Effects of Variable Weather Conditions on Baled Proportion of Varied Amounts of Harvestable Cereal Straw, Based on Simulations

Abstract

:1. Introduction

- It is a bulky material, even when compacted

- It is a biological, hygroscopic and degradable material that needs to be stored at moisture content <18% (wet basis, w.b.) to avoid spoilage due to mould growth

- The collection period is short (a few weeks), particularly in the Nordic countries

- Annual supply varies, mainly due to yearly yield differences and recovery difficulties due to wet weather conditions during baling

- Weather variations mean that the time available for cereal harvesting and straw recovery operations varies between years

2. Materials and Methods

2.1. Outline

- An existing model [30] was applied for predicting hourly grain moisture content of standing ripe winter wheat during 22/23 harvesting seasons

- Predicted moisture content data for grain and straw were used as input to a simulation model for cereal harvesting operations, which included a module for straw baling. The operations were simulated for 22/23 harvesting seasons on an hourly basis

- Several baling parameters were evaluated on representative virtual farms for the four Swedish regions in terms of their effects on amounts of baled straw, baled straw ratio and annual variation in both.

2.2. Weather Data

2.3. Estimation of Hourly Moisture Content of Swathed Cereal Straw

2.4. Simulation Model for Harvesting and Straw Baling Operations

2.5. Virtual Farms

2.6. Premises and Input Data for Simulating Harvesting and Baling Operations

- Harvestable amount of straw: 600–2800 t·year−1

- Baling capacity (square bales): 15 t·h−1

- Daily harvesting capacity: 6% of cereal crop area and 22% grain moisture ceiling for operating (parameters for this operation under Swedish conditions [30])

- 20 days as a maximum after crop maturation to perform harvesting operations on individual fields to avoid unreasonable delays in the simulations due to precipitation or other reasons (ripening periods are given in Table 1)

- Daily schedule for harvesting and baling operations: 11.00–20.00 h, including weekends

- Grain drying capacity was assumed not to be a limiting factor

- 2 days as a minimum waiting time between harvesting and baling operations, for swathed straw moisture content to reach equilibrium with air relative humidity and for weeds to dry

- 16 days as a maximum between harvesting and baling operations on individual fields

- A baling period until September 15, 18, 18 and 22 for Västmanland, Östergötland, Västra Götaland and Skåne, respectively

- Baling operations carried out by contractors. To replicate a real farm that does not own a large baler and hires a baler only when there are sufficient amounts of dry straw, the following requirements were set to start the operation on a certain day:

- ⚬

- At least 60 tonnes sufficiently dry swathed straw (≤18% w.b.), i.e., approx. 4 h effective baling time

- ⚬

- Straw moisture content ≤18% for at least 4 h on the first day of a baling batch; on the following days the operation continued as long as dry straw was available

- Number of fields in the virtual farms: 32

- Individual field data on expected ripening period according to Table 1

- Maximum precipitation of 0.1 mm in the current simulation hour, resulting in approximately 1.6% higher straw moisture content at around 18% (w.b.) moisture content.

