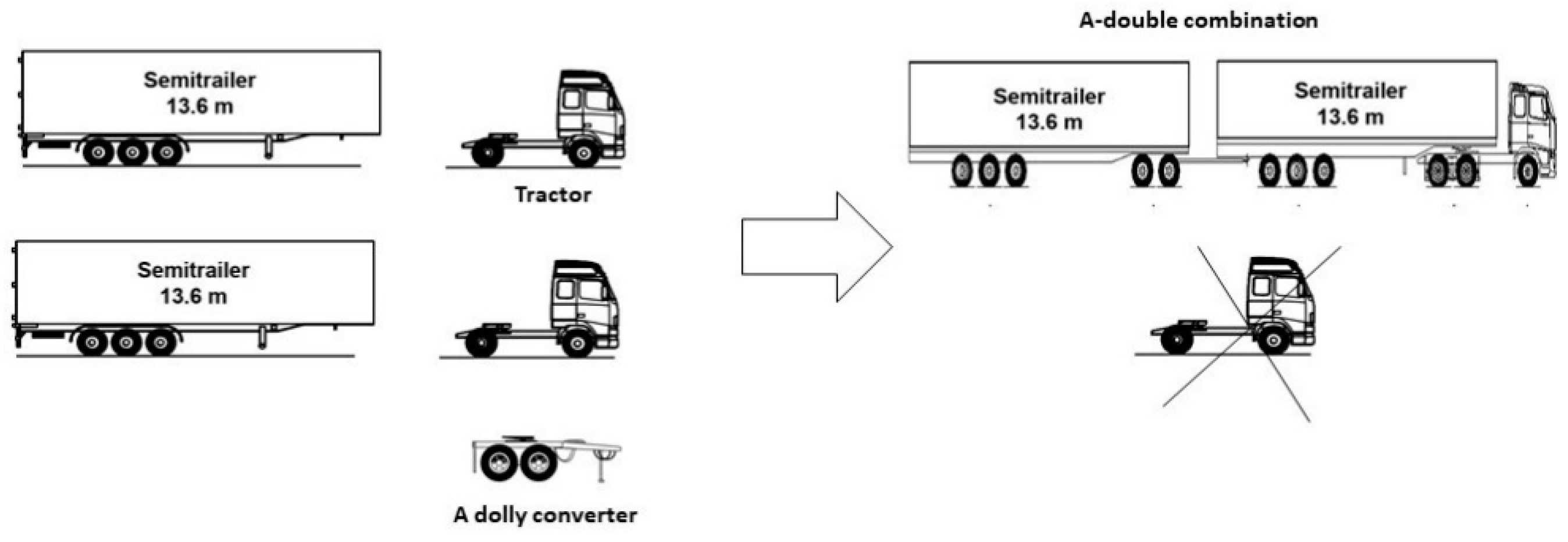

Evaluating the Effects of the A-Double Vehicle Combinations If Introduced to a Line-Haul Freight Transport Network

