Study of the Properties of Full Component Recycled Dry-Mixed Masonry Mortar and Concrete Prepared from Construction Solid Waste

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

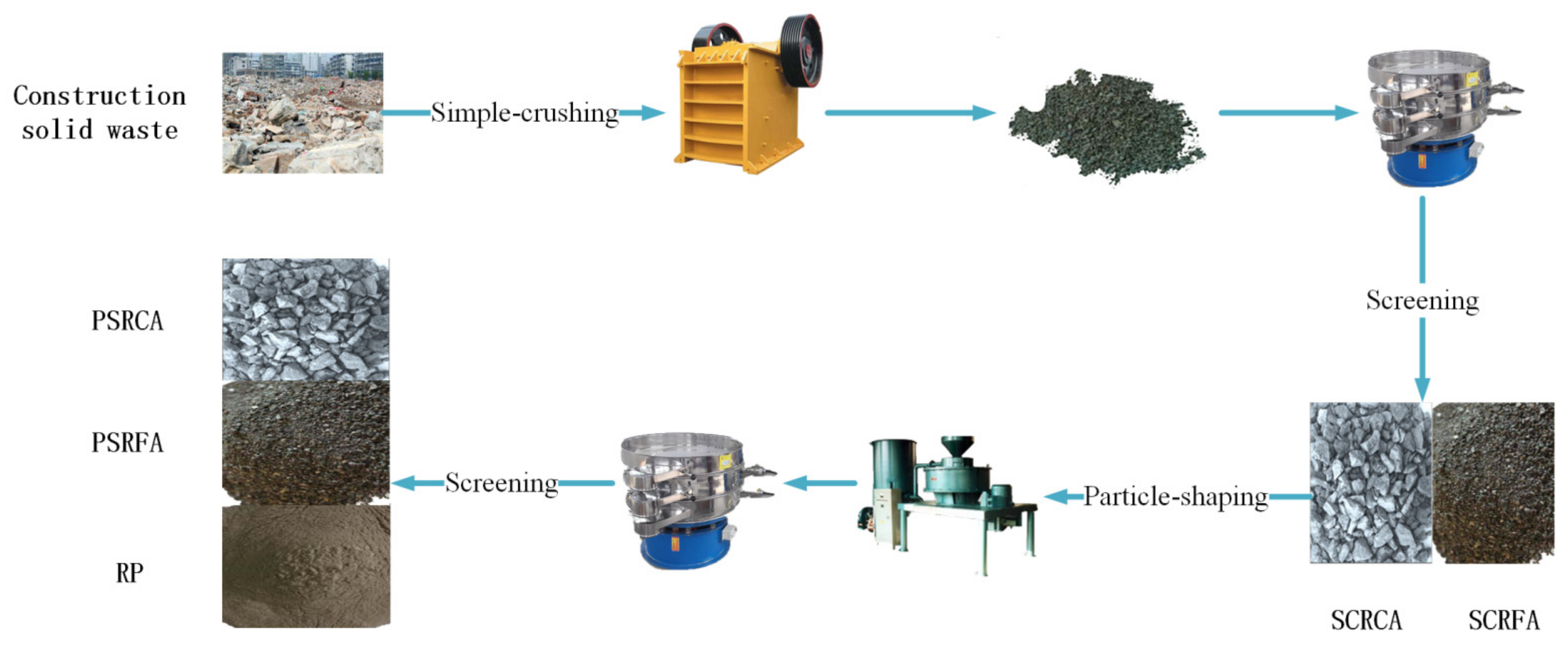

2.2. Treatment of Construction Solid Waste

2.3. Preparation and Performance Research of Dry-Mixed Masonry Mortar

2.4. Preparation and Performance Research of Fully Recycled Concrete

3. Results and Discussion

3.1. Research on the Performance of Construction Solid Waste Treatment Products

3.1.1. Performance Analysis of Coarse Aggregate

3.1.2. Performance Analysis of Fine Aggregate

3.1.3. Performance Analysis of RP

3.2. Research on the Performance of Dry-Mixed Masonry Mortar

3.2.1. Basic Performance

3.2.2. Mechanical Properties

3.2.3. Micro Analysis of Dry-Mixed Masonry Mortar

3.3. Concrete Performance Research

3.3.1. Work Performance

3.3.2. Mechanical Properties

3.3.3. Interface Analysis of Concrete Failure Mode

4. Conclusions

- (1)

- After particle shaping, the performance of PSRCA and PSRFA is close to the basic performance of NCA and RS and is much higher than that of SCRCA and SCRFA.

