Improvements and Evaluation on Bitter Orange Leaves (Citrus aurantium L.) Solar Drying in Humid Climates

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Instrumentation

2.3. Direct Solar Drying

- (a)

- The humid air passes through the air conditioner’s evaporator; therefore, it is cooled and dehumidified.

- (b)

- The hot and humid air is cooled in the evaporator to a point below the dew temperature (for Campeche 22 °C); therefore, the excess moisture contained in the air condenses. After this process, we have cold and dry air. The air continues to cool until it reaches approximately 14 °C, the minimum evaporator temperature and the equipment cooling limit.

- (c)

- Then, this air is redirected through a duct (1) towards the condensation chamber: The air is forced to pass around the compressor and condenser, with an average temperature of 60 °C. The temperature increases only due to the gain of sensible heat since the absolute humidity remains constant, taking advantage of the sensible heat dissipated by the condenser.

- (d)

2.4. Sustainability of the IS

2.5. Solar Drying Modeling Fitting

2.6. Colorimetric Study

3. Results

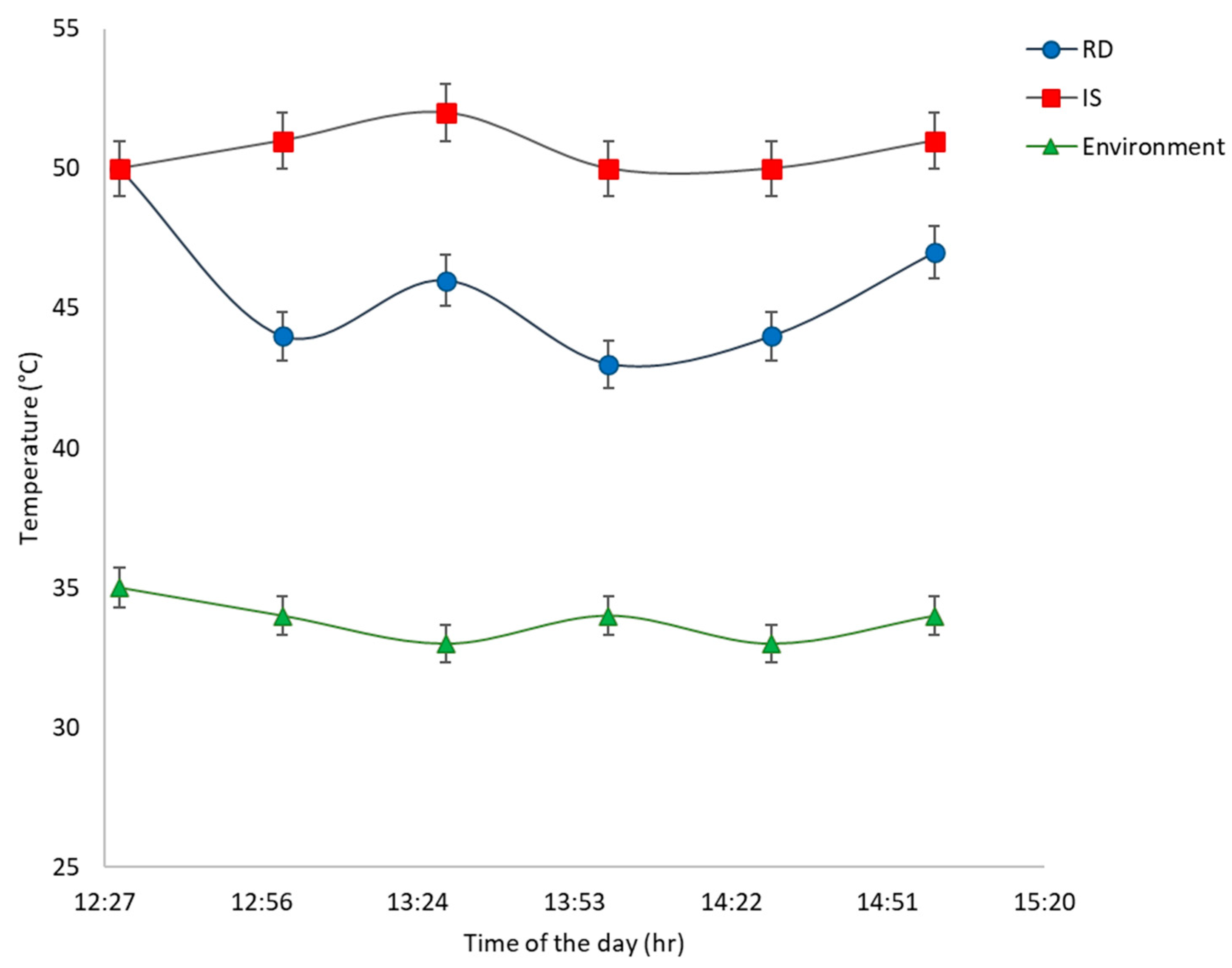

3.1. Climatological Parameters

3.2. Dehumidification Process

