1. Introduction

Biofuels are renewable energy sources that have helped foster a new business cycle in the global economy [

1]. The two principal biofuels are ethanol—extracted from agricultural products, and biodiesel—produced from animal fats, vegetable oils, or both.

In 2011, nearly 124 billion litres of biofuel were produced globally; 20% of the biofuels consisted of biodiesel, and 80% of biofuels produced were ethanol [

2]. Biodiesel, being non-toxic, is an environmentally friendly fuel. Various raw materials produce biodiesel, including rapeseed oil, palm oil, sunflower oil, and soybean oil, and non-edible Jatropha, Linseed, Neem, and Polanga sources, as discussed in the literature [

3]. Brazil and the USA are the largest producers of biofuels. In 2009, the USA and Brazil contributed 54% and 34%, respectively, to global ethanol production. In 2011, Brazil produced 23 billion litres of ethanol, ranking as the world’s second-biggest ethanol producer [

2]. Simultaneously, the U.S. produced more than 54 billion litres, making it the top ethanol-producing country in the world [

4]. Brazilian soil has important mineral contents and a tropical climate that favours the growth of crops. These crops contain raw materials called biomass feedstocks that are used to produce biofuels [

5]. The USA has significantly increased the amount of soybean oil for biodiesel production, which has boosted biofuel production [

6]. Brazil and the U.S. together have produced nearly 70% of the ethanol produced in the world.

On 9 March 2007, a Memorandum of Understanding (MOU) was signed between the two countries that aimed to establish and support more collaborative efforts on biofuels. There were three critical agreements highlighted in this MOU: (1) to advance research activities shared by both the U.S. and Brazil, (2) to support other countries in building their local biofuel industries, and (3) to advance the development of biofuels globally through multilateral collaboration [

7]. To achieve these targets and boost the bioeconomy, (bioeconomy is a type of economy that utilizes natural renewable resources, from both ocean and land, to obtain materials, food, and energy in a sustainable manner. It endeavours to ensure that no compromise is made to safeguard the future availability of these renewable resources) in each country, energy regulators and legislative bodies have been active and vigilant. This research article portrays the role of the critical stakeholders that make the USA and Brazil world leaders in bio-energies. Its focus is to answer fundamental questions: what are the critical historical government initiatives and institutional processes that helped develop bio-economies in Brazil and the USA? Since the nineteenth century, the systematic and timely interventions of American and Brazilian national institutions have helped to structure the biofuel sector in each country. This study identifies these interventions as creating and developing renewable energy institutes, sustainable energy policies, and legal initiatives to blend biofuel with regular gasoline. In addition, many sustainable legislative guidelines have provided financial incentives, subsidies to construct new biorefineries and have increased the demand for biofuel. These interventions include policies to offer credit, grants for the construction of mills and new refineries, mandatory mixing targets in gasoline, investments in research, and the creation of national demand for ethanol. Analyzing this historical process is critical to understand how sugarcane-based fuels evolved and developed in the U.S. and Brazil. A biofuel system faces various challenges, such as high operational cost, regulatory compliance, reliance on limited suppliers of raw materials, and price volatility, as discussed in the literature [

8,

9]. This study reviews how governance systems in the USA and Brazil overcome such challenges.

The analysis is divided into five sections.

Section 1 consists of an introduction, discusses the context of the work and presents the research methodology of this work.

Section 2 discusses historical efforts made by the Brazilian government to boost the biofuel industry in the country.

Section 3 outlines historical initiatives taken by the American government to become the world’s top producer of biofuel.

Section 4 considers the economic outcomes resulting from bio-energy policies in the U.S. and Brazil, and

Section 5 concludes this research work and makes future recommendations. This study does not include the development of an energy policy framework for a country. Interested readers are referred to the literature [

10].

Research Methodology

The methodology of this work is adopted from the literature [

11,

12,

13] and modified. It is predominantly based on performing modified desk research, which utilizes the historical trajectory of biofuel policies in Brazil and the USA. The findings also provide a comparative analysis between the two countries to justify the sustainability of biofuel in both countries. The methodology and research steps used in this study are shown in

Figure 1. Step 1 identifies the research objectives, as presented in this

Section 1 of the paper. This work aims to analyze the historical contributions of Brazilian and U.S. Governments in the development and sustainability of biofuel in their countries. This study also presents a comparison of biofuel development in both countries on a time scale. It also aims to analyze the economic implications of governance decision-making over time in both countries. Steps 2 and 3 of the methodology, as presented in

Section 2 and

Section 3, involve performing the desk research on biofuel policies in Brazil and the U.S., respectively. The literature resources used in this study were books, peer-reviewed articles, and reports from government and semi-government institutions in Brazil and the USA.

An international narrative on biofuel policies in both countries was assessed using the technical information from multi-lateral international organizations such as United Nations, dossiers from industry groups, and bodies representing sustainable bio-economies. Other resources used in desk research were media reports, web-based data, and publicly available and existing grey literature on biofuel policies in Brazil and the USA. In step 4 of this research, the economic implications of the decisions and developments made over time are discussed. These timely decisions and actions resulted in biofuel sustainability in both countries and are presented in

Section 4 of this paper. Finally, the last step, 5, conferred in

Section 5, includes the conclusions drawn from this study.

2. The Historical Trajectory of Biofuel Policies in Brazil

To understand the process of ethanol production from sugar cane in Brazil, it is essential to analyze the entire product cycle, i.e., starting from the colonial period and projected to the middle of the 21st century. There have been various factors concurrent with Brazil’s economy, politics, institutions, and a plethora of social factors that have contributed to the history of biofuels in Brazil. This study defines institutions as regulatory or non-regulating departments/bodies created by the government or private entities, which develop formal or informal strategies and rules for the growth of bioenergy in the country. The almost 500-year-old history of sugar cane in Brazil can be explained through historical institutionalism [

14]. Brazilian institutions have been the center of political activity in the country. Studying the role and contributions of such historical institutionalism can aid in exploring the transition from edible sugar cane to biofuel. This investigation also provides insights into how different institutions have influenced biofuel transformation.

In Brazil, colonization by the Portuguese empire began around 1530 [

15], and in 1532, sugar cane started to be cultivated, as discussed in the literature [

14]. Due to its use as a sugar source, sugar cane became an essential product in the Brazilian economy. Additionally, it influenced the country’s culture since people of different ethnicities came to plant sugar cane, giving rise to mixed races in the country. The sugar industry in Brazil developed actively in the colonial period due to investments made by Portuguese institutions [

16]. In 1875, Brazil issued a decree granting low-rate loans to build modern sugar plants using imported equipment [

17]. The new factories produced residual molasses, which started to be used in the manufacturing of ethanol. Sugar was the most exported product during the colonial period and only lost strength in the economy in the 19th century due to strong external competition.