3. Results

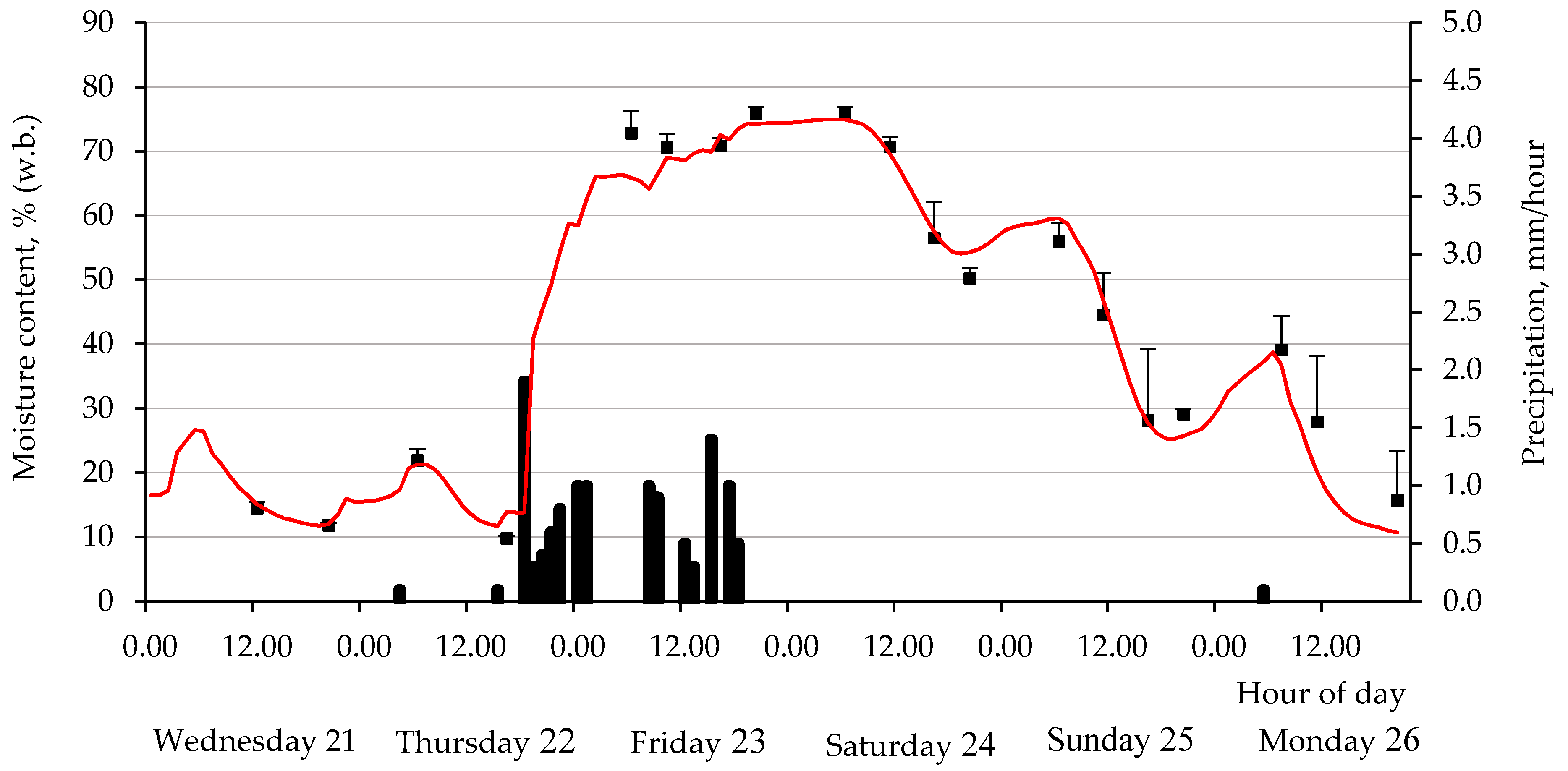

3.1. Predicted Moisture Content of Swathed Cereal Straw

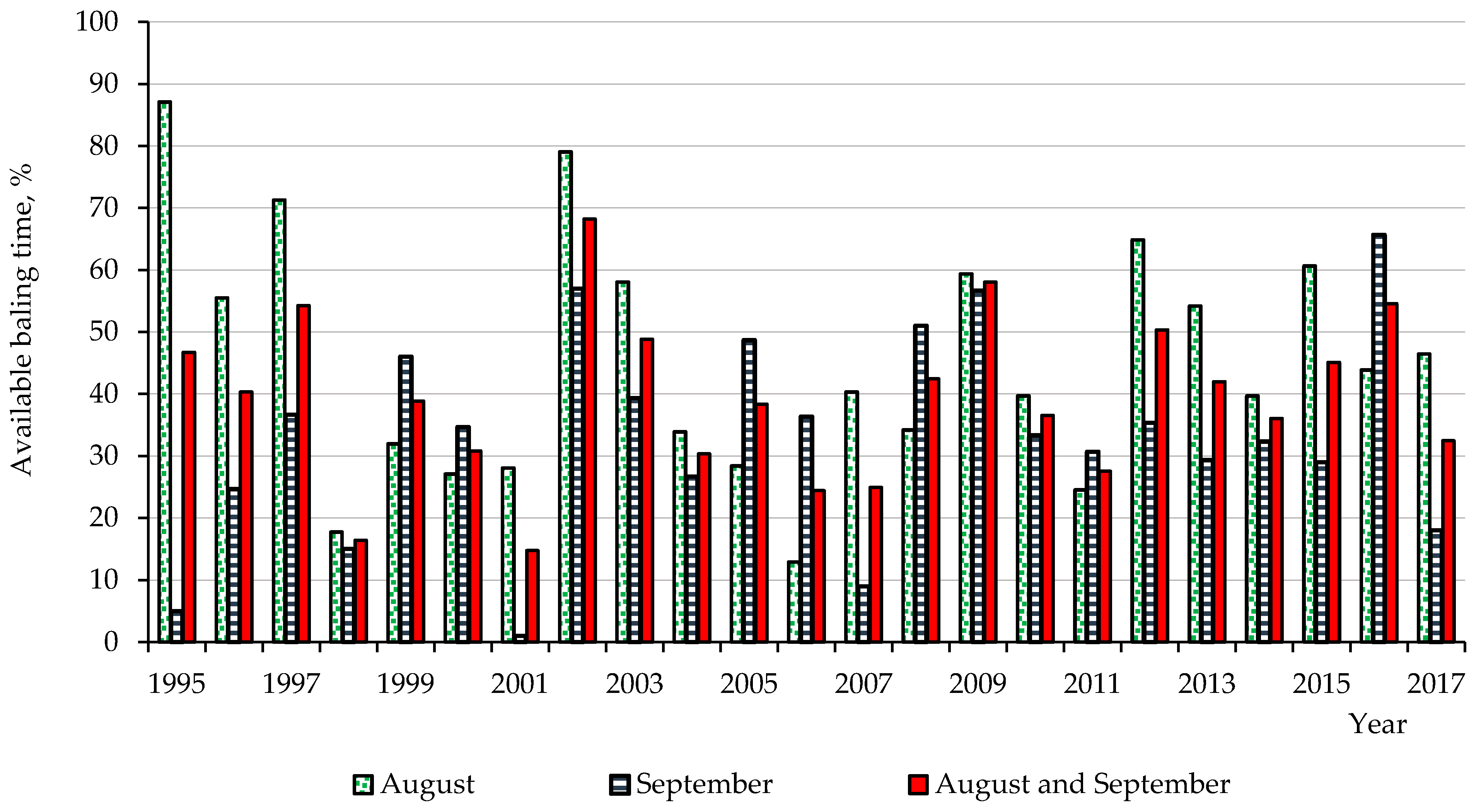

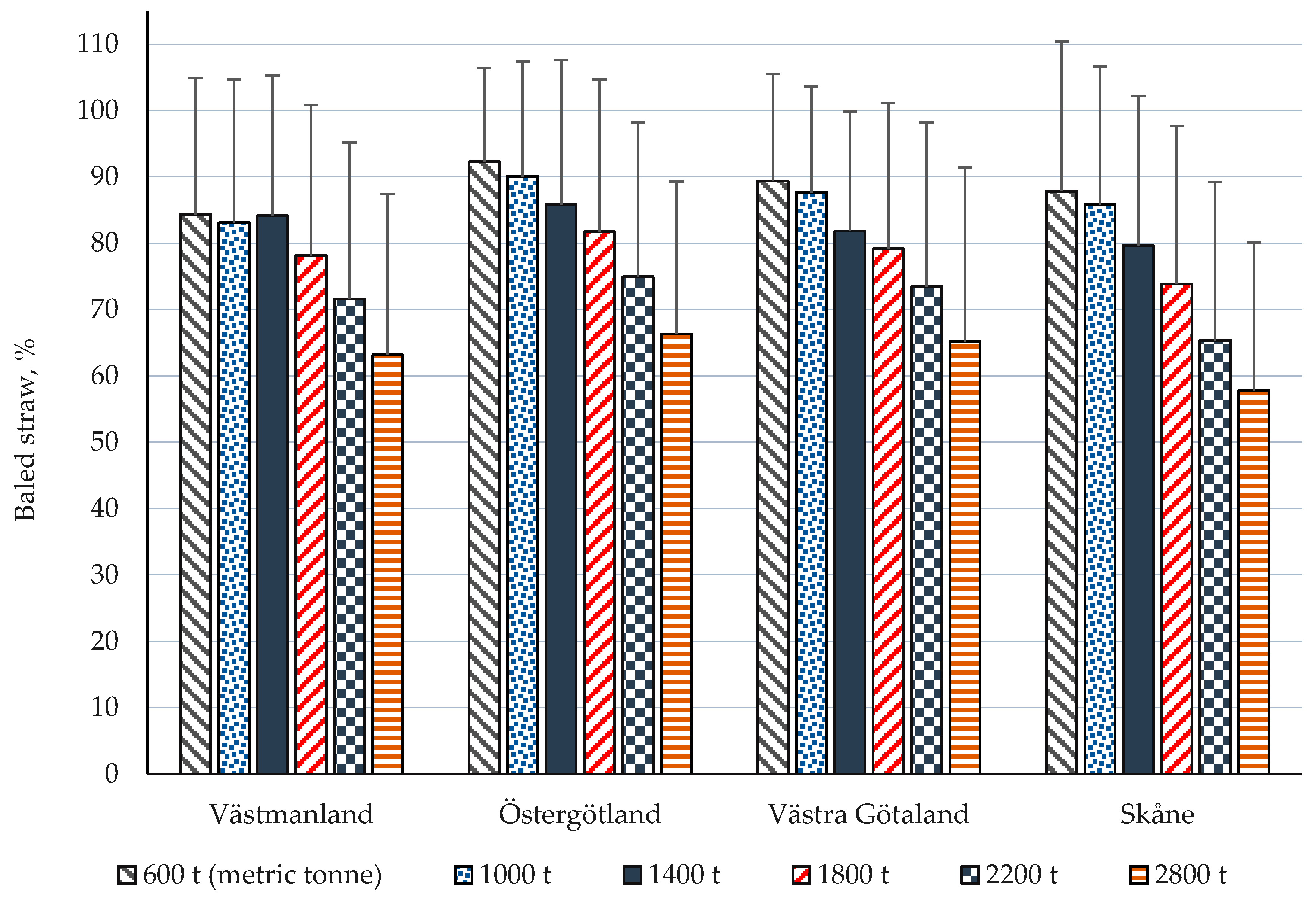

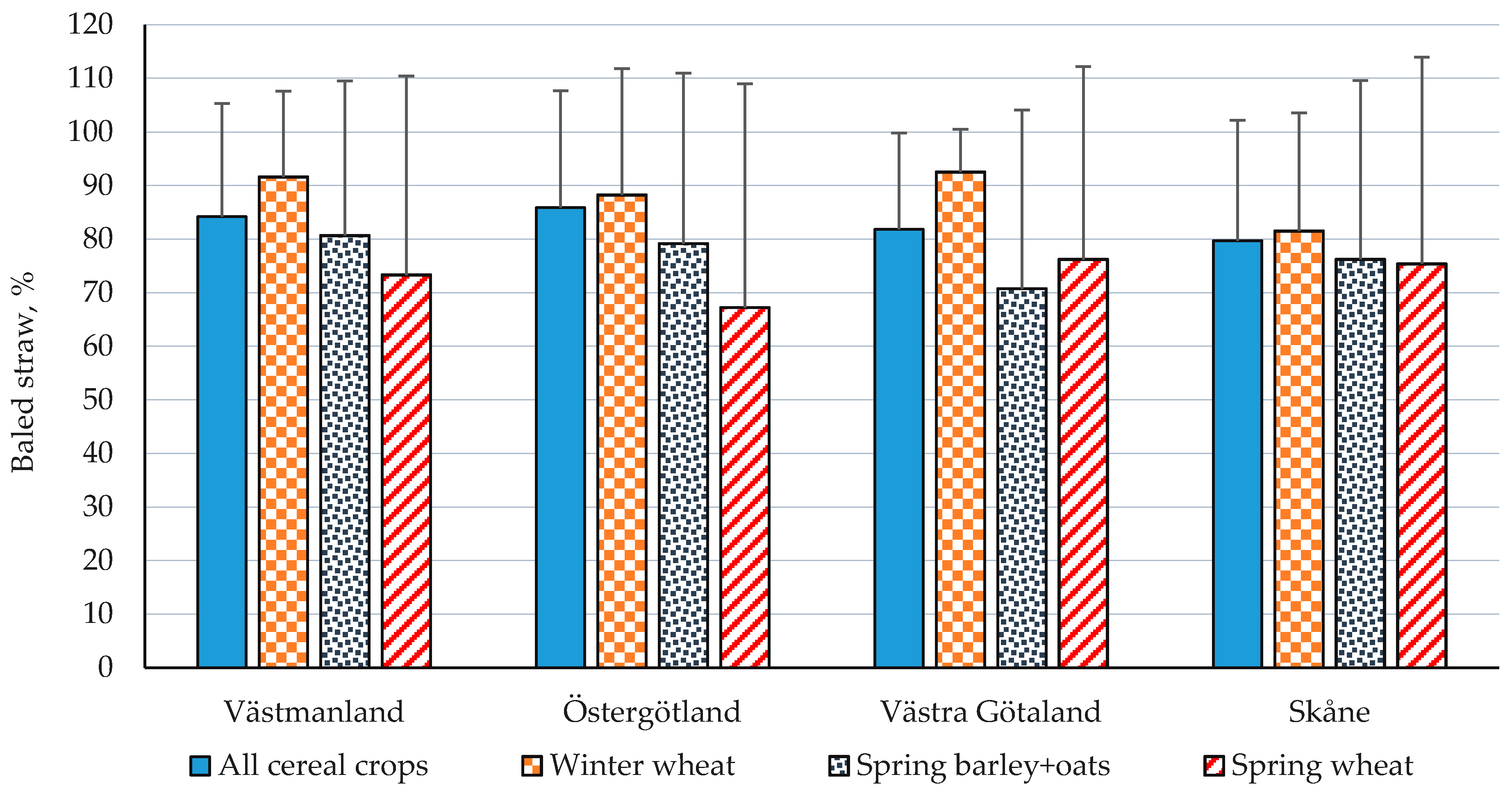

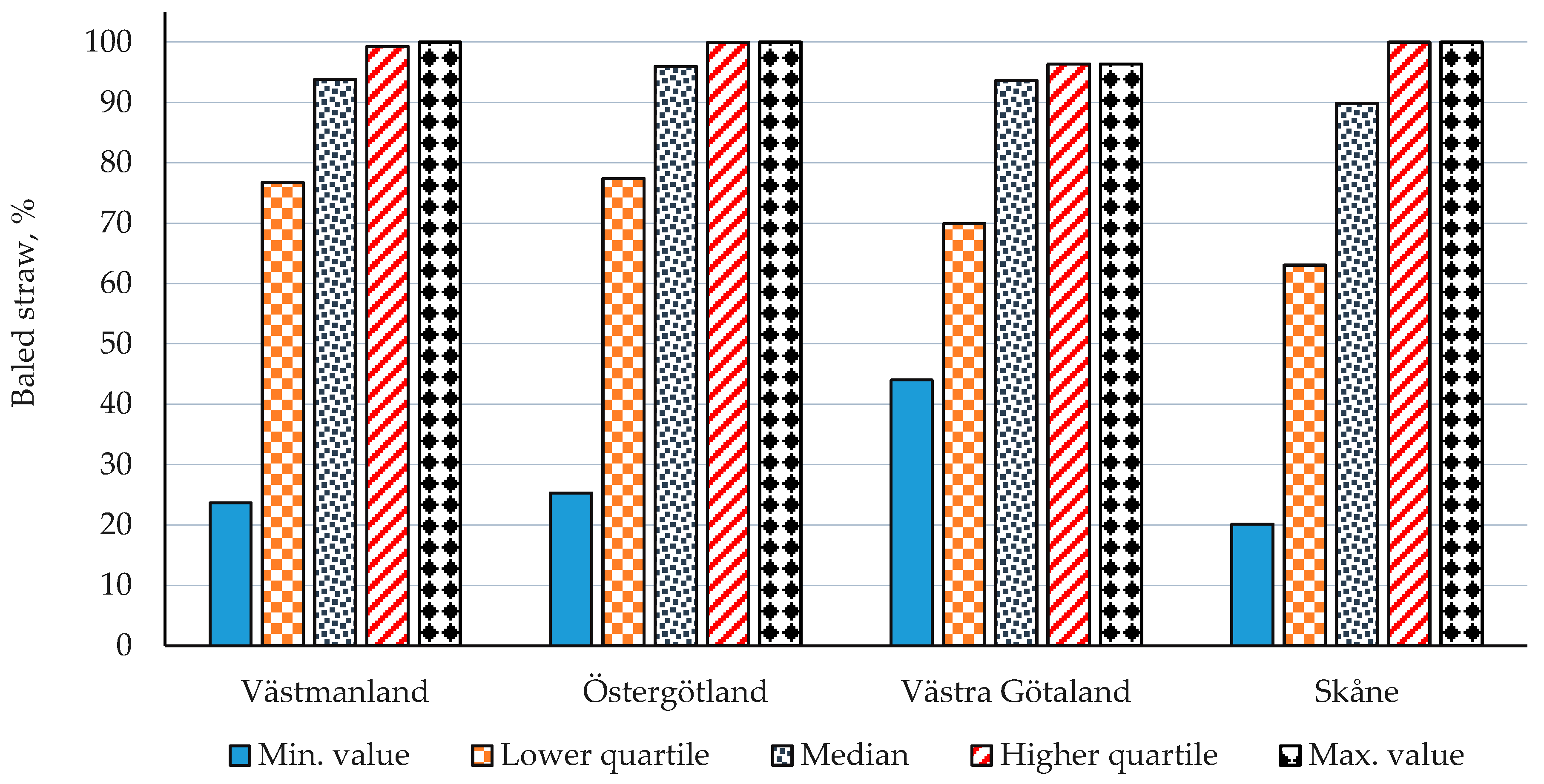

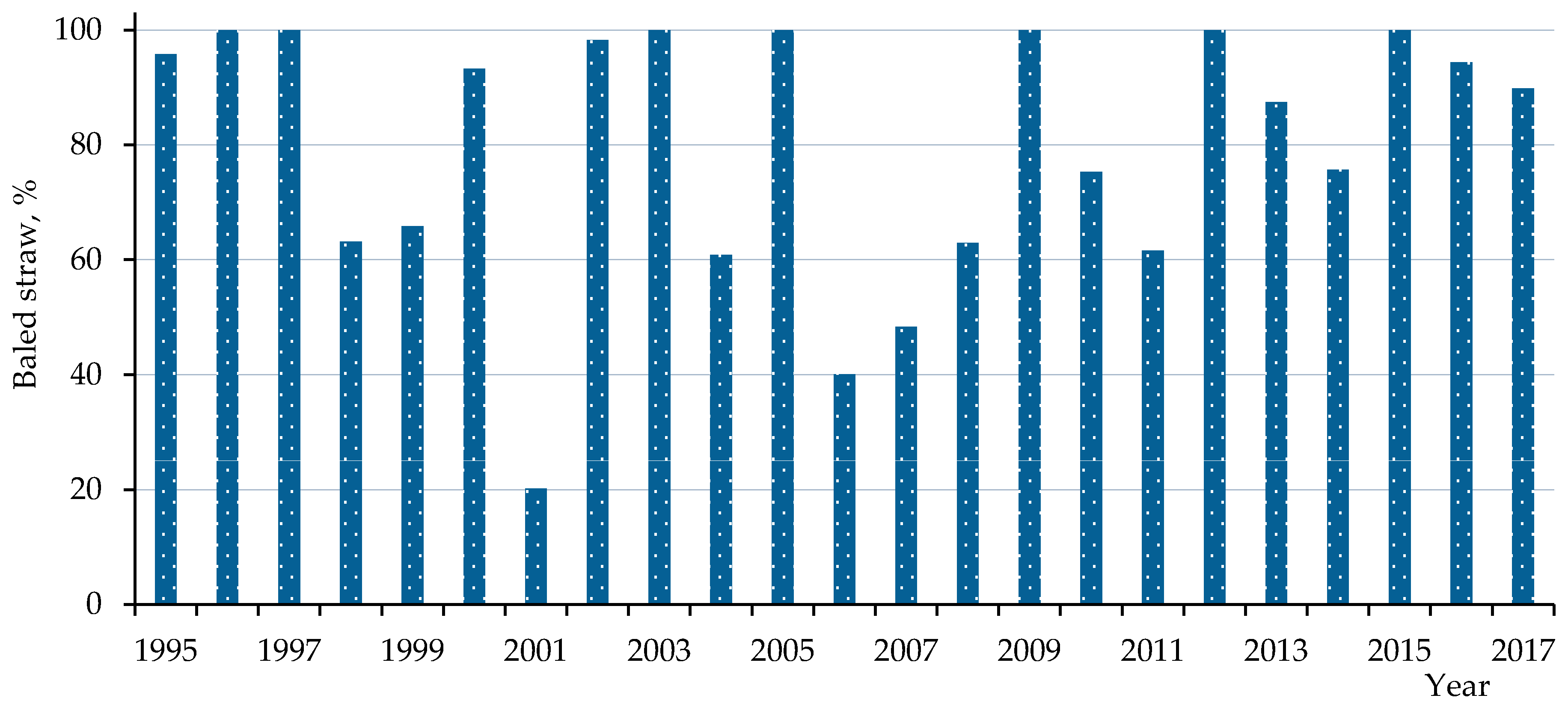

3.2. Estimated Straw Baling Coefficient

3.3. Moisture Content of Baled Straw

3.4. Sensitivity Analysis

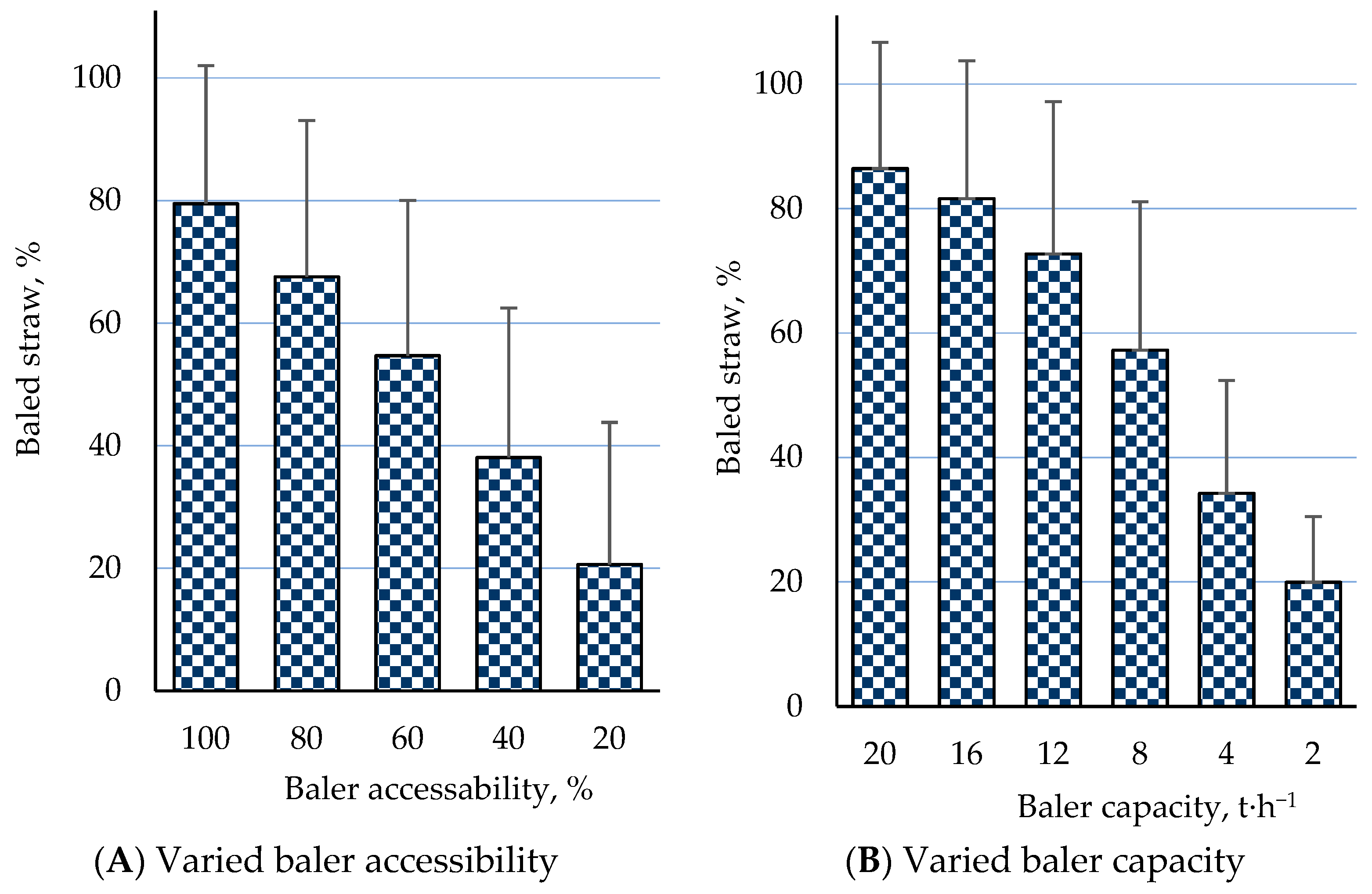

3.4.1. Limited Baler Accessibility

3.4.2. Reduced Baler Capacity

4. Discussion

4.1. Weather Conditions

4.2. Moisture Content Prediction Models for Standing Mature Wheat and Swathed Cereal Straw

4.3. Farm Premises and Assumptions for Simulating Baling Operations

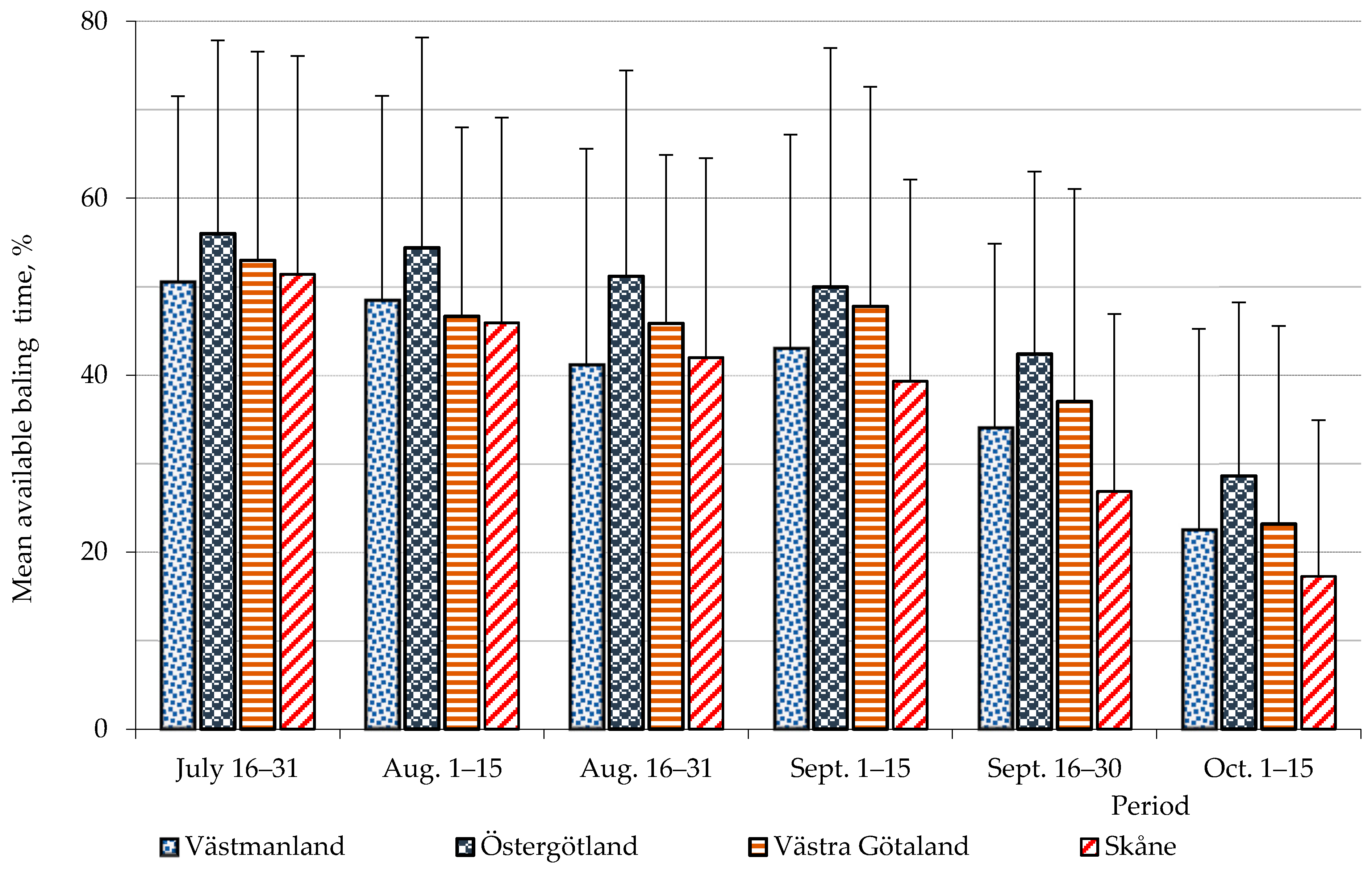

4.4. Available Baling Time

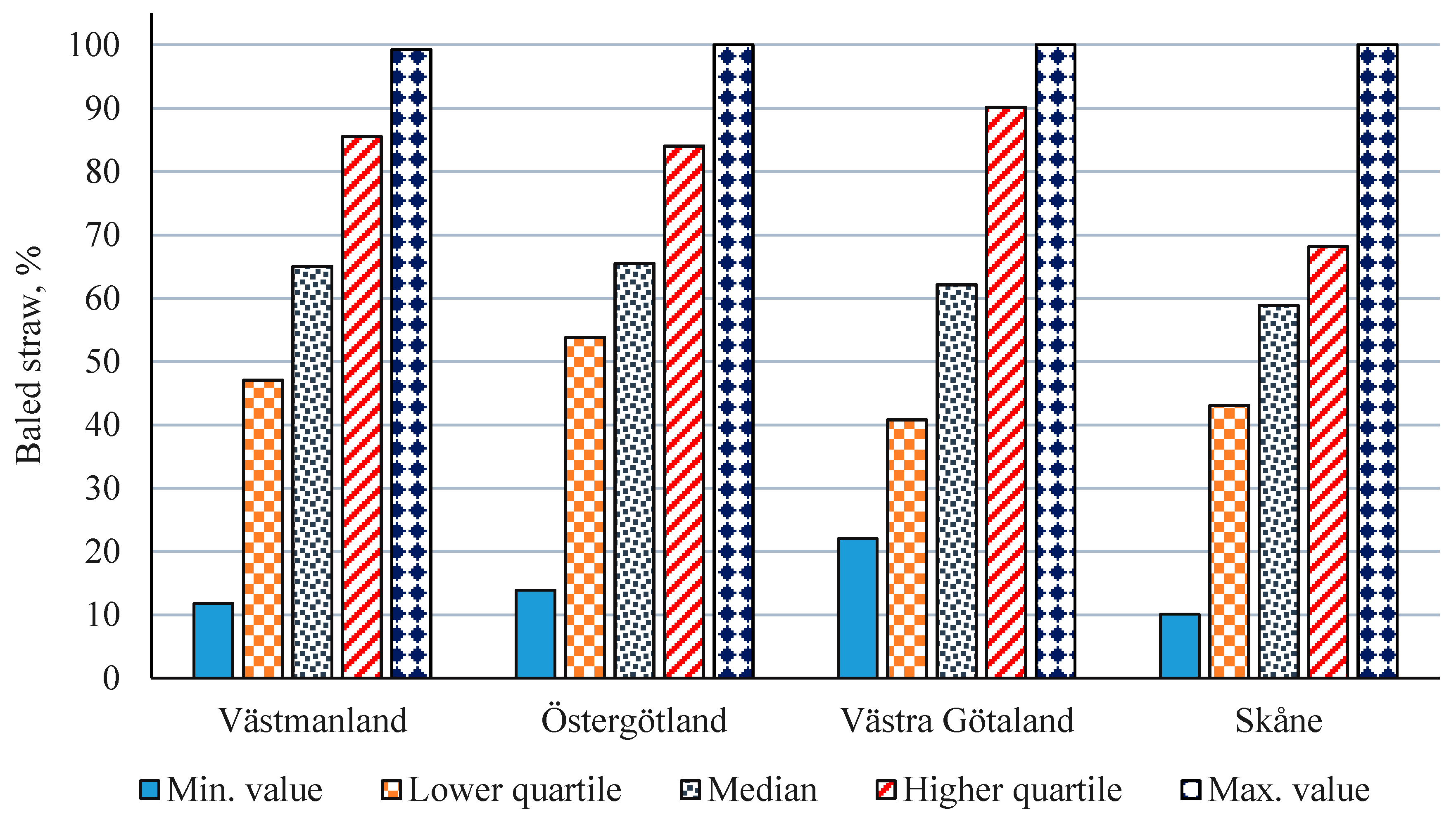

4.5. Baling Coefficient

4.6. Baled Proportions with a High Amount of Harvestable Straw

