1. Introduction

The increasing awareness of environmental protection has attracted global attention, with most industries taking the issue of sustainability seriously [

1,

2]. In 2015, countries around the world signed the Paris Agreement, which focuses primarily on reducing CO

2 and other greenhouse gas emissions [

3]. Various countries have also promoted their own plans for carbon reduction strategies and green buildings [

4,

5,

6,

7,

8,

9,

10].

In the United States, the Regional Greenhouse Gas Initiative (RGGI), established in 2009, was the first mandatory program to reduce greenhouse gas emissions. RGGI is a cooperative effort among certain states to limit and reduce CO

2 emissions from the power sector [

11]. British Columbia, Canada, began implementing a carbon tax in 2008. As of 1 April 2021, B.C.’s carbon tax rate has been increased to

$45 per tCO

2e (Canadian dollars) [

12]. The Tokyo Metropolitan Government of Japan launched a green building program in 2002 to encourage energy saving technologies and environmentally friendly design in buildings [

13]. The Tokyo Cap-and-Trade Program was launched in 2010 as the first mandatory carbon trading system in Japan. On aggregate, the emissions from 2015 to 2019 were reduced by 27% compared with base-year emissions [

14].

In 2015, Taiwan’s government announced the “Greenhouse Gas Reduction and Management Act”, the goal of which was a 50% reduction in carbon emissions by 2050, compared with 2005. According to statistics from the International Energy Agency [

15] and Environmental Protection Administration in Taiwan [

16], Taiwan’s CO

2 emission from fuel combustion in 2018 was 257.0 MtCO

2, accounting for 0.77% of global emissions, and ranking 21st in the world. The average per capita emission is 10.83 tCO

2, ranking 20th in the world.

To achieve the goal of carbon reduction, the efforts of the building and construction industry are indispensable. Past studies have shown that the building and construction industry is responsible for 38% of all carbon emissions in the world and for about 35% of energy consumption [

17]. The residential sector accounts for 11.49% of Taiwan’s total carbon emissions, mainly from electricity emissions such as air conditioners [

18].

The development of the building and construction industry has clearly become a key factor in reducing global carbon emissions, with the proportion of construction renovation projects being much greater than that of new construction projects. Developing methods for providing a high-quality living environment in an energy-efficient, low-carbon way is a key factor in building renovations.

Many studies have pointed out that building envelopes have significant benefits regarding carbon reduction. Basbagill et al. [

19] showed that the choice of building envelope has a great impact on carbon emissions during the life cycle of a building. The thermal insulation performance of windows and exterior walls influences the carbon emissions caused by urban household energy use. Therefore, high insulation performance can effectively alleviate heat in summer and cold in winter and thus further reduce household energy use [

20].

We adopted life cycle assessment (LCA) to evaluate carbon emissions and costs. The LCA of buildings was used to assess the impact of buildings on the environment during their entire life cycle. The International Organization for Standardization (ISO) has developed a series of LCA-related standards [

21,

22], with the basic concept of evaluating the environmental impact of products in different life cycles (from cradle to grave). The scope includes the stages of raw material acquisition, manufacturing, use, and waste [

23].

In the carbon footprint evaluation system for the building industry developed by the Low Carbon Building Alliance (LCBA) in Taiwan, the carbon footprint throughout all stages in the life cycle of a new building project includes the following five stages: manufacturing and transportation of materials; construction; daily use; renovation; and demolition. The life cycle for new building projects is generally defined as 60 years [

24,

25]. At present, almost all the carbon emissions of buildings in Taiwan are assessed using this system.

The carbon emissions of materials production are closely related to the local energy structure and energy efficiency. The carbon emission coefficients of different countries and regions vary. The use of the carbon emission database, which is calculated based on the local energy structure, is conducive to the accuracy of calculations. The LCBA carbon footprint database is also currently the most commonly used database in Taiwan’s building industry. According to standards of PAS2050 [

26] and ISO 14,067 [

27], the LCBA carbon footprint database integrates Taiwan’s existing construction engineering data and traces the carbon emissions data back to the raw materials.

Machine learning (ML) can solve specific problems or tasks through relative information and experiences and has been widely used in various prediction model studies, such as image and speech recognition [

28,

29], market analysis [

30], etc. In the ML approach, a prediction model can be trained with input data to obtain the goal without solving theoretic equations.

