Abstract

The circular economy is a process through which elements that have already been used are reincorporated and given a second use so that they can reduce the consumption of virgin raw materials. This article shows how, from the reuse of an agro-industrial waste such as corn husks, a biomaterial can be developed that manages to standardize the properties of materials such as paper and cardboard, thus allowing the development of single-use products that replace the excessive expense of materials such as polymers. In this article, it will be possible to show how from the process of transforming an agro-industrial waste into a raw material base, it is possible not only to reduce the number of raw materials discarded but also to redesign a product that not only contributes to the environmental component but also facilitates the processes of economic sustainability when generating products. As a practical case, a comparison is made between traditional fast-food packaging and how from these, a new packaging proposal can be generated, which starts from the principles of circular economy and complements sustainable design processes to make more efficient manufacturing of the mentioned product.

1. Introduction

Sustainability and in turn sustainable development have been configured as concepts of common use in today’s society, thus encouraging the linking of processes, activities, and developments that enhance these concepts within any project of society [1], thus promoting the importance of understanding and recognizing actions in favor of giving good use and preserving the existing resources in the environment [2], this with the intention of promoting a mentality oriented towards changes in the traditional models of production and consumption, not only from the companies but also from consumer behavior [3].

Understanding the importance of creating new practices in the behavior not only of consumers but also in production processes (in turn associated with the existing supply and demand in the market for goods and services [4]), it is necessary to incorporate strategies that facilitate the use of resources and waste, reduce the stages of processes, and make the cycle of production, use, and final disposal of goods and services more efficient [3].

Under the previous premise, the importance of incorporating sustainable design processes with circular economy strategies [5] is identified, through which it is possible to reach creation and development solutions that not only generate innovative products and services but also contribute to the sustainable development of the place or region in which they are implemented. It is necessary that in the transformation of society’s actions, the resources available now are taken advantage of, thus allowing the continuity of the life cycle of large quantities of raw materials [6] and thus avoiding their unnecessary disposal.

In each region or country, there are different sources of waste depending on the productive activities of said sector [7]; this opens the possibility that from the use of these raw materials, new practices of exploitation can be incorporated, offering the possibility of transforming those waste in products or elements that meet the needs of society without the need to consume new materials or reduce the existing waste rate of said space [8].

It is for this reason that innovative and creative alternatives should be sought that contribute to the changes in the processes that have traditionally been carried out in the field of production and development processes [5]; therefore, in this article, it is analyzed how from the use of a waste from the food industry, a product can be developed that replaces the traditional packaging of polymers and paper, thus allowing the reduction of the use of natural resources and at the same time improving the final disposal capacity of the same [9].

The processes for the use of waste as a raw material are one of the main actions promoted by the circular economy to improve the use of existing resources in the environment [10], this with the intention that small, medium, and large producers can reduce the acquisition of virgin raw materials [11], which implies a shortage or reduction of resources in the environment.

Within the reuse of raw materials, strategies not only of circular economy but also of sustainable design must be applied [12], through which it is understood not only the impacts associated with the transformation actions of the raw material but also how the behavior will be the subsequent disposal of the substitution of the original material for one with fewer implications for the environment [13].

It is important to understand that when it is sought to establish the reincorporation of a material into a production process, it is necessary to make an analysis of the properties or characteristics, physical, mechanical, and visual, of the material [14], since when reused, the initial capacities are reduced, and they must fulfill functions that do not imply the need for 100% of the initial capacities [15].

During the process of transformation of the reincorporated waste, it is necessary to also work a process mediated through design, in which not only a functional but also an aesthetic component is supplied [16]; this is because although the function to comply with the product must be totally practical, the user or consumer will feel a better link or attraction to said element if it visually generates a link or acquisition interest [17].

For the case of the present study, an analysis is developed based on how the reincorporation of the residues associated with corn [18] can be the source of raw material for the development of a material with properties and capacities like those of paper/cardboard, by means of which the consumption of trees or other species can be replaced for the elaboration of a lot of products or objects, but principally one of the biggest things that can be changed with the use of this biomaterial is the elaboration of packaging [19].

It is for the anterior premise that the main objective of this research is to be able to understand if it is possible to take advantage of waste for the development of raw materials that can be used later as a basis for product design; however, under the conditions of the research and the difficulties associated with the spread of the COVID-19 pandemic, an in-depth analysis of the characteristics or properties of the material is not developed, reaching only the ability to understand the malleability of the material to be used as the main structure for short-use packaging from use of the corn waste (mainly the husks).

2. Materials and Methods

2.1. Study Case

This project was ejected between July 2020 and May 2021, and for the case of this study, the city of Medellín, Colombia, is taken as a reference, and occasionally one of the main places of commercialization of fruits and vegetables in the city, such as the José Maria Villa Retail Square, in which there are high rates of food waste, which, by not being sold in a period, are discarded and are not reused in other processes [19].

According to the Superintendency of Public Services and the National Planning Department of Colombia, during 2015, 9,967,844 tons of garbage were generated [19] covering not only polymers but also waste from agribusiness, one of the sectors with the highest variety and supply nationwide. Agribusiness has a national supply of available food of 28.5 million tons, of which 9.76 million tons are lost and wasted annually, which is equivalent to 34% of the total produced in the country [19].

In turn, one of the products at the national level that has great applications in traditional Colombian gastronomy is corn, this in relation to the large quantities of products at the national level [20]. Thus, corn and its derivatives allow it to occupy a very important place in terms of its production, with an annual generation that exceeds more than 1.7 million tons [19], which are not used one hundred percent since elements such as the stem and shells are discarded, these being optimal raw materials for the development of various products or applications [21].

It is because of the above that, seeking to obtain a raw material based on one of the wastes that are commonly discarded, the use of corn and, in turn, its husks is taken as a starting point, as it is an element with high amounts of cellulose and easily obtained in the local environment [20].

The fibers of the corn husks are implemented in the development of a biomaterial, based on the studies and research proposed by Minaya, Galarreta, Símpalo, Bonifacio, and Miñan at the University Católica de Trujillo Benedicto XVI in Peru [22] and the degree thesis by Andy Huatoca [23], in which it is indicated that the residues from corn present in their leave high contents of cellulose, a fundamental component for the creation of materials with properties similar to those of paper or cardboard.

With the possibility of obtaining a material that resembles the structural properties of paper/cardboard, the various possibilities that it may have in the local environment are analyzed, with the intention of aiming at the fulfillment of ODS 12 focused on production and consumption. This material is prioritized as the basis for the creation of fast-food packaging [24] since these are used in very short periods and their production involves the consumption of virgin raw materials mainly from trees [25].

2.2. Development Methodology

Within the process of obtaining a new raw material, the ability to understand in a practical way the behavior of the waste that is going to transform is vital, not only by identifying its parts but also by recognizing the transformation capacity of each one of the components found in this, such as the husks, the leaf, or even the grains [20].

Corn presents two conditions of high utilization capacity for the development of biomaterials from the reincorporation of its elements in the production chain: polylactic acid, by means of which bioplastics can be generated in the form of films [26], and the high percentages of cellulose found in the shells of said food [27].

Taking corn husks as working material and under the approaches of how to take advantage of this element as raw material for the development of materials comparable to paper/cardboard [23], a manufacturing process is structured in which the main stages of transformation of the material are based on obtaining the raw material (from the José María Villa retail market), the cleaning and drying of the material, the temporary humidification to facilitate the cooking process, and finally the crushing, shaping of pasta, and manufacturing of test pieces [22].

