Selecting Suitable, Green Port Crane Equipment for International Commercial Ports

Abstract

:1. Introduction

2. Literature Review

2.1. Green Ports

2.2. DEA Applied in Green Ports

3. Methodology

3.1. Modified SBM-DEA Model

3.2. Modified SBM-DEA Model for Evaluating Green Energy Index Process

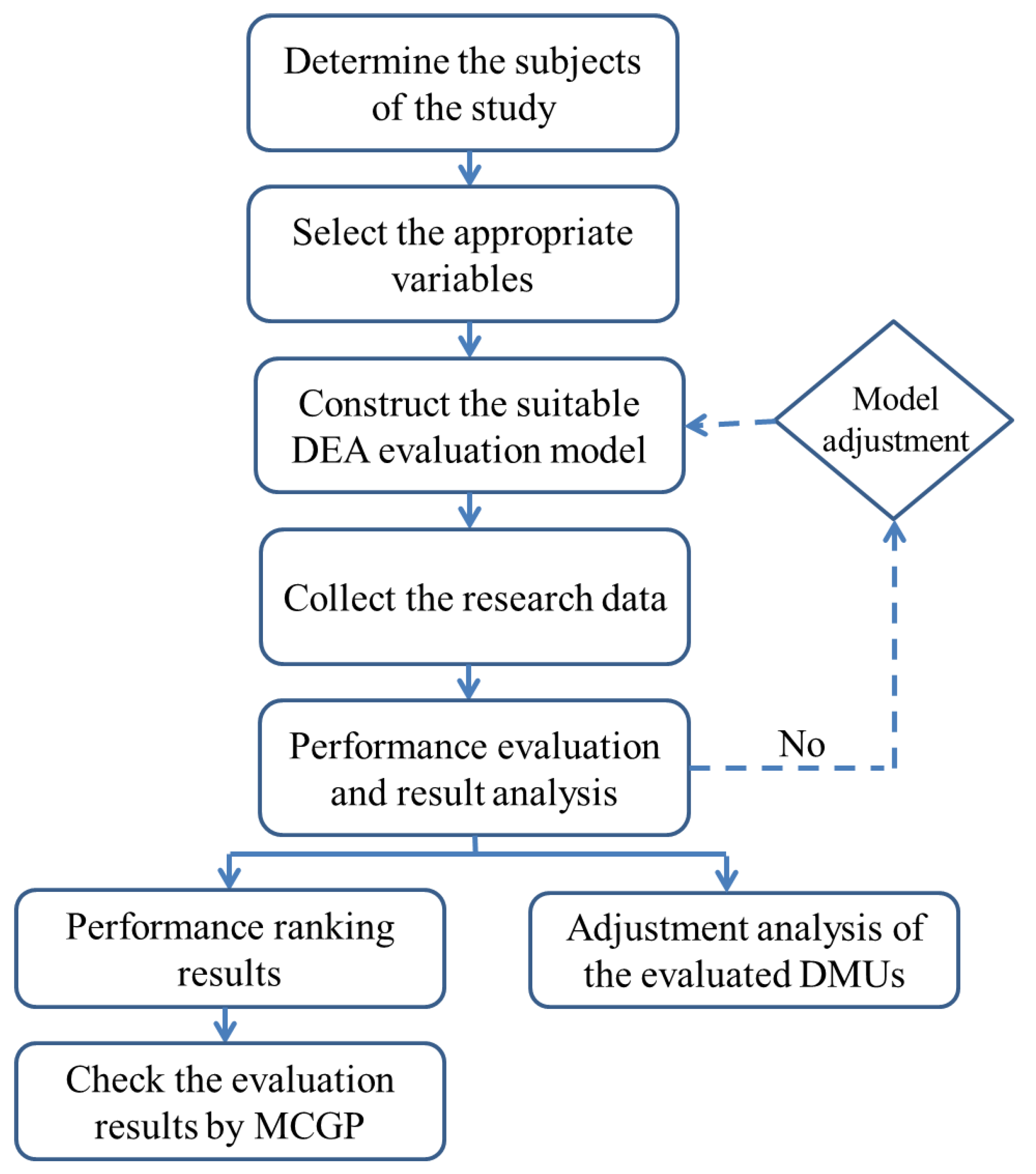

- Step 1: First, determine the research subjects of the study;

- Step 2: Select appropriate variables (green energy index) through the literature review;

- Step 3: Construct the suitable modified SBM-DEA model for the performance evaluation;

- Step 4: Based on the research results of previous steps, this study should interview some relevant enterprises to investigate the practical operational data of the selected variables;

- Step 5: Use the new proposed model (such as the new Equations (6) and (7) in this study) to conduct performance evaluation processing on the collected data. If some infeasibility problem occurs, it is necessary to go back to Step 3 and make appropriate adjustments to the constructed modified SBM-DEA model. After doing so, repeat Step 5;

- Step 6: Each evaluated DMU can obtain its super-efficiency with Formulation (8);

- Step 7: Then, determine the maximum value to calculate the green energy index for each evaluated DMU via Formulation (9). Based on the results of the green energy index, obtain performance ranking results and screen out the efficient benchmarking DMUs;

- Step 8: Conduct an in-depth analysis of the most suitable adjustment for the each DMU;

- Step 9: Finally, check the modified SBM-DEA model evaluation results through the MCGP method (Equations (10)–(14)).

