Big Data Analytics in Sustainable Supply Chain Management: A Focus on Manufacturing Supply Chains

Abstract

:1. Introduction

- What are the elements of big data analytics?

- How does big data analytics enhance SSCM in manufacturing supply chains?

- What are the challenges that inhibit the implementation of big data analytics in manufacturing supply chains?

2. Literature Review

2.1. Sustainable Supply Chain Management

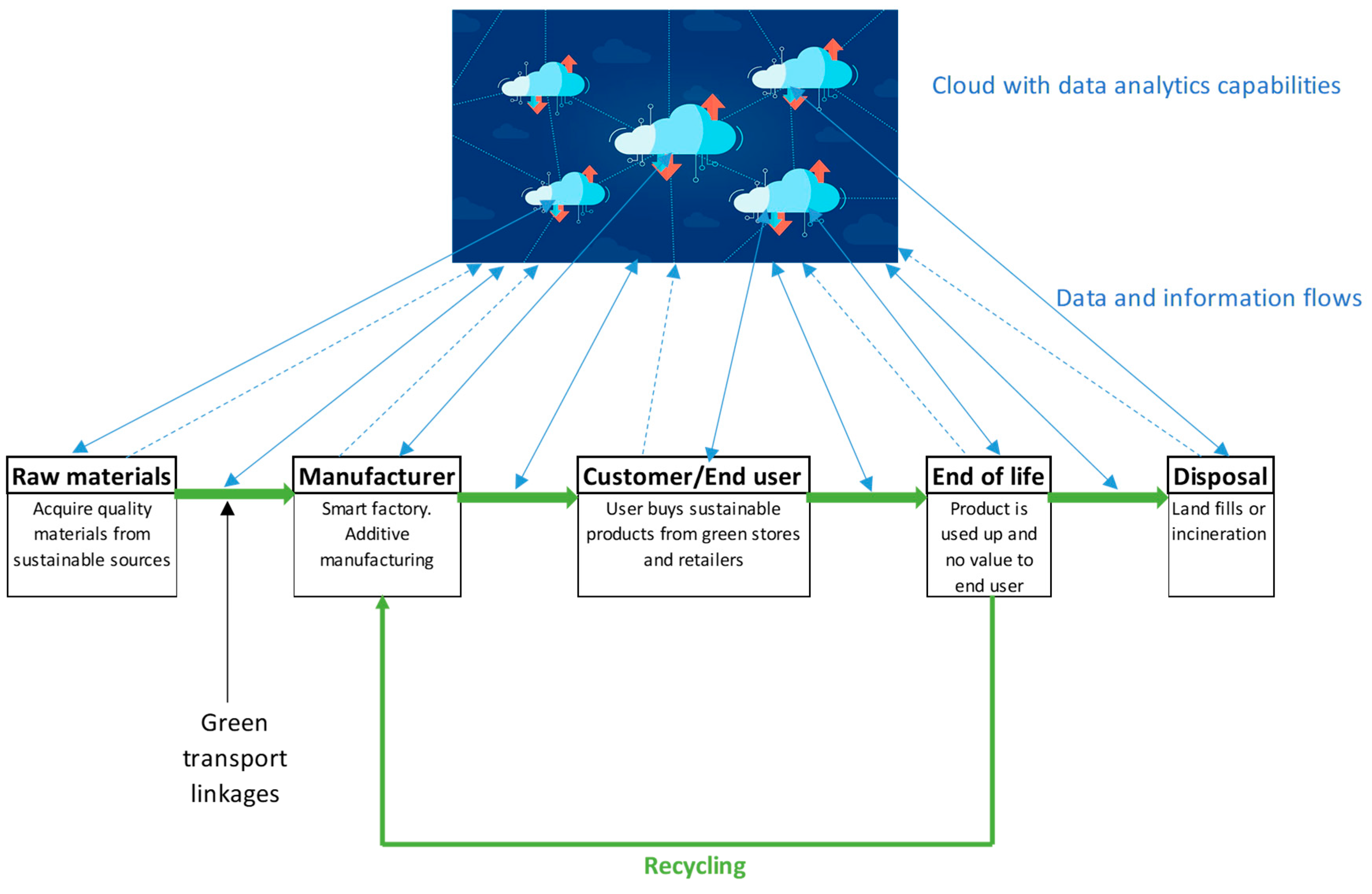

2.2. Manufacturing Supply Chains

2.3. Big Data Analytics

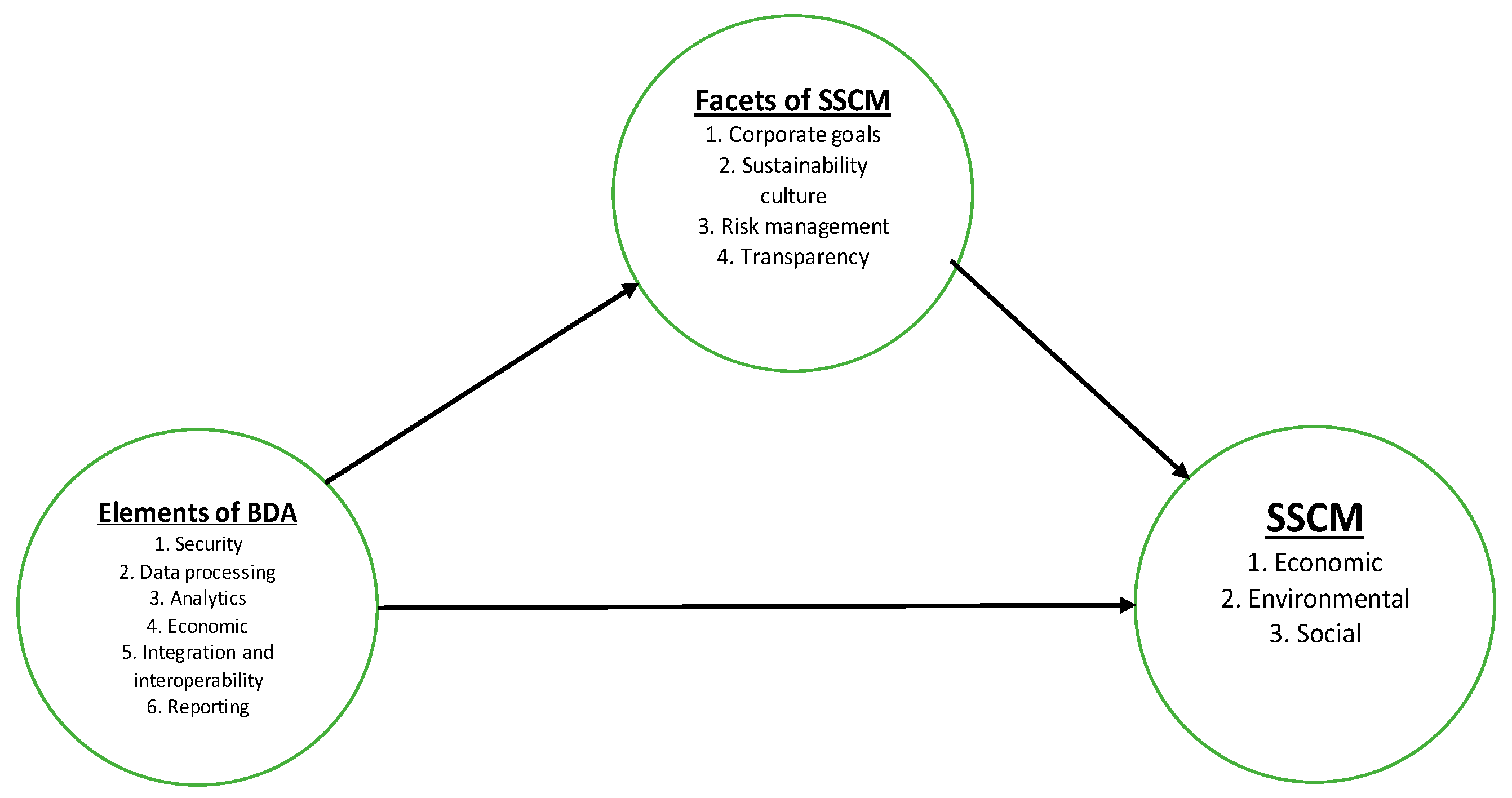

2.4. Dimensions of Big Data Analytics

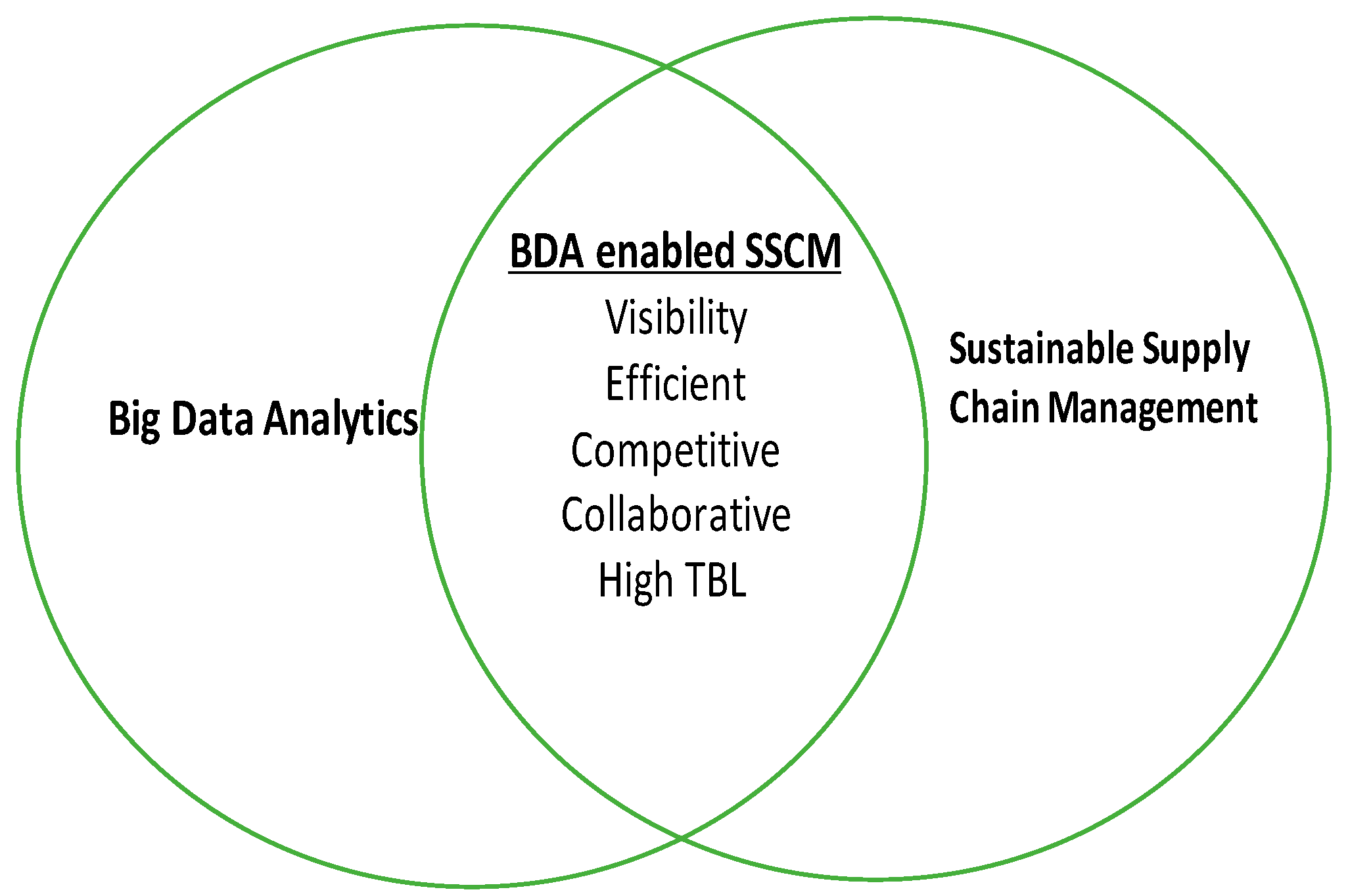

2.5. Big Data Analytics and SSCM

2.6. Challenges of Big Data Analytics Implementation

3. Methodology

3.1. Selection of Literature and Analysis

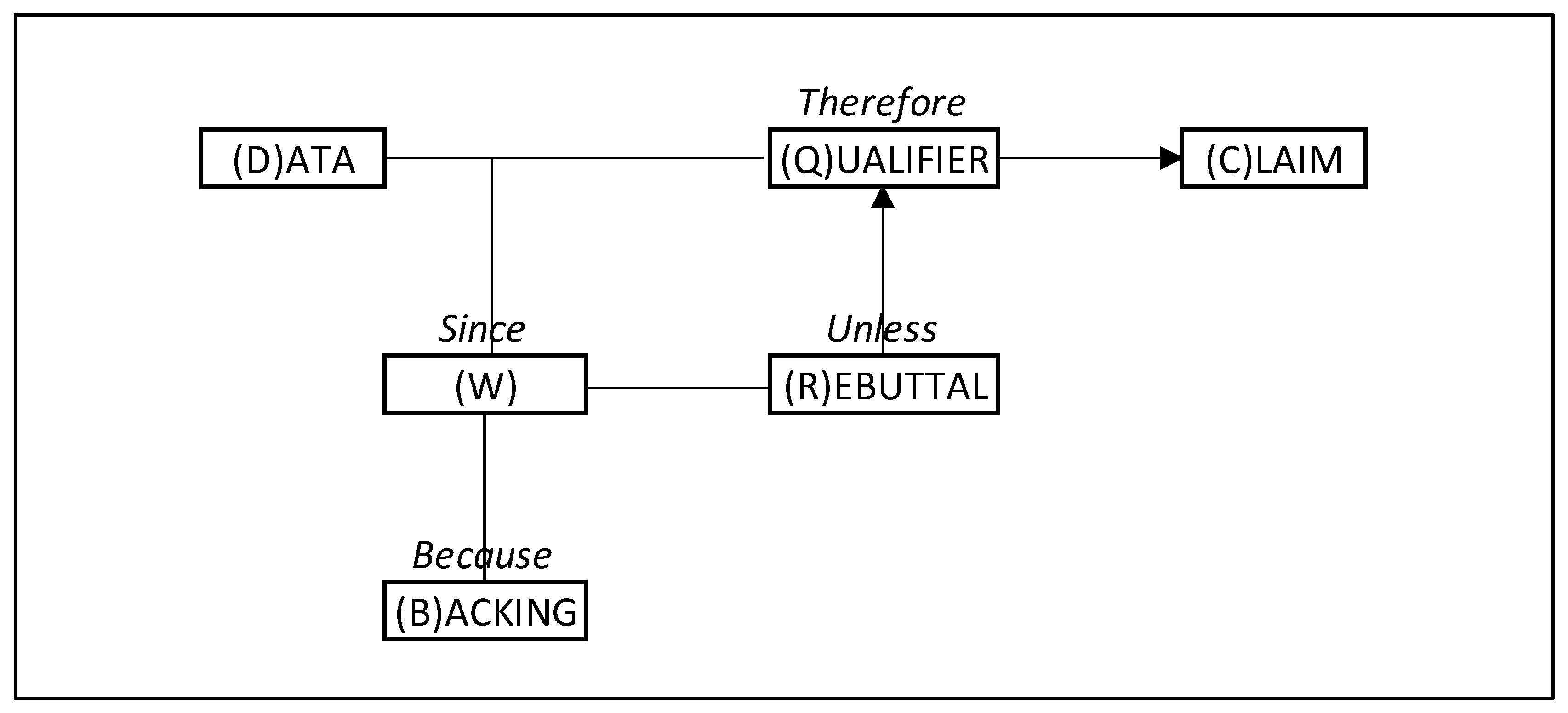

3.2. Steps in Toulmin Argumentation Model

- Claim: The first step in an argument is making a claim. A claim can be seen as a conclusion (Trent, 1968). In addition, a claim is a standard, an assertion or a thesis of the research [59]. Under this step the main question seeks to know the position that the author or proponent of an argument wants the readers to take. For instance, in this study, the claim is that the implementation of BDA can result in better SSCM, especially in manufacturing supply chains, which are usually complex and global and blamed for emissions.

