1. Introduction

With its high consumption of resources and energy, the construction sector is one of the major sources of environmental pollution. Currently, this discipline accounts for 35% of global energy consumption [

1]. Therefore, both the reduction of resource consumption of buildings and the application of resource-efficient and sustainable material and construction solutions are gaining increasing attention and interest. In addition, the need for cost-effective and material-efficient construction is growing [

2]. As a result, the use of natural and renewable materials, such as wood, has been increasing in the recent decade. This raw material has been used as a building material in traditional construction for centuries and its material properties as well as its building physics characteristics provide it with good prerequisites as a material for innovative and sustainable construction solutions [

3]. Due to the increasing awareness of sustainability and resource conservation, it is therefore gaining importance in contemporary architecture [

4].

In the context of building physics, acoustics are a major challenge in multi-storey timber construction and protection against noise has an important role to be considered [

5]. The perceived acoustic quality in lightweight buildings is different from that in solid buildings. In particular, the transmission of low-frequency sound, such as impact sound, has a very high potential for disturbance in buildings made of wood which can impair user comfort [

6]. The sound insulation of ceilings is based, among other aspects, on the parameters of usage and must meet defined requirements in residential buildings. Often, the acoustic requirements according to the standards do not meet the expectations of the residents. Even if the requirements of building construction standards are fulfilled, the experienced noise and vibration disturbances of the residents tend to increase [

7]. The current acoustic requirements for residential buildings are based on experience in heavy weight buildings in the construction sector, as these constructions have been dominant in Europe in the past decades [

8]. The description of subjective perception and the low-frequency transmission behavior due to impact sound in multi-storey timber buildings is already subject of various acoustic questions [

7,

9,

10,

11,

12]. Furthermore, the extension of the ecological consideration of materials and constructions under the aspect of holistic evaluation in the context of sustainability is becoming increasingly important.

In order to establish the relation between building-physical quality and the environmental performance, with a focus on the acoustic requirements of wooden ceiling constructions, typical timber constructions were selected and examined in more detail as an example with regard to their acoustic behaviour. Common concrete ceiling construction is used as a reference. With the aim of demonstrating the potential of the materials used in the building sector, the acoustic evaluation is extended to include ecological characteristics. Ecology and economy represent a central task of holistic and sustainable planning and design. This is the motivation for subjecting the considered systems to a life cycle analysis.

2. Materials and Methods

In order to quantify acoustic and ecological evaluation methods and to examine the applicability to integrative design approaches, typical ceiling constructions made from concrete and timber were investigated from which the relevant data for the evaluation are available [

7,

10,

13]. The specific acoustic performance of wooden ceiling constructions is the focus of this analysis, as timber constructions tend to have higher impact sound transmission due to the inherent lower bulk density of the material [

10]. By varying different construction details, components can be generated that differ in their respective building physical properties and ecological characteristic values. Depending on the requirements, the properties can be adapted to the demands, by for example changing the thickness of the components and the materials used. For the acoustic analysis, measurement data of the weighted impact sound level L

n,w and the spectrum adaptation term C

I from the Fraunhofer Institute for Building Physics IBP [

7,

10], measured with the standard tapping machine according to DIN EN ISO 10140-5 [

14], was used. Further, numerical values of tested example constructions of solid wood from the component catalog according to [

13] were considered. Studies at the Fraunhofer IBP have shown that when using the standard tapping machine as an impact sound source in lightweight construction, the spectrum adaptation term C

I should be added to single-number values of the weighted impact sound level L

n,w in an extended frequency range according to DIN EN ISO 717-2 [

15] to represent walking noise appropriately [

5,

7,

10,

12]. In the context of this paper, the acoustic behavior of wooden ceiling constructions in the low-frequency range is investigated on the basis of typical example constructions in order to demonstrate and discuss optimization approaches and potential for improvement.

From the perspective of sustainable design of structures and buildings, the methodology of life cycle assessment (LCA) is becoming increasingly important to provide the basis for a holistic evaluation. It is the most relevant instrument for the systematic analysis of environmentally decisive impacts of products, services and processes and are standardised in the DIN EN ISO 14040 [

16] and DIN EN ISO 14044 [

17]. The basis for the analysis is the recording of all relevant material flows that can be assigned to a product, service or process over the entire life cycle, for example various energy sources and other raw materials, secondary products or emissions into the environment. The effects caused by these material flows are then quantified with the help of impact indicators (e.g., climate change).

