A Review of Modeling Rotating Packed Beds and Improving Their Parameters: Gas–Liquid Contact

Abstract

:1. Introduction

- Absorbent formulation, in which a highly soluble, reactive, absorbent, and aqueous solution of alkanolamines is made and blended by adding activators or promoters, such as sterically hindered amine AMP, and effective promoters, such as PZ.

- Process intensification involves the application of PI techniques or devices and optimization parameters. This category contains many techniques that can be considered to enhance transport in numerous processes, such as bioremediation [17], water deaeration [18], and absorption. As regards devices, many popular contactors are available, such as rotating discs, membranes, and RPBs.

2. RPB Advantages and Configurations

| Type of Rotor | CCF | Improvements | Patent No. | Inventor(s) | Published Year |

|---|---|---|---|---|---|

| Single | CC | Contact zone and seals | US 2,172,222 | W. J. Podbielniak [41] | 1939 |

| Contact zone | US 2,281,796 | W. J. Podbielniak [42] | 1935 | ||

| US 2,758,783 | W. J. Podbielniak [43] | 1951 | |||

| US 2,878,993 | W. J. Podbielniak [44] | 1959 | |||

| US 2,941,872 | C. W. Pilo et al. [45] | 1960 | |||

| US 3,034,730 | C. W. Pilo et al. [46] | 1962 | |||

| Contact zone, reduced entrainment | US 3,233,880 | W. J. Podbielniak [47] | 1962 | ||

| Multi-rotor | Contact zone, increased capacity | US 3,344,981 | W. J. Podbielniak [48] | 1965 | |

| Single | Contact zone | US 3,415,501 | C. W. Pilo et al. [49] | 1965 | |

| Multi-rotor | Contact zone, increased capacity | US 3,486,743 | D. B. Todd [50] | 1967 | |

| Single | CC & COC | Contact zone | US 4,283,255 | C. Ramshaw and R. H. Mallinson [8] | 1981 |

| Single | CC | US 4,397,794 | C. W. Pilo [51] | 1981 | |

| Single | Liquid distribution and contact zone | US 6,884,401 B2 | S. Yang et al. [52] | 2002 | |

| Multi-rotor | Contact zone | US 7,344,126 B2 | J Ji et al. [53] | 2004 | |

| Single | CC & COC | US 8,448,926 B2 | M. D. Mello et al. [54] | 2011 | |

| Multi-rotor | US 20130319235A1 | H. Wolf et al. [55] | 2012 | ||

| Single | CC | US 20160317967 A1 | M. Kotagiri et al. [56] | 2016 | |

| Single | US 20170028311A1 | B. K. Namdeo et al. [57] | 2017 | ||

| Two stages | US 20170157554A1 | C. H. Yu and C. S Tan [58] | 2017 | ||

| Multi-rotor | CC & COC | US20180016159A1 | M. V. D. e Mello et al. [59] | 2018 |

- less maintenance due to their static seal;

- possibility of multiple feeds and more flexibility;

- no need for liquid distributers;

- more liquid hold-up and residence time;

- multi-rotor operability on one shaft.

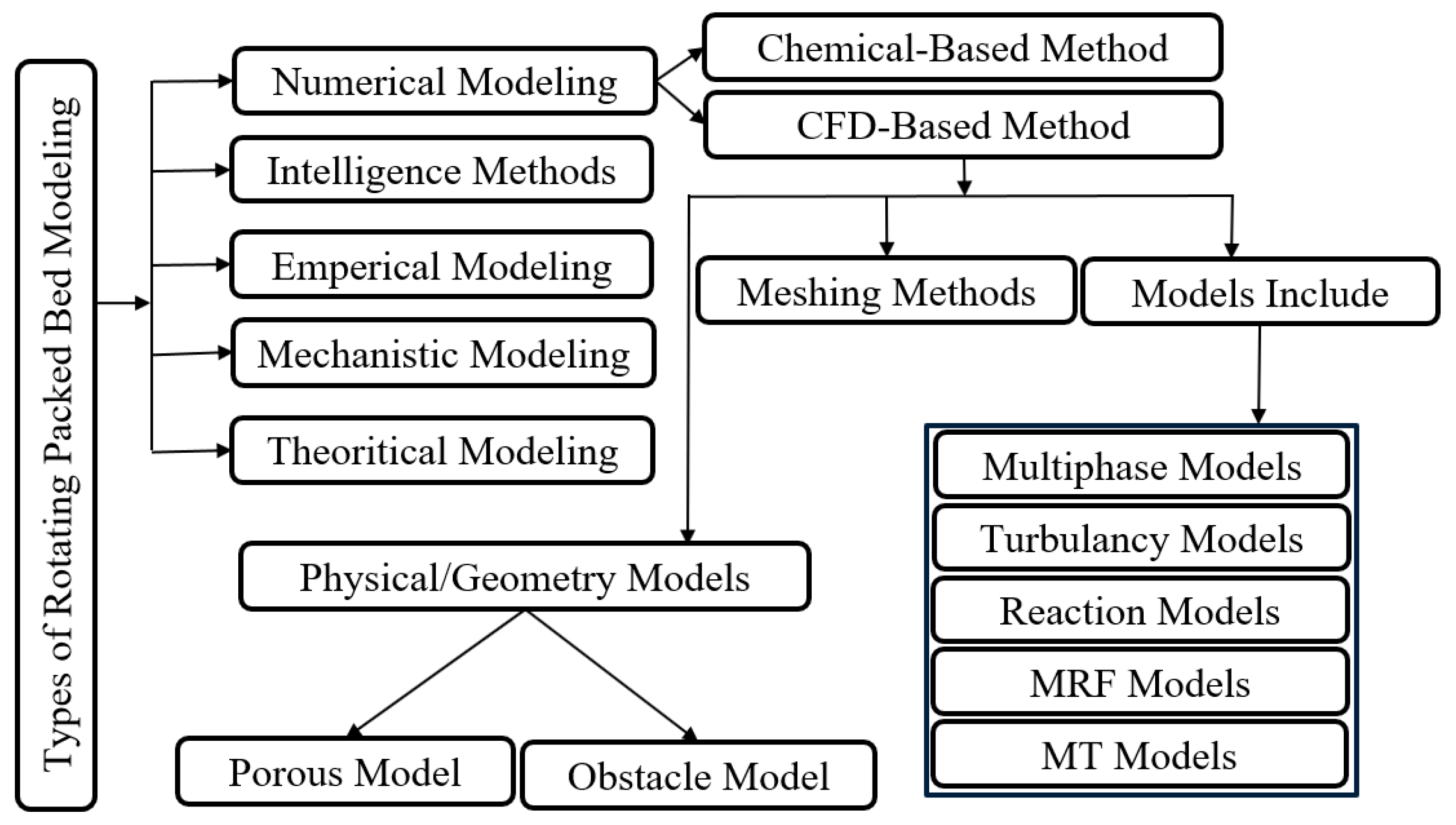

3. Modeling Rotating Packed Beds

3.1. Hydrodynamic Modeling

3.1.1. Liquid Behavior and Hold-Up

| Author | Year | RPB Type | Kind of Packing | Liquid Form | Correlation |

|---|---|---|---|---|---|

| Burns et al. [92] | 2000 | Glass sphere | : Inertia flow : Viscos flow | ||

| C. C. Lin et al. [93] | 2000 | Glass sphere | , | ||

| Chen et al. [33] | 2003 | Metal wire mesh | For complete wetted packing: For partial wetted packing: | ||

| Yi et al. [94] | 2009 | Wire mesh | Droplet | , Cavity zone Bulk zone | |

| Li et al. [95] | 2009 | Film | |||

| Yang et al. [96] | 2010 | Droplet | |||

| Sang et al. [91] | 2017 | For cavity zone | |||

| Sang et al. [97] | 2019 | Simple | Wire mesh | End-effect zone Bulk zone | |

| Wang et al. [98] | Bulk zone Cavity zone | ||||

| Su et al. [99] | 2020 | Metal wire mesh |

- a0: 100 m/s2

- u0: 0.01 m/s

- ν0: 1CS or 10−6 m2/s

3.1.2. Flooding and Pressure Drop

| RPB Type | Year | Kind of Packing | Flows Contacting | Correlation | Div. (%) | Refs. |

|---|---|---|---|---|---|---|

| CRB | 2009 | Concentric ring | Cross-current | , , | ±20 | [128] |

| Simple | 2009 | Wire mesh | Counter-current | ±5 | [129] | |

| Simple | 2010 | Plastic porous plate packing Rippled porous plate packing | Cross-current | ±10 | [130] | |

| RZB | 2013 | Stationary and rotating baffle | Counter-current | 4.02–12.38 3.20–11.32 | [131] | |

| Simple | 2017 | Wire mesh, Sumitomo, foam metal | Counter-current | 7.24 | [106] | |

| Simple | 2017 | Knit meshes and metal foams | Counter-current | , | ±15 | [80] |

3.2. Mass Transfer and Performance Modeling

3.2.1. Mass Transfer Coefficients and Removal Efficiency

| Type of RPB | Absorbent | Absorbing Component | MT Correlations | Div.% | Year | Refs. |

|---|---|---|---|---|---|---|

| CCSR | --- | O2 desorption | ±10 | 2002 | [155] | |

| CCSR | Water | VOC | ±30 | 2002 | [145] | |

| CCSR | Water | VOC | ±30 | 2004 | [156] | |

| CCSR | --- | O2 desorption | ±30 | 2005 | [157] | |

| CCSR | --- | O2 desorption | ±30 | 2005 | [147] | |

| RSB | NaOH | SO2 | For co-rotation: For counter-rotation | ±20 | 2006 | [134] |

| Blade | Water | IPA | ±10 | 2007 | [155] | |

| CRCSR | NaOH | CO2 | Plastic porous plate Steal rippled porous plate | ±10 | 2010 | [130] |

| CCSR | Water | Ammonia and VOC | ±30 | 2011 | [158] | |

| COCSR | NH3 based sol. | SO2 | ±8 | 2014 | [39] | |

| CCSR | A.S | SO2 | SiC structured packing Plastic structured packing | ±5 ±10 | 2015 | [159] |

| CRCSR | NaOH | CO2 | ±10 | 2015 | [160] | |

| CCSR | TEG | H2O | ±20 | 2018 | [161] | |

| CCSR | NaOH | SO2 | ±20 | 2018 | [162] | |

| CCSR | Na2SO3 | SO2 | ±15 | 2018 | [142] | |

| COCSR | NaClO | VOC | ±30 | 2018 | [163] | |

| CCSR | MEA | CO2 | Bulk and end-effect zone Cavity zone | ±20 | 2019 | [97] |

3.2.2. Effective Interfacial Surface Area and Performance

| Author | Year | RPB type | Packing | System | Correlation | Div. % |

|---|---|---|---|---|---|---|

| Rajan et al. [121] | 2011 | RSB | MF | NaOH-CO2 | : for co-rotation : for counter-rotation | ±15 |

| Dong et al. [160] | 2015 | Simple | SSWM | ±10 | ||

| Chen et al. [149] | 2016 | Simple | PTFE WM | : for PWP : for KWP | ±20 | |

| Luo et al. [154] | 2017 | CCSR | SSWM | ±15 | ||

| Xie et al. [170] | 2019 | Simple | Expanded SS mesh | MEA | ±20 |

3.3. Numerical Methods

- Obstacle simplification (use of a simple geometry model or a representative elementary unit (REU), as used in [170];

- Porous areas (use of mathematical methods that include viscosity and inertia resistance, which appear as a source term in momentum equations), which are suitable for RPB simulation on pilot and industrial scales;

- Eddy viscosity models;

- Reynolds stress transport models (RSM).