3.3. MCGP Model for Choosing Suitable Crane Equipment

4. Empirical Research for a Real Case Example

4.1. Data Collection and Evaluating Green Performance of Various Cranes

4.2. Modified SBM-DEA Model Analysis Result

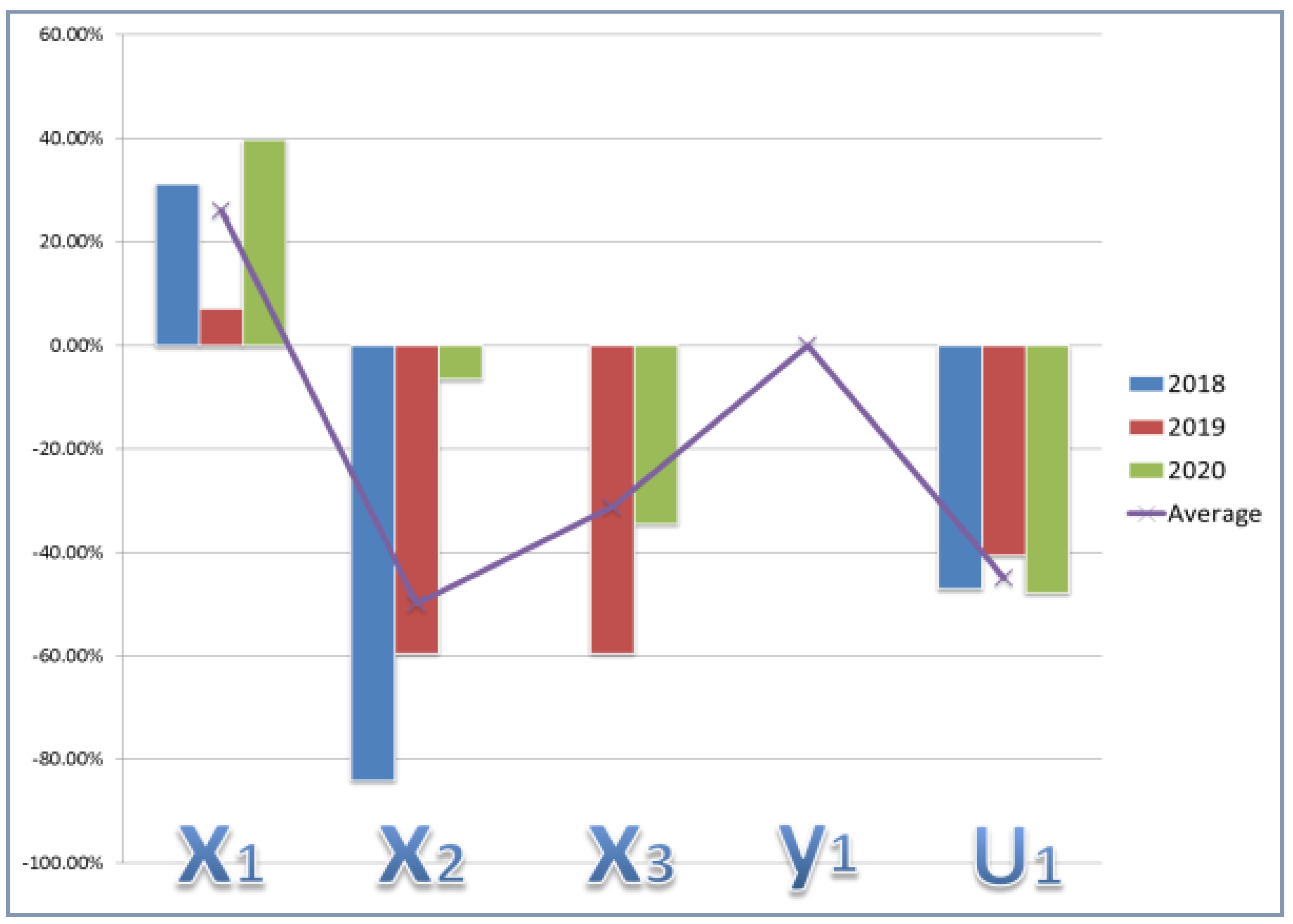

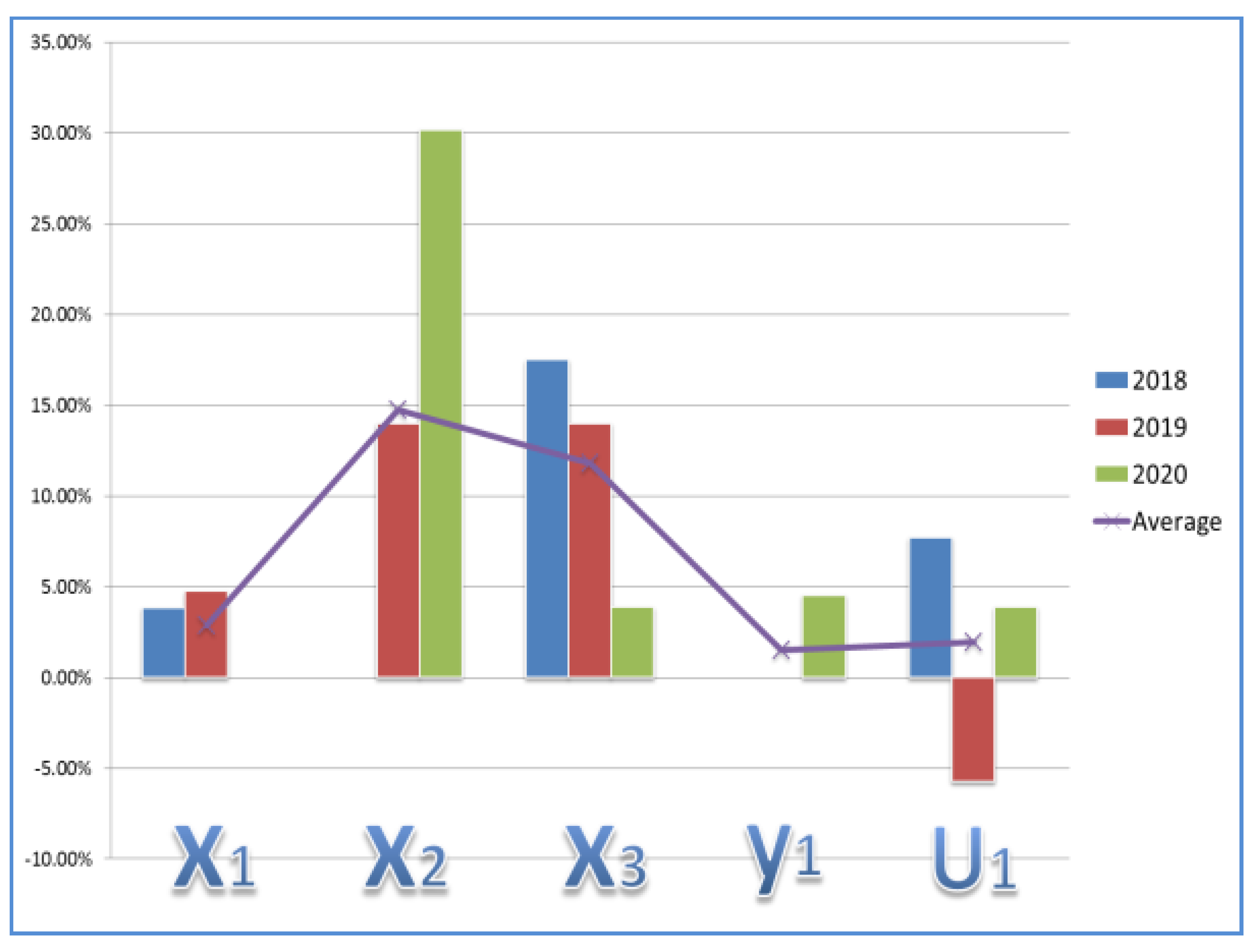

4.3. Suitable Adjustment for Each Variable Analysis

4.4. Using MCGP to Solve the Case Example of Choosing Between Crane Equipment

- The first goal is Y1: the working capacity is the RTG benchmark. The DMU of the RTG was 71,341 and 77,989 in the Table 6 RTG 2020 results; 71,341 was the benchmark value and 77,989 was the AVE value;

- The second goal is U1: the emission volume is the RTG benchmark. The DMU of the RTG was 88,143 and 92,889 in the Table 6 RTG 2020 results;

- The third goal is X1: the operational duration is the DMU of the RTG crane’s input. The DMU of the RTG was 3397 and 4014 in the Table 6 RTG 2020 results;

- The fourth goal is X2: the energy consumption is the DMU of the RTG crane’s input. The DMU of the RTG was 153,429 and 186,553 in the Table 6 RTG 2020 results;

- The fifth goal is X3: the total energy cost is the DMU of the RTG crane’s input. The DMU of RTG was 504,154 and 610,634 in the Table 6 RTG 2020 results.

