Development of a Novel Helical-Ribbon Mixer Dryer for Conversion of Rural Slaughterhouse Wastes to an Organic Fertilizer and Implications in the Rural Circular Economy

Abstract

:1. Introduction

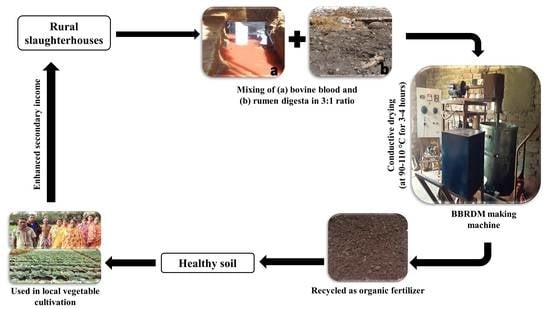

2. Materials and Methods

2.1. Raw Material Characterization

2.2. Parameters Measured for Dryer Fabrication

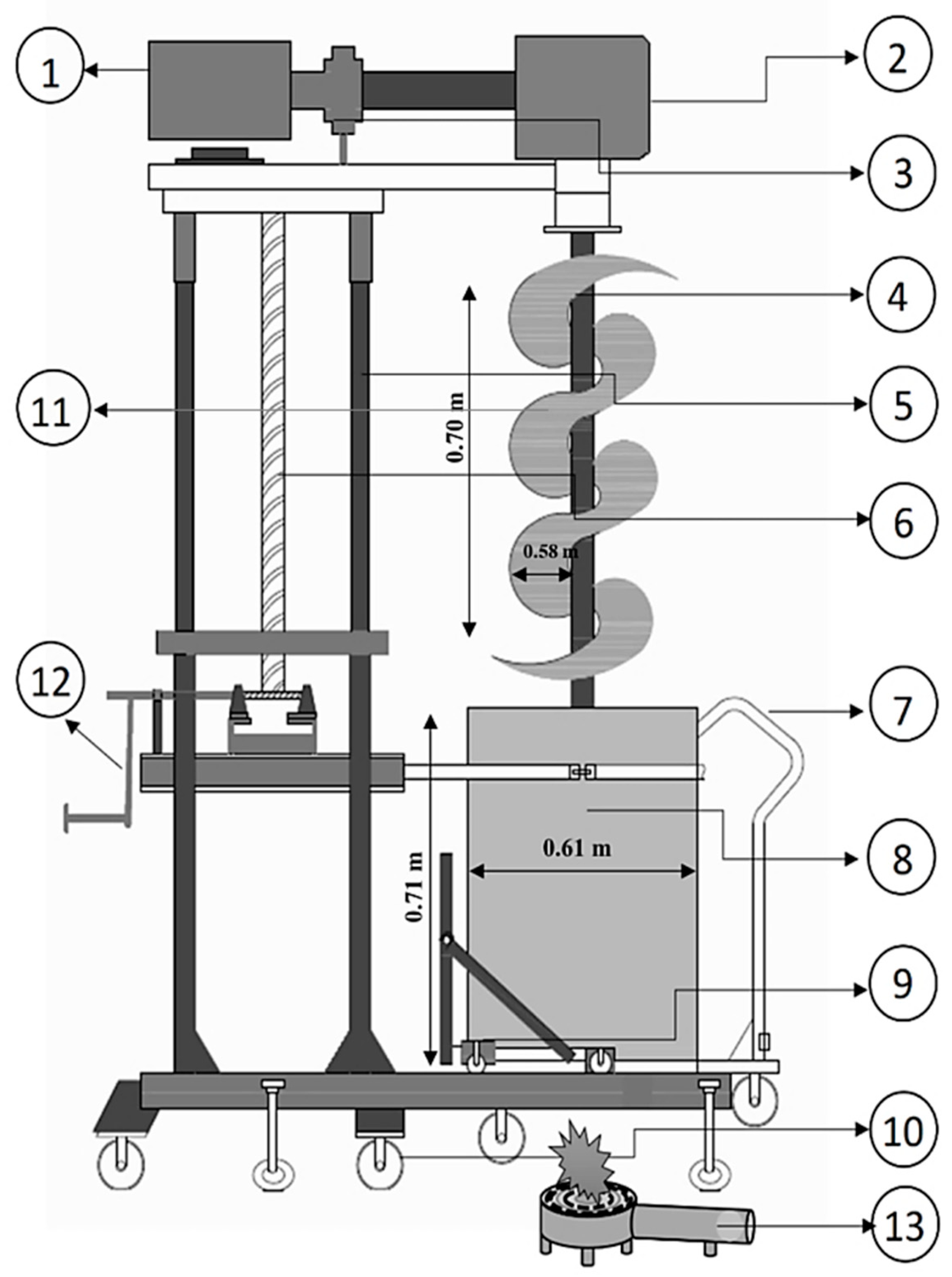

2.3. Process and Equipment Description

2.4. Moisture Removal, Drying Time and Energy Consumption of the Drying Process

2.5. Performance Evaluation of the Fabricated Dryer

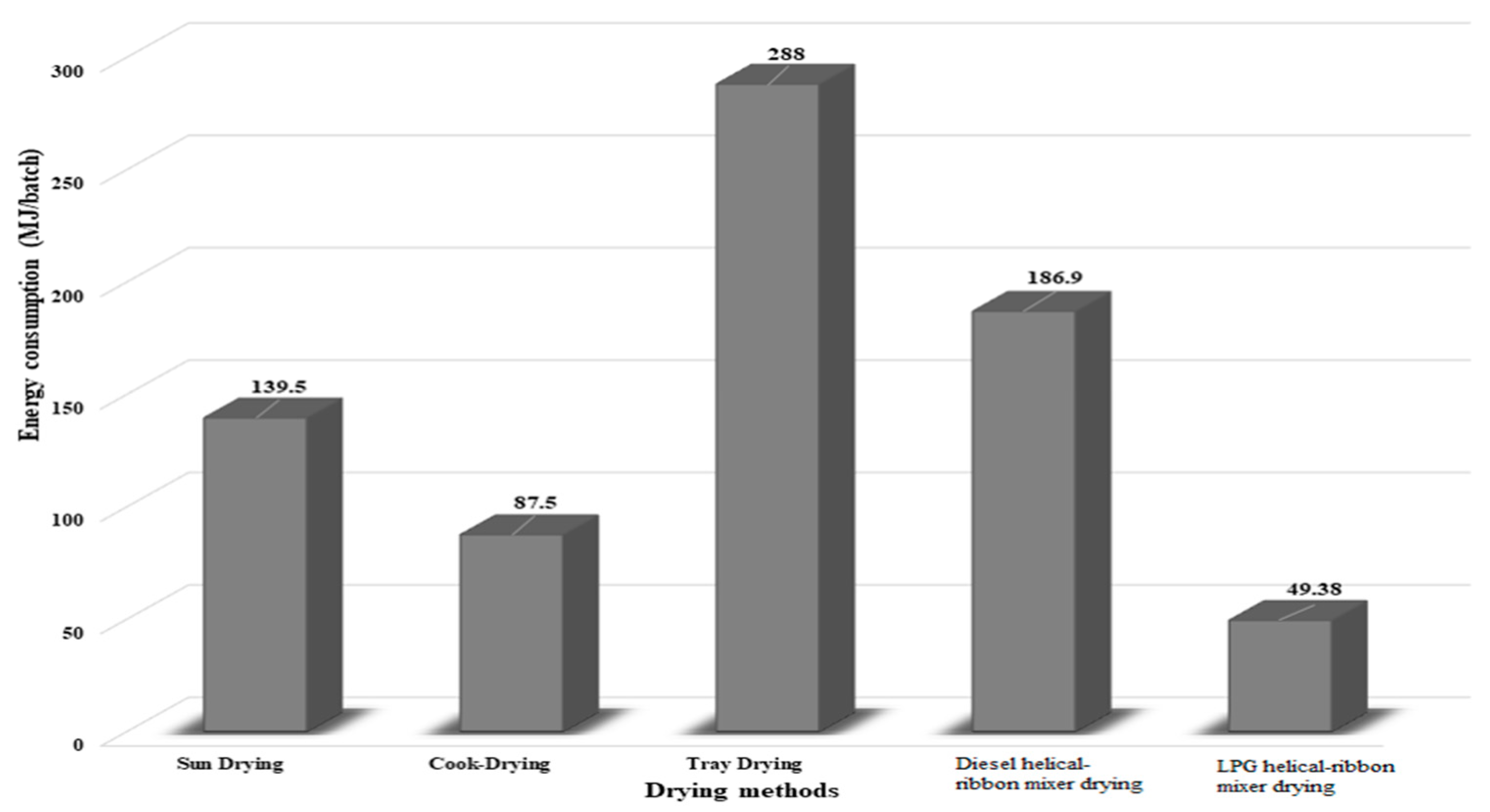

2.6. Performance Study of Previously Used Methods for BBRDM Production

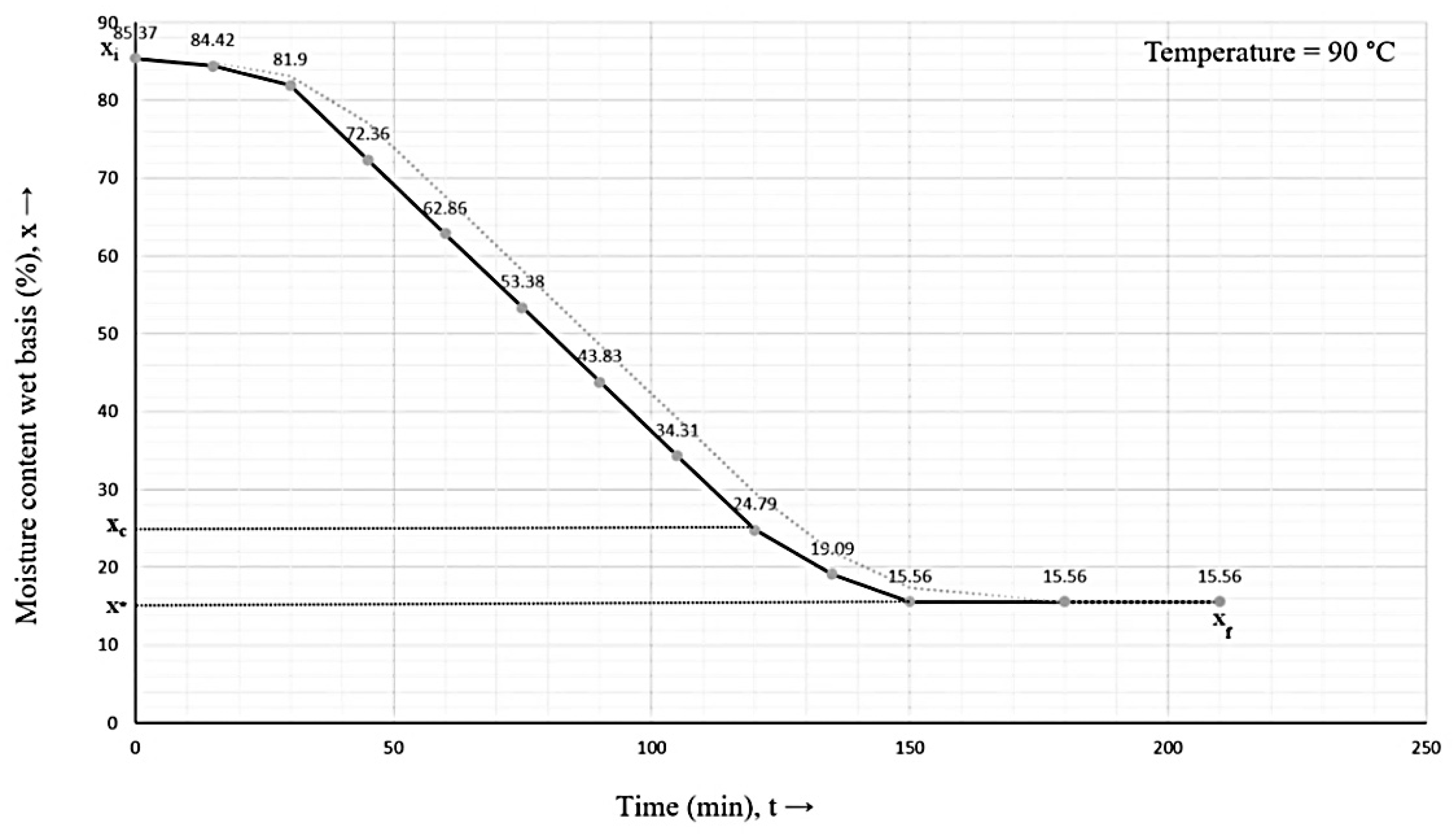

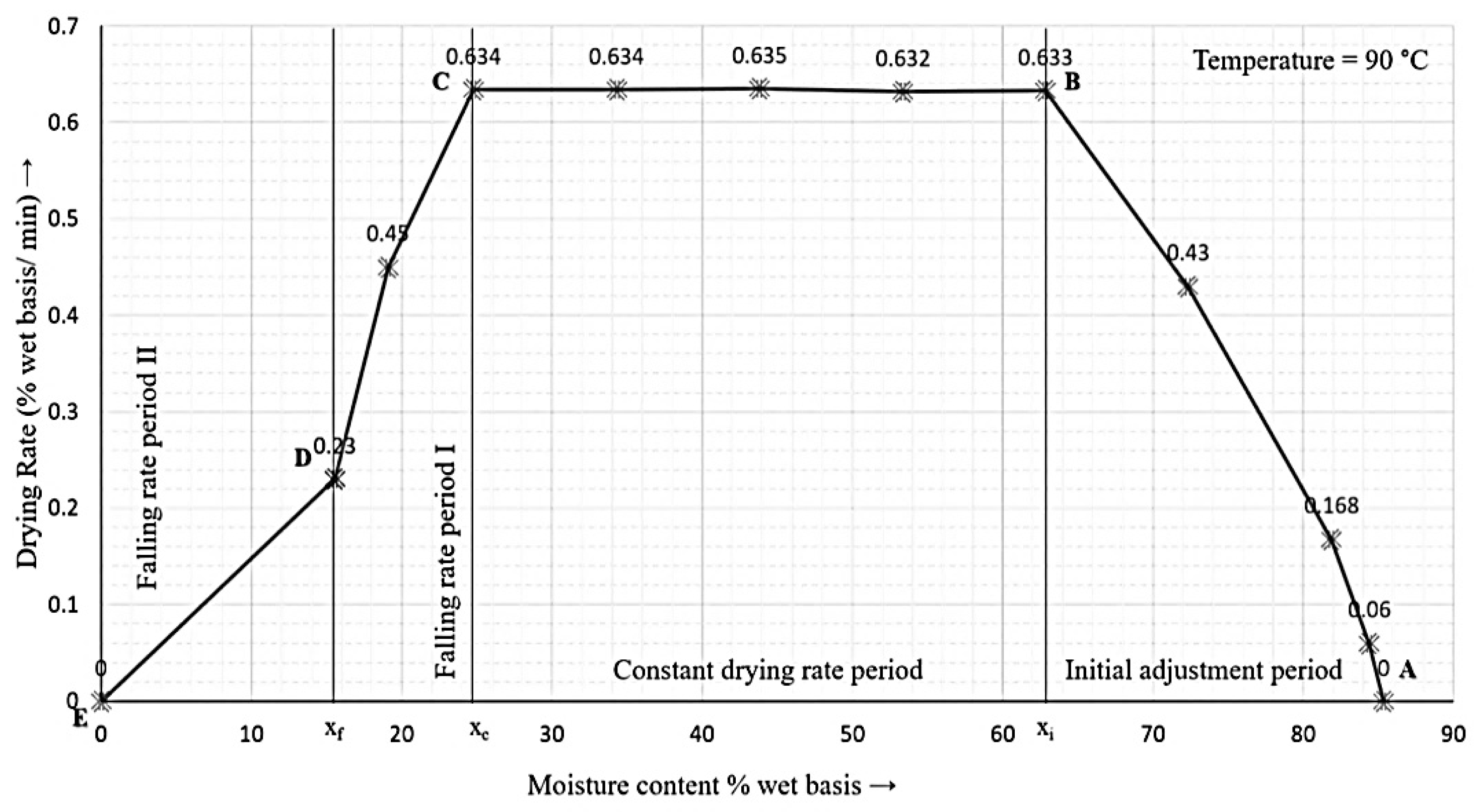

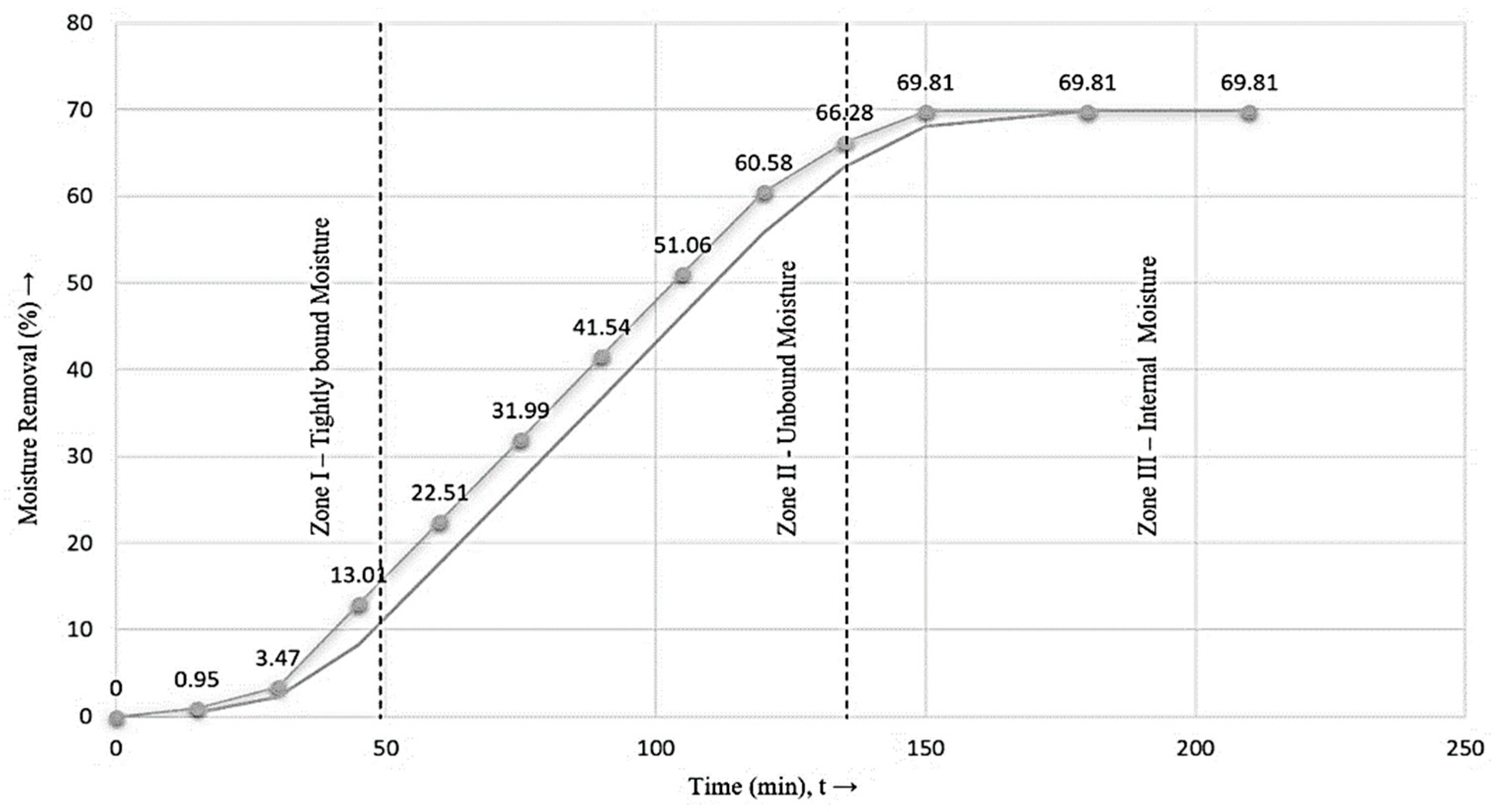

2.7. Experimental Drying Curves of Drying Process in Fabricated Drying Unit

2.8. Preparation of a Sustainable Business Case for In Situ BBRDM Production

2.8.1. Assessment of End-User Readiness

2.8.2. Assessment of Supply Sector Readiness

3. Results and Discussion

3.1. Waste Characterization

3.2. Waste Recycling through the Drying Process

