Using Big Data for Sustainability in Supply Chain Management

Abstract

:1. Introduction

2. Literature Review

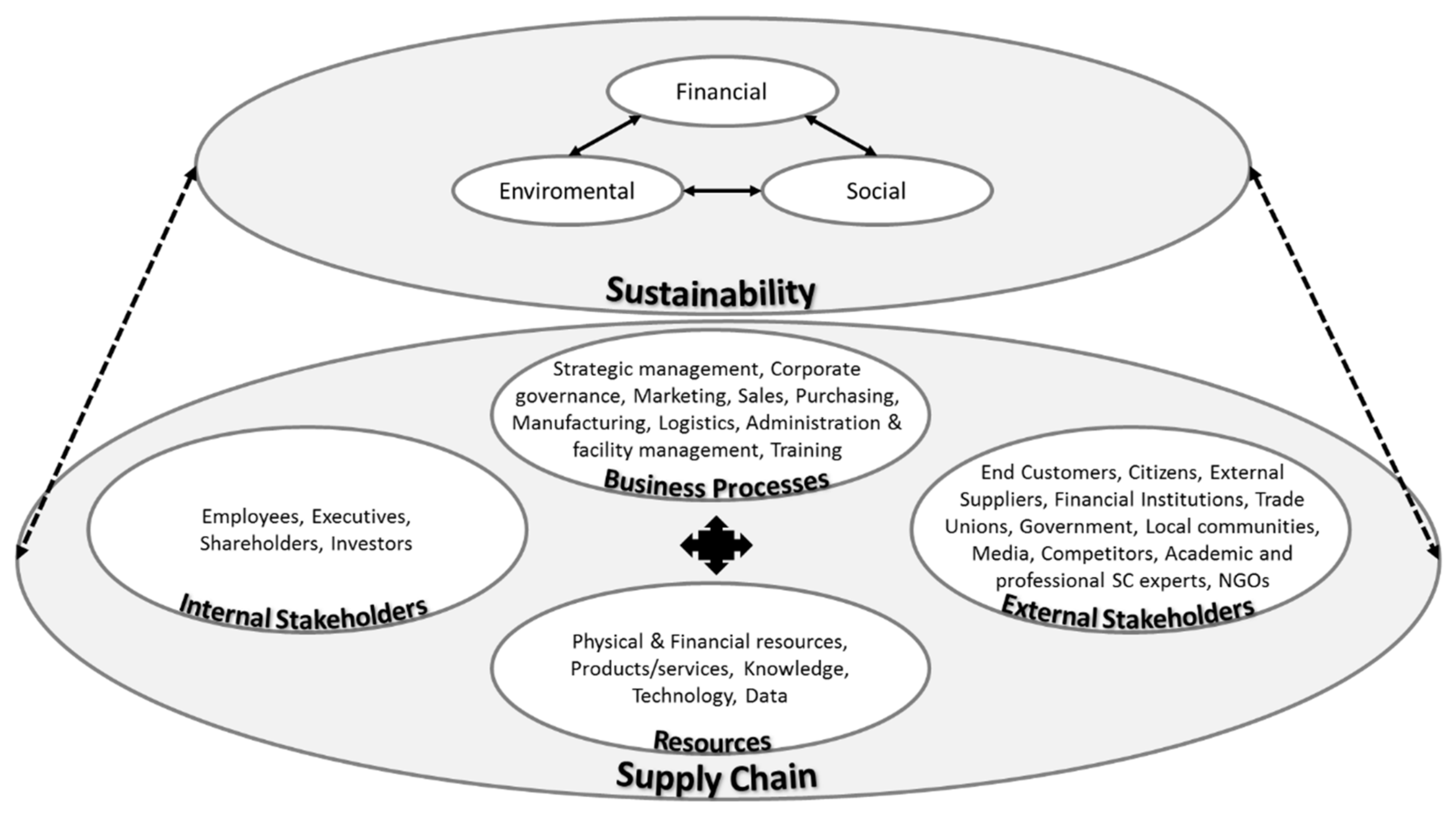

2.1. Sustainable Supply Chain

2.2. SSCM Frameworks

- (1)

- (2)

- They are focused on solving specific aspects instead of adopting a holistic approach that allows them to boost the economic, environmental, and social performance of the supply chain [32].

- (3)

- While some frameworks focus almost exclusively on the selection of indicators, others value only qualitative aspects to determine whether an SC has a coherent orientation toward sustainability. Therefore, they do not take advantage of the possibilities of combining both methods [6].

