Heat Transfer Measurement within Green Roof with Incinerated Municipal Solid Waste Aggregates

Abstract

:1. Introduction

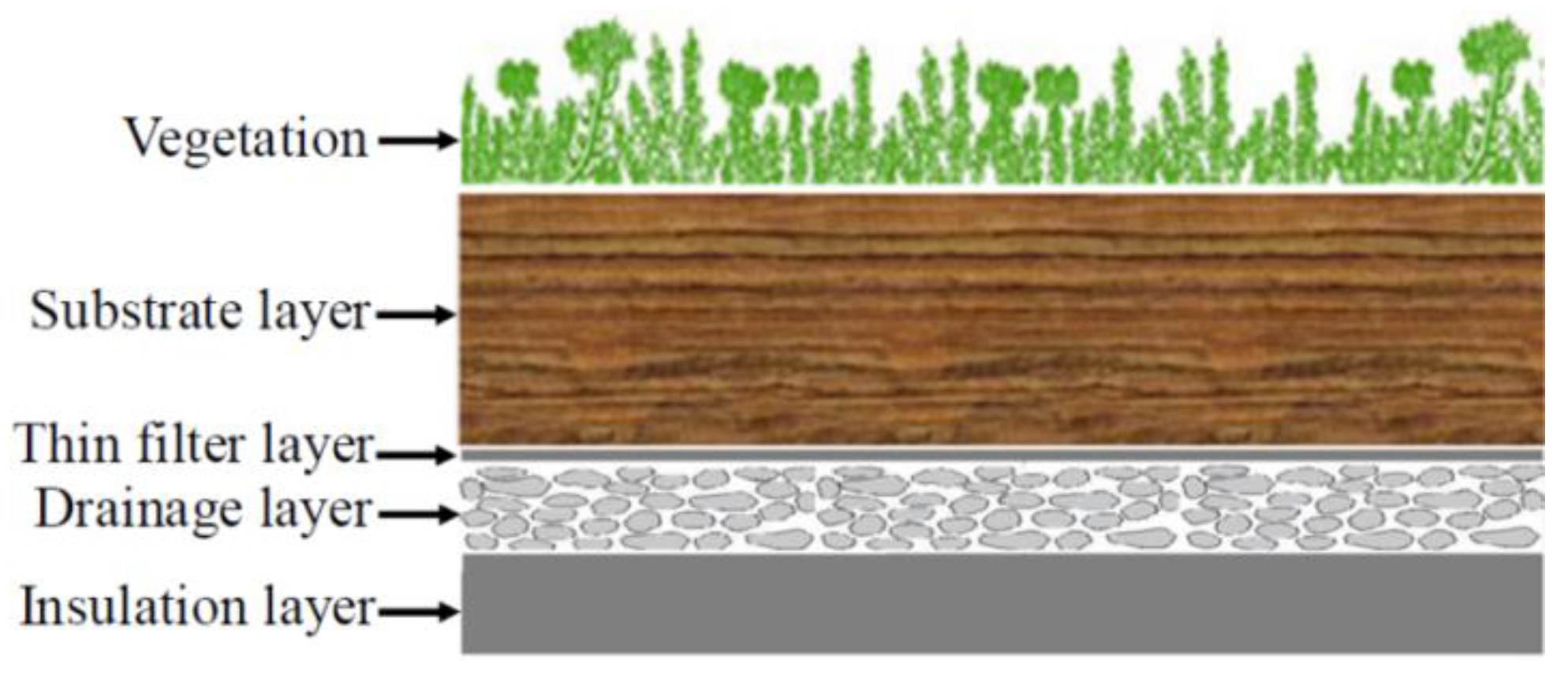

2. Experimental Program

2.1. Methodology

2.2. Materials Properties

3. Results and Discussion