- Taylor analogy breakup (TAB) for We < 100;

- Wave model for We > 100.

| Physical Model | Dimensions | Multiphase Model | Turbulence Model | Solving Approach | Scope | Published Year | Refs. |

|---|---|---|---|---|---|---|---|

| Obstacle | 2D and 3D | Single phase | Realizable k-ε | --- | Pressure field and gas flow characteristics analysis | 2010 | [176] |

| Porous | 3D | --- | Standard k-ε | --- | Pressure field and hydrodynamic analysis | 2012 | [177] |

| Obstacle | 2D | Single phase | Standard k-ε | SIMPLE | Hydrodynamic analysis | 2013 | [184] |

| Obstacle | 2D | VOF | RSM | SIMPLE | Hydrodynamic analysis | 2013 | [178] |

| Porous | 3D | Euler | Standard k-ε | --- | Hydrodynamic analysis | 2013 | [185] |

| Obstacle | 2D | DPM | RNG k-ε | SIMPLE | Mixing and droplet size analysis | 2014 | [179] |

| Obstacle | 3D | VOF | RNG k-ε | PISO/ PRESTO | Hydrodynamic and MT analysis | 2014 | [180] |

| Obstacle | 2D | VOF | RSM | SIMPLE | Micro-mixing efficiency analysis | 2016 | [186] |

| Obstacle | 2D | VOF | --- | PISO/ PRESTO | Hydrodynamic and MT analysis | 2017 | [187] |

| Real | 3D | Single phase | Realizable k-ε | --- | Pressure drop and gas flow characteristics analysis | 2017 | [183] |

| Obstacle | 2D | VOF | SST k-ω | PISO/ PRESTO | Hydrodynamic analysis | 2017 | [188] |

| Obstacle | 2D & 3D | VOF | Realizable k-ε, RSM, k-ω | SIMPLE | Hydrodynamic and droplet size analysis | 2017 | [189] |

| Obstacle | 2D | VOF | Realizable k-ε | SIMPLE/PRESTO | Micro-mixing efficiency analysis | 2018 | [190] |

| Porous | 2D and 3D | Single phase | Realizable k-ε | SIMPLE | Gas flow characteristics analysis | 2018 | [191] |

| Obstacle | 2D | VOF | Standard k-ε | SIMPLE | Hydrodynamic analysis | 2018 | [192] |

| Obstacle | 3D | Single phase | Standard k-ε | SIMPLE/PRESTO | Droplet behaviors | 2019 | [193] |

| Obstacle | 2D | VOF | Realizable k-ε | PISO | Hydrodynamic analysis | 2019 | [194] |

| Obstacle | 2D | VOF | Realizable k-ε | SIMPLE/PRESTO | Micro-mixing efficiency analysis | 2019 | [195] |

| Obstacle | 2D | VOF | Realizable k-ε | SIMPLE/PRESTO | Hydrodynamic analysis | 2019 | [66] |

| Obstacle | 2D | VOF | RSM | PISO/ PRESTO | MT analysis | 2016 | [181] |

| Real | 2D | VOF, Euler | RSM, LES | --- | Hydrodynamic and liquid behavior analysis | 2019 | [196] |

| REU | 3D | VOF | SST k-ω | PISO | Hydrodynamic analysis | 2019 | [170] |

| Obstacle | 3D | VOF | SST k-ω | SIMPLE | Hydrodynamic and liquid behavior analysis | 2019 | [197] |

| Real | 3D | Single phase | Realizable k-ε | SIMPLE C/PRESTO | Gas flow characteristics analysis | 2020 | [198] |

4. Dimensional Analysis

- Brute force;

- Rate model.

- liquid films λ < 60 g;

- liquid droplets and small filaments λ > 100 g.

5. Power Consumption

6. Future Perspective

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| a | Effective gas–liquid surface (interfacial) area per unit volume of the packed bed, m2/m3 |

| ac | Centrifugal acceleration, m/s2 |

| ae,as | Specific surface area, m2/m3 |

| at | Surface area of the packing per unit volume of the bed, m2/m3 |

| aw | Wetted surface area, m2/m3 |

| A, B, C | Experimental constant, |

| Ci, CO2 | Absorbing component (CO2) inlet concentration, ppm |

| Co, CO2 | Absorbing component (CO2) outlet concentration, ppm |

| Ca | Concentration of absorbent media, mol/L or g/L |

| Cs | Concentration of absorbent salt, g/L |

| CCO2* | |

| d | Diameter of packing or equivalent spherical diameter , m |

| db | Average droplet diameter in bulk zone, m |

| de | Average droplet diameter in end zone, m |

| dh | Hydraulic diameter, m |

| di | Inner diameter of RZB rotor, m |

| do | Inner diameter of RZB rotor, m |

| dp | Pore diameter, mm |

| dN | Diameter of nozzles, mm |

| dw | Dimeter of wire/fiber, mm |

| Average diameter of droplet, mm | |

| d1 | Diameter of droplet at demarcation point, m |

| D | Diffusivity of the phase, m2/s |

| Di | Inner diameter of the casing of rotating bed, m |

| E | Reaction enhancement factor |

| Ei | Instantaneous reaction enhancement factor |

| f | Friction factor in RPB or friction coefficient of mechanical seal in RZBs |

| fd | The fraction of volume the liquid distributer occupies in the inner radius of RPBs |

| fG | Dry resistance coefficient, which depends on the QG and ω |

| fw | Wetted resistance coefficient, which depends on QL, ω and β, |

| Fv | F-factor, kg1/2/m1/2s |

| g | Gravitational acceleration of earth, m/s2 |

| G | Gas mass flow rate, kg/s or kg/h |

| h | The (axial) height of packing in RPBs or the height of the annual space at the inner edge of the RZB‘s rotor, m |

| hc | The height of the concentric rings, rotors and packing beds in CRBs, m |

| hf | The minimum height of the RPB required to prevent its operation in a flooding regime |

| H | Henry’s constant, atm.m3/mol |

| Hs | Solubility coefficient of CO2 in solution, kmol/m3·Pa |

| HTU | Height of a transfer unit, m |

| kG | Gas phase mass transfer coefficient, g mol/(atm·m2·s) |

| kL | Liquid phase mass transfer coefficient, m/s |

| k1 | Reaction rate constant, m3/s |

| k2 | Second-order rate of reaction, m3/kmol·s |

| K | Collision kinetic energy loss |

| KGa | Overall volumetric gas phase mass transfer coefficient, gmol/(atm·m3·s) |

| KLa | Overall volumetric liquid phase mass transfer coefficient, 1/s |

| K1 | Departure coefficient of gas (the departure of power for a real liquid flow with a gas flow equal to zero) in RZBs |

| K2 | Departure coefficient of real liquid (the departure of power for a real liquid flow from that of the ideal liquid flow when no gas flows through the rotor) in RZBs |

| kR | Pseudo first-order rate constant, 1/s |

| L, | Liquid mass flow rate, kg/s or kg/h |

| Lp | Perimeter of rotational baffle channel in contact with fluid, m |

| Mass flow rate, kg/s or ton/h | |

| n or N | Rotational speed, rpm and number |

| NG | Power requirement for a gas flow through the rotor, W |

| Ni | Absorption rate of a component, kmol/m2·s |

| NL | Power requirement for the liquid flow through the rotor, including liquid acceleration and friction losses, W |

| NLD | Power transmitted to liquid flow by a rotation disk and rotational baffles for the ideal liquid flow at a zero gas flow, W |

| NLR | Power requirement for a liquid flow at a zero gas flow, W |

| NM | Power requiremnt due to mechanical friction, proportional to ω, W |

| Nw | Power requiremnt due to frictional windage drag of a rotor, proportional to ω1.5, W |

| Ntot | Total power (Load) consumption, W |

| NT | Number of theoretical trays |

| Pc | Pressing pressure between the stationary and rotational rings in RZBs |

| ΔP | Total pressure drop, kPa |

| ΔPc | Pressure drop due to centrifugal force, kPa |

| ΔPcw | Wet pressure drop due to centrifugal force without a gas flow, kPa |

| ΔPd | Dry pressure drop, kPa |

| ΔPf | Pressure drop due to frictional force, kPa |

| ΔPk | Pressure drop due to kinetic energy, kPa |

| ΔPm | Pressure drop due to momentum gain by gas radial motion in rotors, kPa |

| ΔPw | Wet pressure drop, kPa |

| ΔPTs | Total pressure drop through stationary rotors (of RSBs), kPa |

| q | Dimensionless initial velocity of liquid |

| Q | Flow rate, m3/h |

| QC, CO2 | Captured CO2, L/min |

| QCO2 | CO2 flow rate, L/min |

| Qm | Minimum wetting rate of packing, m3/m·h |

| Qs | Specific flow rate, m3/h |

| r | Radius of packing or coordinate direction parallel to disk surface, m |

| ravg | Average radius of a packed bed, m |

| rRB | Radius of rotational baffle in RZBs, m |

| ri | Inside radial length of packing, mm |

| ro | Outside radial length of packing, mm |

| rh | Hydraulic radius, m |

| rs | Radius of the stationary housing, m |

| rM1 | Outer radius of the annular face with a stationary ring against the rotating ring in RZBs, m |

| rM2 | Inner radius of the annular face with a stationary ring against the rotating ring in RZBs, m |

| Δr | Distance between the rotational and stationary baffles, m |

| RCO2 | Rate of CO2 absorption per unit volume, mol/m3·s |

| Ri | Inner rotor radius, m |

| Ro | Outer rotor diameter, m |

| Rp | Quadratic mean of radius of packing, m |

| s | Number of packing splits in RSB |

| S | Area of rotational baffle channel through which fluid passes in a radial direction, m2 |

| t | Treatment time, min |

| T | Temperature, K |

| Liquid mean radial velocity, m/s | |

| uL,r | Liquid velocity in the radial direction, m/s |

| ug | Gas superficial velocity, m/s |

| uL,s | Liquid superficial velocity, m/s |

| ujet | Liquid jet velocity, m/s |

| u0 | Liquid initial velocity, m/s |

| uθ | Gas tangential velocity, m/s |

| Vb | Packing volume = , m3 |

| Vi | Volume inside the inner radius of the bed, m3 |

| Vo | Volume between the outer radius of the bed and the stationary housing, m3 |

| VL | The volume held by liquid in the packing, m3 |

| WTEG | TEG concentration, % |

| Y | Mole fraction, % |

| Yi | Mole fraction of a component in the inlet gas stream, % |

| Yo | Mole fraction of a component in the outlet gas stream, % |

| Yw | Mole fractions of water in a gas phase, % |

| Y* | Gas phase mole fraction of CO2 in equilibrium with the concentration of CO2 in liquid |

