Design, Materials, and Extrusion-Based Additive Manufacturing in Circular Economy Contexts: From Waste to New Products

Abstract

:1. Introduction

- RQ 1.1: “What are the similarities and differences between the two contexts?”

- RQ 1.2: “What are the emerging trends related to this research intersection?”

2. Materials and Methods

- Analysis of the repositories for the academic context.

- Analysis of blogs and sites of design projects for the practice-based context.

- Analysis and comparison of the results from the two contexts.

3. Results and Discussion

3.1. General Analysis

- Their application field;

- The R-imperatives strategies;

- The extrusion-based AM technology and scale;

- The valorized waste (secondary raw material);

- The new recycled material.

3.2. Academic Context

3.3. Practice-Based Context

3.4. Future Perspectives

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. List of the Selected Case Studies from the Academic Context

| Year | Reference | Application Fields | Waste and/or Scrap | Recycled Material | Extrusion-Based AM Technology | Product |

|---|---|---|---|---|---|---|

| 2015 | 1. 10–20 citations, R7 [36] | Building | Cellulose microfibers | Raw natural polysaccharides, fillers, low impact chemicals, and water. | DIW Robotic arm (Custom, Kuka. Water allows reprints.) | Temporary large-scale architectural structures |

| 2016 | 1. 20–50 Citations, R7 [37] | Building | Wax | Wax | FFF (FreeFAB Gantry) | Molds for panels |

| 2017 | 1. <10 citations, R2–R7 [38] | Furnishing Accessories | Coffee powder waste | PLA filled with coffee powder | FFF | Molds for cups |

| 2. <10 citations, R3–R6–R7 [39] | Furnishing Accessories | Electric and Electronic Equipment Plastic Waste | Waste-based Thermoplastic | FFF | Vases | |

| 2018 | 1. 20–50 citations, R7 [40] | Medical | Ready-to-eat meal pouches | Waste-based Thermoplastic (mainly LDPE) | FFF | Medical gloves, finger cots |

| 2. 50–100 citations, R3–R7 [41] | Military | PET from packaging waste | Recycled PET | FFF | Radio bracket | |

| 3. 50–100 citations, R7 [42] | Tools and Equipment | ABS waste | Recycled ABS | FFF (Athena 3D Printer) | Camera tripod, camera hood | |

| 4. 10–20 citations, R7 [43] | Tools and Equipment | E-waste ABS | Recycled ABS | FFF (Lulzbot Mini) | Pipe Connectors | |

| 5. <10 citations, R2–R7 [44] | Naval sector | Wood flour | PLA filled with wood flour and lignocellulosic fibers | FFF (Cincinnati Big Area Additive Manufacturing) | Tooling mold for boat roof | |

| 6. 20–50 citations, R3–R7 [45] | Furniture | Low/medium density fiberboard scraps, melamine, paper | PLA filled with shredded wood scrapes | FFF (RE:3D Gigabot) | Desk cable feedthrough parts, drawer knobs | |

| 7. 20–50 citations, R6–R7 [46] | Gardening | Mussel shells | Calcium carbonate composite with mussel shells | DIW (Custom from Makerbot. Water allows reprints.) | Fertilizer flowerpot | |

| 2019 | 1. 20–50 citations, R3–R7 [47] | Household appliances, Tools and Equipment | PC from EoL products | Recycled PC | FFF (Gigabot X) | Elastomer tooling molds, Household part replacement, car ice scraper |

| 2. 20–50 citations, R7 [48] | Sport | Bamboo and flax fibers | PLA filled with bamboo or flax fibers | FFF | Biking brake levers | |

| 3. 20–50 citations, R7 [49] | Sport | ABS and PP waste | Recycled ABS or PP | FFF (Gigabot X) | Skateboard, Kayak paddle, Snowshoe | |

| 4. < 10 citations, R7 [50] | Ecology | Oyster shells | Concrete composite (sand, rocks, vermiculite) filled with oyster shells. | FFF | Marine bio-shelters for seawalls | |

| 5. 10–20 citations, R7 [51] | Urban Furniture, Scenery | Fibrillated fibers from poplars | PLA filled with poplar fibers | FFF (Cincinnati Big Area Additive Manufacturing) | Podium structure | |

| 6. <10 citations, R7 [52] | Scenery | Glass Fiber Reinforced Polymer from Constructions | Acrilic-based thermoset resin filled with shredded rGFRP | DIW (UV-assisted, Custom) | Amusement park arc | |

| 2020 | 1. 20–50 citations, R2–R7 [53] | Medical | Waste from rigid and flexible windshield wiper blades | Waste-based polymer composite | FFF (Deltabot RepRap, Lulzbot TAZ 6) | Fingertip grips for hand prostheses, molds for fingertips |

| 2. <10 citations, R7 [54] | Medical | Scraps from hemp shives. | PLA filled with hemp shives | FFF (Printer D300) | Customized Neck orthosis, Laryngoscope blades | |

| 3. <10 citations, R7 [55] | Military, Medical | Plastic waste (PET) | Recycled PET | FFF (Gigabot X) | Air Force training aid, Face shield frames | |

| 4. <10 citations, R7 [56] | Tools and Equipment | PET from bottles | Recycled PET | FFF (Lulzbot Taz 5) | Quadricopter airframe | |

| 5. <10 citations, R7 [57] | Education | Plastic waste (PET) | Recycled PET | FFF | Learning tool For recycling processes | |

| 6. <10 citations, R7 [58] | Gardening | Pozzolan powder waste | PLA filled with Pozzolan powder waste | FFF (Ultimaker 3) | Irrigation system module | |

| 7. 10–20 citations, R7 [59] | Buildings | Concrete shredded waste | Concrete filled with concrete waste | DIW (Custom) | Room module (partial) | |

| 8. <10 citations, R7 [60] | Furniture | Plastic waste from 3D-printed models and single-use tableware | Recycled PLA | FFF | Ornamental customized brick wall | |