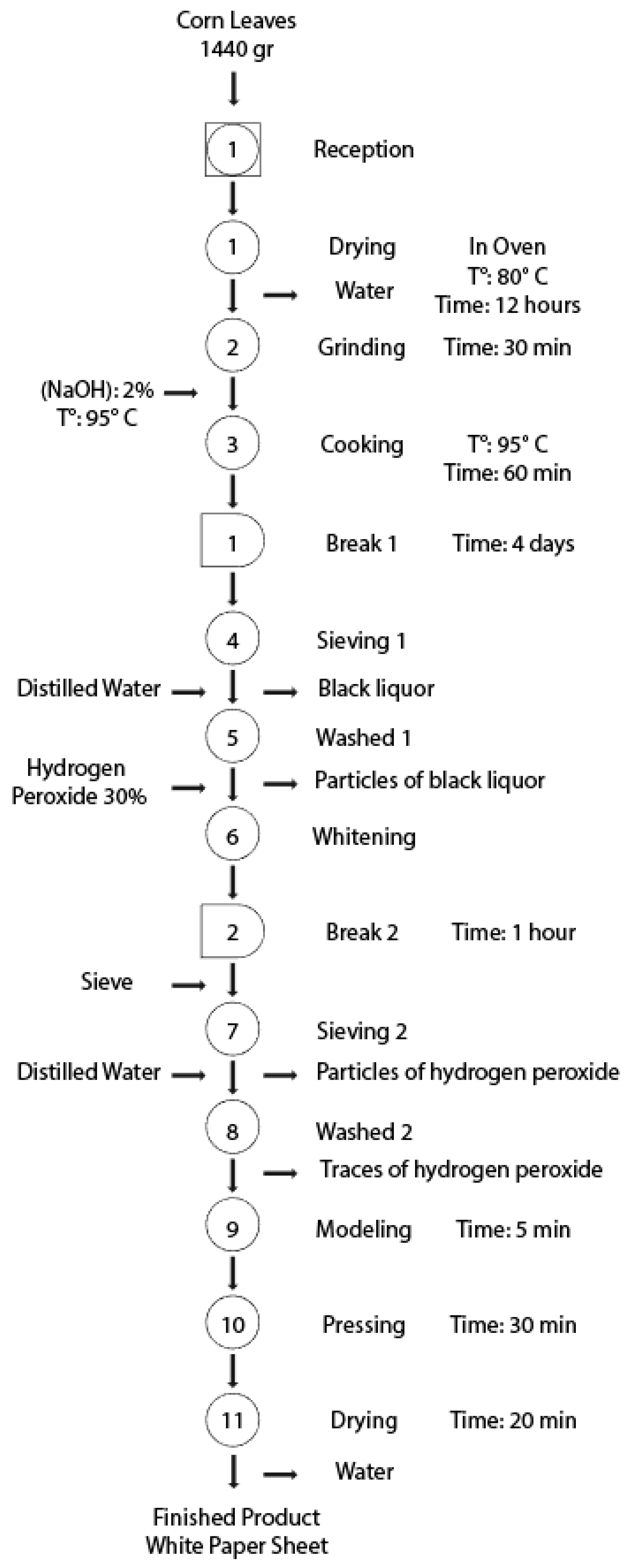

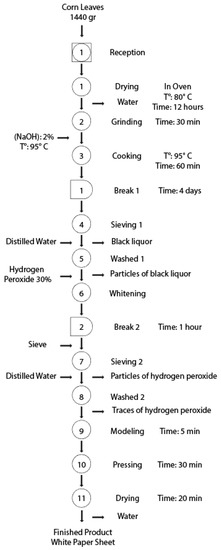

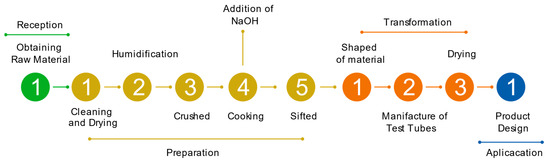

In Figure 1, it can be seen how a process of obtaining a raw material from the residues obtained from corn is established [22]; however (and although this process is directly linked to a circular economy process), it is necessary to review the different stages of said production, because there are actions that continue to affect the environment [28], due to times, processes, or the incorporation of chemicals that do not allow easy disposal at the end of the process.

Figure 1.

Structure of work to develop paper with corn waste developed by University Católica de Trujillo Benedicto XVI [22].

The process of obtaining cellulose for the creation of paper presented previously establishes a starting point through which a restructuring of the activities that are framed in it can be generated [29]; it is thus and through an analysis of the impacts that can be associated with this development that it is necessary to restructure a guide of actions that make this transformation of raw material more efficient and sustainable (mainly from the environmental component) [30].

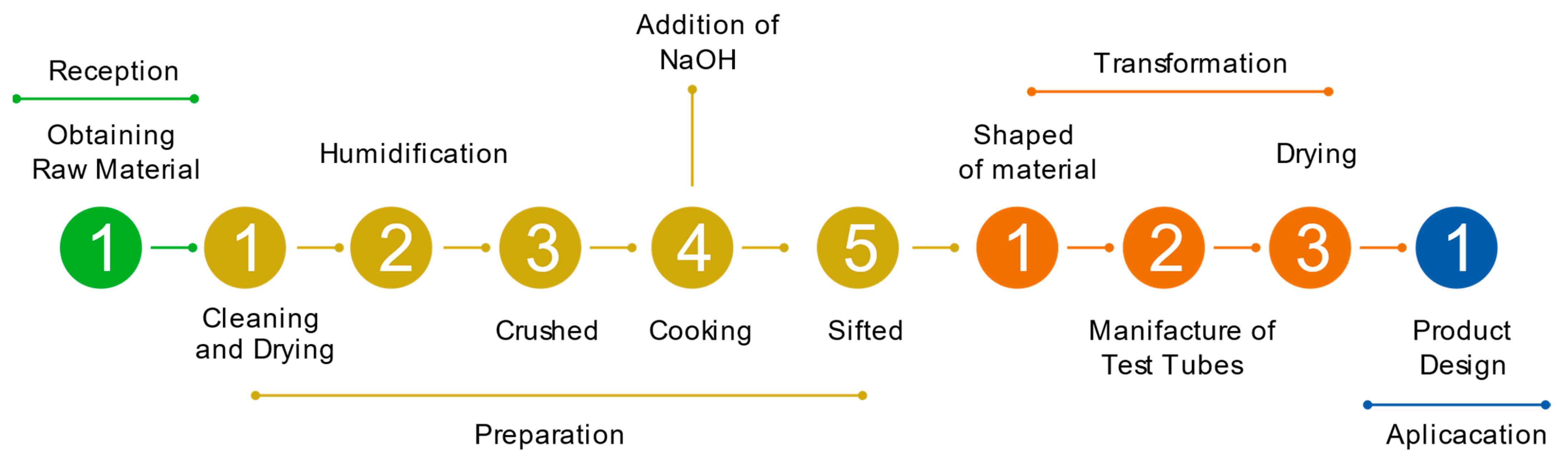

With the previous premise and under the working model proposed in the research on the use of agro-industrial waste [22], the development proposed for the initial stage of obtaining the raw material is presented in Figure 2 as a starting point for the use of corn residues for product development:

Figure 2.

Restructuration of paper developed with corn waste; personal development graphic.

Figure 2 presents a contrast with the work proposal generated by the researchers from the Catholic University of Trujillo [22], since as a differentiated factor, the design process is focused on actions that avoid downtime in obtaining the material and seeks to make the use of resources much more efficient and, in turn, better manage the waste generated [31].

The present process is based on an experimental methodology from the development of test tubes, in which comparisons of various pieces are generated that in their manufacture had variations in their development, controlling and modifying punctual variables that allow the recognition of different characteristics in the execution of tests to the base material [32]. It is important to note that the tests or characterizations carried out on the product are developed from a basic starting point, without the need to incorporate complex engineering processes, in relation to the scope of the project [33].

Compared with the manufacturing and development process from which the reinterpretation of the workflow is proposed, a series of modifications is generated by means of which it is sought to reduce the impacts associated with obtaining the biomaterial [34]. The following are the main structural changes regarding the biomaterial development process:

- -

- The drying process in the original elaboration is generated for twelve hours in an oven at 80 degrees Celsius, while in the current process, it is left for 12 h at room temperature on absorbent material to minimize the internal humidity of the raw material [35].

- -

- After cooking, the material is left to rest for 4 days with the liquor that it distills; for the current process, it is left for 4 h, simplifying production times. The decrease in time is based on research and the course directed by the Architect Cárdenas Oleas, in which it is indicated that when cooking the raw material with a chemical that allows breaking the lignin, no more than two to four hours of rest is needed to continue the craft paper manufacturing process [35].

- -

- The bleaching process of paper-making is eliminated. This is because the amount of water in addition to the incorporation of hydrogen peroxide generates a high percentage of waste whose disposal is highly complex due to the contamination generated by combining water with peroxide [36].

The previous exercise by means of which the process of transformation and obtaining of the biomaterial is restructured is made from an analysis in which reverse engineering processes are proposed (by analyzing all the steps of an established production), designing for X to detail the production process and omit unnecessary or easily replaceable steps [37], and finally, the strategy of responsible production and consumption, by understanding the impacts associated with each of the activities inherent to paper manufacturing and how these affect the three sustainable development aspects [38].

Once the initial workflow is structured, an approach is made to the experimental process through which the manufacture of the biomaterial is generated. It is important to recognize that although the process is made under a detailed analysis in which it is sought to have control over each of the manufacturing stages, the development is structured in an artisanal way, providing the possibility of facilitating its replicability for any individual under various productive contexts and thus fostering the ability to expand production spaces in society [6].

2.3. Test Tube Fabrication

With the work structure drawn from the flow diagram presented in Figure 3 and understanding each of the modifications to the original work structure [39], the different moments of the biomaterial manufacturing process are shown below for obtaining the base raw material and in turn the possibility of developing products with this new material [40].

Figure 3.

Corn’s husk in natural state.