- Grounds: A claim can only hold if there is evidence, facts or grounds that support it. Grounds can also be in the form of logical reasoning or statistics. Grounds are opinions or citations from authority. The pertinent question at this point relates to what the author puts forward to persuade the reader to agree to the claim [60]. In the current study, evidence that supports the claim will be sought from published peer-reviewed academic research.

- Warrant: A warrant certifies the claim as true based on the grounds or evidence. Warrants refer to the common beliefs within a particular discipline. They generally provide the reasons connecting the grounds to the claim. The pertinent question to ask here relates to what the connection between ground and the claim would be [59]. More specifically, the grounds support the stated claim since BDA has smart technologies that help collect and analyse relevant data that can result in optimized supply chain operations, reduction of emissions and prevention of unethical behaviour.

- Backing: In cases where a warrant is not acceptable to readers as is, backers are introduced. Backers are items meant to certify the supposition of the warrant [60]. As such, backing supports the warrant. The pertinent question under this step relates to the reliability of the movement from grounds to claim. For instance, the warrant presented in (4) above is supported by data integration and the quality of data collected by the smart sensors that are part of BDA.

- Rebuttal: In some cases, arguments face conflicting perspectives. These might be objections raised by readers or counterarguments. The objections should be addressed so as not to weaken the claim. A rebuttal may also refer to an alternative interpretation of evidence. A rebuttal recognizes that the claim might not hold under some situations and thus acts as “safety valve” [60] p. 45. The question in this step relates to the possibilities that might negate the arguments [59]. This is related to the likely reasons why BDA may not promote SSCM. For instance, there might be a relationship between BDA and SSCM but not necessarily a positive one.

- Qualifiers: Arguments are about chances, not certainty. Qualifiers make a claim flexible. It uses words like “possibly” or “presumably” to qualify the claim.

4. Discussion

Big data analytics promotes sustainable supply chain management.

Claim: Big data analytics presumably promotes sustainable supply chain management in manufacturing supply chains.

Grounds: BDA enhances supply chain management integration, which results in better risk management, transparency, sustainability organizational culture and integration of sustainability with corporate strategy. Thus, better economic, social and environmental performance is a result of BDA deployment.

Warrant: Since BDA incorporates smart technologies in the form of IoT that detect, sense and continuously collect and analyse data across the supply chain for responsive and insight-based decision making, it is likely to increase transparency, improve risk management and encourage a sustainability culture with a supply chain. This results in reduced disruptions, emissions and unethical behaviour. The positive results of BDA deployment can be realized by examining data related to economic, social and environmental performance of firms, which will be sufficient indicator of SSCM performance.

Backing: the warrant presented above is supported because the dimensions of BDA, such as integration, analytics, data processing, security and the economic, promote SSCM, which results in benefits, such as end-to-end visibility, cost savings and supply chain competitiveness.