- (4)

- They lack a methodology that specifies which tasks must be carried out, who should carry them out, which stakeholders should be involved, what technological system must be implemented to support the qualitative and quantitative analyses, and how to integrate the results of these analyses in decision making to improve the sustainability of the SC. The SC sustainability assessment should serve to optimize resources, improve processes, enhance product innovations, reduce costs, reinforce productivity, and promote SC values [33].

- (5)

- They do not describe how to use the possibilities of the new information and communications technologies such as Big Data Analytics (BDA) to generate information and relevant knowledge about the current and future sustainability performance of the SC from structured data and nonstructured data sources [34,35]

- (6)

- The lack of verified Sustainable Supply Chain Management (SSCM) frameworks, which raises a serious question on their applicability and has become a concern for the practitioners [36].

2.3. Big Data and Sustainable Supply Chains

3. SSCM-IRIS Framework

3.1. Methodology

3.2. Human Resources

3.3. Stakeholders

3.4. Maturity Model

3.5. Organizational

3.6. Technology

4. SSCM-IRIS Framework Validation

4.1. Expert Assessment

4.2. Case Study

- Vessel speed optimization

- Vessel consumption reduction

- Terminal capacity optimization

- Sustainable supply chain awareness global training

- -

- To obtain a good view of the project scope and consequences, as well as to improve the sustainability of the supply chain quickly and without serious problems

- -

- To perfectly control the project, because all the activities to be carried out during the whole project life cycle were clearly defined, and the rest of the dimensions of the framework gave suitable support to the execution of these activities

- -

- To achieve all the goals set out at the beginning of the project and to accomplishe the timespan initially established without significant deviations

- -

- To clarify and update the strategy for the environmental, social, and economic sustainability of the supply chain, considering the situation of each enterprise that belongs to the supply chain

- -

- To communicate the sustainable strategy throughout the supply chain members

- -

- To align enterprises, unit, and individual goals with the supply chain sustainability strategy

- -

- To link objectives to long-term targets and annual budgets

- -

- To conduct periodic sustainability performance reviews to measure the sustainability objectives achievement and to develop actions plans to improve the supply chain sustainability.

- -

- To generate new information using Big Data to measure the sustainability performance of the supply chain from structured and unstructured data sources, both internal to the supply chain and external.

- Ensuring data security to avoid that different external stakeholders can access sensitive data.

- Involving more stakeholders in the different stages of the validation.

- Improving accuracy/communication of sentiment analysis method.

5. Discussion

5.1. Theoretical Implications

- (1)

- The proposal of a methodology dimension, which integrates sustainability assessment with sustainability improvement projects. None of the existing frameworks include a methodology to guide during all the activities in the whole Supply Chain Sustainability Management project life cycle, which integrates the assessment of sustainability with the action plans to improve SC sustainability. As a result, big opportunities to make improvements in SC sustainability can be missed [33]. In contrast to existing frameworks, the SSCM-IRIS framework guides during the whole project life explaining all the phases, activities and tasks that should be done and how and by whom, from the SC sustainability strategy definition till the business processes reengineering to improve the SC sustainability.

- (2)

- The combination of qualitative methods for sustainability objectives and strategy planning definition with quantitative methods to assess if all the SC companies meet their goals in all sustainability dimensions and at different levels. As [6] state, the qualitative and quantitative approaches for sustainability assessment are not combined in existing frameworks; therefore, they do not benefit from the advantages of combining both types of assessment.

- (3)

- (4)

- The SSCM-IRIS framework adopts a holistic approach through a Sustainability Balanced Scorecard that allows the SC environmental, social, and economic sustainability performance to be analyzed and improved. This is an important lack of existing frameworks that are mainly focused on specific sustainability issues instead of adopting a holistic approach that would enable them to improve all the SC environmental, social, and economic sustainability performance [32].

- (5)

- The SSCM-IRIS framework improves the analysis of the impact of SC sustainability, as well as the SC future impact using Big Data analytics. Unlike existing frameworks that focus on measuring only the past economic, social, or environmental impact of the SC [34,35], the SSCM-IRIS framework provides the design, architecture and software necessary to take advantage of the possibilities that the new technologies, such as Big Data, offer to improve the diagnostic analysis and to carry out a predictive analysis of the future impact of the SC sustainability.