- Indices:

- Parameters:

- Decision variables:

5. Conclusions and Implications

5.1. Conclusions

5.2. Managerial Implications

5.3. Limitations

- (i)

- To mitigate the disadvantages of the DEA method, we used the MCGP method to verify the DEA results. To better cope with uncertainty, decision makers can use the novel MCGP method in conjunction with the multi-criteria decision-making approach;

- (ii)

- Our study, a real-world case example, used data collected in Taiwan.

5.4. Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Carey, M. In The Shadow of Melting Glaciers: Climate Change and Andean Society; Oxford University Press: New York, NY, USA, 2010. [Google Scholar]

- Barragán, J.M.; de Andrés, M. Analysis and trends of the world’s coastal cities and agglomerations. Ocean Coast. Manag. 2015, 114, 11–20. [Google Scholar] [CrossRef]

- Chang, C.-C.; Wang, C.-M. Evaluating the effects of green port policy: Case study of Kaohsiung harbor in Taiwan. Transp. Res. Part D Transp. Environ. 2012, 17, 185–189. [Google Scholar] [CrossRef]

- Wan, C.; Zhang, D.; Yan, X.; Yang, Z. A novel model for the quantitative evaluation of green port development—A case study of major ports in China. Transp. Res. Part D Transp. Environ. 2018, 61, 431–443. [Google Scholar] [CrossRef]

- Barnes-Dabban, H.; Van Tatenhove, J.P.M.; Van Koppen, K.C.S.A.; Termeer, K.J.A.M. Institutionalizing environmental re-form with sense-making: West and central Africa ports and the ‘green port’ phenomenon. Mar. Policy 2017, 86, 111–120. [Google Scholar] [CrossRef]

- Meng, B.; Kuang, H.; Niu, E.; Li, J.; Li, Z. Research on the Transformation Path of the Green Intelligent Port: Outlining the Perspective of the Evolutionary Game “Government–Port–Third-Party Organization”. Sustainability 2020, 12, 8072. [Google Scholar] [CrossRef]

- Twrdy, E.; Zanne, M. Improvement of the sustainability of ports logistics by the development of innovative green infra-structure solutions. Transp. Res. Procedia 2020, 45, 539–546. [Google Scholar] [CrossRef]

- Liu, P.; Wang, C.; Xie, J.; Mu, D.; Lim, M.K. Towards green port-hinterland transportation: Coordinating railway and roadin-frastructure in Shandong Province, China. Transp. Res. D Transp. Environ. 2021, 94, 102806. [Google Scholar] [CrossRef]

- Espino, G.D.L.L.; Rodríguez, I.P.; Czitrom, S.P. Water quality of a port in NW Mexico and its rehabilitation with swell energy. Mar. Pollut. Bull. 2010, 60, 123–130. [Google Scholar] [CrossRef]

- Otene, B.B.; Nnadi, P. Water Quality Index and Status of Minichinda Stream, Port Harcourt, Nigeria. IIARD Int. J. Geogr. Environ. Manag. 2019, 5, 1–9. [Google Scholar]

- Lee, S.; Lee, E.; Yoo, H.S.; Lee, M.J. Analysis of trends in marine water quality using environmental impact as-sessment monitoring data: A case study of Busan new port. J. Coast. Res. 2020, 102, 39–46. [Google Scholar] [CrossRef]

- Bolognese, M.; Fidecaro, F.; Palazzuoli, D.; Licitra, G. Port Noise and Complaints in the North Tyrrhenian Sea and Frame Work for Remediation. Environments 2020, 7, 17. [Google Scholar] [CrossRef] [Green Version]

- Di Vaio, A.; Varriale, L.; Trujillo, L. Management Control Systems in port waste management: Evidence from Italy. Util. Policy 2019, 56, 127–135. [Google Scholar] [CrossRef]

- Prati, M.V.; Costagliola, M.A.; Quaranta, F.; Murena, F. Assessment of ambient air quality in the port of Naples. J. Air Waste Manag. Assoc. 2015, 65, 970–979. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kontos, S.; Liora, N.; Poupkou, A.; Giannaros, C.; Garane, K.; Melas, D. Air-Quality Impact of Cruise and Passenger Ship Emissions in the Port of Thessaloniki. Springer Atmos. Sci. 2017, 1129–1134. [Google Scholar] [CrossRef]

- Casazza, M.; Lega, M.; Jannelli, E.; Minutillo, M.; Jaffe, D.; Severino, V.; Ulgiati, S. 3D monitoring and modelling of air quality for sustainable urban port planning: Review and perspectives. J. Clean. Prod. 2019, 231, 1342–1352. [Google Scholar] [CrossRef]

- Progiou, A.G.; Bakeas, E.; Evangelidou, E.; Kontogiorgi, C.; Lagkadinou, D.; Sebos, I. Air pollutant emissions from Pi-raeusport: External costs and air quality levels. Transp. Res. D Transp. Environ. 2021, 91, 102586. [Google Scholar] [CrossRef]