The evaluation of the environmental impacts of the investigated ceiling systems was performed using the GENERIS

® [

18] tool for life cycle building assessment, developed by the Fraunhofer IBP. GENERIS

® enables the preparation of life cycle assessment studies in accordance with current standardization and in compliance with certification systems for sustainable buildings like the German Sustainable Building Council: DGNB and BREEAM. It also serves as decision support during the entire planning process. It uses the ÖKOBAUDAT database [

19], with which the Federal Ministry of the Interior, for Building and the Interior (BMI) provides all stakeholders with a standardized database for the life cycle assessment of buildings, in compliance with DIN EN 15804 [

20].

The 2020-II version of ÖKOBAUDAT was used to assess the constructions. The database contains generic and manufacturer-specific data sets. Generic data sets were used to ensure proper comparability. Due to the lack of generic data for the polystyrene board, an EPS rigid foam board from Styropor® was used. The constructions are built up by the different layers according to the structure. Each material is matched with a dataset from the database and provided with a respective end-of-life scenario.

3. Challenges of Wooden Ceiling Constructions in an Acoustic Context

For the acoustic comparison of wooden ceiling constructions, raw ceiling constructions made of wooden beams and solid timber are first compared on the basis of their respective evaluated impact sound level. In order to identify the specific properties of lightweight construction, the reinforced concrete construction method is also taken into consideration in this paper. To compare the impact sound levels of different constructions, it is advisable to use characteristic values such as the frequency weighted impact sound level L

n,w in combination with the spectrum adaptation term C

I according to [

15].