- (6)

- The framework was applied to a case study. This is an important advantage over other existing frameworks because there is a lack of verified Sustainable Supply Chain Management (SSCM) frameworks, which raises a serious question on their applicability and has become a concern for the practitioners [36].

5.2. Managerial Implications

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Brundtland, G.H.; Khalid, M.; Agnelli, S.; Al-Athel, S.; Chidzero, B.J.N.Y. Our Common Future: Brundtland Report; ONU: Ada, OH, USA, 1987. [Google Scholar]

- Maes, M.J.; Jones, K.; Toledano, M.B.; Milligan, B. Mapping synergies and trade-offs between urban ecosystems and the sustainable development goals. Environ. Sci. Policy 2019, 93, 181–188. [Google Scholar] [CrossRef]

- Cortado, F.-J.; Chalmeta, R. Use of social networks as a CSR communication tool. Cogent Bus. Manag. 2016, 3, 1187783. [Google Scholar] [CrossRef] [Green Version]

- Thoeni, A.; Tjoa, A. Information technology for sustainable supply chain management: A literature survey. Enterp. Inf. Syst. 2017, 11, 828–858. [Google Scholar] [CrossRef]

- Azevedo, S.G.; Carvalho, H.; Duarte, S.; Machado, V. Influence of green and lean upstream supply chain management practices on business sustainability. IEEE Trans. Eng. Manag. 2012, 59, 753–765. [Google Scholar] [CrossRef]

- Ansari, Z.N.; Kant, R. Exploring the framework development status for sustainability in supply chain management: A systematic literature synthesis and future research directions. Bus. Strat. Environ. 2017, 26, 873–892. [Google Scholar] [CrossRef]

- Mentzer, J.T.; Dewitt, W.; Keebler, J.S.; Min, S.; Nix, N.W.; Smith, C.D.; Zacharia, Z.G. What is supply chain management? In Supply Chain Management; Mentzer, J.T., Ed.; Sage Publications: Thousand Oaks, CA, USA, 2001; pp. 1–25. [Google Scholar]

- Lummus, R.R.; Vokurka, R.J. Defining supply chain management: A historical perspective and practical guidelines. Ind. Manag. Data Syst. 1999, 99, 11–17. [Google Scholar] [CrossRef] [Green Version]

- Tan, K.C.; Lyman, S.B.; Wisner, J.D. Supply chain management: A strategic perspective. Int. J. Oper. Prod. Manag. 2002, 22, 614–631. [Google Scholar] [CrossRef]

- Christiansen, B. Handbook of Research on Global Supply Chain Management; IGI Global: Battle Creek, MI, USA, 2015. [Google Scholar]

- Fawcett, S.E.; Magnan, G.M.; McCarter, M.W. Benefits, barriers, and bridges to effective supply chain management. Supply Chain Manag. Int. J. 2008, 13, 35–48. [Google Scholar] [CrossRef] [Green Version]

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of 21st Century Business; Capstone: Oxford, UK, 1997. [Google Scholar]

- Bastas, A.; Liyanage, K. Integrated quality and supply chain management business diagnostics for organizational sustainability improvement. Sustain. Prod. Consum. 2019, 17, 11–30. [Google Scholar] [CrossRef]

- Ramezankhani, M.; Torabi, S.A.; Vahidi, F. Supply chain performance measurement and evaluation: A mixed sustainability and resilience approach. Comput. Ind. Eng. 2018, 126, 531–548. [Google Scholar] [CrossRef]

- Min, H.; Kim, I. Green supply chain research: Past, present, and future. Logist. Res. 2012, 4, 39–47. [Google Scholar] [CrossRef]

- Kamali, F.P.; Borges, J.A.R.; Osseweijer, P.; Posada, J.A. Towards social sustainability: Screening potential social and governance issues for biojet fuel supply chains in Brazil. Renew. Sustain. Energy Rev. 2018, 92, 50–61. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, X.; Tang, O.; Price, L.; Zhang, S.; Zhu, W. Supply chain collaboration for sustainability: A literature review and future research agenda. Int. J. Prod. Econ. 2017, 194, 73–87. [Google Scholar] [CrossRef]

- Saputri, V.H.L.; Sutopo, W.; Hisjam, M.; Ma’Aram, A. Sustainable agri-food supply chain performance measurement model for GMO and Non-GMO using data envelopment analysis method. Appl. Sci. 2019, 9, 1199. [Google Scholar] [CrossRef] [Green Version]

