1. Introduction

The economy of Pakistan is primarily dependent on the agricultural and industrial sectors, and its progress is linked to a continuous supply of energy resources [

1]. The main constraint on economic development is the reliance on uncertain energy resources. In the last decade, the power sector of Pakistan has failed to overcome the energy-related crisis despite its vast energy resources [

1,

2]. Pakistan is facing a gap of 4500–5500 MW between the demand and supply of electricity, registering a shortfall of 40% [

3,

4]. This energy shortage resulted in a 3–6% loss of GDP (gross domestic product) in the country. More than 30% of the Pakistani population (55 million) lack access to electricity [

2]. These energy crises are expected to become even worse, reaching 10% due to the growing population, industrialization, theft, line losses, and economic development [

5,

6,

7]. The described energy crises become severe during summer when power shortages are prolonged to up to 6–8 and 12–16 h in urban and rural areas, respectively [

8]. The NEPRA (National Electric Power Regulatory Authority) reported a historic gap of 6650 MW between power demand and supply in 2012 [

3,

9,

10]. As reported in [

2], the energy demand of Pakistan is increasing at an annual rate of approximately 11–13% due to an increase in growth, living standards, and industrialization. The authors of [

1] estimated that the energy demand would rise to 54,000 MW in 2020 and 113,000 MW in 2030.

Energy consumption is an index of a society’s prosperity [

11,

12]. Pakistan’s per capita electricity consumption was 448 kWh in 2014, six times lower than the world’s average (2516 kWh) [

13].

Figure 1 compares the energy consumption of several countries, including Pakistan, and shows that the USA, France, Germany, Turkey, and China have markedly higher per capita energy consumption than Pakistan. This situation has adverse effects on the economy of the country due to negative impacts on marketing, employment, and poverty [

14]. The authors of [

14] reported that the major shortfall in energy production vs. demand has negatively affected not only domestic use, but also various dimensions of industrial sectors. This study further showed that 70% of industrial investors have shifted their businesses to other countries due to the severe energy shortfall, which has reached 40%. This situation is pushing the country toward alarming levels of poverty and unemployment and a reduction in exports. The GOP (government of Pakistan) is seeking cost-effective, clean, sustainable, and alternative energy sources to address the energy crises and maintain economic growth [

1]. The generation of cheap, clean, and green energy is considered a prime objective that a country must fulfill to achieve sustainable development. In 2018, renewable energy contributed 1.1% to the total energy mix of the country. However, the GOP plans to increase its share by 5% by 2030 [

13]. In [

15], the authors discussed the availability of biomass energy resources in Pakistan and its potential to improve energy generation. The authors of [

13] discussed a Pakistani energy policy regarding biomass energy conversion as a primary source of renewable energy to produce electricity. The study showed that Pakistan possesses the potential to run 15 million biogas plants.

Despite this energy crisis, there is hope for improvement. The country can address its energy shortfall in several ways, such as adopting renewable energy (RE) resources and making rational use of biomass for bioenergy production. As a country with a large agricultural sector, Pakistan has several possible solutions, such as the utilization of agricultural, bovine, and poultry waste for biogas production and the cultivation of bioenergy crops on marginal lands. Implementing these solutions would help to overcome these energy crises.

There are huge gaps in the available literature about the productive use of marginal lands for the cultivation of biomass crops and indigenous halophyte plants (which need very low water and other inputs for biomass production). In addition, little literature is available describing the current scenario of biogas, biodiesel, and bioethanol production from agricultural crops and wastes in Pakistan. Therefore, there is a dire need to provide updated information about the aforementioned aspects. This review article presents a detailed discussion regarding the policy framework for biomass as a renewable resource and describes the current research and relevant industries for the processing and conversion of biomass to energy to meet upcoming energy issues. Pakistan’s energy policies need to be amended to meet the energy supply and demand. In the future, massive energy projects on biomass-based bioenergy need to be implemented in Pakistan.

Pakistan is located in the South Asian region. Its total geographical area is about 79.61 Mha (million hectares), of which only 22.05 Mha is classified as cultivated land and 70% is arid to semi-arid [

17]. The ecology of the Khyber Pakhtunkhwa (KPK) province, including the northern area, is characterized as semi-arid to humid. The Sindh province is mainly arid, while the ratios of arid to semi-arid areas in Punjab and Baluchistan are 29:58 and 43:57, respectively [

17]. Approximately 6.3 Mha has deteriorated owing to excessive salinity, with almost half of this being under irrigated agriculture [

18]. This large area, afflicted by excess salinity, waterlogging, and water-scarce land, can be effectively used for bioenergy crops without disturbing food and feed crop rotation. There is the possibility of growing alternative crops for fuel that have almost no competition with animal feed in villages, and they can be grown easily on these unproductive and marginal lands. About 28.5 million hectares of land are unproductive in Pakistan [

18]. This land can be used for the production of jatropha (

Jatropha curcas), castor bean (

Ricinus communis) (biodiesel crops), kallar grass (

Laptochloa fusca), mott grass (

Pennisetum purpureum), and switchgrass (

Panicum virgatum) for bioethanol and biogas production [

7,

17].