| 9. <10 citations, R2–R7 [61] | Urban Furniture | ABS shredded waste | Recycled ABS mixed with virgin ABS | FFF (Ultimaker 3) | Joints for shading modules | |

| 10. <10 citations, R7 [62] | Urban furniture, Scenery | Glass Fiber Reinforced Polymers from Wind blades | Acrylic-based thermoset resin filled with shredded rGFRP | DIW (UV-assisted, Custom) | Amusement park Arc, freeform fountain | |

| 11. <10 citations, R7 [63] | Furniture, Fashion | Mussel shells | Sodium Alginate composite filled with shredded mussel shells | DIW (Custom from Makerbot. Ion cross-linking allows reprints.) | Lamp, Hairpin | |

| 2021 | 1. <10 citations, R7 [64] | Ecology | Seashells from canning industry and glass from smashed car windows | Geopolymer formulation with recycled binders | DIW (Delta Wasp) | Artificial reefs |

| 2. <10 citations, R7 [65] | Tools and Equipment | Glass Fiber Reinforced Polymers from Wind blades | Acrylic-based thermoset resin filled with shredded rGFRP | DIW (UV-assisted, Custom) | 3D printer extrusion head support | |

| 3. <10 citations, R7 [66] | Medical | Potato starch | PLA with thermoplastic potato starch | FFF (Prusa i3 MK3S) | Personalized Anatomical models |

Appendix B. List of the Selected Case Studies from the Practice-Based Context

| Year | Project | Application Fields | Waste and/or Scrap | Recycled Material | Extrusion-Based AM Technology | Product |

|---|---|---|---|---|---|---|

| 2015 | 1. “Project Seafood”, R7 [67] | Fashion | Plastic waste from beaches | Waste-based Thermoplastic (mainly PET) | FFF (Ultimaker Original) | Sunglasses |

| 2016 | 1. HiveHaven honeycombs, R7 [68] | Ecology | Plastic waste (Bottles) | Recycled HDPE | FFF | Honeycombs |

| 2. “Print Your City”, R7 [69] | Urban Furniture | Plastic waste from citizen | Waste-based Thermoplastic | FFF Robotic Arm (Kuka) | Benches | |

| 2017 | 1. “Dolphin Board of Awesome”, R7 [70] | Sport | Algae and plastic waste (Bottles) | Recycled PET And PLA filled with algae | FFF | Surfboards |

| 2. Concrete 3D Tiles, R2–R7 [71] | Building | Glass and construction rubble | Concrete with 40% glass and rubble | FFF | Molds for 3D Tiles | |

| 3. Adaptable 3D Design Façade, R7 [72] | Building | Plastic waste (mainly bottles) | Waste-based Thermoplastic (mainly PET) | FFF | Customized Building façades | |

| 4. “Algae Lab”, R7 [73] | Exhibition, Furnishing Accessories. | Algae and starch | Algae-based Thermoplastic | FFF | Utensils for Museum exhibitions | |

| 2018 | 1. “Million Waves Project”, R7 [74] | Medical | Plastic waste from ocean | Waste-based Thermoplastic (mainly PET) | FFF | Upper limbs prosthesis |

| 2. On-demand spare parts, R3–R7 [75] | Tools and Equipment, Aerospace | Plastic waste from astronauts | Waste-based Thermoplastic | FFF (Custom) | Spare parts | |

| 3. “Living Seawall”, R2–R7 [76] | Ecology | Plastic waste | Concrete filled With recycled plastic fibers | FFF | Molds for 3D Tiles for marine habitat walls | |

| 4. “Cabin of 3D Printed Curiosities”, R7 [77] | Buildings | Ceramic waste | Waste-based ceramic | DIW (Custom) | 3D tiles for roof and lateral walls | |

| 5. 100 m2 House, R7 [78] | Buildings | Concrete debris from demolition sites | Concrete filled with demolition debris | DIW Robotic arm (Cybe Construction) | 100 m2 house | |

| 6. “Gaia”, R7 [79] | Buildings | Vegetable fibers (rice—industrial scraps) | Concrete composite (25% soil, 40% straw chopped rice, 25% rice husk, 10% lime) | FFF (BigDelta WASP 12MT) | Zero environmental impact house module | |

| 7. “The Robotic Playground”, R7 [80] | Urban Furniture, Toys | Plastic waste (PLA) | Recycled PLA | FFF Robotic Arm (Caracol) | Co-designed tables, chairs, outdoor toys | |

| 8. “Print Your City”, R7 [81] | Urban Furniture | Plastic waste from citizen | Waste-based Thermoplastic | FFF Robotic Arm (Kuka) | Multifunctional Benches | |

| 9. Paper Pulp 3D Printer, R7 [82] | Furniture | Paper waste | Recycled paper pulp | DIW (Custom) | Lamps | |

| 10. “Not Only Hollow”, R7 [83] | Furniture | Reclaimed polycarbonate (CDs, food molds) | Waste-based Thermoplastic (mainly PC) | FFF Robotic Arm (Custom) | Cabinet | |

| 11. “Botella light”, R7 [84] | Furniture | Plastic waste (Bottles) | Waste-based Thermoplastic (PET) | FFF | Lamps | |

| 12. “Second Nature” R7 [85] | Furnishing accessories | Plastic waste from ocean, nets | Waste-based Thermoplastic | FFF (Custom) | Tableware | |

| 2019 | 1. “Tera”, R7 [86] | Buildings | Building waste from industries | Biopolymer Filled with basalt | FFF Robotic Arm (Autodesk) | House module |

| 2. “GENESIS Eco Screen”, R6–R7 [87] | Urban Furniture, Ecology | Plastic waste (Bottles) | Recycled PET | FFF (BigRep) | Ecowalls for urban biodiversity habitats | |

| 3. “The 3D Bar”, R7 [88] | Furniture, Exhibition | Coffee cups waste (PLA) | Recycled PLA | FFF Robotic Arm (Caracol) | Bar, stools, tables | |

| 4. “Deciduous” R7 [89] | Exhibition | Plastic waste (Bottles) | Recycled PETG | FFF Robotic Arm | Pavilion | |