- -

- Reception:

As can be seen in Figure 3, the first stage of the process is consolidated with the obtaining of the raw material from the José Maria Villa Retail Plaza in the city of Medellín, Antioquia, in which the material is discarded or commonly relegated to be reincorporated as compost or food for different animals [19]. This activity is structured as the main circular economy foundation of the entire work process [5].

- -

- Preparation:

As presented in Figure 4, once the raw material has been obtained, it is necessary to start a treatment process of said element, which allows separating the contaminating components or elements from the base structure with the intention of preserving the structural quality of the material to be processed (corn husks), avoiding the presence of any external agent that promotes rapid decomposition or degradation of the same, such as garbage, external fibers, insects, and any other element that may alter the execution of the creation of the test tubes. This can be seen in Figure 4, in which the corn mats are filled with various external agents.

Figure 4.

Cleaning process.

Once the raw material is free of any external agent or contaminant, it must start a drying process, in which the internal humidity is considerably reduced, thus preventing the raw material from decomposing more quickly.

After a drying process at room temperature (Figure 5), the raw material remains rigid to the touch and has a rough feeling, indicating that the internal humidity level has decreased to a percentage lower than 10% (basic sensation of hygroscopic touch [41]), thus promoting the ability to last over time without being exposed to degradation or rapid decomposition [42].

Figure 5.

Drying process of the corn husk.

With the dry raw material, the fiber is cut so that it can be easily reprocessed; This activity is done manually or supported by a tool that allows the maintenance of a constant length and less than 3 cm to later facilitate the grinding in a processing machine (blender type) [42]; this process can be seen in Figure 6.

Figure 6.

Manual shredding process.

With the material in a state of internal humidity in percentages not perceptible to the touch and cut into an easy-to-handle size, a cooking process is implemented in which the material is humidified by combining the material with water and with a minimum percentage of sodium hydroxide (NaOH) (1% of the weight of water and fiber) as an element that enhances the breaking of the internal chains of lignin, which is a natural binder that is responsible for shaping the fiber-like structure of the baskets and which is present in various cellulose-rich raw materials [22].

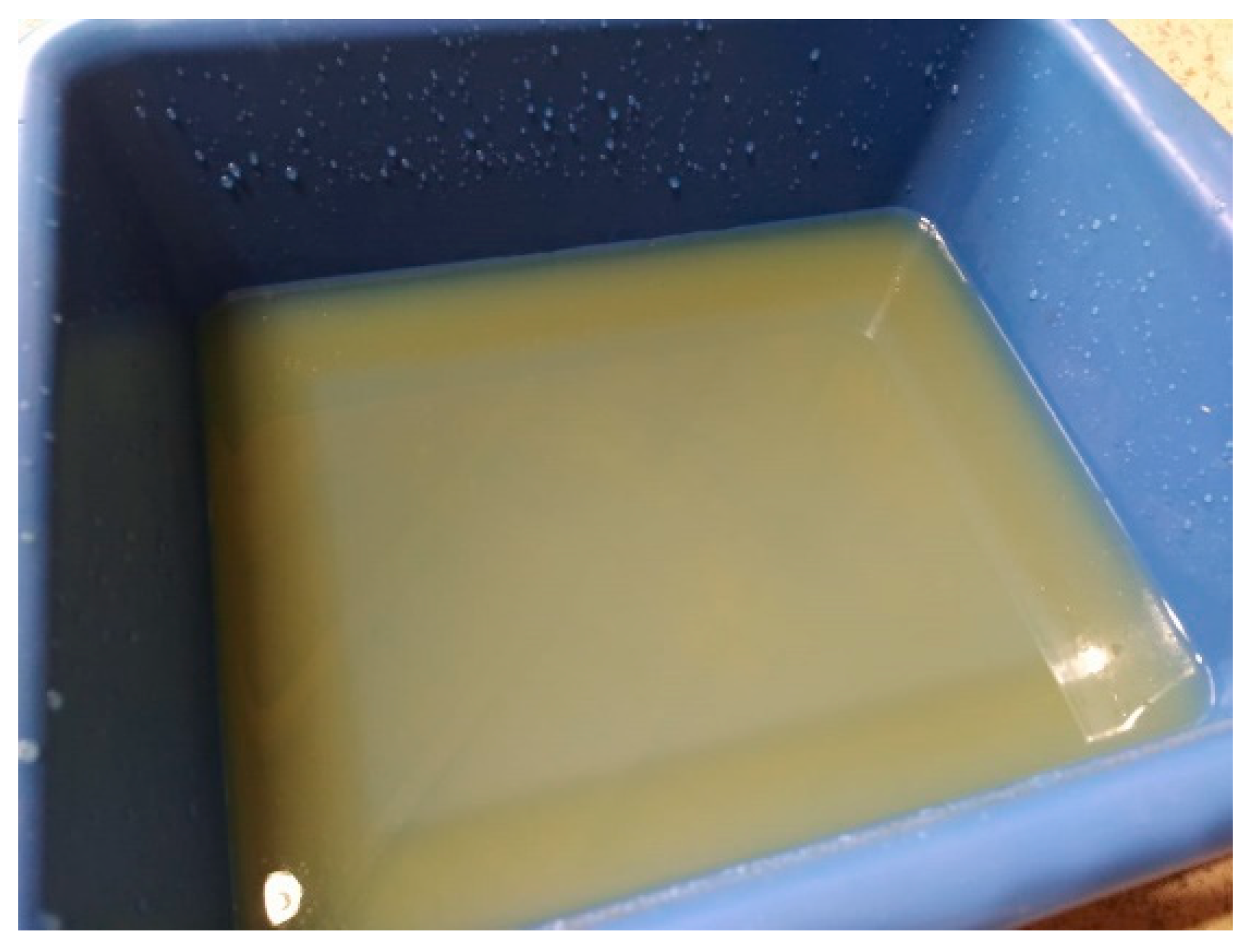

When cooking the fiber with water and NaOH, the lignin chains are broken (Figure 7), releasing a substance known as liquor [29], which provides a black color to the process and must be sieved and cleaned to allow the cellulose pulp obtained not to be of such a dark color for your future handling processes (such as pigmentation or printing).

Figure 7.

Cooking process with water and NaOH.

Once cooked and sieved, the material obtained remains as can be seen in Figure 8, in which the fibers have lost their base color and their texture has a brittle and viscous appearance to the touch.

Figure 8.

Washed and screened material after cooking.

- -

- Transformation:

By having clean and sieved raw material, we proceed to carry out the dough shaping process for which water is added to the fiber obtained, and it is crushed in a mechanical process supported by a machine that facilitates the ability to minimize the size of the fibers cut previously.