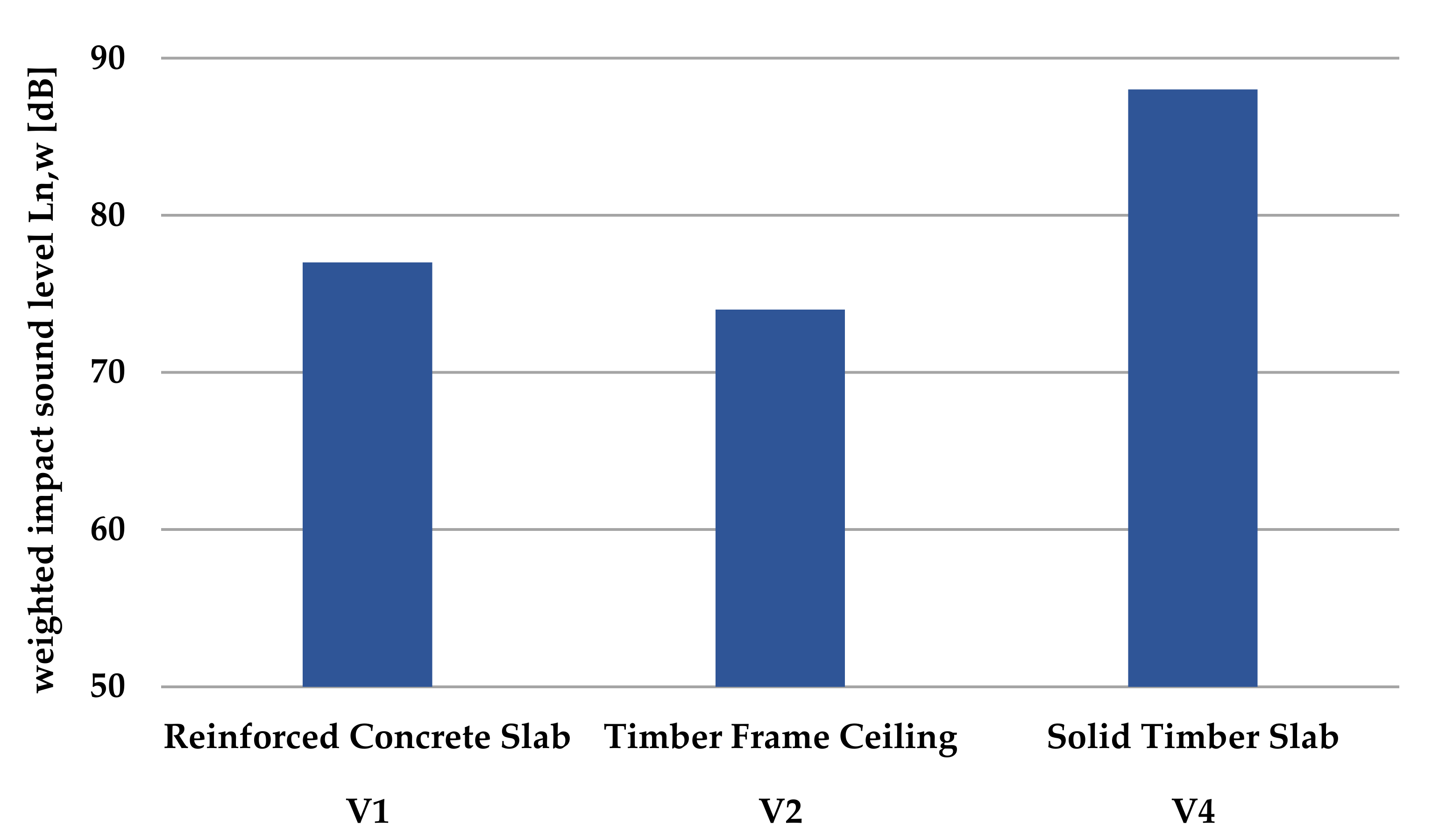

In the first investigation, four types of raw ceiling constructions made of timber and reinforced concrete were compared. The buildup of the three most relevant basic types are described in the following. The raw ceiling construction in timber beam construction is approximately 180 mm deep and the intermediate space is filled with a 100 mm thick insulation layer of mineral wool. On the underside, the construction is covered with wooden battens and plasterboard. The top of the beams is covered with a wood chipboard to create a plane surface [

7]. The solid timber ceiling slab consists of a 140 mm thick cross laminated timber plate. The reinforced concrete raw construction has about the same thickness as the solid wood slab [

10]. An overview of the weighted impact sound level L

n,w of selected constructions from the investigations is given in

Figure 1. The weighted impact sound level of the cross laminated timber plate (V4) was calculated based on the generally valid approximate solution for plates with a mass per unit area between 35 kg/m

2 and 130 kg/m

2 according to [

21,

22].

It is shown that the reinforced concrete construction (V1), despite its mass, has no significant advantage compared to the wooden beam construction (V2) from an acoustic point of view. In general, it emerges that additional constructive measures are necessary for the shown variants of the raw constructions in order to optimize the acoustic behavior and to comply with the limit values according to the standard. In residential buildings, floor slabs must not exceed the limit value of 50 dB [

23]. The impact sound level of ceiling constructions can be significantly reduced not only by a floor construction but also by means of a suspended ceiling or a combination. Possible ceiling construction improvement measures (in comparison to the abovementioned basic types) are shown schematically in

Figure 2.

Further variants for the acoustic improvement of ceiling constructions considered in this paper are listed in

Table 1. Here, the three mentioned raw ceiling constructions (basic types) are shown with two constructive improvement measures each. Only the most relevant results over 13 variants investigated as part of the research are shown here. The measures according to

Table 1 can reduce the weighted impact sound level L

n,w of the reinforced concrete ceiling up to 35 dB depending on the floor construction [

7]. With timber constructions, a combination of floor construction measures and the use of a suspended ceiling has the greatest reduction effect on impact sound. Values of weighted impact sound levels of acoustically optimized floor constructions can be found in

Table 2. In addition, the recommendation of combining the weighted impact sound level L

n,w and the spectrum adaptation value C

I mentioned at the beginning is also presented in the last column, as is more correlated with the subjective perception of impact sound within a building.

If the raw ceiling constructions are acoustically improved by flooring and suspended ceilings, the improvement is recognizable by the single number value. However, the evaluation method according to DIN EN ISO 717-2 [

15] only covers a frequency range between 100 and 3150 Hz which does not include the lower frequencies relevant for impact sound. Therefore, the spectrum adaptation term C

I is used for the behavior of the constructions in the low-frequency range between 50 and 100 Hz.

These types of constructive measures change the impact sound level of ceilings. In order to analyze this behavior, investigations were carried out at the Fraunhofer IBP which clarify the frequency-dependent performance of ceiling constructions according to DIN EN ISO 717-2 standards [

7,

10,

15]. In the following, the wooden beam ceiling and the reinforced concrete ceiling are used as examples for the frequency-dependent comparison. The curves are shown in

Figure 3. It is shown that both the reinforced concrete (V1) and the wooden beam (V2) raw ceiling construction have a high impact sound level in the low-frequency range below 250 Hz. Nevertheless, the timber beam ceilings result is about 6 dB higher at 50 Hz and even 15 dB higher at 160 Hz than the reinforced concrete ceiling. This underlines the problem of increased low-frequency sound transmission in timber construction which is due to the lower density and therefore also the lower mass per unit area compared to reinforced concrete. The frequency curve for impact sound in reinforced concrete (V1) stagnates at about 70 dB above a frequency of 150 Hz, while the curve for the timber beam ceiling (V2) decreases.