At the start of the 20th century, sugar mills were modernized, and production continued to grow [

18]. Since the colonial period, sugar had been the product with the most investments and institutional interventions, leading the country to have a surplus production, which was quickly engaged to produce biodiesel and ethanol. Around 1920, ethanol production was supported by the Brazilian government. This initiative allowed investments from the private sector and increased the production and development of biofuel [

19]. In 1929, due to the Great Depression, the sugar industry suffered losses, dramatically reducing exports [

20]. In 1931, the Brazilian government published a decree that determined all imported gasoline used in Brazil would be used with 5% ethanol [

21,

22]. This decree was an institutional intervention and aimed to balance the manufacturers’ losses when there was a decrease in sugar prices and exports fell.

In 1933, Brazilian president Getúlio Vargas laid the foundation of the Instituto de Açúcar e do Álcool, abbreviated as IAA, which in English was called the Institute of Sugar and Alcohol. (Alcohol has been a popularly used word for ethanol. Based on its percentage dilution, ethanol has different uses. For example, hydrated ethanol is used directly in flex-fuel engines, while anhydrous ethanol is mixed with the gasoline to develop various compositions of ethanol-gasoline mixture). The IAA was responsible for regulating the international sugar trade in Brazil [

23]. The main objective of the IAA was to balance domestic production between the consumption of sugar and ethanol. By 1990, the IAA was extinct. Nevertheless, the IAA was a very active institute during its life, serving to increase sugar production in Brazil from one million tons in 1933 to almost 8.5 million tons in 1981 [

18].

On 29 April 1938, Decree-Law No. 395 was launched, which declared the supply of crude oil and its derivates as a matter of public utility [

24]. This act created the National Petroleum Council (CNP), which was an inter-ministerial body. The CNP consisted of the delegates of industry and commerce. The National Petroleum Council aimed to define Brazilian fuel policies [

25] and was the first move to nationalize oil refineries in Brazil [

26]. From 1931 to 1938, alcohol was mixed only with imported gasoline; however, in 1938, Decree-Law No. 737 made it mandatory to add 5% (

volume by volume) anhydrous alcohol to gasoline produced in the country [

27]. The percentages were stipulated by the IAA and the CNP [

28]. In the 1960s, the CNP was merged into the Ministry of Mines and Energy, abbreviated as MME [

29].

During the Second World War (1939–1945), there was an interruption in the sugar supply from producers in the northeast of Brazil to the central south of the country—its primary market. The Brazilian government, through the IAA, offered financial incentives to produce sugar cane closer to the consumers. In that era, there was a halt in importing gasoline into the country. The IAA, in addition to providing financial aids, also issued administrative acts that promoted the blending of anhydrous ethanol with already imported gasoline [

30]. Both initiatives by the IAA caused sugar cane production in the southeast region to expand. In 1959, many social actors and corporations, such as farmers, mills, and refineries in the São Paulo state of Brazil, created the Cooperative of Producers of Sugar, Alcohol, and Sugar cane to invest even more [

31]. From 1965 to 1974, the IAA expanded sugar production for export, which increased by 250% in this period [

31].

In the oil crisis of the 1970s, there was a dictatorship in Brazil. As a result, oil imports to the country were high, while there was a decrease in sugar prices in the international market, and the solution was to invest in biofuels [

32]. In the same period, Brazil imported about 70% of crude oil to be consumed internally, and hence the country was dependent on foreign policies to have access to fossil-based oil. The world oil crisis affected Brazil from 1973 to 1979 because the cost of the products increased by more than 40% per year. This period marked a slowdown in the growth of the Brazilian economy with fuel rationing, reduction of the gross domestic product (GDP), and rampant inflation. From 1974 to 1978, the country’s foreign debt jumped from

$17.2 billion to

$43.5 billion [

33].

In 1975, the Brazilian government created the National Alcohol Program (ProÁlcool), which was intended to increase the production and consumption of ethanol and reduce the dependence on imported petroleum. Ethanol was primarily meant to be used in vehicles as fuel. In addition, ProÁlcool also provided resources and financial incentives to produce ethanol from sugar cane [

34]. Between 1975 and 1989, the Brazilian government boosted the bio-economy by investing more than 11 billion U.S. dollars in ProÁlcool [

35]. Although ProÁlcool was encouraged by the Brazilian government to increase ethanol production as an alternative fuel to gasoline, this program also increased the country’s public debt due to such a considerable investment [

1]. However, this subsidy was crucial to enable inefficient producers of the northeast to stay in business [

36]. The green plant chosen was sugar cane because of its abundance in the country. Sugar cane needs to undergo processes of milling, purification, fermentation, and distillation. In 1975, the government also instituted the Pró-Óleo (Plan for the Production of Vegetable Oils for Energy Purposes), which aimed to generate more production of vegetable oil that could be mixed with diesel oil [

37]. With an agenda to control prices and develop parity between raw sugar and ethanol (aimed to move producers from sugar to ethanol), the Brazilian government also created the National Alcohol Commission (CAN). The institutional outcomes were fruitful, and ethanol production jumped to 3.676 billion litres in 1979 from 580 million litres in 1975 [

38].

The programs created by the government aimed to encourage the automotive industry to use ethanol, and manufacturers started to develop vehicles powered by alcohol. The IAA, CNA, ProÁlcool, and Pró-Óleo were fundamental to encourage the biofuels industry in Brazil. However, in the 1980s, ethanol production slowed down due to new challenges such as the fall in oil prices, declining government incentives, high policy costs, lack of policies to support ethanol production, and many more, as discussed in the literature [

39]. Additionally, the country was facing the transition from a dictatorial political regime (1964–1985) to a democratic political rule, affecting the Brazilian biofuel industry. In addition, the Brazilian government had difficulty paying its foreign debt, so the increase in oil imports, which in 1983 already registered 57% of all imports, worsened the situation [

32].

Nevertheless, even in the face of a crisis, in 1985, 96% of the cars sold were powered by ethanol. Due to ProAlcool, by 1986, Brazil was producing approximately 12 billion litres of ethanol, and ethanol-powered vehicles represented about 90% of new vehicle sales [

38]. Then, from 1985 to 1990, there was a fall from 85% to 11.4% in the sale of vehicles powered by ethanol. This trend was mainly due to the demise of the IAA and the lack of government incentives for sugar production [

38].

In the early 90s, the oil price fell, so ethanol lost its attractiveness and entered a phase of stagnation. However, the alcohol crisis ended when a new combination was introduced to the market, which achieved the same performance as hydrated alcohol. A unique combination was made of only 6% gasoline and 34% methanol, and a significant contribution was made of hydrated ethanol, which was 60% [

40]. The creation of the flex engine marked a new horizon to produce ethanol as fuel; a car could be driven on gasoline, ethanol, or their combination. In this way, the bi-fuel car models helped consumers choose the fuel with the lowest price. By that time, some researchers stepped up research into the invention of other forms of alternative and organic fuels that could replace alcohol fuel, which had been criticized for some time because of its energy expenditure for production. In this period, Brazilian researcher Expedito José de Sá Parente invented biodiesel, which worked well in a diesel-based fuel. In 1997, the National Agency of Petroleum, Natural Gas, and Biofuels was formed in Rio de Janeiro, Brazil, with the mission to organize the entire fuel industry [

41].

