3.5. Total Carbon Footprint

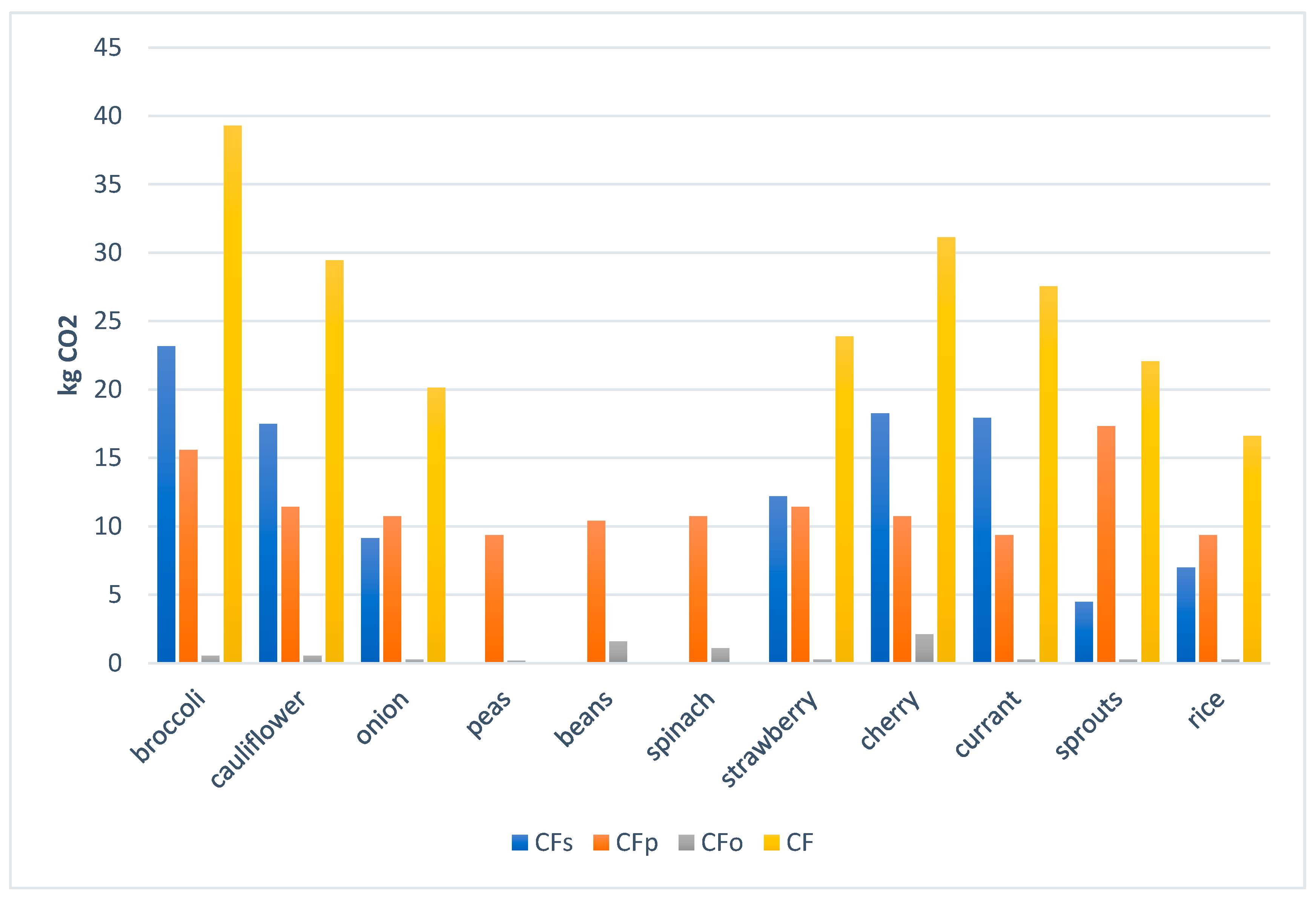

The total carbon footprint of CF was computed by adding up the component results for all three specified stages of internal transport. For a few products, not all the necessary data for carbon footprint calculation for the transport of raw materials in the first stage were obtained (peas, beans, spinach). Hence it was not possible to calculate a total carbon footprint for these types of produce. The values of the total carbon footprint range from 16.610 kgCO

2 to 39.279 kg CO

2. Thus, despite a similar amount of raw material (approximately 20 t) for all products, the total carbon footprint of CF emitted during the internal transport process differs more than twice. The highest total carbon footprint was determined for broccoli (39.279 kg CO

2), cherries (31.115 kg CO

2) and cauliflower (29.441 kg CO

2), while the lowest was determined for rice (16.610 kg CO

2), onions (20.131 kg CO

2) and sprouts (22.062 kg CO

2) (

Figure 1).