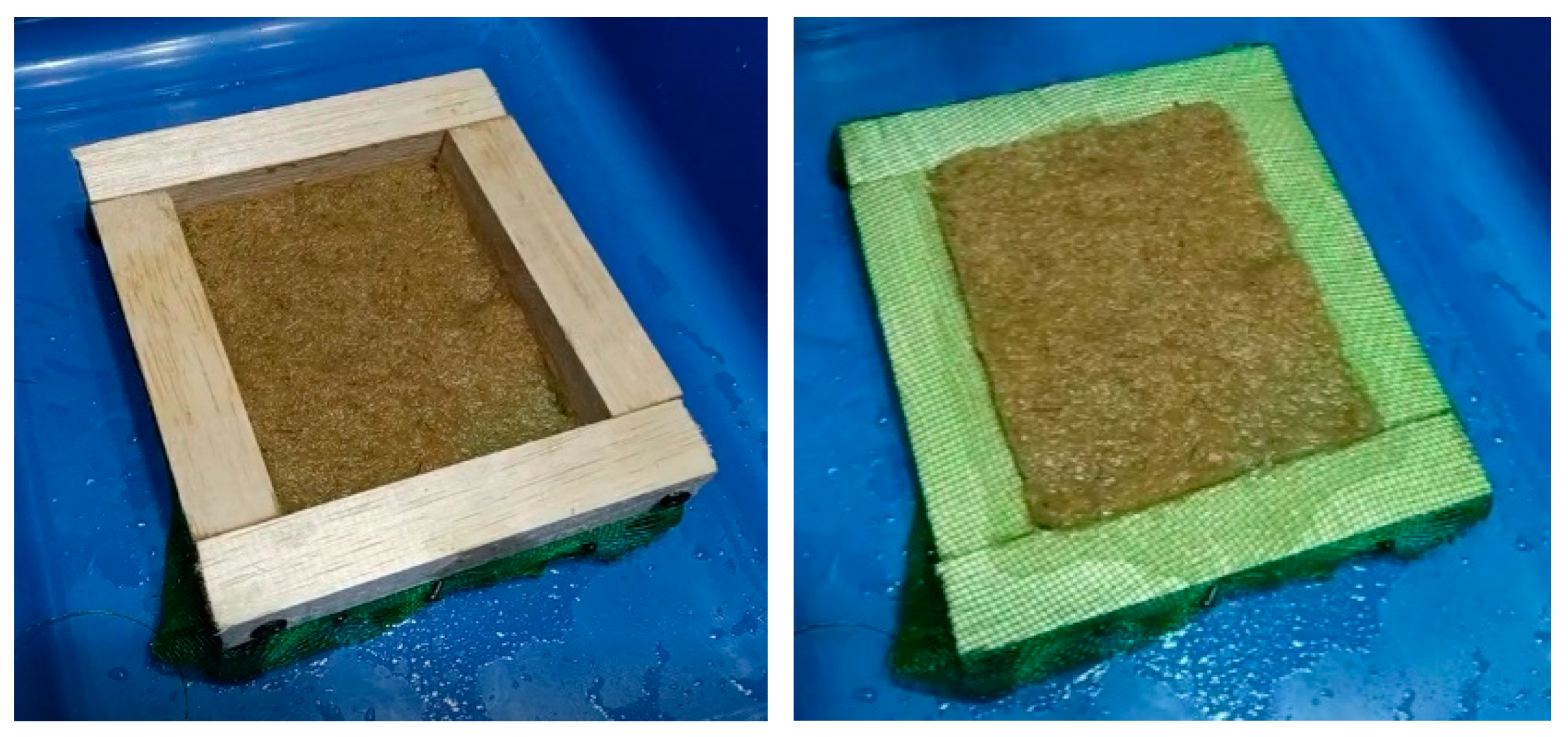

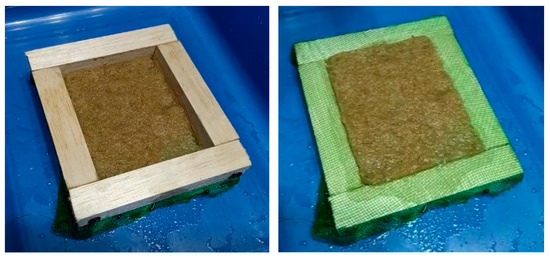

With the shaped pulp, it is placed in a container in which, with the help of a mesh frame (Figure 9), an immersion process can be generated to obtain the basic shape of the paper test tubes [42]. For this case study, a dimensioning is not generated according to a technical standard (however, the tests related to the use of paper and its applications are found in the ASTM standard [21], but rather a square shape is structured through which they can evaluate the basic structural capacities perceptible by the view of the biomaterial and that in turn facilitate the comparison with traditional paper/cardboard) [35].

Figure 9.

Shaping of cellulose pulp.

The immersion process consists of introducing the mesh frame into the container that contains the crushed fiber particles so that they form in the frame and can begin a drying process in the open air (Figure 10), allowing the internal moisture found in the material to pass through the mesh.

Figure 10.

Immersion process.

In the Figure 11, the drying process is generated at room temperature and without the help of external elements; it is necessary to analyze the atmospheric conditions and the spatial location during the process [43]. Drying commonly occurs within eight to twelve hours. Once the material is free of moisture and its handling is easy to the touch, it can be implemented in various applications. In this way, the process of transformation of the recovered material can be concluded by obtaining a biomaterial developed under the premise of the circular economy [44].

Figure 11.

Biomaterial shaping.

3. Results

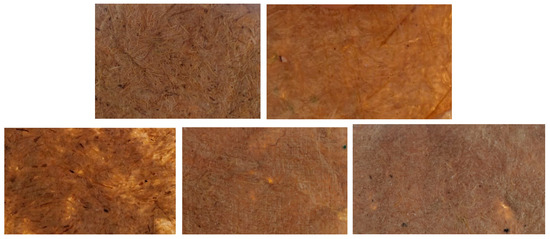

Once the entire test tube manufacturing process has been generated, it is possible to obtain a material that not only visually complies with the appearance of paper/cardboard but that, from its basic structure, resembles the same mechanical properties of said traditional material [45]. It is the possibility of achieving this development not only implies the success of the reincorporation of raw materials in a production process but also encourages a process through which it is possible to end the inordinate amount of consumption of virgin resources for manufacturing of single-use or very short-lived products [44].

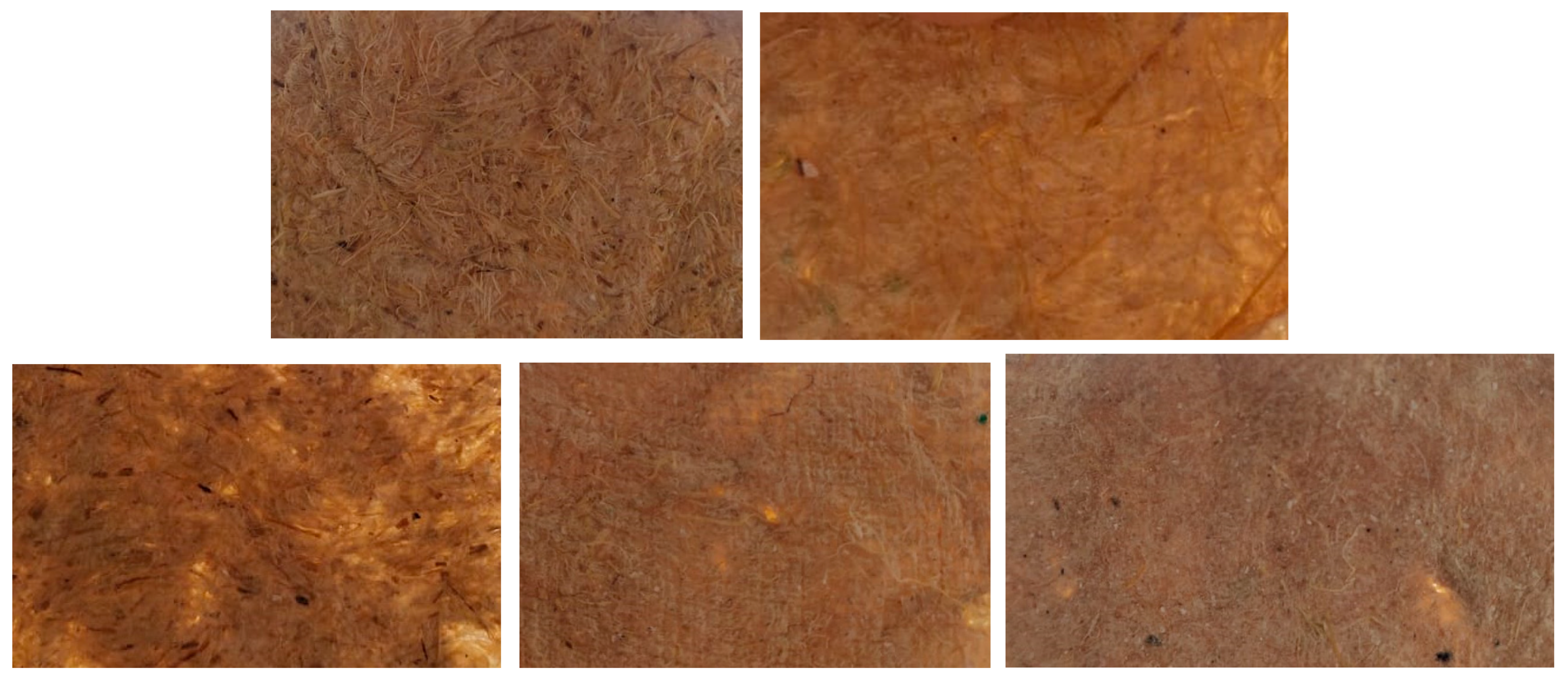

As can be seen in the Figure 12, the developed biomaterial resembles in its main structure the material that wants to be replaced, however, understanding that its manufacture was done through a traditional process without the use of machinery or industrial equipment. The surface finish presents irregularities, which can be easily corrected by subjecting the material to a compression process [46].

Figure 12.

Biomaterial structure.

The biomaterial obtained with the transformation process manages to have a high percentage of elasticity without reaching the point of breaking or deforming in a plastic way, which makes the development totally suitable to be able to build simple packages that in turn do not need to generate a compressive strength due to storage or use of very heavy elements within it [46].

3.1. Principal Characteristics

Some of the main characteristics that can be rescued from the material obtained without the need to generate tests or material tests are the following:

- Whiteness:

One of the elements that characterizes in a simple way the different elements and/or developments associated with paper is the color they handle, since a very white color (both glossy and matte) is commonly associated with distinguishing this raw material from others.

However, based on the principles of applying the processes of the zero waste design methodology and seeking to implement the SDG of responsible production and consumption [1], it is defined that in the present development, a bleaching process of the material will not be generated, since the execution of this activity implies the incorporation of a large quantity of chemicals that cannot be easily disposed of at the end of the raw material production [36].