In the early 2000s, various risks such as volatility in oil prices, oil supply security, climate change, and a political wish to subsidize farmers led the international community to show interest in biofuels [

42]. As a result, biofuel was reborn due to high oil prices and the need to seek new and sustainable renewable energy resources. International goals also played an essential role in exploring new and sustainable renewable energy resources that could collaborate to reduce carbon dioxide (CO

2) emissions and dependence on non-renewable energy resources. To this end, Brazil focused on developing its ethanol industry and advancing the sustainable biofuel industry.

During the 2000s, many studies were published to support investments in the production of biofuels [

43,

44,

45,

46,

47]. These studies provided information on production costs, technological requirements, land available for production, and levels of reduction of CO

2 emissions. Studies also pointed out that biofuel could replace oil and become a strong ally for rural development in a country [

48]. The expansion of biofuel had a positive impact on the social, political, economic, and environmental contexts, which directly contributed to rural development and the increase in biofuel demand [

49].

In 2003, the Brazilian government improved the mandatory percentage of ethanol added to gasoline to 25% and the fuel mixture was called E25 (E25 indicates a fuel mixture consists of 25% ethanol and 75% gasoline). In addition, it introduced vehicles with flexible fuel on the market that could use any mixture composition of ethanol and gasoline [

50]. In 2003, flex-fuels (flexible-fuel vehicle) technology was used in cars, which enabled them to switch between mixtures of gasoline and ethanol [

51]. According to a study, in 2005, a planned 60% of the new vehicles leaving the factory in Brazil would be flex-fuels [

52]. In 2004, the Energy Research Office (Portuguese acronym was EPE), developed by the Brazilian MME, aimed to provide research and studies services in the energy sector. In December 2004, the government established the ‘Programa Nacional de Produção e uso do Biodiesel’, abbreviated as PNPB. In English, it was called the National Biodiesel Production and Use Program. The PNPB was aimed to respond to the high oil prices, growing demands of fuels from sustainable energy resources, and employment opportunities in rural areas [

53]. The PNPB also aimed to increase biofuel production from various vegetable-based oils. In 2008, approximately 92% of all vehicles sold in Brazil used biofuel, i.e., ethanol, gasoline, or both [

14]. Followed by soy and corn, sugar cane (ethanol) is the country’s third most essential industry. More than one million jobs depend on their production and biofuels, producing approximately 1350 gigawatt-hours per year of electricity [

39]. The historical development of the biofuel industry in Brazil is deeply connected with the investments and policies adopted by its government. Since the colonial period, the Brazilian government has boosted sugar cane production through institutional interventions and, consequently, the ethanol industry.

In 2015, Brazil announced to increase the blending composition of ethanol in natural gasoline from 25% to 27% [

54]. As a result, according to a report by state-owned energy firms in Brazil, there was a 6% growth in Brazil’s ethanol production in 2015, which reached 30 billion litres [

55]. The study also highlighted some key contributing factors to this landmark. These were government measures, such as blending requirements of anhydrous ethanol to regular gasoline, boosting the bioeconomy, and good harvesting seasons. As a result, Brazil absorbed almost the entire output of ethanol in the domestic market.

In 2015, 115.6 billion litres of ethanol were produced worldwide, which was more than double the amount produced since the previous decade. It was predicted that by 2025 the production would increase to 128.4 billion litres, with more than half of this increase expected from Brazil alone [

56]. Moreover, Brazil pledged to meet the United Nations Framework Convention on Climate Change (UNFCCC), decreasing greenhouse gas emissions by 43% lower than 2005 by the year 2030 [

57]. To meet (and exceed) this target, the Brazilian government developed various programs and strategies. One of the programs was RenovaBio, launched in December 2016, instituted as “National Biofuels Policy” under the MME, and this was in effect by December 2019. The program aimed to (1) reduce annual carbon intensity targets for a minimum period of ten years, (2) certify biofuel by its efficiency in minimizing emissions of greenhouse gases (GHGs), and (3) dispense decarbonization (decarbonization is a scientific term which means to eliminate the carbon or carbonaceous deposits from internal combustion engines) [

58]. As of 16 March 2015, Brazil practiced mixing levels of 27% ethanol (E27) from 25% ethanol (E25) used from May 2013 to March 2015 in regular gasoline with no tax changes [

58].

With the second-highest biodiesel production, Brazil progressed in the biofuel industry, though the domestic output fell in the first quarter of 2016. In addition, the economic crisis impacted biodiesel production, which declined by 5.5% [

41].

In 2016, biodiesel sales fell in the national market. In the first five months of 2016, total domestic biodiesel production was approximately 1.6 billion litres, corresponding to a decrease of 2.4% in the same period in the first half of the year. The price of biodiesel paid to the mills was BRL 2.47 per litre (the Brazilian real (BRL) is the Brazilian currency; 1 USD = 5.20 BRL on 3 June 2021), while the S-10 diesel (diesel with a sulphur limit of 10 mg/kg) cost BRL 2.11 per litre. However, Brazil has excellent prospects for the future of biodiesel, considering a government decree and the discovery of new raw materials. In April 2016, a presidential order raised the percentage of biodiesel added to diesel. The ruling increased the ratio from 7% (7% biodiesel: 93% gasoline) to 8% by 2017 and 10% by 2019. In 2015, Brazil produced 3.9 billion litres of biodiesel which was 15% more than the 2014 production. This production level ranked the country as the second top producer of biodiesel after the U.S., ahead of Argentina and Germany [

59]. Since biodiesel was made from edible vegetable oil, there was a need to look for other sustainable raw materials as biomass feedstock. These crops do not compromise the food industry yet still meet the high production requirements of biodiesel. In this regard, the São Paulo Research Foundation (FAPESP) supported research works on macaúba (Acrocomia aculeata) oil [

59]. This oil comes from the macaúba fruit, which is a palm tree growing throughout Brazil.