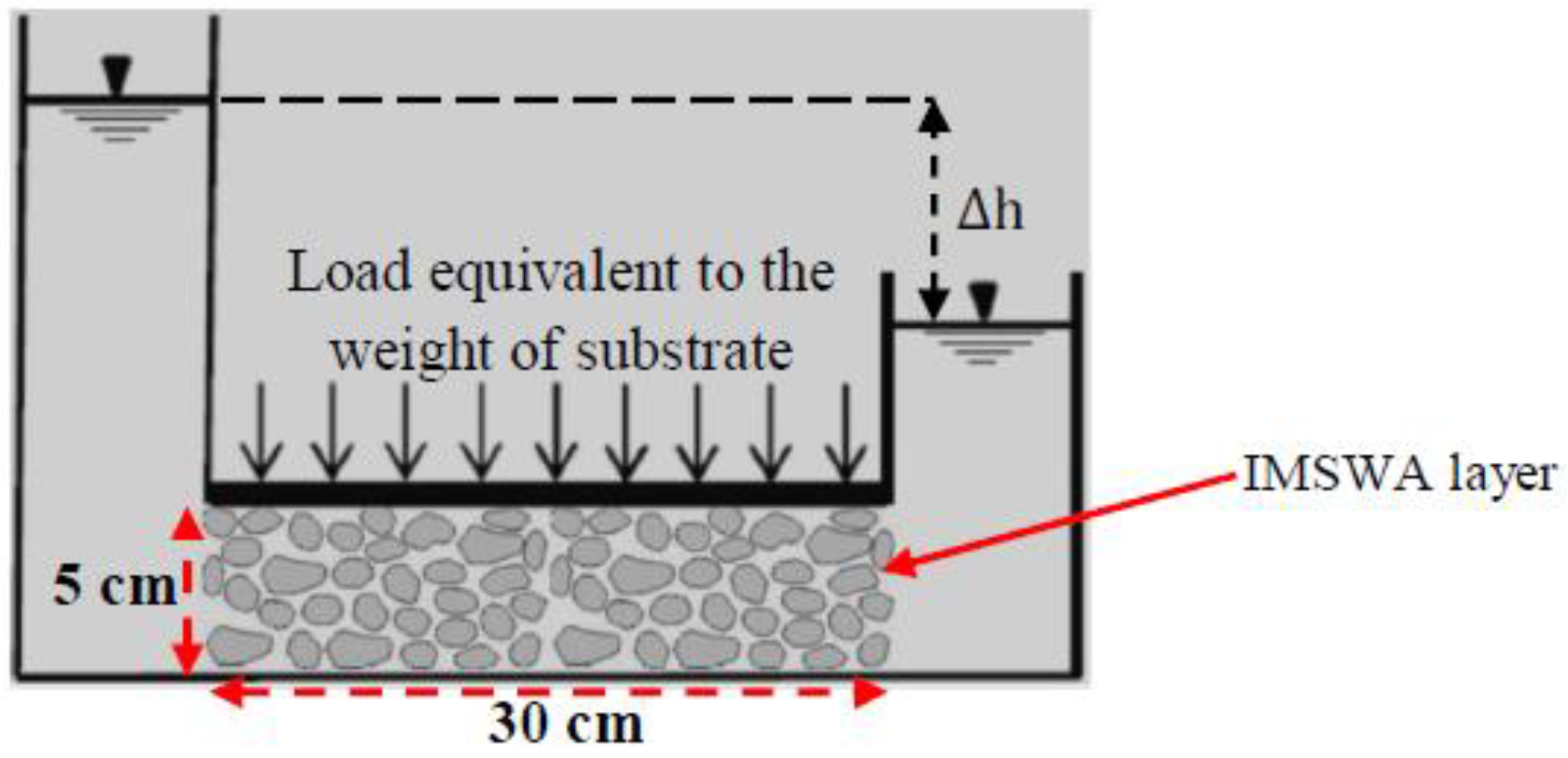

3.1. Water Transmissivity (IMSWA Layer)

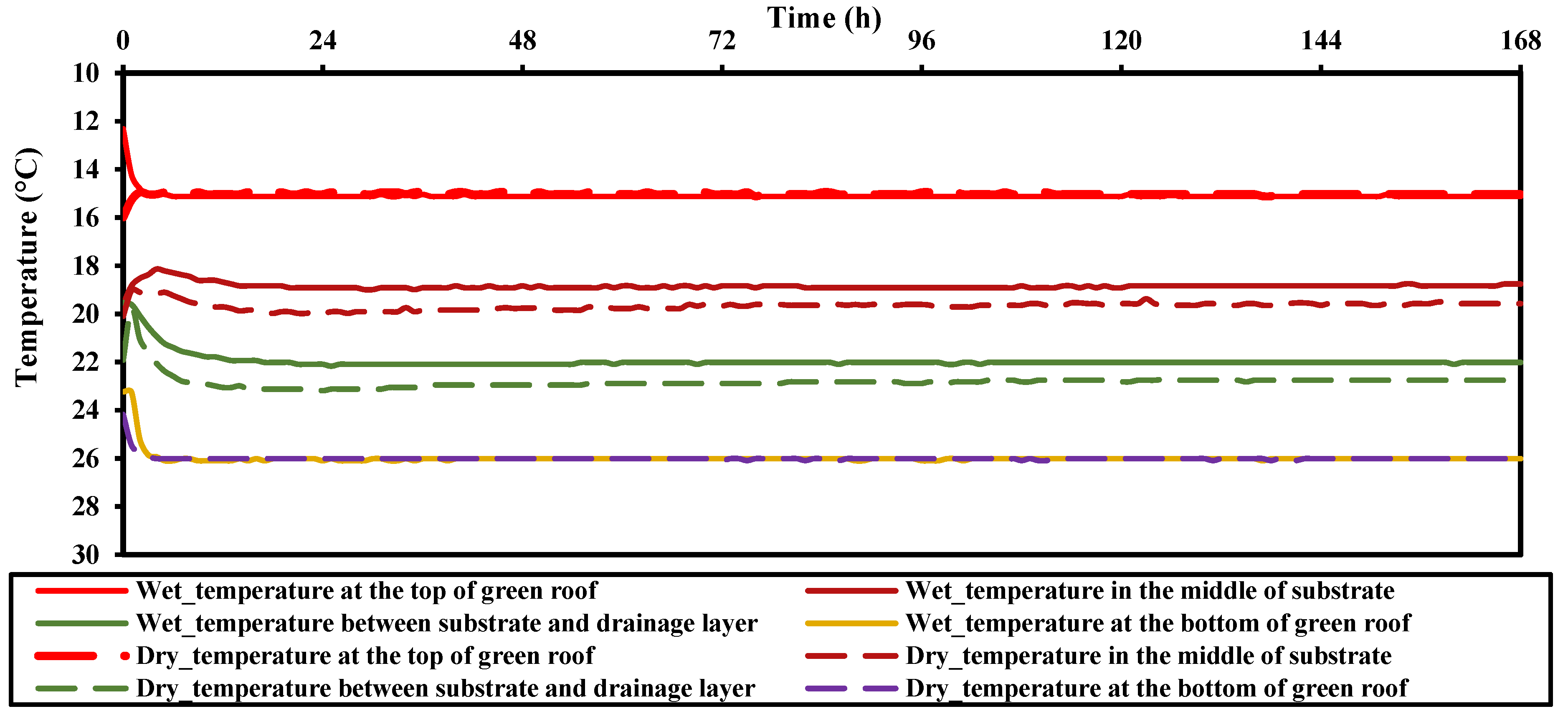

3.2. Temperature Distribution

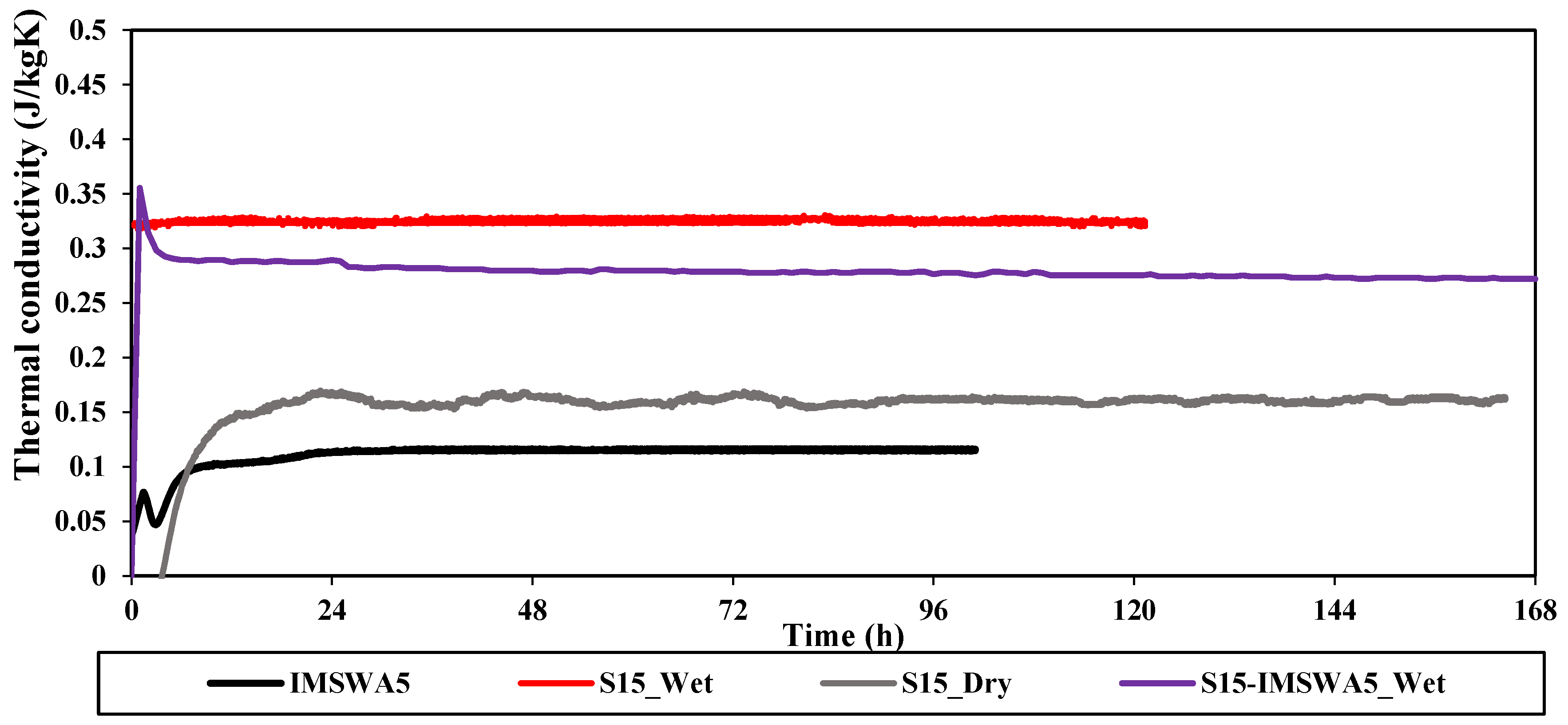

3.3. Thermal Resistance

3.4. Green Roof Layers’ Heat Resistance

4. Conclusions

- This study contributes to the body of knowledge related to green roof and the results demonstrate to what extent the use of substrate in wet and dry conditions affect the thermal resistance of the system, once the green roof layers contain coarse recycled materials.