- Hussain, M.; Ajmal, M.M.; Gunasekaran, A.; Khan, M. Exploration of social sustainability in healthcare supply chain. J. Clean. Prod. 2018, 203, 977–989. [Google Scholar] [CrossRef]

- Ashby, A.L.; Leat, M.; Smith, M. Making connections: A review of supply chain management and sustainability literature. Supply Chain Manag. Int. J. 2012, 17, 497–516. [Google Scholar] [CrossRef]

- Ha-Brookshire, J. Toward moral responsibility theories of corporate sustainability and sustainable supply chain. J. Bus. Ethic. 2017, 145, 227–237. [Google Scholar] [CrossRef]

- Gold, S.; Schleper, M.C. A pathway towards true sustainability: A recognition foundation of sustainable supply chain management. Eur. Manag. J. 2017, 35, 425–429. [Google Scholar] [CrossRef]

- Seuring, S.; Sarkis, J.; Müller, M.; Rao, P. Sustainability and supply chain management—An introduction to the special issue. J. Clean. Prod. 2008, 16, 1545–1551. [Google Scholar] [CrossRef]

- Chowdhury, M.H.; Agarwal, R.; Quaddus, M. Dynamic capabilities for meeting stakeholders’ sustainability requirements in supply chain. J. Clean. Prod. 2019, 215, 34–45. [Google Scholar] [CrossRef]

- Reefke, H.; Sundaram, D. Key themes and research opportunities in sustainable supply chain management—Identification and evaluation. Omega 2017, 66, 195–211. [Google Scholar] [CrossRef] [Green Version]

- Gharaei, A.; Karimi, M.; Shekarabi, S.A.H. An integrated multi-product, multi-buyer supply chain under penalty, green, and quality control polices and a vendor managed inventory with consignment stock agreement: The outer approximation with equality relaxation and augmented penalty algorithm. Appl. Math. Model. 2019, 69, 223–254. [Google Scholar] [CrossRef]

- Yuqiuge, H.; Petri, H.; Ahm, S. Virtual factory system design and implementation: Integrated sustainable manufacturing. Int. J. Syst. Sci. 2018, 5, 116–132. [Google Scholar]

- Izadikhah, M.; Saen, R.F. Assessing sustainability of supply chains by chance-constrained two-stage DEA model in the presence of undesirable factors. Comput. Oper. Res. 2017, 100, 343–367. [Google Scholar] [CrossRef]

- Tajbakhsh, A.; Hassini, E. A data envelopment analysis approach to evaluate sustainability in supply chain networks. J. Clean. Prod. 2015, 105, 74–85. [Google Scholar] [CrossRef]

- Muñoz-Torres, M.J.; Fernández-Izquierdo, M.Á.; Rivera-Lirio, J.M.; Ferrero-Ferrero, I.; Escrig-Olmedo, E.; Gisbert-Navarro, J.V.; Marullo, M.C. An assessment tool to integrate sustainability principles into the global supply chain. Sustainability 2018, 10, 535. [Google Scholar] [CrossRef] [Green Version]

- Pawlowski, J.; Bick, M. The global knowledge management framework: Towards a theory for knowledge management in globally distributed settings. Electron. J. Knowl. Manag. 2012, 10, 92–108. [Google Scholar]

- Elhidaoui, S.; Benhida, K.; Benhida, K.; Elfezazi, S.; El Hachadi, A. Environmental dimension in sustainable supply chain management. Framework and literature review. Int. J. Adv. Appl. Sci. 2020, 7, 74–90. [Google Scholar]

- Wollmuth, J.; Ivanova, V. 6 Steps for a More Sustainable Supply Chain. 2014. Available online: https://www.greenbiz.com/blog/2014/01/24/6-steps-more-sustainable-supply-chain (accessed on 14 June 2021).

- Bag, S.; Wood, L.C.; Xu, L.; Dhamija, P.; Kayikci, Y. Big data analytics as an operational excellence approach to enhance sustainable supply chain performance. Resour. Conserv. Recycl. 2020, 153, 104559. [Google Scholar] [CrossRef]

- Kaur, H.; Singh, S.P. Heuristic modeling for sustainable procurement and logistics in a supply chain using big data. Comput. Oper. Res. 2018, 98, 301–321. [Google Scholar] [CrossRef]

- Yadav, G.; Luthra, S.; Jakhar, S.K.; Mangla, S.K.; Rai, D.P. A framework to overcome sustainable supply chain challenges through solution measures of industry 4.0 and circular economy: An automotive case. J. Clean. Prod. 2020, 254, 120112. [Google Scholar] [CrossRef]