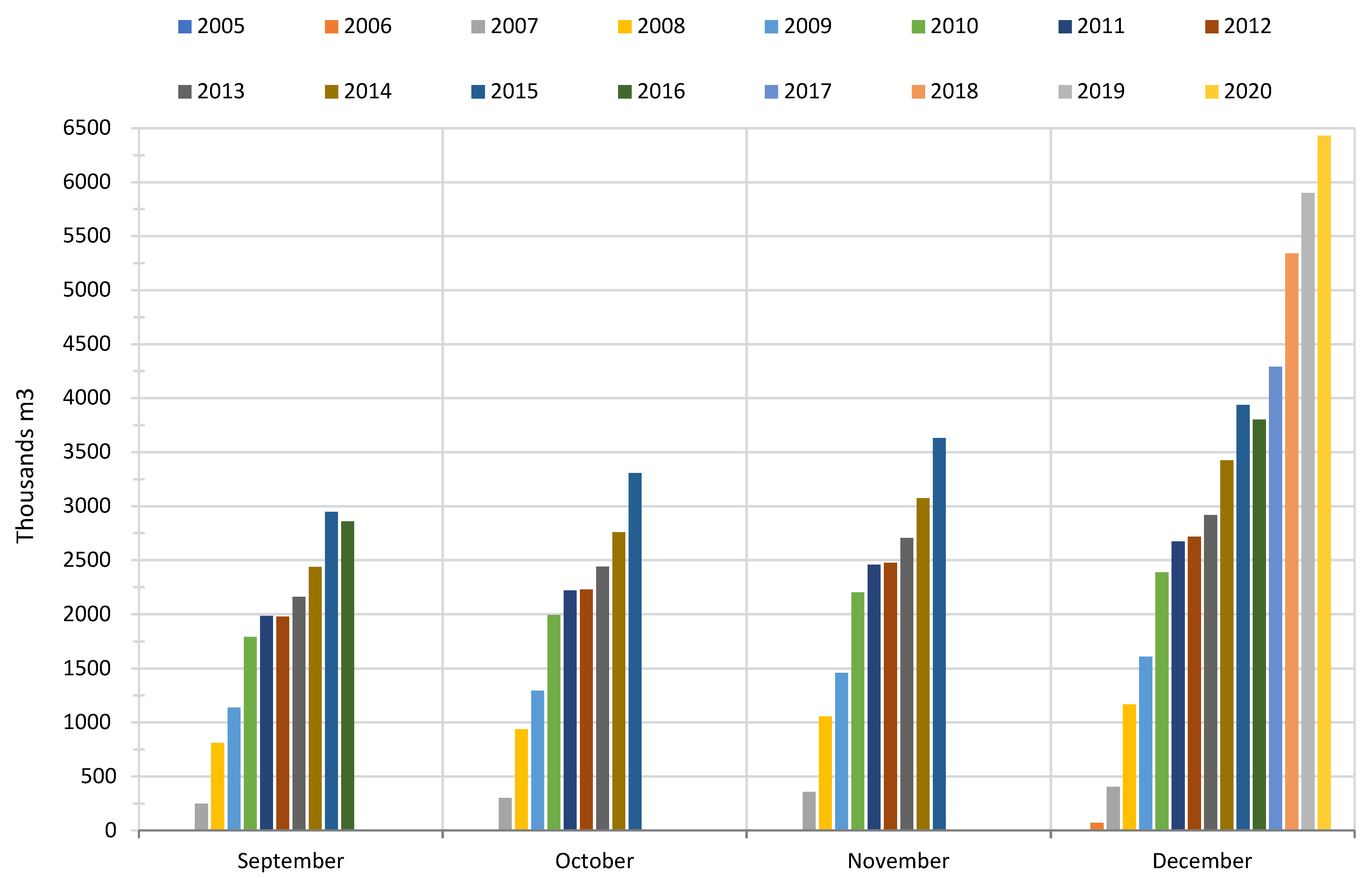

The accumulated production of biodiesel has been on the edge of growth from 2005 to 2020. As indicated in

Figure 2, there had been a massive leap in biodiesel production in Brazil from 0.736 thousand m

3 produced in 2005 (not shown on the scale) to 6430 thousand m

3 in 2020.

Biodiesel can be used as a fuel on its own, or it can be mixed with diesel oil; therefore, it is considered a substitute for diesel oil. In Brazil, plants, animal fat, and waste products are used in the production of biodiesel. The Brazilian territory has many oil-based plants that can be utilized as biomass feedstocks to produce biodiesel. These biomass feedstocks are soybean, canola, pine nut, babassu, sunflower, castor bean, peanut, palm, coconut, sesame, linseed, and macaúba. The tropical climate is conducive to oleaginous plants due to the quality of the soil and the abundance of freshwater; however, each region has different characteristics that facilitate the development of plants. The use of sewage sludge, residual oils, and macaúba as biodiesel raw material eliminates the debate of food versus fuel [

64].

In Brazil, there are two principal biofuels: biodiesel and ethanol. However, the country continues to produce more ethanol than biodiesel, and the vast production quantity of ethanol ranks Brazil as the second largest in the world. The country has great potential to increase the production of all types of plants, so the biodiesel programs have focused on expanding the plantations in lands considered unsuitable for planting. In 2018, Brazil boosted biodiesel production to 5.35 billion litres, which increased 25% compared to 2017, and a ten percent (B10) blend of biodiesel was used in March 2018. In 2019, there was an eight percent increase in biodiesel production compared to 2018, and it reached 5.8 billion litres per annum [

58].

By 2023, Brazil aims to enhance the blend of biodiesel to 15% (B15), with an annual increase of 1% [

65]. A higher mix of biodiesel could potentially reduce the importation of fossil-based diesel fuel into the country. However, this could also potentially raise the demand for soybeans since the oil extracted from soybeans is used as biomass feedstock to produce 80% biodiesel in Brazil.

According to the National Supply Company (CONAB), in March 2019/April 2020, it is estimated that [

66]:

Brazil recorded ethanol production from corn and sugar cane reaching 35.6 billion litres, representing a growth of 7.5% compared to 2018/2019.

The total ethanol production from sugar cane was projected as 34 billion litres, registering a rise of 5.1% compared to last year’s (2019) harvest.

Corn-based ethanol production jumped from 791.4 million litres in 2018/2019 to 1.6 billion litres in 2019/2020, representing a growth of approximately 102%.

The anhydrous ethanol from sugar cane used in the mixture with gasoline reached 10.1 billion litres, increasing 8.5%.

The anhydrous ethanol from corn used in the mixture with gasoline was 390.7 million litres, increasing 66.8% compared to last season.

Hydrated sugar cane ethanol could reach 23.9 billion litres, increasing 3.7%, while the total amount of hydrous ethanol from corn will be 1.25 billion litres, registering a 124.5% growth compared to 2018/2019.

Sugar production was 29.8 million tons, an increase of 2.6% compared to the 2018/2019 harvest (CONAB, 23 April 2020, para. 8).

Brazil is investing in the new National Biofuels Policy (RenovaBio) that came into force in the country in December 2019, aiming to increase the production capacity of biofuels (ethanol and biodiesel), reduce emissions of carbon dioxide, and estimate competition between plants [

67].

