Comparative Performance of Low Global Warming Potential (GWP) Refrigerants as Replacement for R-410A in a Regular 2-Speed Heat Pump for Sustainable Cooling

Abstract

:1. Introduction

2. Refrigerant Properties

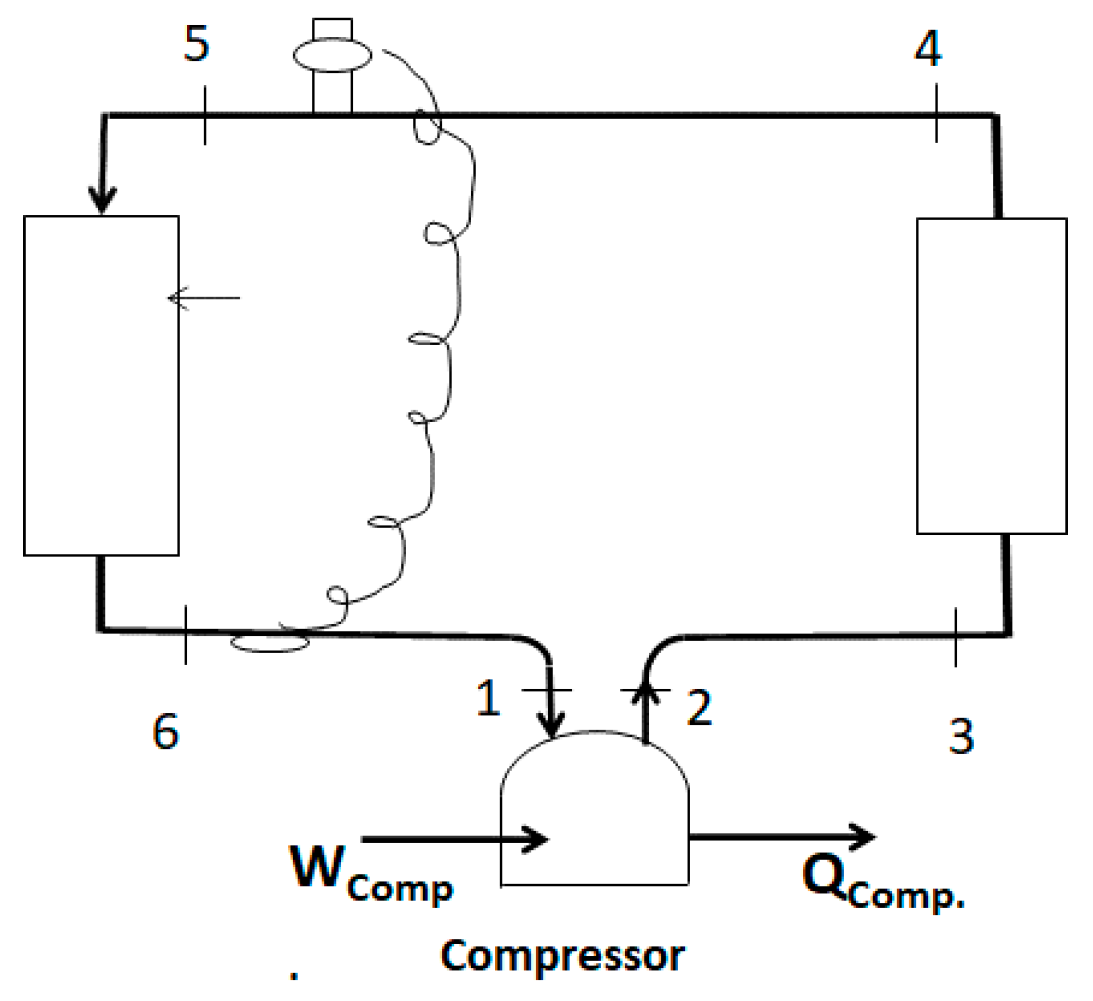

3. Model Description, Features, and Assumptions

3.1. Compressor Model

3.2. Heat Exchanger Model

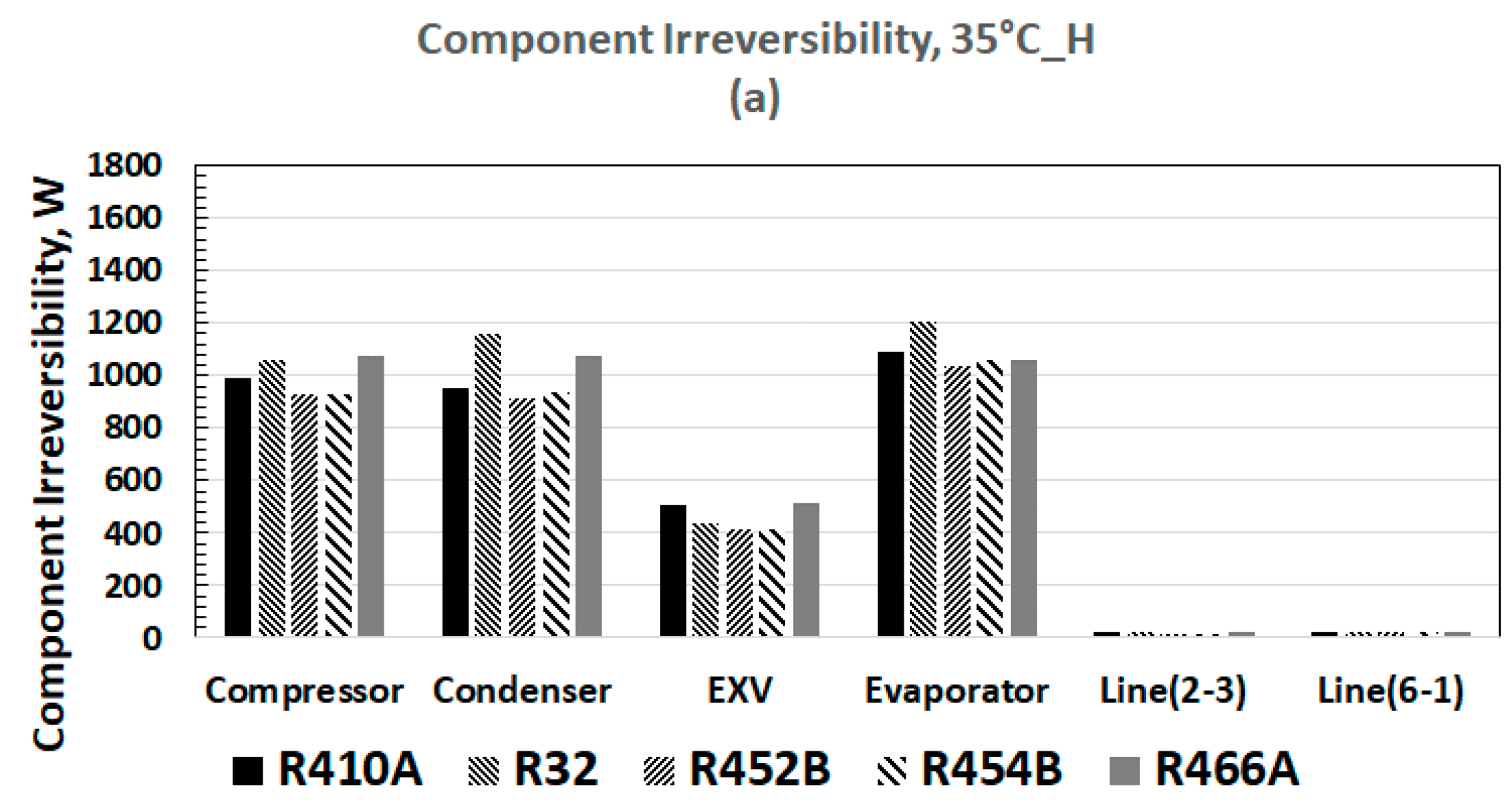

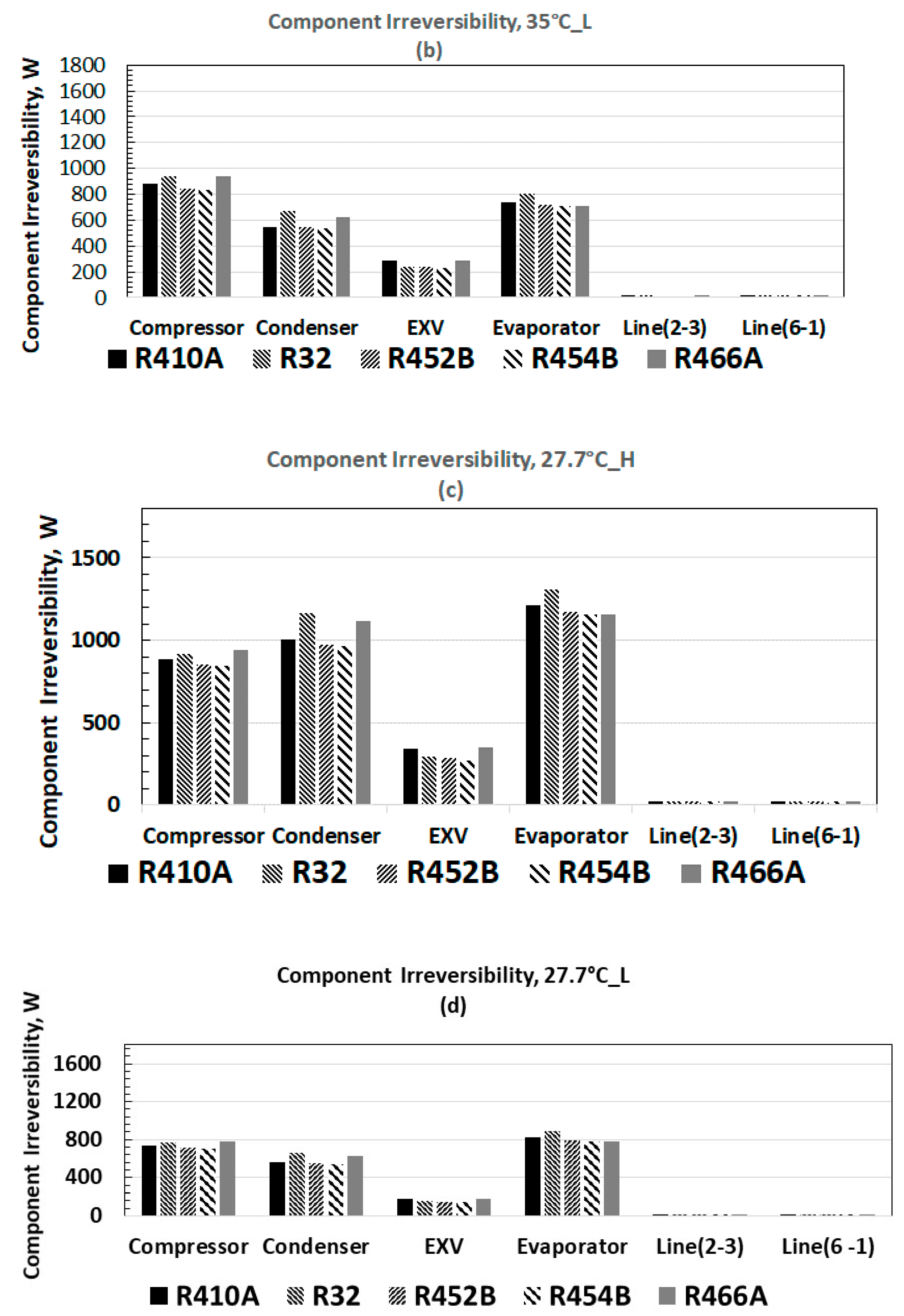

3.3. Heat Transfer and Pressure Drop Correlations

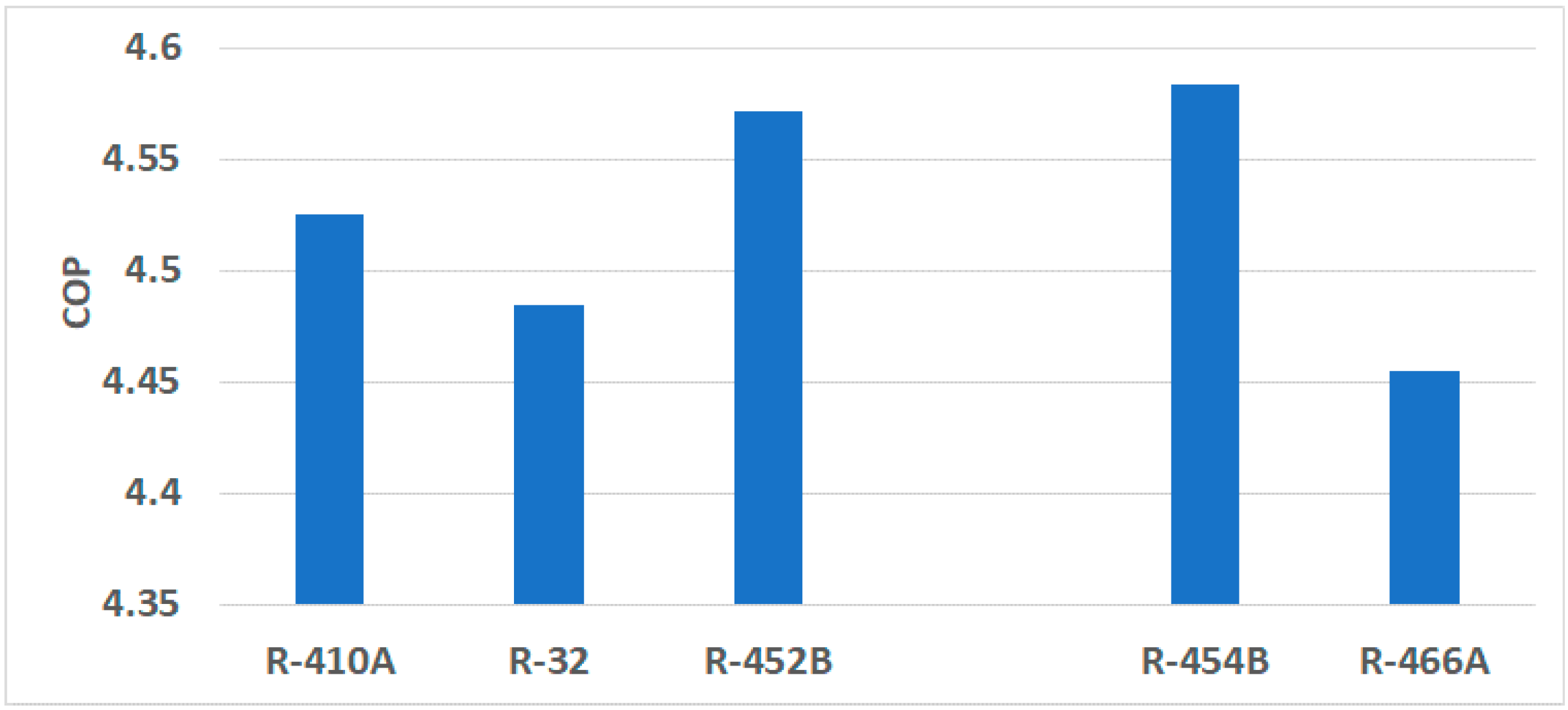

4. Model Description, Features, and Assumptions

5. General Mass, Energy, and Exergy Balances

6. Energy, Entropy Generation, and Irreversibility

7. Component-Wise Irreversibility

8. Results