3.3. Estimation of CO2 Emissions

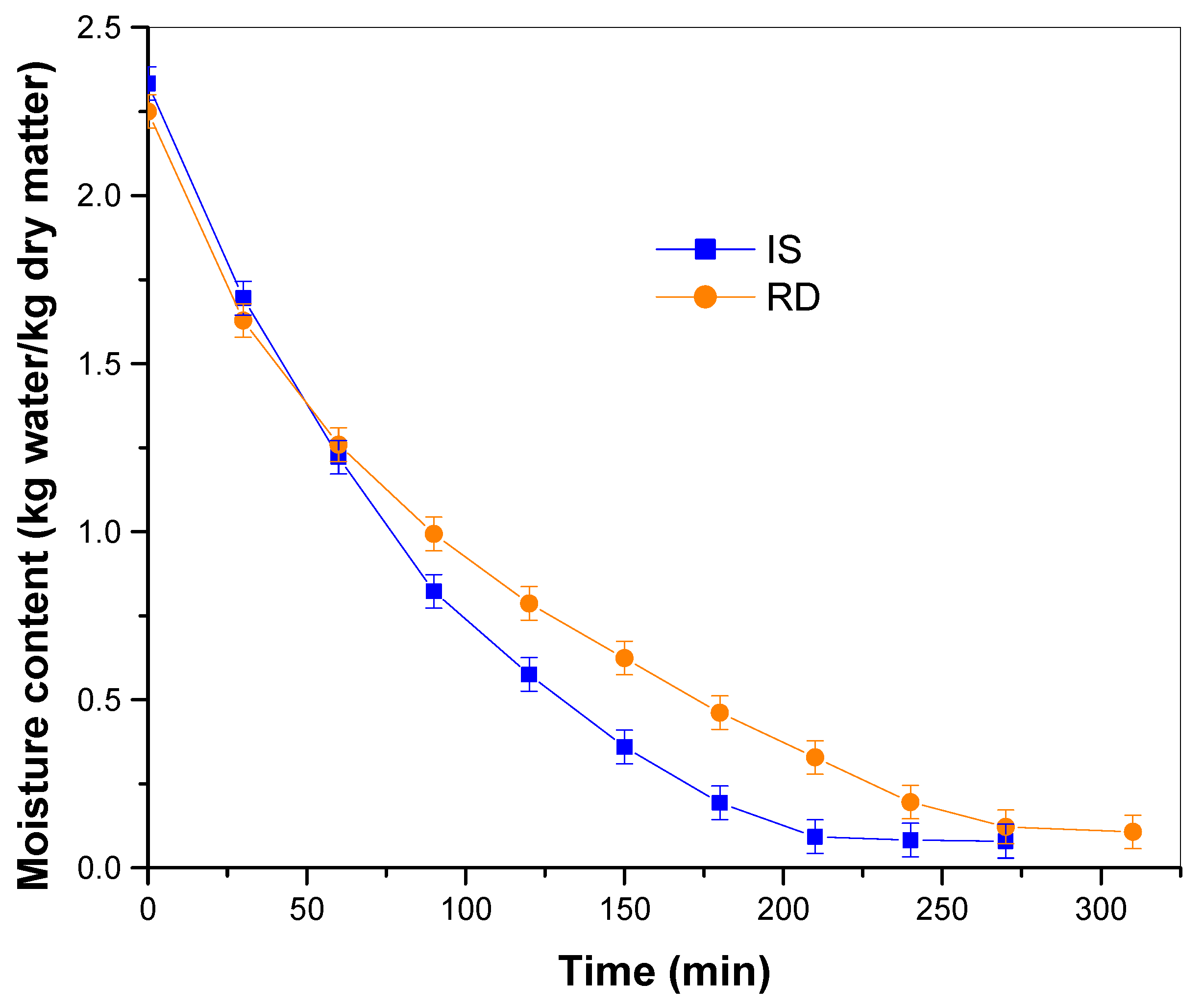

3.4. Solar Drying Kinetics

3.5. Mathematical Modeling

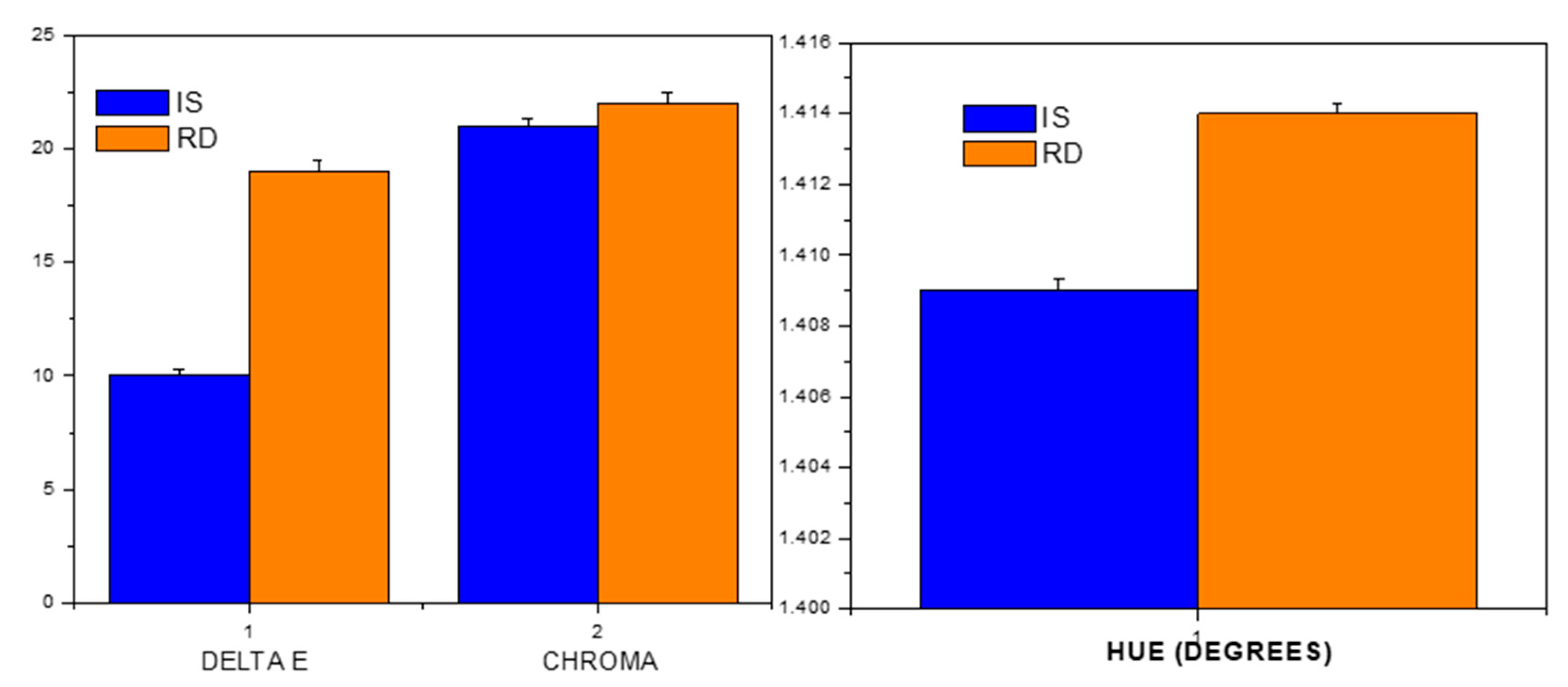

3.6. Colorimetric Study

4. Discussion

4.1. Climatological Parameters

4.2. Dehumidification Process

4.3. Estimation of CO2 Emissions

4.4. Solar Drying Kinetics

4.5. Mathematical Modeling

4.6. Colorimetric Study

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Mendoza, F.; Dejmek, P.; Aguilera, J.M. Calibrated color measurements of agricultural foods using image analysis. Postharvest Biol. Technol. 2006, 41, 285–295. [Google Scholar] [CrossRef]