- Saggi, M.K.; Jain, S. A survey towards an integration of big data analytics to big insights for value-creation. Inf. Process. Manag. 2018, 54, 758–790. [Google Scholar] [CrossRef]

- Adams, M.N. Perspectives on data mining. Int. J. Mark. Res. 2010, 52, 11–19. [Google Scholar] [CrossRef]

- Gao, Q.; Guo, S.; Liu, X.; Manogaran, G.; Chilamkurti, N.; Kadry, S. Simulation analysis of supply chain risk management system based on IoT information platform. Enterp. Inf. Syst. 2020, 14, 1354–1378. [Google Scholar] [CrossRef]

- Mani, V.; Gunasekaran, A.; Delgado, C. Enhancing supply chain performance through supplier social sustainability: An emerging economy perspective. Int. J. Prod. Econ. 2018, 195, 259–272. [Google Scholar] [CrossRef]

- Marjani, M.; Nasaruddin, F.H.; Gani, A.; Karim, A.; Hashem, I.A.T.; Siddiqa, A.; Yaqoob, I. Big IoT data analytics: Architecture, opportunities, and open research challenges. IEEE Access 2017, 5, 5247–5261. [Google Scholar] [CrossRef]

- Mahmood, A.; Zen, H.; Hilles, S.M.S. Big data and privacy issues for connected vehicles in intelligent transportation systems. In Encyclopedia of Big Data Technologies; Sakr, S., Zomaya, A., Eds.; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Olshannikova, E.; Olsson, T.; Huhtamäki, J.; Kärkkäinen, H. Conceptualizing big social data. J. Big Data 2017, 4, 3. [Google Scholar] [CrossRef]

- Mamonov, S.; Triantoro, T.M. The strategic value of data resources in emergent industries. Int. J. Inf. Manag. 2018, 39, 146–155. [Google Scholar] [CrossRef]

- Hazen, B.T.; Skipper, J.B.; Ezell, J.D.; Boone, C.A. Big data and predictive analytics for supply chain sustainability: A theory-driven research agenda. Comput. Ind. Eng. 2016, 101, 592–598. [Google Scholar] [CrossRef]

- Wadmann, S.; Hoeyer, K. Dangers of the digital fit: Rethinking seamlessness and social sustainability in data-intensive healthcare. Big Data Soc. 2018, 5. [Google Scholar] [CrossRef] [Green Version]

- Raut, R.D.; Mangla, S.K.; Narwane, V.S.; Gardas, B.B.; Priyadarshinee, P.; Narkhede, B.E. Linking big data analytics and operational sustainability practices for sustainable business management. J. Clean. Prod. 2019, 224, 10–24. [Google Scholar] [CrossRef]

- Bibby, L.; Dehe, B. Defining and assessing industry 4.0 maturity levels—Case of the defence sector. Prod. Plan. Control. 2018, 29, 1030–1043. [Google Scholar] [CrossRef]

- Waller, M.A.; Fawcett, S.E. Data science, predictive analytics, and big data: A revolution that will transform supply chain design and management. J. Bus. Logist. 2013, 34, 77–84. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Papadopoulos, T.; Childe, S.J.; Shibin, K.; Wamba, S.F. Sustainable supply chain management: Framework and further research directions. J. Clean. Prod. 2017, 142, 1119–1130. [Google Scholar] [CrossRef] [Green Version]

- Gunasekaran, A.; Papadopoulos, T.; Dubey, R.; Wamba, S.F.; Childe, S.J.; Hazen, B.; Akter, S. Big data and predictive analytics for supply chain and organizational performance. J. Bus. Res. 2017, 70, 308–317. [Google Scholar] [CrossRef]

- Papadopoulos, T.; Gunasekaran, A.; Dubey, R.; Altay, N.; Childe, S.J.; Fosso-Wamba, S. The role of big data in explaining disaster resilience in supply chains for sustainability. J. Clean. Prod. 2017, 142, 1108–1118. [Google Scholar] [CrossRef] [Green Version]

- De, A.; Wang, J.; Tiwari, M. Hybridizing basic variable neighbourhood search with particle swarm optimization for solving sustainable ship routing and bunker management problem. IEEE Trans. Intell. Transp. Syst. 2019, 21, 986–997. [Google Scholar] [CrossRef]