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AHRI | Air-Conditioning, Heating, and Refrigeration Institute |

| ASHRAE | American Society of Heating, Refrigeration, and Airconditioning Engineering |

| CFC | Chlorofluorocarbon |

| COP | Coefficient of Performance, dimensionless |

| CV | Control Volume |

| D | Density |

| EXV | Expansion Valve |

| E | Energy, J/s |

| %∆E | Percent energy change relative to input energy, dimensionless |

| g | Gravitational acceleration, m/s2 |

| GWP | Global Warming Potential |

| HP | Heat Pump |

| HPDM | Heat Pump Design Model |

| h | Enthalpy, kJ/kg |

| HT | Heat transfer coefficient, W/m2/K |

| I | Irreversibility, J/s |

| LCCP | Life Cycle Cost Performance |

| m | Mass flow rate, kg/h |

| Q | Rate of heat transfer, J/s |

| s | specific entropy, kJ/kg-K |

| T | Temperature, K |

| TEWI | Total Equivalent Warming Index |

| v | Velocity, m/s |

| W | Rate of work, J/s |

| z | Height above datum, m |

| Subscripts | |

| a | Actual, or air |

| Carnot | Carnot |

| Comp. | Compressor |

| Cond. | Condenser |

| Evap. | Evaporator |

| EXV | Expansion valve |

| In | Inflow |

| i | Inlet |

| Out | Outflow |

| o | Outlet |

| r | Refrigerant |

| total | Total value of a category |

| (2–3) | Connecting line, compressor to condenser inlet |

| (6–1) | Connecting line, evaporator to compressor inlet |

| Greek | |

| σ | Rate of entropy generation, W/K |

| Efficiency | |

| Acronym | |

| AHRI | Air-Conditioning, Heating, and Refrigeration Institute of the United States |