- Tunde-Akintunde, T.Y.; Ogunlakin, G.O. Influence of drying conditions on the effective moisture diffusivity and energy requirements during the drying of pretreated and untreated pumpkin. Energy Convers. Manag. 2011, 52, 1107–1113. [Google Scholar] [CrossRef]

- Fudholi, A.; Othman, M.; Ruslan, M.H.; Yahya, M.; Zaharim, A.; Sopian, K. The effects of drying air temperature and humidity on the drying kinetics of seaweed. In Proceedings of the 4th WSEAS International Conference on Energy and Development- Environment- Bomedicine, Corfu Island, Greece, 14–16 July 2011; pp. 129–133. [Google Scholar]

- Allaf, T.; Allaf, K. (Eds.) Instant Controlled Pressure Drop (D.I.C.) in Food Processing, From Fundamental to Industrial Applications; Springer: La Rochelle, France, 2014; ISBN 9781461486688. [Google Scholar]

- Estrada, J.A.; Litchfield, J.B. High humidity drying of corn: Effect on drying rate and product quality. Dry. Technol. 1993, 11, 65–84. [Google Scholar] [CrossRef]

- Lim-Law, C.; Mujumdar, A.S. Energy Efficiency and Energy Saving in Drying. In Drying of Foods, Vegetables and Fruits; Jangam, S.V., Law, C.L., Mujumdar, A.S., Eds.; Singatur: Godalming, UK, 2010; pp. 147–154. ISBN 9789810867591. Available online: https://www.yumpu.com/en/document/read/31827931/drying-of-foods-vegetables-and-fruits-volume-3-national (accessed on 19 August 2021).

- Liu, H.; Yousaf, K.; Chen, K.; Fan, R.; Liu, J.; Soomro, S.A. Design and Thermal Analysis of an Air Source Heat Pump Dryer for Food Drying. Sustainability 2018, 10, 3216. [Google Scholar] [CrossRef] [Green Version]

- Muftah, A.F.; Alghoul, M.A.; Fudholi, A.; Abdul-Majeed, M.M.; Sopian, K. Factors affecting basin type solar still productivity: A detailed review. Renew. Sustain. Energy Rev. 2014, 32, 430–447. [Google Scholar] [CrossRef]

- Allaf, K. Transfer Phenomena and Industrial Applications, 1st ed.; Lebanese University, Faculty of Science: Hadath, Lebano, 1982. [Google Scholar]

- López-vidaña, E.C.; César-Munguía, A.L.; García-Valladares, O.; Pilatowsky Figueroa, I.; Brito Orosco, R. Thermal performance of a passive, mixed-type solar dryer for tomato slices (Solanum lycopersicum). Renew. Energy 2020, 147, 845–855. [Google Scholar] [CrossRef]

- Castillo-Téllez, B.; Pilatowsky Figueroa, I.; Castillo Téllez, M.; Marzoug, R.; Allaf, K. Experimental analysis of saline diffusion during saltwater freezing for desalination purposes. Water Environ. J. 2020, 34, 929–936. [Google Scholar] [CrossRef]

- Şevik, S.; Aktaş, M.; Dolgun, E.C.; Arslan, E.; Tuncer, A.D. Performance analysis of solar and solar-infrared dryer of mint and apple slices using energy-exergy methodology. Sol. Energy 2019, 180, 537–549. [Google Scholar] [CrossRef]

- FAO Dried Fruit. Available online: http://www.fao.org/3/au111e/au111e.pdf (accessed on 19 August 2021).