This article is focused on compiling first-hand information about the existing feedstock and the possible use of uncultivated land for the cultivation of alternative energy crops for biodiesel, bioethanol, and biogas. The findings in this paper will help Pakistan to address its energy crises. In addition, we intend to explore the potential of different agricultural and municipal solid wastes for energy production and their roles in mitigating the energy crises of the country. More importantly, this article will help in identifying alternative pathways for poor farmers growing crops on marginal lands to supplement their agricultural income. Furthermore, it will also help to reduce greenhouse gas (GHG) emissions, resulting in a cleaner and healthier environment. In this review article, we comprehensively discuss various aspects related to energy crises and possible solutions that involve bioenergy options.

In

Section 2, the need for fossil fuels, the energy demand, and the oil import bill are discussed. Available marginal lands and their possible utilization for the cultivation of energy crops are explored in

Section 3. Biomass conversion technologies and feedstock for biofuel and the relevant industry are described in detail in

Section 4 and

Section 5, respectively. In

Section 6, an overview of feedstock development and the current research in Pakistan is provided. Potential crops and other available feedstocks for biogas production, potential biodiesel crops, and feedstock for bioethanol production are discussed comprehensively in

Section 7, respectively. In

Section 10, a detailed description of the policy for bioenergy production is discussed. Finally, future perspectives and conclusions are presented in

Section 11.

2. Need for Fossil Fuels, Energy Demand, and Oil Import Bill

In today’s society, energy is integral to daily life and plays a very important role in socio-economic development [

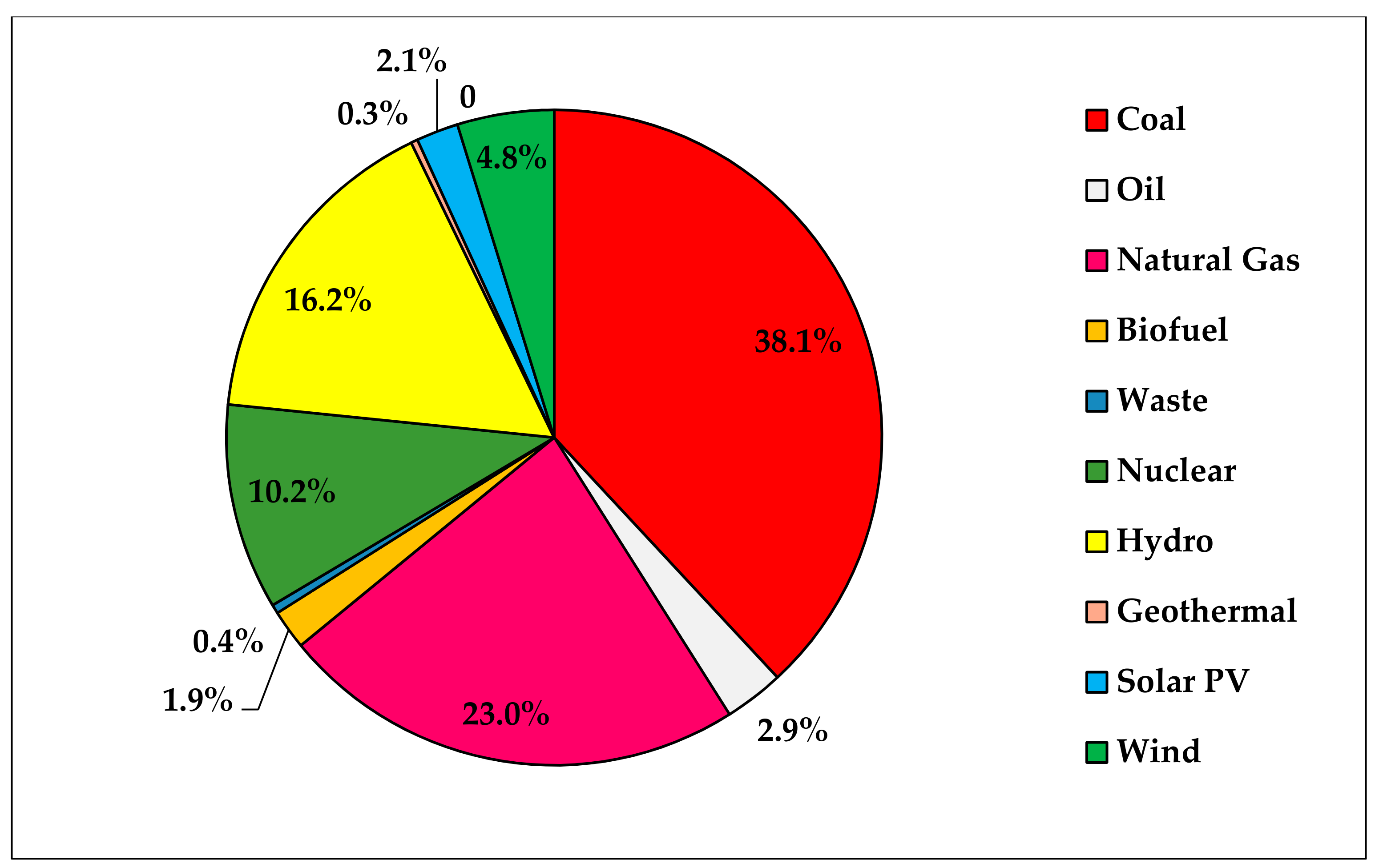

19]. Globally, the main contributors to the energy mix are fossil fuels (nearly 64%), hydro (16.2%), nuclear (10.2%), and renewable resources (5%) (