- De, A.; Choudhary, A.; Tiwari, M.K. Multiobjective approach for sustainable ship routing and scheduling with draft restrictions. IEEE Trans. Eng. Manag. 2019, 66, 35–51. [Google Scholar] [CrossRef] [Green Version]

- Chen, L.; Jia, G. Environmental efficiency analysis of China’s regional industry: A data envelopment analysis (DEA) based approach. J. Clean. Prod. 2017, 142, 846–853. [Google Scholar] [CrossRef]

- Wu, L.; Yue, X.; Jin, A.; Yen, D.C. Smart supply chain management: A review and implications for future research. Int. J. Logist. Manag. 2016, 27, 395–417. [Google Scholar] [CrossRef]

- Ramadan, M.; Shuqqo, H.; Qtaishat, L.; Asmar, H.; Salah, B. Sustainable competitive advantage driven by big data analytics and innovation. Appl. Sci. 2020, 10, 6784. [Google Scholar] [CrossRef]

- Mani, V.; Delgado, C.; Hazen, B.T.; Patel, P. Mitigating supply chain risk via sustainability using big data analytics: Evidence from the manufacturing supply chain. Sustainability 2017, 9, 608. [Google Scholar] [CrossRef] [Green Version]

- Cheng, T.C.E.; Kamble, S.S.; Belhadi, A.; Ndubisi, N.O.; Lai, K.-H.; Kharat, M.G. Linkages between big data analytics, circular economy, sustainable supply chain flexibility, and sustainable performance in manufacturing firms. Int. J. Prod. Res. 2021, 1–15. [Google Scholar] [CrossRef]

- Chalmeta, R.; Santos-Deleón, N.J. Sustainable supply chain in the era of industry 4.0 and big data: A systematic analysis of literature and research. Sustainability 2020, 12, 4108. [Google Scholar] [CrossRef]

- Lukman, R.; Glavič, P. What are the key elements of a sustainable university? Clean Technol. Environ. Policy 2006, 9, 103–114. [Google Scholar] [CrossRef]

- Holmberg, J.; Larsson, J. A sustainability lighthouse—Supporting transition leadership and conversations on desirable futures. Sustainability 2018, 10, 3842. [Google Scholar] [CrossRef] [Green Version]

- Orenga-Roglá, S.; Chalmeta, R. Framework for implementing a big data ecosystem in organizations. Commun. ACM 2019, 62, 58–65. [Google Scholar] [CrossRef]

- Chalmeta, R.; Palomero, S. Methodological proposal for business sustainability management by means of the Balanced Scorecard. J. Oper. Res. Soc. 2011, 62, 1344–1356. [Google Scholar] [CrossRef]

- Fobbe, L. Analysing organisational collaboration practices for sustainability. Sustainability 2020, 12, 2466. [Google Scholar] [CrossRef] [Green Version]

- Ahern, M.; Clouse, A.; Turner, R. CMMI Distilled: A Practical Introduction to Integrated Process Improvement; SEI; Addison Wesley: Boston, MA, USA, 2004. [Google Scholar]

- Dos Santos-Neto, J.B.S.; Costa, A.P.C.S. Enterprise maturity models: A systematic literature review. Enterp. Inf. Syst. 2019, 13, 719–769. [Google Scholar] [CrossRef]

- Figge, F.; Hahn, T.; Schaltegger, S.; Wagner, M. The sustainability balanced scorecard—Linking sustainability management to business strategy. Bus. Strat. Environ. 2002, 11, 269–284. [Google Scholar] [CrossRef]

- Kaplan, R.; Norton, D. Translating Strategy into Action: The Balanced Scorecard; Harvard Business School Press: Boston, MA, USA, 1996. [Google Scholar]

- Díaz-Curbelo, A.; Gento, Á.M.; Redondo, A.; Aqlan, F. A fuzzy-based holistic approach for supply chain risk assessment and aggregation considering risk interdependencies. Appl. Sci. 2019, 9, 5329. [Google Scholar] [CrossRef] [Green Version]

- Palomero, S.; Chalmeta, R. A guide for supply chain integration in SMEs. Prod. Plan. Control. 2012, 25, 372–400. [Google Scholar] [CrossRef] [Green Version]

- Azevedo, S.G.; Carvalho, H.; Ferreira, L.; Matias, J. A proposed framework to assess upstream supply chain sustainability. Environ. Dev. Sustain. 2017, 19, 2253–2273. [Google Scholar] [CrossRef]