Abbreviations

| AMP | 2-amino-2-mthyl-1-propanol |

| ATU | area per transfer unit, m2 |

| CCD | Charge-coupled device camera |

| CRB | Concentric ring rotating bed |

| DEA | Diethanolamine |

| DEAB | 4-diethylamino-2-butanol |

| DEEA | N,N-diethyl ethanolamine |

| DIPA | Diisopropandamine |

| DMEA | N,N-dimethyl ethanolamine |

| 1DMA2P | 1-dimethylamino-2-propanol |

| DO | Dissolved oxygen in water |

| GS | Gamma scanning |

| LDV | Laser doppler velocimetry |

| LIF | Laser-induced fluorescence |

| LES | Large eddy simulation |

| IPA | Isopropyl alcohol |

| HETP | Height equivalent to a theoretical plate |

| MEA | Monoethanolamine |

| MDEA | Methyldiethanolamine |

| NMP | N-methyl-2-pyrrolidone |

| NTU | number of transfer units |

| PIV | Particle image velocimetry |

| PZ | Piperazine |

| RSB | Rotating split bed |

| RTNR | Real-time neutron radiography |

| RZB | Rotating zigzag bed |

| SST | Shear–stress transport |

| TEG | Triethylene glycol |

| VOF | Volume of fluid |

| XCT | X-ray computational tomography scanner |

| Greek Letters | |

| β | Liquid hold-up, volume of liquid sustained per unit volume of packing, dimensionless |

| βv | mean saturation of packing, the ratio of the overall liquid volume and of the PB total void volume |

| <β> | radial saturation mean of the RPB |

| γ | Contacting angle, degree |

| δ | Liquid film thickness, m |

| Mean thickness of liquid, m | |

| ε | Porosity of packing |

| ζ | Liquid maldistribution of injector, % |

| ν | Kinematic viscosity of liquid, m2/s |

| ρ | density, kg/m3 |

| ω | Angular speed, rad/s or s−1 |

| σ | Surface tension of liquid, N/m or kg/s2 |

| σw | Surface tension of water in 25 °C, 0.072 kg/s2 |

| σc | Critical surface tension of packing, N/m or kg/s2 |

| ξ | the ratio of liquid jet to the exit-gas kinetic energy |

| φ | Fractional opening area of rotational baffle in RZBs, dimensionless shape factor number |

| λ | Gravity factor |

| τ | Gas treatment capacity of packing, 1/hr |

| Subscripts | |

| B, b | Packing |

| L | Liquid phase |

| G | Gas phase |

| W | Water |

| IMZ | Inner wire mesh packing zone |

| OPZ | Outer resin pin zone |

| Dimensionless groups | |

| A | Absorption factor, |

| Ca | Capillary number |

| Froude number | |

| Galileo number | |

| Hatta numbers | (where k is reaction rate constant of CO2, m3/kmol·s in case of NaOH solution) |

| Hy | Dimensionless Henry’s constant |

| Kapitza number | |

| Modified Galileo number | |

| Molar Ratio | |

| Ohnesorge number | |

| Reynolds number | |

| Particle Reynolds number | |

| Rotational Reynolds number | |

| Schmidt number | |

| Weber number | |

References

- Reay, D. The Role of Process Intensification in Cutting Greenhouse Gas Emissions. Appl. Therm. Eng. 2008, 28, 2011–2019. [Google Scholar] [CrossRef]

- Harmsen, J. Process Intensification in the Petrochemicals Industry: Drivers and Hurdles for Commercial Implementation. Chem. Eng. Process. Process Intensif. 2010, 49, 70–73. [Google Scholar] [CrossRef]

- Keil, F.J. Process Intensification. Rev. Chem. Eng. 2018, 34, 135–200. [Google Scholar] [CrossRef] [Green Version]

- Neumann, K.; Gladyszewski, K.; Groß, K.; Qammar, H.; Wenzel, D.; Górak, A.; Skiborowski, M. A Guide on the Industrial Application of Rotating Packed Beds. Chem. Eng. Res. Design. 2018, 134, 443–462. [Google Scholar] [CrossRef]

- Stankiewicz, A.I.; Moulijn, J.A. Process Intensification: Transforming Chemical Engineering. Chem. Eng. Prog. 2000, 96, 22–34. [Google Scholar]

- Rao, D.P. The Story of “HIGEE”. Indian Chem. Eng. 2015, 57, 282–299. [Google Scholar] [CrossRef]

- Ehinmowo, A.; Aliyu, A.; Alagbe, S.; Adedipe, O.; Olumi, O. Offshore Topside Rotating Packed Bed as Process Intensified Alternative for Natural Gas Sweetening and Dehydration. Am. Chem. Sci. J. 2015, 8, 1–12. [Google Scholar] [CrossRef]

- Ramshaw, C.; Mallinson, R.H. Mass Transfer Process. U.S. Patent 4,283,255A, 11 August 1981. [Google Scholar]

- Peel, J.; Howarth, C.R.; Ramshaw, C. Process Intensification: Higee Seawater Deaeration. Chem. Eng. Res. Des. 1998, 76, 585–593. [Google Scholar] [CrossRef]

- Garcia, G.E.C.; Van Der Schaaf, J.; Kiss, A.A. A Review on Process Intensification in HiGee Distillation. J. Chem. Technol. Biotechnol. 2017, 92, 1136–1156. [Google Scholar] [CrossRef] [Green Version]

- Guo, J.; Jiao, W.; Qi, G.; Yuan, Z.; Liu, Y. Applications of High-Gravity Technologies in Gas Purifications: A Review. Chin. J. Chem. Eng. 2019, 27, 1361–1373. [Google Scholar] [CrossRef]

- Merkel, T.C.; Lin, H.; Wei, X.; Baker, R. Power Plant Post-Combustion Carbon Dioxide Capture: An Opportunity for Membranes. J. Memb. Sci. 2010, 359, 126–139. [Google Scholar] [CrossRef]

- Kunze, C.; Spliethoff, H. Assessment of Oxy-Fuel, Pre- and Post-Combustion-Based Carbon Capture for Future IGCC Plants. Appl. Energy 2012, 94, 109–116. [Google Scholar] [CrossRef]

- Kang, J.L.; Wong, D.S.H.; Jang, S.S.; Tan, C.S. A Comparison between Packed Beds and Rotating Packed Beds for CO2 Capture Using Monoethanolamine and Dilute Aqueous Ammonia Solutions. Int. J. Greenh. Gas Control 2016, 46, 228–239. [Google Scholar] [CrossRef]

- Yeh, J.T.; Pennline, H.W.; Resnik, K.P. Study of CO2 Absorption and Desorption in a Packed Column. Energy Fuels 2001, 15, 274–278. [Google Scholar] [CrossRef]

- Pourkargar, D.B.; Shahri, S.M.K.; Rioux, R.M.; Armaou, A. Spatiotemporal Modeling and Parametric Estimation of Isothermal CO2 Adsorption Columns. Ind. Eng. Chem. Res. 2016, 55, 6443–6453. [Google Scholar] [CrossRef]

- Rosli, S.S.; Wong, C.Y.; Yunus, N.M.; Lam, M.K.; Show, P.L.; Cheng, C.K.; Wang, D.K.; Da Oh, W.; Lim, J.W. Optimum Interaction of Light Intensity and CO2 Concentration in Bioremediating N-Rich Real Wastewater via Assimilation into Attached Microalgal Biomass as the Feedstock for Biodiesel Production. Process Saf. Environ. Prot. 2020, 141, 355–365. [Google Scholar] [CrossRef]

- Harbold, G.; Park, J. Using the GasTran Deaeration System to Achieve Low Dissolved Oxygen Levels for Superior Line Speed and Product Quality: A Case Study in Carbonated Soft Drink Bottling. In Proceedings of the 7th International Conference on Process Intensification, Albany, NY, USA, 15–17 September 2008. [Google Scholar]

- Hosseinzadeh, A.; Hosseinzadeh, M.; Vatani, A.; Mohammadi, T. Mathematical Modeling for the Simultaneous Absorption of CO2 and SO2 Using MEA in Hollow Fiber Membrane Contactors. Chem. Eng. Process. Process Intensif. 2017, 111, 35–45. [Google Scholar] [CrossRef]

- Thiels, M.; Wong, D.S.; Yu, C.-H.; Kang, J.-L.; Jang, S.S.; Tan, C.-S. Modelling and Design of Carbon Dioxide Absorption in Rotating Packed Bed and Packed Column. IFAC-PapersOnLine 2016, 49, 895–900. [Google Scholar] [CrossRef]

- Cheng, H.-H.; Lai, C.-C.; Tan, C.-S. Thermal regeneration of alkanolamine solutions in a rotating packed bed. Int. J. Greenh. Gas Control. 2013, 16, 206–216. [Google Scholar] [CrossRef]

- Mohammaddoost, H.; Azari, A.; Ansarpour, M.; Osfouri, S. Experimental investigation of CO2 removal from N2 by metal oxide nanofluids in a hollow fiber membrane contactor. Int. J. Greenh. Gas Control. 2018, 69, 60–71. [Google Scholar] [CrossRef]

- Luo, Y.; Luo, J.-Z.; Yue, X.-J.; Song, Y.-J.; Chu, G.-W.; Liu, Y.; Le, Y.; Chen, J.-F. Feasibility studies of micromixing and mass-transfer in an ultrasonic assisted rotating packed bed reactor. Chem. Eng. J. 2018, 331, 510–516. [Google Scholar] [CrossRef]