Figure 2) [

16]. In Pakistan, the energy demand is increasing at an annual growth rate of 5–7% [

10]. It reached a peak in 2017–2018, but a clear decline was recorded in 2019, and it even fell to negative digits in 2020. As in other countries, 2020 was a unique year for Pakistan due to the challenges of the COVID-19 pandemic. Drastic measures such as lockdowns were taken to reduce the spread of the virus, which disrupted traditional economic activities, resulting in slower GDP growth and less electricity demand [

20] (

Figure 3). Pakistan mainly depends on fossil fuels, including oil and natural gas, for energy production (

Figure 4). However, fossil fuel sources of energy such as petroleum and natural gas are gradually diminishing [

21,

22,

23,

24]. Owing to increased global energy requirements and environmental concerns due to fossil fuels and GHG emissions, alternative options are necessary to ensure economic wellbeing [

25,

26]. Despite regular reports of increasing global energy demands, millions of people in developing nations still lack access to energy sources. Fossil fuel sources of energy, such as petroleum and natural gas, are gradually diminishing on a global scale, including in developing countries such as Pakistan. Emergent countries are facing the worst of the energy crises, such as Pakistan, which spent almost USD 7 billion to import fossil fuels to meet the country’s energy needs [

20,

27].

In Pakistan, 65% of energy generation is from fossil fuel sources [

20] (

Figure 4). Pakistan has limited local energy resources and depends heavily on imported oil, but the oil import bill places a heavy burden on the country’s economy [

27,

28]. A dramatic increase in oil consumption almost every year with a slow increase in oil production is apparent in

Figure 5. This increase in oil consumption is due to the growing population, industrialization, and reliance on oil for energy production. Pakistan should pursue renewable resources to address the problems associated with these energy crises.

5. Feedstocks for Biofuels, Their Uses, and Relevant Industry in Pakistan for Processing

The major worldwide feedstocks used for biodiesel production include edible oils from palm (

Arecaceae), rapeseed (

Brassicaceae), sunflower (

Helianthus annus), soybean (

Glycine max), jatropha, algae

(Mesostigmatophyceae), and peanut (

Arachis hypogaea), and waste products such as used cooking oil and tallow [

22,

23,

51]. The initial research on biodiesel resources in Pakistan was completed by Pakistan State Oil (PSO), which grew jatropha on marginal land. Another project aims to identify feedstock that would be usable for biodiesel production. The Punjab Government has funded a mega-project to establish a research institute at the University of Agriculture Faisalabad named the Punjab Bioenergy Institute (PBI), Faisalabad, Pakistan. The goals of the PBI are to develop and grow different energy crops using agriculture residues and algae for bioenergy production. Another alternative and complementary option is the production of biogas through the anaerobic digestion of organic matter from biomass, e.g., manure, kitchen waste, and crop residues [

52,

53,

54]. The use of microalgae has attracted major attention for its potential use for biodiesel production on a commercial scale [

51,

55]. Pakistan is blessed with good climatic conditions that support significant biodiversity. Pakistan has abundant algal flora that can be used to recognize native floral assets for biodiesel production [

55,

56].

In Pakistan, 25 out of 85 sugar mills have considerably high co-generation potential and could generate 2900 GWh of electricity for the national grid per annum. Overall, Pakistan’s 85 sugar mills produce about 33.5 M sugar per year with a crushing capacity of 597,900 TCD (tons of cane per day). These mills generate 3 GW of electricity during the crushing season, and this energy is used for their own needs and operations [

10,

57,

58]. However, the crushing season lasts only a few months. After crushing, mills can be utilized to generate electricity for the national grid. Sugar mills have the potential to generate 1900 MWh from 18 Mt of bagasse per year. Twelve sugar mills received letters of intent from AEDB to generate 387 MW of electricity in 2018 [

10,

59].

Biogas generally consists of methane and carbon dioxide, and it may also have other elements such as nitrogen, hydrogen sulfide, halogenated compounds, and organic silicon compounds [

60,

61]. Biogas can be used for power generation and heat production.

Biogas can be burned to produce steam, which then drives an engine. In developing countries, it is mainly used by individuals for lighting, cooking, and heating in their houses [

21,

61]. The quantity of dung produced in Pakistan is sufficient to meet the energy needs of 28 million rural people [

21]. A comprehensive scheme was launched by the Directorate General of New and Renewable Resources (DGNRER) under the Ministry of Petroleum and Natural Resources between 1974 and 1987 to establish 4137 small biogas plants throughout the country. These units were designed to produce 3000–5000 cubic feet of biogas daily. However, this program failed due to a lack of financial support from the government and technical training for the people, as well as its high cost [

21].