| 5. “Conifera” R6–R7 [90] | Exhibition | Wood waste | PLA filled with wood waste | FFF (Delta WASP 3M Industrial 4.0) | Architectural installation | |

| 6. “Strats”, R7 [91] | Urban Furniture | Plastic waste | Waste-based Thermoplastic | FFF | Stools, lounge chairs, tables | |

| 7. “Beyond Digital”, R7 [92] | Furniture | Industrial Plastic waste (PP) | Recycled PP | FFF Robotic Arm (Caracol) | Office desk | |

| 8. Plumen and Batch works lamps, R7 [93] | Furniture | Plastic waste (Bottles, household appliances) | Waste-based Thermoplastic (mainly PET) | FFF | Lamps | |

| 9. “Ice-Dream”, R7 [94] | Furniture | Industrial scraps from thermoforming | Recycled PLA | FFF (Delta WASP 3M Industrial 4.0) | Chairs, tables | |

| 10. AVR Tables and Stools, R7 [95] | Furniture | Plastic waste (Bottles) | Waste-based Thermoplastic (PET) | FFF | Tables, stands, stools, desks | |

| 11. “Feel The Peel”, R7 [96] | Furnishing Accessories | PP waste, Orange peels | Recycled PP filled with orange peels | FFF (Delta WASP 2040 Industrial 4.0) | Cups, tableware | |

| 2020 | 1. “Second Nature”, R7 [97] | Urban Furniture | Ropes from fishing and shipping | Waste-based Thermoplastic | FFF Robotic Arm (Kuka) | Benches |

| 2. “Let the waste be the hero”, R7 [98] | Furniture | Plastic waste (Toys) | Waste-based Thermoplastic | FFF | Stools, tables, lamps, plant pots | |

| 3. Oil palm fibers chairs, R7 [99] | Furniture | Oil palm waste fibers | PLA filled with oil palm fibers | FFF | Chairs | |

| 4. Model No. Furniture, R7 [100] | Furniture | Agricultural waste | Waste-based Thermoplastic | FFF | Tables, Benches | |

| 5. “Volta”, R7 [101] | Furnishing accessories | Plastic waste (Bottles) | Recycled PETG | FFF Robotic Arm (Kuka) | Vases, tableware, home elements | |

| 6. “Reprint Ceramics”, R7 [102] | Furniture, Furnishing accessories | Ceramic waste | Clay from ceramic waste | DIW (Deltabot) | Lamps, vases | |

| 7. “Co.ffee Era”, R7 [103] | Furnishing accessories | Coffee waste | Thermoplastic filled with coffee waste | FFF (Ultimaker) | Furnishings | |

| 8. “Was orange”, R7 [104] | Furnishing accessories | Orange peels | Thermoplastic filled with orange peels | FFF (Ultimaker) | Furnishings | |

| 2021 | 1. “Tecla”, R7 [105] | Buildings | Vegetable fibers (rice—industrial scraps) | Vegetable fibers scraps with local soil and raw earth | DIW (Crane WASP) | Eco-sustainable 3D-printed habitat |

| 2. “R-IGLO”, R2–R7 [106] | Exhibition | Plastic waste(PET) | Recycled PET | FFF Robotic Arm | Self-sustainable exhibition structure | |

| 3. Recycled 3D-Printed Chair, R7 [107] | Furniture | Post-consumer plastic waste (PET) | Recycled PET | FFF | Chair | |

| 4. “91–92”, R7 [108] | Furniture, Furnishing accessories | Plastic waste (PET) | Recycled PET or PETG | FFF | Stools, Vases | |

| 5. “Aectual”, R7 [109] | Furniture | Plastic waste | Waste-based and bio-based Thermoplastic | FFF | Customized room dividers |

References

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A New Sustainability Paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- Aloini, D.; Dulmin, R.; Mininno, V.; Stefanini, A.; Zerbino, P. Driving the Transition to a Circular Economic Model: A Systematic Review on Drivers and Critical Success Factors in Circular Economy. Sustainability 2020, 12, 10672. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation (EMF). Towards the Circular Economy; EMF: Cowes, UK, 2013. [Google Scholar]

- Alhawari, O.; Awan, U.; Bhutta, M.K.S.; Ülkü, M.A. Insights from Circular Economy Literature: A Review of Extant Definitions and Unravelling Paths to Future Research. Sustainability 2021, 13, 859. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and Its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Den Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product Design in a Circular Economy: Development of a Typology of Key Concepts and Terms: Key Concepts and Terms for Circular Product Design. J. Industr. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- Van Dam, K.; Simeone, L.; Keskin, D.; Baldassarre, B.; Niero, M.; Morelli, N. Circular Economy in Industrial Design Research: A Review. Sustainability 2020, 12, 10279. [Google Scholar] [CrossRef]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The Circular Economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Campbell-Johnston, K.; Vermeulen, W.J.V.; Reike, D.; Brullot, S. The Circular Economy and Cascading: Towards a Framework. Resour. Conserv. Recycl. 2020, 7, 100038. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product Design and Business Model Strategies for a Circular Economy. J. Industr. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef] [Green Version]

- Sumter, D.; de Koning, J.; Bakker, C.; Balkenende, R. Key Competencies for Design in a Circular Economy: Exploring Gaps in Design Knowledge and Skills for a Circular Economy. Sustainability 2021, 13, 776. [Google Scholar] [CrossRef]

- Evrard, D.; Ben Rejeb, H.; Zwolinski, P.; Brissaud, D. Designing Immortal Products: A Lifecycle Scenario-Based Approach. Sustainability 2021, 13, 3574. [Google Scholar] [CrossRef]

- Pourhejazy, P.; Kwon, O.K. A Practical Review of Green Supply Chain Management: Disciplines and Best Practices. J. Int. Logist. Trade 2016, 14, 156–164. [Google Scholar] [CrossRef]