- Gobbi, G.P.; Di Liberto, L.; Barnaba, F. Impact of port emissions on EU-regulated and non-regulated air quality indicators: The case of Civitavecchia (Italy). Sci. Total. Environ. 2020, 719, 134984. [Google Scholar] [CrossRef]

- Ee, J.Y.C.; Chan, J.Y.; Kang, G.L. Carbon reduction analysis of Malaysian green port operation. Prog. Energy Environ. 2021, 15, 1–7. [Google Scholar]

- Fabregat, A.; Vázquez, L.; Vernet, A. Using Machine Learning to estimate the impact of ports and cruise ship traffic on urbanair quality: The case of Barcelona. Environ. Model. Softw. 2021, 139, 104995. [Google Scholar] [CrossRef]

- Li, J.; Hu, Z.; Shi, V.; Wang, Q. The benefit of manufacturer encroachment considering consumer’s environmental awarenessand product competition. Ann. Oper. Res. 2021, in press. [Google Scholar]

- Li, J.; Hu, Z.; Shi, V.; Wang, Q. Manufacturer’s encroachment strategy with substitutable green products. Int. J. Prod. Econ. 2021, 235, 108102. [Google Scholar] [CrossRef]

- Budiyanto, M.A.; Huzaifi, M.H.; Sirait, S.J.; Prayoga, P.H.N. Evaluation of CO2 emissions and energy use with different container terminal layouts. Sci. Rep. 2021, 11, 1–14. [Google Scholar] [CrossRef]

- Dong, G.; Zhu, J.; Li, J.; Wang, H.; Gajpal, Y. Evaluating the Environmental Performance and Operational Efficiency of Container Ports: An Application to the Maritime Silk Road. Int. J. Environ. Res. Public Health 2019, 16, 2226. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abu Aisha, T.; Ouhimmou, M.; Paquet, M. Optimization of Container Terminal Layouts in the Seaport—Case of Port of Montreal. Sustainability 2020, 12, 1165. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Wang, F.; He, Y. Electric Vehicle Routing Problem with Battery Swapping Considering Energy Consumption and Carbon Emissions. Sustainability 2020, 12, 10537. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Banker, R.D.; Charnes, A.; Cooper, W.W. Some models for estimating technical and scale inefficiencies in data envel-opment analysis. Manag. Sci. 1984, 30, 1078–1092. [Google Scholar] [CrossRef] [Green Version]

- Andersen, P.; Petersen, N.C. A Procedure for Ranking Efficient Units in Data Envelopment Analysis. Manag. Sci. 1993, 39, 1261–1264. [Google Scholar] [CrossRef]

- Zhu, J. Super-efficiency and DEA sensitivity analysis. Eur. J. Oper. Res. 2001, 129, 443–455. [Google Scholar] [CrossRef]

- Lee, H.S.; Chou, M.T.; Kuo, S.G. Evaluating port efficiency in Asia Pacific region with recursive data envelopment analysis. J. East. Asia Soc. Transp. Stud. 2005, 6, 544–559. [Google Scholar]

- Tovar, B.; Wall, A. Environmental efficiency for a cross-section of Spanish port authorities. Transp. Res. Part D Transp. Environ. 2019, 75, 170–178. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, Z.; Yang, Y.; Wu, J. Green efficiency evaluation and improvement of Chinese ports: A cross-efficiency model. Transp. Res. Part D Transp. Environ. 2020, 88, 102590. [Google Scholar] [CrossRef]

- Tone, K. A slacks-based measure of efficiency in data envelopment analysis. Eur. J. Oper. Res. 2001, 130, 498–509. [Google Scholar] [CrossRef] [Green Version]

- Na, J.-H.; Choi, A.-Y.; Ji, J.; Zhang, D. Environmental efficiency analysis of Chinese container ports with CO2 emissions: An inseparable input-output SBM model. J. Transp. Geogr. 2017, 65, 13–24. [Google Scholar] [CrossRef]

- Wang, C.-N.; Day, J.-D.; Lien, N.T.K.; Chien, L.Q. Integrating the Additive Seasonal Model and Super-SBM Model to Compute the Efficiency of Port Logistics Companies in Vietnam. Sustainability 2018, 10, 2782. [Google Scholar] [CrossRef] [Green Version]

- Xiao, Y.; Qi, G.; Jin, M.; Yuen, K.F.; Chen, Z.; Li, K.X. Efficiency of Port State Control Inspection Regimes: A Compara-tive Study. Transp. Policy 2021, 106, 165–172. [Google Scholar] [CrossRef]

- Wanke, P.F. Physical infrastructure and shipment consolidation efficiency drivers in Brazilian ports: A two-stage net-work-DEA approach. Transp. Policy 2013, 29, 145–153. [Google Scholar] [CrossRef]