6. Feedstock Development and Current Research in Pakistan

Pakistan has vast biomass resources, including crop residues, animal waste, municipal solid waste, and forest residues, which collectively produce 230 billion tons of biomass annually [

13,

62]. Farmers burn or use residues for heating and cooking purposes. In addition, due to poverty, people have cut down trees for household use, which has ultimately led to deforestation. This activity further increases pollution by releasing smoke into the environment [

63,

64]. These resources can be efficiently converted to energy by using advanced biochemical and thermochemical conversion technologies. The World Bank reported that annual crop residue processing is 26 Mt, which can produce 1,874,786 TJ/y of energy (

Figure 7). In addition, the total annual productivity of crop residues is about 115 Mt, with the capacity to generate 524,580 GWh of electricity per year [

10,

58]. The Pakistan Council of Appropriate Technology (PCAT), Islamabad, Pakistan was also working to organize renewable energy resources for the R&D of biogas technology in the country. In 2001, PCAT merged with the National Institute of Silicon Technology (NIST), Islamabad, Pakistan which implemented a comprehensive plan to improve and better distribute biogas plants in the rural areas of the country. PCRET has installed 1200 biogas plants throughout Pakistan on a cost-sharing basis, whereby 50% of the cost is to be borne by the beneficiary (HDIP), Islamabad, Pakistan. The National Development Vision—2004 and PCRET Vision—2020 have been established to meet the targets of providing 250 m

3/day biogas plants to 50,000 families, and of generating 500 MW of electric power using municipal and/or agricultural solid waste [

21].

The yield in oil per acre of different crops varies; for corn, sunflower, soybean, rapeseed, and palm oil, the yields are 72, 408, 192, 508, and 2540 L per acre per year, respectively [

65,

66]. In contrast, algae can produce 20,000–60,000 L of oil per acre per year [

67]. In recent years, more emphasis has been placed on microbial oil, which has great potential for the production of biodiesel in the future. The marginal land in Pakistan that is waterlogged and salt-affected can be used to grow algae, which can survive in salt-affected soil and brackish water. Algae have shown very promising growth in industrial waste water [

23,

51,

68]. The huge quantity of algal biomass produced from wastewater can be used as a source for biodiesel as well as bioethanol production [

68]. After the oil is extracted from algae for biodiesel production, the remaining dried mass can also be subjected to fermentation for bioethanol production. The produced algae-based biofuels (third-generation biofuel; biofuel produced from nonfood biomasses that do not compete with food production for land) would be more cost-effective than first- (biofuel produced from biomasses that are also used as food sources, e.g., soybeans, palm, canola) or second-generation biofuels (biofuel produced from nonfood biomasses, but their production competes with food crops for land, e.g., from jatropha seed), yet the quality of biofuel would remain the same [

69,

70].

The conversion process of biomass into bio-oil, hydrogen-containing gases, and biochar makes pyrolysis a promising and popular technology among people [

71,

72]. However, in addition to producing useful gases, the pyrolysis process also produces a high amount of detrimental gases, such as CO

2 and CO. Ash, as a product of pyrolysis, consists of heavy metals that are considered hazardous waste [

73,

74].

Recently, with joint efforts between Guangzhou Institute of Energy Conversion (GIEC), China, and UAF, Pakistan, a 125 kWh biogasification plant was successfully installed at PBI, UAF. This plant has a good capacity to utilize agricultural wastes such as corn stalks, corn cobs, sorghum stalks, rice straws, wheat straw, and tree branches. Many industrialists present for the inauguration and the demonstration of the abovementioned plant showed interest in using it to produce renewable and environmentally friendly bioenergy to run their industries.

As an agricultural country, Pakistan is blessed with vast natural sources of energy in the form of agricultural wastes (

Figure 7). It is estimated that the wheat

(Triticum aestivum), cotton (

Gossypium), rice (

Oryza sativa), maize (

Zea mays), sugarcane (

Saccharum officinarum), rapeseed/mustard, sunflower, and canola (

Brassica napus) crops grown in Pakistan have a total biomass potential of 123.47 million ton/year, producing a high amount of thermal energy and around 20,339 million liters of bioethanol annually [

10,

13,

22,

75,

76,

77,

78]. At the same time, alternative crops such as jatropha can produce 1800–2800 L/ha/yr of biodiesel, while switchgrass and kallar grass can produce 2200–4400 l/ha/yr and 821 M liters of bioethanol per year, respectively. Moreover, switchgrass can be cultivated at a low cost and requires very little input, while producing high biomass yields, even on marginal soils [

79,

80]. Initially, switchgrass was successfully grown at an experimental station of the University of Agriculture, Pakistan. However, it is vital to explore different agronomical factors affecting its growth and yield.

The best use of the substantial biomass potential is the generation of producer gas, which can be used to dry crops by applying gasifier technologies. Several attempts have been made in the past to introduce biogas and gasification units to rural areas of Pakistan. Unfortunately, these technologies have not become popular in Pakistan. On the contrary, China and India, neighboring countries of Pakistan, maintain more than 50 million and 3 million family biogas units (plants), respectively, compared to only a few thousand in Pakistan. The reason for the failure of biogas technology in Pakistan is associated with an absence of effective R&D and backup mechanisms. The literature reveals that more than 4180 institutes/centers in the world work solely on biogas technology [

6]. By using waste (manures) from cows, buffaloes, and poultry, reasonable quantities of feedstocks can be processed to produce energy that can provide a solution to the prevailing energy crisis in Pakistan.