- Diaz, A.; Schöggl, J.-P.; Reyes, T.; Baumgartner, R.J. Sustainable Product Development in a Circular Economy: Implications for Products, Actors, Decision-Making Support and Lifecycle Information Management. Sustain. Prod. Consum. 2021, 26, 1031–1045. [Google Scholar] [CrossRef]

- Dieckmann, E.; Sheldrick, L.; Tennant, M.; Myers, R.; Cheeseman, C. Analysis of Barriers to Transitioning from a Linear to a Circular Economy for End of Life Materials: A Case Study for Waste Feathers. Sustainability 2020, 12, 1725. [Google Scholar] [CrossRef] [Green Version]

- Hernandez, R.J.; Miranda, C.; Goñi, J. Empowering Sustainable Consumption by Giving Back to Consumers the ‘Right to Repair’. Sustainability 2020, 12, 850. [Google Scholar] [CrossRef] [Green Version]

- Laura, C.; Rognoli, V. Materials Designers: A New Design Discipline. In Material Designers—Boosting Talent towards Circular Economies; MaDe Book Scientific: Milan, Italy, 2021; pp. 43–47. [Google Scholar]

- Zhou, Z.; Rognoli, V.; Ayala-García, C. Educating Designers through Materials Club. In Proceedings of the 4th International Conference on Higher Education Advances (HEAd’18), Universitat Politècnica València, Valencia, Spain, 20 June 2018. [Google Scholar]

- Virtanen, M.; Manskinen, K.; Eerola, S. Circular Material Library. An Innovative Tool to Design Circular Economy. Des. J. 2017, 20, S1611–S1619. [Google Scholar] [CrossRef]

- Parisi, S.; Rognoli, V.; Sonneveld, M. Material Tinkering. An Inspirational Approach for Experiential Learning and Envisioning in Product Design Education. Des. J. 2017, 20, S1167–S1184. [Google Scholar] [CrossRef] [Green Version]

- Rognoli, V.; Bianchini, M.; Maffei, S.; Karana, E. DIY Materials. Mater. Des. 2015, 86, 692–702. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Ingemarsdotter, E.; Jamsin, E.; Kortuem, G.; Balkenende, R. Circular Strategies Enabled by the Internet of Things—A Framework and Analysis of Current Practice. Sustainability 2019, 11, 5689. [Google Scholar] [CrossRef] [Green Version]

- Despeisse, M.; Baumers, M.; Brown, P.; Charnley, F.; Ford, S.J.; Garmulewicz, A.; Knowles, S.; Minshall, T.H.W.; Mortara, L.; Reed-Tsochas, F.P.; et al. Unlocking Value for a Circular Economy through 3D Printing: A Research Agenda. Technol. Forecast. Soc. Chang. 2017, 115, 75–84. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, I.A.; Godina, R.; Carvalho, H. Waste Valorization through Additive Manufacturing in an Industrial Symbiosis Setting. Sustainability 2020, 13, 234. [Google Scholar] [CrossRef]

- Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic Recycling in Additive Manufacturing: A Systematic Literature Review and Opportunities for the Circular Economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- ASTM International. ISO/ASTM 52900-15 Standard Terminology for Additive Manufacturing—General Principles—Terminology; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Nieto, D.M.; Molina, S.I. Large-Format Fused Deposition Additive Manufacturing: A Review. Rapid Prototyp. J. 2019, 26. [Google Scholar] [CrossRef]

- Boparai, K.S.; Singh, R.; Singh, H. Development of Rapid Tooling Using Fused Deposition Modeling: A Review. Rapid Prototyp. J. 2015, 22, 20. [Google Scholar] [CrossRef]

- Sauerwein, M.; Doubrovski, E.; Balkenende, R.; Bakker, C. Exploring the Potential of Additive Manufacturing for Product Design in a Circular Economy. J. Clean. Prod. 2019, 226, 1138–1149. [Google Scholar] [CrossRef]