This is how the characteristic of the whiteness of the color for the current development will not be considered, and the material will be handled in its original color, which is characterized by an opaque or matte yellow tone.

It is important to note that, in this case, the material could not have a natural whiteness either, because the color of the manufacturing base fibers (dry corn mats) have a yellow color, so the white tone could not be achieved in an organic way and reach; this could only be performed through the physicochemical alteration of the base matter.

- Brightness:

As presented in the previous feature, gloss is a process that is generated on the paper to create a glossy, satin, or matte effect. The degree of gloss of the paper depends on the drying process as well as the fillers or chemical components used in its manufacture [36].

In this project, no extra addition of components is generated with the intention of generating aesthetic finishes; therefore, the material takes on a matte yellow appearance [46]. However, understanding that the product can be used as a commercial element, color tests are generated through the incorporation of natural pigments to verify the ability to visually modify the structure.

As can be seen in Figure 13, the absorption of color by the biomaterial is very good, managing to generate variations in color from the use of pigments that do not generate waste that is difficult to dispose of and, in turn, generating a more striking appearance for commercial purposes.

Figure 13.

Biomaterial pigmentation test.

- Opacity:

The opacity of the material is given in relation to how the fiber distribution process is in the area that has been arranged to generate the product mold; therefore, when developing a manual/artisan paper manufacturing process, the uniform distribution of the fibers is truncated by the manufacturing tools, since to allow uniformity in the material, a compression process must be carried out with a roller to generate stability in the distribution of fiber in space [23].

Opacity can be analyzed by means of a visual process in which the paper is observed against the light, and thus an opaque paper (as opposed to transparency) should not be confused with a matte paper (as opposed to gloss). If the opacity is well-distributed throughout the paper, it is a good-quality paper [36]. This characteristic depends on various factors, such as the union of the fibers, the fillers and/or pigments used, among other external factors.

As can be seen in Figure 14, the distribution of the fibers in several of the specimens is of equal consistency, and these are distributed in a very uniform way on the sheet, avoiding generating spaces with lower densities that can generate break points in the material [45].

Figure 14.

Comparison of test piece fibers to analyze opacity.

In an analysis of both structural and visual properties, it is possible to understand in-depth how the performance of the raw material obtained is and how it can be linked to different creation processes; however, for the present case study, the fundamental analysis factor lies in demonstrating the capacity and functionality of the developed biomaterial [32], applying the use of the raw material and at the same time modifying the production stages.

To understand in a better way the ability to develop the biomaterial, a comparison was made between two kinds of test tubes, with just one structural change: the use of NaOH to break the lignin chains.

In the first instance, the visual factor (shown in Figure 15) is presented as a great differentiator in the ability to understand how the test tubes behave; however, in view of the need to be able to use this biomaterial in production processes, it is necessary to generate a deeper contrast, mainly in the basic properties compared to the visual and sensory component [47]. The following table presents what are the main characteristics of each of the production processes for the development of the biomaterial.

Figure 15.

Visual comparison of test tubes (left test tube without NaOH and right test tube with NaOH).

Table 1 shows the need to add an external component that allows the construction of the material through a chemical process. It is important to note that although the biomaterial development process is already a previously proven development, in this study, it is possible to show how it can be much more practical and effective without losing the initial capacities of the raw material that is generated [46].

Table 1.

Comparison of test tube fabrication.

3.2. Applicability

In this research project, not only is the development of a biomaterial with the ability to homologate the basic properties present in a paper and/or cardboard proposed but also a way is sought to simplify a production process to minimize impacts not only from the consumption of raw materials but also from the design, manufacturing, and final disposal process [44].

Looking for an application that allows contrasting the information raised with the development of the generated biomaterial and how it can be used as a basic raw material in a production process [48], the design of packaging for fast food made from the developed material is proposed, which not only generates an application of the circular economy from the use and reincorporation of waste but also achieves a design process that minimizes the consumption and production of traditional packaging [46].

To understand the applicability of the developed biomaterial, a base product is taken to compare how through redesign and change of raw material, not only the economic and environmental aspect but also the social aspect, can be improved, thus aiming at the fulfillment of the three main components of sustainable development [49].