- Castillo-Téllez, M.; Pilatowsky-Figueroa, I.; López-Vidaña, E.C.; Sarracino-Martínez, O.; Hernández-Galvez, G. Dehydration of the red chilli (Capsicum annuum L., costeño) using an indirect-type forced convection solar dryer. Appl. Therm. Eng. 2017, 114, 1137–1144. [Google Scholar] [CrossRef]

- Prakash, O.; Kumar, A. Historical review and recent trends in solar drying systems. Int. J. Green Energy 2013, 10, 690–738. [Google Scholar] [CrossRef]

- Toĝrul, I.T.; Pehlivan, D. Modelling of thin layer drying kinetics of some fruits under open-air sun drying process. J. Food Eng. 2004, 65, 413–425. [Google Scholar] [CrossRef]

- Lakshmi, D.V.N.; Muthukumar, P.; Layek, A.; Nayak, P.K. Drying kinetics and quality analysis of black turmeric (Curcuma caesia) drying in a mixed mode forced convection solar dryer integrated with thermal energy storage. Renew. Energy 2018, 120, 23–34. [Google Scholar] [CrossRef]

- Demissie, P.; Hayelom, M.; Kassaye, A.; Hailesilassie, A.; Gebrehiwot, M.; Vanierschot, M. Design, development and CFD modeling of indirect solar food dryer. Energy Procedia 2019, 158, 1128–1134. [Google Scholar] [CrossRef]

- Salinas, J.G.; Alvarado, J.A.; Bergenståhl, B.; Tornberg, E. The influence of convection drying on the physicochemical properties of yacón (Smallanthus sonchifolius). Heat Mass Transf. und Stoffuebertragung 2018, 54, 2951–2961. [Google Scholar] [CrossRef] [Green Version]

- Krokida, M.K.; Karathanos, V.T.; Maroulis, Z.B.; Marinos-Kouris, D. Drying kinetics of some vegetables. J. Food Eng. 2003, 59, 391–403. [Google Scholar] [CrossRef]

- Putra, R.N.; Ajiwiguna, T.A. Influence of Air Temperature and Velocity for Drying Process. Procedia Eng. 2017, 170, 516–519. [Google Scholar] [CrossRef]

- Pu, H.; Li, Z.; Hui, J.; Raghavan, G.S.V. Effect of relative humidity on microwave drying of carrot. J. Food Eng. 2016, 190, 167–175. [Google Scholar] [CrossRef]

- Ju, H.-Y.; Zhao, S.-H.; Mujumdar, A.S.; Fang, X.-M.; Gao, Z.-J.; Zheng, Z.-A.; Xiao, H.-W. Energy efficient improvements in hot air drying by controlling relative humidity based on Weibull and Bi-Di models. Food Bioprod. Process. 2018, 111, 20–29. [Google Scholar] [CrossRef]

- Lee, S.J.; Boonsupthip, W. Mathematical Modeling of Browning Induction Period in Drying Onion as Influenced by Temperature, Equilibrium Relative Humidity, and Inhibitor. Dry. Technol. 2015, 33, 120–127. [Google Scholar] [CrossRef]

- Ju, H.-Y.; El-Mashad, H.M.; Fang, X.-M.; Pan, Z.; Xiao, H.-W.; Liu, Y.-H.; Gao, Z.-J. Drying characteristics and modeling of yam slices under different relative humidity conditions. Dry. Technol. 2016, 34, 296–306. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.; Gao, Z.; Xie, Y.; Wang, H. Computer vision online measurement of shiitake mushroom (Lentinus edodes) surface wrinkling and shrinkage during hot air drying with humidity control. J. Food Eng. 2021, 292, 110253. [Google Scholar] [CrossRef]

- Raju, R.; Heyes, J.; Archer, R.; Chen, Q. Drying behaviour of fermented Fijian Theobroma cacao using dehumidified air. AIP Conf. Proc. 2019, 2199, 20001. [Google Scholar] [CrossRef]

- Dai, J.W.; Rao, J.Q.; Wang, D.; Xie, L.; Xiao, H.W.; Liu, Y.H.; Gao, Z.J. Process-Based Drying Temperature and Humidity Integration Control Enhances Drying Kinetics of Apricot Halves. Dry. Technol. 2015, 33, 365–376. [Google Scholar] [CrossRef]