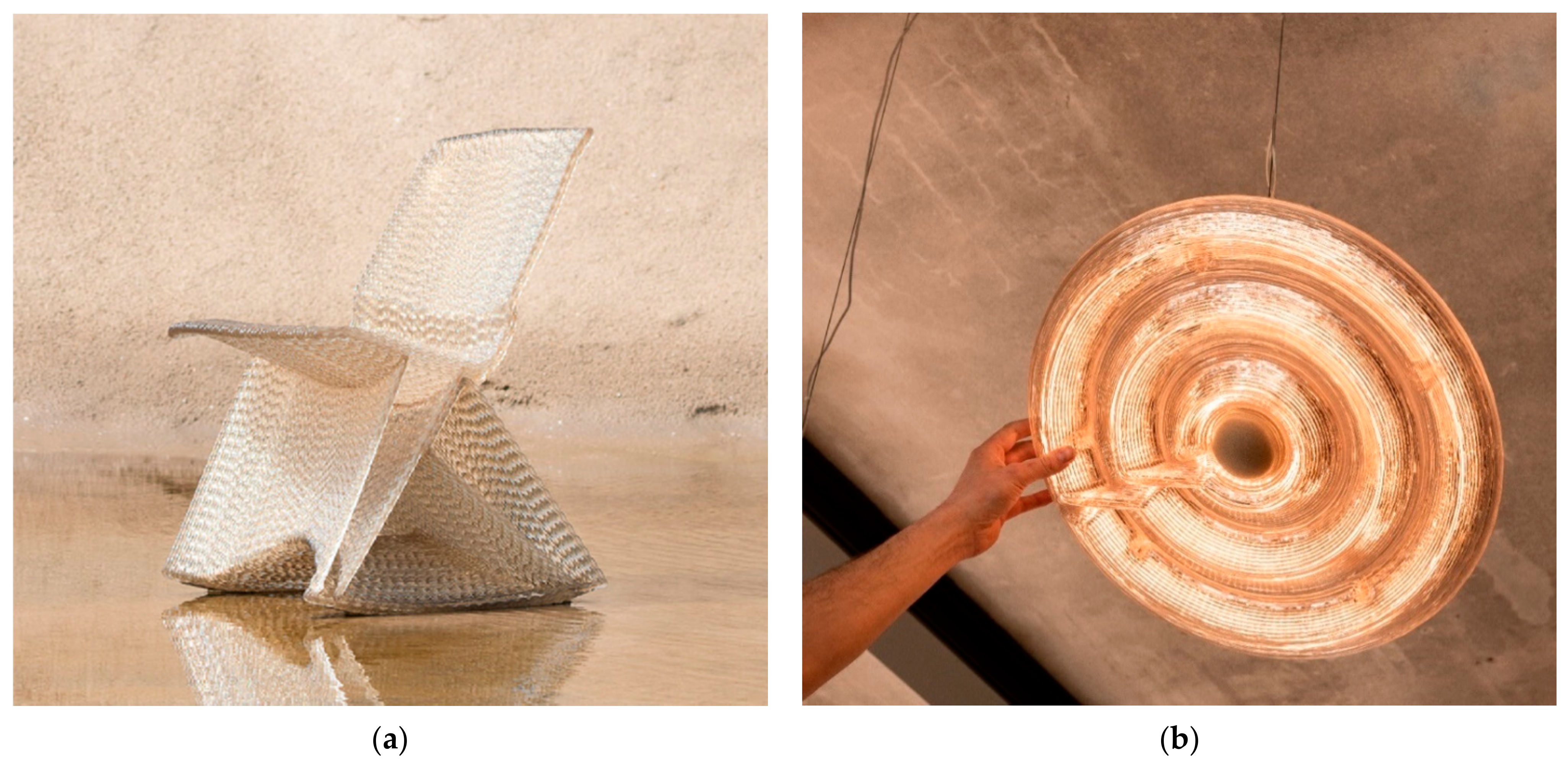

- Chubby—Kooij. Available online: https://dirkvanderkooij.com/chubby (accessed on 12 March 2021).

- Chinese Company 3D Prints 10 Houses in a Day with Construction Waste. Available online: https://www.dezeen.com/2014/04/24/chinese-company-3d-prints-buildings-construction-waste/ (accessed on 13 March 2021).

- Endless by Dirk Vander Kooij at DMY Berlin. Available online: https://www.dezeen.com/2011/06/04/dezeen-screen-endless-by-dirk-vander-kooij-at-dmy-berlin/ (accessed on 13 March 2021).

- Fresnel Light—Kooij. Available online: https://dirkvanderkooij.com/fresnel-light (accessed on 12 March 2021).

- Mikula, K. 3D Printing Filament as a Second Life of Waste Plastics—A Review. Environ. Sci. Pollut. Res. 2021, 28, 12321–12333. [Google Scholar] [CrossRef] [PubMed]

- Mogas-Soldevila, L.; Oxman, N. Water-Based Engineering & Fabrication: Large-Scale Additive Manufacturing of Biomaterials. MRS Proc. 2015, 1800, 7. [Google Scholar] [CrossRef]

- Gardiner, J.B.; Janssen, S.; Kirchner, N. A Realisation of a Construction Scale Robotic System for 3D Printing of Complex Formwork. In Proceedings of the ISARC 2016—International Symposium on Automation and Robotics in Construction, Auburn, AL, USA, 18–21 July 2016. [Google Scholar]

- Canavarro, V.; Alves, J.L.; Rangel, B. Coffee Powder Reused as a Composite Material. In Materials Design and Applications; da Silva, L.F.M., Ed.; Advanced Structured Materials; Springer International Publishing: Cham, Switzerland, 2017; Volume 65, pp. 113–123. ISBN 978-3-319-50783-5. [Google Scholar]

- Petruzzi, C.; Lucchio, L.D.; Maria Cafiero, L.; Tuffi, R.; Ubertini, A.; Caretto, F. Hospital of Objects. Recycling Plastic from the Small Electronic Devices to Redesign Old Objects by the 3d Printers. Des. J. 2017, 20, S2716–S2723. [Google Scholar] [CrossRef] [Green Version]

- Hart, K.R.; Frketic, J.B.; Brown, J.R. Recycling Meal-Ready-to-Eat (MRE) Pouches into Polymer Filament for Material Extrusion Additive Manufacturing. Addit. Manuf. 2018, 21, 536–543. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Lambeth, R.H. Recycled Polyethylene Terephthalate as a New FFF Feedstock Material. Addit. Manuf. 2018, 21, 174–182. [Google Scholar] [CrossRef]

- Zhong, S.; Pearce, J.M. Tightening the Loop on the Circular Economy: Coupled Distributed Recycling and Manufacturing with Recyclebot and RepRap 3-D Printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef] [Green Version]

- Mohammed, M.I.; Wilson, D.; Gomez-Kervin, E.; Vidler, C.; Rosson, L.; Long, J. The Recycling of E-Waste ABS Plastics by Melt Extrusion and 3D Printing Using Solar Powered Devices as a Transformative Tool for Humanitarian Aid. In Proceedings of the SFF 2018: 29th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, University of Texas, Austin, TX, USA, 13–15 August 2018; p. 14. [Google Scholar]

- Gardner, D.J.; Tekinalp, H.; Sauerbier, P. Lignocellulosic-Filled Polymer Feedstocks for Large Scale Additive Manufacturing of Low Cost Composites. In Proceedings of the International Forest Products Congress, Trabzon, Turkey, 26–29 September 2018; pp. 13–22. [Google Scholar]

- Pringle, A.M.; Rudnicki, M.; Pearce, J.M. Wood Furniture Waste–Based Recycled 3-D Printing Filament. For. Product. J. 2018, 68, 86–95. [Google Scholar] [CrossRef] [Green Version]

- Sauerwein, M.; Doubrovski, E.L. Local and Recyclable Materials for Additive Manufacturing: 3D Printing with Mussel Shells. Mat. Today Commun. 2018, 15, 214–217. [Google Scholar] [CrossRef]