4.7. Validity of Results

4.8. Equation for Rough Estimation of Performance of a Straw Baling System

- Adays: number of available days for straw baling.

- Edays: number of effective days that the baling operation requires for a given amount of straw; and where:

- Pelength: period length for straw baling operations (e.g., 45), days

- Atime: available expected time proportion for straw baling (e.g., 0.45 for the regions studied, see Figure 3)

- Afbaler: access factor to a baler, (0.1 if the chance of getting a baler when needed is 10%, 1.0 if a baler is always available when needed)

- Rflow: reducing factor for baling a higher straw proportion than average (0.5 to 1.0: 0.5 for baling a higher straw proportion than average a 1 for mean available baling time according to Figure 3)

- Mfmatching: matching factor to compensate restrictions of the baling system, e.g., not enough straw ready to be baled on an available baling day (0.3 if the baling system operates with difficulties and 0.8 if everything goes smoothly, without bottlenecks); and

- Ha: area to be baled, ha

- Stamount: amount of straw per hectare, t·ha−1

- Bacap: baling capacity, t·h−1

- Whday: working hours per day, h·day−1

5. Conclusions

- The estimated available baling time during working hours (11.00–21.00 h) was 39–49%, depending on the region. The time decreased from around 50% at the beginning of August to 30–40% at the end of September. The annual variation was large, with a standard deviation of around 22% in all regions.

- A reasonable balance between a large amount of harvestable straw and a high proportion of baled straw (over 80% on average) was reached at 1400 t·year−1 harvestable straw with the baling capacity of 15 t·h−1 (one baler) and a baling period to mid-September.

- An 80% proportion of baled straw is not standard. A lower ratio, e.g., around 60% on average, would be reached at 2800 t·year−1 harvestable straw with the same baling capacity.

- A rough estimate showed that approximately 25% of days in the baling season were effective baling days on average. Matching factors between sufficiently dry swathed straw amount and the baling system set restrictions on utilising most of the available baling time.

- In one to two baling seasons out of 10, the proportion of baled straw was reduced to about 60% or less, even for an “optimised" system with the baling capacity of 15 t·h−1, 1400 t·year−1 harvestable straw and a baling period of 45 days per year.

- A baling system where a high proportion of harvestable straw is baled in most years requires the number of available working days for the operation to be greater than the average number of effective baling days that a given amount of straw demands with a certain baling capacity.