| DB | Dry Bulb temperature |

| DOE | Department of Energy, U.S. |

| GHG | Greenhouse Gas |

| GWP | Global Warming Potential |

| HP | Heat Pump |

| HFC | Hydrofluorocarbons |

| HFO | Hydrofluoroolefin |

| HPDM | DOE/ORNL Heat Pump Design Model |

| HVAC | Heating, Ventilation, Air Conditioning |

| ODP | Oxygen Depletion Potential |

| ORNL | Oak Ridge National Laboratory |

| WB | Wet Bulb temperature |

References

- IPCC. 2019: Summary for Policymakers. In IPCC Special Report on the Ocean and Cryosphere in a Changing Climate; Pörtner, H.-O., Roberts, D.C., Masson-Delmotte, V., Zhai, P., Tignor, M., Poloczanska, E., Mintenbeck, K., Nicolai, M., Okem, A., Petzold, J., et al., Eds.; IPCC: Geneva, Switzerland, 2019. [Google Scholar]

- Molina, M.J.; Rowland, F.S. Stratospheric sink for chlorofluoromethanes: Chlorine atom-catalysed destruction of ozone. Nature 1974, 249, 810–812. [Google Scholar] [CrossRef]

- McLinden, M.O.; Huber, M.L. (R) Evolution of refrigerants. J. Chem. Eng. Data 2020, 65, 4176–4193. [Google Scholar] [CrossRef]

- Wang, X.; Amrane, K.; Johnson, P. Low Global Warming Potential (GWP) Alternative Refrigerants Evaluation Program (Low-GWP AREP). International Refrigeration and Air Conditioning Conference. Paper 1222. 2012. Available online: http://docs.lib.purdue.edu/iracc/1222 (accessed on 7 July 2021).

- McGowan, M.K. Progress Report on Alternative Refrigerants. ASHRAE J. 2019, 61, 38–41. [Google Scholar]

- Heredia-Aricapa, Y.; Belman-Flores, J.M.; Mota-Babiloni, A.; Serrano-Arellano, J.; García-Pabón, J.J. Overview of low GWP mixtures for the replacement of HFC refrigerants: R134a, R404A and R410A. Int. J. Refrig. 2020, 111, 113–123. [Google Scholar] [CrossRef]

- Pham, H.M.; Rajendran, R. R32 and HFOs as Low-GWP Refrigerants for Air Conditioning. International Refrigeration and Air Conditioning Conference. Paper 1235. 2012. Available online: http://docs.lib.purdue.edu/iracc/1235 (accessed on 18 July 2021).

- Yu, B.; Ouyang, H.; Shi, J.; Liu, W.; Chen, J. Evaluation of low-GWP and mildly flammable mixtures as new alternatives for R410A in air-conditioning and heat pump system. Int. J. Refrig. 2021, 121, 95–104. [Google Scholar] [CrossRef]

- Yang, C.; Seo, S.; Takata, W.; Thu, K.; Miyazaki, T. The life cycle climate performance evaluation of low-GWP refrigerants for domestic heat pumps. Int. J. Refrig. 2021, 121, 33–42. [Google Scholar] [CrossRef]

- Sieres, J.; Ortega, I.; Cerdeira, F.; Alvarez, E. Drop-in performance of the low-GWP alternative refrigerants R452B and R454B in an R410A liquid-to-water heat pump. Appl. Therm. Eng. 2021, 182, 116049. [Google Scholar] [CrossRef]

- Shen, B.; Rice, K. DOE/ORNL Heat Pump Design Model. 2016. Available online: http://hpdmflex.ornl.gov/ (accessed on 18 July 2021).

- Gallaher, M.; Scott, T.; Oliver, Z.; Clark-Sutton, K.; Anderson, B. Benefit-Cost Evaluation of US Department of Energy Investment in HVAC, Water Heating, and Appliance Technologies. 2017. Available online: https://www.energy.gov/eere/buildings/downloads/benefit-cost-evaluation-us-department-energy-investment-hvac-water-heating (accessed on 18 July 2021).

- DOE/ORNL Heat Pump Design Model, Related Reports/Papers. Available online: https://web.ornl.gov/~doehpdm/hpdm/Related_Reports.html (accessed on 18 July 2021).

- Rice, C.K. The Effect of Void Fraction Correlation and Heat Flux Assumption on Refrigerant Charge Inventory Predictions. ASHRAE Trans. 1987, 93, 341–367. [Google Scholar]

- Dabiri, A.E.; Rice, C.K. A Compressor Simulation Model with Corrections for the Level of Suction Gas Superheat. ASHRAE Trans. 1981, 87, 771–782. [Google Scholar]

- Shen, B.; Shrestha, S.S.; Abdelaziz, O. Model Validations for Low-GWP refrigerants in Mini-Split Air Conditioning Units. Sci. Technol. Built Environ. 2016, 22, 1254–1262. [Google Scholar] [CrossRef] [Green Version]

- Mahderekal, I.; Shen, B.; Vineyard, E.A. System Modeling of Gas Engine Driven Heat Pump. In Proceedings of the International Refrigeration and Air Conditioning Conference at Purdue, West Lafayette, IN, USA, 16–19 July 2012. [Google Scholar]