The first use of domestic biogas plants in Pakistan was in 1959, and at present, there are a considerable number of such units (plants) working throughout the country. The Pakistani government started the Biogas Support Program (BSP) in 2000, and it has achieved its target of installing 1200 biogas units [

81,

82,

83,

84]. Moreover, almost 10,000 such units are expected to be installed in the next 5 years, and these units will harvest almost 27% of the country’s biogas potential. A biogas unit with a size of 10 m

3 saves almost 92,062 PKR (Pakistani currency rupees) per year that would otherwise have been spent on conventional fuels [

84,

85]. Biogas energy-generating systems are in great demand, and their numbers are slowly increasing. These systems are not too costly and can be easily run with a smaller budget than other systems. Some potential biogas plants are installed and work efficiently in industries and dairy farms. Biogas energy can be a productive alternative energy source for more than 70% of the country’s people who live in rural areas. There is a dire need to develop a national policy that would bring this valuable technology to each farmer’s doorstep.

7. Potential Crops and Other Feedstocks for Biogas Production

Pakistan is also facing a deficiency of CNG (compressed natural gas), which is considered an alternative to petrol and diesel. The shortfall of CNG reached 220 M cubic feet in KPK and Punjab. The Federal Petroleum Ministry reported that the CNG shortage has reached up to 38% of the total demand in Pakistan [

10,

86]. Half of the installed CNG stations (3400) were shut down due to an extreme gas shortage in 2012. Therefore, the government was forced to restrict CNG use to vehicles and industrial supply [

87]. Biogas can be a good alternative to CNG. Biogas from biomass is a promising renewable energy source whose importance is increasing in Europe and elsewhere. European countries are effectively producing energy from biogases while mitigating GHG to protect the environment.

Many crops are being studied for biogas production through anaerobic digestion. These include sunflower (

Helianthus Anus L.), sorghum (

Sorghum bicolor L.), the cup plant, tall herb meadow (

Filipendulionulmariae), small-sedge poor-fen meadow (

Caricionfuscae), montane hay meadow (

Polygono-trisetion), poor oat grass meadows (

Arrhenaterion), hemp (

Cannabis sativa), and sudan grass (

Sorghum sudanense) [

60,

75,

76,

77,

78,

88,

89,

90,

91,

92,

93,

94,

95,

96,

97,

98,

99]. Interestingly, Pakistan has great potential and a favorable environment to produce a high biomass yield from energy crops such as maize, sunflower, switchgrass, and sorghum. Crops such as sorghum, kallar grass, and mott grass can grow under salt stress and in waterlogged conditions. In addition to producing huge amounts of biomass in marginal soils, crops such as kallar grass can reclaim the soil. Sorghum could be a potential crop for biogas production, as it produces high biomass yields in a short period (90–110 days) using low inputs. Sorghum is a drought-tolerant C

4 crop and has high nutrient use efficiency. Observations in previous studies showed that sorghum cultivars (Hageri, Jawar 2011 and JS 2002) produced reasonable biomass and biogas yields under semi-arid conditions in Pakistan. The biogas yields of these cultivars ranged from 2700 to 3600 m

3N per ha (norm cubic meter, which is a unit to measure gas flow rate, and norm refers to normal or standard conditions for gas measurement, i.e., 0 °C and 1 atmosphere) [

75,

76]. Biomass produced by these crops in marginal soils can be co-digested with liquid cow manure for biogas and biomethane production. The biogas potential of several crops and straws is reported in

Table 2.

Abideen et al. [

99] conducted a very comprehensive study on the available perennial halophyte species (grasses and shrubs) present in the coastal area of Pakistan and found they have high growth rates, biomass potential, and quality for bioenergy production. They determined the lignocellulose contents of 23 species of grasses and shrubs from the provinces of Sindh and Baluchistan. Some of these species have very low lignin contents (

Table 3) and high biomass yields, which may enhance the digestibility of their biomass in co-digestion and make them potential candidates for biogas and biomethane production [

100,

101]. Species with low lignin contents are listed in the table. However, more research work is needed to assess these species for their biomass potential and digestibility for biogas production.

Our neighbor Bangladesh has installed 6000 biogas plants that run purely on bovine waste to fulfill the energy needs of countryside people. Nepal and Vietnam construct 20,000 and 18,000 small biogas plants every year, respectively [

1].

