Agro-Industrial Symbiosis and Alternative Heating Systems for Decreasing the Global Warming Potential of Greenhouse Production

Abstract

:1. Introduction

2. Conceptual Framework for the Utilization of Industrial Heat in Greenhouses

3. Materials and Methods

3.1. Goal, Scope, and System Boundary Definition

3.2. Scenario Description

3.3. Life Cycle Inventory (LCI)

| Inventory | Unit | Tomato | Cucumber |

|---|---|---|---|

| Needed cultivation area a | m2 | 24.4 | 11.5 |

| Infrastructural impact b | kg CO2-eq. | 140 | 140 |

| Primary heat demand c | MWh | 9.84 | 2.73 |

| Primary electricity demand c | MWh | 3.32 | 7.64 |

| Fertilizer application c: | |||

| NH3 | kg | 9.9 | 5.7 |

| K2O | kg | 20.4 | 10.1 |

| P2O5 | kg | 5.0 | 2.7 |

| Irrigation water d | m3 | 34 | 16 |

| Stone wool a,c | kg | 9.5 | 4.5 |

| CO2 e | kg | 146 | 69 |

| Packaging | |||

| Cardboard f | kg | 150 | - |

| Plastic film g | kg | - | 7 |

| Green waste a,h | kg | 400 | 700 |

| Transportation: | |||

| From input production to greenhouse | km | 50 | 50 |

| From greenhouse to retailer | km | 100 | 100 |

4. Results

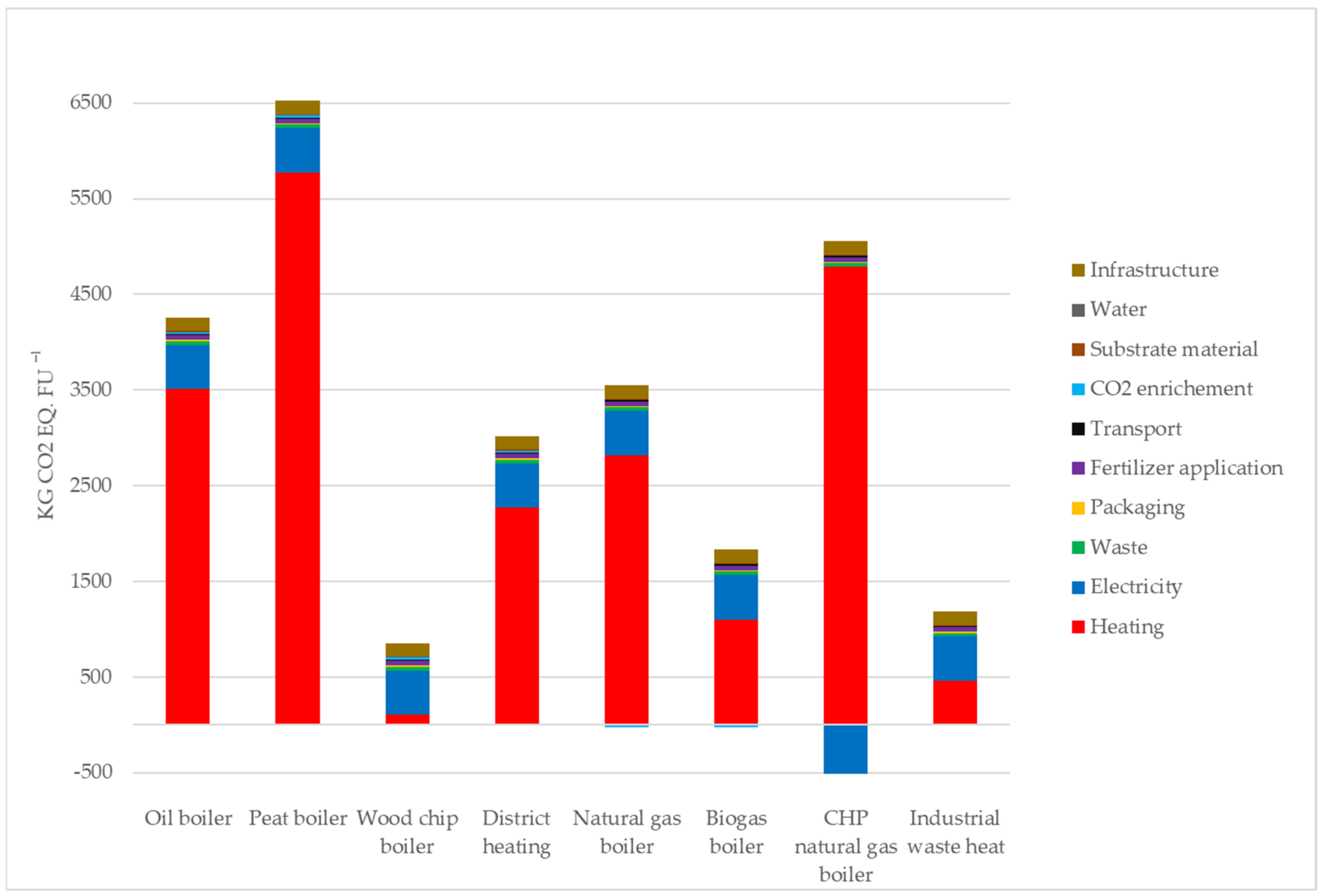

4.1. LCIA of Greenhouse Tomato Production

