Role of Industry 4.0 in Supply Chains Sustainability: A Systematic Literature Review

Abstract

:1. Introduction

Research Question

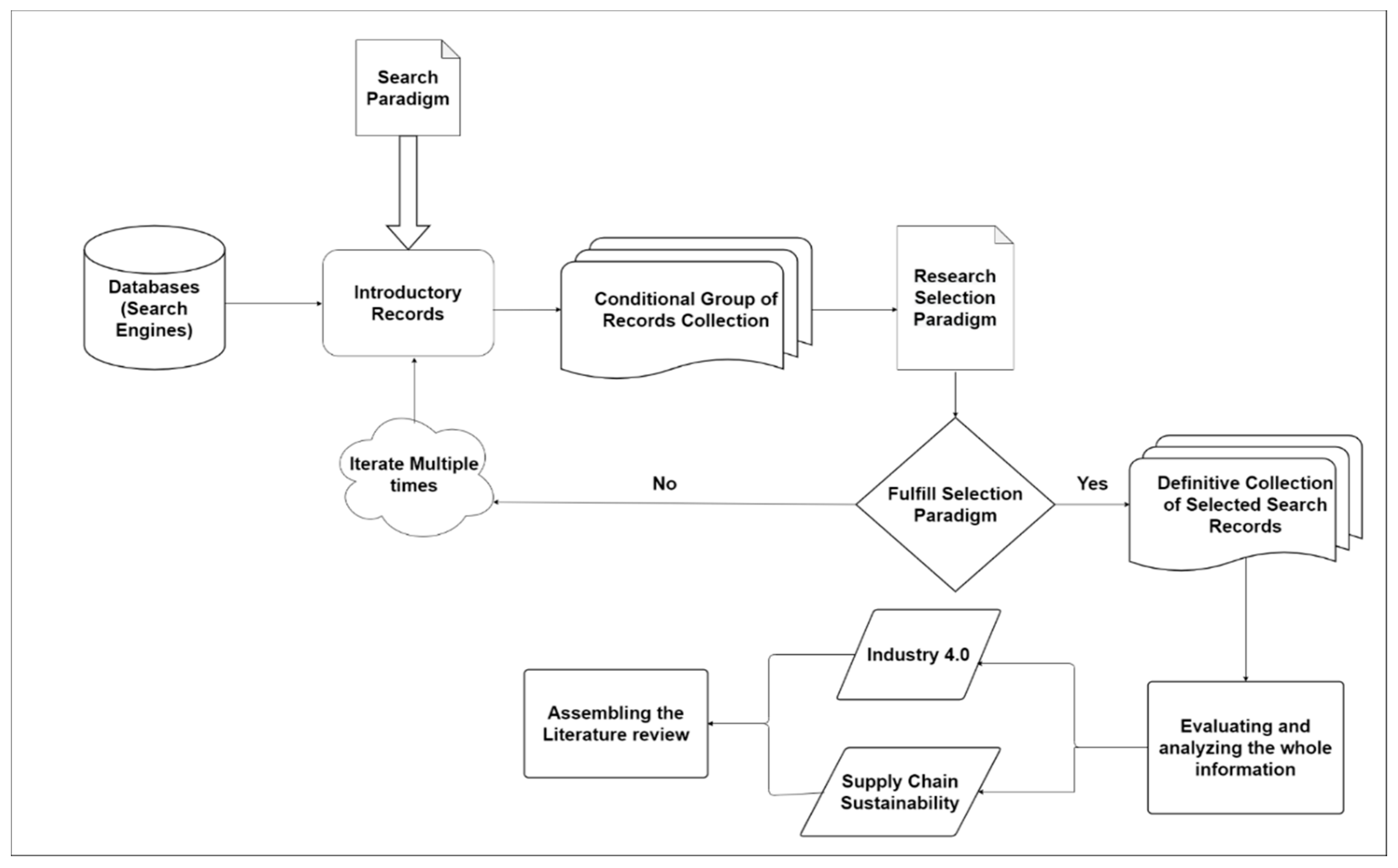

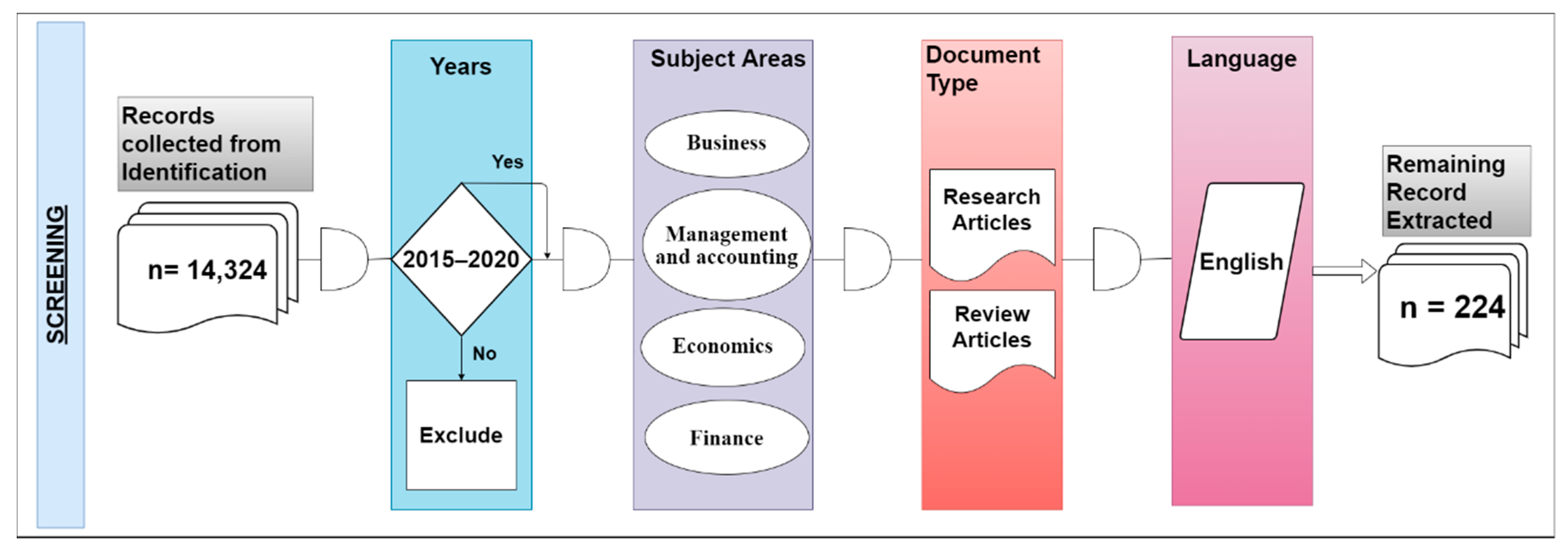

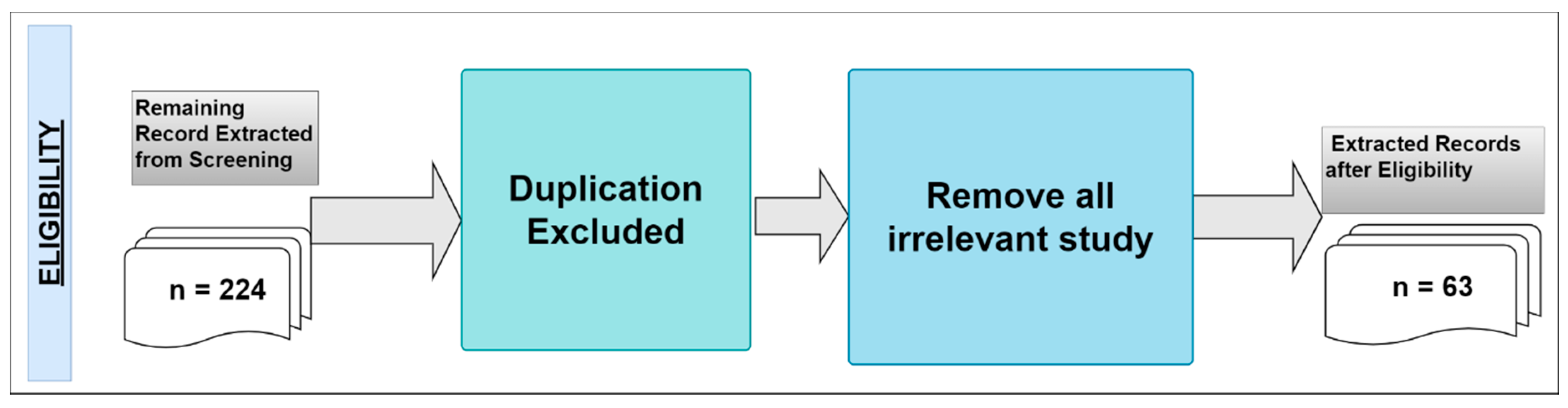

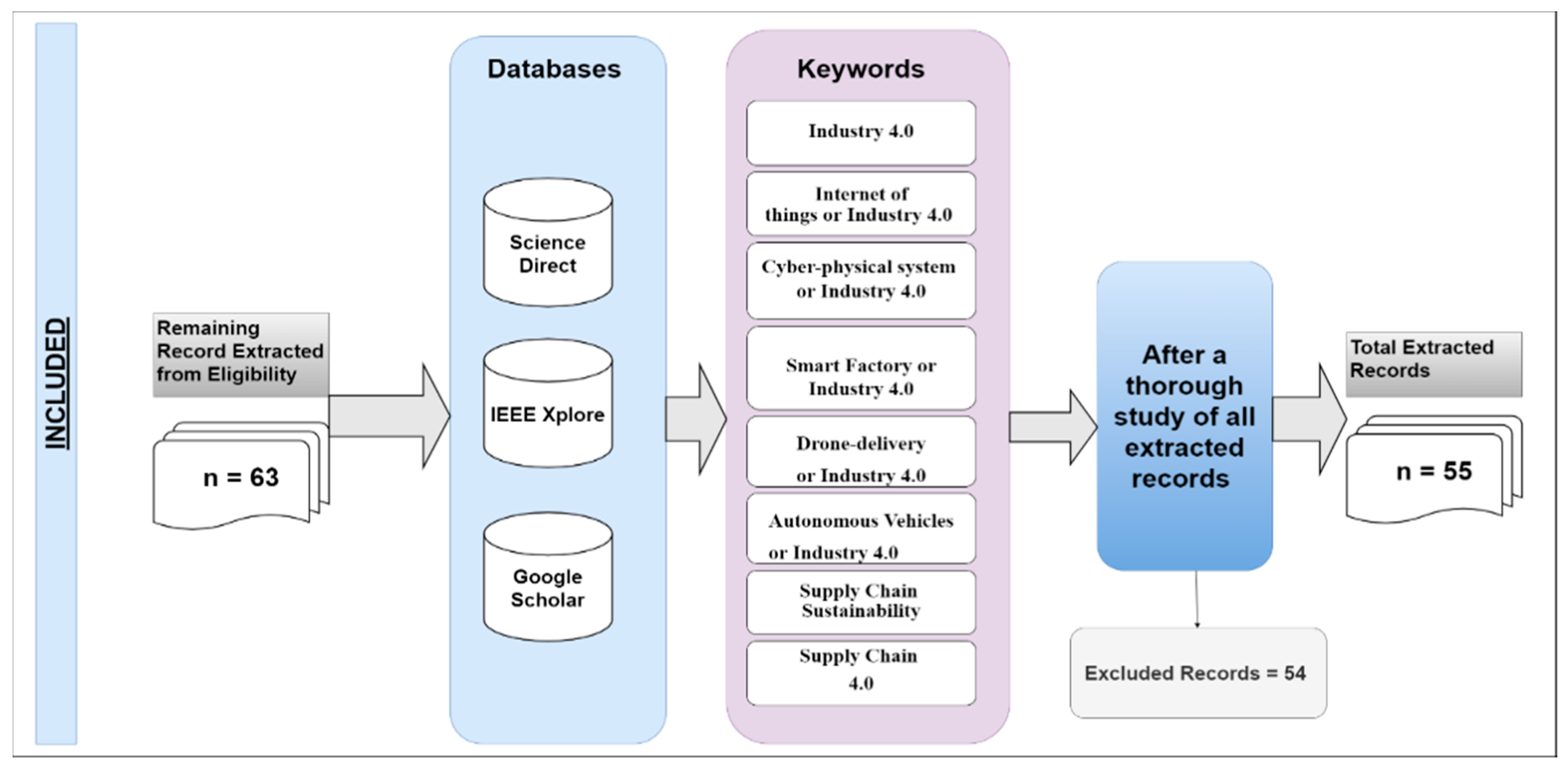

2. Review Methodology

Prisma Framework

3. Review Discussion and Findings

3.1. Demographics

3.1.1. Contribution by Publishers

3.1.2. Contribution by Journal

3.1.3. Contribution by Top Author’s

3.1.4. Contribution by Country