- Assoa, Y.B.; Sauzedde, F.; Boillot, B.; Boddaert, S. Development of a building integrated solar photovoltaic/thermal hybrid drying system. Energy 2017, 128, 755–767. [Google Scholar] [CrossRef]

- Ceylan, I.; Kaya, M.; Gürel, A.E.; Ergun, A. Energy Analysis of a New Design of a Photovoltaic Cell-Assisted Solar Dryer. Dry. Technol. 2013, 31, 1077–1082. [Google Scholar] [CrossRef]

- Ziaforoughi, A.; Esfahani, J.A. A salient reduction of energy consumption and drying time in a novel PV-solar collector-assisted intermittent infrared dryer. Sol. Energy 2016, 136, 428–436. [Google Scholar] [CrossRef]

- Cámara de Diputados Reglamento de la ley de Transición Energética; Diario Oficial de la Federación: Ciudad de México, Méxco, 2017; pp. 1–13.

- Castro, A.M.; Mayorga, E.Y.; Moreno, F.L. Mathematical modelling of convective drying of fruits: A review. J. Food Eng. 2018, 223, 152–167. [Google Scholar] [CrossRef]

- Kumar, D.; Tarafdar, A.; Kumar, Y.; Badgujar, P.C. Intelligent modeling and detailed analysis of drying, hydration, thermal, and spectral characteristics for convective drying of chicken breast slices. J. Food Process Eng. 2019, 42, 1–14. [Google Scholar] [CrossRef]

- López-Vidaña, E.C.; Castillo Téllez, M.; Pilatowsky Figueroa, I.; Santis Espinosa, L.F.; Castillo-Téllez, B. Moisture sorption isotherms, isosteric heat, and Gibbs free energy of stevia leaves. J. Food Process. Preserv. 2021, 45, 1–11. [Google Scholar] [CrossRef]

- Radhika, G.B.; Satyanarayana, S.V.; Rao, D.G. Mathematical model on thin layer drying of finger millet (Eluesine coracana). Adv. J. Food Sci. Technol. 2011, 3, 127–131. [Google Scholar]

- Greenhouse Gas Protocol Global Emission Model for Integrated Systems (GEMIS). Available online: https://ghgprotocol.org/Third-Party-Databases/GEMIS (accessed on 19 August 2021).

- Reich, N.H.; Alsema, E.A.; Van Sark, W.G.J.H.M.; Nieuwlaar, E. CO2 Emissions of PV in the perspective of a Renewable Energy Economy. In Proceedings of the 22nd European Photovoltaic Solar Energy Conference and Exhibition, Milan, Italy, 3–7 September 2007; pp. 3538–3542. [Google Scholar]

- Castrejón, A.; Santamaría, G. Instalaciones Solares Fotovoltaicas. 2010. Available online: https://www.todostuslibros.com/libros/instalaciones-solares-fotovoltaicas_978-84-9771-655-0 (accessed on 19 August 2021).

- Erbay, Z.; Icier, F. A review of thin layer drying of foods: Theory, modeling, and experimental results. Crit. Rev. Food Sci. Nutr. 2010, 50, 441–464. [Google Scholar] [CrossRef]

- Ozdemir, M.; Devres, Y.O. The thin layer drying characteristics of hazelnuts during roasting. Food Sci. Technol. Res. 2000, 42, 225–233. [Google Scholar] [CrossRef]

- Akpinar, E.K.; Bicer, Y. Modelling of thin layer drying kinetics of sour cherry in a solar dryer and under open Sun. J. Sci. Ind. Res. (India) 2007, 66, 764–771. [Google Scholar] [CrossRef]

- Madamba, P.S. Thin layer drying models for osmotically pre-dried young coconut. Dry. Technol. 2003, 21, 1759–1780. [Google Scholar] [CrossRef]

- Castro-Muñoz, R.; Nieves-Segura, N. Sorption isotherms and isosteric heat estimation of purple cactus pear (Opuntia stricta) juice embedded in gelatin–maltodextrin matrix. J. Food Process Eng. 2018, 41, 1–7. [Google Scholar] [CrossRef]