- Alkahtani, M.; Choudhary, A.; De, A.; Harding, J.A. A decision support system based on ontology and data mining to improve design using warranty data. Comput. Ind. Eng. 2019, 128, 1027–1039. [Google Scholar] [CrossRef] [Green Version]

- Runeson, P.; Höst, M. Guidelines for conducting and reporting case study research in software engineering. Empir. Softw. Eng. 2009, 14, 131–164. [Google Scholar] [CrossRef] [Green Version]

- Robson, C. Real World Research; Blackwell Publishers: Oxford, UK, 2002. [Google Scholar]

- Wang, M.; Wang, B.; Abareshi, A. Blockchain technology and its role in enhancing supply chain integration capability and reducing carbon emission: A conceptual framework. Sustainability 2020, 12, 550. [Google Scholar] [CrossRef]

- Junaid, M.; Xue, Y.; Syed, M.W.; Li, J.Z.; Ziaullah, M. A neutrosophic AHP and TOPSIS framework for supply chain risk assessment in automotive industry of Pakistan. Sustainability 2020, 12, 154. [Google Scholar] [CrossRef] [Green Version]

- Scholz, R.W. Sustainable digital environments: What major challenges is humankind facing? Sustainability 2018, 8, 726. [Google Scholar] [CrossRef] [Green Version]

| Activities | Tasks | Related Dimensions |

|---|---|---|

| Feasibility Study | Analysis of the financial, organizational, operational, and technological project viability | Human Resources: FI and PMO Stakeholders: internal to the focal enterprise |

| Project Plan development | Commitment of the managers of the SC and members of the SC Definition of timeframe and sequence of the project’s activities Definition of quality control mechanisms | Human Resources: MSC and PMO Stakeholders: internal to the focal enterprise and the SC |

| Definition of project’s responsibilities | Creation of the project teams Evaluation of team’s knowledge about sustainability Selection of team leaders and assignment of their responsibilities Schedule of follow-up meetings and training program implementation | Human Resources: HRM, PMO, and SSCMT Stakeholders: internal to the focal enterprise and the SC |

| Development of Project Communication Plan | Make the project known to all the SC internal stakeholders, stressing that the project will have a positive effect on the SC by making both the SC and the SC members more competitive and sustainable Explain how the SC companies are going to be affected | Human Resources: SSCMT, HRM, and PMO Stakeholders: internal to the focal enterprise and the SC |

| Activities | Tasks | Related Dimensions |

|---|---|---|

| Qualitative evaluation of SC companies | Interviews with managers of the companies in the SC Interviews with heads of department Survey through online questionnaire for other employees | Human Resources: MSC, ESC, and SSCMT Stakeholders: internal to the focal enterprise and the SC Technology: Application web Maturity Model: questionnaires and interviews |

| Definition of SC sustainability objectives | Senior managers of the companies in the SC at meetings with the SSCM team | Human Resources: MSC and SSCMT Stakeholders: internal to the focal enterprise and the SC |

| Selection of external stakeholders | Selection of external stakeholders based on the objectives | Human Resources: MSC and SSCMT Stakeholders: internal to the focal enterprise and the SC |

| Selection of the sustainability strategy of the SC | Senior managers of the companies at the SC meetings with the SSCM team and SC stakeholders | Human Resources: SSCMT Stakeholders: all |

| Activities | Tasks | Related Dimensions |

|---|---|---|

| Sustainability Balanced Scorecard (SBSC) development | Definition of objectives, goals, and indicators for level 1 (economic, social, and environmental) and level 2 dimensions (internal stakeholders, external stakeholders, departments/business processes, and resources). Definition of objective cause-and-effect relationships and indicators of cause-and-effect relationships Strategic map design Assessment and validation with interviews and questionnaires for the top managers of the SC companies and external stakeholders | Human Resources: MSC and SSCMT Stakeholders: all Technology: Application web/Form Maturity Model: questionnaires and interviews, SBSC |

| Allocation of weights and definition of the sustainability index to measure level of maturity | Selection of panel of experts Designation of the number of rounds Definition of interview structure in each round Definition of weights for each indicator Definition of the sustainability index | Human Resources: MSC and SSCMT Stakeholders: all Technology: Application web/form Maturity Model: Method Delphi, sustainability index |