Abstract

:1. Introduction

2. Literature Review

2.1. Impacts on Transport Cost

2.2. Impacts on Road Infrastructure

2.3. Impacts on CO2 Emissions

2.4. Impact on Road Traffic Safety

2.5. Impact on Modal Shift

3. Method

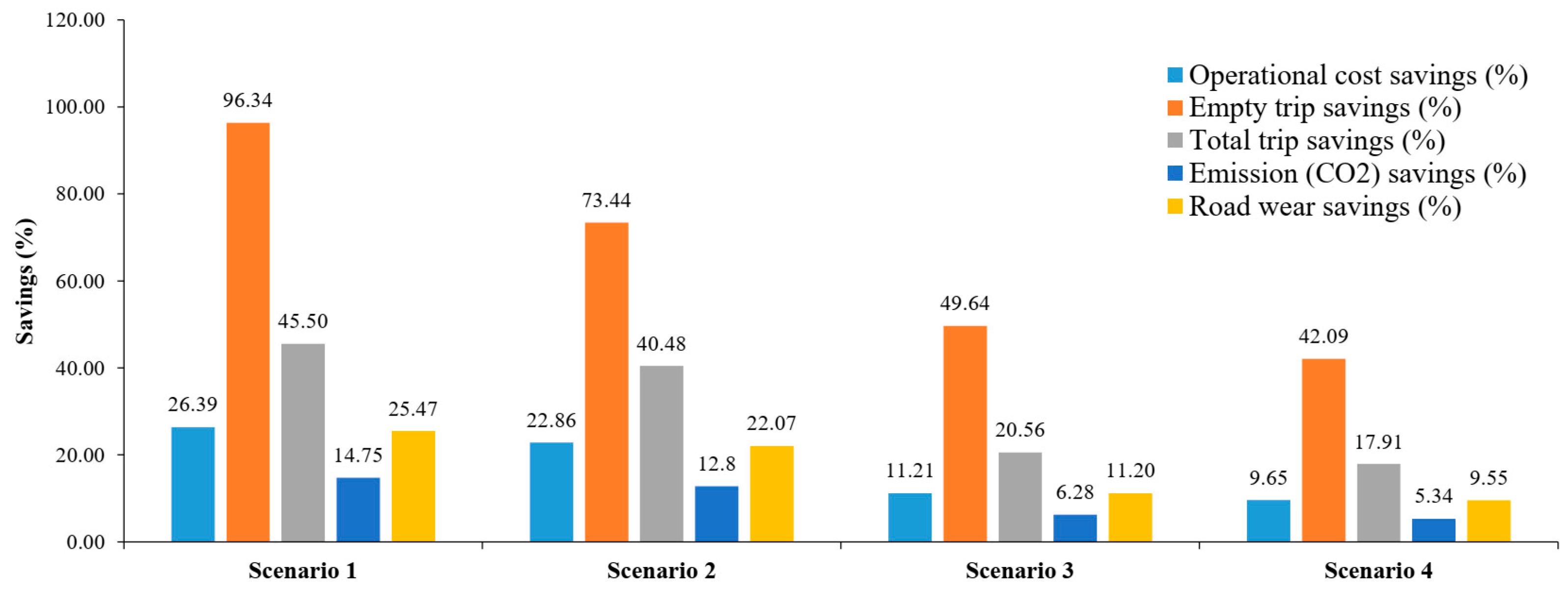

3.1. Scenarios

- Scenario 1: GVW of the A-double combination is restricted to 60 tonnes;

- Scenario 2: as scenario 1 and the allowable trip delay is limited to 3 h. Note that a 3-h limit is suggested based on inputs from field practitioners;

- Scenario 3: as scenario 1 and the A-double trips are allowed only during the night from 10 p.m. to 5 a.m.;

- Scenario 4: as scenario 3 and the allowable trip delay is limited to 3 h.

- Operational cost saving:

- Empty trip saving:

- Total trip saving:

- CO2-emission (Kg) saving:

- Road wear saving:

3.2. Data

3.3. Cost-Benefit Model

3.3.1. Operational Costs

3.3.2. CO2-Emission Cost

3.3.3. Road Wear Cost

4. Results and Discussions

4.1. Main Scenarios

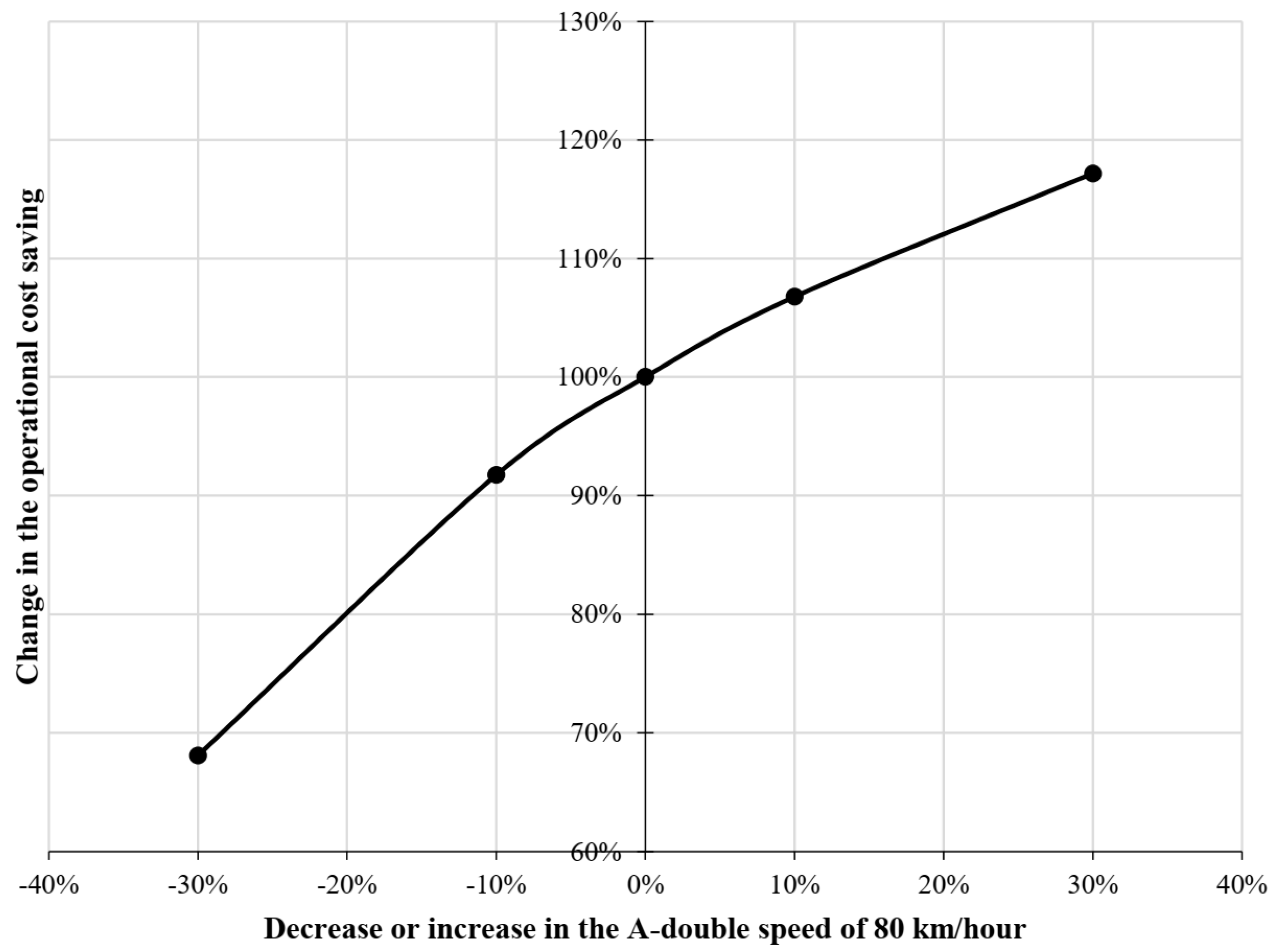

4.2. Sensitivity Analysis

5. Conclusions, Implications, Limitations, and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pinchasik, D.R.; Hovi, I.B.; Vierth, I.; Mellin, A.; Liimatainen, H.; Kristensen, N.B. Reducing CO2 Emissions from Freight; TemaNord; Nordic Council of Ministers: Copenhagen, Denmark, 2019; ISBN 9789289359023. [Google Scholar]

- Zeng, A.Z.; Rossetti, C. Developing a framework for evaluating the logistics costs in global sourcing processes: An implementation and insights. Int. J. Phys. Distrib. Logist. Manag. 2003, 33, 785–803. [Google Scholar] [CrossRef]

- Liljestrand, K. Improvement actions for reducing transport’s impact on climate: A shipper’s perspective. Transp. Res. Part D Transp. Environ. 2016, 48, 393–407. [Google Scholar] [CrossRef]

- Piecyk, M.I.; McKinnon, A.C. Forecasting the carbon footprint of road freight transport in 2020. Int. J. Prod. Econ. 2010, 128, 31–42. [Google Scholar] [CrossRef]

- Leach, D.Z.; Savage, C.J.; Maden, W. High-capacity vehicles: An investigation of their potential environmental, economic and practical impact if introduced to UK roads. Int. J. Logist. Res. Appl. 2013, 16, 461–481. [Google Scholar] [CrossRef]