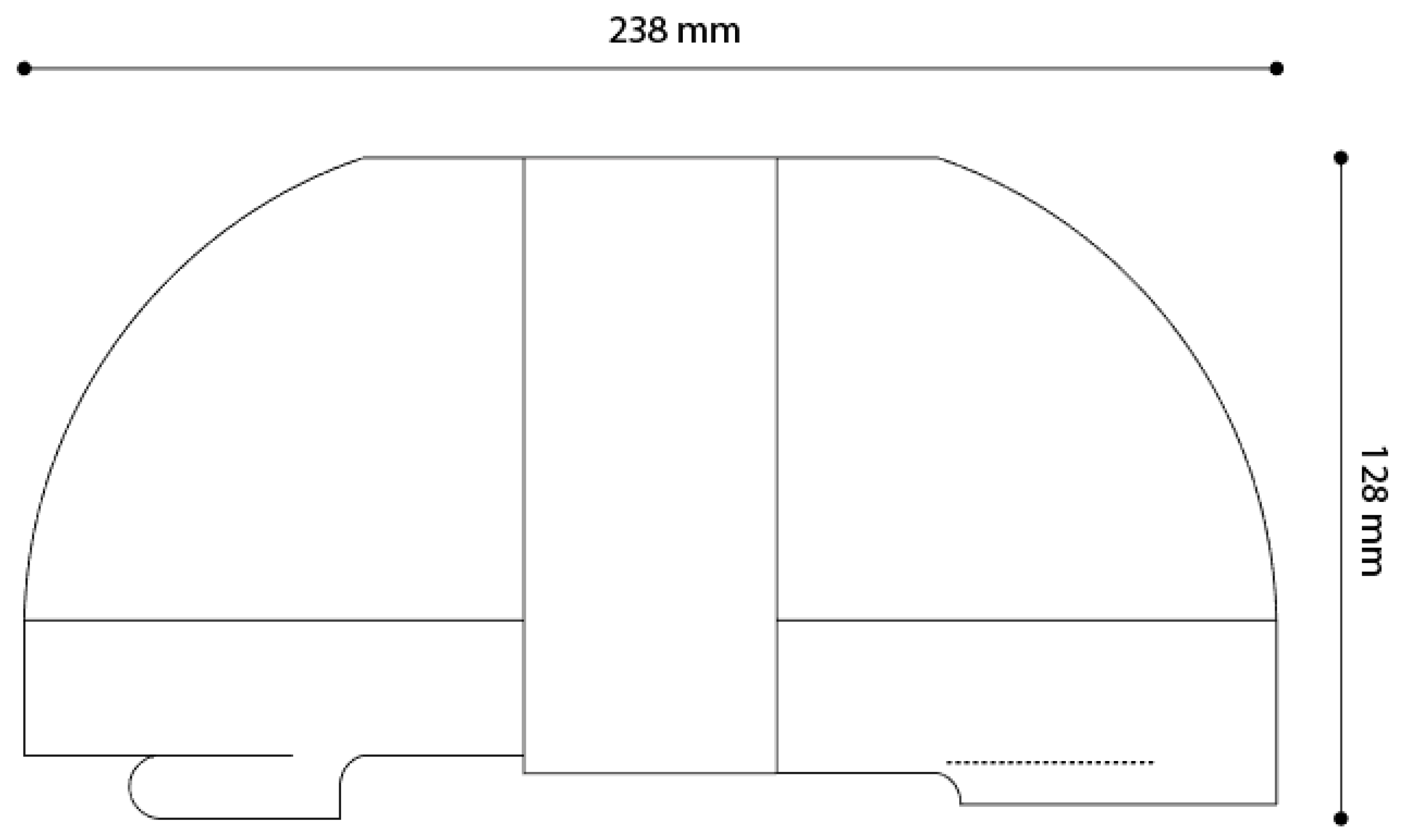

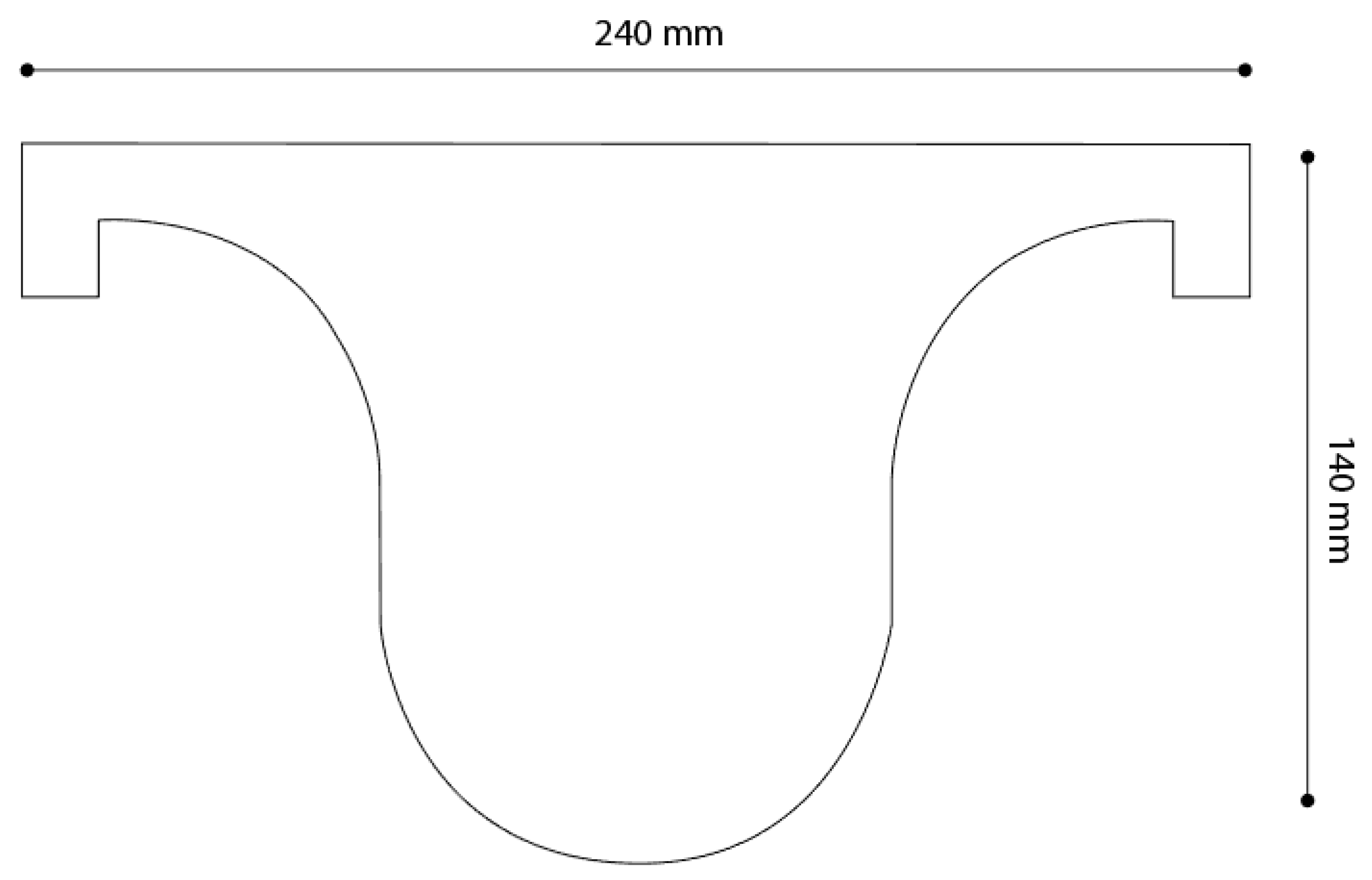

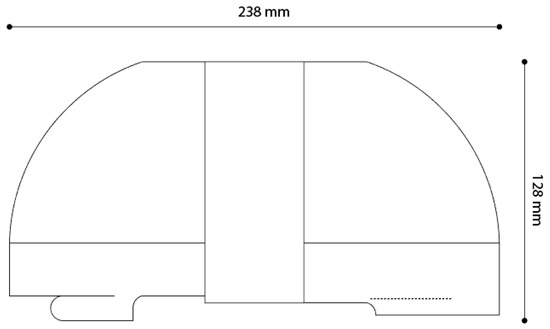

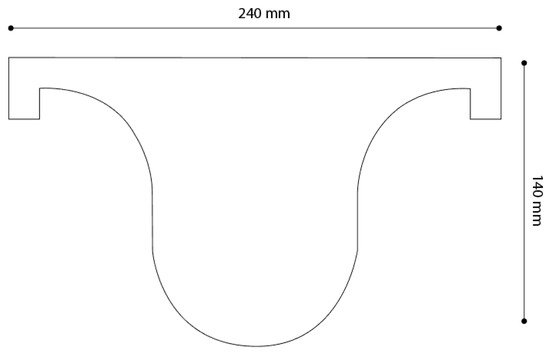

As presented in Figure 16, the traditional structure of a fast-food package is a simple form that is structurally composed of folds by means of which a support is generated in which the food can be kept for a short period of time and which will later be discarded [49].

Figure 16.

Reference fast food packaging structure.

The previous structure corresponds to a hamburger package, which is commonly manufactured by a die-cutting process and is made in a type of thin cardboard that is easy to handle, which in turn also allows printing or color modifications [50].

For the packaging restructuring proposal, not only is the material in which it is going to be manufactured considered but it also seeks to integrate the component of the form by means of which a harmonic process is achieved in the circular economy and sustainable development [51].

The form that is proposed to generate the new packaging proposal in Figure 17 also seeks to reduce the manufacturing time of the same, since being a much simpler form, with fewer folds and components, not only accelerates the production process but also facilitates the assembly of the product [49].

Figure 17.

Packaging redesign proposal.

The developed biomaterial exhibits excellent behavior against bending stimuli, without breaking or structurally modifying, which is why this characteristic is used to reinforce the proposed design concept.

In Figure 18, it can be seen not only how the main appearance of the element is developed from the biomaterial but also how it behaves in contact with the user and with the product to be supported [52].

Figure 18.

Functional prototype of the packaging redesign proposal.

It is also important to carry out a basic analysis regarding the implications of producers in the change processes of both raw materials and the incorporation of new manufacturing processes [45]. Although the development of the biomaterial presented above does not represent greater difficulty in terms of the use of machines or tools, this activity is not standardized, which makes the replicability process in different industries much more complex [7].

The previous premise raises a scenario in which it is necessary not only to begin a transformation in terms of the mentality of small and large producers regarding the management of raw materials but also to begin to change production practices in favor of making more efficient development processes.

Although the changes not only in mentality but also in the restructuring of processes are activities that take a considerable period, it is vital for the different companies or production plants that the changes begin to be made gradually, thus promoting evolution as to the fact that the entire set of activities developed can be coupled with the guidelines that arise from the circular economy and sustainable design [45].

Finally, this investigation presents a very important analysis to understand the existing need to review the traditionally proposed processes; although the manufacture of paper and recycled paper is a process that has been carried out over the years, it is still necessary to look for alternatives that reduce the production of waste or consumption virgin raw materials.

The biomaterial obtained is not only characterized as an element that manages to enhance the ability to recycle organic matter that is already in a waste state but also links the ability to integrate methodologies that seek to reduce the productive impact, simplifying the production and development steps [53].

4. Discussion

In the first instance, it is necessary to break the traditional scheme in terms of the activities associated with the production processes of the development of serial products (this regardless of the industry or type of products), since it is necessary that the engineering component and design processes are rethought to reduce impacts on both the production and consumption of raw materials [54].

Research on the alternative capacities that can be obtained from hundreds of residues is vital, as was the case with corn in the present project, as well as the ability of companies or institutions to allow spaces for analysis in which characteristics of various waste and/or discarded raw materials are evaluated for how they can be reincorporated.

In the same vein, it is also imperative that the physical, chemical, and structural characteristics of the materials or raw materials obtained during their reincorporation in the processes are evaluated to enhance their skills and give them the best use [55].

Under the previous premise and knowing the scope of this project, an in-depth study can be derived by means of which a deep characterization of which and how are the characteristics and behavior of the raw material obtained in the present study are made to evaluate in what other fields it can be used [56].

Additionally, as an extra study, a life-cycle analysis, or a measurement of the ecological footprint that this product generates, can be considered, thus making a real comparison with other products that fulfill the same function to check if the proposal remains only a reuse process or also implies a decrease in environmental impact [57].

Alternatives should be sought by means of which disclosure processes can be facilitated regarding the true impacts associated with production and consumption practices, both of companies and individuals, with the possibility of training the community in how to work in these areas of knowledge and how to promote change scenarios.

The ability to propose improvement processes both for the design and creation and the incorporation of new products [58] must be hand-in-hand with actions that promote the ideology of responsible production and consumption [59], avoiding the ambiguity of continuing to produce large quantities of elements that do not turn out to be utilitarian for society but simply appear as ephemeral fashions or trends, with short life cycles and large amounts of waste associated with their manufacture [60].

It is precisely because of the above that the processes of design and sustainable development methodologies must be replicated, not only for the ability to create innovative and sustainable products but also to allow a change of consciousness regarding how society relates to the elements and services of its environment.