- Transmissivity through 5-cm IMSWA drainage layer is very high. Therefore, IMSWAs with a size of 7 mm had adequate capacity to horizontally pass a high amount of water for a green roof system.

- Temperature across the depth of green roof specimen with dry substrate (S15-IMSWA5_Dry) was about 4% higher than that with unsaturated substrate (S15-IMSWA5_Wet). The presence of moisture caused the substrate layer to be affected more by the outside cold temperature, resulting in an increase in energy consumption.

- According to the heat transfer measurement during the convergence duration (longer than 72 h), a difference of less than 1% between the Rc-values of specimens at the end and 24 h before the end of the data set was observed. Moreover, 2.4% difference was noticed between the Rc-values of specimens at the first and the last 67% of the convergence duration. Therefore, the aforementioned differences were less than 5%, meeting the ISO-conversion method’s requirements.

- The Rc-value of the dry substrate including air-spaces was about twice that of the unsaturated substrate including water content. Therefore, the presence of air-spaces in the dry substrate provided more heat resistance than in the case of water in the unsaturated substrate.

- As per the results, the Rc-value of the dry substrate layer was about twice that of IMSWA5 as the drainage layer. Moreover, no significant difference was observed between the Rc-value of the unsaturated substrate layer and IMSWA5, while the thickness of the former was three times that of the latter. Therefore, the presence of air-spaces among IMSWAs played a key role in promoting the thermal resistance of drainage layer.

- The Rc-value of green roof system with dry substrate (1.26 m2 K/W) was 1.7 times higher than that of the green roof system with unsaturated substrate (0.735 m2 K/W), while the reverse was obtained for the thermal conductivity. Therefore, the air-spaces among dry soil particles outperformed the water content in media mixtures to promote the heat resistance of rooftops.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Manso, M.; Teotónio, I.; Silva, C.M.; Cruz, C.O. Green Roof and Green Wall Benefits and Costs: A Review of the Quantitative Evidence. Renew. Sustain. Energy Rev. 2021, 135, 110111. [Google Scholar] [CrossRef]

- Nations Goal 11: Make Cities Inclusive, Safe, Resilient. Available online: https://scholar.google.com/scholar_lookup?title=Goal%2011%3A%20make%20cities%20inclusive%2C%20safe%2C%20resilient%20and%20sustainable&publication_year=2018&author=U.%20Nations (accessed on 24 March 2021).

- Nematzadeh, M.; Shahmansouri, A.A.; Fakoor, M. Post-Fire Compressive Strength of Recycled PET Aggregate Concrete Reinforced with Steel Fibers: Optimization and Prediction via RSM and GEP. Constr. Build. Mater. 2020, 252, 119057. [Google Scholar] [CrossRef]

- Shahmansouri, A.A.; Akbarzadeh Bengar, H.; AzariJafari, H. Life Cycle Assessment of Eco-Friendly Concrete Mixtures Incorporating Natural Zeolite in Sulfate-Aggressive Environment. Constr. Build. Mater. 2021, 268, 121136. [Google Scholar] [CrossRef]

- AzariJafari, H.; Gregory, J.; Kirchain, R. Potential Contribution of Deflection-Induced Fuel Consumption to U.S. Greenhouse Gas Emissions. Transp. Res. Rec. 2020, 2674, 931–937. [Google Scholar] [CrossRef]

- Carter, T.; Jackson, C.R. Vegetated Roofs for Stormwater Management at Multiple Spatial Scales. Landsc. Urban Plan. 2007, 80, 84–94. [Google Scholar] [CrossRef]

- Ebadati, M.; Ehyaei, M.A. Reduction of Energy Consumption in Residential Buildings with Green Roofs in Three Different Climates of Iran. Adv. Build. Energy Res. 2020, 14, 66–93. [Google Scholar] [CrossRef]

- Kazemi, M.; Courard, L. Simulation of Humidity and Temperature Distribution in Green Roof with Pozzolana as Drainage Layer: Influence of Outdoor Seasonal Weather Conditions and Internal Ceiling Temperature. Sci. Technol. Built Environ. 2021, 27, 509–523. [Google Scholar] [CrossRef]