- Song, C.; Liu, Q.; Ji, N.; Deng, S.; Zhao, J.; Li, Y.; Song, Y.; Li, H. Alternative pathways for efficient CO2 capture by hybrid processes—A review. Renew. Sustain. Energy Rev. 2018, 82, 215–231. [Google Scholar] [CrossRef]

- Sang, L.; Luo, Y.; Chu, G.-W.; Liu, Y.-Z.; Liu, X.-Z.; Chen, J.-F. Modeling and experimental studies of mass transfer in the cavity zone of a rotating packed bed. Chem. Eng. Sci. 2017, 170, 355–364. [Google Scholar] [CrossRef]

- Yue, X.-J.; Luo, Y.; Chen, Q.-Y.; Chu, G.-W.; Luo, J.-Z.; Zhang, L.-L.; Chen, J.-F. Investigation of micromixing and precipitation process in a rotating packed bed reactor with PTFE packing. Chem. Eng. Process. Process. Intensif. 2018, 125, 227–233. [Google Scholar] [CrossRef]

- Guo, F.; Zheng, C.; Guo, K.; Feng, Y.; Gardner, N.C. Hydrodynamics and mass transfer in cross-flow rotating packed bed. Chem. Eng. Sci. 1997, 52, 3853–3859. [Google Scholar] [CrossRef]

- Liu, H.-S.; Lin, C.-C.; Wu, S.-C.; Hsu, H.-W. Characteristics of a Rotating Packed Bed. Ind. Eng. Chem. Res. 1996, 35, 3590–3596. [Google Scholar] [CrossRef]

- Tsai, C.-Y.; Chen, Y.-S. Effective interfacial area and liquid-side mass transfer coefficients in a rotating bed equipped with baffles. Sep. Purif. Technol. 2015, 144, 139–145. [Google Scholar] [CrossRef]

- Munjal, S.; Dudukovć, M.P.; Ramachandran, P. Mass-transfer in rotating packed beds—I. Development of gas—liquid and liquid—solid mass-transfer correlations. Chem. Eng. Sci. 1989, 44, 2245–2256. [Google Scholar] [CrossRef]

- Munjal, S.; Duduković, M.P.; Ramachandran, P. Mass-transfer in rotating packed beds—II. Experimental results and comparison with theory and gravity flow. Chem. Eng. Sci. 1989, 44, 2257–2268. [Google Scholar] [CrossRef]

- Lin, C.C.; Chien, K.S. Mass-Transfer Performance of Rotating Packed Beds Equipped with Blade Packings in VOCs Absorption into Water. Sep. Purif. Technol. 2008, 63, 138–144. [Google Scholar] [CrossRef]

- Chen, Y.H.; Chang, C.Y.; Su, W.L.; Chen, C.C.; Chiu, C.Y.; Yu, Y.H.; Chiang, P.C.; Chiang, S.I.M. Modeling Ozone Contacting Process in a Rotating Packed Bed. Ind. Eng. Chem. Res. 2004, 43, 228–236. [Google Scholar] [CrossRef]

- Jassim, M.S.; Rochelle, G.; Eimer, D.; Ramshaw, C. Carbon Dioxide Absorption and Desorption in Aqueous Monoethanolamine Solutions in a Rotating Packed Bed. Ind. Eng. Chem. Res. 2007, 46, 2823–2833. [Google Scholar] [CrossRef]

- Zheng, C.; Guo, K.; Feng, Y.; Yang, C.; Gardner, N.C. Pressure Drop of Centripetal Gas Flow through Rotating Beds. Ind. Eng. Chem. Res. 2000, 39, 829–834. [Google Scholar] [CrossRef]

- Sandilya, P.; Rao, D.P.; Sharma, A.; Biswas, G. Gas-Phase Mass Transfer in a Centrifugal Contactor. Ind. Eng. Chem. Res. 2001, 40, 384–392. [Google Scholar] [CrossRef]

- Cheng, H.H.; Tan, C.S. Carbon Dioxide Capture by Blended Alkanolamines in Rotating Packed Bed. Energy Procedia 2009, 1, 925–932. [Google Scholar] [CrossRef] [Green Version]

- Lin, C.C.; Lin, Y.H.; Tan, C.S. Evaluation of Alkanolamine Solutions for Carbon Dioxide Removal in Cross-Flow Rotating Packed Beds. J. Hazard. Mater. 2010, 175, 344–351. [Google Scholar] [CrossRef]

- Chu, G.W.; Luo, Y.; Shan, C.Y.; Zou, H.K.; Xiang, Y.; Shao, L.; Chen, J.F. Absorption of SO2 with Ammonia-Based Solution in a Cocurrent Rotating Packed Bed. Ind. Eng. Chem. Res. 2014, 53, 15731–15737. [Google Scholar] [CrossRef]

- Lin, C.-C.; Chen, B.-C. Carbon Dioxide Absorption into NaOH Solution in a Cross-Flow Rotating Packed Bed. J. Ind. Eng. Chem. 2007, 13, 1083–1090. [Google Scholar]

- Podbielniak, W.J. Centrifugal Fluid-Treating Apparatus and Seal. Google Pat. 2172222, 5 September 1939. [Google Scholar]

- Podbielniak, W.J. Art of Effecting Countercurrent Contact between Fluids. U.S. Patent 2,281,796, 8 March 1935. [Google Scholar]

- Podbielniak, W.J. Centrifugal Countercurrent Exchange Device. U.S. Patent 2758783A, 5 November 1951. [Google Scholar]

- Podbielniak, W.J. Centrifugal Countercurrent Contacting Method and Apparatus. U.S. Patent 2878993, 5 July 1959. [Google Scholar]

- Wilhelm, P.C.; Wilhelm, D.S. Apparatus for Intimate Contacting of Two Fluid Media Having Different Specific Weight. U.S. Patent 2,941,872, 9 June 1960. [Google Scholar]

- Pilo, C.W.; Dahlbeck, S.W. Means for the Distribution of a Liquid on Rotating Surfaces. U.S. Patent 3034730, 23 September 1962. [Google Scholar]

- Podbielniak, W.J. Continuous Centrifugal Vaporliquid Contactor. U.S. Patent 3,233,880, 3 August 1962. [Google Scholar]

- Podbielniak, W.J. Centrifugal Apparatus with Axially-Extended Rotor. U.S. Patent 3,344,981, 8 February 1965. [Google Scholar]

- Pilo, C.W. Centrifugal Contact Apparatus. U.S. Patent 3,415,501, 27 December 1965. [Google Scholar]

- Todd, D.B. Multistage Vapor-Liquid Contactor. U.S. Patent 3,486,743, 16 June 1967. [Google Scholar]

- Pilo, C.W. Rotary Gas Washers. U.S. Patent 4,397,794, 7 December 1981. [Google Scholar]

- Yang, S.; Lin, C.-C.; Tseng, I.-M.; Liu, W.-T.; Yu, H.-T. Method for Removing Volatile Components from a High Viscosity Liquid by Using Rotation Pack Bed. U.S. Patent 6,884,401 B2, 17 July 2002. [Google Scholar]

- Ji, Z.J.; Xu, Y.Y. Equipment of Zigzag High-Gravity Rotating Beds. U.S. Patent 7,344,126 B2, 12 April 2004. [Google Scholar]

- Marcus, D.E.M.; Mannel, L.; Krishniah, P.; David, B. Liquid Distributor for a Rotating Packed Bed. U.S. Patent 8,448,926 B2, 9 June 2011. [Google Scholar]

- Hartwing, W.; Petar, A.; Klaus Ennebach, M.H.T. Rotating Packed Bed. U.S. Patent 20130319235A1, 3 August 2012. [Google Scholar]

- Murali, K.; Namdeo, B.K.; Gandham, S.G.; Sheshachala, S.N.; Annaji, R.K.T. Rotating Packed Bed Unit. U.S. Patent 2016/0317967 A1, 16 November 2016. [Google Scholar]

- Namdeo, B.K.; Gandham, G.; Sheshachala, S.N.; Annaji, R.K.T. Rotating Packed Bed Assembly. U.S. Patent 20170028311A1, 2 February 2017. [Google Scholar]

- Tan, C.H.; Yu, C.S. Apparatus for Absorbing a Component from a Gas Mixture. U.S. Patent 20170157554A1, 8 June 2017. [Google Scholar]

- E Mello, M.V.D.; Huang, H.-M. System and Methods for Deaerating Sea Water Using a Rotating Packed Bed. U.S. Patent 20180016159A1, 18 January 2018. [Google Scholar]

- Lin, C.C.; Chu, C.R. Feasibility of Carbon Dioxide Absorption by NaOH Solution in a Rotating Packed Bed with Blade Packings. Int. J. Greenh. Gas Control 2015, 42, 117–123. [Google Scholar] [CrossRef]

- Liu, Y.; Gu, D.; Xu, C.; Qi, G.; Jiao, W. Mass Transfer Characteristics in a Rotating Packed Bed with Split Packing. Chin. J. Chem. Eng. 2015, 23, 868–872. [Google Scholar] [CrossRef]

- Wang, G.Q.; Xu, O.G.; Xu, Z.C.; Ji, J.B. New HIGEE-Rotating Zigzag Bed and Its Mass Transfer Performance. Ind. Eng. Chem. Res. 2008, 47, 8840–8846. [Google Scholar] [CrossRef]

- Lin, C.C.; Chen, B.C.; Chen, Y.S.; Hsu, S.K. Feasibility of a Cross-Flow Rotating Packed Bed in Removing Carbon Dioxide from Gaseous Streams. Sep. Purif. Technol. 2008, 62, 507–512. [Google Scholar] [CrossRef]

- Kapitza, P.L. Rectification Apparatus. U.S. Patent 2,593,763, 22 April 1952. [Google Scholar]

- Visscher, F.; Van Der Schaaf, J.; Nijhuis, T.A.; Schouten, J.C. Rotating Reactors-A Review. Chem. Eng. Res. Des. 2013, 91, 1923–1940. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, T.; Liu, Z.; Wang, S.; Gao, Y.; Wu, M. Mass Transfer in a Rotating Packed Bed: A Critical Review. Chem. Eng. Process. Process Intensif. 2019, 139, 78–94. [Google Scholar] [CrossRef]

- Wang, G.Q.; Zhou, Z.J.; Li, Y.M.; Ji, J.B. Qualitative relationships between structure and performance of rotating zigzag bed in distillation. Chem. Eng. Process. Process Intensif. 2019, 135, 141–147. [Google Scholar] [CrossRef]