A biogas plant with a 100-cubic-foot capacity is able to handle 50 kg of manure and is sufficient for households. Biogas plants with this capacity can produce 3 kWh of electricity. Landhi Colony (Karachi) is one of the biggest cattle associations, with an animal population of 400,000, making it very suitable for biogas plants [

62,

104]. In this colony, animals produce about 4200 tons of manure every day, with an electricity-generating potential of 20–22 MW. Other sources for biogas production include wet wastes such as manure and sewage [

105,

106], which are also well suited to produce biogas through anaerobic digestion, which can be combusted to produce transport fuel. There are about 72 million bovines (cows and buffaloes), 81 million tons per year of crop residues, and about 785 million birds in poultry farms across the country (

Figure 8) [

82]. The bovines and birds produce 360 million kg and 39.2 million kg of collectible dung per day, respectively. This, along with the crop residue, could yield 27.5 million cubic meters of biogas per day [

21,

107], which could generate 1900 MW of power per day [

10,

13,

21]. Of this total, 14.68 million m

3 per day of biogas production from animal dung and poultry could produce 1012 MW of power in Punjab. Exploring these biomass resources, growing tolerant crops on marginal land, and the co-digestion of produced biomass for biogas and biomethane production may be the best solution for mitigating energy crises and cleaning the country’s environment.

Similarly, 560 kWh and 220 kWh per tons of electricity can be produced from MSW (municipal solid waste) by thermochemical and biochemical conversion, respectively [

10]. In Pakistan, enough biomass can be supplied to run about 15 M biogas plants. Bovine waste can be efficiently converted to biogas to overcome the prevailing energy crises. Interestingly, bananas may also be a promising source of RE in Pakistan [

10]. Studies have reported 173,000 banana trees per km

2 countrywide, having a caloric value of 18 MJ/kg. The banana crop is harvested thrice per year, resulting in 7–8 kg residue per tree, which can be a rich source of energy when using conversion technologies [

15,

20]. Pakistan is ranked the fourth highest country in terms of the production of sugar from sugarcane [

54,

82,

108]. Sugarcane is cultivated on a large scale and produces a huge amount of waste along with bagasse during the crushing season. In 2010–2011, sugarcane production was 63,920,000 metric tons, with around 5,752,800 metric tons of waste, which can generate approximately 9475 GWh bioenergy [

108].

8. Potential Biodiesel Crops (Jatropha, Castor Bean, Safflower, and Cellulosic Feedstocks)

The International Energy Agency (IEA) aims to have biofuels meet more than a quarter of the world’s demand for transportation fuels by 2050, in order to reduce reliance on petroleum and coal. These biodiesel crops include jatropha (

Jatropha curcas), castor beans, and non-edible safflower crops, as well as switchgrass (

Panicum virgatum) and kallar grass for bioethanol. Jatropha can produce 1800–2800 L/ha/year biodiesel. Among the diverse array of potential bioenergy crops,

Jatropha curcas has high potential to be grown in many countries as a biodiesel feedstock because it grows well in adverse conditions, especially in arid regions and on marginal land.

J. curcas is a highly drought-tolerant crop and is also perennial. Several studies have shown that

J. curcas biodiesel reduces GHG emissions by about 80–88% compared to fossil diesel [

109,

110]. However, if

J. curcas is cultivated on what was previously primary forest land, the impacts will most likely be negative and lead to carbon debts.

In the Sindh province of Pakistan, the cultivation of Jatropha is increasing (from 5 acres in 2004 to thousands of acres in 2014) due to the interest of some public and private organizations, such as the alternative energy development board (AEDB) and Pakistan State Oil (PSO). Pakistan is an agricultural country, with about 60–70% of the population in villages depending on agriculture for their income [

111]. This substantial part of the population can improve their standard of living by cultivating non-edible biodiesel crops, i.e., jatropha, castor oil, and safflower, on marginal land. With small investments, pilot-scale technology can be designed to make their farm machinery run on biodiesel fuel. Areas of land that are not currently being used due to water shortage or soil salinity can be used for non-edible oil crops. The government of Pakistan can reduce the amount that it pays to import oil by making farmers aware of, and motivated to take advantage of, the benefits of these options. This will also benefit Pakistan’s local economy. Jatropha biodiesel is safer and more environmentally friendly compared to fossil fuel owing to its characteristics [

111] (

Table 4).

The non-edible oil obtained from jatropha can be easily used in modified diesel engines, or it can be refined further to be used in standard diesel engines. Additionally, the seed coat can be efficiently used in biogasification plants [

109,

110,

112]. The diesel obtained from jatropha has several benefits, including a higher octane number, higher flash point, and lower sulfur contents than other types of diesel [

113]. There is not much of an incentive structure under which farmers would grow jatropha. There is also no opportunity for the commercial-scale refining of biodiesel in Pakistan. Provincial governments have plans to build up commercial-scale capacity, but the economic investment from private companies has yet to materialize. A study revealed that, in the first year of growing jatropha, large numbers of irrigations were required to establish the crop. This makes jatropha’s drought tolerance in its early stages questionable [

114,

115]. In addition, farmers face several challenges in continuing to cultivate jatropha, including their insufficient knowledge about the maintenance and agronomy of jatropha planting, their lack of a comprehensive R&D road map, and ambiguity with respect to marketing [

116]. The government should take decisive steps to create awareness and motivation and to develop the market. Castor bean and safflower are promising indigenous non-edible oilseed crops [

117,

118] that have the potential to be future biodiesel crops in Pakistan. Both are salt-, drought-, and heat-tolerant crops and can be grown in arid to semi-arid areas with low inputs. In addition, they are short-duration crops that can be harvested within only 100–120 days after sowing. The castor bean is frequently used as an effective medicinal plant [

44] and in paints and varnishes [

119,

120]. The Potohar region (Rawalpindi, Chakwal, and Attok areas) (

Figure 6) of Pakistan has a climate that ranges from true semi-arid in the southwest to a sub-humid, sub-tropical lowland climate in the east and northeast. It is mainly characterized by high temperatures in June and July (average 40–50 °C) with occasional hot, dry winds and dust storms; cold nights in winter (average about 4 °C); and two rainy seasons. Rainfall ranges from 350 mm in the southwest to 1000 mm (with most of it falling in the months of July and August) in the northwest region [

17].