- Chao, S.-L.; Yu, M.-M.; Hsieh, W.-F. Evaluating the efficiency of major container shipping companies: A framework of dynamic network DEA with shared inputs. Transp. Res. Part A Policy Pr. 2018, 117, 44–57. [Google Scholar] [CrossRef]

- Saeedi, H.; Behdani, B.; Wiegmans, B.; Zuidwijk, R. Assessing the technical efficiency of intermodal freight transport chains using a modified network DEA approach. Transp. Res. Part E Logist. Transp. Rev. 2019, 126, 66–86. [Google Scholar] [CrossRef]

- Kwon, D.S.; Cho, J.H.; Sohn, S.Y. Comparison of technology efficiency for CO2 emissions reduction among European coun-tries based on DEA with decomposed factors. J. Clean. Prod. 2017, 151, 109–120. [Google Scholar] [CrossRef]

- Cui, Q. Investigating the airlines emission reduction through carbon trading under CNG2020 strategy via a Network Weak Disposability DEA. Energy 2019, 180, 763–771. [Google Scholar] [CrossRef]

- Yang, M.; Hou, Y.; Ji, Q.; Zhang, D. Assessment and optimization of provincial CO2 emission reduction scheme in China: An improved ZSG-DEA approach. Energy Econ. 2020, 91, 104931. [Google Scholar] [CrossRef]

- Ren, F.R.; Tian, Z.; Liu, J.; Shen, Y.T. Analysis of CO2 emission reduction contribution and efficiency of China’s solar photo-voltaic industry: Based on input-output perspective. Energy 2020, 199, 117493. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Gong, Y.; Wei, F.; Huang, Q. CO2 emission performance evaluation of Chinese port enterprises: A modified me-ta-frontier non-radial directional distance function approach. Transp. Res. D Transp. Environ. 2020, 89, 102605. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, X.; Guo, J.; Wei, G.; Dooling, T.A. Efficiency evaluation and PM emission reallocation of China ports based on improved DEA models. Transp. Res. Part D Transp. Environ. 2020, 82, 102317. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W. Programming with linear fractional functionals. Nav. Res. Logist. Q. 1963, 10, 273–274. [Google Scholar] [CrossRef]

- Tone, K. A slacks-based measure of super-efficiency in data envelopment analysis. Eur. J. Oper. Res. 2002, 143, 32–41. [Google Scholar] [CrossRef] [Green Version]

- Fang, H.-H.; Lee, H.-S.; Hwang, S.-N.; Chung, C.-C. A slacks-based measure of super-efficiency in data envelopment analysis: An alternative approach. Omega 2013, 41, 731–734. [Google Scholar] [CrossRef]

- Chang, C.-T. Revised multi-choice goal programming. Appl. Math. Model. 2008, 32, 2587–2595. [Google Scholar] [CrossRef]

- Schrage, L. LINGO Release 8.0; LINGO System Inc.: Chicago, IL, USA, 2002. [Google Scholar]

- Shen, C.-W.; Peng, Y.-T.; Tu, C.-S. Multi-Criteria Decision-Making Techniques for Solving the Airport Ground Handling Service Equipment Vendor Selection Problem. Sustainability 2019, 11, 3466. [Google Scholar] [CrossRef] [Green Version]

| References | Research Topics | Method | Inputs | Outputs | ||||

|---|---|---|---|---|---|---|---|---|

| Types of Crane Equipment | Working Times | Energy Cost | Energy Consumption | Working Capacity | CO2 Emission | |||

| Casazza et al. [16] | Sustainable urban port | 3D monitoring | √ | √ | √ | |||

| Dong et al. [24] | Green port | DEA | √ | √ | √ | √ | ||

| Aisha et al. [25] | Sustainable terminals | ε-constraint | √ | √ | √ | √ | √ | |

| Li et al. [26] | Sustainable electric vehicle | Genetic algorithm | √ | √ | √ | |||

| Progiou et al. [17] | Port emissions | Simulation | √ | √ | √ | |||

| Budiyanto et al. [23] | Container terminal | Case study | √ | √ | √ | |||

| Current study | Green port crane | Modified SBM-DEA | √ | √ | √ | √ | √ | |

| Index | DMU (port crane equipment) | |

| Inputs | ||

| Good outputs | ||

| Undesirable outputs | ||

| Variables | Weights of peers (DMU- j) | |

| Input i of DMU- j | ||

| Output r of DMU- j | ||

| Undesirable output h of DMU- j | ||

| Under achievement of input target i | ||

| Over achievement of output target r | ||

| Under achievement of undesirable output target h | ||

| Extra slacks of input target i | ||

| Extra slacks of output target r | ||

| Extra slacks of undesirable output target h | ||

| Parameters | Super-efficiency of DMU- j | |

| Maximum value of | ||

| GIj | Green energy index of DMU- j |

| DMU | Input | Output | Evaluation Results | |||||

|---|---|---|---|---|---|---|---|---|

| Working Time (Hours) | Energy Consumption (kwh) | Total Energy Cost (TWD) | Working Capacity (Moves) | CO2 Emission Volume (kg) | Efficiency | GIj * | Rank | |