- Chu, G.W.; Luo, Y.; Xing, Z.Y.; Sang, L.; Zou, H.K.; Shao, L.; Chen, J.F. Mass-Transfer Studies in a Novel Multiliquid-Inlet Rotating Packed Bed. Ind. Eng. Chem. Res. 2014, 53, 18580–18584. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, F.; Gu, D.; Qi, G.; Jiao, W.; Chen, X. Gas-Phase Mass Transfer Characteristics in a Counter Airflow Shear Rotating Packed Bed. Can. J. Chem. Eng. 2014, 53, 18580–18584. [Google Scholar] [CrossRef]

- Chamchan, N.; Chang, J.Y.; Hsu, H.C.; Kang, J.L.; Wong, D.S.H.; Jang, S.S.; Shen, J.F. Comparison of Rotating Packed Bed and Packed Bed Absorber in Pilot Plant and Model Simulation for CO2 Capture. J. Taiwan Inst. Chem. Eng. 2017, 73, 20–26. [Google Scholar] [CrossRef]

- Yu, C.H.; Chen, M.T.; Chen, H.; Tan, C.S. Effects of Process Configurations for Combination of Rotating Packed Bed and Packed Bed on CO2 Capture. Appl. Energy 2016, 175, 269–276. [Google Scholar] [CrossRef]

- Zhao, B.; Tao, W.; Zhong, M.; Su, Y.; Cui, G. Process, Performance and Modeling of CO2 Capture by Chemical Absorption Using High Gravity: A Review. Renew. Sustain. Energy Rev. 2016, 65, 44–56. [Google Scholar] [CrossRef]

- Saha, D. Prediction of Mass Transfer Coefficient in Rotating Bed Contactor (Higee) Using Artificial Neural Network. Heat Mass Transf. 2009, 45, 451–457. [Google Scholar] [CrossRef]

- Lashkarbolooki, M.; Vaferi, B.; Mowla, D. Using Artificial Neural Network to Predict the Pressure Drop in a Rotating Packed Bed. Sep. Sci. Technol. 2012, 47, 2450–2459. [Google Scholar] [CrossRef]

- Zhao, B.; Su, Y.; Tao, W. Mass Transfer Performance of CO2 Capture in Rotating Packed Bed: Dimensionless Modeling and Intelligent Prediction. Appl. Energy 2014, 136, 132–142. [Google Scholar] [CrossRef]

- Li, W.; Wei, S.; Jiao, W.; Qi, G.; Liu, Y. Modelling of Adsorption in Rotating Packed Bed Using Artificial Neural Networks (ANN). Chem. Eng. Res. Des. 2016, 114, 89–95. [Google Scholar] [CrossRef]

- Liu, Z.W.; Liang, F.N.; Liu, Y.Z. Artificial Neural Network Modeling of Biosorption Process Using Agricultural Wastes in a Rotating Packed Bed. Appl. Therm. Eng. 2018, 140, 95–101. [Google Scholar] [CrossRef]

- Liu, T.; Liu, Y.; Wang, D.; Li, Y.; Shao, L. Artificial neural network modeling on the prediction of mass transfer coefficient for ozone absorption in RPB. Chem. Eng. Res. Des. 2019, 152, 38–47. [Google Scholar] [CrossRef]

- Mirzaei, S.; Shamiri, A.; Aroua, M.K. A review of different solvents, mass transfer, and hydrodynamics for postcombustion CO2 capture. Rev. Chem. Eng. 2015, 31, 521–561. [Google Scholar] [CrossRef]

- Neumann, K.; Hunold, S.; Skiborowski, M.; Górak, A. Dry Pressure Drop in Rotating Packed Beds-Systematic Experimental Studies. Ind. Eng. Chem. Res. 2017, 56, 12395–12405. [Google Scholar] [CrossRef]

- Hendry, J.R.; Lee, J.G.M.; Attidekou, P.S. Pressure Drop and Flooding in Rotating Packed Beds. Chem. Eng. Process. Process Intensif. 2020, 151, 107908. [Google Scholar] [CrossRef]

- Burns, J.R.; Ramshaw, C. Process Intensification: Visual Study of Liquid Maldistribution in Rotating Packed Beds. Chem. Eng. Sci. 1996, 51, 1347–1352. [Google Scholar] [CrossRef]

- Yang, Y.; Xiang, Y.; Chu, G.; Zou, H.; Luo, Y.; Arowo, M.; Chen, J.F. A Noninvasive X-ray Technique for Determination of Liquid Holdup in a Rotating Packed Bed. Chem. Eng. Sci. 2015, 138, 244–255. [Google Scholar] [CrossRef]

- Kelleher, T.; Fair, J.R. Distillation Studies in a High-Gravity Contactor. Ind. Eng. Chem. Res. 1996, 35, 4646–4655. [Google Scholar] [CrossRef]

- Vásquez, P.A.S.; Costa, F.E.; Rela, P.R.; Calvo, W.A.P.; LeRoux, G.A.C.; Hamada, M.M. Gamma Scanning Evaluation for Random Packed Columns. In Proceedings of the IEEE Nuclear Science Symposium Conference Record, Fajardo, PR, USA, 23–29 October 2005. [Google Scholar] [CrossRef]

- Aferka, S.; Viva, A.; Brunazzi, E.; Marchot, P.; Crine, M.; Toye, D. Tomographic Measurement of Liquid Hold up and Effective Interfacial Area Distributions in a Column Packed with High Performance Structured Packings. Chem. Eng. Sci. 2011, 66, 3413–3422. [Google Scholar] [CrossRef]

- Gao, X.Y.; Chu, G.W.; Ouyang, Y.; Zou, H.K.; Luo, Y.; Xiang, Y.; Chen, J.F. Gas Flow Characteristics in a Rotating Packed Bed by Particle Image Velocimetry Measurement. Ind. Eng. Chem. Res. 2017, 56, 14350–14361. [Google Scholar] [CrossRef]

- Shoji, E.; Yamagiwa, K.; Kubo, M.; Tsukada, T.; Takami, S.; Sugimoto, K.; Ito, D.; Saito, Y.; Teratani, S. Flow Visualization of Heavy Oil in a Packed Bed Using Real-Time Neutron Radiography. Chem. Eng. Sci. 2019, 196, 425–432. [Google Scholar] [CrossRef]

- Li, H.; Yuan, Z.; Liu, Y.; Liu, H. Characteristics of Liquid Flow in a Countercurrent Rotating Bed. Chem. Eng. Process. Process Intensif. 2019, 136, 72–81. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y. Characteristics of Fin Baffle Packing Used in Rotating Packed Bed. Chin. J. Chem. Eng. 2010, 18, 55–60. [Google Scholar] [CrossRef]

- Sang, L.; Luo, Y.; Chu, G.W.; Zhang, J.P.; Xiang, Y.; Chen, J.F. Liquid Flow Pattern Transition, Droplet Diameter and Size Distribution in the Cavity Zone of a Rotating Packed Bed: A Visual Study. Chem. Eng. Sci. 2017, 158, 429–438. [Google Scholar] [CrossRef]

- Burns, J.R.; Jamil, J.N.; Ramshaw, C. Process Intensification: Operating Characteristics of Rotating Packed Beds-Determination of Liquid Hold-Up for a High-Voidage Structured Packing. Chem. Eng. Sci. 2000, 55, 2401–2415. [Google Scholar] [CrossRef]

- Lin, C.C.; Chen, Y.S.; Liu, H.S. Prediction of Liquid Holdup in Countercurrent-Flow Rotating Packed Bed. Chem. Eng. Res. Des. 2000, 78, 397–403. [Google Scholar] [CrossRef]

- Yi, F.; Zou, H.K.; Chu, G.W.; Shao, L.; Chen, J.F. Modeling and Experimental Studies on Absorption of CO2 by Benfield Solution in Rotating Packed Bed. Chem. Eng. J. 2009, 145, 377–384. [Google Scholar] [CrossRef]

- Li, W.; Wu, W.; Zou, H.; Chu, G.; Shao, L.; Chen, J. Process Intensification of VOC Removal from High Viscous Media by Rotating Packed Bed. Chin. J. Chem. Eng. 2009, 17, 389–393. [Google Scholar] [CrossRef]

- Xiang, Y.; Wen, L.; Chu, G.; Shao, L.; Xiao, G.; Chen, J. Modeling of the Precipitation Process in a Rotating Packed Bed and Its Experimental Validation. Chin. J. Chem. Eng. 2010, 18, 249–257. [Google Scholar] [CrossRef]

- Sang, L.; Luo, Y.; Chu, G.W.; Sun, B.C.; Zhang, L.L.; Chen, J.F. A Three-Zone Mass Transfer Model for a Rotating Packed Bed. AIChE J. 2019, 65. [Google Scholar] [CrossRef]

- Wang, D.; Liu, T.; Ma, L.; Wang, F.; Shao, L. Modeling and Experimental Studies on Ozone Absorption into Phenolic Solution in a Rotating Packed Bed. Ind. Eng. Chem. Res. 2019, 58, 7052–7062. [Google Scholar] [CrossRef]

- Su, M.J.; Le, Y.; Chu, G.W.; Li, Y.B.; Zhang, L.L.; Luo, Y. Intensification of Droplet Dispersion by Using Multilayer Wire Mesh and Its Application in a Rotating Packed Bed. Ind. Eng. Chem. Res. 2020, 59, 3584–3592. [Google Scholar] [CrossRef]

- Hacking, J.A.; Delsing, N.F.E.J.; de Beer, M.M.; van der Schaaf, J. Improving Liquid Distribution in a Rotating Packed Bed. Chem. Eng. Process. Process Intensif. 2020, 149, 107861. [Google Scholar] [CrossRef]

- Razi, N.; Bolland, O.; Svendsen, H. Review of Design Correlations for CO2 Absorption into MEA Using Structured Packings. Int. J. Greenh. Gas Control 2012, 9, 193–219. [Google Scholar] [CrossRef]

- Suess, P.; Spiegel, L. Hold-up of Mellapak Structured Packings. Chem. Eng. Process. Process Intensif. 1992, 31, 119–124. [Google Scholar] [CrossRef]

- Wolf-Zöllner, V.; Seibert, F.; Lehner, M. Extended Performance Comparison of Different Pressure Drop, Hold-up and Flooding Point Correlations for Packed Columns. Chem. Eng. Res. Des. 2019, 147, 699–708. [Google Scholar] [CrossRef]