3.1.5. Year-Wise Publications

3.2. Taxonomy

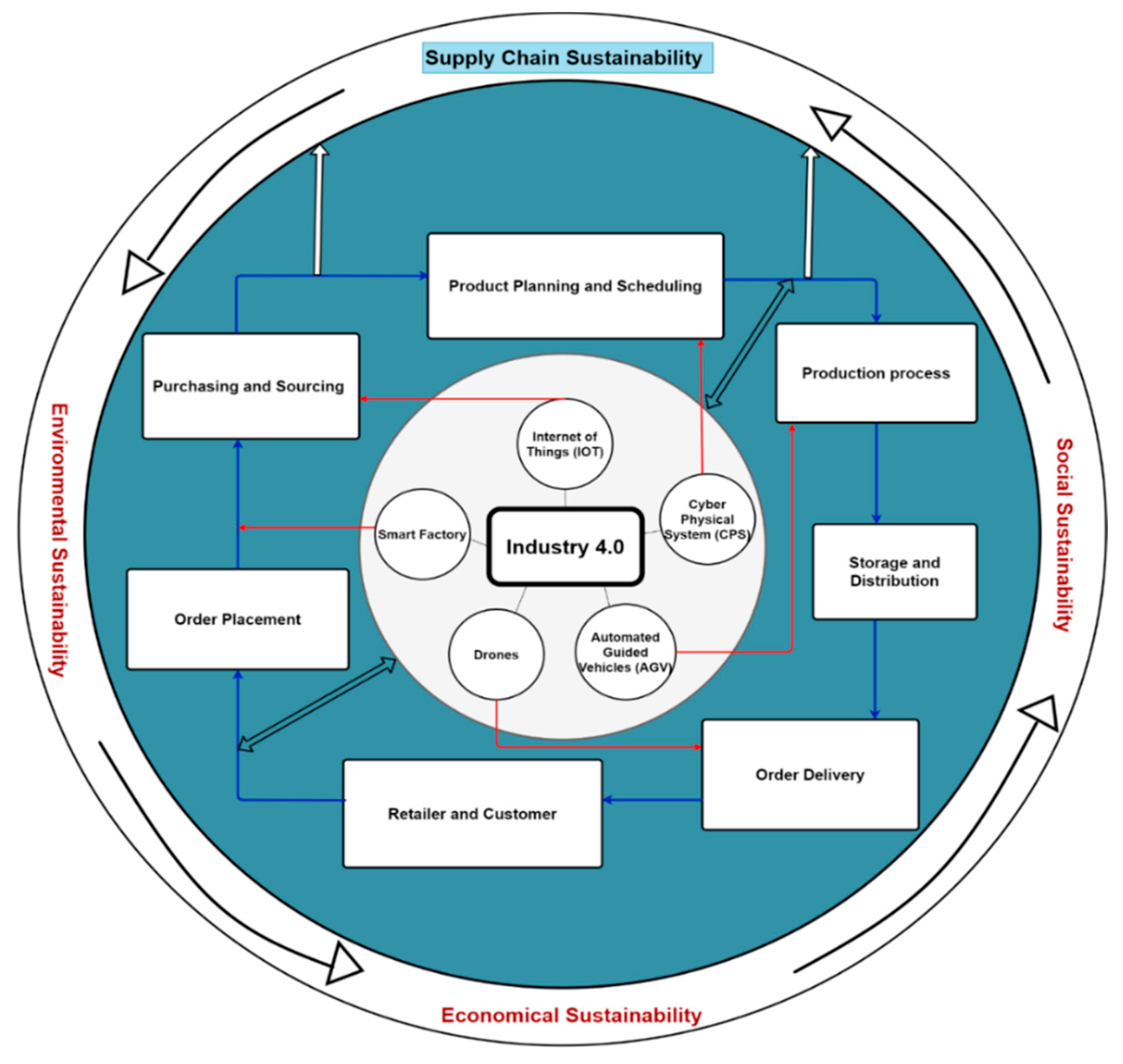

4. Research Framework

5. Discussion

5.1. Managerial Implications

5.2. Theoretical Implications

5.3. Limitations and Guidelines for Future Research

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Duarte, S.; Cruz-Machado, V. Exploring Linkages between Lean and Green Supply Chain and the Industry 4.0. In Proceedings of the 11th International Conference on Management Science and Engineering Management, Melbourne, Australia, 1–4 August 2018; pp. 1242–1252. [Google Scholar]