| GC | 4487 | 534,344 | 1,528,224 | 134,595 | 278,928 | 1.07794 | 0.99983 | 2 |

| RMG | 3556 | 174,728 | 499,706 | 74,670 | 91,205 | 0.92779 | 0.86056 | 4 |

| RTG | 4983 | 235,677 | 674,063 | 109,617 | 123,029 | 1.07813 | 1.00000 | 1 |

| ECH | 4464 | 418,122 | 1,241,924 | 102,671 | 112,548 | 1.01733 | 0.94361 | 3 |

| DMU | Input | Output | Evaluation Results | |||||

|---|---|---|---|---|---|---|---|---|

| Working Time (Hours) | Energy Consumption (kwh) | Total Energy Cost (TWD) | Working Capacity (Moves) | CO2 Emission Volume (kg) | Efficiency | GIj * | Rank | |

| GC | 3323 | 445,287 | 1,280,598 | 106,811 | 223,893 | 1.09938 | 0.95843 | 2 |

| RMG | 3726 | 168,256 | 552,876 | 78,236 | 96,662 | 0.88134 | 0.76834 | 4 |

| RTG | 3397 | 117,838 | 485,277 | 74,737 | 84,842 | 1.14707 | 1.00000 | 1 |

| ECH | 3478 | 312,197 | 629,643 | 79,997 | 87,692 | 1.02027 | 0.88946 | 3 |

| DMU | Input | Output | Evaluation Results | |||||

|---|---|---|---|---|---|---|---|---|

| Working Time (Hours) | Energy Consumption (kwh) | Total Energy Cost (TWD) | Working Capacity (Moves) | CO2 Emission Volume (kg) | Efficiency | GIj * | Rank | |

| GC | 3712 | 442,106 | 1,388,211 | 63,635 | 123,968 | 1.01786 | 0.94071 | 2 |

| RMG | 3235 | 158,952 | 499,118 | 49,402 | 54,047 | 1.01518 | 0.93824 | 3 |

| RTG | 3313 | 149,582 | 469,690 | 53,008 | 61,514 | 1.08201 | 1.00000 | 1 |

| ECH | 3047 | 259,434 | 812,980 | 48,752 | 60,026 | 0.75103 | 0.69410 | 4 |

| DMU | X1: Working Time (Hours) | X2: Energy Consumption (kWh) | X3: Total Energy Cost (TWD) | Y1: Working Capacity (Moves) | U1: CO2 Emission (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Benchmark | Change Rate * | Benchmark | Change Rate * | Benchmark | Change Rate * | Benchmark | Change Rate * | Benchmark | Change Rate * | ||

| GC | 2018 | 5885 | 31.18% | 85,583 | −83.98% | 1,528,224 | 0.00% | 134,595 | 0.00% | 147,983 | −46.95% |

| 2019 | 3977 | 7.14% | 179,571 | −59.38% | 563,853 | −59.38% | 63,635 | 0.00% | 73,847 | −40.43% | |

| 2020 | 4644 | 39.75% | 416,843 | −6.39% | 840,692 | −34.35% | 106,811 | 0.00% | 117,085 | −47.70% | |

| Ave | 4835 | 26.02% | 227,332 | −49.92% | 977,590 | −31.24% | 101,681 | 0.00% | 112,972 | −45.03% | |

| RMG | 2018 | 3556 | 0.00% | 168,173 | −3.75% | 480,994 | −3.74% | 78,220 | −4.75% | 87,790 | −3.74% |

| 2019 | 3088 | −4.55% | 139,407 | −12.30% | 437,739 | −12.30% | 49,402 | 0.00% | 57,330 | 6.07% | |

| 2020 | 3726 | 0.00% | 129,227 | −23.20% | 532,175 | −3.74% | 81,959 | −4.76% | 93,042 | −3.74% | |

| Ave | 3456 | −1.52% | 145,602 | −13.08% | 483,636 | −6.60% | 69,861 | −3.17% | 79,387 | −0.47% | |

| RTG | 2018 | 5175 | 3.85% | 235,677 | 0.00% | 792,201 | 17.53% | 109,617 | 0.00% | 132,532 | 7.72% |

| 2019 | 3471 | 4.76% | 170,554 | 14.02% | 535,548 | 14.02% | 53,008 | 0.00% | 57,992 | −5.73% | |

| 2020 | 3397 | 0.00% | 153,429 | 30.20% | 504,154 | 3.89% | 71,341 | 4.54% | 88,143 | 3.89% | |