ML has previously been used to predict the energy consumption of specific buildings: Robinson et al. [

31] constructed predictive models for the energy consumption of commercial buildings in the United States using various ML methods; Ciulla et al. [

32] used artificial neural networks to predict the demand for thermal energy linked to the winter acclimatization of non-residential buildings in Europe.

There has been less application of ML for prediction of carbon emissions than for energy consumption. A case study in Italy used an artificial neural network to predict building energy and various environmental indicators at the same time [

33]. Reviewing the past literature, aside from there being fewer ML predictive models for carbon emissions, little discussion can be found on Taiwan’s climate and its architectural form, and very few scholars have studied the building renovation process.

Furthermore, several studies [

34,

35,

36,

37] have shown that the decision-making process to improve building energy efficiency often involves multiple criteria in addition to energy consumption and carbon emissions. A multi-purpose optimization system can assist designers in decision-making during the design or renovation process.

As stated above, accurate calculations and simulation of building energy consumption and carbon emissions are time-consuming and laborious. The purpose of this research is to use ML methods to develop a model for predicting energy consumption and carbon emissions based on Taiwan’s climate and common building patterns. The results can be used to quickly evaluate the sustainability of a building in the initial stage of architectural design or the renovation phase.

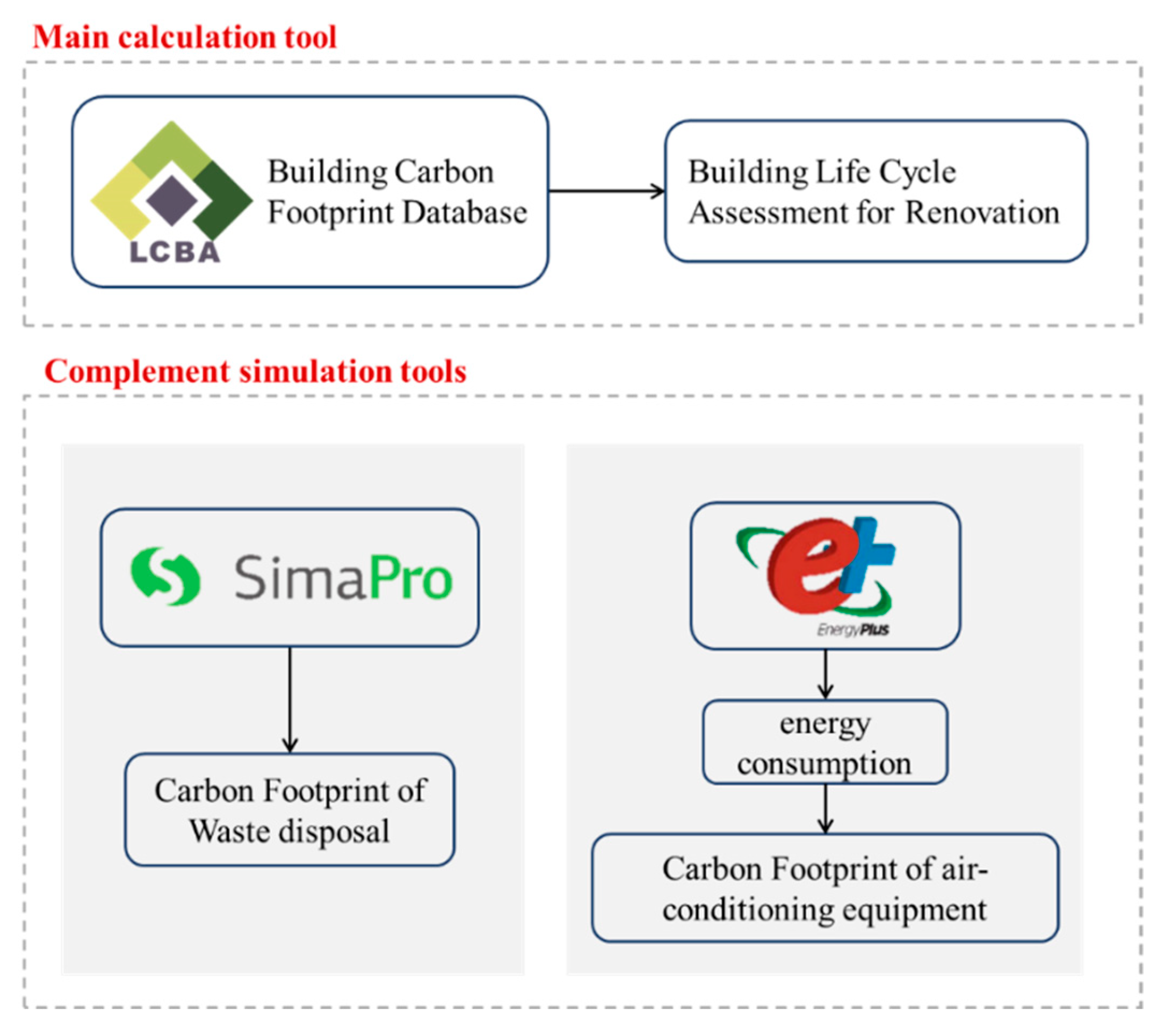

This study considered the LCCO2 of a building envelope renovation project in Taiwan and studied the local construction methods for typical row houses. Through EnergyPlus, SimaPro, and the local database (LCBA database), the annual energy consumption and the LCCO2 of 744 cases with various climate zones, orientations, insulation types, and glazing types were calculated, and the results were used to develop an ML model.

In

Section 2, we introduce the methodology, which is mainly divided into data collection and ML training processes.

Section 3 explains the results, including data observation, the results of adjusting hyperparameters, and the final prediction model, and

Section 4 presents the conclusion.

4. Conclusions

In this study, our goal was to use ML to predict the annual energy consumption and life-cycle carbon footprint of row houses in Taiwan for the renovation behavior of buildings. In terms of applicability, only simple material properties and climatic conditions needed to be input; in terms of model performance, it had high accuracy.

Therefore, compared with the current technologies generally used, which usually require the building of a 3D model and need detailed material properties to obtain accurate energy consumption and carbon emissions, when using the ML model developed in this research, as long as one enters the eight features listed in