- (2)

- As the replacement rate of RP increases, the performance indicators of dry-mixed masonry mortar gradually decrease. To ensure the application of products in actual projects, the maximum replacement rate of RP should not be greater than 20%.

- (3)

- When the RP replacement rate is 20%, the performance of the product can not only meet the requirements of use, but also reduce the amount of cement to the greatest extent, and realize the comprehensive utilization of waste resources, energy savings, and emission reduction.

- (4)

- In the concrete prepared with different aggregate combinations, the failure mode of SCRCA and DCRFA concrete mainly damage the interface between the old and the new mortar, and the aggregate cannot play the role of skeleton support. The damage morphology of the concrete prepared by the PSRCA and PSRFA treated by the particle-shaping technology is the same as that of the NCA and RS concrete, and the damage is mainly caused by the crushing of the aggregate.

- (5)

- In follow-up research, we can further study the influence of different types of aggregates on the performance of concrete, such as NCA and PSRFA, NCA and SCRFA, PSRCA and RS, PSRCA and SCRFA, etc.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Abbreviations | Long Noun |

| RCA | recycled coarse aggregate |

| RFA | recycled fine aggregate |

| RP | recycled powder |

| SFRFA | steel fiber reinforced recycled fine aggregate |

| SCRFA | simple-crushed fine aggregate |

| SCRCA | simple-crushed coarse aggregate |

| PSRFA | particle-shaping fine aggregate |

| PSRCA | particle-shaping coarse aggregate |

| NCA | natural aggregate |

| RS | river sand |

References

- Tang, Q.; Ma, Z.; Wu, H.; Wang, W. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review. Cem. Concr. Compos. 2020, 114, 103807. [Google Scholar] [CrossRef]

- Kapoor, K.; Singh, S.; Singh, B.; Singh, P. Effect of recycled aggregates on fresh and hardened properties of self compacting concrete. Mater. Today Proc. 2020, 32, 600–607. [Google Scholar] [CrossRef]

- Lu, W. Big data analytics to identify illegal construction waste dumping: A Hong Kong study. Resour. Conserv. Recycl. 2019, 141, 264–272. [Google Scholar] [CrossRef]

- Guerra, B.C.; Bakchan, A.; Leite, F.; Faust, K.M. BIM-based automated construction waste estimation algorithms: The case of concrete and drywall waste streams. Waste Manag. 2019, 87, 825–832. [Google Scholar] [CrossRef]

- Vitale, F.; Nicolella, M. Mortars with Recycled Aggregates from Building-Related Processes: A ‘Four-Step’ Methodological Proposal for a Review. Sustainability 2021, 13, 2756. [Google Scholar] [CrossRef]

- Wu, H.; Zuo, J.; Zillante, G.; Wang, J.; Yuan, H. Status quo and future directions of construction and demolition waste research: A critical review. J. Clean. Prod. 2019, 240, 118163. [Google Scholar] [CrossRef]

- Seror, N.; Portnov, B.A. Estimating the effectiveness of different environmental law enforcement policies on illegal C&D waste dumping in Israel. Waste Manag. 2020, 102, 241–248. [Google Scholar] [CrossRef]

- Xiao, J.; Ma, Z.; Ding, T. Reclamation chain of waste concrete: A case study of Shanghai. Waste Manag. 2016, 48, 334–343. [Google Scholar] [CrossRef] [PubMed]

- Mistri, A.; Bhattacharyya, S.K.; Dhami, N.K.; Mukherjee, A.; Barai, S.V. A review on different treatment methods for enhancing the properties of recycled aggregates for sustainable construction materials. Constr. Build. Mater. 2020, 233, 117894. [Google Scholar] [CrossRef]

- Superti, V.; Houmani, C.; Hansmann, R.; Baur, I.; Binder, C. Strategies for a Circular Economy in the Construction and Demolition Sector: Identifying the Factors Affecting the Recommendation of Recycled Concrete. Sustainability 2021, 13, 4113. [Google Scholar] [CrossRef]

- Koushkbaghi, M.; Alipour, P.; Tahmouresi, B.; Mohseni, E.; Saradar, A.; Sarker, P.K. Influence of different monomer ratios and recycled concrete aggregate on mechanical properties and durability of geopolymer concretes. Constr. Build. Mater. 2019, 205, 519–528. [Google Scholar] [CrossRef]