- Tunde-Akintunde, T.Y. Mathematical modeling of sun and solar drying of chilli pepper. Renew. Energy 2011, 36, 2139–2145. [Google Scholar] [CrossRef]

- Page, G.E. Factors influencing the maximum rates of air drying shelled corn in thin layers. Master’s. Thesis, Purdue University, West Lafayette, IN, USA, 1949. [Google Scholar]

- Diamante, L.M.; Munro, P.A. Mathematical modelling of the thin layer solar drying of sweet potato slices. Sol. Energy 1993, 51, 271–276. [Google Scholar] [CrossRef]

- Henderson, S.M.; Pabis, S. Grain drying theory II: Temperature effects on drying coefficients. J. Agric. Eng. Res. 1961, 6, 169–174. [Google Scholar]

- Togrul, I.T.; Pehlivan, D. Mathematical modelling of solar drying of apricots in thin layers. J. Food Eng. 2002, 55, 209–216. [Google Scholar] [CrossRef]

- Koua, K.B.; Fassinou, W.F.; Gbaha, P.; Toure, S. Mathematical modelling of the thin layer solar drying of banana, mango and cassava. Energy 2009, 34, 1594–1602. [Google Scholar] [CrossRef]

- Sharaf-Eldeen, Y.I.; Blaisdell, J.L.; Hamdy, M.Y. A Model for Ear Corn Drying. Trans. ASAE 1980, 23, 1261–1265. [Google Scholar] [CrossRef]

- Wang, C.Y.; Singh, R.P. A single layer drying equation for rough rice. Am. Soc. Agric. Eng. 1978, 3001. [Google Scholar] [CrossRef]

- Midilli, A.; Kucuk, H.; Yapar, Z. A new model for single-layer drying. Dry. Technol. 2002, 20, 1503–1513. [Google Scholar] [CrossRef]

- Kaleta, A.; Górnicki, K. Some remarks on evaluation of drying models of red beet particles. Energy Convers. Manag. 2010, 51, 2967–2978. [Google Scholar] [CrossRef]

- Guiné, R.P.F.; Barroca, M.J. Effect of drying treatments on texture and color of vegetables (pumpkin and green pepper). Food Bioprod. Process. 2012, 90, 58–63. [Google Scholar] [CrossRef]

- Muvunzi, R.; Dimitrov, D.; Matope, S.; Harms, T. Heat transfer in a hot stamping process: A review. R&D J. 2017, 33, 75–84. [Google Scholar]

- Jayendra Kumar, A.; Singh, R.R.B.; Patil, G.R.; Patel, A.A. Effect of temperature on moisture desorption isotherms of kheer. LWT- Food Sci. Technol. 2005, 38, 303–310. [Google Scholar] [CrossRef]

- Barbosa-Canovas, V.; Fontana, A.J.; Schidt, S.J.; Labuza, T.P. Water Activity in Foods. Fundamentals and Applications, 1st ed.; Blackwell Publishing: Ames, IA, USA, 2007; ISBN 9780813824086. [Google Scholar]

- Kaya, A.; Aydin, O. An experimental study on drying kinetics of some herbal leaves. Energy Convers. Manag. 2009, 50, 118–124. [Google Scholar] [CrossRef]

- Castillo Téllez, M.; Pilatowsky Figueroa, I.; Castillo Téllez, B.; López Vidaña, E.C.; López Ortiz, A. Solar drying of Stevia (Rebaudiana Bertoni) leaves using direct and indirect technologies. Sol. Energy 2018, 159, 898–907. [Google Scholar] [CrossRef]

- Mohamed, L.A.; Kouhila, M.; Jamali, A.; Lahsasni, S.; Kechaou, N.; Mahrouz, M. Single layer solar drying behaviour of citrus aurantium leaves under forced convection. Energy Convers. Manag. 2005, 46, 1473–1483. [Google Scholar] [CrossRef]

| VARIABLE | DESCRIPTION | MODEL | ACCURACY |

|---|---|---|---|

| Global solar irradiance | LI-COR Pyranometer | LI-200R | Azimuth: <±1% on 360° to 45° of elevation |