- Sanchez Rodrigues, V.; Piecyk, M.; Mason, R.; Boenders, T. The longer and heavier vehicle debate: A review of empirical evidence from Germany. Transp. Res. Part D Transp. Environ. 2015, 40, 114–131. [Google Scholar] [CrossRef]

- Liimatainen, H.; Pöllänen, M.; Nykänen, L. Impacts of increasing maximum truck weight—Case Finland. Eur. Transp. Res. Rev. 2020, 12, 14. [Google Scholar] [CrossRef] [Green Version]

- Aurell, J.; Wadman, T.; Trucks, V. Vehicle Combinations Based on the Modular Concept. 2007. Available online: https://nvfnorden.org/wp-content/uploads/2020/10/2007-Vehicle-combinations-based-on-the-modular-concept-Background-and-analysis.pdf (accessed on 4 April 2021).

- International Transport Forum. High Capacity Transport: Towards Efficient, Safe and Sustainable Road Freight. 2019. Available online: https://www.itf-oecd.org/sites/default/files/docs/high-capacity-transport.pdf (accessed on 4 April 2021).

- McKinnon, A. Improving the sustainability of road freight transport by relaxing truck size and weight restrictions. In Supply Chain Innovation for Competing in Highly Dynamic Markets: Challenges and Solutions; IGI Global: Hershey, PA, USA, 2011; pp. 185–198. ISBN 9781609605858. [Google Scholar]

- Lindqvist, D.; Salman, M.; Bergqvist, R. A cost benefit model for high capacity transport in a comprehensive line-haul network. Eur. Transp. Res. Rev. 2020, 12, 60. [Google Scholar] [CrossRef]

- Pålsson, H.; Winslott Hiselius, L.; Wandel, S.; Khan, J.; Adell, E. Longer and heavier road freight vehicles in Sweden: Effects on tonne- and vehicle-kilometres, CO2 and socio-economics. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 603–622. [Google Scholar] [CrossRef]

- Bergqvist, R.; Behrends, S. Assessing the effects of longer vehicles: The case of pre- and post-haulage in intermodal transport chains. Transp. Rev. 2011, 31, 591–602. [Google Scholar] [CrossRef]

- Duo2 Duo2.nu—Climate Friendly Transports. Available online: https://duo2.nu/?page_id=221&lang=en (accessed on 14 April 2021).

- Åkerman, I.; Jonsson, R. European Modular System for Road Freight Transport—Experiences and Possibilities. 2007. Available online: https://unece.org/DAM/trans/wp24/wp24-presentations/documents/pres08-11.pdf (accessed on 11 January 2021).

- Knight, I.; Newton, W.; Barlow, T.; McCrae, I.; Dodd, M. Longer and/or Longer and Heavier Good Vehicles (LHVs): A Study of the Likely Effects if Permitted in the UK: Final Report. 2008. Available online: http://data.parliament.uk/DepositedPapers/Files/DEP2008-1410/DEP2008-1410.pdf (accessed on 11 December 2020).

- Trailer Total Finland Staat 34,5 Meter Combinaties Toe. Available online: https://trailertotaal.nl/nieuwsarchief/item/finland-staat-345-meter-combinaties-toe (accessed on 14 March 2021).

- The Green Car Congress. SEAT Expands the Fleet of Duo Trailers and Giga Trailers to Promote More Sustainable Logistics. Available online: https://www.greencarcongress.com/2020/01/20200119-seat.html (accessed on 17 April 2021).

- Pålsson, H.; Sternberg, H. LRN 2016 SPECIAL—High capacity vehicles and modal shift from rail to road: Combining macro and micro analyses. Int. J. Logist. Res. Appl. 2018, 21, 115–132. [Google Scholar] [CrossRef]

- Vierth, I.; Haraldsson, M. Socio-economic effects of longer and/or heavier road transport vehicles: The Swedish case. In Proceedings of the 12th International Symposium on Heavy Vehicle Transport Technology; 2012. [Google Scholar]

- Palander, T. The environmental emission efficiency of larger and heavier vehicles—A case study of road transportation in Finnish forest industry. J. Clean. Prod. 2017, 155, 57–62. [Google Scholar] [CrossRef]

- Leduc, G. Longer and Heavier Vehicles: An Overview of Technical Aspects; Joint Research Centre (Seville Site): Seville, Spain, 2009. [Google Scholar]

- The Danish Road Directorate. Evaluation of Trial with European Modular System: Final Report. 2011. Available online: https://www.vejdirektoratet.dk/udgivelse/danish-trial-ems-european-modular-system-evaluation (accessed on 12 December 2020).