4.2. LCIA of Greenhouse Cucumber Production

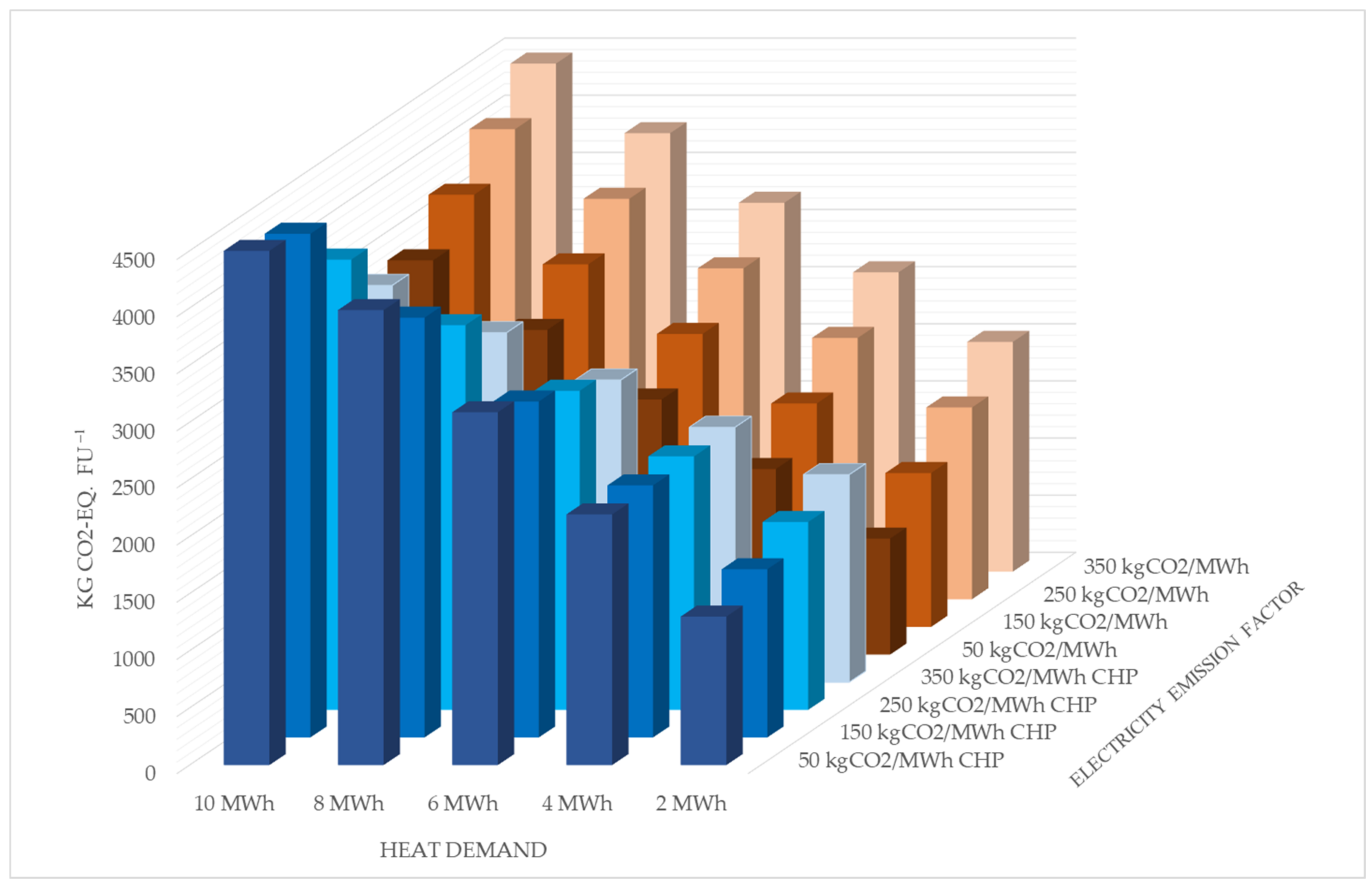

4.3. Sensitivity Analysis

4.3.1. CHP System

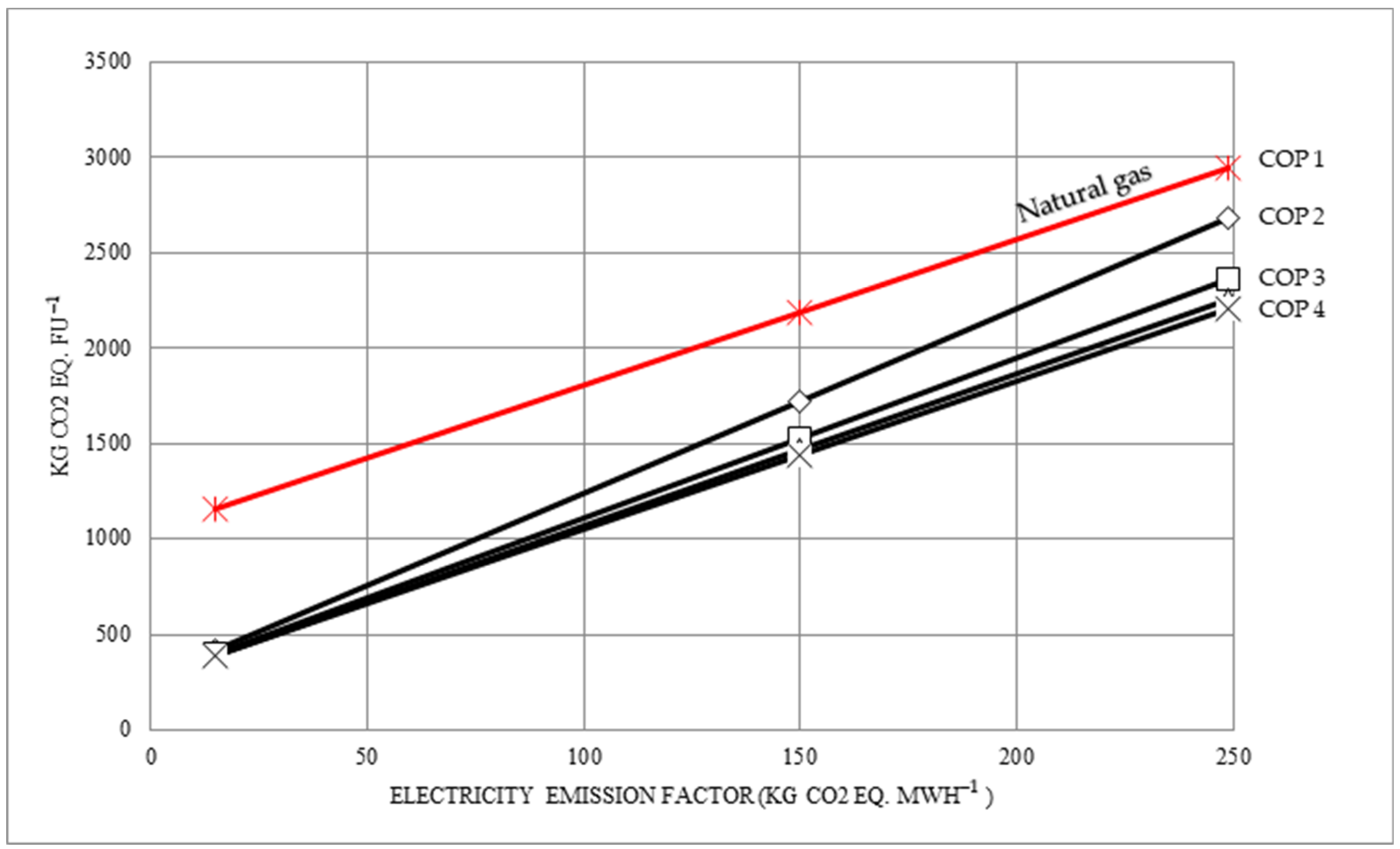

4.3.2. Agro-Industrial Symbiosis

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shukla, P.R.; Skea, J.; Buendia, E.C.; Masson-Delmotte, V.; Pörtner, H.-O.; Roberts, D.C.; Zhai, P.; Slade, R.; Connors, S.; van Diemen, R.; et al. Summary for Policymakers. In Climate Change and Land: An IPCC Special Report on Climate Change, Desertification, Land Degradation, Sustainable Land Management, Food Security, and Greenhouse Gas Fluxes in Terrestrial Ecosystems; IPCC: Geneva, Switzerland, 2019; in press. [Google Scholar]

- Foley, J. The Other Inconvenient Truth. TED Talks, Filmed in October 2010. Available online: http://www.ted.com/talks/jonathan_foley_the_other_inconvenient_truth#t540163 (accessed on 7 February 2021).

- Natural Resources Institute Finland. Tilastotietokanta: Puutarhatilastot. Available online: https://stat.luke.fi/puutarhatilastot (accessed on 24 November 2020).

- Theurl, M.C.; Haberl, H.; Erb, K.H.; Lindenthal, T. Contrasted greenhouse gas emissions from local versus long-range tomato production. Agron. Sustain. Dev. 2014, 34, 593–602. [Google Scholar] [CrossRef] [Green Version]