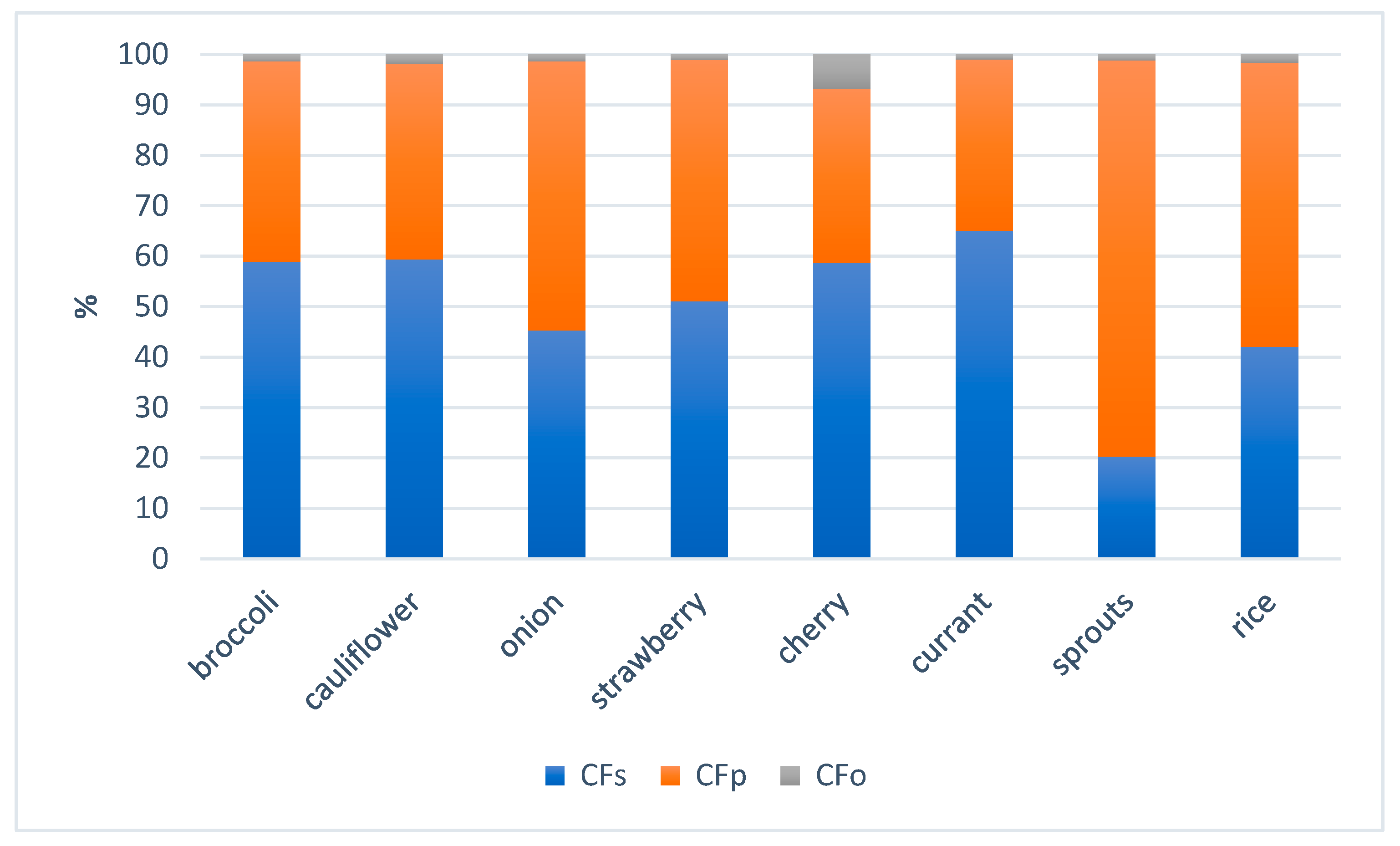

The contribution of the different stages of internal transport to the total carbon footprint is an important indicator (

Figure 2). For most products, most of the emissions were found for the raw material transport stage from the loading/unloading point to the production line workstations, ranging from 20% to 65%. The dominant ones were for broccoli, cauliflower, cherry and currant and were respectively: 58.97%, 59.37%, 58.67% and 65.07%. In contrast, for several products, the dominant emitter was the transportation of finished products (53.34% for onions, 78.50% for sprouts, 56.31% for rice). The least impact on the total carbon footprint was caused by the transport of post-production waste and ranged from 1% to 7%, rounding up to 1–2% for seven of the eight products analysed, while only for transporting waste cherries the carbon footprint amounted to 6.82%.