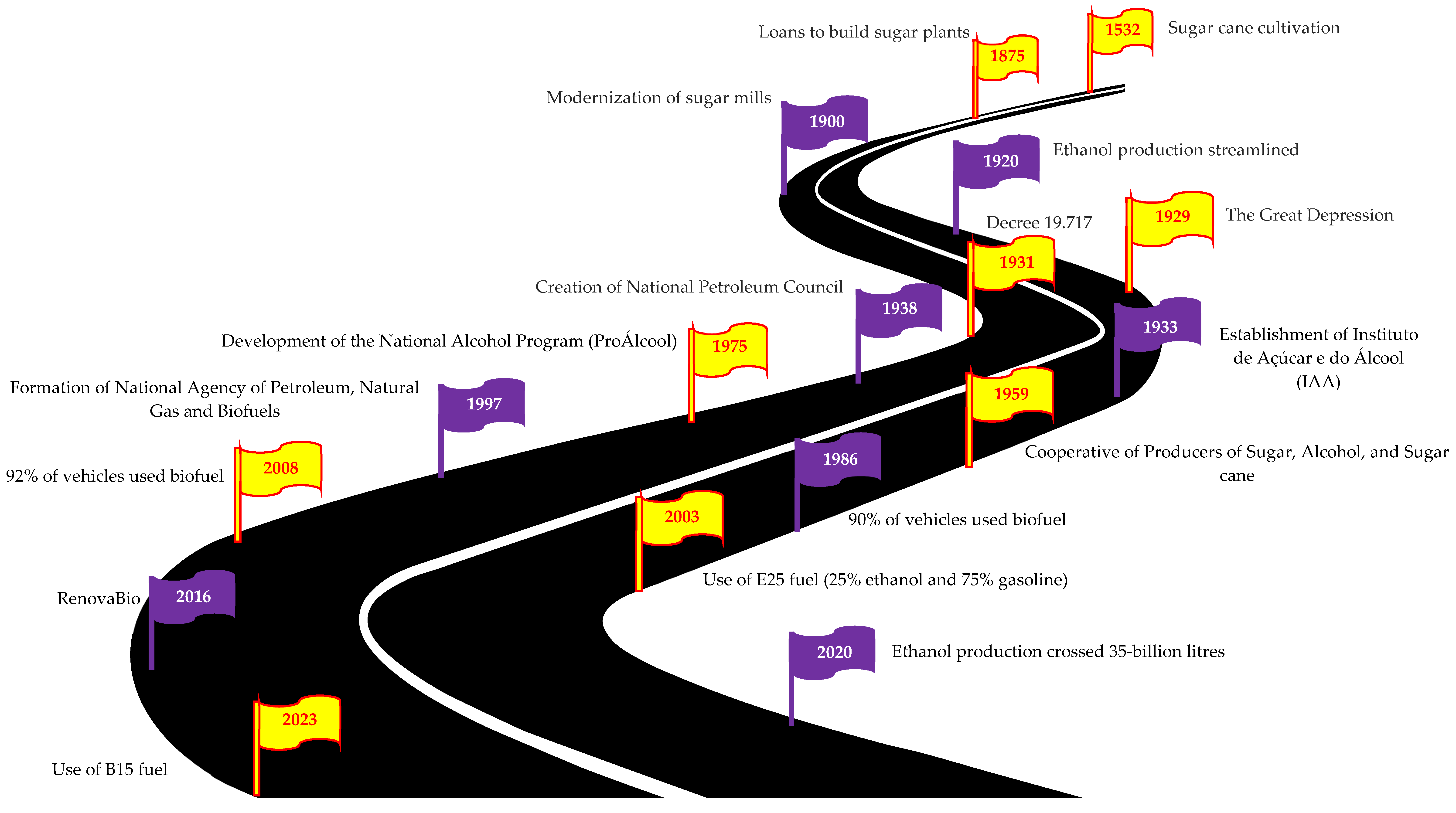

Figure 3 shows the historical trajectory curve of significant biofuel policies and developments in Brazil and summarizes this section. As sketched in

Figure 3, the history of biofuel in Brazil is dated back to 1532, when sugar cane was cultivated to be used as a biofuel resource. Later, the government established various sugar mills to process sugar canes. Thus,

Figure 3 indicates different governance steps on a timeline that helped ensure the country’s biofuel sustainability, as discussed in

Section 2 of this paper.

3. Historical Progression of Biofuel Sustainability in the U.S.

In 1826, the history of ethanol presented its first record when Samuel Morey (1762–1843), an American inventor, described the mixture of ethanol and turpentine as fuel for engines [

68]. According to the Energy Information Agency (2019), in the 1850s, ethanol was used as a lighting fuel [

69]. In the Civil War period (1861–1865), the U.S. government applied an alcohol tax to raise money to finance the war. The tariff on ethanol raised its price and damaged the production levels, and it was only in 1906 that the ethanol tax was lifted. In 1908, Henry Ford manufactured a car powered by gasoline and alcohol. In 1919, ethanol was considered to be an alcoholic beverage, and its use for fuel was banned.

In 1933, ethanol was, again, used as fuel. This increased use of ethanol and its high production was temporarily continued during World War II and was attributed to the shortage of oil due to Second World War. In the 1970s, the oil crisis contributed to the revitalization of ethanol use as a fuel source. In addition, the U.S. government created tax incentives and environmental regulations to expand the alternative fuels market [

69].

In the United States, between the 1920s and 1930s, the first ethanol blended with regular gasoline was used to boost the octane amount, and it was in high demand during the second world war. During that period, the appeal of biofuel was as an agricultural product used as automobile fuel only; however, in the 1970s, biofuels resurfaced as a factor in national energy security. Soon after, biofuels showed the potential to reduce the consequences of climate change since they replace fossil fuel with plant biomass and possibly delay the release of greenhouse gases [

70].

In 1970, the United States established the Environmental Protection Agency (EPA), which aimed to protect the environment and human health. The EPA haD responsibilities that include implementing the biofuel policy and regulating air quality, among others. In 1978, the U.S. Congress enacted the Energy Tax Act of 1978, which provided benefits to support the utilization of sustainable fuels [

1]. This federal subsidy ended in 2011. In 2005, the EPA founded the Renewable Fuel Standard (RFS), which established guidelines for ethanol to have a 20% emission reduction. Although auto manufacturers approved blends up to E10 (10% ethanol, 90% gasoline) in their gasoline vehicles, the amount of ethanol varied from region to region [

71]. The Energy Research Office (EPE) released the analysis of the biofuel’s situation in 2015: the USA continued to lead ethanol production with 56 billion litres. Domestic demand was 52 billion litres [

72]. From 2000 to 2015, ethanol production was raised to 56 billion litres from 6.2 billion litres, representing a nine-fold increase [

72].

In 2005, the U.S. Renewable Fuel Standard (RFS) presented biofuel production goals and the criteria that must be determined to develop products that use renewable energy and can cause less environmental impact. As a regulatory institution, the RFS had the principal mandate of biofuels production and mitigating greenhouse gas (GHG) emissions in the U.S. Such goals involved defining carbon and energy utilization emissions in various production phases of the biofuel; the RFS has been under political negotiations [

70]. The objectives of the RFS began to be measured when the production of biofuels increased, intensifying the dialogues regarding the benefits of renewable energy and GHG from biofuels. It was defined that 1st-generation biofuels, such as ethanol produced from corn, should produce 20% lower GHG from gasoline; advanced biofuels should decrease the emissions of greenhouse gases by 50%, while the use of cellulosic based biofuel should reduce greenhouse gases by 60% [

73]. Cellulosic ethanol, another potential biomass feedstock, provides a tremendous economic opportunity for ethanol producers. The California Low Carbon Fuel Standard (CA-LCFS) was designed to decrease GHG emissions in the state’s transportation sector.