- Vermeulen, P.C.M.; van der Lans, C.J.M. Combined heat and power (CHP) as a possible method for reduction of the CO2 footprint of organic greenhouse horticulture. Acta Hortic. 2011, 915, 61–68. [Google Scholar] [CrossRef]

- Bosona, T.; Gebresenbet, G. Life cycle analysis of organic tomato production and supply in Sweden. J. Clean. Prod. 2018, 196, 635–643. [Google Scholar] [CrossRef]

- Van Woerden, S. The application of life cycle analysis in glasshouse horticulture. In Proceedings of the International Conference LCA in Foods, Gothenburg, Sweden, 31 March 2001; pp. 136–140. [Google Scholar]

- Nienhuis, J.K.; De Vreede, P.J.A. Utility of the environmental life cycle assessment method in horticulture. Acta Hortic. 1996, 429, 531–538. [Google Scholar] [CrossRef]

- Pluimers, J.C.; Kroeze, C.; Bakker, E.J.; Challa, H.; Hordijk, L. Quantifying the environmental impact of production in agriculture and horticulture in The Netherlands: Which emissions do we need to consider? Agric. Syst. 2000, 66, 167–189. [Google Scholar] [CrossRef]

- Boulard, T.; Raeppel, C.; Brun, R.; Lecompte, F.; Hayer, F.; Carmassi, G.; Gaillard, G. Environmental impact of greenhouse tomato production in France. Agron. Sustain. Dev. 2011, 31, 757–777. [Google Scholar] [CrossRef] [Green Version]

- Mariani, L.; Cola, G.; Bulgari, R.; Ferrante, A.; Martinetti, L. Space and time variability of heating requirements for greenhouse tomato production in the Euro-Mediterranean area. Sci. Total Environ. 2016, 562, 834–844. [Google Scholar] [CrossRef]

- Vox, G.; Teitel, M.; Pardossi, A.; Minuto, A.; Tinivella, F.; Schettini, E. Sustainable greenhouse systems. In Sustainable Agriculture: Technology, Planning and Management; Nova Science Publishers, Inc.: Bari, Italy, 2010; pp. 1–79. ISBN 978-1-60876-269-9. [Google Scholar]

- Yrjänäinen, H.; Silvenius, F.; Kaukoranta, T.; Näkkilä, J.; Särkkä, L.; Tuhkanen, E.-M. Kasvihuonetuotteiden ilmastovaikutuslaskenta; MTT Raportti; MTT: Jokioinen, Finland, 2013; Volume 83, pp. 1–43. ISBN 978-952-487434-2. [Google Scholar]

- Finnish Horticultural Trades Association; Kangas, N.; Jalkanen, J.; Mononen, H.; Tuominen, J.; Rantala, M.; Ojala, I.; Remes, L. Kasvihuonealan Vastuullisuus. 2019. Available online: https://kauppapuutarhaliitto.fi/wp-content/uploads/2019/06/vastuullisuusraportti_240619.pdf (accessed on 10 November 2020).