For the purpose of comparing the carbon footprint, a comparison was made in relation to the weight of the raw material (

Table 11). As a result of the internal transport, the factors for the analysed cases were estimated in the range of 1 to 1.9 kg of CO

2/t of transported raw material.

The high carbon footprint of individual products can be directly attributed to the high number of cycles. Thus, reducing the carbon footprint would mainly involve introducing solutions that reduce the number of forklift trips. An appropriate mechanical pre-treatment of broccoli, e.g., by crushing it (before being transported to the production company) to obtain a more regular shape, might result in increasing the weight of the produce per unit of volume per one FLT trip. It may also be essential to reorganise the distribution of goods in the warehouse, so that, for example, the average handling time of the products with the highest number of cycles, such as broccoli, could be reduced. In addition, consideration should be given to increasing the distance for the transport of the waste product (which is not abundant) in order to reduce the distance for the raw material and the finished product.

According to the computation, cherries have the highest carbon footprint at the level of production waste, which is due to the characteristic delicate structure of this fruit as well as the substantial weight of their stones. In order to reduce the carbon footprint of soft fruits, which are easily damaged mechanically, the fruits should be properly separated, e.g., using additional baskets, separators, etc. However, in this case, it is necessary to optimise the process; it should be estimated whether an adequate separation would not result in a significant increase in volume and consequently an increase in cycles during the first and second stages, which would be a disadvantageous situation, since it is this stage of transportation that is the key CO2 emitter.

Due to the fact that part of the post-production waste is a product with full nutritional value and is rejected as a consumer product only for visual reasons (shape, size, mechanical damage), it seems reasonable to utilise such waste. Composting is the standard operation of utilising such waste adopted in the aforementioned company. The implementation of additional processes for the management of the waste (e.g., production of vegetable pastes, freeze-dried vegetable and fruit bars, vegaburgers, etc.) would not only solve the problem of wasting wholesome produce, but also reduce the carbon footprint associated with part of the waste product which would become the raw material for the next stage. This is particularly important given the efforts of governments and policy makers to move from a linear to a circular economy and to follow the 5Rs, i.e., reducing, reusing, restoring, refurbishing and recycling of resources along the entire product chain [

23]. Eriksson and Spångberg checked four waste management options: incineration, anaerobic digestion, conversion and donation in the aspect of life cycle assessment for tomatoes, apples, bananas, oranges and sweet peppers. The authors’ findings show that it was conversion and donation that significantly contributed to the reduction of greenhouse gas emissions compared to incineration and anaerobic digestion [

24]. Other authors also suggest the production of freeze-dried vegetable snacks with hydrocolloids (sodium alginate with calcium lactate and the mixture of locust bean gum with xanthan gum) from vegetables that are wasted in the production of frozen vegetables [

25].

The proposed methodology for determining the carbon footprint based on actual data is a universal tool for estimating the carbon footprint of internal transport, which can be used to develop a list of raw materials that will provide a product with a maximally reduced carbon footprint generated at the stage of internal transport. It should be emphasized at this point that calculating the total CF requires knowing the entire production process or the overall functioning of the organisation. The possible ranges are: from cradle to grave and from cradle to gate. In the case of the strategy from cradle to grave, all stages from the extraction of raw materials to disposal are taken into account. On the other hand, the strategy focused on cradle-to-grave emissions considers many hypothetical scenarios, e.g., product use or disposal, and uses average values for situations that may or may not happen. This increases uncertainty and exposes the enterprise to calculation errors. Most entrepreneurs, however, decide to calculate the total of CF for their products using the cradle to gate strategy, where the stages from raw material extraction to the delivery of the finished product to the customer are counted. This results in a lower risk of making a mistake [

26]. The model proposed by the authors can thus become a component of a universal application estimating the carbon footprint based on individual processes. In the case of the Unifreeze company (from which the data for this article was taken), there are the following stages/individual processes: production of raw material, transport from supplier to enterprise, production line, internal transport, storage, delivery to the recipient, sales and waste disposal. The CF calculator application should take into account the variety of possible data models and should allow the user to match them to the actual production process. It should also be possible for the user to input data from various sources, e.g., from the database or from measuring devices [

27]. According to [

28], it is essential to study the techniques used in manufacturing products in terms of their carbon footprint, since this makes it possible to identify and improve the weakest links in the production chain. Therefore, it is necessary to continue research in this area and extend it to as many products and processes as possible.