- Shen, B.; Ally, M.R. Energy and Exergy Analysis of Low-Global Warming Potential Refrigerants as Replacement for R410A in Two-Speed Heat Pumps for Cold Climates. Energies 2020, 13, 5666. [Google Scholar] [CrossRef]

- Shen, B.; Abdelaziz, O.; Shrestha, S.; Elatar, A. Model-Based Optimizations of Packaged Rooftop Air Conditioners Using Low Global Warming Potential Refrigerants. Int. J. Refrig. 2018, 87, 106–117. [Google Scholar] [CrossRef]

- ANSI/AHRI Standard 540-99. Positive Displacement Refrigerant Compressors and Compressor Units; Air Conditioning and Refrigeration Institute: Arlington, VA, USA, 2010. [Google Scholar]

- Braun, J.E.; Klein, S.A.; Mitchell, J.W. Effectiveness models for cooling towers and cooling coils. ASHRAE Trans. 1989, 95 Pt 2, 164–174. [Google Scholar]

- Thome, J.R.; Hajal, J. Two-Phase Flow Pattern Map for Evaporation in Horizontal Tubes: Latest Version. Heat Transf. Eng. 2002, 24, 1–2. [Google Scholar] [CrossRef]

- Cavallini, A.; Col, D.D.; Doretti, L.; Matkovic, M.; Rossetto, L.; Zilio, C.; Censi, G. Condensation in Horizontal Smooth Tubes: A New Heat Transfer Model for Heat Exchanger Design. Heat Transfer. Eng. 2006, 27, 1–38. [Google Scholar] [CrossRef]

- Choi, J.Y.; Kedzierski, M.A.; Domanski, P.A. Generalized pressure drop correlation for evaporation and condensation in smooth and micro-fin tubes. In Proceedings of the International Institute of Refrigeration (IIR), Paderborn, Germany, 3–5 October 2001; Volume 1, pp. 9–16. [Google Scholar]

- Stephan, K. Heat Transfer in Condensation and Boiling; Springer: New York, NY, USA, 1992; p. 84. [Google Scholar]

- Bell, K.J. An approximate generalized design method for multicomponent/partial condensers. In AIChE Symposium Series; American Institute of Chemical Engineers: New York, NY, USA, 1972; Volume 69, pp. 72–79. [Google Scholar]

- Lemmon, E.W.; Bell, I.H.; Huber, M.L.; McLinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 10.0; National Institute of Standards and Technology, Standard Reference Data Program: Gaithersburg, MD, USA, 2018.

- Warke, K., Jr. Advanced Thermodynamics for Engineers; McGraw-Hill: New York, NY, USA, 1995; ISBN 0-07-068292-5. [Google Scholar]

- Ally, M.R.; Munk, J.D.; Baxter, V.D.; Gehl, A.C. Data, exergy, and energy analyses of a vertical-bore, ground-source heat pump for domestic water heating under simulated occupancy conditions. Appl. Therm. Eng. 2015, 89, 192–203. [Google Scholar] [CrossRef] [Green Version]

- Ally, M.R.; Munk, J.D.; Baxter, V.D.; Gehl, A.C. Exergy and energy analysis of a ground-source heat pump for domestic water heating under simulated occupancy conditions. Int. J. Refrig. 2013, 36, 1417–1430. [Google Scholar] [CrossRef]

- Ally, M.R.; Munk, J.D.; Baxter, V.D.; Gehl, A.C. Exergy analysis and operational efficiency of a horizontal ground-source heat pump system operated in a low-energy test house under simulated occupancy conditions. Int. J. Refrig. 2012, 35, 1092–1103. [Google Scholar] [CrossRef]

| Refrigerant | GWP | Safety Category | Glide (K) | Critical T (°C) |

|---|---|---|---|---|

| R-410A a | 1924 | A1 | 0.1 | 71.34 |

| R-452B b | 676 | A2L | 1.3 | 79.68 |

| R-454B c | 476 | A2L | 1.5 | 77 |

| R-466A d | 733 | A1 | 1.5 | 83.8 |

| R-32 | 677 | A2L | 0 | 78.12 |

| Parameters | Indoor Fin-and-Tube Coil | Outdoor Fin-and-Tube Coil |

|---|---|---|

| Face area, (m2) | 0.307 | 2.07 |

| Total Tube Number | 84 | 64 |

| Number of rows | 3 (cross counter-flow) | 2 (cross counter-flow) |

| Number of parallel circuits | 9 | 6 |

| Fin density, (fins/m) | 551 | 866 |

| Indoor Blower (High/Low) | Outdoor Fan | |

| Flow Rate, (m3/s) | 0.790/0.653 | 1.652 |

| Power (W) | 322/203 | 300 |

| Outdoor Condition | Capacity (kW) | COP (W/W) | Compressor Disc T (°C/°F) | Compressor Efficiency |

|---|---|---|---|---|

| 35 °C_H | 17.6 | 3.7 | 73.38/164.1 | 74% |

| 27.7 °C_H | 18.7 | 4.5 | 64.11/147.4 | 73% |

| 35 °C_L | 13.0 | 3.9 | 70.38/158.7 | 67% |

| 27.7 °C_L | 13.9 | 4.8 | 60.23/140.5 | 67% |

| R-410A | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 35 °C_H | 35 °C (Low Speed) | 27.7 °C (High Speed) | 27.7 °C (Low Speed) | |||||||||||||

| State | P | T | h | s | P | T | h | s | P | T | h | s | P | T | h | s |

| Point | kPa | C | kJ/kg | kJ/kg-K | kPa | C | kJ/kg | kJ/kg-K | kPa | C | kJ/kg | kJ/kg-K | kPa | C | kJ/kg | kJ/kg-K |