- Almutairi, K.; Esfahani, E.M.; Mostafaeipour, A.; Issakhov, A.; Kaewpraek, C.; Techato, K. A Novel Policy to Optimize Energy Consumption for Dairy Product Warehouses: A Case Study. Sustainability 2021, 13, 2445. [Google Scholar] [CrossRef]

- Kaewpraek, C.; Ali, L.; Rahman, M.A.; Shakeri, M.; Chowdhury, M.S.; Jamal, M.S.; Mia, M.S.; Pasupuleti, J.; Dong, L.K.; Techato, K. The Effect of Plants on the Energy Output of Green Roof Photovoltaic Systems in Tropical Climates. Sustainability 2021, 13, 4505. [Google Scholar] [CrossRef]

- Nawaz, R.; McDonald, A.; Postoyko, S. Hydrological Performance of a Full-Scale Extensive Green Roof Located in a Temperate Climate. Ecol. Eng. 2015, 82, 66–80. [Google Scholar] [CrossRef]

- Cascone, S.; Catania, F.; Gagliano, A.; Sciuto, G. A Comprehensive Study on Green Roof Performance for Retrofitting Existing Buildings. Build. Environ. 2018, 136, 227–239. [Google Scholar] [CrossRef]

- Oberndorfer, E.; Lundholm, J.; Bass, B.; Coffman, R.R.; Doshi, H.; Dunnett, N.; Gaffin, S.; Köhler, M.; Liu, K.K.; Rowe, B. Green Roofs as Urban Ecosystems: Ecological Structures, Functions, and Services. BioScience 2007, 57, 823–833. [Google Scholar] [CrossRef]

- Kazemi, M.; Courard, L. Modelling Thermal and Humidity Transfers within Green Roof Systems: Effect of Rubber Crumbs and Volcanic Gravel. Adv. Build. Energy Res. 2020, 1–26. [Google Scholar] [CrossRef]

- Tabares-Velasco, P.C.; Zhao, M.; Peterson, N.; Srebric, J.; Berghage, R. Validation of Predictive Heat and Mass Transfer Green Roof Model with Extensive Green Roof Field Data. Ecol. Eng. 2012, 47, 165–173. [Google Scholar] [CrossRef]

- Bollman, M.A.; DeSantis, G.E.; Waschmann, R.S.; Mayer, P.M. Effects of Shading and Composition on Green Roof Media Temperature and Moisture. J. Environ. Manag. 2021, 281, 111882. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.J.; Lin, H.T.; Chou, C.Y. Physical Properties and Thermal Performance of Calcined Sludge as Planting Substrate in Green Roofs. Appl. Mech. Mater. 2011, 71–78, 3–11. [Google Scholar] [CrossRef]

- Sun, T.; Bou-Zeid, E.; Wang, Z.-H.; Zerba, E.; Ni, G.-H. Hydrometeorological Determinants of Green Roof Performance via a Vertically-Resolved Model for Heat and Water Transport. Build. Environ. 2013, 60, 211–224. [Google Scholar] [CrossRef]

- Kotsiris, G.; Androutsopoulos, A.; Polychroni, E.; Nektarios, P.A. Dynamic U-Value Estimation and Energy Simulation for Green Roofs. Energy Build. 2012, 45, 240–249. [Google Scholar] [CrossRef]

- Côté, J.; Konrad, J.-M. A Generalized Thermal Conductivity Model for Soils and Construction Materials. Can. Geotech. J. 2011. [Google Scholar] [CrossRef]

- Farouki, O.T. Thermal Properties of Soils; Cold Regions Research and Engineering Lab.: Hanover, NH, USA, 1981. [Google Scholar]

- Johansen, O. Thermal Conductivity of Soils; Cold Regions Research and Engineering Lab.: Hanover, NH, USA, 1977. [Google Scholar]

- Lu, S.; Ren, T.; Gong, Y.; Horton, R. An Improved Model for Predicting Soil Thermal Conductivity from Water Content at Room Temperature. Soil Sci. Soc. Am. J. 2007, 71, 8–14. [Google Scholar] [CrossRef]

- Berretta, C.; Poë, S.; Stovin, V. Moisture Content Behaviour in Extensive Green Roofs during Dry Periods: The Influence of Vegetation and Substrate Characteristics. J. Hydrol. 2014, 511, 374–386. [Google Scholar] [CrossRef]

- He, Y.; Yu, H.; Dong, N.; Ye, H. Thermal and Energy Performance Assessment of Extensive Green Roof in Summer: A Case Study of a Lightweight Building in Shanghai. Energy Build. 2016, 127, 762–773. [Google Scholar] [CrossRef]

- Pianella, A.; Clarke, R.E.; Williams, N.S.G.; Chen, Z.; Aye, L. Steady-State and Transient Thermal Measurements of Green Roof Substrates. Energy Build. 2016, 131, 123–131. [Google Scholar] [CrossRef]