Owing to its aridity tolerance, well-developed deep root system, and capability of growing in soil that is not very fertile, castor is a very promising potential biodiesel crop for the Potohar region, which has fairly alkaline soils with a pH of 7.5–8.5. Potential cultivars of safflower and castor bean and agronomy developed for the specific climatic conditions of Pakistan (

Table 5) make it a promising non-edible oil crop for biodiesel production that could improve the socio-economic position of farmers. Unfortunately, the appropriate market for these crops is limited, and as a result, the area of their cultivation is decreasing (

Table 6). If the government takes an interest and provides guidance to farmers in arid and semi-arid areas, a large, currently uncultivated area can be cultivated for the growth of these crops. Experiments were conducted at UAF to explore the impact of different optimizing parameters on the biodiesel productivity from mustard oil. The observations in this study indicated that mustard could have resource potential as a biodiesel crop, and alkali-catalyzed trans-esterification is an efficient and economical process to produce biodiesel [

121]. However, the recommendations of the aforementioned study are not appropriate because mustard oil is an edible oil consumed as food. Therefore, using the mustard crop as biodiesel poses a risk to food security.

A study conducted on various feedstocks for biodiesel production suggested that waste cooking oils and fats are the most economically feasible options to obtain biodiesel due to their easy and almost free availability in Pakistan. The researcher also concluded that systematic management is required to collect this huge quantity of waste cooking oil and efficiently convert it to biodiesel. This can help to drastically reduce the import bills that are spent on diesel every year [

122,

123,

124,

125]. In KPK, 17 species were explored for biodiesel production. The results of this study revealed that higher oil contents were obtained using

Sirogonium sticticum, Chroococcus turgidus, Uronesma, and

Temnogyra reflexa. In addition, 22% more biodiesel was obtained by direct trans-esterification compared to extraction/trans-esterification [

125,

126].

The Nuclear Institute of Agriculture and Biology (NIAB), Faisalabad, Pakistan developed the castor variety “NIAB Gold” especially for biodiesel production. It is a short-duration variety, ripens in 90 days, and has an oil content of 50%. A study was designed to evaluate this variety for biodiesel production. The findings of the study indicated that all the tested parameters of biodiesel meet ASTM standards (American Society for Testing and Materials, West Conshohocken, Pennsylvania, United States) [

127].

9. Feedstock for Bioethanol Production

Bioethanol is another bioenergy resource that can be used to overcome energy crises and mitigate environmental deterioration. It is estimated that wheat, cotton, rice, maize, sugarcane, rapeseed/mustard, sunflower, and canola crops in Pakistan have total biomass potentials of 35.27, 40.78, 9.24, 8.5, 29.0, 0.20, 0.35, and 0.13 million tons per year, respectively. Of the total biomass (123.47 million tons), 65% (81 million tons) can produce a total of 20,339 million liters of bioethanol (at 340, 250, 430, 360, 70, 60, and 65 L/ton, respectively) annually [

108].

Switchgrass can produce 2200–4400 l/ha/year bioethanol with an annual biomass production of around 5.5–11 dried t/ha/year on normal-quality land. Another crop that can be grown on saline soil (>6.5 Mha) is

kallar grass (

Leptochla afusca), with a potential of 40 t/ha/year, and fibrous wastes can yield 821 and 139.86 million liters of bioethanol per year, respectively [

131,

132].

Pakistan’s total production of oilseed is around 5.58 million tons. From 2012 to 2013 (July–March), sunflower, cotton, canola, mustard, and rapeseed were the major crops grown in Pakistan as a whole. Cottonseed made up 50–60% of local oil production, but most cotton is grown for lint purposes [

132,

133]. Cottonseed was cultivated on an area of 7.14 Mha, with a total of 3.39 Mt of seed and 0.41 Mt of oil produced; rapeseed/mustard was cultivated on an area of 0.45 Mha, with a total production of 0.16 m t of seed and 0.05 Mt of oil; sunflower was cultivated on an area of 0.7 Mha, with a total production of 0.38 Mt of seed and 0.14 Mt of oil; and canola was cultivated on an area of 0.03 Mha, with a total production of 0.02 Mt of seed and 0.01 Mt of oil [

134]. Pakistan still spends a lot of money on importing edible oil, but imports can be reduced with better production technologies and government policies. The characteristics that make crop biomass appropriate for biofuel include its suitability to many site conditions in arid and semi-arid areas of the country, easy propagation, high survival rate under drought and harsh conditions, rapid economic returns, low input requirements, easy degradability, short duration, fast growth, and high biomass production per unit area.