The concept of sustainability must be understood as a transversal axis to the different areas of knowledge [61], thus establishing the need for all professionals to achieve a vision that integrates the ability to link actions with their profession [56] and ensuring that they always have systemic thinking that involves the triad of the economic, social, and environmental fields [62].

The ability to make sustainability become a common theme should be promoted by the new generations [57], and totally wide spaces must be generated in which the older community can make visible the importance of the management of goods and existing resources and how they can improve or affect the quality of life of present and future generations [63].

Thus, understanding the results obtained is not the only point of importance for a project once it has been completed; it is also necessary to evaluate and monitor a series of actions that allow generating new research in the future, expanding and creating scenarios that contribute to improving the knowledge of the various areas of knowledge about the interaction that design has with them and the great benefits that can be obtained.

Finally, and as a fundamental and main recommendation of this research project, the need arises, not only for the concept of both sustainability and sustainable development to be a deepening approach [60] but also for alternatives to be sought by means of which the knowledge of this area permeates all generations, social strata, and populations in different communities worldwide [64].

5. Conclusions

The ability to structure new creation and development processes must be conditioned by the possibility of having creative and innovative visions of how to work under new ways of thinking, with the intention of restructuring the processes that have traditionally been seen throughout history.

For the present project, in which the use of a waste as a new source of creation is structured, it is possible to observe the great capacity to reincorporate raw materials in processes with fewer implications, thus reducing the carbon footprint associated with the consumption of virgin materials.

For the present project, in which the use of waste as a new source of creation is structured, the great capacity to reincorporate raw materials in processes with fewer implications can be observed, thus allowing the possibility of evaluating the environmental impact (footprint carbon) between the new process and the traditional work structure to check whether there are lesser impacts.

Due to the large amount of research around the processes of how to implement actions from the circular economy to improve the use and management of resources, it is necessary to start processes through which current developments begin to be modified, thus giving a new version of the developed work processes.

In the present development, one of the factors that generate change and add value from the sustainability component is the ability to minimize both the production process of the biomaterial manufacturing and, in turn, reduce the waste generated from the process.

Author Contributions

Conceptualization, H.D.C.C. and C.M.G.A.; Formal analysis, B.E.A.Á.; Investigation, H.D.C.C.; Methodology, H.D.C.C.; Project administration, C.M.G.A.; Supervision, C.M.G.A.; Writing—original draft, H.D.C.C.; Writing—review & editing, B.E.A.Á. All authors have read and agreed to the published version of the manuscript.

Funding

The development of this research was paid for by the main researcher’s own funds, this as a requirement for obtaining the master’s degree in sustainable development from the ITM University Institution in Medellín, Colombia.

Conflicts of Interest

The authors declare no conflict of interest, and the founding sponsors had no role in the design of the study; in the collection, analysis, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Chavarro, D.; Vélez, M.I.; Tovar, G.; Montenegro, I.; Hernández, A.; Olaya, A. Los Objetivos de Desarrollo Sostenible en Colombia y el aporte de la ciencia, la tecnología y la innovación. Colcienc. Subdirección Gen. Unidad Diseño Y Evaluación Políticas 2017, 2, 100–117. [Google Scholar]

- Luth, J.; Mccormick, K.; Richter, J.L.; Pantzar, M. Greening the Economy Compendium; Lund University: Lund, Sweden, 2016. [Google Scholar]

- Wever, R.; van Kuijk, J.; Boks, C. User-centred design for sustainable behaviour. Int. J. Sustain. Eng. 2008, 1, 9–20. [Google Scholar] [CrossRef]

- Gómez, P.J.E. Economía ambiental, una retrospectiva teórica. Apunt. Contab. 2003. Available online: https://revistas.uexternado.edu.co/index.php/contad/article/view/1308/1245 (accessed on 26 July 2021).

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Camara de Comercio de Valencia. Cuaderno de Comercio y Sostenibilidad: Economía Circular; Cámara de Comercio de Valencia: Valencia, España, 2020; p. 30. [Google Scholar]

- Gupta, S.; Dangayach, G.S.; Singh, A.K. Key determinants of sustainable product design and manufacturing. Procedia CIRP 2015, 26, 99–102. [Google Scholar] [CrossRef][Green Version]

- Dantas, T.E.T.; de-Souza, E.D.; Destro, I.R.; Hammes, G.C.; Rodriguez, M.T.; Soares, S.R. How the combination of Circular Economy and Industry 4.0 can contribute towards achieving the Sustainable Development Goals. Sustain. Prod. Consum. 2021, 26, 213–227. [Google Scholar] [CrossRef]

- Bulkeley, H.; Mccormick, K. Sustainability through Urban Living Labs; Lund University: Lund, Sweden, 2018. [Google Scholar]

- Balaceanu, C.D.; Tilea, M.; Penu, D. Perspectives on Eco Economics. Circular Economy and Smart Economy. Acad. J. Econ. Stud. 2017, 3, 105–109. [Google Scholar]

- McCormick, K.; Anderberg, S.; Coenen, L.; Neij, L. Advancing sustainable urban transformation. J. Clean. Prod. 2013, 50, 1–11. [Google Scholar] [CrossRef]

- Antoine, C.; Aránguiz, S.; Montt, C. Formación para el Diseño Social. Percepciones y expectativas entre los estudiantes de la Facultad de Diseño de la Universidad del Pacífico, Chile. Cuad. del Cent. Estud. Diseño y Comun. 2019. [Google Scholar] [CrossRef]

- CEGESTI. Manual Para la Implementación de Ecodiseños; Universidad Tecnológica de Delft: San José, Costa Rica, 1999. [Google Scholar]

- Aparicio-Peralta, C.C.; Halabi-Echeverry, A.X.; Puentes-Parodi, A. Sustainable requirements and value proposition for milk Ultra-high temperature (UHT) packaging. Supply Chain Forum An Int. J. 2020, 21, 16–25. [Google Scholar] [CrossRef]

- Casarejos, F.; Bastos, C.R.; Rufin, C.; Frota, M.N. Rethinking packaging production and consumption vis-à-vis circular economy: A case study of compostable cassava starch-based material. J. Clean. Prod. 2018, 201, 1019–1028. [Google Scholar] [CrossRef]

- Sanchis Gisbert, R. Ecodiseño en el Desarrollo de Productos; Universidad Politécnica de Valencia: Valencia, España, 2020. [Google Scholar]

- Ford, A.; Moodie, C.; Hastings, G. The role of packaging for consumer products: Understanding the move towards ‘plain’ tobacco packaging. Addict. Res. Theory 2012, 20, 339–347. [Google Scholar] [CrossRef]

- Bozzola, M.; Dal Palù, D.; De Giorgi, C. Design for Leftovers. From Food Waste to Social Responsibility. Des. J. 2017, 20 (Suppl. 1), S1692–S1704. [Google Scholar] [CrossRef]

- Rees, W.; Tremma, O.; Manning, L. Sustainability cues on packaging: The influence of recognition on purchasing behavior. J. Clean. Prod. 2019, 235, 841–853. [Google Scholar] [CrossRef]

- Gaviria, L.J.; Osorio, E.Y.R.; Antioquia, I.U.C.M. Aprovechamiento Gastronómico De Frutas En Sobrecosecha De La Plaza Minorista José María, Medellín (Colombia); Revista de Turismo, Patrimonio y Desarrollo: Medellín, Colombia, 2019. [Google Scholar]

- Ortas, L. El cultivo del Maíz: Fisiología y Aspectos Generales; AGRIGAN S.A.: Huesca, Spain, 2008; Volume 4, pp. 15–20. [Google Scholar]

- Restrepo, S.; Arroyave, G.; Vásquez, D. Uso de fibras vegetales en materiales compuestos de matriz polimérica: Una revisión con miras a su aplicación en el diseño de nuevos productos Use of vegetable fibers in polymer matrix composites: A review. SENA Cent. Nac. Asist. Técnica a la Ind. 2016, 80, 77–86. [Google Scholar]

- Minaya Luna, C.J.; Galarreta Oliveros, G.I.; Símpalo López, W.D.; Bonifacio Maza, N.A.; Miñan Olivos, G.S. Elaboración de papel biodegradable a partir de hojas de maíz blanco (Zea mays L.). YACHAQ 2018, 1. [Google Scholar] [CrossRef]

- Andy Huatatoca, L.S. Elaboración de Papel Artesanal a Base de los Residuos Vegetales de los Tallos de Maíz (Zea Mays l) y Cáscara de Plátano (Musa Paradisiaca l) Utilizando los Métodos Químicos de Jayme-Wise, Kurshner y Hoffner; Universidad Nacional de Chimborazo: Riobamba, Ecuador, 2020; p. 57. [Google Scholar]

- Aarnio, T.; Hämäläinen, A. Challenges in packaging waste management in the fast food industry. Resour. Conserv. Recycl. 2008, 52, 612–621. [Google Scholar] [CrossRef]