Rebuttal: BDA is likely to promote SSCM in manufacturing supply chains unless the supply chain partners do not provide quality data or face some challenges in BDA implementation.

5. Conclusions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Brandenburg, M.; Gruchmann, T.; Oelze, N. Sustainable supply chain management—A conceptual framework and future research perspectives. Sustainablity 2019, 11, 7239. [Google Scholar] [CrossRef] [Green Version]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Tsai, F.M.; Bui, T.D.; Tseng, M.L.; Ali, M.H.; Lim, M.K.; Chiu, A.S. Sustainable supply chain management trends in world regions: A data-driven analysis. Resour. Conserv. Recycl. 2021, 167, 105421. [Google Scholar] [CrossRef]

- Ammar, M.; Haleem, A.; Javaid, M.; Walia, R.; Bahl, S. Improving material quality management and manufacturing organizations system through Industry 4.0 technologies. In Materials Today: Proceedings; Elsevier: Amsterdam, The Netherlands, 2021; pp. 5089–5096. [Google Scholar]

- El-Haddadeh, R.; Osmani, M.; Hindi, N.; Fadlalla, A. Value creation for realising the sustainable development goals: Fostering organisational adoption of big data analytics. J. Bus. Res. 2021, 131, 402–410. [Google Scholar] [CrossRef]

- Tseng, M.L.; Wu, K.J.; Lim, M.K.; Wong, W.P. Data-driven sustainable supply chain management performance: A hierarchical structure assessment under uncertainties. J. Clean. Prod. 2019, 227, 760–771. [Google Scholar] [CrossRef]

- Jose, C.; Jabbour, C.; Fiorini, P.D.C.; Ndubisi, N.O.; Queiroz, M.M.; Piato, É.L. Digitally-enabled sustainable supply chains in the 21st century: A review and a research agenda. Sci. Total Environ. 2020, 725, 7. [Google Scholar]

- Jha, A.K.; Agi, M.A.; Ngai, E.W. A note on big data analytics capability development in supply chain. Decis. Support Syst. 2020, 138, 113382. [Google Scholar] [CrossRef]

- Hazen, A.T.; Skipper, J.B.; Ezell, J.D.; Boone, C.A. Big data and predictive analytics for supply chain sustainability: A theory-driven research agenda. Comput. Ind. Eng. 2016, 101, 592–598. [Google Scholar] [CrossRef]

- Singh, S.K.; El-Kassar, A.N. Role of big data analytics in developing sustainable capabilities. J. Clean. Prod. 2019, 213, 1264–1273. [Google Scholar] [CrossRef]

- Wamba, S.F.; Akter, S.; Edwards, A.; Chopin, G. How ‘big data’ can make big impact: Findings from a systematic review and a longitudinal case study. Int. J. Prod. Econ. 2015, 165, 234–246. [Google Scholar] [CrossRef]

- Babiceanu, R.F.; Seker, R. Big Data and virtualization for manufacturing cyber-physical systems: A survey of the current status and future outlook. Comput. Ind. 2016, 18, 128–137. [Google Scholar] [CrossRef]

- Li, Q.; Liu, A. Big data driven supply chain management. Procedia CIRP 2019, 81, 1089–1094. [Google Scholar] [CrossRef]

- Lnenicka, M.; Komarkova, J. Big and open linked data analytics ecosystem: Theoretical background and essential elements. Gov. Inf. Q. 2019, 36, 129–144. [Google Scholar] [CrossRef]

- Seuring, S. A review of modeling approaches for sustainable supply chain management. Decis. Support Syst. 2013, 54, 1513–1520. [Google Scholar] [CrossRef]

- Srivastava, K.S. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Raut, R.D.; Mangla, S.K.; Narwane, V.S.; Dora, M.; Liu, M. Big Data Analytics as a mediator in Lean, Agile, Resilient, and Green (LARG) practices effects on sustainable supply chains. Transp. Res. Part E Logist. Transp. Rev. 2021, 145, 102170. [Google Scholar] [CrossRef]

- Gladwin, T.N.; Kennelly, J.J.; Krause, T.-S. Shifting Paradigms for Sustainable Development: Implications for Management Theory and Research. Acad. Manag. Rev. 1995, 20, 874–907. [Google Scholar] [CrossRef] [Green Version]

- Giri, C.B.; Dey, S. Game theoretic models for a closed-loop supply chain with stochastic demand and backup supplier under dual channel recycling. Decis. Mak. Appl. Manag. Eng. 2020, 3, 162–189. [Google Scholar]

- Mageto, J.; Prinsloo, G.; Luke, R. Determinants of logistics outsourcing performance among small and medium enterprises. Int. J. Logist. Syst. Manag. 2020, 35, 541–565. [Google Scholar] [CrossRef]

- Savitz, A. The Triple Bottom Line: How Today’s Best-Run Companies are Achieving Economic, Social and Environmental Success—And How You Can Too, 2nd ed.; John Wiley & Sons: San Francisco, CA, USA, 2013. [Google Scholar]