- Fabiani, C.; Coma, J.; Pisello, A.L.; Perez, G.; Cotana, F.; Cabeza, L.F. Thermo-Acoustic Performance of Green Roof Substrates in Dynamic Hygrothermal Conditions. Energy Build. 2018, 178, 140–153. [Google Scholar] [CrossRef]

- Almeida, R.; Simões, N.; Tadeu, A.; Palha, P.; Almeida, J. Thermal Behaviour of a Green Roof Containing Insulation Cork Board. An Experimental Characterization Using a Bioclimatic Chamber. Build. Environ. 2019, 160, 106179. [Google Scholar] [CrossRef]

- He, Y.; Yu, H.; Ozaki, A.; Dong, N. Thermal and Energy Performance of Green Roof and Cool Roof: A Comparison Study in Shanghai Area. J. Clean. Prod. 2020, 267, 122205. [Google Scholar] [CrossRef]

- Wanielista, M.; Kelly, M.; Hardin, M. A Comparative Analysis of Greenroof Designs Including Depth of Media, Drainage Layer Materials, and Pollution Control Media; Florida Department of Environmental Protection: Tallahassee, FL, USA, 2008. [Google Scholar]

- Palla, A.; Gnecco, I.; Lanza, L.G. Unsaturated 2D Modelling of Subsurface Water Flow in the Coarse-Grained Porous Matrix of a Green Roof. J. Hydrol. 2009, 379, 193–204. [Google Scholar] [CrossRef]

- Kazemi, M.; Madandoust, R.; de Brito, J. Compressive Strength Assessment of Recycled Aggregate Concrete Using Schmidt Rebound Hammer and Core Testing. Constr. Build. Mater. 2019, 224, 630–638. [Google Scholar] [CrossRef]

- Madandoust, R.; Kazemi, M.; Talebi, P.K.; de Brito, J. Effect of the Curing Type on the Mechanical Properties of Lightweight Concrete with Polypropylene and Steel Fibres. Constr. Build. Mater. 2019, 223, 1038–1052. [Google Scholar] [CrossRef]

- Bengar, H.A.; Shahmansouri, A.A.; Sabet, N.A.Z.; Kabirifar, K.; Tam, V.W. Impact of Elevated Temperatures on the Structural Performance of Recycled Rubber Concrete: Experimental and Mathematical Modeling. Constr. Build. Mater. 2020, 255, 119374. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Dashti, J.; Ganjavi, B. Optimizing Compressive Behavior of Concrete Containing Fine Recycled Refractory Brick Aggregate Together with Calcium Aluminate Cement and Polyvinyl Alcohol Fibers Exposed to Acidic Environment. Constr. Build. Mater. 2018, 164, 837–849. [Google Scholar] [CrossRef]

- Baradaran-Nasiri, A.; Nematzadeh, M. The Effect of Elevated Temperatures on the Mechanical Properties of Concrete with Fine Recycled Refractory Brick Aggregate and Aluminate Cement. Constr. Build. Mater. 2017, 147, 865–875. [Google Scholar] [CrossRef]

- Mehrabi, P.; Shariati, M.; Kabirifar, K.; Jarrah, M.; Rasekh, H.; Trung, N.T.; Shariati, A.; Jahandari, S. Effect of Pumice Powder and Nano-Clay on the Strength and Permeability of Fiber-Reinforced Pervious Concrete Incorporating Recycled Concrete Aggregate. Constr. Build. Mater. 2021, 287, 122652. [Google Scholar] [CrossRef]

- Yousefi Moghadam, S.; Ranjbar, M.M.; Madandoust, R.; Kazemi, M. Analytical Study on the Behavior of Corrosion-Damaged Reinforced Concrete Beams Strengthen with FRP. Rev. Romana De Mater. 2017, 47, 514–521. [Google Scholar]

- Coma, J.; Pérez, G.; Castell, A.; Solé, C.; Cabeza, L.F. Green Roofs as Passive System for Energy Savings in Buildings during the Cooling Period: Use of Rubber Crumbs as Drainage Layer. Energy Effic. 2014, 7, 841–849. [Google Scholar] [CrossRef]

- Coma, J.; Pérez, G.; Solé, C.; Castell, A.; Cabeza, L.F. Thermal Assessment of Extensive Green Roofs as Passive Tool for Energy Savings in Buildings. Renew. Energy 2016, 85, 1106–1115. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Z.; Courard, L.; Groslambert, S.; Jehin, T.; Léonard, A.; Jianzhuang, X. Use of Recycled Concrete Aggregates from Precast Block for the Production of New Building Blocks: An Industrial Scale Study. Resour. Conserv. Recycl. 2020, 157, 104786. [Google Scholar] [CrossRef]

- Kazemi, M.; Hajforoush, M.; Talebi, P.K.; Daneshfar, M.; Shokrgozar, A.; Jahandari, S.; Saberian, M.; Li, J. In-Situ Strength Estimation of Polypropylene Fibre Reinforced Recycled Aggregate Concrete Using Schmidt Rebound Hammer and Point Load Test. J. Sustain. Cem.-Based Mater. 2020, 9, 289–306. [Google Scholar] [CrossRef]