- Li, J.; Zhou, H.; Chen, W.; Chen, Z. Mechanical Properties of a New Type Recycled Aggregate Concrete Interlocking Hollow Block Masonry. Sustainability 2021, 13, 745. [Google Scholar] [CrossRef]

- Meng, D.; Wu, X.; Quan, H.; Zhu, C. A strength-based mix design method for recycled aggregate concrete and consequent durability performance. Constr. Build. Mater. 2021, 281, 122616. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; You, I.; Zi, G. Effects of waste liquid–crystal display glass powder and fiber geometry on the mechanical properties of ultra-high-performance concrete. Constr. Build. Mater. 2021, 266, 120938. [Google Scholar] [CrossRef]

- Naeini, M.; Mohammadinia, A.; Arulrajah, A.; Horpibulsuk, S. Recycled Glass Blends with Recycled Concrete Aggregates in Sustainable Railway Geotechnics. Sustainablity 2021, 13, 2463. [Google Scholar] [CrossRef]

- Thomas, C.; de Brito, J.; Cimentada, A.; Sainz-Aja, J. Macro- and micro-properties of multi-recycled aggregate concrete. J. Clean. Prod. 2020, 245, 118843. [Google Scholar] [CrossRef]

- Bravo-German, A.; Bravo-Gómez, I.; Mesa, J.; Maury-Ramírez, A. Mechanical Properties of Concrete Using Recycled Ag-gregates Obtained from Old Paving Stones. Sustainability 2021, 13, 3044. [Google Scholar] [CrossRef]

- Wang, R.; Yu, N.; Li, Y. Methods for improving the microstructure of recycled concrete aggregate: A review. Constr. Build. Mater. 2020, 242, 118164. [Google Scholar] [CrossRef]

- Shah, M.C.; Gupta, K.K.; Nainwal, A.; Negi, A.; Kumar, V. Investigation of mechanical properties of concrete with natural aggregates partially replaced by recycled coarse aggregate (RCA). Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Hassan, R.Y.; Faroun, G.A.; Mohammed, S.K. Mechanical properties of concrete made with coarse and fine recycled aggregates. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Gao, D.; Wang, F. Effects of recycled fine aggregate and steel fiber on compressive and splitting tensile properties of concrete. J. Build. Eng. 2021, 44, 102631. [Google Scholar] [CrossRef]

- Kaarthik, M.; Maruthachalam, D. A sustainable approach of characteristic strength of concrete using recycled fine aggregate. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Pacheco, J.; de Brito, J.; Chastre, C.; Evangelista, L. Experimental investigation on the variability of the main mechanical properties of concrete produced with coarse recycled concrete aggregates. Constr. Build. Mater. 2019, 201, 110–120. [Google Scholar] [CrossRef]

- Duan, Z.; Singh, A.; Xiao, J.; Hou, S. Combined use of recycled powder and recycled coarse aggregate derived from construction and demolition waste in self-compacting concrete. Constr. Build. Mater. 2020, 254, 119323. [Google Scholar] [CrossRef]

- Boudali, S.; Abdulsalam, B.; Rafiean, A.; Poncet, S.; Soliman, A.; ElSafty, A. Influence of Fine Recycled Concrete Powder on the Compressive Strength of Self-Compacting Concrete (SCC) Using Artificial Neural Network. Sustainablity 2021, 13, 3111. [Google Scholar] [CrossRef]

- Gupta, T.; Siddique, S.; Sharma, R.K.; Chaudhary, S. Behaviour of waste rubber powder and hybrid rubber concrete in aggressive environment. Constr. Build. Mater. 2019, 217, 283–291. [Google Scholar] [CrossRef]

- Gebremariam, A.T.; Vahidi, A.; Di Maio, F.; Moreno-Juez, J.; Vegas-Ramiro, I.; Łagosz, A.; Mróz, R.; Rem, P. Comprehensive study on the most sustainable concrete design made of recycled concrete, glass and mineral wool from C&D wastes. Constr. Build. Mater. 2021, 273, 121697. [Google Scholar] [CrossRef]

- Huo, W.; Zhu, Z.; Chen, W.; Zhang, J.; Kang, Z.; Pu, S.; Wan, Y. Effect of synthesis parameters on the development of unconfined compressive strength of recycled waste concrete powder-based geopolymers. Constr. Build. Mater. 2021, 292, 123264. [Google Scholar] [CrossRef]

- Liu, D.; Quan, X.; Zhou, L.; Huang, Q.; Wang, C. Utilization of waste concrete powder with different particle size as absorbents for SO2 reduction. Constr. Build. Mater. 2021, 266, 121005. [Google Scholar] [CrossRef]

