapkevica, M.; Bhatnagar, A.; Kriipsalu, M.; Hogland, M.; Klavins, M.; et al. Mobility of metals and valorization of sorted fine fraction of waste after landfill excavation. Waste Biomass Valor. 2016, 7, 593–602. [Google Scholar] [CrossRef]

- Burlakovs, J.; Kriipsalu, M.; Klavins, M.; Bhatnagar, A.; Vincevica-Gaile, Z.; Stenis, J.; Jani, Y.; Mykhaylenko, V.; Denafas, G.; Turkadze, T.; et al. Paradigms on landfill mining: From dump site scavenging to ecosystem services revitalization. Resour. Conserv. Recycl. 2017, 123, 73–84. [Google Scholar] [CrossRef] [Green Version]

- Burlakovs, J.; Pilecka, J.; Grinfelde, I.; Ozola-Davidane, R. Clay minerals and humic substances as landfill closure covering material constituents: First studies. Res. Rural Dev. 2020, 35, 219–226. [Google Scholar] [CrossRef]

- Pehme, K.-M.; Jäärats, A.; Orupõld, K.; Kriipsalu, M.; Tamm, T. Community forestry on remediated landfill site. SGEM Int. Multidisc. Sci. GeoConf. Surv. Geol. Min. Ecol. Manag. 2018, 18, 203–210. [Google Scholar] [CrossRef]

- Pehme, K.-M.; Orupõld, K.; Kuusemets, V.; Tamm, O.; Jani, Y.; Tamm, T.; Kriipsalu, M. Field study on the efficiency of a methane degradation layer composed of fine fraction soil from landfill mining. Sustainability 2020, 12, 6209. [Google Scholar] [CrossRef]

| Property/Process | Risk | Reference |

|---|---|---|

| Excessive content of chemical elements and constituents | Soil and groundwater pollution with arsenic, sulphates, barium | [107,108,112,118,119,120,121,122] |

| Content of lime | Changes in soil pH | [107,108,112,119] |

| Leaching | Groundwater and surface water contamination | [118,121,122,123,124] |

| Mobility and soil–water interaction | Groundwater and surface water contamination | [117,125,126,127,128] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vincevica-Gaile, Z.; Teppand, T.; Kriipsalu, M.; Krievans, M.; Jani, Y.; Klavins, M.; Hendroko Setyobudi, R.; Grinfelde, I.; Rudovica, V.; Tamm, T.; et al. Towards Sustainable Soil Stabilization in Peatlands: Secondary Raw Materials as an Alternative. Sustainability 2021, 13, 6726. https://doi.org/10.3390/su13126726

Vincevica-Gaile Z, Teppand T, Kriipsalu M, Krievans M, Jani Y, Klavins M, Hendroko Setyobudi R, Grinfelde I, Rudovica V, Tamm T, et al. Towards Sustainable Soil Stabilization in Peatlands: Secondary Raw Materials as an Alternative. Sustainability. 2021; 13(12):6726. https://doi.org/10.3390/su13126726

Chicago/Turabian StyleVincevica-Gaile, Zane, Tonis Teppand, Mait Kriipsalu, Maris Krievans, Yahya Jani, Maris Klavins, Roy Hendroko Setyobudi, Inga Grinfelde, Vita Rudovica, Toomas Tamm, and et al. 2021. "Towards Sustainable Soil Stabilization in Peatlands: Secondary Raw Materials as an Alternative" Sustainability 13, no. 12: 6726. https://doi.org/10.3390/su13126726