- Hamer, P.J.C.; Langton, F.A. Micro-turbine CHP units: Simulations of energy efficiency and cost in ornamentals production. Acta Hortic. 2005, 691, 633–640. [Google Scholar] [CrossRef]

- Andrews, R.; Pearce, J.M. Environmental and economic assessment of a greenhouse waste heat exchange. J. Clean. Prod. 2011, 19, 1446–1454. [Google Scholar] [CrossRef] [Green Version]

- Maare, O. Economical heat supply of greenhouses—Experiences from Denmark. Acta Hortic. 1992, 312, 37–44. [Google Scholar] [CrossRef]

- Heravi, S.M. Waste Heat Heated Greenhouses Energy System. Master’s Thesis, University of Gävle, Gävle, Sweden, 2013. [Google Scholar]

- Bredenbeck, H. The use of waste from a power plant for greenhouse heating in commercial application in Germany. ISHS Acta Hortic. 1992, 312, 29–35. [Google Scholar] [CrossRef]

- Vourdoubas, J. Possibilities of Using Industrial Waste Heat for Heating Greenhouses in Northern Greece. J. Agric. Sci. 2018, 10, 116. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S.; Pasetti, M. Industrial symbiosis for greener horticulture practices: The CO2 enrichment from energy intensive industrial processes. Procedia CIRP 2018, 69, 562–567. [Google Scholar] [CrossRef]

- Vermeulen, P. Alternative sources of CO2 for the greenhouse horticulture. In Proceedings of the 2nd International Symposium on Energy Challenges and Mechanics, Aberdeen, UK, 19 August 2014. [Google Scholar]

- Torrellas, M.; Antón, A.; López, J.C.; Baeza, E.J.; Parra, J.P.; Muñoz, P.; Montero, J.I. LCA of a tomato crop in a multi-tunnel greenhouse in Almeria. Int. J. Life Cycle Assess. 2012, 17, 863–875. [Google Scholar] [CrossRef]

- Dias, G.M.; Ayer, N.W.; Khosla, S.; van Acker, R.; Young, S.B.; Whitney, S.; Hendricks, P. Life cycle perspectives on the sustainability of Ontario greenhouse tomato production: Benchmarking and improvement opportunities. J. Clean. Prod. 2017, 140, 831–839. [Google Scholar] [CrossRef]

- Pineda, I.T.; Cho, J.H.; Lee, D.; Lee, S.M.; Yu, S.; Lee, Y.D. Environmental impact of fresh tomato production in an urban rooftop greenhouse in a humid continental climate in South Korea. Sustainability 2020, 12, 9029. [Google Scholar] [CrossRef]

- Gibbs, D. Industrial symbiosis and eco-industrial development: An introduction. Geogr. Compass 2008, 2, 1138–1154. [Google Scholar] [CrossRef]

- Sharfman, M.; Graedel, T.E.; Allenby, B.R. Industrial Ecology; Prentice Hall: Englewood Cliffs, NJ, USA, 1995; pp. 1–363. ISBN 0130467138. [Google Scholar]

- Chertow, M. Industrial Symbiosis: Literature and Taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef] [Green Version]

- Koppelmäki, K.; Eerola, M.; Albov, S.; Kivelä, J.; Helenius, J.; Winquist, E.; Virkkunen, E. ‘Palopuro Agroecological Symbiosis’ A pilot case study on local sustainable food and farming (Finland). In Challenges for the New Rurality in a Changing World, Proceedings from the 7th International Conference on Localized Agri-Food Systems, 8–10 May 2016, Södertörn University, Stockholm, Sweden, 2016; Rytkönen, P., Hård, U., Eds.; Södertörn Högskola: Huddinge, Sweden, 2016. [Google Scholar]

- Koppelmäki, K.; Parviainen, T.; Virkkunen, E.; Winquist, E.; Shculte, R.P.O.; Helenius, J. Ecological intensification by integrating biogas production into nutrient cycling: Modeling the case of Agroecological Symbiosis. Agric. Syst. 2019, 170, 39–48. [Google Scholar] [CrossRef]

- Helenius, J.; Hagolani-Albov, S.E.; Koppelmäki, K. Co-creating Agroecological Symbioses (AES) for sustainable food systems networks. Front. Sustain. Food. Syst. 2020, 4, 229. [Google Scholar] [CrossRef]