- Vieira, J.; Correia, J.R.; de Brito, J. Post-fire residual mechanical properties of concrete made with recycled concrete coarse aggregates. Cem. Concr. Res. 2011, 41, 533–541. [Google Scholar] [CrossRef]

- Xiao, J.; Li, J.; Zhang, C. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- Butler, L.; West, J.; Tighe, S. The effect of recycled concrete aggregate properties on the bond strength between RCA concrete and steel reinforcement. Cem. Concr. Res. 2011, 41, 1037–1049. [Google Scholar] [CrossRef]

- Ismail, S.; Hamid, M.A.A.; Yaacob, Z. Static and Dynamic Behaviors of Fibre Reinforced Recycled Aggregate Mortar. Key Eng. Mater. 2021, 882, 237–246. [Google Scholar] [CrossRef]

- Sun, J.; Chen, J.; Liao, X.; Tian, A.; Hao, J.; Wang, Y.; Tang, Q. The Workability and Crack Resistance of Natural and Recycled Aggregate Mortar Based on Expansion Agent through an Environmental Study. Sustainablity 2021, 13, 491. [Google Scholar] [CrossRef]

- Poon, C.; Shui, Z.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Tam, V.W.; Gao, X.; Tam, C.M. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cem. Concr. Res. 2005, 35, 1195–1203. [Google Scholar] [CrossRef] [Green Version]

- Guo, Y.; Li, Q.; Yue, G.; Zheng, S.; Wang, L. Effect of Quality and Replacement Rate on the Double Recycled Aggregate Concrete. In Proceedings of the 6th International Conference on Environmental Science and Civil Engineering(ESCE 2020), Nanchang, China, 4–5 January 2020; IOP Publishing: Bristol, UK; Volume 455, pp. 960–965. [Google Scholar]

- Du, T.; Wang, W.H.; Lin, H.L.; Liu, Z.X.; Liu, J. Experimental study on interfacial strength of the high performance recycled ag-gregate concrete. ASCE Conf. Proc. 2010, 366, 2821–2828. [Google Scholar] [CrossRef]

- Al-Bayati, H.K.A.; Das, P.K.; Tighe, S.L.; Baaj, H. Evaluation of various treatment methods for enhancing the physical and morphological properties of coarse recycled concrete aggregate. Constr. Build. Mater. 2016, 112, 284–298. [Google Scholar] [CrossRef]

| Component | CaO | CO2 | Al2O3 | SO3 | SiO2 | Fe2O3 | MgO | K2O | Na2O | LOSS | Moisture Content |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Water reducing agent | 2.94 | 65.19 | 0.17 | 24.71 | 0.32 | 0.05 | 0.13 | 0.03 | 6.44 | 0.02 | 0.05 |

| Cement | 65.71 | - | 4.33 | 1.92 | 19.75 | 3.79 | 0.34 | 0.55 | 0.90 | 2.18 | 0.09 |

| Water Absorption/% | Moisture Content/% | Content of Needle-Like Particles/% | Crushing Index/% | Bulk Density/(kg/m3) | Apparent Density/(kg/m3) | Moisture Content/% |

|---|---|---|---|---|---|---|

| 1.7 | 0.42 | 4.05 | 11.2 | 1460 | 2510 | 0.42 |

| Fineness Modulus | Bulk Density/(kg/m3) | Apparent Density/(kg/m3) | Porosity/% | Powder Content/% | Clay Lump/% | Crushing Index/% | Moisture Content/% |

|---|---|---|---|---|---|---|---|

| 2.4 | 1450 | 2590 | 40 | 1.0 | 0.7 | 13 | 0.23 |

| Number | Types of Fine Aggregate | Cement/(kg/m3) | RP | Fine Aggregate/(kg/m3) | Water Reducing Agent | |