- Reich, M.J.; Woern, A.L.; Tanikella, N.G.; Pearce, J.M. Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing. Materials 2019, 12, 1642. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Depuydt, D.; Balthazar, M.; Hendrickx, K.; Six, W.; Ferraris, E.; Desplentere, F.; Ivens, J.; Vuure, A.W.V. Production and Characterization of Bamboo and Flax Fiber Reinforced Polylactic Acid Filaments for Fused Deposition Modeling (FDM). Polym. Compos. 2019, 40, 1951–1963. [Google Scholar] [CrossRef]

- Byard, D.J.; Woern, A.L.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Green Fab Lab Applications of Large-Area Waste Polymer-Based Additive Manufacturing. Addit. Manuf. 2019, 27, 515–525. [Google Scholar] [CrossRef] [Green Version]

- Dunn, K.; Haeusler, M.H.; Zavoleas, Y.; Bishop, M.; Dafforn, K.; Sedano, F.; Yu, D.; Schaefer, N. Recycled Sustainable 3D Printing Materials for Marine Environments. In Blucher Design Proceedings; Editora Blucher: Porto, Portugal, 2019; pp. 583–591. [Google Scholar]

- Zhao, X.; Tekinalp, H.; Meng, X.; Ker, D.; Benson, B.; Pu, Y.; Ragauskas, A.J.; Wang, Y.; Li, K.; Webb, E.; et al. Poplar as Biofiber Reinforcement in Composites for Large-Scale 3D Printing. ACS Appl. Bio Mater. 2019, 2, 4557–4570. [Google Scholar] [CrossRef]

- Mantelli, A.; Levi, M.; Turri, S.; Suriano, R. Remanufacturing of End-of-Life Glass-Fiber Reinforced Composites via UV-Assisted 3D Printing. Rapid Prototyp. J. 2019, 26, 981–992. [Google Scholar] [CrossRef]

- Dertinger, S.C.; Gallup, N.; Tanikella, N.G.; Grasso, M.; Vahid, S.; Foot, P.J.S.; Pearce, J.M. Technical Pathways for Distributed Recycling of Polymer Composites for Distributed Manufacturing: Windshield Wiper Blades. Resour. Conserv. Recycl. 2020, 157, 104810. [Google Scholar] [CrossRef]

- Calì, M.; Pascoletti, G.; Gaeta, M.; Milazzo, G.; Ambu, R. A New Generation of Bio-Composite Thermoplastic Filaments for a More Sustainable Design of Parts Manufactured by FDM. Appl. Sci. 2020, 10, 5852. [Google Scholar] [CrossRef]

- Little, H.A.; Tanikella, N.G.; Reich, M.J.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Towards Distributed Recycling with Additive Manufacturing of PET Flake Feedstocks. Materials 2020, 13, 4273. [Google Scholar] [CrossRef]

- Niemand, J.; Mathew, S.J.; Gonzalez, F. Design and Testing of Recycled 3D Printed Foldable Unmanned Aerial Vehicle for Remote Sensing. In Proceedings of the 2020 International Conference on Unmanned Aircraft Systems (ICUAS), Athens, Greece, 1–4 September 2020; IEEE: Athens, Greece, 2020; pp. 892–901. [Google Scholar]

- Juraschek, M.; Büth, L.; Thiede, S.; Herrmann, C. 3-CYCLE—A Modular Process Chain for Recycling of Plastic Waste with Filament-Based 3D Printing for Learning Factories. In Enhancing Future Skills and Entrepreneurship; Sangwan, K.S., Herrmann, C., Eds.; Sustainable Production, Life Cycle Engineering and Management; Springer International Publishing: Cham, Switzerland, 2020; pp. 79–87. ISBN 978-3-030-44247-7. [Google Scholar]

- Schiavone, N.; Verney, V.; Askanian, H. Pozzolan Based 3D Printing Composites: From the Formulation Till the Final Application in the Precision Irrigation Field. Materials 2020, 14, 43. [Google Scholar] [CrossRef]

- Xiao, J.; Zou, S.; Yu, Y.; Wang, Y.; Ding, T.; Zhu, Y.; Yu, J.; Li, S.; Duan, Z.; Wu, Y.; et al. 3D Recycled Mortar Printing: System Development, Process Design, Material Properties and on-Site Printing. J. Build. Eng. 2020, 32, 101779. [Google Scholar] [CrossRef]

- Bruce, C.; Sweet, K.; Ok, J. Closing the Loop—Recycling Waste Plastic. In Proceedings of the RE: Anthropocene, Design in the Age of Humans; Chulalongkorn University, Bangkok, Thailand, 5–6 August 2020; Volume 1, pp. 135–144. [Google Scholar]

- Esirger, S.B.; Örnek, M.A. Recycled Plastic to Performative Urban Furniture. J. Digit. Landsc. Archit. 2020, 166–172. [Google Scholar] [CrossRef]

- Romani, A.; Mantelli, A.; Suriano, R.; Levi, M.; Turri, S. Additive Re-Manufacturing of Mechanically Recycled End-of-Life Glass Fiber-Reinforced Polymers for Value-Added Circular Design. Materials 2020, 13, 3545. [Google Scholar] [CrossRef] [PubMed]

- Sauerwein, M.; Zlopasa, J.; Doubrovski, Z.; Bakker, C.; Balkenende, R. Reprintable Paste-Based Materials for Additive Manufacturing in a Circular Economy. Sustainability 2020, 12, 8032. [Google Scholar] [CrossRef]

- Ly, O.; Yoris-Nobile, A.I.; Sebaibi, N.; Blanco-Fernandez, E.; Boutouil, M.; Castro-Fresno, D.; Hall, A.E.; Herbert, R.J.H.; Deboucha, W.; Reis, B.; et al. Optimisation of 3D Printed Concrete for Artificial Reefs: Biofouling and Mechanical Analysis. Constr. Build. Mater. 2021, 272, 121649. [Google Scholar] [CrossRef]

- Mantelli, A.; Romani, A.; Suriano, R.; Levi, M.; Turri, S. Direct Ink Writing of Recycled Composites with Complex Shapes: Process Parameters and Ink Optimization. Adv. Eng. Mater. 2021, 2100116. [Google Scholar] [CrossRef]

- Haryńska, A.; Janik, H.; Sienkiewicz, M.; Mikolaszek, B.; Kucińska-Lipka, J. PLA—Potato Thermoplastic Starch Filament as a Sustainable Alternative to the Conventional PLA Filament: Processing, Characterization, and FFF 3D Printing. ACS Sustain. Chem. Eng. 2021, 9, 6923–6938. [Google Scholar] [CrossRef]

- Project Seafood, Creating Waves of Change on Our Shores. Available online: https://ultimaker.com/learn/project-seafood-creating-waves-of-change-on-our-shores (accessed on 9 February 2021).