- Bartzas, G.; Zaharaki, D.; Komnitsas, K. Life cycle assessment of open field and greenhouse cultivation of lettuce and barley. Inf. Process. Agric. 2015, 2, 191–207. [Google Scholar] [CrossRef] [Green Version]

- Jolliet, O. Bilan écologique de la production de tomates en serre. Revue Suisse Vitic. Rev. Suisse Vitic 1993, 25, 261–267. [Google Scholar]

- Silvenius, F.; Usva, K.; Katajajuuri, J.-M.; Jaakkonen, K.A. Kasvihuonetuotteiden Ilmastovaikutus- Laskenta ja Vesijalanjälki; MTT Raportti; Luonnonvarakeskus (Luke): Helsinki, Finland, 2019; Volume 82, pp. 1–25. ISBN 978-952-326-872-2. [Google Scholar]

- Hilmkvist, N. Is Organic Greenhouse Production of Tomato in Scania Feasible? Experiences and Reflections According to Swedish Growers in Scania. Master’s Thesis, Applied Climate Strategy, Lund University, Lund, Sweden, 2015. [Google Scholar]

- Statistics Finland, Sähkön ja Lämmön Tuotannon CO2-Päästöt. Available online: https://www.stat.fi/til/salatuo/index.html (accessed on 17 February 2021).

- Motiva. CO2-päästökertoimet. Available online: https://www.motiva.fi/ratkaisut/energiankaytto_suomessa/co2-laskentaohje_energiankulutuksen_hiilidioksidipaastojen_laskentaan/co2-paastokertoimet (accessed on 11 March 2021).

- Grönroos, J.; Nikander, A. Kasvihuone ja Ympäristö. Kyselytutkimuksen Tulokset; Suomen Ympäristökeskus: Helsinki, Finland, 2002. [Google Scholar]

- IPCC. Guidelines for National Greenhouse Gas Inventories Volume 4 Agriculture, Forestry and Other Land Use, BMC Public Health. 2006. Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/vol4.html (accessed on 2 February 2021).

- Nelson, P.V. Greenhouse Operation and Management, 6th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2002; pp. 1–692, ISBN-13 978-0132439367. [Google Scholar]

- Nilsen, S.; Hovland, K.; Dons, C.; Sletten, S.P. Effect of CO2 enrichment on photosynthesis, growth and yield of tomato. Sci. Hortic. 1983, 20, 1–14. [Google Scholar] [CrossRef]

- Chalabi, Z.S.; Biro, A.; Bailey, B.J.; Aikman, D.P.; Cockshull, K.E. Optimal control strategies for carbon dioxide enrichment in greenhouse tomato crops—Part 1: Using pure carbon dioxide. Biosyst. Eng. 2002, 81, 323–332. [Google Scholar] [CrossRef]

- Jalkanen, J. (Finnish Horticultural Trades Association, Helsinki, Finland). Personal communication, 2020. [Google Scholar]

- Keitaanpää, T. Kannattavuuteen Vaikuttavat Tekijät Suljetun Kierron Kaupallisessa Vihanneskasvihuoneessa. Bachelor’s Thesis, HAMK Häme University of Applied Sciences, Hämeenlinna, Finland, 2011. [Google Scholar]

- Cellura, M.; Longo, S.; Mistretta, M. Life Cycle Assessment (LCA) of protected crops: An Italian case study. J. Clean. Prod. 2012, 28, 56–62. [Google Scholar] [CrossRef]

- Liski, J.; Repo, A.; Känkänen, R.; Vanhala, P.; Seppälä, J.; Antikainen, R.; Grönroos, J.; Karvosenoja, N.; Lähtinen, K.; Leskinen, P.; et al. Metsäbiomassan Energiakäytön Ilmastovaikutukset Suomessa; Suomen Ympäristökeskus: Helsinki, Finland, 2011; ISBN 978-952-11-3840-9. [Google Scholar]

- Cherubini, F.; Peters, G.P.; Berntsen, T.; Strømman, A.H.; Hertwich, E. CO2 emissions from biomass combustion for bioenergy: Atmospheric decay and contribution to global warming. Glob. Chang. Biol. Bioenergy 2011, 3, 413–426. [Google Scholar] [CrossRef] [Green Version]

- Helmisaari, H.S.; Hanssen, K.H.; Jacobson, S.; Kukkola, M.; Luiro, J.; Saarsalmi, A.; Tamminen, P.; Tveite, B. Logging residue removal after thinning in Nordic boreal forests: Long-term impact on tree growth. For. Ecol. Manag. 2011, 261, 1919–1937. [Google Scholar] [CrossRef]