- The most uncertain item of this study was the prediction of changes in straw moisture content for the swathed straw, due to the complexity of straw wetting and drying processes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Model for Estimating Moisture Content of Swathed Cereal Straw

| Process | Condition | Equations (Time Step = One Hour) | Value of Parameter |

|---|---|---|---|

| Quantity of bound water at equi-librium moisture content | A = 582.3 B = 2.69 | ||

| Quantity of bound water | |||

| Change in dew water due to dew ** | E < 0 | ||

| Change in dew water due to evaporation ** | E ≤ 0 | ||

| Quantity of water due to dew | |||

| Change in precipitation water due to absorption | P > 0 | b = 0.45 McMax = 3.5 | |

| Change in precipitation water due to evaporation ** | E > 0 | c = 0.35 | |

| Quantity of water due to precipitation | |||

| and: if (qb(t) + qd(t) + qp(t)) > 3.5 qdm then qp(t) = 3.5 qdm − qb(t) − qd(t) | |||

| Actual moisture content, decimal (dry base) | |||

- qeq(t): quantity of water at equilibrium moisture content at time t, kg·m−2

- qdm: quantity of dry matter (straw), kg·m−2

- RH(t): air relative humidity at time t, decimal

- qb(t): quantity of bound water at time t, kg·m−2

- qeq(t), qeq(t − 1), qeq(t − 2): quantity of bound water at time t, t − 1, t − 2, kg·m−2

- Δqd(t): change in absorbed or dried dew water per time step (one hour), kg·m−2 h−1

- E(t): potential evapotranspiration of water at time t, mm h−1 (or kg·m−2 h−1);

- qd(t): quantity of dew water at time t, kg·m−2

- Δqpa(t): change in precipitation water due to absorption per time step (one hour), kg·m−2 h−1

- Ic(t): interception storage capacity at time t, kg·m−2

- P: precipitation, mm/h (or kg·m−2 h−1)

- McMax: maximal moisture content of straw: 3.5 (dry base) (empirical determination)

- Δqpe(t): change in precipitation water due to evaporation per time step (one hour), kg·m−2 h−1

- qp(t): quantity of precipitation water at time t, kg·m−2

- Mc(t): actual moisture content of straw at time t, decimal (dry base).

References

- Kretschmer, B.; Allen, B.; Hart, K. Mobilising Cereal Straw in the EU to Feed Advanced Biofuel Production; Institute for European Environmental Policy: Bruxelles, Belgium, 2012; Available online: http://minisites.ieep.eu/assets/938/IEEP_Agricultural_residues_for_advanced_biofuels_May_2012.pdf (accessed on 20 August 2021).

- Edwards, R.A.H.; Šúri, M.; Huld, M.A.; Dallemand, J.F. GIS-Based Assessment of Cereal Straw Energy Resource in the European Union. In Proceedings of the 14th European Biomass Conference & Exhibition, Biomass for Energy, Industry and Climate Protection, Paris, France, 17–21 October 2005; Available online: https://www.academia.edu/22384487/GIS_based_assessment_of_cereal_straw_energy_resource_in_the_European_Union?from=cover_pag (accessed on 20 August 2021).

- Scarlat, N.; Martinov, M.; Dallemand, J.F. Assessment of the availability of agricultural crop residues in the European Union: Potential and limitations for bioenergy use. Waste Manag. 2010, 30, 1889–1897. [Google Scholar] [CrossRef] [PubMed]

- Eurostat. Agricultural Production—Crops. Statistics Explained. 2020. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Agricultural_production_-_crops#Cereals (accessed on 13 August 2021).

- European Commission. Greening Our Energy Supply—The Role of Bioenergy from Forestry and Agriculture. 2010. Directorate General for Agriculture and Rural Development. Available online: https://ec.europa.eu/info/sites/default/files/food-farming-fisheries/sustainability_and_natural_resources/documents/leaflet-greening-our-energy-supply_en.pdf (accessed on 13 August 2021).

- Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Source. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32018L2001&from=EN#d1e1665-82-1 (accessed on 13 August 2021).

- Scarlat, N.; Dallemand, J.F.; Monforti-Ferrario, F.; Nita, V. The role of biomass and bioenergy in a future bioeconomy: Policies and facts. Environ. Dev. 2015, 15, 3–34. [Google Scholar] [CrossRef]

- Morone, P. Sustainability Transition towards a Biobased Economy: Defining, Measuring and Assessing. Sustainability 2018, 10, 2631. [Google Scholar] [CrossRef] [Green Version]

- D’Adamo, I.; Falcone, P.M.; Morone, P. A New Socio-economic Indicator to Measure the Performance of Bioeconomy Sectors in Europe. Ecol. Econ. 2020, 176, 106724. [Google Scholar] [CrossRef]

- Bastos Lima, M.G. Corporate Power in the Bioeconomy Transition: The Policies and Politics of Conservative Ecological Modernization in Brazil. Sustainability 2021, 13, 6952. [Google Scholar] [CrossRef]

- Eziyi, I.; Krothapalli, A. Sustainable Rural Development: Solar/Biomass Hybrid Renewable Energy System. Energy Procedia 2014, 57, 1492–1501. [Google Scholar] [CrossRef] [Green Version]

- Spinelli, L.; Pari, L.; Magagnotti, N. New biomass products, small-scale plants and vertical integration as opportunities for rural development. Biomass Bioenergy 2018, 115, 244–252. [Google Scholar] [CrossRef]

- Ekman, A.; Wallbergb, O.; Joelsson, E.; Börjesson, P. Possibilities for sustainable biorefineries based on agricultural residues—A case study of potential straw-based ethanol production in Sweden. Appl. Energy 2013, 102, 299–308. [Google Scholar] [CrossRef]

- Yamakawa, C.K.; Qin, F.; Mussatto, S.I. Advances and opportunities in biomass conversion technologies and biorefineries for the development of a bio-based economy. Biomass Bioenergy 2018, 119, 54–60. [Google Scholar] [CrossRef]

- AGROinLOG. Success Case of the Integration of a Logistics Centre into an Agro-Industry of the Grain-Milling and Feed Sector. Integrated Biomass Logistics Centres for the Agro-Industry, 2020. Available online: http://agroinlog-h2020.eu/wp-content/uploads/2020/06/AGROinLOG_D5.7_Success-case-IBLC-Sweden_FV_30042020_RISE.pdf (accessed on 13 August 2021).

- D’Adamo, I.; Falcone, P.M.; Huisingh, D.; Morone, P. A circular economy model based on biomethane: What are the opportunities for the municipality of Rome and beyond? Renew. Energy 2021, 163, 1660–1672. [Google Scholar] [CrossRef]

- Sheldon, R.A. Biocatalysis and biomass conversion: Enabling a circular economy. Philos. Trans. R. Soc. A 2020, 378, 20190274. [Google Scholar] [CrossRef]

- Sherwood, J. The significance of biomass in a circular economy. Bioresour. Technol. 2020, 300, 122755. [Google Scholar] [CrossRef]

- European Commission. The Revised Renewable Energy Directive. Factsheet: Renewable Energy Directive. Available online: https://ec.europa.eu/energy/sites/default/files/documents/directive_renewable_factsheet.pdf (accessed on 13 August 2021).

- Nilsson, D.; Bernesson, S. Halm som Bränsle. Del 1: Tillgångar och Skördetidpunkter (Straw as Fuel. Part 1: Available Resources and Harvest Times); Department of Energy and Technology, Swedish University of Agricultural Sciences: Uppsala, Sweden, 2009; Available online: https://pub.epsilon.slu.se/4854/1/nilsson_d_et_al_100630.pdf (accessed on 20 August 2021).

- Nilsson, D.; Bernesson, S. Halm som Bränsle. Del 3: Dynamisk Simulering av Hanteringssystem (Straw as Fuel. Part 3: Dynamic Simulation of Handling Systems); Department of Energy and Technology, Swedish University of Agricultural Sciences: Uppsala, Sweden, 2010; Available online: https://pub.epsilon.slu.se/4852/1/nilsson_d_et_al_100630_2.pdf (accessed on 20 August 2021).