3.3. Experimental Drying Curves Obtained during the Drying Process

3.4. End-User Readiness for Accepting the Recycling Process

3.5. Supply Sector Readiness for Delivery of BBRDM

| Non-recurring costs (INR) | |

| Equipment fabrication cost | 250,000 |

| Water connection | 10,000 |

| Sub-total | 260,000 |

| Annual recurring costs (INR) | |

| Operation and maintenance costs | 50,000 |

| Fuel and electricity charges | 100,000 |

| Local transport | 20,000 |

| Sub-total | 170,000 |

| Annual labor cost (INR) | |

| One skilled laborer @ 10,000 per month. | 120,000 |

| One manager @ 20,000 per month | 240,000 |

| Sub-total | 360,000 |

| Total cost (INR) | 790,000 |

3.6. Interest and Depreciation

3.7. Financial Viability

4. Conclusions and Policy Implications

5. Patent

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adhikari, B.B.; Chae, M.; Bressler, D.C. Utilization of slaughterhouse waste in value-added applications: Recent advances in the development of wood adhesives. Polymers 2018, 10, 176. [Google Scholar] [CrossRef] [Green Version]

- Domingo, J.L.; Nadal, M. Domestic waste composting facilities: A review of human health risks. Environ. Int. 2009, 35, 382–389. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Xu, T.; Feng, H.; Chen, S. Greenhouse gas emissions from landfills: A review and bibliometric analysis. Sustainability 2019, 11, 2282. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, R.; Jilani, G.; Arshad, M.; Zahir, Z.A.; Khalid, A. Bio-conversion of organic wastes for their recycling in agriculture: An overview of perspectives and prospects. Ann. Microbiol. 2007, 57, 471–479. [Google Scholar] [CrossRef]

- Marchaim, U.; Levanon, D.; Danai, O.; Musaphy, S.; Chen, Y.; Inbar, Y.; Klinger, I. A suggested solution for slaughterhouse wastes: Uses of the residual materials after anaerobic digestion. Bioresour. Technol. 1991, 37, 127–134. [Google Scholar] [CrossRef]

- Franke-Whittle, I.H.; Insam, H. Treatment alternatives of slaughterhouse wastes, and their effect on the inactivation of different pathogens: A review. Crit. Rev. Microbiol. 2013, 39, 139–151. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bhunia, S.; Bhowmik, A.; Mukherjee, J. Waste management of rural slaughterhouses in developing countries. In Advanced Organic Management: Sustainable Practices and Approaches; Hussain, C.M., Hait, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; accepted. [Google Scholar]

- Myers, K.P.; Olsen, C.W.; Setterquist, S.F.; Capuano, A.W.; Donham, K.J.; Thacker, E.L.; Merchant, J.A.; Gray, G.C. Are swine workers in the United States at increased risk of infection with zoonotic influenza virus? Clin. Infect. Dis. 2006, 42, 14–20. [Google Scholar] [CrossRef] [PubMed]

- Fraser, C.; Donnelly, C.A.; Cauchemez, S.; Hanage, W.P.; Van Kerkhove, M.D.; Hollingsworth, T.D.; Griffin, J.; Baggaley, R.F.; Jenkins, H.E.; Lyons, E.J.; et al. Pandemic potential of a strain of influenza A (H1N1): Early findings. Science 2009, 324, 1557–1561. [Google Scholar] [CrossRef] [Green Version]

- Cook, E.A.J.; de Glanville, W.A.; Thomas, L.F.; Kariuki, S.; de Clare Bronsvoort, B.M.; Fèvre, E.M. Working conditions and public health risks in slaughterhouses in western Kenya. BMC Public Health 2017, 17, 14. [Google Scholar] [CrossRef] [Green Version]

- Salminen, E.; Rintala, J. Anaerobic digestion of organic solid poultry slaughterhouse waste: A review. Bioresour. Technol. 2002, 83, 13–26. [Google Scholar] [CrossRef]

- Jeung, J.H.; Chung, W.J.; Chang, S.W. Evaluation of anaerobic co-digestion to enhance the efficiency of livestock manure anaerobic digestion. Sustainability 2019, 11, 7170. [Google Scholar] [CrossRef] [Green Version]

- Nkoa, R. Agricultural benefits and environmental risks of soil fertilization with anaerobic digestates: A review. Agron. Sustain. Dev. 2014, 34, 473–492. [Google Scholar] [CrossRef] [Green Version]

- Roy, M.; Karmakar, S.; Debsarcar, A.; Sen, P.K.; Mukherjee, J. Application of rural slaughterhouse waste as an organic fertilizer for pot cultivation of solanaceous vegetables in India. Int. J. Recycl. Org. Waste Agric. 2013, 2, 6. [Google Scholar] [CrossRef] [Green Version]

- Jones, P.; Martin, M. A Review of the Literature on the Occurrence and Survival of Pathogens of Animals and Humans in Green Compost; WRAP Research Report; The Waste and Resources Action Programme: Oxon, UK, 2003; Available online: https://www.gwmc.ca/pdf_files/Literature%20Review%20-%20Human%20and%20Animal%20Pathogens%20in%20Compost.pdf (accessed on 3 July 2021).