The CA-LCFS was legislated on January 19, 2007, by Governor’s Executive Order S-01–07. However, this regulation was not enforced until 2011. The standard aimed to eliminate 16 million metric tons of CO

2 in the air per annum. This goal was based on the increased use of alternate fuels, including biofuels [

74]. Cellulosic ethanol, created from crop residues, was categorized as low CI (CI is the carbon intensity and is expressed as gram mass of CO

2 carbon dioxide equivalent released per megajoule of energy provided by combustion of fuel) fuel in CA-LCFS [

75]. However, due to inadequate technology and high capital and operational costs, none of the 2.2 million gallons of cellulosic ethanol produced in the U.S. were used in California in 2015 [

76].

Some studies [

77,

78] argued that high biofuel production in the U.S. led to many challenges, such as increased global demand and high prices for agricultural raw materials. These challenges would cause an increase in the risk of invasion of rainforests and grassland by agriculture and consequently would release more carbon than would have been saved by using biofuel. In this regard, the EPA took measures such as including indirect land-use changes in RFS rulemaking. The EPA also found a 16% reduction in carbon emissions when ethanol was used as a fuel instead of gasoline and not the stipulated 20% [

79]. In response to EPA findings, the Renewable Fuels Association (RFA) suggested that the EPA energy costs and corn ethanol’s carbon calculations were “wholly insufficient”, as reported by [

80]. As a result of protracted negotiations on the methodological framework of energy and carbon accounting, the EPA qualified corn ethanol, revised its previous estimations, and pegged the GHG reduction capacity as over 20%; in comparison, the threshold was set at 21%.

The EPA began to monitor the variations in land use in the USA, mainly associated with corn ethanol production, which represents 90% of biofuel production. The second RFS stated that after December 2007, “renewable” biofuels could not be obtained from the land converted to agriculture production. As a result, the EPA monitored only agricultural acres, including cropland, pasture, and the Conservation Reserve Program (CRP). All biofuel was obtained from the current agricultural land as per compliance with the RFS. However, some researchers, such as [

81], found adverse effects in the conversion of CRP land. The transformation of CRP to cropland would release carbon, which has not been counted as the carbon release in carbon ethanol production, while also compromising many other ecological benefits of CRP.

The EPA legalized that the production of biofuel, mainly corn-based ethanol, can reduce GHG emissions, making it an active policy to combat climate change.

From 2000 to 2007, there was an annual increase of 22% in ethanol production in the U.S. [

82]. A study reported that if the U.S. utilizes all grown crops of corn to manufacture ethanol, the country will replace merely 12% of gasoline [

82]. This replacement would register the ethanol used as a small dent in the local demand for fossil-based oil. In 2008, the corn oil yield per acre was 400 gallons, while cellulose was planned to produce more than 1000 gallons per acre. Therefore, the U.S. Congress legislated that, in comparison to corn, there could be 250% more ethanol production per acre if cellulose was used as biomass feedstock. That is, by 2022, the 36 billion gallons of biofuels should be dedicated to ethanol production, of which 16 billion gallons must be cellulose-based [

83].

In January 2008, the industrial capacity to produce ethanol was at 7.9 million gallons per year. Completing all ongoing projects was predicted to have an annual production of more than 13 billion gallons. With the higher crude oil prices, this surge in ethanol production was attributed to the U.S. government’s support for ethanol producers in tax benefits or incentives. Moreover, ethanol was utilized as a fuel additive. In terms of government support, the Energy Policy Act of 2005 (EPAct 2005) and the Energy Independence and Security Act (EISA) of 2007 were quite fruitful. Both initiatives were aimed to increase the sustainability of ethanol production, reduce external dependence on oil, and mitigate climate change. One of the requirements by the EPAct 2005 was to mix gasoline with 5.4 billion gallons of biofuels in 2008. Another requirement was to increase this blending amount of biofuel to 7.5 billion gallons in 2012 [

84]. The EPAct 2005, a bill passed on 29 July 2005 by the U.S. Congress and U.S. president, signed on 8 August 2005, making it a law, also promoted economic incentives, donations, and income tax credits.

Moreover, various loans and subsidies were provided to support research and development activities in biofuel. Subsequently, the EISA, originally named the Clean Energy Act of 2007, boosted the target to 9 billion gallons of biofuels for 2008. Biofuel production was mandated to reach 36 billion gallons by the year 2022 [

85]. For the 2022 goal of EISA, it was determined that the advanced biofuels manufactured from non-cornstarch-based feedstock would be used to produce 21 billion gallons of biofuel. The EISA also included incentives to limit and reduce GHG emissions, resulting from the burning of fossil-based fuel, by at least 20%. It was determined that the use of advanced biofuels and biodiesel should reduce emissions of GHG by at least 50%, and the biofuels obtained from cellulosic products must contribute to reducing emissions of GHG by 60% [

86].

Furthermore, to ensure the sustainable use of biofuel in the U.S. economy, EISA offered various subsidies, donations, loans, and cash prizes to support biofuel research and provided incentives for bio-refineries that helped to replace 80% of fossil fuels and use cellulosic biofuel. This legislation’s tax credits supported advanced biofuels, including biodiesel and cellulosic biofuel. During this period of the two laws, the ethanol plants increased to 134 in number, and this increase was twofold before these laws were introduced, and such numbers continued to grow [

82]. In 1978, the Energy Tax Law created the first subsidy for ethanol, which removed the excise duty on gasoline when mixed with ethanol, leading to the rapid expansion of ethanol [

87]. The American Jobs Creation Act of 2004 helped socio-economically and replaced this exemption with a tax credit of

$0.51 per gallon for gasoline mixture [

88]. The U.S. government also protected domestic ethanol producers by requiring a tax of

$0.54 per gallon on imported ethanol to offset the costs of ethanol tax credits. In 2008, unlike crude oil or gasoline, most ethanol plants were located in the Midwest, facilitating transportation by truck or train. However, the U.S. Congress approved finance to construct a pipeline dedicated to ethanol, stimulating biofuel expansion.

In 2015, the EPA reported that the production and consumption of biodiesel continued to grow in the USA. Considering September 2015 as a benchmark every year, the EPA stated that USA biodiesel production was 135 million gallons in 2016, 107 million gallons in 2015, and 114 million gallons in 2014. The data highlights the resumption of growth in this segment [

89].

In October 2016, the U.S. Energy Information Administration (EIA) reported that U.S. biodiesel production was 142 million gallons; in this quantity, 68% of biodiesel was produced in the Midwestern United States. Production came from a total of 93 biodiesel production sites, having the capability to produce 2.1 billion gallons of biodiesel per annum. In October 2016, 74 million gallons of biodiesel were sold as B100 (100% biodiesel), while 65 million gallons were mixed with diesel fuel and were used as blended fuel. In addition, as reported by the EIA, in October 2016, 1018 million pounds of biomass feedstock were utilized to produce biodiesel [

89].

Figure 4 shows the monthly biodiesel production in the United States for the period from 2009 to 2020. For example,

Figure 4 indicates that biodiesel production in December 2009 was 61 million gallons, increasing to 158 million gallons in December 2020. The highest production was recorded in October 2018, when biodiesel production reached 171 million gallons [

89].