- Legenvre, H.; Henke, M.; Ruile, H. Making sense of the impact of the internet of things on Purchasing and Supply Management: A tension perspective. J. Purch. Supply Manag. 2020, 26, 100596. [Google Scholar] [CrossRef]

- Matana, G.; Simon, A.; Filho, M.G.; Helleno, A. Method to assess the adherence of internal logistics equipment to the concept of CPS for industry 4.0. Int. J. Prod. Econ. 2020, 228, 107845. [Google Scholar] [CrossRef]

- Gupta, R.; Tanwar, S.; Kumar, N.; Tyagi, S. Blockchain-based security attack resilience schemes for autonomous vehicles in industry 4.0: A systematic review. Comput. Electr. Eng. 2020, 86, 106717. [Google Scholar] [CrossRef]

- Bechtsis, D.; Tsolakis, N.; Vlachos, D.; Iakovou, E. Sustainable supply chain management in the digitalization era: The impact of Automated Guided Vehicles. J. Clean. Prod. 2017, 142, 3970–3984. [Google Scholar] [CrossRef] [Green Version]

- Osterrieder, P.; Budde, L.; Friedli, T. The smart factory as a key construct of industry 4.0: A systematic literature review. Int. J. Prod. Econ. 2020, 221, 10747. [Google Scholar] [CrossRef]

- Simoni, M.D.; Kutanoglu, E.; Claudel, C.G. Optimization and analysis of a robot-assisted last mile delivery system. Transp. Res. Part E Logist. Transp. Rev. 2020, 142, 102049. [Google Scholar] [CrossRef]

- Bag, S.; Telukdarie, A.; Pretorius, J.; Gupta, S. Industry 4.0 and supply chain sustainability: Framework and future research directions. Benchmarking Int. J. 2018, 28, 1410–1450. [Google Scholar] [CrossRef]