A study revealed that waste from dates (

Phoenix dactylifera L.) is a good source for bioethanol production. The researcher concluded that bioethanol yield could be enhanced by up to 25% through a

Saccharomyces cerevisiae strain [

135].

Pakistan is the fifth largest sugarcane producer in the world. It is estimated that, in the sugarcane-processing season, 3 Mt of molasses is produced, which could be an excellent feedstock for bioethanol production [

57]. This study suggested that mixing E10 (10% bioethanol produced from molasses) with 90% gasoline could be a viable option to reduce dependence on gasoline-importing countries. The joint production of sugar and bioethanol (from molasses) is a promising option; although the cost of bioethanol production is slightly higher, it can play an important role in the socio-economic development of farmer communities and environmental safety.

10. The Policy for Bioenergy Production

The government of Pakistan (GOP) established the National Institute of Silicon Technology and the Pakistan Council of Appropriate Technology (PCAT) in 2001 to promote RE in the country. Later on, both of them were merged and renamed “Pakistan Council of Renewable Energy Technologies (PCERET)” [

83]. Another institute, AEDB (Alternative Energy Development Board), was established by GOP in 2003 to promote, facilitate and provide funds to initiate RE technology and projects. Considering the large biomass potential, GOP has taken steps and revised RE policies to construct additional bioenergy plants in the country [

136].

It is estimated that RE contributed approximately 1.3% to the mixed energy of Pakistan during 2018–2019, which is slightly higher than in previous years (

Figure 9). This slight increase is due to the policy shifts of the current GOP as they are striving to enhance the RE share in the total energy mix. Acknowledging the importance of RE, the government plans to increase its share by 20% by 2025 and 30% by 2030 in the national grid [

20,

136]. Among various RE technologies, biomass is a promising, viable, environment-friendly alternative energy option. The NEPRA is establishing a mechanism to boost the power capacity of Pakistan by offering attractive incentives to IPPs (independent power plants) for power generation. Wastes from various sources, such as sugar, pulp processing, livestock, and vegetable and fruit stores, are being used as feedstock for bioenergy in electricity production. The NEPRA and AEDB are determined to make policies and formulate a transparent draft for a tariff to fill the gaps in biomass energy production. The GOP should devise the best policies and strategies to get the maximum benefits from available biomass in the country. Subsidized advance biomass technologies should be provided to the people of rural areas to develop awareness of and responsibility for the safe use of biomass as an energy source.

To overcome the prevailing energy crises, Pakistan needs an efficient road map, good governance, and effective policies. In drafting effective and reliable policies, many factors must be taken into consideration, i.e., precise forecasts of future energy demand, the development of appropriate and cost-effective technologies, chalking out short- and long-term planning, and effective and viable project management [

3,

10,

62].

11. Future Perspectives and Conclusions

This study concludes that an unsustainable supply of fossil fuel necessitates the search for suitable alternatives. This article also highlights the availability of indigenous biomass (halophytes, agriculture waste, and energy crops) and MSW. These sustainable and RE sources can be efficiently utilized for eco-friendly energy production with proper management through an effective supply chain and the creation of awareness among farmers. Moreover, uncultivated marginal lands can be effectively utilized for growing non-edible bioenergy crops without risking food security. To avoid competition between feed and fuel, crops being used as a source of feedstock for biofuels can be replaced with halophytes. This approach will be beneficial in the future for producing biofuels without affecting high-quality water and land resources. Non-edible oilseed crops are available in Pakistan and are potential biodiesel crops (castor bean, safflower, and jatropha). However, more research is required to explore these crops and others, including weeds, having higher oil contents for biodiesel production in marginal soils. There are limitations concerning the utilization of edible oil for biodiesel production, as it could create food energy competition and enhance the cost of production of food crops. Concerning anaerobic digestion, the selected species should have good qualitative characteristics, such as lignin <10% and cellulose/hemicellulose >25–30%, and should also be non-invasive. The unexplored aspects of the agronomy of these wild plants need careful study, especially with regards to land degradation and ecological consequences before, large-scale cultivation. This study can be further extended by modeling the exact biomass resource data from the field, as well as from industries and government institutions. The finding of this study is expected to help policy-makers and energy-related government institutions to devise rational policies regarding modeling and utilizing biomass to resolve energy crises in our country. Moreover, a strict environmental policy is needed to prevent the burning of residues in the field. A cost-effective and efficient use of available biomass would be an excellent option to reduce the energy crises. The GOP should start R&D projects to promote small biomass conversion technologies, such as biogas plants and advanced combustion systems, in rural and small city areas. Pakistan’s energy policies need to be amended to meet the energy supply and demand. In the future, massive energy projects on biomass-based bioenergy need to be implemented in Pakistan. Currently, biomass-to-energy conversion technologies are costly, and future research should be carried out to formulate cost-effective, efficient, and eco-friendly technologies. The generation of electricity from renewable sources should be considered, and the dependence on fossil fuel sources should be decreased.