- Mafini, C.; Loury-Okoumba, W.V. Extending green supply chain management activities to manufacturing small and medium enterprises in a developing economy. S. Afr. J. Econ. Manag. Sci. 2018, 21, 1–12. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. Core issues in sustainable supply chain management-A Delphi study. Bus. Strategy Environ. 2008, 17, 455–466. [Google Scholar] [CrossRef]

- Stock, T.; Seliger, G. Opportunities of sustainable manufacturing in industry 4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar] [CrossRef] [Green Version]

- Bag, S.; Wood, L.C.; Xu, L.; Dhamija, P.; Kayikci, Y. Big data analytics as an operational excellence approach to enhance sustainable supply chain performance. Resour. Conserv. Recycl. 2020, 153, 104559. [Google Scholar] [CrossRef]

- Rusinko, C. Green manufacturing: An evaluation of environmentally sustainable manufacturing practices and their impact on competive outcomes. IEEE Trans. Eng. Manag. 2007, 54, 445–454. [Google Scholar] [CrossRef]

- Singh, A.; Trivedi, A. Sustainable green supply chain management: Trends and current practices. Compet. Rev. 2016, 26, 265–288. [Google Scholar] [CrossRef]

- Niemann, W.; Hall, G.; Oliver, K. “South African 3PL firms” approaches to sustainable supply chain management. J. Contemp. Manag. 2017, 14, 204–237. [Google Scholar]

- Singh, A.; Jain, D.; Mehta, I.; Mitra, J.; Agrawal, S. Application of big data in supply chain management. In Proceedings of the 5th International Conference of Materials Processing and Characterization (ICMPC 2016), Hyderabad, India, 12–13 March 2016; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Moktadir, M.A.; Ali, S.M.; Paul, S.K.; Shukla, N. Barriers to big data analytics in manufacturing supply chains: A case study from Bangladesh. Comput. Ind. Eng. 2019, 128, 1063–1075. [Google Scholar] [CrossRef]

- Nguyen, T.; Zhou, L.; Spiegler, V.; Ieromonachou, P.; Lin, Y. Big data analytics in supply chain management: A state-of-the-art literature review. Comput. Oper. Res. 2018, 98, 254–264. [Google Scholar] [CrossRef] [Green Version]

- Gandomi, A.; Haider, M. Beyond the hype: Big data concepts, methods, and analytics. Int. J. Inf. Manag. 2015, 35, 137–144. [Google Scholar] [CrossRef] [Green Version]

- Mani, V.; Delgado, C.; Hazen, B.T.; Patel, P. Mitigating supply chain risk via sustainability using big data analytics: Evidence from the manufacturing supply chain. Sustainability 2017, 9, 608. [Google Scholar] [CrossRef] [Green Version]

- Edelenbos, J.; Hirzalla, F.; van Zoonen, L.; Bouma, G.; Slob, A.; Woestenburg, A. Governing the complexity of smart data cities: Setting a research agenda. In Smart Technologies for Smart Governments; Springer: Berlin/Heidelberg, Germany, 2017; pp. 35–54. [Google Scholar]

- Tiwari, S.; Wee, H.M.; Daryanto, Y. Big data analytics in supply chain management between 2010 and 2016: Insights to industries. Comput. Ind. Eng. 2018, 115, 319–330. [Google Scholar] [CrossRef]

- Matheus, R.; Janssen, M. Transparency dimensions of big and open linked data. In Proceedings of the Conference on e-Business, e-Services and e-Society, Heidelberg, The Netherlands, 13–15 October 2015; Springer: Cham, Switzerland, 2015. [Google Scholar]

- Reggi, L.; Dawes, S. Open government data ecosystems: Linking transparency for innovation with transparency for participation and accountability. In Proceedings of the International Conference on Electronic Governments, Guimarães, Portugal, 5–8 September 2016; Springer: Cham, Switzerland, 2016. [Google Scholar]

- Ahmed, E.; Yaqoob, I.; Hashem, I.A.T.; Khan, I.; Ahmed, A.I.A.; Imran, M.; Vasilakos, A.V. The role of big data analytics in Internet of Things. Comput. Netw. 2017, 129, 459–471. [Google Scholar] [CrossRef]

- Ojo, D.; Estevez, E. Improving government enterprise architecture practice—Maturity factor analysis. In Proceedings of the 45th Hawaii International Conference on System Sciences, Maui, HI, USA, 4–7 January 2012. [Google Scholar]

- Hilbert, M. Big data for development: A review of promises and challenges. Dev. Policy Rev. 2016, 34, 135–174. [Google Scholar] [CrossRef] [Green Version]

- Moro, V.R.; Morea, D. Big data for the sustainability of healthcare project financing. Sustainability 2019, 11, 3748. [Google Scholar] [CrossRef] [Green Version]