The U.S. has been using various biomass feedstocks to produce biodiesel, and their contributions are presented in

Figure 5. It reveals that, in January 2020, a quantity of 521 million pounds of soybean oil had been the top biomass feedstock producing biodiesel in the USA. For total feedstocks of 1,042 million pounds used to produce biodiesel in the same month, soybean oil made a 50% contribution towards the feedstock inputs to produce biodiesel. The other biomass feedstocks were distributed among corn oil 17%, canola oil 10%, animal fats 6%, recycled feeds 11%, and other inputs 6% [

90].

In January 2017, the U.S. Department of Agriculture (USDA) reported through World Agricultural Production that the soybean production in the U.S. was expected to be 117.21 million tons by 2016/2017. However, the result represented a decrease of 1.48 (million metric tons) compared to December 2016, which produced 118.69 million tons [

91,

92].

Figure 6 summarizes the historical trajectory curve of significant development and biofuel policies in the U.S.

Figure 6 shows that the history of biofuel in the U.S. is dated back to 1826 when ethanol and turpentine were used as biofuel resources. Later, the U.S. government worked on developing hybrid vehicles that could use biofuel as a fuel source and introduced different biofuel policies down the road.

Figure 6 also presents various institutions formed from 1826 to the present, which helped transform the U.S. economy into a bioeconomy, as discussed in

Section 3 of this paper.

In the past, public policies such as Proalcool and The Energy Tax Act had been strategically important to put both countries in privileged positions. Outcomes of these initiatives have increased the production of biofuels in the U.S. and Brazil. Biofuels have boosted the markets of both countries; they have generated new jobs, reduced pollution in the atmosphere, and encouraged the agriculture industry. In 2015, the International Renewable Energy Agency (IRENA) reported that around 7.7 million people are associated with employment-related to the renewable energy industry [

93]. The economic cycle of biofuels has generated many sustainable competitive advantages for the countries that are producing biofuels. However, there are some disadvantages. For example, with more agricultural land dedicated to growing raw materials for biofuel production, crop prices could increase, initiating a debate of (bio)fuel versus food.

Additionally, with the use of vast land for palm oil, a raw material for biofuel production, forest ecosystems have been upset, causing deforestation problems [

94].

According to the RFA, in 2019, 15.8 million gallons of ethanol were produced in the U.S. This top production represented 54% of world production, followed by Brazil, which made 30% of world production in the same period, registering Brazil as the second-top producer of ethanol fuel [

95]. Production of ethanol fuel and comparison of the U.S. and Brazil from 2014 to 2019 is shown in

Figure 7.

Figure 7 indicates a higher production of ethanol in the U.S. than in Brazil from 2014 to 2019. As shown in

Figure 7, in 2014, the U.S. produced 14,313 million gallons. There was a gradual increase in this production until 2018, when the production reached 16,091 million gallons, while in 2019, there was a decrease in ethanol production to 15,776 million gallons in the U.S. In 2014 and 2016, Brazil produced 6760 million gallons, and in 2015, production was at 7200 million gallons.

Figure 7 shows that from 2017, Brazil increased ethanol production until 2019, when the production reached 8570 million gallons, though it was 7206 million gallons less than U.S. ethanol production in 2019.

According to the USDA, in 2018–2019, land used to plant corn was beyond 90 million acres, and between 10% and 20% of this corn crop was dedicated for export to various other countries [

96]. The Federal Agricultural Improvement and Reform Act of 1996 supported farmers in their planting decision-making process. This act allowed them to take independent planting decisions on the highest profitable crops. There was a boost in corn plantations due to such provisions, which increased to nearly 90 million acres by 2010 from 60.2 million acres in 1983 [

96]. In 2020, approximately 40% of the total use of cultivated corn was destined to produce ethanol. This surge in corn production is attributed to using advanced technologies in the field, such as sophisticated machinery and better crop management, including various varieties of seeds and fertilizer use. Likewise, a robust pest management system that consists of using less harmful pesticides, improved irrigation, crop rotation, and reduced cropping also helps in higher corn productions. The increased demand to produce ethanol raised corn prices, causing farmers to increase the cultivated area of corn, which led to a decrease in soybean planting. Other sources of land, such as pasture, were used for corn plantations. Federal policies also encourage corn production, and farmers are entitled to receive payments from the government to help and stabilize their earnings. Other incentives include disaster relief funds, loans for marketing, flexibility in the timeline of production and delivery contracts, insurance of crops, and conservation payments for local farmers [

96]. Strategically, farmers know that the main foreign competitors are in the southern hemisphere, so they plant corn after they discover the size of the U.S. crops.

According to the RFA 2019 report, in 2018, the U.S. ethanol industry broke records in production, total consumption, and exports [

97]. In 2018, 210 ethanol plants in the U.S. produced approximately 16.1 billion gallons of renewable ethanol fuels, total consumption reached 16.2 billion gallons, exports exceeded 1.6 billion gallons, and the mixing rate reached 10.75%. However, domestic use dropped in this same period, which led to a drop in ethanol prices and affected farmers [

97].

Renewable energy regulations made by the U.S. government have improved their economy. In 2018, the American ethanol industry employed 71,367 people, created 294,516 jobs, contributed

$25 billion in domestic income, and increased the gross domestic product (GDP) by

$46 billion. The U.S. ethanol industry also generated nearly

$10 billion in taxes, while more than

$26 billion was spent on raw materials and other services and products [

98].

Figure 8 summarizes and compares the timeline of significant milestones in policies, governments’ strategies, and biofuels laws in the USA and Brazil. The accordion process shown in

Figure 8 displays the list of important biofuel events in chronological order and consists of four panels. The horizontal arrow between the USA and Brazil indicates an accordion effect. The first panel in

Figure 8 displays the development of policies until 1900. It shows that until 1900 US government tested the sustainability of different fuels, which could be potentially used as alternative fuels such as ethanol and turpentine. In the same time domain, Brazil focused on cultivating sugar cane as the source of biofuel.

During 1901–1950, US policies were focused on inventing vehicles that could use ethanol and its blends with gasoline. These included modifications in diesel engines. In the same period, the Brazilian government was focusing on establishing regulatory bodies in the country. From 1951 to 2000, the US federal government established major institutions and executive agencies to ensure a clean US environment and protected it. In this same timeline, Brazil introduced sustainable strategic policies that provided laws and legal acts to replace fossil-based fuel with ethanol. Panel four indicates eras from 2001 to 2021, which shows that the US Congress introduced significant clean energy policies and acts that helped streamline the sustainability of biofuels in the country. On the other hand, Brazil introduced important biofuel policies that aimed to reduce carbon emissions.

4. Economic Implications of Biofuel Policies in the U.S. and Brazil

In 2018, the United States produced twice the volume of biofuels generated in Brazil. The mixture of ethane surpassed other countries, exports increased by 20%, and Brazil and Canada were the main customers. In 2019, RFA collaborated with the Brazilian government to establish an open trading platform to ensure biofuels’ optimal carbon intensity score. As mentioned, robust and sustainable energy and institutional policies have leveraged biofuel growth and economic sustainability in both countries.