By constructive measures, such as a floor construction, depending on the design, clear differences in the effectiveness of the measures can be detected in the range between 63 and 125 Hz in

Figure 3. Whereas improvements in the low-frequency range are particularly evident in the wooden beam ceiling due to constructive measures using cement screed in the floor structure (V2-A2), reinforced concrete ceilings may even deteriorate in this range under certain circumstances. This is due to the difference in the insulation materials used (V1-A1 and V1-A4). Between 50 and 100 Hz, the optimization measures of the reinforced concrete ceiling (

Figure 3a) even show a deterioration of the impact sound level by up to 12 dB. These measures mainly show their effect in the higher frequency range. In the case of the wooden beam ceiling, the combination of floor construction improvements and a suspended ceiling (V2-A2-U2) has a great effect of reducing the impact sound level over the entire frequency curve. For example, the impact sound level at 125 Hz is reduced by almost 15 dB. This is also visible in the spectrum adaptation term C

I according to

Table 2 by means of the negative sign and the resulting lower combined value L

n,w and C

I in the last column.

The results of this part of the investigation have shown that the impact sound insulation in timber construction can be at a high level comparable to solid concrete constructions through a sensible conceptual design of the ceilings. The combination of floor construction measures and the use of a suspended ceiling is particularly effective at reducing impact sound. Further, the requirements according to DIN 4109-1 [

23] are stricter for residential buildings than for office buildings. Depending on the room size and equipment, the expected impact sound insulation can differ by +2 dB or −2 dB [

13], as sound protection does not depend on sound insulation alone. For this reason, the spectrum adaptation term C

I should be considered when planning and designing buildings. However, there ensues the dilemma. The implications of design for impact sound on the economical and ecological aspects of construction will be discussed in the following section.

4. Life Cycle Analysis

The ecological consideration of materials and constructions as a supplement to the planning and design of buildings is gaining increasing importance under the aspect of holistic assessment. By applying the methodology of life cycle assessment, life cycle-based data can be generated and potential environmental impacts can be quantified. Further, the results can be used for ecological improvement and significantly influence the development of products and constructions.

The environmental impacts are quantified on the basis of the total energy input from renewable (PERT) and non-renewable resources (PENRT). Furthermore, the expected global warming potential (GWP), the acidification potential of soil and water (AP) and the eutrophication potential (EP) are investigated. For the balancing of the environmental impacts, the constructions according to

Section 3 are used and the database ÖKOBAUDAT [

19] is used as basis for the balancing. Thermal utilization was chosen as the end-of-life scenario, but without the credits from substituted electricity and heat generation from thermal utilization (Module D). According to the product category rules for wood-based materials as per standardized calculation rules [

24], the energy for heat and electricity from natural gas combustion is substituted and the avoided emissions are credited. This results in high credits for wood components and can lead to a negative CO

2 balance over the entire life cycle. This can give the impression that the processing and use of wood building materials is completely CO

2 neutral or even negative. In fact, however, this is only the case in comparison to the currently defined state of the art and is therefore not considered in this study. The end-of-life scenario for wood and plastic components is set to incineration. All other components are set to a generic end-of-life which includes the separation and sorting as well as recycling, thermal utilisation or landfilling.

4.1. Ecological Consideration of the Studied Constructions

Constructions made of wood have a more beneficial global warming potential compared to constructions made of concrete (

Figure 4). The differences become clear on the basis of the raw ceiling constructions. In this case, the reinforced concrete ceiling has twice as high values as the solid timber construction as seen in

Figure 4 and

Figure 5. The higher CO

2 emissions are caused by the costly and energy-intensive manufacturing process of concrete and cement. Due to their CO

2 storage potential, wood-based construction materials have a lower environmental impact and thus a negative CO

2 balance in the production phase. At the end of life, the stored CO

2 is released.

Figure 5 serves as an illustration. In this diagram, the global warming potential (GWP) of the investigated constructions is subdivided according to the life phases of production (module A1-A3) and end of life (module C).