- 3D Printing Is Still a Goal for Creators of Recycled Plastic Bee Boxes. Available online: https://3dprint.com/116029/hivehaven-3d-print-bee-boxes/ (accessed on 16 February 2021).

- Print Your City Amsterdam—XXX Bench. Available online: https://www.printyour.city/amsterdam (accessed on 9 February 2021).

- The World’s First 3D Printed, Recyclable Surfboard—Magicseaweed. Available online: https://magicseaweed.com/news/the-worlds-first-3d-printed-recyclable-surfboard/10324/ (accessed on 16 February 2021).

- Six of the Best Designers Working in Lebanon Today. Available online: https://www.dezeen.com/2017/06/08/six-best-designers-lebanon-beirut-design-week/ (accessed on 4 February 2021).

- Adaptable and Circular 3D Design Façade from Recycled Plastic. Available online: https://materialdistrict.com/article/adaptable-circular-3d-design-facade/ (accessed on 25 May 2021).

- NEWS—Klarenbeek & Dros—Designers of the Unusual. Available online: https://ericklarenbeek.com/indexmobile.htm (accessed on 26 May 2021).

- The Million Waves Project Looks to Solve Two Global Issues at Once. Available online: https://www.waste360.com/plastics/million-waves-project-looks-solve-two-global-issues-once (accessed on 4 February 2021).

- NASA Installs Tether Refabricator Aboard ISS for In-Space 3D Printing. Available online: https://3dprintingindustry.com/news/nasa-installs-tether-refabricator-aboard-iss-for-in-space-3d-printing-148728/ (accessed on 9 February 2021).

- Living Seawall. Available online: https://www.reefdesignlab.com/living-seawalls (accessed on 14 March 2021).

- Emerging Objects. Cabin of 3D Printed Curiosities. Available online: http://emergingobjects.com/project/cabin-of-3d-printed-curiosities/ (accessed on 11 February 2021).

- Arup and CLS Architetti’s 3D-Printed House Was Built in a Week. Available online: https://www.dezeen.com/2018/11/19/video-mini-living-3d-printing-cls-architetti-arup-movie/ (accessed on 11 February 2021).

- The First 3D Printed House with Earth: Gaia. Available online: https://www.3dwasp.com/en/3d-printed-house-gaia/ (accessed on 4 February 2021).

- The Robotic Playground—Caracol-AM. Additive Manufacturing Services. Available online: https://www.caracol-am.com/portfolio/robotic-playground-2/ (accessed on 16 February 2021).

- Print Your City Thessaloniki—Zero Waste Lab. Available online: https://www.printyour.city/thessaloniki (accessed on 9 February 2021).

- Paper Pulp Printer. Available online: http://www.beerholthuis.com/portfolio/paper-pulp-printer/ (accessed on 4 February 2021).

- “Not Only Hollow” Cabinet: Adorno Design. Available online: https://adorno.design/pieces/not-only-hollow-cabinet/ (accessed on 9 February 2021).

- UNC Botella Light: Better Future Factory. Available online: https://betterfuturefactory.com/portfolio_page/unc-botella-light/ (accessed on 9 February 2021).

- The New Raw. Second Nature—Seashells. Available online: https://thenewraw.org/Second-nature-Seashells (accessed on 11 February 2021).

- TERA: Experience Mars on Earth. Available online: https://www.aispacefactory.com/tera (accessed on 9 March 2021).

- GENESIS Eco Screen: A 3D Printed Urban Biodiversity Habitat Made of Recycled Plastic. Available online: https://3dprint.com/251283/genesis-eco-screen-3d-printed-urban-biodiversity-habitat-of-recycled-plastic/ (accessed on 16 February 2021).

- The 3D Bar—Caracol-AM. Additive Manufacturing Services. Available online: https://www.caracol-am.com/portfolio/the-3d-bar/ (accessed on 16 February 2021).

- Deciduous—3D Printed Pavilion. Available online: https://www.m-e-a-n.design/projects/deciduous-3d-printed-pavilion (accessed on 11 February 2021).

- Arthur Mamou-Mani Uses Bioplastic Bricks on Conifera Installation for COS. Available online: https://www.dezeen.com/2019/04/08/arthur-mamou-mani-cos-installation-bioplastic-bricks-circular-design-milan/ (accessed on 25 May 2021).

- Strats, Furniture. Available online: https://www.joachimfroment.com/strats-furniture (accessed on 9 February 2021).

- Maire Tecnimont Beyond Digital—Caracol-AM. Additive Manufacturing. Available online: https://www.caracol-am.com/portfolio/maire-tecnimont-beyond-digital/ (accessed on 16 February 2021).

- Plumen X Batch.Works: Designing with Plastic Waste. Available online: https://plumen.com/blog/2019/11/19/plumen-x-batch-works-designing-with-plastic-waste/ (accessed on 4 February 2021).

- WASP & Fabio Novembre Together for SAMMONTANA. Available online: https://www.3dwasp.com/en/sammontana-3d-printing/ (accessed on 26 April 2021).

- Van Plestik. 3D Printing a Better Future Together. Available online: https://vanplestik.nl/en/2019/04/18/3d-printing-a-better-future-together/ (accessed on 9 February 2021).

- WASP 3D Prints Food and Recycled Polypropylene in a Circular Economy. Available online: https://www.3dwasp.com/en/wasp-3d-prints-food-and-recycled-polypropylene-in-a-circular-economy/ (accessed on 4 February 2021).