Table 9, one can obtain the predicted annual energy consumption and LCCO

2 of a row house in a very short time.

Such a simple and fast ML predictive model can also be integrated into a mul-ti-purpose optimized system in the future to assist designers in decision-making. Usually, the targets involved in building design optimization are complicated, very time-consuming, or need to set many parameters. Integrating the ML model into the op-timization system is convenient to use and has practical applications.

Before performing supervised learning, a credible database for training was necessary. Therefore, this study used the LCBA database, the most commonly used carbon emission database in Taiwan’s building industry, and complemented it with the SimaPro database to calculate building carbon emissions. Furthermore, since different materials cause different energy consumption in the subsequent use phase, we used EnergyPlus to determine the annual energy consumption of air conditioning in each case to obtain more accurate life-cycle carbon emissions results.

Regarding the construction of ML models, selecting the best features is important. Even a low correlation with the target does not mean that the variable has no effect on the ML model. Our results show that even though the importance of features can be preliminarily determined from the correlation map, this only represents the relationship between the two parameters. In the ML model, various parameters may interact with each other and then affect the final prediction result. Therefore, when adjusting the input features of the model, more detailed comparisons and judgments are needed to obtain more suitable input features.

The generalization of ML depends on the dataset used, so the model constructed in this study can only be used to predict the form of row houses. However, the ML model thus constructed does not have to be limited to row houses in Taiwan. If the dataset is expanded to cover different building types, it may become a more flexible and extensive predictive model in the future.

Furthermore, our discussion was only focused on the three representative climate zones of Taiwan. If data on different cities can be added in the future, the scope of application can be expanded. Regarding the selection of materials, since this study adopts the most common structural form in Taiwan, the distribution of U values is somewhat too concentrated, especially with regard to the exterior wall, and whether it will cause problems in the prediction of exterior walls of other structures remains to be studied.

In summary, if the number and diversity of sample data can be increased, the scope of application of prediction models can be continuously expanded. However, with regard to the common renovation behavior of row houses in Taiwan, the prediction model proposed by this study can effectively predict the annual energy consumption and building life-cycle carbon footprint quickly and conveniently.