- Su, Z.; Zhang, M.; Wu, W. Visualizing Sustainable Supply Chain Management: A Systematic Scientometric Review. Sustainability. 2021, 13, 4409. [Google Scholar] [CrossRef]

- Dwivedi, Y.K.; Janssen, M.; Slade, E.L.; Rana, N.P.; Weerakkody, V.; Millard, J.; Snijders, D. Driving innovation through big open linked data (BOLD): Exploring antecedents using interpretive structural modelling. Inf. Syst. Front. 2017, 19, 197–212. [Google Scholar] [CrossRef] [Green Version]

- Birkel, H.; Müller, J.M. Potentials of industry 4.0 for supply chain management within the triple bottom line of sustainability—A systematic literature review. J. Clean. Prod. 2021, 289, 125612. [Google Scholar] [CrossRef]

- Chen, M.; Shiwen, M.; Yunhao, L. Big data: A survey. Mob. Netw. Appl. 2014, 19, 171–209. [Google Scholar] [CrossRef]

- Hardy, K.; Alana, M. Opening up government data for Big Data analysis and public benefit. Comput. Law Secur. Rev. 2017, 33, 30–37. [Google Scholar] [CrossRef] [Green Version]

- Mikalef, P.; de Wetering, R.; Krogstiea, J. Building dynamic capabilities by leveraging big data analytics: The role of organizational inertia. Inf. Manag. 2020. [Google Scholar] [CrossRef]

- Olson, D.L. A review of supply chain data mining publications. J. Supply Chain Manag. Sci. 2020, 1, 15–26. [Google Scholar]

- Günther, W.A.; Mehrizi, M.H.R.; Huysman, M.; Feldberg, F. Debating big data: A literature review on realizing value from big data. J. Strateg. Inf. Syst. 2017, 26, 191–209. [Google Scholar] [CrossRef]

- Jetzek, T.A.M.; Bjørn-Andersen, N. Generating sustainable value from open data in a sharing society. In Proceedings of the International Working Conference on Transfer and Diffusion of IT, Bangalore, India, 27–29 June 2013; Springer: Berlin/Heidelberg, Germany, 2014; pp. 62–82. [Google Scholar]

- Zuiderwijk, A.; Janssen, M.; Choenni, S.; Meijer, R.; Alibaks, R.S. Socio-technical impediments of open data. Electron. J. E-Gov. 2012, 10, 156–172. [Google Scholar]

- Chalmeta, R.; Santos-deLeón, N.J. Sustainable supply chain in the era of industry 4.0 and big data: A systematic analysis of literature and research. Sustainability 2020, 12, 4108. [Google Scholar] [CrossRef]

- Rozados, I.V.; Tjahjono, B. Big data analytics in supply chain management: Trends and related research. In Proceedings of the 6th International Conference on Operations and Supply Chain Management, Bali, Indonesia, 10–12 December 2014. [Google Scholar]

- Chase, C. Next Generation Demand Management: People, Process, Analytics, and Technology; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Ramanathan, U.; Subramanian, N.; Parrott, G. Role of social media in retail network operations and marketing to enhance customer satisfaction. Int. J. Oper. Prod. Manag. 2017, 37, 105–123. [Google Scholar] [CrossRef] [Green Version]

- Alharthi, A.; Krotov, V.; Bowman, M. Addressing barriers to big data. Bus. Horiz. 2017, 60, 285–292. [Google Scholar] [CrossRef]

- Trent, J.D. Toulmin’s model of an argument: An examination and extension. Q. J. Speech 1968, 54, 252–259. [Google Scholar] [CrossRef]

- Hitchcock, D.; Verheij, B. Arguing on the Toulmin Model; Springer: Berlin/Heidelberg, Germany, 2006; Volume 10. [Google Scholar]

- Karbach, J. Using Toulmin’s model of argumentation. J. Teach. Writ. 1987, 6, 81–91. [Google Scholar]

- Brockriede, W.; Ehninger, D. Toulmin on argument: An interpretation and application. Q. J. Speech 1960, 46, 44–53. [Google Scholar] [CrossRef]

- Govindan, K.; Kaliyan, M.; Kannan, D.; Haq, A.N. Barriers analysis for green supply chain management implementation in Indian industries using analytic hierarchy process. Int. J. Prod. Econ. 2014, 147, 555–568. [Google Scholar] [CrossRef]

- Hung, J.L.; He, W.; Shen, J. Big data analytics for supply chain relationship in banking. Ind. Mark. Manag. 2020, 86, 144–153. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Manoj, T.K.; Dubey, R.; Wamba, F.S. Big data and predictive analytics applications in supply chain management. Comput. Ind. Eng. 2016, 101, 525–527. [Google Scholar] [CrossRef]

- Huang, T.; Lan, L.; Fang, X.; An, P.; Min, J.; Wang, F. Promises and challenges of big data computing in health sciences. Big Data Res. 2015, 2, 2–11. [Google Scholar] [CrossRef]