- The New Raw. Second Nature—Bench. Available online: https://thenewraw.org/Second-nature-Bench (accessed on 15 February 2021).

- Let Waste Be the Hero • Better Future Factory. Available online: https://betterfuturefactory.com/portfolio_page/circular-brainstorm-room-furniture/ (accessed on 3 April 2021).

- Nataša Perković Makes Textured Designs from Palm Oil Byproducts. Available online: https://www.dezeen.com/2020/06/13/natasa-perkovic-palm-oil-homeware-design/ (accessed on 4 February 2021).

- Model No. 3D Prints Furniture from Agricultural Waste. Available online: https://3dprint.com/274719/model-no-3d-prints-furniture-from-agricultural-waste/ (accessed on 26 May 2021).

- Supernovas. Volta. Available online: https://supernovas.world/collections/volta/ (accessed on 9 March 2021).

- Reprint Ceramics. Available online: http://hanneke-deleeuw.com/new-page-66 (accessed on 9 March 2021).

- Co.ffee Era: Sostenibilità a Misura di Quartiere, Milano. Available online: https://www.coffee-era.net (accessed on 9 February 2021).

- Krill Design Milano: Was Orange, Autogrill. Available online: https://www.krilldesign.net/autogrill (accessed on 9 February 2021).

- 3D Printed House TECLA: Eco-Housing WASP. Available online: https://www.3dwasp.com/en/3d-printed-house-tecla/ (accessed on 24 April 2021).

- R-Iglo. The 3D Printed (Work)Space That Grows on You. Available online: https://www.royal3d.nl/r-iglo (accessed on 10 May 2021).

- Covestro: 3D Printing Material Made of Recycled PET. Available online: https://www.covestro.com/press/covestro-introduces-3d-printing-material-made-from-recycled-pet/ (accessed on 26 May 2021).

- 91-92 Project. Available online: https://ninetyoneninetytwo.com/ (accessed on 27 May 2021).

- Aectual. Sustainable—Innovative—Yours. Available online: https://www.aectual.com/sustainability/circular (accessed on 24 April 2021).

- Cinderela. New Circular Economy Business Model for More Sustainable Urban Construction. Available online: https://www.cinderela.eu/ (accessed on 24 April 2021).

- Repair3D. Recycling and Repurposing of Plastic Waste for Advanced 3D Printing Applications. Available online: http://www.repair3d.net/ (accessed on 24 April 2021).

- FiberEUse. Large Scale Demonstration of New Circular Economy Value-Chains Based on the Reuse of End-of-Life Fiber Reinforced Composites. Available online: http://fibereuse.eu/ (accessed on 24 April 2021).

- Cirmap—CIrcular Economy via Customisable Furniture with Recycled MAterials for Public Places. Available online: https://www.nweurope.eu/projects/project-search/cirmap-circular-economy-via-customisable-furniture-with-recycled-materials-for-public-places/ (accessed on 24 April 2021).

- Re-Print Vancouver. Local Recycling for 3D Printing. Available online: https://wordpress.kpu.ca/birkzukowsky/ (accessed on 24 April 2021).

- Barbara Project. Available online: https://www.barbaraproject.eu/ (accessed on 26 May 2021).

- Horizon Europe. Available online: https://ec.europa.eu/info/horizon-europe_en (accessed on 8 April 2021).

- Arthur Mamou-Mani and Dassault Systèmes Explore Lifecycles of Materials. Available online: https://www.dezeen.com/2020/11/20/arthur-mamou-mani-dassault-systemes-video/ (accessed on 26 May 2021).

- WYVE and Its 3D Printed Eco-Surfboards. Available online: https://www.3dnatives.com/en/hexa-surfboard-3d-printed-eco-surfboards-150120204/ (accessed on 16 February 2021).

- Covestro TPU Used to Make 3D Printed Insoles. Available online: https://3dprint.com/280665/covestro-tpu-used-to-make-3d-printed-insoles/ (accessed on 26 May 2021).

- Print Your City Customizator. Available online: http://printyourcity.thenewraw.org/ (accessed on 24 April 2021).

| Context | Repositories and Database | Keywords | Eligibility Criteria |

|---|---|---|---|

| Academic research | Scopus DRS Digital Library Google Scholar | “Additive Manufacturing” “3D Printing”, “Recycled,” “Reprintable”, “End of Life”, “Waste-based”, “Upcycling”, “Reuse”, “Repurpose”, “Reverse”, “Recyclables” | - Well-defined applications with tangible artefacts; - Details of the materials and the waste/scraps; - Details of the technology (Material Extrusion AM). |

| Practice | Dezeen.com 3DPrint.com Materialdistrict.com | “3D Printing”, “Recycled”, “Recyclable”, “Waste”,“3D-Printed Products”, “Upcycling”, “Reuse”, “Repurpose”, “Reverse”, “Recyclables” | - Well-defined applications with tangible artefacts; - Possibility to detect the waste, material and technology (Material Extrusion AM); |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romani, A.; Rognoli, V.; Levi, M. Design, Materials, and Extrusion-Based Additive Manufacturing in Circular Economy Contexts: From Waste to New Products. Sustainability 2021, 13, 7269. https://doi.org/10.3390/su13137269

Romani A, Rognoli V, Levi M. Design, Materials, and Extrusion-Based Additive Manufacturing in Circular Economy Contexts: From Waste to New Products. Sustainability. 2021; 13(13):7269. https://doi.org/10.3390/su13137269

Chicago/Turabian StyleRomani, Alessia, Valentina Rognoli, and Marinella Levi. 2021. "Design, Materials, and Extrusion-Based Additive Manufacturing in Circular Economy Contexts: From Waste to New Products" Sustainability 13, no. 13: 7269. https://doi.org/10.3390/su13137269

APA StyleRomani, A., Rognoli, V., & Levi, M. (2021). Design, Materials, and Extrusion-Based Additive Manufacturing in Circular Economy Contexts: From Waste to New Products. Sustainability, 13(13), 7269. https://doi.org/10.3390/su13137269