- Glithero, N.J.; Wilson, P.; Ramsden, S.J. Straw use and availability for second generation biofuels in England. Biomass Bioenergy 2013, 55, 311–321. [Google Scholar] [CrossRef] [Green Version]

- SMHI. Ladda ner Meteorologiska Observationer. (Swedish Meteorological and Hydrological Institute. Download Meteorological Observations). Available online: https://www.smhi.se/data/meteorologi/ladda-ner-meteorologiska-observationer/#param=airtemperatureInstant,stations=all (accessed on 10 June 2021).

- Henriksson, A.; Stridsberg, S. Möjligheter att Använda Halmeldning till Energiförsörjningen i Södra Sverige (The Potential of Using Straw as a Fuel for the Support of Energy in the Agricultural Area of Southern Sweden); Department of Agricultural Engineering, Swedish University of Agricultural Sciences: Uppsala, Sweden, 1992; Available online: https://pub.epsilon.slu.se/3883/ (accessed on 20 August 2021).

- Lindqvist, J. Potential för Biobränsleproduktion i Uddevalla Kommun (Biofuel, Bioenergy, Potential, Municipality of Uddevalla). Master’s Thesis, Department of Technology and Society, Lund University, Lund, Sweden, 2007. Available online: https://lup.lub.lu.se/luur/download?func=downloadFile&recordOId=4468201&fileOId=4469151 (accessed on 20 August 2021).

- Broberg, A. Potential för Biogasproduktion i Västra Götaland. Hushållningssällskapet (Potential of biogas production in Västra Götaland. The Rural Economy and Agricultural Societies), 2009. Available online: https://docplayer.se/134805689-Potential-for-biogasproduktion-i-vastra-gotaland.html (accessed on 10 June 2021).

- Gustafsson, E. Lokal Handlingsplan för Bioenergi—Tingsryds Kommun. Energikontor Sydost (Local Handling Plan for Bioenergy—Municipality of Tingsryds. Energy Division), 2012. Available online: http://static.wm3.se/sites/2/media/25367_Lokal_handlingsplan_f%C3%B6r_bioenergi_Tingsryd_2012-05-09.pdf?1418646636 (accessed on 10 June 2021).

- Sternberg, H. Underlag för Potentialberäkningar av Förnybar Energi (Basic Data for Potential Renewable Energy Estimations). County Administrative Board of Dalarna, Report 2013:03, 2013. Available online: https://www.lansstyrelsen.se/download/18.4df86bcd164893b7cd92d381/1534488489669/2013-03Underlagf%C3%B6rpotentialber%C3%A4kningaravf%C3%B6rnybarenergi.pdf (accessed on 10 June 2021).

- De Toro, A.; Eckersten, H.; Nkurunziza, L.; von Rosen, D. Effects of Extreme Weather on Yield of Major Arable Crops in Sweden; Department of Energy and Technology, Swedish University of Agricultural Sciences: Uppsala, Sweden, 2015; Available online: https://pub.epsilon.slu.se/12606/8/deToro_a_etal_151109.pdf (accessed on 20 August 2021).

- De Toro, A.; Gunnarsson, C.; Lundin, G.; Jonsson, N. Cereal harvesting—Strategies and costs under variable weather conditions. Biosyst. Eng. 2012, 111, 429–439. [Google Scholar] [CrossRef]

- Gunnarsson, C.; de Toro, A.; Jonsson, N.; Lundin, G. Spannmålsskörd—Strategier och Kostnader vid Varierande Väderlek. In JTI-Rapport. Lantbruk & industri, No. 403; Jordbrukstekniska Institutet: Uppsala, Sweden, 2012; Available online: https://www.diva-portal.org/smash/get/diva2:959461/FULLTEXT01.pdf (accessed on 20 August 2021).

- Donaldson, G.F. Allowing for Weather Risk in Assessing Harvest Machinery Capacity. Am. J. Agric. Econ. 1968, 50, 24–40. [Google Scholar] [CrossRef]

- Van Kampen, J.H. Optimizing Harvesting Operations on a Largescale Grain Farm. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 30 May 1969. Available online: https://edepot.wur.nl/192243 (accessed on 20 August 2021).

- Philips, P.R.; O’Callaghan, J.R. Cereal harvesting—A mathematical model. J. Agric. Eng. Res. 1974, 19, 415–433. [Google Scholar] [CrossRef]

- Van Elderen, E. Models and techniques for scheduling farm operations: A comparison. Agric. Syst. 1980, 5, 1–17. [Google Scholar] [CrossRef]

- Abawi, G.Y. A Simulation Model of Wheat Harvesting and Drying in Northern Australia. J. Agric. Eng. Res. 1993, 54, 141–158. [Google Scholar] [CrossRef]

- Sokhansanj, S.; Mani, S.; Bi, X. Dynamic simulation of Mcleod Harvesting System for Wheat, Barley and Canola Crops. In Proceedings of the ASAE/CSAE Annual International Meeting, Ottawa, ON, Canada, 1–4 August 2004; Paper No. 048010. Available online: https://elibrary.asabe.org/abstract.asp?aid=17710 (accessed on 20 August 2021).

- De Toro, A. Assessment of Field Machinery Performance in Variable Weather Conditions Using Discrete Event Simulation; Swedish University of Agricultural Sciences: Uppsala, Sweden, 2004; Volume 462, Available online: https://pub.epsilon.slu.se/553/ (accessed on 20 August 2021).

- Nawi, N.M.; Chen, G.; Zare, D. The effect of different climatic conditions on wheat harvesting strategy and return. Biosyst. Eng. 2010, 106, 493–502. [Google Scholar] [CrossRef]

- Nilsson, D.; Karlsson, S. A model for the field drying and wetting processes of cutflax straw. Biosyst. Eng. 2005, 92, 25–35. [Google Scholar] [CrossRef]

- Nilsson, D.; Bernesson, S. Halm som Bränsle. Del 2: Fuktegenskaper (Straw as Fuel. Part 2: Moisture Characteristics); Department of Energy and Technology, Swedish University of Agricultural Sciences: Uppsala, Sweden, 2009; Available online: https://pub.epsilon.slu.se/4854/ (accessed on 20 August 2021).

- LantMet. Lantmet Väderstationer. (Ordnance Survey: Weather Stations). Available online: https://www.slu.se/fakulteter/nj/om-fakulteten/centrumbildningar-och-storre-forskningsplattformar/faltforsk/vader/lantmet/ (accessed on 10 June 2021).

- SMHI. Extracting STRÅNG Data. (Swedish Meteorological and Hydrological Institute). Available online: http://strang.smhi.se/extraction/index.php (accessed on 10 June 2021).

- Lehmann, D. Verlustvorgänge und schimmelbildung bei der trocknung und lagerung von halmfutter (Processes of decomposition and mold growth during drying and storage of straw forage). Landtech. Forshung 1971, 19, 180–187. [Google Scholar]

- Sedlbauer, K. Prediction of Mould Fungus Formation on the Surface of and Inside Building Components; Fraunhofer Institute for Building Physics: Stuttgart, Germany, 2001; Available online: https://www.ibp.fraunhofer.de/content/dam/ibp/ibp-neu/de/dokumente/dissertationen/ks_dissertation_etcm45-30729.pdf (accessed on 20 August 2021).

- Ramberg, D.T.; Jeppson, P.; Wang, A. Simulation of Relative Humidity and Temperature and Modeling of Mold Growth in Exterior Walls Insulated with Straw Bales in a Southern Swedish climate. In Proceedings of the BS2015: 14th Conference of International Building Performance Simulation Association, Hyderabad, India, 7–9 December 2015; Available online: http://www.ibpsa.org/proceedings/BS2015/p2859.pdf (accessed on 10 June 2021).

- Hedlin, C.P. Sorption isotherms of five types of grain straw at 70 degrees F. Can. Agric. Eng. 1967, 9, 37–39. Available online: https://nrc-publications.canada.ca/eng/view/ft/?id=efb99a49-f9d7-4050-b4ca-8f155722704e (accessed on 10 June 2021).