- Muzen, A.; Cassanello, M.C. Liquid Holdup in Columns Packed with Structured Packings: Countercurrent vs. Cocurrent Operation. Che. Eng. Sci. 2005, 60, 6226–6234. [Google Scholar] [CrossRef]

- Alix, P.; Raynal, L. Liquid Distribution and Liquid Hold-up in Modern High Capacity Packings. Chem. Eng. Res. Des. 2008, 86, 585–591. [Google Scholar] [CrossRef]

- Lashkarbolooki, M. A General Model for Pressure Drop Prediction across a Rotating Packed Bed. Sep. Sci. Technol. 2017, 52, 1843–1851. [Google Scholar] [CrossRef]

- Bašić, A.; Duduković, M.P. Liquid Holdup in Rotating Packed Beds: Examination of the Film Flow Assumption. AIChE J. 1995, 41, 301–316. [Google Scholar] [CrossRef]

- Piché, S.; Larachi, F.; Grandjean, B.P.A. Improved Liquid Hold-up Correlation for Randomly Packed Towers. Chem. Eng. Res. Des. 2001, 79, 71–80. [Google Scholar] [CrossRef]

- Liu, W.; Chu, G.W.; Luo, Y.; Liu, Y.Z.; Meng, F.Y.; Sun, B.C.; Chen, J.F. Mass Transfer in a Rotating Packed Bed Reactor with a Mesh-Pin Rotor: Modeling and Experimental Studies. Chem. Eng. J. 2019, 369, 600–610. [Google Scholar] [CrossRef]

- Guo, K.; Guo, F.; Feng, Y.; Chen, J.; Zheng, C.; Gardner, N.C. Synchronous Visual and RTD Study on Liquid Flow in Rotating Packed-Bed Contractor. Chem. Eng. Sci. 2000, 55, 1699–1706. [Google Scholar] [CrossRef]

- Xinlin, D.; Xiaoyong, H.; Yigang, D.; Yuanxin, W.; Dinghuo, L. A Model for the Mass Transfer Coefficient in Rotating Packed Bed. Chem. Eng. Commun. 2000, 178, 249–256. [Google Scholar] [CrossRef]

- Rao, D.P.; Bhowal, A.; Goswami, P.S. Process Intensification in Rotating Packed Beds (HIGEE): An Appraisal. Ind. Eng. Chem. Res. 2004, 43, 1150–1162. [Google Scholar] [CrossRef]

- Sivakumar, S.V.; Kaistha, N.; Rao, D.P. Innovations for Process Intensification in the Process Industry. 2004. Available online: https://www.rgipt.ac.in/oldsite/author_doc/S%20-%20122%20.pdf (accessed on 19 February 2021).

- Neumann, K.; Hunold, S.; Groß, K.; Górak, A. Experimental Investigations on the Upper Operating Limit in Rotating Packed Beds. Chem. Eng. Process. Process Intensif. 2017, 121, 240–247. [Google Scholar] [CrossRef]

- Li, Y.; Lu, Y.; Wang, G.; Nie, Y.; Ying, H.; Ji, J.; Liu, X. Liquid Entrainment and Flooding in a Rotating Zigzag Bed. Ind. Eng. Chem. Res. 2015, 54, 2554–2563. [Google Scholar] [CrossRef]

- Kuźniewska-Lach, I. Estimation of Phase Velocities at Flooding Point in Packed Columns for Any Gas/Liquid System. Can. J. Chem. Eng. 1999, 77, 439–446. [Google Scholar] [CrossRef]

- Stankiewicz, A.; Moulijn, J.A. Re-Engineering the Chemical Processing Plant, 1st ed.; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar] [CrossRef]

- Lockett, M.J.; Victor, R.A.; Billingham, J.F. Structured Packing Flooding: Its Measurement and Prediction, 8th Conference of Distillation and Absorption; Symposium Series 152; IChemE: London, UK, 2006; pp. 400–408. ISBN 0852955057. [Google Scholar]

- Singh, S.P.; Counce, R.M.; Wilson, J.H.; Villiers-Fisher, J.F.; Jennings, H.L.; Lucero, A.J.; Reed, G.D.; Ashworth, R.A.; Elliott, M.G. Removal of Volatile Organic Compounds from Groundwater Using a Rotary Air Stripper. Ind. Eng. Chem. Res. 1992, 31, 574–580. [Google Scholar] [CrossRef]

- Lockett, M.J. Flooding of Rotating Structured Packing and Its Application to Conventional Packed Columns. Chem. Eng. Res. Des. 1995, 73, 379–384. [Google Scholar]

- Rajan, S.; Kumar, M.; Ansari, M.J.; Rao, D.P.; Kaistha, N. Limiting Gas Liquid Flows and Mass Transfer in a Novel Rotating Packed Bed (HiGee). Ind. Eng. Chem. Res. 2011, 50, 986–997. [Google Scholar] [CrossRef]

- Gudena, K.; Rangaiah, G.P.; Lakshminarayanan, S. Optimal Design of a Rotating Packed Bed for VOC Stripping from Contaminated Groundwater. Ind. Eng. Chem. Res. 2011, 51, 835–847. [Google Scholar] [CrossRef]

- Li, S.; Deng, S.; Zhao, L.; Zhao, R.; Lin, M.; Du, Y.; Lian, Y. Mathematical Modeling and Numerical Investigation of Carbon Capture by Adsorption: Literature Review and Case Study. Appl. Energy 2018, 221, 437–449. [Google Scholar] [CrossRef]

- Kumar, M.P.; Rao, D.P. Studies on a High-Gravity Gas-Liquid Contactor. Ind. Eng. Chem. Res. 1990, 29, 917–920. [Google Scholar] [CrossRef]

- Foumeny, E.A.; Kulkarni, A.; Roshani, S.; Vatani, A. Elucidation of Pressure Drop in Packed-Bed Systems. Appl. Therm. Eng. 1996, 16, 195–202. [Google Scholar] [CrossRef]

- Chandra, A.; Goswami, P.S.; Rao, D.P. Characteristics of Flow in a Rotating Packed Bed (HIGEE) with Split Packing. Ind. Eng. Chem. Res. 2005, 44, 4051–4060. [Google Scholar] [CrossRef]

- Sung, W.D.; Chen, Y.S. Characteristics of a Rotating Packed Bed Equipped with Blade Packings and Baffles. Sep. Purif. Technol. 2012, 93, 52–58. [Google Scholar] [CrossRef]

- Wang, G.Q.; Jiao, Y.Q.; Xu, Z.C.; Ji, J.B. Studies on Performance of Crossflow Concentric-Ring Rotating Bed. Ind. Eng. Chem. Res. 2009, 48, 10643–10649. [Google Scholar] [CrossRef]

- Llerena-Chavez, H.; Larachi, F. Analysis of Flow in Rotating Packed Beds via CFD Simulations-Dry Pressure Drop and Gas Flow Maldistribution. Chem. Eng. Sci. 2009, 64, 2113–2126. [Google Scholar] [CrossRef]

- Jiao, W.Z.; Liu, Y.Z.; Qi, G.S. Gas Pressure Drop and Mass Transfer Characteristics in a Cross-Flow Rotating Packed Bed with Porous Plate Packing. Ind. Eng. Chem. Res. 2010, 49, 3732–3740. [Google Scholar] [CrossRef]

- Li, Y.; Ji, J.; Xu, Z.; Wang, G.; Li, X.; Liu, X. Pressure Drop Model on Rotating Zigzag Bed as a New High-Gravity Technology. Ind. Eng. Chem. Res. 2013, 52, 4638–4649. [Google Scholar] [CrossRef]

- Treybal, R.E. Mass-Transfer Operations, 3rd ed.; McGraw-Hill Book Company: London, UK, 1980. [Google Scholar] [CrossRef] [Green Version]

- Tan, L.S.; Shariff, A.M.; Lau, K.K.; Bustam, M.A. Factors Affecting CO2 Absorption Efficiency in Packed Column: A Review. J. Ind. Eng. Chem. 2012, 18, 1874–1883. [Google Scholar] [CrossRef]

- Reddy, K.J.; Gupta, A.; Rao, D.P.; Rama, O.P. Process Intensification in a HIGEE with Split Packing. Ind. Eng. Chem. Res. 2006, 45, 4270–4277. [Google Scholar] [CrossRef]

- Tung, H.H.; Mah, R.S.H. Modeling Liquid Mass Transfer in Higee Separation Process. Chem. Eng. Commun. 1985, 39, 147–153. [Google Scholar] [CrossRef]

- Kang, J.L.; Sun, K.; Wong, D.S.H.; Jang, S.S.; Tan, C.S. Modeling Studies on Absorption of CO2 by Monoethanolamine in Rotating Packed Bed. Int. J. Greenh. Gas Control 2014, 25, 141–150. [Google Scholar] [CrossRef]

- Joel, A.S.; Wang, M.; Ramshaw, C. Modelling and Simulation of Intensified Absorber for Post-Combustion CO2 Capture Using Different Mass Transfer Correlations. Appl. Therm. Eng. 2015, 74, 47–53. [Google Scholar] [CrossRef]

- Oko, E.; Wang, M.; Ramshaw, C. Study of Mass Transfer Correlations for Intensified Absorbers in Post-Combustion CO2 Capture Based on Chemical Absorption. Energy Procedia 2017, 114, 1630–1636. [Google Scholar] [CrossRef]

- Sun, B.; Zou, H.; Chu, G.; Shao, L.; Zeng, Z.; Chen, J. Determination of Mass-Transfer Coefficient of CO2 in NH3 and CO2 Absorption by Materials Balance in a Rotating Packed Bed. Ind. Eng. Chem. Res. 2012, 51, 10949–10954. [Google Scholar] [CrossRef]

- Yu, C.H.; Wu, T.W.; Tan, C.S. CO2 Capture by Piperazine Mixed with Non-Aqueous Solvent Diethylene Glycol in a Rotating Packed Bed. Int. J. Greenh. Gas Control 2013, 19, 503–509. [Google Scholar] [CrossRef]

- Yu, C.H.; Cheng, H.H.; Tan, C.S. CO2 Capture by Alkanolamine Solutions Containing Diethylenetriamine and Piperazine in a Rotating Packed Bed. Int. J. Greenh. Gas Control 2012, 9, 136–147. [Google Scholar] [CrossRef]