In contrary to the global warming potential, the constructions made of wood have a higher share of primary energy consumption than concrete constructions (

Figure 6). This could be due to the energy-intensive drying process in wood manufacturing and underlines the general problem of gray energy in the construction sector. In addition, the percentage of renewable primary energy in the case of concrete structures is only about 25%, hence concrete constructions are inferior in terms of their environmental profile compared to timber constructions which is also due to the manufacturing process. With a percentage of around 70%, the timber constructions achieve a higher ratio of renewable energy use, but offer less theoretical potential for optimization.

Figure 7 shows the percentages of the respective total environmental impacts of the individual component layers for variants V1-A1 (reinforced concrete with mineral wool insulation and screed) and V4-A6 (solid wood with mineral wool insulation, screed and filling). In both diagrams it is shown that a significant part of the environmental impact is caused by the raw ceiling constructions. In the case of the timber construction, the screed has a larger share of the energy demand, as timber construction performs more beneficially than reinforced concrete according to the selected indicators and thus the comparative impact of the screed increases.

In order to discuss possible effects between the environmental impact and the acoustic performance,

Figure 8 shows the corrected weighted impact sound level L

n,w on the primary axis and the GWP on the secondary axis. It can be seen that as the impact sound level of the constructions decreases, the GWP increases. This relation is particularly evident for the V4, V4-A6 and V4-A6-U2 variants (solid timber slab with improvement measures according to

Table 1). A reasonable explanation for this effect is that the impact sound level, especially in timber construction, is lowered by increasing the mass, such as the application of filling and cement screed. This kind of increase in mass causes an increase in the environmental impact, in this case the GWP, while the materials remain the same.

The effect of acoustic optimization also becomes evident when comparing the environmental footprint of a timber beam ceiling (V2-A2-U1) and a solid timber ceiling (V4-A6-U2), each with a floor construction and suspension. The solid timber ceiling is acoustically optimized with a cement screed and fill. The numbers show that the construction with cement screed and filling makes a significant contribution to the environmental impact. The measure can reduce the impact sound level by 5 dB (8%), but the GWP of the structure increases by 90%. For a comparable impact sound level, the variant V4-A6 (without suspension) only shows an increase in GWP of about 60%.

This comparison indicates the tendency that acoustic optimizations can result in relevant changes to the environmental profile and should therefore be selected and dimensioned with care.

4.2. Optimization from an Ecological Point of View

Optimizations, for example in the selection of an insulation material, must always be evaluated in the context of a suitable functional unit. This can be, for example, a specific impact sound level. By referring to a defined function, the material-specific properties are considered. Example: Insulation material A has a higher, volume-related GWP than insulation material B. However, since less material is required to fulfil a certain function, this results in a saving in the context of a comparable construction.

Furthermore, it makes sense to use constructions, building components and products as long as possible [

25]. Already in the planning process and the optimization of components, reuse should be considered through constructive measures. This can be achieved, for example, through the standardization of elements or through easy adaptability [

26].

5. Summary and Discussion

Based on the acoustic analysis of the examined constructions, the possibilities for improvement could be presented, considering the ecological aspects. The acoustic requirements for residential buildings are stricter than for office buildings. If the spectrum adaptation term C

I is included in the evaluation of impact sound levels, the requirements for residential buildings are hardly met. Raw ceiling constructions made of both reinforced concrete and timber require constructive optimizations, as these cannot fulfil the minimum acoustic requirements. It becomes evident that the low frequencies are more problematic in the timber construction than in the reinforced concrete construction and this affects the acoustic quality of ceilings which underlines the challenge and relevance of acoustics in timber construction. It also highlights that if the acoustic measures are suboptimal planned and executed, they may not lead to any improvement and may even lead to a deterioration of the acoustic quality. In addition, the perceived acoustic quality of lightweight structures differs from solid structures which is why low-frequency sound transmission is the most frequent cause of complaints in timber and lightweight structures [

27]. This underlines that the currently used evaluation systems for airborne and impact sound transmission should be extended to include low frequencies up to 50 Hz with the help of the spectrum adaptation term C

I [

15]. This aspect is further investigated at the Fraunhofer Institute IBP in order to develop a method for the psychoacoustic evaluation of the acoustic quality of buildings in timber construction [

28].