- Chen, Y.X.; Huang, X.D.; Han, Z.Y.; Huang, X.; Hu, B.; Shi, D.Z.; Wu, W.X. Effects of bamboo charcoal and bamboo vinegar on nitrogen conservation and heavy metals immobility during pig manure composting. Chemosphere 2010, 78, 1177–1181. [Google Scholar] [CrossRef] [PubMed]

- Haan, C.; Steinfeld, H.; Blackburn, H. Livestock and the Environment. In Chapter 5: Beyond Production Systems, Processing of Livestock Products; Food and Agriculture Organization: Rome, Italy, 1996; Available online: https://www.fao.org/ag/againfo/resources/documents/Lxehtml/tech/ch5d.htm (accessed on 18 June 2021).

- Mann, I.; Koulikovskii, A.; Matyas, Z.; WHO. Guidelines on Small Slaughterhouses and Meat Hygiene for Developing Countries. In Veterinary Public Health Unit; Koulikovskii, I., Matyas, Z., Eds.; World Health Organization: Geneva, Switzerland, 1983; Available online: https://apps.who.int/iris/handle/10665/66404 (accessed on 16 June 2021).

- Koei, N. Global Study on Reconstruction of Public Live Markets, Slaughterhouses, and Related Waste Management Systems. 2009. Available online: https://documents1.worldbank.org/curated/en/156701468147583817/pdf/696530ESW0P1000l0Study0of0Livestock.pdf%20 (accessed on 18 June 2021).

- Bhunia, S.; Bhowmik, A.; Mallick, R.; Mukherjee, J. Agronomic efficiency of animal-derived organic fertilizers and their effects on biology and fertility of soil: A review. Agronomy 2021, 11, 823. [Google Scholar] [CrossRef]

- Palatsi, J.; Viñas, M.; Guivernau, M.; Fernandez, B.; Flotats, X.J.B.T. Anaerobic digestion of slaughterhouse waste: Main process limitations and microbial community interactions. Bioresour. Technol. 2011, 102, 2219–2227. [Google Scholar] [CrossRef]

- Salminen, E.; Rintala, J.; Härkönen, J.; Kuitunen, M.; Högmander, H.; Oikari, A. Anaerobically digested poultry slaughterhouse wastes as fertiliser in agriculture. Bioresour. Technol. 2001, 78, 81–88. [Google Scholar] [CrossRef]

- Sankar, K.J.A.; Vasudevan, V.N.; Sunil, B.; Latha, A.; Irshad, A.; Mathew, D.K.D.; Saifuddeen, S.M. Development of organic briquettes from slaughterhouse waste as nutrient source for plant growth. Waste Biomass Valor. 2021. [Google Scholar] [CrossRef]

- USDA FAS. Livestock and Poultry: World Markets and Trade; United States Department of Agriculture- Foreign Agricultural Service: Washington, DC, USA, 2020.

- Kennedy, U.; Sharma, A.; Phillips, C.J. The sheltering of unwanted cattle, experiences in India and implications for cattle industries elsewhere. Animals 2018, 8, 64. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Roy, M.; Das, R.; Debsarcar, A.; Sen, P.K.; Mukherjee, J. Conversion of rural abattoir wastes to an organic fertilizer and its application the field cultivation of tomato in India. Renew. Agric. Food Syst. 2016, 31, 350–360. [Google Scholar] [CrossRef]

- Roy, M.; Das, R.; Kundu, A.; Karmakar, S.; Das, S.; Sen, P.; Debsarcar, A.; Mukherjee, J. Organic cultivation of tomato in India with recycled slaughterhouse wastes: Evaluation of fertilizer and fruit safety. Agriculture 2015, 5, 826–856. [Google Scholar] [CrossRef] [Green Version]

- Musa, M.A.; Idrus, S. Physical and biological treatment technologies of slaughterhouse wastewater: A review. Sustainability 2021, 13, 4656. [Google Scholar] [CrossRef]

- Bhunia, S.; Bhowmik, A.; Mallick, R.; Debsarcar, A.; Mukherjee, J. Application of recycled slaughterhouse wastes as an organic fertilizer for successive cultivations of bell pepper and amaranth. Sci. Hortic. 2021, 280, 109927. [Google Scholar] [CrossRef]

- Donner, M.; Verniquet, A.; Broeze, J.; Kayser, K.; De Vries, H. Critical success and risk factors for circular business models valorising agricultural waste and by-products. Resour. Conserv. Recycl. 2021, 165, 105236. [Google Scholar] [CrossRef]

- The Royal Institute of International Affairs. How the Circular Economy Can Help Realize the Sustainable Development Goals. 2020. Available online: https://circulareconomy.earth/publications/the-circular-economy-and-the-sdgs (accessed on 12 July 2021).