- Hjort, M.; Haraldsson, M.; Jansen, J.M. Road Wear from Heavy Vehicles—An Overview. 2008. Available online: https://nanopdf.com/download/road-wear-from-heavy-vehicles-an-overview_pdf (accessed on 12 December 2020).

- Hewitt, J.; Stephens, J.; Smith, K.; Menuez, N. Infrastructure and Economic Impacts of Changes in Truck Weight Regulations in Montana. Transp. Res. Rec. J. Transp. Res. Board 1999, 1653, 42–51. [Google Scholar] [CrossRef]

- Ceuster, G.D.; Breemersch, T.; Herbruggen, B.V.; Verweij, K.; Davydenko, I.; Kligender, M.; Jacob, B.; Arki, H.; Bereni, M. Effects of Adapting the Rules on Weights and Dimensions of Heavy Commercial Vehicles as Established within Directive 96/53/EC. Final Report. 2008. Available online: https://ec.europa.eu/transport/sites/default/files/themes/strategies/studies/doc/2009_01_weights_and_dimensions_vehicles.pdf (accessed on 12 December 2020).

- Tunnell, M.A.; Brewster, R.M. Energy and Emissions Impacts of Operating Higher-Productivity Vehicles. Transp. Res. Rec. J. Transp. Res. Board 2005, 1941, 107–114. [Google Scholar] [CrossRef]

- Aarts, L.; Feddes, G. Experiences with longer and heavier vehicles in the Netherlands. In International Conference on Heavy Vehicles HVParis 2008; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; pp. 123–136. [Google Scholar]

- Kyster-Hansen, H.; Sjögrenr, J. Roadmap High Capacity Transports on Road in Sweden. 2013. Available online: https://www.lindholmen.se/sites/default/files/content/PDF/2013-08-13_roadmap_hct-roads_final.pdf (accessed on 12 December 2020).

- Grislis, A.; Grīslis, A. Longer combination vehicles and road safety. Transport 2011, 25, 336–343. [Google Scholar] [CrossRef]

- Af Wåhlberg, A.E. Meta-analysis of the difference in accident risk between long and short truck configurations. J. Risk Res. 2008, 11, 315–333. [Google Scholar] [CrossRef]

- Klingender, M.; Ramakers, R.; Henning, K. In-depth Safety Impact Study on longer and/or heavier commercial vehicles in Europe. In Proceedings of the PEITS 2009—2009 2nd Conference on Power Electronics and Intelligent Transportation System, Shenzhen, China, 19–20 December 2009; 2009; Volume 1, pp. 368–373. [Google Scholar]

- Castillo-Manzano, J.I.; Castro-Nuño, M.; Fageda, X. Analyzing the safety impact of longer and heavier vehicles circulating in the European market. J. Saf. Res. 2021, 77, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Meers, D.; van Lier, T.; Macharis, C. Longer and heavier vehicles in Belgium: A threat for the intermodal sector? Transp. Res. Part D Transp. Environ. 2018, 61, 459–470. [Google Scholar] [CrossRef]

- Backman, H.; Nordström, R. Improved Performance of European Long Haulage Transport. 2002. Available online: http://worldcat.org/isbn/9188752380 (accessed on 12 December 2020).