|---|---|---|---|---|---|---|

| Substitution Rate/% | Consumption/(kg/m3) | |||||

| a-1 | RS | 340.0 | 0 | 0.0 | 1360 | 2.04 |

| a-2 | RS | 306.0 | 10 | 34.0 | 1360 | 2.04 |

| a-3 | RS | 272.0 | 20 | 68.0 | 1360 | 2.04 |

| a-4 | RS | 238.0 | 30 | 102.0 | 1360 | 2.04 |

| b-1 | PSRFA | 340.0 | 0 | 0.0 | 1360 | 2.04 |

| b-2 | PSRFA | 306.0 | 10 | 34.0 | 1360 | 2.04 |

| b-3 | PSRFA | 272.0 | 20 | 68.0 | 1360 | 2.04 |

| b-4 | PSRFA | 238.0 | 30 | 102.0 | 1360 | 2.04 |

| c-1 | SCRFA | 340.0 | 0 | 0.0 | 1360 | 2.04 |

| c-2 | SCRFA | 306.0 | 10 | 34.0 | 1360 | 2.04 |

| c-3 | SCRFA | 272.0 | 20 | 68.0 | 1360 | 2.04 |

| c-4 | SCRFA | 238.0 | 30 | 102.0 | 1360 | 2.04 |

| Number | Aggregate Combination | Cement /(kg/m3) | RP | Coarse Aggregate/(kg/m3) | Fine Aggregate/(kg/m3) | Water Reducing Agent /(kg/m3) | |

|---|---|---|---|---|---|---|---|

| Substitution Rate/% | Consumption /(kg/m3) | ||||||

| d-1 | NCA + RS | 320.0 | 20.0 | 80.0 | 1136.0 | 696.0 | 4.8 |

| 3-1 | PSRCA + PSRFA | 320.0 | 20.0 | 80.0 | 1136.0 | 696.0 | 4.8 |

| f-1 | SCRCA + SCRFA | 320.0 | 20.0 | 80.0 | 1136.0 | 696.0 | 4.8 |

| Type | Fine Powder Content/% | Clay Lump/% | Water Absorption/% | Content of Needle Like Particles/% | Crushing Index/% | Apparent Density/(kg/m3) | Porosity/% | Moisture Content/% | |

|---|---|---|---|---|---|---|---|---|---|

| 1 h | 24 h | ||||||||

| SCRCA | 1.9 | 0.6 | 2.3 | 3.7 | 6 | 18 | 2430 | 44 | 0.29 |

| PSRCA | 1.1 | 0.2 | 1.7 | 2.3 | 4 | 15 | 2470 | 44 | 0.21 |

| Type | Fine Powder Content/% | Clay Lump/% | Crushing Index/% | Water Requirement Ratio/% | Strength Ratio/% | Apparent Density /(kg/m3) | Bulk Density /(kg/m3) | Porosity/% | Moisture Content/% |

|---|---|---|---|---|---|---|---|---|---|

| SCRFA | 1.8 | 1.4 | 24 | 1.31 | 0.96 | 2360 | 1380 | 44 | 0.19 |

| PSRFA | 3.2 | 0.8 | 22 | 1.27 | 0.87 | 2440 | 1333 | 42 | 0.12 |

| Type | CaO | CO2 | Al2O3 | SO3 | SiO2 | Fe2O3 | MgO | K2O | Na2O | LOSS | Moisture Content/% |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RP | 13.31 | 14.87 | 14.57 | 0.52 | 45.24 | 4.30 | 1.66 | 3.74 | 1.50 | 0.29 | 0.11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Z.; Kong, Z.; Cai, G.; Li, Q.; Guo, Y.; Su, D.; Liu, J.; Zheng, S. Study of the Properties of Full Component Recycled Dry-Mixed Masonry Mortar and Concrete Prepared from Construction Solid Waste. Sustainability 2021, 13, 8385. https://doi.org/10.3390/su13158385

Hu Z, Kong Z, Cai G, Li Q, Guo Y, Su D, Liu J, Zheng S. Study of the Properties of Full Component Recycled Dry-Mixed Masonry Mortar and Concrete Prepared from Construction Solid Waste. Sustainability. 2021; 13(15):8385. https://doi.org/10.3390/su13158385

Chicago/Turabian StyleHu, Zhenwen, Zhe Kong, Guisheng Cai, Qiuyi Li, Yuanxin Guo, Dunlei Su, Junzhe Liu, and Shidong Zheng. 2021. "Study of the Properties of Full Component Recycled Dry-Mixed Masonry Mortar and Concrete Prepared from Construction Solid Waste" Sustainability 13, no. 15: 8385. https://doi.org/10.3390/su13158385

APA StyleHu, Z., Kong, Z., Cai, G., Li, Q., Guo, Y., Su, D., Liu, J., & Zheng, S. (2021). Study of the Properties of Full Component Recycled Dry-Mixed Masonry Mortar and Concrete Prepared from Construction Solid Waste. Sustainability, 13(15), 8385. https://doi.org/10.3390/su13158385