| Ave | 4014 | 2.87% | 186,553 | 14.74% | 610,634 | 11.81% | 77,989 | 1.51% | 92,889 | 1.96% | |

| ECH | 2018 | 4667 | 4.55% | 220,741 | −47.21% | 631,346 | −49.16% | 102,671 | 0.00% | 115,232 | 2.38% |

| 2019 | 3047 | 0.00% | 137,571 | −46.97% | 431,974 | −46.87% | 48,752 | 0.00% | 56,575 | −5.75% | |

| 2020 | 3636 | 4.55% | 126,132 | −59.60% | 519,432 | −17.50% | 79,997 | 0.00% | 90,814 | 3.56% | |

| Ave | 3783 | 3.03% | 161,482 | −51.26% | 527,584 | −37.84% | 77,140 | 0.00% | 87,540 | 0.07% | |

| Total AVE | 4022 | 7.60% | 180,242 | −24.88% | 649,861 | −15.97% | 81,667 | −0.41% | 93,197 | −10.87% | |

| Choice | ||||||

|---|---|---|---|---|---|---|

| S1 | S2 | S3 | S4 | Choice Value | Goal | |

| U1 | 123,968 | 54,047 | 61,514 | 60,026 | (71,341, 77,989) | CO2 Emission volume benchmark value |

| Y1 | 63,635 | 49,402 | 53,008 | 48,752 | (88,143, 92,889) | Working capacity benchmark value |

| X1 | −3712 | 3235 | 3313 | 3047 | (3397, 4014) | Energy consumption benchmark value |

| X2 | 442,106 | 158,952 | 149,582 | 259,434 | (153,429, 186,553) | Energy consumption benchmark value |

| X3 | 1,388,211 | 499,118 | 469,690 | 812,980 | (504,154, 610,634) | Total Energy cost benchmark value |

| MCGP Model Solution Programming | MCGP Model Goal |

|---|---|

| Min z= | Objection function |

| dp1 + dn1 + ep1 + en1) | Satisfy the first goal |

| +(dp2 + dn2 + ep2 + en2) | Satisfy the second goal |

| +(dp3 + dn3 + ep3 + en3) | Satisfy the third goal |

| +dp4 + dn4 + ep4 + en4) | Satisfy the fourth goal |

| +(dp5 + dn5 + ep5 + en5) | Satisfy the fifth goal |

| s.t | (63,635s1 + 49,402s2 + 53,008s3 + 48,752s4) + dn1 − dp1 = y1b1 For the first goal, the less the better |

| y1 − ep1 + en1 = 71,341 | For |

| y1 71,341 y1 ≤ 77,989 | For bound of the y1 |

| 12,3968s1 + 54,047s2 + 61,514s3 + 60,026s4 + dn2 − dp2 = y2b2 For the second goal, the less the better y2 − ep2 + en2 = 88,143 | For |

| y2 88,143 y2 92,889 | For bound of the y2 |

| 3712s1 + 3235s2 + 3313s3 + 3047s4 = y3b3 | For the third goal, the less the better |

| y3 − ep3 + en3 = 3397 | For |

| y3 3397 y3 4014 | For bound of the y3 |

| 44,2106s1 + 158,952s2 + 149,582s3 + 259,434s4 = y4b4 | For the fourth goal, the less the better |

| y4 − ep4 + en4 = 153,429 | For |

| y4 153429 y4 186553 | For bound of the y4 |

| 1,388,211s1 + 499,118s2 + 469,690s3 + 12,980s4 = y5b5 | For the fifth goal, the less the better |

| y5 − ep5 + en5 = 504,154 | For |

| y5 504,154 y5 610,634 | For bound of the y5 |

| s1 + s2 +s3 + s4 = 1 | To selection crane equipment |

| b1 = b2 + b3 + b4 | For ensuring the goals, and zero should be achieved |

| b2 + b3 + b4 = 1 | Added auxiliary constraints can force the goals (such that the lower-bound goal is achieved) |

| si >= 0, i = 1, 2, 3,4, , , , , i = 1, 2, … 5. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gan, G.-Y.; Lee, H.-S.; Tao, Y.-J.; Tu, C.-S. Selecting Suitable, Green Port Crane Equipment for International Commercial Ports. Sustainability 2021, 13, 6801. https://doi.org/10.3390/su13126801

Gan G-Y, Lee H-S, Tao Y-J, Tu C-S. Selecting Suitable, Green Port Crane Equipment for International Commercial Ports. Sustainability. 2021; 13(12):6801. https://doi.org/10.3390/su13126801

Chicago/Turabian StyleGan, Guo-Ya, Hsuan-Shih Lee, Yu-Jwo Tao, and Chang-Shu Tu. 2021. "Selecting Suitable, Green Port Crane Equipment for International Commercial Ports" Sustainability 13, no. 12: 6801. https://doi.org/10.3390/su13126801