| 1 | 1061.359 | 14.87 | 430.7143 | 1.817089 | 1105.651 | 16.25 | 431.0992 | 1.814593 | 1040.212 | 14.20 | 430.5215 | 1.818312 | 1085.221 | 15.62 | 430.92 | 1.8157 |

| 2 | 2888.987 | 73.40 | 464.7122 | 1.834438 | 2684.447 | 70.40 | 464.2515 | 1.839454 | 2462.857 | 64.13 | 460.051 | 1.834642 | 2274.147 | 60.26 | 458.55 | 1.8372 |

| 3 | 2882.092 | 72.39 | 463.4805 | 1.831083 | 2677.552 | 69.44 | 463.1207 | 1.836382 | 2455.962 | 63.23 | 459.0115 | 1.831801 | 2267.252 | 59.38 | 457.57 | 1.8345 |

| 4 | 2871.088 | 41.54 | 268.896 | 1.227916 | 2671.264 | 38.47 | 263.292 | 1.210672 | 2442.979 | 34.74 | 256.6313 | 1.189906 | 2259.764 | 31.55 | 251.05 | 1.1723 |

| 5 | 1079.706 | 9.76 | 266.3433 | 1.234775 | 1118.296 | 10.94 | 260.8516 | 1.21458 | 1058.394 | 9.08 | 254.2993 | 1.192601 | 1097.832 | 10.31 | 248.79 | 1.1725 |

| 6 | 407.2555 | 15.04 | 430.7142 | 1.816481 | 424.3339 | 16.41 | 431.0991 | 1.814013 | 398.917 | 14.37 | 430.5214 | 1.81769 | 416.5228 | 15.78 | 430.92 | 1.8151 |

| R-32 | ||||||||||||||||

| 35 °C_H | 35 °C (Low Speed) | 27.7 °C (High Speed) | 27.7 °C (Low Speed) | |||||||||||||

| State | P | T | h | s | P | T | h | s | P | T | h | s | P | T | h | s |

| Point | kPa | C | kJ/kg | kJ/kg-K | kPa | C | kJ/kg | kJ/kg-K | kPa | C | kJ/kg | kJ/kg-K | kPa | C | kJ/kg | kJ/kg-K |

| 1 | 1061.469 | 14.18 | 524.1352 | 2.150371 | 1107.133 | 15.59 | 524.3509 | 2.145538 | 1042.474 | 13.58 | 524.0378 | 2.152434 | 1088.6 | 15.02 | 524.27 | 2.1475 |

| 2 | 2989.789 | 89.48 | 576.3498 | 2.176396 | 2763.523 | 85.49 | 574.951 | 2.182654 | 2542.181 | 77.63 | 568.6604 | 2.175724 | 2336.758 | 72.47 | 565.84 | 2.1786 |

| 3 | 2982.894 | 88.41 | 575.0437 | 2.173084 | 2756.628 | 84.47 | 573.7388 | 2.179593 | 2535.286 | 76.66 | 567.527 | 2.17284 | 2329.864 | 71.53 | 564.77 | 2.1759 |

| 4 | 2974.717 | 42.10 | 279.8036 | 1.263794 | 2751.912 | 38.80 | 272.9427 | 1.242711 | 2525.482 | 35.22 | 265.6775 | 1.220089 | 2324.141 | 31.83 | 258.92 | 1.1988 |

| 5 | 1076.865 | 48.38 | 276.9964 | 1.27303 | 1118.302 | 46.77 | 270.2463 | 1.248131 | 1057.801 | 45.06 | 263.0799 | 1.224142 | 1099.742 | 43.46 | 256.41 | 1.1996 |

| 6 | 398.9618 | 14.37 | 524.1352 | 2.149511 | 416.3821 | 15.77 | 524.3509 | 2.144718 | 391.5507 | 13.77 | 524.0378 | 2.151556 | 409.3778 | 15.21 | 524.27 | 2.1466 |

| R-452B | ||||||||||||||||

| 35 °C_H | 35 °C (Low Speed) | 27.7 °C (High Speed) | 27.7 °C (Low Speed) | |||||||||||||

| State | P | T | h | s | P | T | h | s | P | T | h | s | P | T | h | s |

| Point | kPa | C | kJ/kg | kJ/kg-K | kPa | C | kJ/kg | kJ/kg-K | kPa | C | kJ/kg | kJ/kg-K | kPa | C | kJ/kg | kJ/kg-K |

| 1 | 1003.319 | 15.48 | 466.4158 | 1.943559 | 1044.556 | 16.84 | 466.7978 | 1.940519 | 985.6956 | 14.89 | 466.2443 | 1.944891 | 1027.981 | 16.30 | 466.65 | 1.9417 |

| 2 | 2719.935 | 77.64 | 506.1041 | 1.963472 | 2529.294 | 74.76 | 505.6864 | 1.969666 | 2313.192 | 67.83 | 500.6442 | 1.964187 | 2138.389 | 63.86 | 498.88 | 1.9671 |

| 3 | 2713.04 | 76.70 | 504.963 | 1.960471 | 2522.4 | 73.85 | 504.6174 | 1.966868 | 2306.297 | 66.96 | 499.6449 | 1.961559 | 2131.494 | 63.01 | 497.93 | 1.9646 |

| 4 | 2703.663 | 40.94 | 271.4447 | 1.236906 | 2517.077 | 37.89 | 265.6463 | 1.218998 | 2295.245 | 34.03 | 258.4618 | 1.196515 | 2125.103 | 30.88 | 252.70 | 1.1782 |