- Almeida, G.; Rémond, R.; Perré, P. Hygroscopic behaviour of lignocellulosic materials: Dataset at oscillating relative humidity variations. J. Build. Eng. 2018, 19, 320–333. [Google Scholar] [CrossRef]

- Angus, J.F.; Mackenzie, D.H.; Morton, R.; Schafer, C.A. Phasic development in field crops. II. Thermal and photoperiodic responses of spring wheat. Field Crop. Res. 1981, 4, 269–283. [Google Scholar] [CrossRef]

- Jordbruksverket. Hektar-och Totalskörd Efter län och Gröda. År 1965–2020. (Swedish Board of Agriculture. Hectare Yields and Total Production: County and Crop. Year 1965–2020). Available online: https://statistik.sjv.se/PXWeb/pxweb/sv/Jordbruksverkets%20statistikdatabas/Jordbruksverkets%20statistikdatabas__Skordar/JO0601J02.px/ (accessed on 19 August 2021).

- Jordbruksverket. Normskörd i kg/ha efter län, Gröda och typ av Normskörd. År 2003–2021. (Swedish Board of Agriculture. Standard Yields in kg/ha per County, Crop, and Type of Standard Yield, Year 2003–2021). Available online: https://statistik.sjv.se/PXWeb/pxweb/sv/Jordbruksverkets%20statistikdatabas/Jordbruksverkets%20statistikdatabas__Skordar__Normskord/JO0602A01.px/?rxid=5adf4929-f548-4f27-9bc9-78e127837625 (accessed on 19 August 2021).

- Swain, G. Desorption Equilibrium Moisture Content (EMC) of Straw. JTI—Swedish Inst. of Agric. and Envir. Eng., 1985, Report No. 63. Available online: http://www.diva-portal.org/smash/get/diva2:959801/FULLTEXT01.pdf (accessed on 10 June 2021).

- Larsen, S.U.; Bruun, S.; Lindedam, J. Straw yield and saccharification potential for ethanol in cereal species and wheat cultivars. Biomass Bioenergy 2012, 45, 239–250. [Google Scholar] [CrossRef]

- Suardi, A.; Stefanoni, W.; Bergonzoli, S.; Latterini, F.; Jonsson, N.; Pari, L. Comparison between Two Strategies for the Collection of Wheat Residue after Mechanical Harvesting: Performance and Cost Analysis. Sustainability 2020, 12, 4936. [Google Scholar] [CrossRef]

- Hakala, K.; Heikkinen, J.; Sinkkob, T.; Pahkala, K. Field trial results of straw yield with different harvesting methods, and modelled effects on soil organic carbon. A case study from Southern Finland. Biomass Bioenergy 2016, 95, 8–18. [Google Scholar] [CrossRef]

- Gunnarsson, C.; (Research Institutes of Sweden (RISE), Gothenburg, Sweden; Carina.gunnarsson@ri.se). Personal communication, 2018.

- Johansson, F.; (Industrigatan 1, 523 78 Trädet, Sweden). Executive Manager/Agricultural Marketing Agent, Lundby Maskin Station. Personal communication, 2020.

- Lundin, G. Underlag för Bestämning av Leveranssäkerhet och Erforderlig Maskininsatsvid Halmbärgning (Basic Data for Determination of Delivery Security and Required Machine Input for Straw Recovery); Unpublished material; 1984. [Google Scholar]

- Nilsson, D. Bärgning, Transport, Lagring och Förädling av Halm till Bränsle; Metoder, Energibehov, Kostnader (Harvesting, Transport, Storage and Upgrading of Straw as a Fuel—Methods, Energy Needs, Costs); Department of Energy and Technology, Swedish University of Agricultural Sciences: Uppsala, Sweden, 1991; Available online: https://pub.epsilon.slu.se/3893/1/nilsson_d_090904.pdf (accessed on 19 August 2021).

- Brundin, S. Fastbränsle från Jordbruket. Kostnader för Halm- och Gräsbränslesystem (Solid Fuels from Agriculture. Straw and Grass Feedstock Costs for Energy); Swedish University of Agricultural Sciences: Uppsala, Sweden, 1988. [Google Scholar]

- Brück, I.G.M.; Van Elderen, E. Field drying of hay and wheat. J. Agric. Eng. Res. 1969, 14, 105–116. [Google Scholar] [CrossRef]

- Thompson, N. Modelling the field drying of hay. J. Agric. Sci. 1981, 97, 241–260. [Google Scholar] [CrossRef]

- Smith, E.A.; Duncan, E.J.; McGechan, M.B.; Haughey, D.P. A model for the field drying of grass in windrows. J. Agric. Eng. Res. 1988, 41, 251–274. [Google Scholar] [CrossRef]

- Atzema, A.J. A model for the drying of grass with real time weather data. J. Agric. Eng. Res. 1992, 53, 231–247. [Google Scholar] [CrossRef]

- Ref-ET: Software. Reference Evapotranspiration Calculator; Version 4.1. University of Idaho, 2016. Available online: https://www.uidaho.edu/cals/kimberly-research-and-extension-center/research/water-resources/ref-et-software (accessed on 10 June 2021).

| Region/County | Winter Wheat | Spring Wheat | Spring Barley | Oats |

|---|---|---|---|---|

| Västmanland | 30 July–20 August | 21 August–12 September | 13 August–3 September | 15 August–5 September |

| Östergötland | 28 July–18 August | 19 August–9 September | 10 August–1 September | 13 August–3 September |

| Västra Götaland | 28 July–18 August | 19 August–9 September | 10 August–1 September | 13 August–3 September |

| Skåne | 21 July–11 August | 13 August–3 September | 7 August–28 August | 9 August–30 August |

| Region/County | Winter Wheat | Spring Wheat | Spring Barley | Oats | Total |

|---|---|---|---|---|---|

| Västmanland | 31 | 12 | 32 | 25 | 100 |

| Östergötland | 66 | 5 | 19 | 10 | 100 |

| Västra Götaland | 36 | 6 | 24 | 34 | 100 |

| Skåne | 51 | 4 | 40 | 5 | 100 |

| Region/County | Winter Wheat | Spring Wheat | Spring Barley | Oats |

|---|---|---|---|---|

| Västmanland | 5573 | 4316 | 4617 | 4149 |

| Östergötland | 6829 | 4228 | 5088 | 4035 |

| Västra Götaland | 6189 | 3747 | 4926 | 4433 |

| Skåne | 7722 | 5200 | 5998 | 4900 |

| Winter Wheat | Spring Wheat | Spring Barley | Oats | |

|---|---|---|---|---|

| Straw: grain ratio [20] * | 0.6 | 0.66 | 0.37 | 0.52 |

| Region/County | Winter Wheat | Spring Wheat | Spring Barley | Oats |

|---|---|---|---|---|

| Västmanland | 3344 | 2848 | 1708 | 2157 |

| Östergötland | 4097 | 2790 | 1883 | 2098 |

| Västra Götaland | 3713 | 2473 | 1823 | 2305 |

| Skåne | 4633 | 3432 | 2219 | 2548 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toro, A.d.; Gunnarsson, C.; Jonsson, N.; Sundberg, M. Effects of Variable Weather Conditions on Baled Proportion of Varied Amounts of Harvestable Cereal Straw, Based on Simulations. Sustainability 2021, 13, 9449. https://doi.org/10.3390/su13169449

Toro Ad, Gunnarsson C, Jonsson N, Sundberg M. Effects of Variable Weather Conditions on Baled Proportion of Varied Amounts of Harvestable Cereal Straw, Based on Simulations. Sustainability. 2021; 13(16):9449. https://doi.org/10.3390/su13169449

Chicago/Turabian StyleToro, Alfredo de, Carina Gunnarsson, Nils Jonsson, and Martin Sundberg. 2021. "Effects of Variable Weather Conditions on Baled Proportion of Varied Amounts of Harvestable Cereal Straw, Based on Simulations" Sustainability 13, no. 16: 9449. https://doi.org/10.3390/su13169449

APA StyleToro, A. d., Gunnarsson, C., Jonsson, N., & Sundberg, M. (2021). Effects of Variable Weather Conditions on Baled Proportion of Varied Amounts of Harvestable Cereal Straw, Based on Simulations. Sustainability, 13(16), 9449. https://doi.org/10.3390/su13169449