As reported by the International Energy Agency (IEA), the largest producers of ethanol and biodiesel fuel are the U.S., followed by Brazil. Together in 2017, they comprised 84% of global ethanol production and 26% of biodiesel production. However, both countries face problems related to the variation in the cost of producing biofuels, gasoline, and diesel, the discrepancy in the equilibrium price of oil for ethanol and biodiesel, and the different policies and interventions [

99].

In both countries, biofuel production is affected by production cost, price, and profitability. Typically, biofuel production cost includes the costs of raw materials; the chemical plant’s operational costs, which converts raw materials into biofuel; and fixed and working capital if a new plant is built [

100,

101]. Regarding raw materials to produce ethanol, corn is mainly used in the U.S. The primary raw material is sugar cane in Brazil, while both countries use soy to produce biodiesel [

99]. The costs of these raw materials are subject to several factors, such as area planted, productivity, harvest, market price, technology, and price of gasoline and diesel fuels to maximize profit margin [

9].

Additionally, co-products are in high demand, raising their price. These include dried distillers’ grains (DDGs) produced from corn, bagasse produced from sugar cane, and bran made from soy. Most of the biofuel produced in the U.S. and Brazil is consumed domestically. Therefore, biofuel consumption in Brazil and the U.S. is mandated. However, compliance with local renewable energy policies is only attainable when the production cost is lower than fossil-based fuel.

In the United States, gasoline and diesel production costs are lower than in Brazil due to the economies of scale used by high-tech refineries that expand production to share the fixed cost and reduce the average cost of products. In both countries, the costs of fuel distribution are approximately equivalent. However, in Brazil, oil production has higher costs, which makes the use and production of ethanol more economical in Brazil as opposed to the United States [

99].

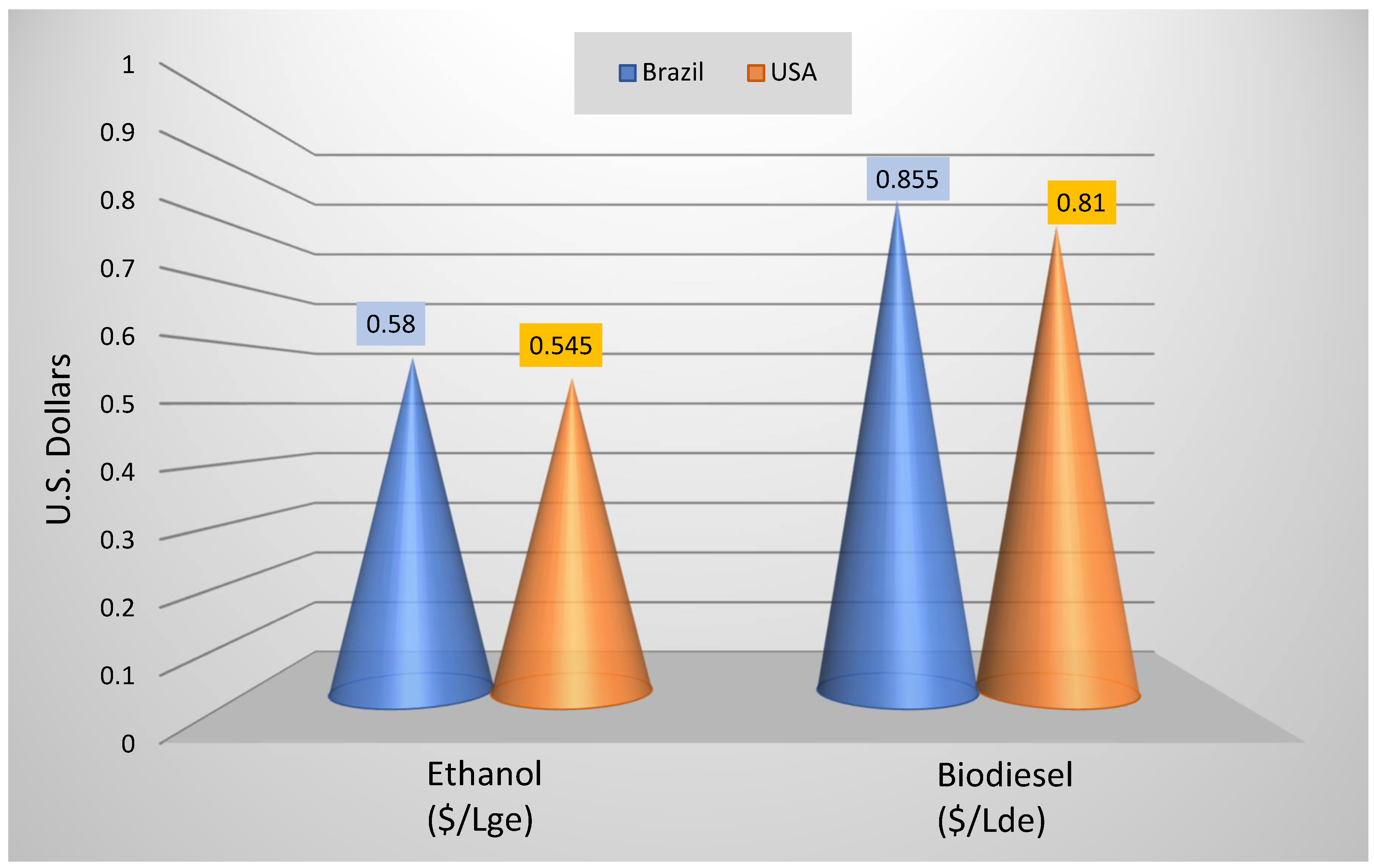

Figure 9 shows the cost comparison of ethanol and biodiesel production in 2017 for the U.S. and Brazil.

As shown in

Figure 9, biodiesel and ethanol production costs are slightly higher in Brazil than in the U.S. Since both countries mostly use soybean oil as feedstock, the average production costs of biodiesel are broadly aligned.

Figure 9 also shows that the average production costs of ethanol in both countries are lower than that of biodiesel, which has been non-competitive with the higher prices of fossil diesel. This trend is based on the fact that in 2017 the soybean oil cost was nearly three times more than the average crude oil prices in either country. In 2017, the increased price of crude oil decreased the cost premiums of biofuel. The average crude oil price of

$51/bbl (which is a round figure of

$50.88/bbl) [

102] raised the competitiveness of biofuel in Brazil in 2017.

Moreover, it also caused the reduction of the biodiesel premium over fossil-based diesel. However, such an effect in the U.S. was minimal. This trend was because of the reason that the rise in diesel and gasoline costs was due to higher oil prices. Additionally, at the same time, the production costs of biofuel increased due to higher costs of process energy and higher fertilizer prices.

The U.S. and Brazil have made significant contributions to reduce GHG emissions by using biofuels on a large scale. It is anticipated that other countries will also implement similar regulations and gain numerous positive environmental and socio-economic consequences.