| Activities | Tasks | Related Dimensions |

|---|---|---|

| Design | Functional, technological and graphic design Identification of data sources, procedures to extract data and calculate each indicator, language, format of the data, periodicity, norms of conduct, standards of development, etc. Ontology development | Human Resources: PMO, ITD, and SSCMT Stakeholders: internal to the focal enterprise and the SC Technology: BD-IRIS Framework |

| Select technology tools and suppliers | Hardware requirements Selection of BI (ETL, DWH, OLAP, etc.), Big Data and visualization tools Selection of suppliers for installation, training and/or consultancy | Human Resources: PMO, ITD, and FI Stakeholders: internal to the focal enterprise Technology: BD-IRIS Framework |

| DWH-SSCM development | Software installation Design of the design architecture Implementation of the DWH | Human Resources: PMO and ITD Stakeholders: internal to the focal enterprise Technology: ETL/DWH Technology: BD-IRIS Framework |

| Software development for measurement of indicators | Software installation Develop and/or parameterize the appropriate software for calculating the current value of the indicators, and its predictive analysis, using the BI and Big Data tools | Human Resources: PMO and ITD Stakeholders: internal to the focal enterprise Technology: Big Data Technology: BD-IRIS Framework |

| Data visualization | Software installation Parameterization in the form of dashboards, reports, etc. Verification and validation (User Acceptance Test) | Human Resources: PMO, ITD, SSCMT, and MSC Stakeholders: internal to the focal enterprise Technology: BD-IRIS Framework |

| Activities | Tasks | Related Dimensions |

|---|---|---|

| Quantitative analysis and maturity model | Get the value of each indicator Diagnostic analysis Predictive analysis Determine current and future level of maturity | Human Resources: SSCMT, MSC and FI Stakeholders: internal to the focal enterprise and the SC Technology: BD-IRIS Framework Maturity Model: SBSC Organizational: SCI-IRIS methodology |

| Activities | Tasks | Related Dimensions |

|---|---|---|

| Improvement actions | Definition and prioritization of sustainability improvement projects Communication of the affected chain to the companies and to external stakeholders Training in SSCM for staff and heads of department Implementation of sustainability improvement projects Share resources and information of SSCM practices among the members of the SC Establish control mechanisms | Human Resources: SSCMT, MSC, FI and HRM Stakeholders: all Organizational: SCI-IRIS methodology |

Semistructured interview questions to the Board

|

| Level | Description |

|---|---|

| Level 0: No sustainability | None of the SC companies meet the sustainability levels in any of its dimensions—financial, environmental or social. |

| Level 1: Partially sustainable in specific areas | Some of the companies in the SC have a good sustainability performance in one or several of the dimensions of sustainability but not in all of them or in the same dimensions. |

| Level 2: Sustainable in specific areas | All the SC companies have a good sustainability performance in one or several of its dimensions. |

| Level 3: Partially sustainable | Some of the companies in the SC meet the sustainability goals in all its dimensions, but other companies either fail to meet the goals in all the dimensions or do not meet any of the goals at all. |

| Level 4: Totally sustainable | All the SC companies meet the sustainability goals in all its dimensions. Vision, goals, corporate structure and employees are aligned to work to achieve a total sustainability—financial, environmental, and social. |

| Perspective | Indicator | Units |

|---|---|---|

| Environmental | Carbon footprint decrease | metric tons of CO2e |

| Fuel consumption reduction | Metric tons | |

| Speed reduction | Knots | |

| Economical | Increase in profit | USD million |

| Cost reductions | USD million | |

| % New contracts | % | |

| Social | Customer satisfaction survey | 0–10 |

| Employee satisfaction survey | 0–10 | |

| Social media sentiment | Bad-Good |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chalmeta, R.; Barqueros-Muñoz, J.-E. Using Big Data for Sustainability in Supply Chain Management. Sustainability 2021, 13, 7004. https://doi.org/10.3390/su13137004

Chalmeta R, Barqueros-Muñoz J-E. Using Big Data for Sustainability in Supply Chain Management. Sustainability. 2021; 13(13):7004. https://doi.org/10.3390/su13137004

Chicago/Turabian StyleChalmeta, Ricardo, and José-Eduardo Barqueros-Muñoz. 2021. "Using Big Data for Sustainability in Supply Chain Management" Sustainability 13, no. 13: 7004. https://doi.org/10.3390/su13137004

APA StyleChalmeta, R., & Barqueros-Muñoz, J.-E. (2021). Using Big Data for Sustainability in Supply Chain Management. Sustainability, 13(13), 7004. https://doi.org/10.3390/su13137004