- Adamiec, J. Drying of waste sludges in a fluidized bed dryer with a mixer. Dry. Technol. 2002, 20, 839–853. [Google Scholar] [CrossRef]

- Bhowmik, A.; Bhunia, S.; Mukherjee, J. An Apparatus for Recycling Slaughterhouse Waste and Method Thereof. Indian Patent 370,569, 29 June 2021. [Google Scholar]

- Raheman, H.; Phadatare, A.G. Diesel engine emissions and performance from blends of karanja methyl ester and diesel. Biomass Bioenergy 2004, 27, 393–397. [Google Scholar] [CrossRef]

- Muthukumar, P.; Shyamkumar, P.I. Development of novel porous radiant burners for LPG cooking applications. Fuel 2013, 112, 562–566. [Google Scholar] [CrossRef]

- Krajnc, N. Wood Fuels Handbook; Food and Agricultural Organization: Rome, Italy, 2015. [Google Scholar]

- Pal, U.S.; Khan, M.K. Calculation steps for the design of different components of heat pump dryers under constant drying rate condition. Dry. Technol. 2008, 26, 864–872. [Google Scholar] [CrossRef]

- Doran, P.M. Chapter 11: Unit Operations. In Bioprocess Engineering Principles; Doran, P.M., Ed.; Academic: London, UK, 2013; pp. 445–595. [Google Scholar]

- Stawreberg, L.; Nilsson, L. Modelling of specific moisture extraction rate and leakage ratio in a condensing tumble dryer. Appl. Therm. Eng. 2010, 30, 2173–2179. [Google Scholar] [CrossRef] [Green Version]

- Mustaffar, A.; Phan, A.; Boodhoo, K. Hybrid heat pipe screw dryer: A novel, continuous and highly energy-efficient drying technology. Chem. Eng. Process. 2018, 128, 199–215. [Google Scholar] [CrossRef]

- Ayilara, M.S.; Olanrewaju, O.S.; Babalola, O.O.; Odeyemi, O. Waste management through composting: Challenges and potentials. Sustainability 2020, 12, 4456. [Google Scholar] [CrossRef]

- Zagklis, D.; Konstantinidou, E.; Zafiri, C.; Kornaros, M. Assessing the economic viability of an animal byproduct rendering plant: Case study of a slaughterhouse in Greece. Sustainability 2020, 12, 5870. [Google Scholar] [CrossRef]

- Cantrell, K.B.; Ducey, T.; Ro, K.S.; Hunt, P.G. Livestock waste-to-bioenergy generation opportunities. Bioresour. Technol. 2008, 99, 7941–7953. [Google Scholar] [CrossRef]

- Breitenmoser, L.; Gross, T.; Huesch, R.; Rau, J.; Dhar, H.; Kumar, S.; Hugi, C.; Wintgens, T. Anaerobic digestion of biowastes in India: Opportunities, challenges and research needs. J. Environ. Manag. 2019, 236, 396–412. [Google Scholar] [CrossRef]

- Pakowski, Z.; Adamski, R. On prediction of the drying rate in superheated steam drying process. Dry. Technol. 2011, 29, 1492–1498. [Google Scholar] [CrossRef]

- Mujumdar, A.S.; Menon, A.S. Handbook of Industrial Drying; Marcel Dekker Inc.: New York, NY, USA, 1995. [Google Scholar]

- Kemp, I.C.; Fyhr, B.C.; Laurent, S.; Roques, M.A.; Groenewold, C.E.; Tsotsas, E.; Sereno, A.A.; Bonazzi, C.B.; Bimbenet, J.J.; Kind, M. Methods for processing experimental drying kinetics data. Dry. Technol. 2001, 19, 15–34. [Google Scholar] [CrossRef]

- García-Bernet, D.; Buffière, P.; Latrille, E.; Steyer, J.P.; Escudié, R. Water distribution in biowastes and digestates of dry anaerobic digestion technology. Chem. Eng. J. 2011, 172, 924–928. [Google Scholar] [CrossRef]

- Jiang, N.; Liu, C.; Li, D.; Zhang, Z.; Liu, C.; Wang, D.; Niu, L.; Zhang, M. Evaluation of freeze drying combined with microwave vacuum drying for functional okra snacks: Antioxidant properties, sensory quality, and energy consumption. LWT-Food Sci. Technol. 2017, 82, 216–226. [Google Scholar] [CrossRef]

- Perazzini, H.; Freire, F.B.; Freire, F.B.; Freire, J.T. Thermal treatment of solid wastes using drying technologies: A review. Dry. Technol. 2016, 34, 39–52. [Google Scholar] [CrossRef]

- Huang, L.L.; Zhang, M.; Mujumdar, A.S.; Lim, R.X. Comparison of four drying methods for re-structured mixed potato with apple chips. J. Food Eng. 2011, 103, 279–284. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, M.; Mujumdar, A.S.; Lim, R.X. Drying uniformity analysis of pulse spouted microwave-freeze drying of banana cubes. Dry. Technol. 2016, 34, 539–546. [Google Scholar] [CrossRef]