| Relative humidity | NRG Systems | RH-5X | ±3% |

| Ambient temperature | NRG Systems | 110S | ±1.1 °C |

| Wind velocity and direction | NRG Systems Wind sensor | Series #200P P2546C-OPR | ±3° ±0.3 m/s |

| Model | Equation | Reference |

|---|---|---|

| Newton | [45] | |

| Page | [46] | |

| Modified page | [47] | |

| Henderson and Pabis | [48] | |

| Logarithmic | [49] | |

| Two-term | [50] | |

| Two-term exponential | [51] | |

| Wang and Singh | [52] | |

| Weibull | [53] |

| Drying Operation Mode | Relative Humidity (%) | Water Activity (aw) | ||

|---|---|---|---|---|

| Initial | Final | Initial | Final | |

| RD | 69.6 ± 1.5 | 9.7 ± 0.3 | 0.94 ± 0.02 | 0.49 ± 0.01 |

| IS | 70.1 ± 1.4 | 7.37 ± 0.4 | 0.95 ± 0.02 | 0.40 ± 0.01 |

| Experiment Condition | Model | Parameters | Value | Experiment Condition | Model | Parameters | Value |

|---|---|---|---|---|---|---|---|

| Regular Dryer | Modified Page | k | 0.8795 | Integrated system | Modified Page | k | 1.2311 |

| n | 1.4078 | n | 1.2522 | ||||

| Ra2 | 0.9980 | Ra2 | 0.9974 | ||||

| RMSE | 0.0128 | RMSE | 0.0135 | ||||

| χ2 | 2.039 × 10−4 | χ2 | 2.091 × 10−4 | ||||

| Page | k | 0.8346 | Page | k | 1.2974 | ||

| n | 1.4078 | n | 1.2522 | ||||

| Ra2 | 0.9980 | Ra2 | 0.9974 | ||||

| RMSE | 0.0128 | RMSE | 0.0135 | ||||

| χ2 | 1.882 × 10−4 | χ2 | 2.091 × 10−4 | ||||

| Henderson and Pabis | a | 1.0441 | Henderson and Pabis | a | 1.0175 | ||

| k | 0.966 | k | 1.317 | ||||

| Ra2 | 0.9844 | Ra2 | 0.9922 | ||||

| RMSE | 0.0358 | RMSE | 0.0234 | ||||

| χ2 | 1.478 × 10−3 | χ2 | 6.333 × 10−4 | ||||

| Newton | k | 0.9322 | Newton | k | 1.2989 | ||

| Ra2 | 0.9825 | Ra2 | 0.9919 | ||||

| RMSE | 0.0379 | RMSE | 0.0239 | ||||

| χ2 | 0.00154 | χ2 | 0.00061 |

| Analyzed Leaves | Color Parameter | ||

|---|---|---|---|

| L* | a* | b* | |

| RD | 51.42 | 3.42 | 21.64 |

| IS | 36.05 | 3.09 | 18.92 |

| Raw material | 33.96 | −3.72 | 13.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jorge de Jesús, C.-G.; Margarita, C.T.; Beatriz, C.-T.; Francisco Román, L.-Z.; Gerardo Alberto, M.-P.; Carlos Jesahel, V.-G. Improvements and Evaluation on Bitter Orange Leaves (Citrus aurantium L.) Solar Drying in Humid Climates. Sustainability 2021, 13, 9393. https://doi.org/10.3390/su13169393

Jorge de Jesús C-G, Margarita CT, Beatriz C-T, Francisco Román L-Z, Gerardo Alberto M-P, Carlos Jesahel V-G. Improvements and Evaluation on Bitter Orange Leaves (Citrus aurantium L.) Solar Drying in Humid Climates. Sustainability. 2021; 13(16):9393. https://doi.org/10.3390/su13169393

Chicago/Turabian StyleJorge de Jesús, Chan-González, Castillo Téllez Margarita, Castillo-Téllez Beatriz, Lezama-Zárraga Francisco Román, Mejía-Pérez Gerardo Alberto, and Vega-Gómez Carlos Jesahel. 2021. "Improvements and Evaluation on Bitter Orange Leaves (Citrus aurantium L.) Solar Drying in Humid Climates" Sustainability 13, no. 16: 9393. https://doi.org/10.3390/su13169393