- Saberian, M.; Li, J.; Perera, S.T.; Anupiya, M.; Ren, G.; Roychand, R.; Tokhi, H. An Experimental Study on the Shear Behaviour of Recycled Concrete Aggregate Incorporating Recycled Tyre Waste. Constr. Build. Mater. 2020, 264, 120266. [Google Scholar] [CrossRef]

- ISO 9869-1. Thermal Insulation, Building Elements, In-Situ Measurement of Thermal Resistance and Thermal Transmittance-Part 1: Heat Flow Meter Method; BSI: London, UK, 2014. [Google Scholar]

- Coma, J.; de Gracia, A.; Chafer, M.; Perez, G.; Cabeza, L.F. Thermal Characterization of Different Substrates under Dried Conditions for Extensive Green Roofs. Energy Build. 2017, 144, 175–180. [Google Scholar] [CrossRef] [Green Version]

- Ladani, H.J.; Park, J.-R.; Jang, Y.-S.; Shin, H.-S. Hydrological Performance Assessment for Green Roof with Various Substrate Depths and Compositions. KSCE J. Civ. Eng. 2019, 23, 1860–1871. [Google Scholar] [CrossRef]

- Zhao, M.; Tabares-Velasco, P.C.; Srebric, J.; Komarneni, S.; Berghage, R. Effects of Plant and Substrate Selection on Thermal Performance of Green Roofs during the Summer. Build. Environ. 2014, 78, 199–211. [Google Scholar] [CrossRef]

- ASTM D4611-16. Standard Test Method for Specific Heat of Rock and Soil, ASTM International: West Conshohocken, PA, USA, 2018.

- ISO 16586 Soil Quality—Determination of Soil Water Content as a Volume Fraction on the Basis of Known Dry Bulk Density Gravimetric Method. Available online: https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/03/23/32317.html (accessed on 27 October 2020).

- Künzel, H.M. Simultaneous Heat and Moisture Transport in Building Components. One-And Two-Dimensional Calculation Using Simple Parameters; IRB-Verlag: Stuttgart, Germany, 1995; p. 65. [Google Scholar]

- Awulachew, S.B.; Lemperiere, P.; Tulu, T. Training Material on Agricultural Water Management; International Water Management Institute: Addis Ababa, Ethiopia; International Livestock Research Institute: Nairobi, Kenya; Adama University: Adama, Ethiopia, 2009; ISBN 978-92-9146-235-3. [Google Scholar]

- Brouwer, C.; Goffeau, A.; Heibloem, M. Irrigation Water Management: Training Manual No. 1-Introduction to Irrigation; Food and Agriculture Organization of the United Nations: Rome, Italy, 1985; pp. 102–103. [Google Scholar]

- EN 1925 Natural Stone Test Methods. Determination of Water Absorption Coefficient by Capillarity. Available online: https://shop.bsigroup.com/ProductDetail?pid=000000000019973432 (accessed on 10 December 2020).

- Vesuviano, G.; Stovin, V. A Generic Hydrological Model for a Green Roof Drainage Layer. Water Sci. Technol. 2013, 68, 769–775. [Google Scholar] [CrossRef] [Green Version]

- EN 12620 Aggregates for Concrete. European Committee for Standardization. Available online: https://standards.iteh.ai/catalog/standards/cen/aef412e6-36ce-49d3-afaa-5200d721ff84/en-12620-2013 (accessed on 19 January 2021).

- ASTM D4716. Standard Test Method for Determining the (In-Plane) Flow Rate per Unit Width and Hydraulic Transmissivity of a Geosynthetic Using a Constant Head; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Dahanayake, K.C.; Chow, C.L. Comparing Reduction of Building Cooling Load through Green Roofs and Green Walls by EnergyPlus Simulations. In Building Simulation; Springer: Berlin/Heidelberg, Germany, 2018; Volume 11, pp. 421–434. [Google Scholar]

- Poë, S.; Stovin, V.; Berretta, C. Parameters Influencing the Regeneration of a Green Roof’s Retention Capacity via Evapotranspiration. J. Hydrol. 2015, 523, 356–367. [Google Scholar] [CrossRef]

- Desogus, G.; Mura, S.; Ricciu, R. Comparing Different Approaches to in Situ Measurement of Building Components Thermal Resistance. Energy Build. 2011, 43, 2613–2620. [Google Scholar] [CrossRef]

- Rodler, A.; Guernouti, S.; Musy, M. Bayesian Inference Method for in Situ Thermal Conductivity and Heat Capacity Identification: Comparison to ISO Standard. Constr. Build. Mater. 2019, 196, 574–593. [Google Scholar] [CrossRef]

- Sailor, D.J.; Hagos, M. An Updated and Expanded Set of Thermal Property Data for Green Roof Growing Media. Energy Build. 2011, 43, 2298–2303. [Google Scholar] [CrossRef]