- Porkka, A. Maaseudun energiayrittäjyys—Calefa Oy. In Proceedings of the Uusiutuvan Energian Aamupäivä, Webinar. 9 November 2020. [Google Scholar]

- Yu, M.G.; Nam, Y. Feasibility Assessment of Using Power Plant Waste Heat in Large Scale Horticulture Facility Energy Supply Systems. Energies 2016, 9, 112. [Google Scholar] [CrossRef] [Green Version]

- Trinklein, D. Air Pollution Damage on Greenhouse Vegetables. Division of Plant Sciences, 52 Agriculture Lab, Columbia, MO 65211 University of Missouri. Available online: https://ipm.missouri.edu/MPG/2018/3/air_pollution/ (accessed on 9 November 2020).

- Patricio, J.; Angelis-Dimakis, A.; Castillo-Castillo, A.; Kalmykova, Y.; Rosado, L. Region prioritization for the development of carbon capture and utilization technologies. J. CO2 Util. 2017, 17, 50–59. [Google Scholar] [CrossRef] [Green Version]

- Van Dijk, C.J.; Dueck, T.A.; Burgers, W. Risico-Evaluatie Toepassing Groen Gas in de Nederlandse Glastuinbouw; Plant Research International: Wageningen, The Netherlands, 2009; pp. 28–29. Available online: https://edepot.wur.nl/7117 (accessed on 9 November 2020).

- Kanasuo, T. (Agrifutura Oy, Pori, Finland). Personal communication, 2020. [Google Scholar]

| Scenario | Heat Source | Electricity Source | CO2 Source |

|---|---|---|---|

| Scenario 1 | Oil boiler | National grid | External input |

| Scenario 2 | Peat boiler | National grid | External input |

| Scenario 3 | Wood chip boiler | National grid | External input |

| Scenario 4 | District heating | National grid | External input |

| Scenario 5 | Natural gas boiler | National grid | Boiler exhaust gas |

| Scenario 6 | Biogas boiler | National grid | Boiler exhaust gas |

| Scenario 7 | Natural gas CHP boiler | CHP + National grid | Boiler exhaust gas |

| Scenario 8 | Industrial waste heat | National grid | Industry exhaust gas |

| Production Country | CED (MWh) | Heat Source | GWP100 (kg CO2-eq.) | Reference |

|---|---|---|---|---|

| Italy | 1.1 | No heating | 740 | Cellura et al. [45] |

| South Korea | 1.1 | Natural gas | 1700 | Pineda et al. [25] |

| the Netherlands | 6.2 | Natural gas | 1760 | Vermeulen and van der Lans [5] |

| France | 8.8 | Natural gas | 2070 a | Boulard et al. [9] |

| Ontario, Canada | 16.7 | Bunker fuel, natural gas | 3200 | Dias et al. [24] |

| Sweden | 12.8 | Wood chips, natural gas | 547 | Bosona and Gebresenbet [6] |

| Finland | 13.2 | Natural gas/wood chips | 3523/857 | This study |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marttila, M.P.; Uusitalo, V.; Linnanen, L.; Mikkilä, M.H. Agro-Industrial Symbiosis and Alternative Heating Systems for Decreasing the Global Warming Potential of Greenhouse Production. Sustainability 2021, 13, 9040. https://doi.org/10.3390/su13169040

Marttila MP, Uusitalo V, Linnanen L, Mikkilä MH. Agro-Industrial Symbiosis and Alternative Heating Systems for Decreasing the Global Warming Potential of Greenhouse Production. Sustainability. 2021; 13(16):9040. https://doi.org/10.3390/su13169040

Chicago/Turabian StyleMarttila, Miika P., Ville Uusitalo, Lassi Linnanen, and Mirja H. Mikkilä. 2021. "Agro-Industrial Symbiosis and Alternative Heating Systems for Decreasing the Global Warming Potential of Greenhouse Production" Sustainability 13, no. 16: 9040. https://doi.org/10.3390/su13169040

APA StyleMarttila, M. P., Uusitalo, V., Linnanen, L., & Mikkilä, M. H. (2021). Agro-Industrial Symbiosis and Alternative Heating Systems for Decreasing the Global Warming Potential of Greenhouse Production. Sustainability, 13(16), 9040. https://doi.org/10.3390/su13169040