- Morera, V. Fabricación del Papel con Materias Primas Nacionales; Universidad de Buenos Aires: Buenos Aires, Argentina, 2019. [Google Scholar]

- Castro-Aguirre, E.; Iñiguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)—Mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef] [PubMed]

- García, A.V. Obtención de un Polímero Biodegradable a Partir de Almidón de Maíz Obtención de un Polímero Biodegradable a; Escuela de Ingeniería Química ITCA: Santa Tecla, El Salvador, 2015. [Google Scholar]

- Navarro, M.V.F.; Martínez, J.R. Diseño sostenible: Herramienta estratégica de innovación. Rev. Legis. Estud. Soc. y Opinión Pública 2011, 4, 47–88. [Google Scholar]

- Prado-Martínez, M.; Anzaldo-Hernández, J.; Becerra-Aguilar, B.; Palacios-Juárez, H.; de Jesús Vargas-Radillo, J.; Rentería-Urquiza, M. Characterization of maize leaves and of sugarcane bagasse to elaborate of a mixed cellulose pulp. Madera Bosques 2012, 18, 37–51. [Google Scholar]

- Vinodh, S.; Rajanayagam, D. CAD and DFM: Enablers of sustainable product design. Int. J. Sustain. Eng. 2010, 3, 292–298. [Google Scholar] [CrossRef]

- Consejería de Medio Ambiente y Ordenación del Territorio; Guía Didáctica de Educación Ambiental; Fondo Europeo de Desarrollo Regional: Barcelona, España, 2013.

- Castaño Castrillón, H.D.; Suárez, V. Visual analysis of ceramic combinations with educational purposes for the development of artisan products. In Materials Design and Applications II; Springer: Cham, Germany, 2019; Volume 98. [Google Scholar]

- Estrada-Cely, G.E.; Parra-Herrera, J.P. Las implicaciones éticas y bioéticas en la investigación científica. CES Med. Vet. y Zootec. 2016, 11, 115–118. [Google Scholar] [CrossRef]

- Heinrich Boll, S. Manual de BASURA CERO: Una guía para Comunidades; Fronteras Comunes: México D.F., México, 2013; p. 42. [Google Scholar]

- Oleas, P.C. Elaboración de Papel Vegetal Papel Vegetal Recolección de Materia Prima Elaboración del Papel; Universidad de Antioquia: Medellín, Colombia, 2010; pp. 1–4. [Google Scholar]

- Feijoo, G.; Moreira, M.T. Análisis de ciclo de vida y huella de carbono: Casos prácticos. Res. Gate 2020. [Google Scholar] [CrossRef]

- Ulrich, K.T.; Eppinger, S.D. Diseño y Desarrollo de Productos, Quinta Edi; The McGraw-Hill Companies: New York, NY, USA, 2012. [Google Scholar]

- Herrera, F. ODS en Colombia: Los Retos Para el 2030; Programa de las Naciones Unidas para el Desarrollo: Bogotá, Colombia, 2018. [Google Scholar]

- Villalba, J.; Castillo, C.; Cuervo, A. La pasta de papel como material de creación artística. Arte Individuo y Soc. 2018, 30, 195–210. [Google Scholar] [CrossRef]

- Marcinkowski, A.; Kowalski, A.M. The problem of preparation the food packaging waste for recycling in Poland. Resour. Conserv. Recycl. 2012, 69, 10–16. [Google Scholar] [CrossRef]

- Askeland, D.R.; Phulé, P.P. Ciencia e Ingeniería de los Materiales; Cengage Learning Editores S.A.: México D.F., México, 2004; Volume 4, p. 1039. [Google Scholar]

- Aliaga, C. Tecnologías para la Producción de Papel a Partir de Residuos Agrícolas y Plantas; Instituto Tecnológico del Embalaje, Transporte y Logística: Barcelona, España, 2010; pp. 5, 7, 10 and 21. [Google Scholar]

- Belmonte Serrano, M.Á. Requisitos éticos en los proyectos de investigación. Otra oveja negra. Semin. la Fund. Esp. Reumatol. 2010, 11, 7–13. [Google Scholar] [CrossRef]

- UNESCO; PNUMA. Manual de Educación Para un Consumo Sostenible; PNUMA-UNESCO: París, Francia, 2019; p. 61. [Google Scholar]

- Cámara de Comercio de Bogotá. Guía Práctica Sistema de Empaque, Envase, Embalaje y Etiquetas; Cámara de Comercio de Bogotá: Bogotá, Colombia, 2019. [Google Scholar]

- Pane, D.N.; Fikri, M.; Ritonga, H.M. Manual de empaque y embalaje para exportación. J. Chem. Inf. Model. 2018, 53, 1689–1699. [Google Scholar]

- Posada, E.; Almanza, J. Materiales de Ingeniería Para la Sostenibilidad Ambiental y Energética; Indisa S.A: Medellín, Colombia, 2015; pp. 1–10. [Google Scholar]

- Caicedo Pardo, O.F. Creación de Valor Sostenible Mediante el Diseño de Modelos de Negocios Innovadores Creación de Valor Sostenible Mediante el Diseño de Modelos de Negocios Innovadores; 2018; p. 101. Available online: https://repositorio.unal.edu.co/handle/unal/68813 (accessed on 26 July 2021).

- del Rosario Bernatene, M.; Canale, G.J. Innovación sustentable en Diseño a partir de la integración del análisis de Ciclo de Vida (ACV) con Cadenas Globales de Valor (CGV). Cuad. del Cent. Estud. Diseño y Comun. 2019, 22, 151–174. [Google Scholar] [CrossRef]

- Londoño Quintero, Y. Propuesta de una Línea de Empaques Biodegradables a Partir de Fibra de Coco y Bambú Laminado; Universidad San Buenaventura: Medellín, Colombia, 2017; Volume 4, pp. 9–15. [Google Scholar]

- Potosí Benavides, C.C.; Muñoz Guachavez, D.A.; Cordoba-Cely, C. diseño de comida como fuente de innovación social. Rev. la Fac. Ciencias Económicas Adm. Univ. Nariño 2020, 1, 84–109. [Google Scholar] [CrossRef]

- Nemat, B.; Razzaghi, M.; Bolton, K.; Rousta, K. The potential of food packaging attributes to influence consumers’ decisions to sort waste. Sustainability 2020, 12, 2234. [Google Scholar] [CrossRef]

- Maleki, S.; Amiri Aghdaie, S.F.; Shahin, A.; Ansari, A. Investigating the relationship among the Kansei-based design of chocolate packaging, consumer perception, and willingness to buy. J. Mark. Commun. 2020, 26, 836–855. [Google Scholar] [CrossRef]

- Nazzal, L.J.; Kaufman, J.C. The relationship of the quality of creative problem solving stages to overall creativity in engineering students. Think. Ski. Creat. 2020, 38, 100734. [Google Scholar] [CrossRef]

- Veelaert, L.; Du Bois, E.; Moons, I.; Karana, E. Experiential characterization of materials in product design: A literature review. Mater. Des. 2020, 190, 108543. [Google Scholar] [CrossRef]

- Schifferstein, H.N. Changing food behaviors in a desirable direction. Curr. Opin. Food Sci. 2020, 33, 30–37. [Google Scholar] [CrossRef]

- Taware, O.; Kumbhar, S. Sustainable Product Design: A Review. Trends Mech. Eng. Technol. 2018, 8, 105–109. [Google Scholar]

- Crul, M.R.M.; Diehl, J.C. Diseño Para la Sostenibilidad: Un Enfoque Práctico Para Economías en Vías de Desarrollo; Delft University of Technology: Paris, Francia, 2007. [Google Scholar]

- Rueda, S. Libro Verde de Sostenibilidad Urbana y Local en la era de la Información; Ministerio de Agricultura, Alimentación y Medio Ambiente: Madrid, España, 2012; p. 697. [Google Scholar]

- United Nations Global Compact; WBCSD. La Guía Para la Acción Empresarial en los ODS; SDG Compass, United Nations Global Compact: Amsterdam, The Netherlands, 2019; p. 29. [Google Scholar]

- De los Rios, I.C.; Charnley, F.J.S. Skills and capabilities for a sustainable and circular economy: The changing role of design. J. Clean. Prod. 2017, 160, 109–122. [Google Scholar] [CrossRef]

- Hricova, B.; Nakatova, H.; Badida, M. Principles of design for the life-cycle. Ann. DAAAM Proc. Int. DAAAM Symp. 2011, 22, 165–166. [Google Scholar]

- Gutman, V.; Torcuato, F.; Tella, D.; Lopez, A.; Ryan, R.E.O. Ecoinnovación y Producción Verde; CEPAL, Naciones Unidad: Vancouver, BC, Canadá, 2018. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).