- Blank, L.; Tarquin, A. Depreciation Method. In Engineering Economy; McGraw-Hill: New York, NY, USA, 2012; pp. 414–443. ISBN 9780073376301. [Google Scholar]

- Liimatainen, H.; Greening, P.; Dadhich, P.; Keyes, A. Possible Impact of Long and Heavy Vehicles in the United Kingdom—A Commodity Level Approach. Sustainability 2018, 10, 2754. [Google Scholar] [CrossRef] [Green Version]

| Fixed Costs | Formula | Relative Cost Value a | |||

|---|---|---|---|---|---|

| CD | : | Capital depreciation cost (DKK/h) | 1.32 | (1) | |

| IC | : | Insurance cost (DKK/h) | 1.15 | (2) | |

| TRC | : | Tax and registration cost (DKK/h) | 1.07 | (3) | |

| Variable cost | |||||

| TC | : | Tire cost (DKK/km) | 1.83 | (4) | |

| RMC | : | Repair and maintenance cost (DKK/km) | 1.30 | (5) | |

| FC | : | Fuel cost (DKK/km) | Fuel consumption c (L/Km) x fuel cost (DKK/L) | 1.67 | (6) |

| DC | : | Depreciation cost (DKK/km) | 1.18 | (7) | |

| DR | : | Driver cost rate (DKK/h) | 1.00 | (8) | |

| Operational cost | |||||

| OC | : | Operational cost (DKK/KM) | 1.40 | (9) | |

| TOC | : | Total operational cost (DKK) | OC (DKK/Km) x travelled distance per combination | - | (10) |

| CO2 Emission (g/km) | Fuel Consumption (g/km) | Payload (tones) | |

|---|---|---|---|

| The tractor-semitrailer combination | 575.954 | 181.661 | 0 |

| 768.313 | 242.308 | 11 | |

| 878.314 | 276.994 | 18 | |

| The A-double combination | 997.225 | 314.150 | 0 |

| 1315.49 | 414.705 | 25 | |

| 1449.871 | 457.218 | 37 | |

| 1758.198 | 554.614 | 60.4 |

| Allowable Trip-Delay Time (h) | |||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Operational cost saving (%) | 17.07 | 21.12 | 22.86 | 23.34 | 23.70 |

| Empty trip saving (%) | 56.13 | 68.13 | 73.44 | 74.98 | 76.35 |

| Total trip saving (%) | 30.80 | 37.76 | 40.48 | 41.20 | 41.65 |

| Emission (CO2 kg) saving (%) | 9.54 | 11.81 | 12.80 | 13.09 | 13.28 |

| Road wear saving (%) | 16.47 | 20.39 | 22.07 | 22.56 | 22.88 |

| Pallet Weight (kg) | |||||||

|---|---|---|---|---|---|---|---|

| 200 | 300 | 400 | 500 | 600 | 700 | 727 | |

| Operational cost saving (%) | 22.86 | 22.86 | 22.86 | 22.86 | 9.87 | 7.57 | 7.12 |

| Empty trip saving (%) | 73.44 | 73.44 | 73.44 | 73.44 | 73.43 | 73.45 | 73.45 |

| Total trip saving (%) | 40.48 | 40.48 | 40.48 | 40.48 | 19.56 | 15.54 | 14.73 |

| Emission (CO2 kg) saving (%) | 11.78 | 12.36 | 12.80 | 13.30 | 4.99 | 3.57 | 3.29 |

| Road wear saving (%) | 22.07 | 22.07 | 22.07 | 22.07 | 9.53 | 7.31 | 6.87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karam, A.; Reinau, K.H. Evaluating the Effects of the A-Double Vehicle Combinations If Introduced to a Line-Haul Freight Transport Network. Sustainability 2021, 13, 8622. https://doi.org/10.3390/su13158622

Karam A, Reinau KH. Evaluating the Effects of the A-Double Vehicle Combinations If Introduced to a Line-Haul Freight Transport Network. Sustainability. 2021; 13(15):8622. https://doi.org/10.3390/su13158622

Chicago/Turabian StyleKaram, Ahmed, and Kristian Hegner Reinau. 2021. "Evaluating the Effects of the A-Double Vehicle Combinations If Introduced to a Line-Haul Freight Transport Network" Sustainability 13, no. 15: 8622. https://doi.org/10.3390/su13158622

APA StyleKaram, A., & Reinau, K. H. (2021). Evaluating the Effects of the A-Double Vehicle Combinations If Introduced to a Line-Haul Freight Transport Network. Sustainability, 13(15), 8622. https://doi.org/10.3390/su13158622