- Chu, G.W.; Fei, J.; Cai, Y.; Liu, Y.Z.; Gao, Y.; Luo, Y.; Chen, J.F. Removal of SO2 with Sodium Sulfite Solution in a Rotating Packed Bed. Ind. Eng. Chem. Res. 2018, 57, 2329–2335. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, S.; Gao, Y.; Sun, B.; Luo, Y.; Zou, H.; Chu, G.; Chen, J. Absorption of SO2 with Calcium-Based Solution in a Rotating Packed Bed. Sep. Purif. Technol. 2019, 214, 148–155. [Google Scholar] [CrossRef]

- Zhan, J.; Wang, B.; Zhang, L.; Sun, B.C.; Fu, J.; Chu, G.W.; Zou, H. Simultaneous Absorption of H2S and CO2 into the MDEA + PZ Aqueous Solution in a Rotating Packed Bed. Ind. Eng. Chem. Res. 2020, 59, 8295–8303. [Google Scholar] [CrossRef]

- Chen, Y.S.; Liu, H.S. Absorption of VOCs in a Rotating Packed Bed. Ind. Eng. Chem. Res. 2002, 41, 1583–1588. [Google Scholar] [CrossRef]

- Lin, C.C.; Liu, W.T.; Tan, C.S. Removal of Carbon Dioxide by Absorption in a Rotating Packed Bed. Ind. Eng. Chem. Res. 2003, 42, 2381–2386. [Google Scholar] [CrossRef]

- Chen, Y.S.; Lin, C.C.; Liu, H.S. Mass Transfer in a Rotating Packed Bed with Various Radii of the Bed. Ind. Eng. Chem. Res. 2005, 44, 7868–7875. [Google Scholar] [CrossRef]

- Chen, Y.S.; Lin, F.Y.; Lin, C.C.; Tai, C.Y.D.; Liu, H.S. Packing Characteristics for Mass Transfer in a Rotating Packed Bed. Ind. Eng. Chem. Res. 2006, 45, 6846–6853. [Google Scholar] [CrossRef]

- Chen, Q.Y.; Chu, G.W.; Luo, Y.; Sang, L.; Zhang, L.L.; Zou, H.K.; Chen, J.F. Polytetrafluoroethylene Wire Mesh Packing in a Rotating Packed Bed: Mass-Transfer Studies. Ind. Eng. Chem. Res. 2016, 55, 11606–11613. [Google Scholar] [CrossRef]

- Chen, T.L.; Chen, Y.H.; Chiang, P.C. Enhanced Performance on Simultaneous Removal of NOx-SO2-CO2 Using a High-Gravity Rotating Packed Bed and Alkaline Wastes towards Green Process Intensification. Chem. Eng. J. 2020, 393, 124678. [Google Scholar] [CrossRef]

- Luo, Y.; Chu, G.W.; Zou, H.K.; Wang, F.; Xiang, Y.; Shao, L.; Chen, J.F. Mass Transfer Studies in a Rotating Packed Bed with Novel Rotors: Chemisorption of CO2. Ind. Eng. Chem. Res. 2012, 51, 9164–9172. [Google Scholar] [CrossRef]

- Yang, K.; Chu, G.; Zou, H.; Sun, B.; Shao, L.; Chen, J.F. Determination of the Effective Interfacial Area in Rotating Packed Bed. Chem. Eng. J. 2011, 168, 1377–1382. [Google Scholar] [CrossRef]

- Guo, K.; Zhang, Z.; Luo, H.; Dang, J.; Qian, Z. An Innovative Approach of the Effective Mass Transfer Area in the Rotating Packed Bed. Ind. Eng. Chem. Res. 2014, 53, 4052–4058. [Google Scholar] [CrossRef]

- Luo, Y.; Luo, J.Z.; Chu, G.W.; Zhao, Z.Q.; Arowo, M.; Chen, J.F. Investigation of Effective Interfacial Area in a Rotating Packed Bed with Structured Stainless Steel Wire Mesh Packing. Chem. Eng. Sci. 2017, 170, 347–354. [Google Scholar] [CrossRef]

- Lin, C.C.; Jian, G.S. Characteristics of a Rotating Packed Bed Equipped with Blade Packings. Sep. Purif. Technol. 2007, 54, 51–60. [Google Scholar] [CrossRef]

- Lin, C.C.; Wei, T.Y.; Liu, W.T.; Shen, K.P. Removal of VOCs from Gaseous Streams in a High-Voidage Rotating Packed Bed. J. Chem. Eng. Japan 2004, 37, 1471–1477. [Google Scholar] [CrossRef]

- Chen, Y.S.; Lin, C.C.; Liu, H.S. Mass Transfer in a Rotating Packed Bed with Viscous Newtonian and Non-Newtonian Fluids. Ind. Eng. Chem. Res. 2005, 44, 1043–1051. [Google Scholar] [CrossRef]

- Chen, Y.S. Correlations of Mass Transfer Coefficients in a Rotating Packed Bed. Ind. Eng. Chem. Res. 2011, 50, 1778–1785. [Google Scholar] [CrossRef]

- Bai, S.; Chu, G.-W.; Li, S.-C.; Zou, H.-K.; Xiang, Y.; Luo, Y.; Chen, J.-F. SO2 Removal in a Pilot Scale Rotating Packed Bed. Environ. Eng. Sci. 2015, 32, 806–815. [Google Scholar] [CrossRef]

- Mei-ying, D.; Gui-sheng, Q.; You-zhi, L.; Qiang, G.; Song Bin, W.T. Experimental Study on Influential Factors of Mass Transfer in a Cross-Flow Rotating Packed Bed. Chin. J. Process Eng. 2015, 15, 929–934. [Google Scholar] [CrossRef]

- Cao, S.; Liu, P.; Zhang, L.; Sun, B.; Zou, H.; Chu, G.; Luo, Y.; Chen, J. Mass Transfer Study of Dehydration by Triethylene Glycol in Rotating Packed Bed for Natural Gas Processing. Ind. Eng. Chem. Res. 2018. [Google Scholar] [CrossRef]

- Su, M.J.; Luo, Y.; Chu, G.W.; Liu, W.; Zheng, X.H.; Chen, J.F. Gas-Side Mass Transfer in a Rotating Packed Bed with Structured Nickel Foam Packing. Ind. Eng. Chem. Res. 2018, 57, 5394–5400. [Google Scholar] [CrossRef]

- Li, W.; Liu, H.; Li, S.; Li, W.; Chen, Y.; Gao, J.; Cao, Y. Removal of Hydrophobic Volatile Organic Compounds with Sodium Hypochlorite and Surfactant in a Co-Current Rotating Packed Bed. J. Environ. Sci. 2018, 64, 190–196. [Google Scholar] [CrossRef]

- Kolev, N. Packed Bed Columns: For Absorption, Desorption, Rectification and Direct Heat Transfer; Elsevier Science: Amsterdam, The Netherlands, 2006. [Google Scholar] [CrossRef]

- Wagner, I.; Stichlmair, J.; Fair, J.R. Mass Transfer in Beds of Modern, High-Efficiency Random Packings. Ind. Eng. Chem. Res. 1997, 36, 227–237. [Google Scholar] [CrossRef]

- Liu, T.; Wang, D.; Wang, W.; Liang, Q.; Shao, L. Study on the Efficient Production of Ozone Water by a Rotating Packed Bed. Ind. Eng. Chem. Res. 2019, 58, 7227–7232. [Google Scholar] [CrossRef]

- Luo, Y.; Chu, G.W.; Zou, H.K.; Zhao, Z.Q.; Dudukovic, M.P.; Chen, J.F. Gas-Liquid Effective Interfacial Area in a Rotating Packed Bed. Ind. Eng. Chem. Res. 2012, 51, 16320–16325. [Google Scholar] [CrossRef]

- Onda, K.; Takeuchi, H.; Okumoto, Y. Mass Transfer Coefficients between Gas and Liquid Phases in Packed Columns. J. Chem. Eng. Jpn. 1968, 1, 56–62. [Google Scholar] [CrossRef] [Green Version]

- Puranik, S.S.; Vogelpohl, A. Effective Interfacial Area in Irrigated Packed Columns. Chem. Eng. Sci. 1974, 29, 501–507. [Google Scholar] [CrossRef]

- Xie, P.; Lu, X.; Ding, H.; Yang, X.; Ingham, D.; Ma, L.; Pourkashanian, M. A Mesoscale 3D CFD Analysis of the Liquid Flow in a Rotating Packed Bed. Chem. Eng. Sci. 2019, 199, 528–545. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.-Z.; Liu, W.; Xu, Y.-C.; Luo, Y.; Chu, G.-W.; Chen, J.-F. Initial Liquid Dispersion and Mass Transfer Performance in a Rotating Packed Bed. Chem. Eng. Process. Process Intensif. 2019, 140, 136–141. [Google Scholar] [CrossRef]

- Sheng, M.; Sun, B.; Zhang, F.; Chu, G.; Zhang, L.; Liu, C.; Chen, J.-F.; Zou, H. Mass-Transfer Characteristics of the CO2 Absorption Process in a Rotating Packed Bed. Energy Fuels 2015, 30, 4215–4220. [Google Scholar] [CrossRef]

- Yang, Y.C.; Ouyang, Y.; Zhang, N.; Yu, Q.J.; Arowo, M. A Review on Computational Fluid Dynamic Simulation for Rotating Packed Beds. J. Chem. Technol. Biotechnol. 2019, 94, 1017–1031. [Google Scholar] [CrossRef]

- Lu, X.; Xie, P.; Ingham, D.B.; Ma, L.; Pourkashanian, M. A Porous Media Model for CFD Simulations of Gas-Liquid Two-Phase Flow in Rotating Packed Beds. Chem. Eng. Sci. 2018, 189, 123–134. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, W.; Luo, Y.; Chu, G.W.; Liu, W.; Sun, B.C.; Chen, J.F. CFD Simulation and High-Speed Photography of Liquid Flow in the Outer Cavity Zone of a Rotating Packed Bed Reactor. Ind. Eng. Chem. Res. 2019, 58, 5280–5290. [Google Scholar] [CrossRef]

- Yang, W.; Wang, Y.; Chen, J.; Fei, W. Computational Fluid Dynamic Simulation of Fluid Flow in a Rotating Packed Bed. Chem. Eng. J. 2010, 156, 582–587. [Google Scholar] [CrossRef]

- Martínez, E.L.; Jaimes, R.; Gomez, J.L.; Filho, R.M. CFD Simulation of Three-Dimensional Multiphase Flow in a Rotating Packed Bed. In Computer Aided Chemical Engineering; Elsevier BV: Amsterdam, The Netherlands, 2012. [Google Scholar] [CrossRef]