- Choi, Y.; Lee, H.; Irani, Z. Big data-driven fuzzy cognitive map for prioritising IT service procurement in the public sector. Ann. Oper. Res. 2018, 270, 75–104. [Google Scholar] [CrossRef] [Green Version]

- Krumeich, J.; Werth, D.; Loos, P. Prescriptive control of business processes. Bus. Inf. Syst. Eng. 2016, 58, 261–280. [Google Scholar] [CrossRef]

- Lee, K.H. A GA-based optimisation model for big data analytics supporting anticipatory shipping in Retail 4.0. Int. J. Prod. Res. 2017, 55, 593–605. [Google Scholar] [CrossRef]

- Guo, Y. Implementing relationship banking strategies and techniques and improving customer value. Financ. Market. 2017, 2, 14. [Google Scholar]

- Fawcett, E.S.; Waller, M.A. Supply chain game changers—mega, nano, and virtual trends—and forces that impede supply chain design (ie, building a winning team). J. Bus. Logist. 2014, 35, 157–164. [Google Scholar] [CrossRef]

- Tan, K.H.; Zhan, Y.; Ji, G.Y.F.; Chang, C. Harvesting big data to enhance supply chain innovation capabilities: An analytic infrastructure based on deduction graph. Int. J. Prod. Econ. 2015, 165, 223–233. [Google Scholar] [CrossRef]

- Arunachalam, D.; Kumar, N.; Kawalek, J.P. Understanding big data analytics capabilities in supply chain management: Unravelling the issues, challenges and implications for practice. Transp. Res. Part E Logist. Transp. Rev. 2018, 114, 416–436. [Google Scholar] [CrossRef]

- Chatfield, A.T.; Reddick, G.C. Customer agility and responsiveness through big data analytics for public value creation: A case study of Houston 311 on-demand services. Gov. Inf. Q. 2018, 35, 336–347. [Google Scholar] [CrossRef]

| Author(s) | Key Concepts Addressed | Industry | Methodology | BDA/SSCM Dimensions Gleaned | Key Findings | Gap |

|---|---|---|---|---|---|---|

| [25] | Application of BDA to improve operational excellence and sustainable supply chain performance | Mining | Quantitative | Security | BDA management capability influences SSCM | Did not examine the dimensions of BDA or its effect on SSCM |

| [14] | Elements of big and open linked data analytics | Public sector databases | Qualitative; literature review | Economics, data privacy, technical, transparency, social and engagement | Essential elements of big and open data analytics in public databases were identified | Did not identify essential elements of BDA in private enterprises and supply chains, SSCM was not addressed |

| [24] | Applying industry 4.0 to achieve SSCM | Manufacturing | Qualitative; literature review | Data processing, integration, economic, social and environmental | Horizontal and vertical integration coupled with smart factory and end-to-end engineering can result in SSCM | The dimensions of BDA and effect on SSCM was not addressed |

| [38] | BDA and Internet of things | Not mentioned | Qualitative; literature review | Data processing, analytics, security, integration and reporting | Identified literature based on important parameters of IoT and BDA | Dimensions of BDA and SSCM were not identified |

| [56] | Addressing the barriers to BDA | 3PL, local government, car manufacturer and entertainment | Qualitative; literature review | Security breaches, culture, economic | Infrastructure readiness, privacy issues and a vision on big data can overcome the barriers | Link between BDA and SSCM was not addressed |

| [29] | Application of big data in SCM | Manufacturing | Case study/Delphi method | Integration | Big data analytics can reduce delivery time, inventory cost, operational cost and improve customer service through increased visibility | Dimensions of BDA not identified |

| [61] | BDA application in logistics and supply chain | Logistics | Qualitative; literature review | Analytics, integration, data processing | BDA has a wide application across logistics network and research is growing this area | Link between BDA and SSCM not explored |

| [62] | BDA application in supply chain relationship in banking | Banking | Case study | Security, integration | BDA can result in customer segmentation, product affinity | BDA dimensions were not examined |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mageto, J. Big Data Analytics in Sustainable Supply Chain Management: A Focus on Manufacturing Supply Chains. Sustainability 2021, 13, 7101. https://doi.org/10.3390/su13137101

Mageto J. Big Data Analytics in Sustainable Supply Chain Management: A Focus on Manufacturing Supply Chains. Sustainability. 2021; 13(13):7101. https://doi.org/10.3390/su13137101

Chicago/Turabian StyleMageto, Joash. 2021. "Big Data Analytics in Sustainable Supply Chain Management: A Focus on Manufacturing Supply Chains" Sustainability 13, no. 13: 7101. https://doi.org/10.3390/su13137101

APA StyleMageto, J. (2021). Big Data Analytics in Sustainable Supply Chain Management: A Focus on Manufacturing Supply Chains. Sustainability, 13(13), 7101. https://doi.org/10.3390/su13137101