- Cosenza, P.; Guérin, R.; Tabbagh, A. Relationship between Thermal Conductivity and Water Content of Soils Using Numerical Modelling. Eur. J. Soil Sci. 2003, 54, 581–588. [Google Scholar] [CrossRef]

- Sepaskhah, A.R.; Boersma, L. Thermal Conductivity of Soils as a Function of Temperature and Water Content. Soil Sci. Soc. Am. J. 1979, 43, 439–444. [Google Scholar] [CrossRef]

- Narsilio, G.A.; Kress, J.; Yun, T.S. Characterisation of Conduction Phenomena in Soils at the Particle-Scale: Finite Element Analyses in Conjunction with Synthetic 3D Imaging. Comput. Geotech. 2010, 37, 828–836. [Google Scholar] [CrossRef]

- Woodside, W.; Messmer, J.H. Thermal Conductivity of Porous Media. I. Unconsolidated Sands. J. Appl. Phys. 1961, 32, 1688–1699. [Google Scholar] [CrossRef]

- Yun, T.S.; Santamarina, J.C. Fundamental Study of Thermal Conduction in Dry Soils. Granul. Matter 2008, 10, 197–207. [Google Scholar] [CrossRef]

- Toghroli, A.; Mehrabi, P.; Shariati, M.; Trung, N.T.; Jahandari, S.; Rasekh, H. Evaluating the Use of Recycled Concrete Aggregate and Pozzolanic Additives in Fiber-Reinforced Pervious Concrete with Industrial and Recycled Fibers. Constr. Build. Mater. 2020, 252, 118997. [Google Scholar] [CrossRef]

- La Roche, P.; Berardi, U. Comfort and Energy Savings with Active Green Roofs. Energy Build. 2014, 82, 492–504. [Google Scholar] [CrossRef]

| No. | Specimens ID | Thickness (cm) | |

|---|---|---|---|

| Drainage Layer | Substrate | ||

| 1 | S a 15-IMSWA b 5_Dry | 5 | 15 |

| 2 | S15-IMSWA5_Wet | 5 | 15 |

| 3 | IMSWA | 5 | - |

| 4 | S15_Dry | - | 15 |

| 5 | S15_Wet | - | 15 |

| Materials | Substrate with Coarse Recycled Materials | IMSWA |

|---|---|---|

| Porosity | 0.4863 | 0.4726 |

| Specific heat capacity, Dry (J/kg.K) | 810 | 750 |

| Thermal conductivity, Dry, λ (W/m⋅K) | 0.17 | 0.115 |

| Water content (kg/m3) | 87.35 | 8.19 |

| Free water content (kg/m3) | 285.71 | 101.2 |

| Water absorption coefficient, A1 (kg/m2 s0.5) | 0.22 | 0.067 |

| Specimens ID | IMSWA5 | S15_Wet | S15_Dry | S15-IMSWA5_Wet | S15-IMSWA5_Dry | |

|---|---|---|---|---|---|---|

| Test duration (h) | 101 | 122 | 165 | 168 | 168 | |

| Convergence duration (h) | 76 | 73 | 75 | 120 | 120 | |

| Thermal conductivity (W/m⋅K) | 0.115 | 0.32 | 0.16 | 0.27 | 0.16 | |

| Rc-value (m2 K/W) | 24 h before the end of data set | 0.432 | 0.463 | 0.94 | 0.732 | 1.25 |

| End of data set | 0.43 | 0.462 | 0.93 | 0.735 | 1.26 | |

| The first 67% of data during the convergence period | 0.43 | 0.461 | 0.93 | 0.728 | 1.26 | |

| The last 67% of data during the convergence period | 0.43 | 0.462 | 0.94 | 0.726 | 1.25 | |

| Average value during the convergence period | 0.43 | 0.46 | 0.94 | 0.735 | 1.26 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kazemi, M.; Courard, L.; Hubert, J. Heat Transfer Measurement within Green Roof with Incinerated Municipal Solid Waste Aggregates. Sustainability 2021, 13, 7115. https://doi.org/10.3390/su13137115

Kazemi M, Courard L, Hubert J. Heat Transfer Measurement within Green Roof with Incinerated Municipal Solid Waste Aggregates. Sustainability. 2021; 13(13):7115. https://doi.org/10.3390/su13137115

Chicago/Turabian StyleKazemi, Mostafa, Luc Courard, and Julien Hubert. 2021. "Heat Transfer Measurement within Green Roof with Incinerated Municipal Solid Waste Aggregates" Sustainability 13, no. 13: 7115. https://doi.org/10.3390/su13137115

APA StyleKazemi, M., Courard, L., & Hubert, J. (2021). Heat Transfer Measurement within Green Roof with Incinerated Municipal Solid Waste Aggregates. Sustainability, 13(13), 7115. https://doi.org/10.3390/su13137115