| 5 | 1019.907 | 46.44 | 268.8809 | 1.244085 | 1056.263 | 45.08 | 263.1706 | 1.223065 | 1002.14 | 43.39 | 256.0786 | 1.199142 | 1039.702 | 42.03 | 250.38 | 1.1783 |

| 6 | 414.9156 | 15.65 | 466.4158 | 1.942816 | 431.7278 | 17.01 | 466.7976 | 1.939808 | 407.5693 | 15.06 | 466.2443 | 1.944133 | 425.033 | 16.47 | 466.65 | 1.9410 |

| R-454B | ||||||||||||||||

| 35 °C_H | 35 °C (Low Speed) | 27.7 °C (High Speed) | 27.7 °C (Low Speed) | |||||||||||||

| State | P | T | h | s | P | T | h | s | P | T | h | s | P | T | h | S |

| Point | kPa | C | kJ/kg | kJ/kg-K | kPa | C | kJ/kg | kJ/kg-K | kPa | C | kJ/kg | kJ/kg-K | kPa | C | kJ/kg | kJ/kg-K |

| 1 | 992.8041 | 15.61 | 470.8232 | 1.959076 | 1033.58 | 16.97 | 471.2111 | 1.955988 | 975.581 | 15.02 | 470.6514 | 1.960414 | 1017.253 | 16.43 | 471.06 | 1.9572 |

| 2 | 2686.095 | 78.01 | 511.1368 | 1.979282 | 2497.951 | 75.15 | 510.7352 | 1.985649 | 2282.945 | 68.15 | 505.5965 | 1.98014 | 2111.155 | 64.19 | 503.82 | 1.9831 |

| 3 | 2679.2 | 77.08 | 510.0125 | 1.97634 | 2491.056 | 74.25 | 509.6789 | 1.9829 | 2276.05 | 67.28 | 504.608 | 1.977556 | 2104.26 | 63.35 | 502.88 | 1.9807 |

| 4 | 2669.961 | 40.82 | 271.6611 | 1.237731 | 2485.851 | 37.78 | 265.8435 | 1.219752 | 2265.204 | 33.89 | 258.5745 | 1.196988 | 2098.013 | 30.75 | 252.81 | 1.1787 |

| 5 | 1009.186 | 46.50 | 269.0996 | 1.24489 | 1045.218 | 45.13 | 263.3683 | 1.223791 | 991.8043 | 43.41 | 256.188 | 1.199553 | 1028.864 | 42.05 | 250.49 | 1.1787 |

| 6 | 416.5407 | 15.79 | 470.8234 | 1.958314 | 433.3446 | 17.14 | 471.2111 | 1.955258 | 409.2847 | 15.20 | 470.6515 | 1.959636 | 426.6753 | 16.60 | 471.06 | 1.9565 |

| R-466A | ||||||||||||||||

| 35 °C_H | 35 °C (Low Speed) | 27.7 °C (High Speed) | 27.7 °C (Low Speed) | |||||||||||||

| State | P | T | h | s | P | T | h | s | P | T | h | s | P | T | h | s |

| Point | kPa | C | kJ/kg | kJ/kg-K | kPa | C | kJ/kg | kJ/kg-K | kPa | C | kJ/kg | kJ/kg-K | kPa | C | kJ/kg | kJ/kg-K |

| 1 | 1118.061 | 14.37 | 401.5645 | 1.715012 | 1165.676 | 15.81 | 401.8197 | 1.712382 | 1096.501 | 13.71 | 401.4427 | 1.716237 | 1144.537 | 15.18 | 401.71 | 1.7135 |

| 2 | 3058.502 | 79.85 | 433.0141 | 1.731168 | 2836.684 | 76.22 | 432.2095 | 1.734866 | 2614.707 | 69.61 | 428.5904 | 1.730939 | 2411.484 | 65.08 | 426.95 | 1.7326 |

| 3 | 3051.607 | 78.80 | 432.0278 | 1.728548 | 2829.789 | 75.23 | 431.302 | 1.732459 | 2607.812 | 68.68 | 427.7509 | 1.728698 | 2404.589 | 64.17 | 426.16 | 1.7306 |

| 4 | 3039.065 | 41.96 | 256.182 | 1.185408 | 2822.494 | 38.75 | 251.4415 | 1.170867 | 2593.016 | 35.14 | 246.2274 | 1.154662 | 2395.846 | 31.84 | 241.56 | 1.1400 |

| 5 | 1138.159 | 42.91 | 254.0899 | 1.191654 | 1179.142 | 41.80 | 249.4426 | 1.174532 | 1116.282 | 40.58 | 244.3114 | 1.157369 | 1157.968 | 39.48 | 239.71 | 1.1405 |

| 6 | 401.1013 | 14.54 | 401.5647 | 1.714494 | 418.8553 | 15.97 | 401.8197 | 1.711887 | 392.8793 | 13.88 | 401.4424 | 1.715705 | 411.0428 | 15.34 | 401.71 | 1.7130 |

| 27′7 °C_H | 27′7 °C_H | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| R410A | R32 | R452B | R454B | R466A | R410A | R32 | R452B | R454B | R466A | Units | |

| m | 388.95 | 275.69 | 318.86 | 310.47 | 455.07 | 279.87 | 198.41 | 228.88 | 222.75 | 328.27 | kg/h |

| Wrefrig. | 3190.38 | 3417.24 | 3046.85 | 3013.71 | 3431.70 | 2147.22 | 2291.34 | 2049.32 | 2026.88 | 2301.71 | J/s |

| QComp. | −354.26 | −379.45 | −338.32 | −334.64 | −381.05 | −238.43 | −254.43 | −227.56 | −225.07 | −255.58 | J/s |