The ecological assessment of this paper shows that timber constructions offer a GWP saving potential of up to 20% compared to acoustically comparable reinforced concrete constructions. Combined with the high CO2 storage potential of wood constructions, higher environmental qualities can be achieved if alternative solutions are found in the coming future that reduce energy consumption of the drying process during timber production and allow recycling of the building material to avoid the release of CO2 at the end of life. At this time, a significant part of the energy consumption is already covered by renewable energies which seems to be a reasonable approach in terms of reducing the climate impact in the sense of the greenhouse potential. For this reason, a comparison of different construction methods and the necessary optimization measures should be calculated and analyzed for the respective application. Furthermore, comparisons always have to be related to a functional unit, for example a specific acoustic performance, static load or heat transfer.

The LCA results in this study also have limitations, mainly because of the use of generic datasets. Generic datasets provide solid information in case a specific information is not available (e.g., origin or specific manufacturing processes). The downside is, that these often use statistical data and industry standards and therefore don’t always represent the best or the worst-case scenario. With regard to the challenge of increasing the mass per unit area of wooden constructions, further assessments with low emission cement or recycling concrete will provide an additional view and take the technical progress in the corresponding processes into consideration. Additionally, the inclusion of module D with a realistic 2050 scenario (electricity grid mix and state of heat generation) would be valuable for the assessment as well.

For the use of wood as a building material in multistory residential construction, precise knowledge of the material properties and the structural-physical behavior is necessary [

27]. With regard to thermal insulation and moisture performance as well as energy aspects, timber constructions can be comparable to reinforced concrete constructions [

3]. In addition to the acoustic improvement of constructions, the ecological effects should also be considered when considering the development and planning goals. Depending on the design of the ceiling construction, the user comfort can be increased which is a great challenge especially in timber construction. Depending on the construction and improvement measure, a corresponding additional effort and related costs for planning and execution are to be expected. Since low-frequency sound transmission is the most frequent cause of complaints from users, especially in timber constructions, this represents the greatest problem for timber buildings. For this reason, well planned acoustic improvement measures are necessary in order to keep the additional costs as low as possible. It is important to ensure that the improvements show their effect in the desired frequency ranges and do not lead to an undesired deterioration of the overall construction.

6. Outlook

The above-mentioned aspects for the use of wood as a building material in multistory residential buildings are being further investigated as part of the sub-project RP3 of the Cluster of Excellence IntCDC [

9] at the University of Stuttgart. The use of nature-based materials such as wood and the material-specific challenges with regard to their acoustic behavior are part of the current research questions. In particular, innovative approaches are being investigated to develop and implement alternative insulation and decoupling strategies to conventional solutions. In addition to the growing interest in research, there is also a need for the development of standards to promote dissemination in practice.

Modern manufacturing techniques and advances in materials production and manufacturing offer potential for cost reduction in this regard. Modular planning, which is gaining increasing attention in residential construction, also reduces both planning and construction time, which can have an impact on the costs incurred. In addition, digital tools and innovations, such as robotic fabrication, are increasingly gaining application in modern timber construction. Through innovative manufacturing methods, natural-based materials can be made more industrially suitable to further advance the research and development of both sustainable materials and constructions [

29,

30].

The Cluster of Excellence Integrative Computational Design and Construction for Architecture (IntCDC) [

31] at the University of Stuttgart is conducting research on this topic. The project is aiming to use the potential of digital technologies to rethink design, manufacturing and construction based on integration and interdisciplinarity in construction and architecture. Interdisciplinary research from areas such as architecture, civil engineering, building physics, and manufacturing and systems engineering will be used to create methodological foundations that will renew the design and construction process. New forms of efficient and sustainable building systems are to be developed through a higher-level integration of computational design and construction methods. The goal is to use the methodological insights and interdisciplinary results to contribute to the management of environmental, economic and social challenges that cannot be solved with current incremental approaches.

It is a challenge to consider acoustic and other building physical aspects of constructions, components and buildings in the context of holistic assessment. At the same time, however, it is precisely the holistic context that offers potentials for optimizing the environmental impacts [

32]. These challenges are addressed in Collaborative Research Center 1244 entitled ‘Adaptive skins and structures for the built environment of tomorrow’ in sub-project D02 [

33]. In addition, new methods for the planning of adaptive buildings and the exchange of information between the disciplines involved are being developed and tested [

34]. The focus in the second funding period is, among other topics, on handling large amounts of data from simulation and calculation tools.