- Sharma, G.P.; Prasad, S. Optimization of process parameters for microwave drying of garlic cloves. J. Food Eng. 2006, 75, 441–446. [Google Scholar] [CrossRef]

- Cofie, O.O.; Agbottah, S.; Strauss, M.; Esseku, H.; Montangero, A.; Awuah, E.; Kone, D. Solid-liquid separation of faecal sludge using drying beds in Ghana: Implications for nutrient recycling in urban agriculture. Water Res. 2006, 40, 75–82. [Google Scholar] [CrossRef]

- Sontakke, M.S.; Salve, S.P. Solar drying technologies: A review. Int. J. Eng. Sci. 2015, 4, 29–35. [Google Scholar]

- Ashebir, D.; Jezik, K.; Weingartemann, H.; Gretzmacher, R. Change in color and other fruit quality characteristics of tomato cultivars after hot-air drying at low final-moisture content. Int. J. Food Sci. Nutr. 2009, 60, 308–315. [Google Scholar] [CrossRef] [PubMed]

- Hartz, T.K.; Johnstone, P.R. Nitrogen availability from high-nitrogen-containing organic fertilizers. HortTechnology 2006, 16, 39–42. [Google Scholar] [CrossRef] [Green Version]

| Waste parameters | Waste Type | |||

| Permissible Values (as of EPA, 1986) | Bovine Blood | Rumen Content | ||

| pH | 5.5–9.0 | 8.1 | 8.0 | |

| TS (mg L−1) | - | 821,517 | 57,220 | |

| TSS (mg L−1) | 100 | 409,737 | 44,072 | |

| BOD5 (mg L−1) | 30 | 66,011 | 140 | |

| COD (mg L−1) | 250 | 270,403 | 35,997 | |

| Oil and grease (mg L−1) | 10–20 | 25 | 76,992 | |

| Evaluating Parameters | Method of Drying for BBRDM Production | ||||

|---|---|---|---|---|---|

| Sun Drying | Cook Drying | Tray Dryer | Helical-Ribbon Dryer (Diesel) | Helical-Ribbon Dryer (LPG) | |

| Energy consumption (MJ/batch) | 139.5 | 87.5 | 288 | 186.59 | 49.38 |

| Amount of fuel consumption | - | 5 kg Wood | 80 kWh electricity | 5 L +2 kWh electricity | 1 kg +1 kWh electricity |

| Drying temperature (°C) | 30–35 | 50–60 | 70- 80 | 65–70 | 90–110 |

| Drying time (h) | 72–96 | 5–6 | 9–10 | 4.5 | 3.5 |

| Moisture content (%) | 19–21 | 23–25 | 15–18 | 18.8 | 15.6 |

| Production/batch (kg) | 5–6 | 4–5 | 8–10 | 8–10 | 10–15 |

| Nitrogen content (mg kg−1) | Not determined | 49,440 | 5977 | 12,678 | 15,456 |

| Pathogen inactivation | + | ++ | +++ | +++ | +++ |

| Year | Non-Recurring Cost | Recurring Cost | Labor Cost | Total Cost (per Year) | Annual Production (in kg) | Price (INR. per kg) |

|---|---|---|---|---|---|---|

| Year 1 | 260,000 | 170,000 | 360,000 | 790,000 | 21,000 | 39.50 |

| Year 2 | 170,000 | 360,000 | 530,000 | 21,000 | 26.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhowmik, A.; Bhunia, S.; Debsarkar, A.; Mallick, R.; Roy, M.; Mukherjee, J. Development of a Novel Helical-Ribbon Mixer Dryer for Conversion of Rural Slaughterhouse Wastes to an Organic Fertilizer and Implications in the Rural Circular Economy. Sustainability 2021, 13, 9455. https://doi.org/10.3390/su13169455

Bhowmik A, Bhunia S, Debsarkar A, Mallick R, Roy M, Mukherjee J. Development of a Novel Helical-Ribbon Mixer Dryer for Conversion of Rural Slaughterhouse Wastes to an Organic Fertilizer and Implications in the Rural Circular Economy. Sustainability. 2021; 13(16):9455. https://doi.org/10.3390/su13169455

Chicago/Turabian StyleBhowmik, Ankita, Shantanu Bhunia, Anupam Debsarkar, Rambilash Mallick, Malancha Roy, and Joydeep Mukherjee. 2021. "Development of a Novel Helical-Ribbon Mixer Dryer for Conversion of Rural Slaughterhouse Wastes to an Organic Fertilizer and Implications in the Rural Circular Economy" Sustainability 13, no. 16: 9455. https://doi.org/10.3390/su13169455

APA StyleBhowmik, A., Bhunia, S., Debsarkar, A., Mallick, R., Roy, M., & Mukherjee, J. (2021). Development of a Novel Helical-Ribbon Mixer Dryer for Conversion of Rural Slaughterhouse Wastes to an Organic Fertilizer and Implications in the Rural Circular Economy. Sustainability, 13(16), 9455. https://doi.org/10.3390/su13169455