| WComp. | 3544.64 | 3796.69 | 3385.17 | 3348.35 | 3812.76 | 2385.65 | 2545.77 | 2276.88 | 2251.95 | 2557.29 | J/s |

| σComp. | 2.94 | 3.04 | 2.83 | 2.81 | 3.13 | 2.46 | 2.56 | 2.37 | 2.35 | 2.59 | W/K |

| IComp. | 885.04 | 916.05 | 852.52 | 846.46 | 940.18 | 739.94 | 769.94 | 712.89 | 707.36 | 779.82 | J/s |

| QCond. | −21,865.22 | −23,115.92 | −21,361.95 | −21,218.22 | −22,946.12 | −16,055.15 | −16,856.57 | −15,591.57 | −15,472.52 | −16,833.30 | J/s |

| σCond. | 3.33 | 3.87 | 3.24 | 3.21 | 3.71 | 1.88 | 2.18 | 1.83 | 1.81 | 2.10 | W/K |

| ICond. | 1001.13 | 1165.14 | 976.02 | 965.86 | 1115.54 | 566.23 | 655.52 | 549.97 | 543.87 | 631.48 | J/s |

| QEXV | −251.95 | −198.93 | −205.82 | −205.82 | −242.20 | −175.42 | −138.78 | −143.78 | −143.78 | −168.70 | J/s |

| σExv. | 1.13 | 0.97 | 0.93 | 0.91 | 1.15 | 0.60 | 0.51 | 0.49 | 0.48 | 0.61 | W/K |

| IEXV | 339.55 | 292.29 | 281.08 | 272.36 | 345.14 | 179.61 | 153.17 | 147.94 | 143.26 | 183.20 | J/s |

| QEvap. | 19,039.10 | 19,984.41 | 18,614.70 | 18,495.59 | 19,862.70 | 14,159.03 | 14,762.81 | 13,749.75 | 13,647.52 | 14,772.00 | J/s |

| σEvap. | 4.03 | 4.37 | 3.90 | 3.86 | 4.33 | 2.74 | 2.95 | 2.63 | 2.61 | 2.94 | W/K |

| IEvap. | 1208.97 | 1309.29 | 1168.71 | 1157.56 | 1157.56 | 820.80 | 885.44 | 789.36 | 781.27 | 781.27 | J/s |

| Line Loss(2-3) | −112.31 | −86.80 | −88.52 | −85.25 | −106.12 | −75.67 | −58.80 | −60.18 | −58.10 | −71.73 | J/s |

| σ2-3 | 0.07 | 0.07 | 0.06 | 0.06 | 0.07 | 0.05 | 0.05 | 0.04 | 0.04 | 0.05 | W/K |

| I2-3 | 19.97 | 20.34 | 18.48 | 18.21 | 20.90 | 13.59 | 13.93 | 12.80 | 12.65 | 14.20 | J/s |

| Line Loss(6-1) | −112.31 | 0.00 | 0.00 | −0.01 | 0.03 | −75.67 | 0.00 | −0.01 | 0.00 | 0.02 | J/s |

| σ6-1 | 0.07 | 0.07 | 0.07 | 0.07 | 0.07 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | W/K |

| I6-1 | 19.97 | 20.22 | 20.20 | 20.20 | 20.20 | 13.59 | 13.86 | 13.83 | 13.82 | 13.88 | J/s |

| ITotal | 3474.88 | 3723.33 | 3317.01 | 3280.63 | 3739.85 | 2334.03 | 2491.86 | 2226.79 | 2202.23 | 2503.36 | J/s |

| COPCarnot | 290.24 | 290.24 | 290.24 | 290.24 | 290.24 | 290.24 | 290.24 | 290.24 | 290.24 | 290.24 | |

| WCarnot | 65.60 | 68.85 | 64.14 | 63.73 | 68.44 | 48.78 | 50.86 | 47.37 | 47.02 | 50.90 | J/s |

| Wa = WCarnot + Itotal | 3540.48 | 3792.18 | 3381.14 | 3344.36 | 3808.29 | 2382.82 | 2542.72 | 2274.16 | 2249.26 | 2554.26 | J/s |

| E In | 22,584 | 23,781 | 22,000 | 21,844 | 23,675 | 16,545 | 17,309 | 16,027 | 15,899 | 17,329 | J/s |

| E Out | -22,584 | -23,781 | −22,000 | −21,844 | −23,675 | −16,545 | −17,309 | −16,027 | −15,899 | −17,329 | J/s |

| %ΔE | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, B.; Ally, M.R. Comparative Performance of Low Global Warming Potential (GWP) Refrigerants as Replacement for R-410A in a Regular 2-Speed Heat Pump for Sustainable Cooling. Sustainability 2021, 13, 8199. https://doi.org/10.3390/su13158199

Shen B, Ally MR. Comparative Performance of Low Global Warming Potential (GWP) Refrigerants as Replacement for R-410A in a Regular 2-Speed Heat Pump for Sustainable Cooling. Sustainability. 2021; 13(15):8199. https://doi.org/10.3390/su13158199

Chicago/Turabian StyleShen, Bo, and Moonis R. Ally. 2021. "Comparative Performance of Low Global Warming Potential (GWP) Refrigerants as Replacement for R-410A in a Regular 2-Speed Heat Pump for Sustainable Cooling" Sustainability 13, no. 15: 8199. https://doi.org/10.3390/su13158199

APA StyleShen, B., & Ally, M. R. (2021). Comparative Performance of Low Global Warming Potential (GWP) Refrigerants as Replacement for R-410A in a Regular 2-Speed Heat Pump for Sustainable Cooling. Sustainability, 13(15), 8199. https://doi.org/10.3390/su13158199