- Shi, X.; Xiang, Y.; Wen, L.X.; Chen, J.F. CFD Analysis of Liquid Phase Flow in a Rotating Packed Bed Reactor. Chem. Eng. J. 2013, 228, 1040–1049. [Google Scholar] [CrossRef]

- Chengcheng, X.; Weizhou, J.; Youzhi, L.; Liang, G.; Zhiguo, Y.; Qiaoling, Z. Effects of Airflow Field on Droplets Diameter inside the Corrugated Packing of a Rotating Packed Bed. China Pet. Process. Petrochem. Technol. 2014, 16, 38–46. [Google Scholar]

- Sun, Y.; Zhang, Y.; Zhang, L.; Jiang, B.; Zhao, Z. Structure Optimization of a Rotating Zigzag Bed via Computational Fluid Dynamics Simulation. Ind. Eng. Chem. Res. 2014, 53, 13764–13772. [Google Scholar] [CrossRef]

- Yang, Y.; Xiang, Y.; Chu, G.; Zou, H.; Sun, B.; Arowo, M.; Chen, J.F. CFD Modeling of Gas-Liquid Mass Transfer Process in a Rotating Packed Bed. Chem. Eng. J. 2016, 294, 111–121. [Google Scholar] [CrossRef]

- Gao, X.Y.; Liu, L.; Hu, M.L.; Xiang, Y.; Chu, G.W.; Zou, H.K.; Sun, B.C.; Chen, J.F. Numerical Simulation for Mass Transfer Characteristics of CO2 Capture in a Rotating Packed Bed. Chem. Eng. Process. Process Intensif. 2016, 109, 68–79. [Google Scholar] [CrossRef]

- Liu, Y.; Luo, Y.; Chu, G.W.; Luo, J.Z.; Arowo, M.; Chen, J.F. 3D Numerical Simulation of a Rotating Packed Bed with Structured Stainless Steel Wire Mesh Packing. Chem. Eng. Sci. 2017, 170, 365–377. [Google Scholar] [CrossRef]

- Hu, D.D.; Shan, W.Y.; Zhu, G.W. Numerical Simulation of Counter-Current Flow Field in Double Packing Rotating Packed Bed. Key Eng. Mater. 2013, 561, 672–676. [Google Scholar] [CrossRef]

- Zhang, X.; Cheng, Y.; Nie, S.; Ji, H.; Liu, L. Simulation of Multiphase Flow of the Oil-Water Separation in a Rotating Packed Bed for Oil Purification. Math. Probl. Eng. 2013, 2013, 1–9. [Google Scholar] [CrossRef]

- Guo, T.Y.; Shi, X.; Chu, G.W.; Xiang, Y.; Wen, L.X.; Chen, J.F. Computational Fluid Dynamics Analysis of the Micromixing Efficiency in a Rotating-Packed-Bed Reactor. Ind. Eng. Chem. Res. 2016, 55, 4856–4866. [Google Scholar] [CrossRef]

- Xie, P.; Lu, X.; Ingham, D.; Ma, L.; Pourkashanian, M. Mass Transfer Characteristics of the Liquid Film Flow in a Rotating Packed Bed for CO2 Capture: A Micro-Scale CFD Analysis. Energy Procedia 2017, 142, 3407–3414. [Google Scholar] [CrossRef]

- Xie, P.; Lu, X.; Yang, X.; Ingham, D.; Ma, L.; Pourkashanian, M. Characteristics of Liquid Flow in a Rotating Packed Bed for CO2 Capture: A CFD Analysis. Chem. Eng. Sci. 2017, 172, 216–229. [Google Scholar] [CrossRef]

- Guo, T.-Y.; Cheng, K.-P.; Wen, L.-X.; Andersson, R.; Chen, J.-F. Three-Dimensional Simulation on Liquid Flow in a Rotating Packed Bed Reactor. Ind. Eng. Chem. Res. 2017, 56, 8169–8179. [Google Scholar] [CrossRef]

- Ouyang, Y.; Xiang, Y.; Gao, X.Y.; Li, W.L.; Zou, H.K.; Chu, G.W.; Chen, J.F. Micromixing Efficiency in a Rotating Packed Bed with Non-Newtonian Fluid. Chem. Eng. J. 2018, 354, 162–171. [Google Scholar] [CrossRef]

- Wu, W.; Luo, Y.; Chu, G.W.; Liu, Y.; Zou, H.K.; Chen, J.F. Gas Flow in a Multiliquid-Inlet Rotating Packed Bed: Three-Dimensional Numerical Simulation and Internal Optimization. Ind. Eng. Chem. Res. 2018, 57, 2031–2040. [Google Scholar] [CrossRef]

- Ouyang, Y.; Wang, S.; Xiang, Y.; Zhao, Z.; Wang, J.; Shao, L. CFD Analyses of Liquid Flow Characteristics in a Rotor-Stator Reactor. Chem. Eng. Res. Des. 2018, 134, 186–197. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, X.; Yang, T.; Wang, S.; Liu, Z.; Dan, X. Droplet Characteristics of Rotating Packed Bed in H2S Absorption: A Computational Fluid Dynamics Analysis. Processes 2019, 7, 724. [Google Scholar] [CrossRef] [Green Version]

- Wu, W.; Luo, Y.; Chu, G.W.; Su, M.J.; Cai, Y.; Zou, H.K.; Chen, J.F. Liquid Flow Behavior in a Multiliquid-Inlet Rotating Packed Bed Reactor with Three-Dimensional Printed Packing. Chem. Eng. J. 2020, 386, 121537. [Google Scholar] [CrossRef]

- Ouyang, Y.; Xiang, Y.; Gao, X.-Y.; Zou, H.-K.; Chu, G.-W.; Agarwal, R.K.; Chen, J.-F. Micromixing Efficiency Optimization of the Premixer of a Rotating Packed Bed by CFD. Chem. Eng. Process.Process Intensif. 2019, 142, 107543. [Google Scholar] [CrossRef]

- Liu, Y.; Luo, Y.; Chu, G.W.; Larachi, F.; Zou, H.K.; Chen, J.F. Liquid Microflow inside the Packing of a Rotating Packed Bed Reactor: Computational, Observational and Experimental Studies. Chem. Eng. J. 2020, 386, 121134. [Google Scholar] [CrossRef]

- Xu, Y.C.; Li, Y.B.; Liu, Y.Z.; Luo, Y.; Chu, G.W.; Zhang, L.L.; Chen, J.F. Liquid Jet Impaction on the Single-Layer Stainless Steel Wire Mesh in a Rotating Packed Bed Reactor. AIChE J. 2019, 65. [Google Scholar] [CrossRef]

- Wang, J.Q.; Ouyang, Y.; Li, W.L.; Esmaeili, A.; Xiang, Y.; Chen, J.F. CFD Analysis of Gas Flow Characteristics in a Rotating Packed Bed with Randomly Arranged Spherical Packing. Chem. Eng. J. 2020, 385, 123812. [Google Scholar] [CrossRef]

- Harmsen, G.J. Reactive Distillation: The Front-Runner of Industrial Process Intensification. A Full Review of Commercial Applications, Research, Scale-up, Design and Operation. Chem. Eng. Process. Process Intensif. 2007, 46, 774–780. [Google Scholar] [CrossRef] [Green Version]

- Khang, S.J.; Levenspiel, O. New Scale-up and Design Method for Stirrer Agitated Batch Mixing Vessels. Chem. Eng. Sci. 1976, 31, 569–577. [Google Scholar] [CrossRef]

- Kapic, A.; Heindel, T.J. Correlating Gas-Liquid Mass Transfer in a Stirred-Tank Reactor. Chem. Eng. Res. Des. 2006, 84, 239–245. [Google Scholar] [CrossRef]

- Gui, H.; Li, X. Removing Ammonia from Skim by Air Stripping with Rotating Packed Bed. Chin. J. Chem. Eng. 2019, 27, 528–533. [Google Scholar] [CrossRef]

- Vivian, J.E.; Brian, P.L.T.; Krukonis, V.J. The Influence of Gravitational Force on Gas Absorption in a Packed Column. AIChE J. 1965, 11, 1088–1091. [Google Scholar] [CrossRef]

- Chakravarti, S.A.; Shenoy, U.V. Dimensional Analysis of Heat and Mass Transfer Correlations Using Micro-and Macro Scales. Chem. Eng. Commun. 1993, 124, 29–37. [Google Scholar] [CrossRef]

- Shivhare, M.K.; Rao, D.P.; Kaistha, N. Mass Transfer Studies on Split-Packing and Single-Block Packing Rotating Packed Beds. Chem. Eng. Process. Process Intensif. 2013, 71, 115–124. [Google Scholar] [CrossRef]

- Keyvani, M.; Gardner, N.C. Operating Characteristics of Rotating Beds. Chem. Eng. Prog. 1989, 85, 48–52. [Google Scholar]

- Agarwal, L.; Pavani, V.; Rao, D.P.; Kaistha, N. Process Intensification in HiGee Absorption and Distillation: Design Procedure and Applications. Ind. Eng. Chem. Res. 2010, 49, 10046–10058. [Google Scholar] [CrossRef]

- Jiang, X.; Liu, Y.; Gu, M. Absorption of Sulphur Dioxide with Sodium Citrate Buffer Solution in a Rotating Packed Bed. Chinese J. Chem. Eng. 2011, 19, 687–692. [Google Scholar] [CrossRef]

- Lee, J.; Kolawole, T.; Attidekou, P. Carbon Capture from a Simulated Flue Gas Using a Rotating Packed Bed Adsorber and Mono Ethanol Amine (MEA). Energy Procedia 2017, 114, 1834–1840. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghadyanlou, F.; Azari, A.; Vatani, A. A Review of Modeling Rotating Packed Beds and Improving Their Parameters: Gas–Liquid Contact. Sustainability 2021, 13, 8046. https://doi.org/10.3390/su13148046

Ghadyanlou F, Azari A, Vatani A. A Review of Modeling Rotating Packed Beds and Improving Their Parameters: Gas–Liquid Contact. Sustainability. 2021; 13(14):8046. https://doi.org/10.3390/su13148046

Chicago/Turabian StyleGhadyanlou, Farhad, Ahmad Azari, and Ali Vatani. 2021. "A Review of Modeling Rotating Packed Beds and Improving Their Parameters: Gas–Liquid Contact" Sustainability 13, no. 14: 8046. https://doi.org/10.3390/su13148046

APA StyleGhadyanlou, F., Azari, A., & Vatani, A. (2021). A Review of Modeling Rotating Packed Beds and Improving Their Parameters: Gas–Liquid Contact. Sustainability, 13(14), 8046. https://doi.org/10.3390/su13148046