- Cioffi, R.; Travaglioni, M.; Piscitelli, G.; Petrillo, A.; Parmentola, A. smart manufacturing systems and applied industrial technologies for a sustainable industry: A systematic literature review. Appl. Sci. 2020, 10, 2897. [Google Scholar] [CrossRef] [Green Version]

- Chalmeta, R.; Santos-Deleón, N.J. Sustainable supply chain in the era of industry 4.0 and big data: A systematic analysis of literature and research. Sustainability 2020, 12, 4108. [Google Scholar] [CrossRef]

- Ojo, O.O.; Shah, S.; Coutroubis, A.; Jimenez, M.T.; Ocana, Y.M. Potential impact of Industry 4.0 in sustainable food supply chain environment. In Proceedings of the 2018 IEEE International Conference on Technology Management, Operations and Decisions (ICTMOD), Marrakech, Morocco, 21–23 November 2018; pp. 172–177. [Google Scholar]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Bezai, N.E.; Medjdoub, B.; Al-Habaibeh, A.; Chalal, M.L.; Fadli, F. Future cities and autonomous vehicles: Analysis of the barriers to full adoption. Energy Built Environ. 2021, 2, 65–68. [Google Scholar] [CrossRef]

- Delgado, J.M.D.; Oyedele, L.; Ajayi, A.; Akanbi, L.; Akinade, O.; Bilal, M.; Owolabi, H. Robotics and automated systems in construction: Understanding industry-specific challenges for adoption. J. Build. Eng. 2019, 26, 100868. [Google Scholar] [CrossRef]

- Tang, C.S.; Veelenturf, L.P. The strategic role of logistics in the industry 4.0 era. Transp. Res. Part E Logist. Transp. Rev. 2019, 129, 1–11. [Google Scholar] [CrossRef]

- Yavas, V.; Ozkan-Ozen, Y.D. Logistics centers in the new industrial era: A proposed framework for logistics center 4.0. Transp. Res. Part E Logist. Transp. Rev. 2020, 135, 101864. [Google Scholar] [CrossRef]

- Dalenogarea, L.S.; Beniteza, G.B.; Ayalab, N.F.; Franka, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Goodchild, A.; Toy, J. Delivery by drone: An evaluation of unmanned aerial vehicle technology in reducing CO2 emissions in the delivery service industry. Transp. Res. Part D Transp. Environ. 2018, 61, 58–67. [Google Scholar] [CrossRef]

- Wang, J.; Lim, M.K.; Zhan, Y.; Wang, X. An intelligent logistics service system for enhancing dispatching operations in an IoT environment. Transp. Res. Part E Logist. Transp. Rev. 2020, 135, 101886. [Google Scholar] [CrossRef]

- Jeong, H.Y.; Yu, D.J.; Min, B.-C.; Lee, S. The humanitarian flying warehouse. Transp. Res. Part E Logist. Transp. Rev. 2020, 136, 101901. [Google Scholar] [CrossRef]

- Haula, K.; Agbozo, E. A systematic review on unmanned aerial vehicles in Sub-Saharan Africa: A socio-technical perspective. Technol. Soc. 2020, 63, 101357. [Google Scholar] [CrossRef]

- Figliozzi, M.A. Carbon emissions reductions in last mile and grocery deliveries utilizing air and ground autonomous vehicles. Transp. Res. Part D Transp. Environ. 2020, 85, 102443. [Google Scholar] [CrossRef]

- Kirschstein, T. Comparison of energy demands of drone-based and ground-based parcel delivery services. Transp. Res. Part D Transp. Environ. 2020, 78, 102209. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. A review of Internet of Things (IoT) embedded sustainable supply chain for industry 4.0 requirements. Comput. Ind. Eng. 2019, 127, 925–953. [Google Scholar] [CrossRef]

- Esmaeilian, B.; Sarkis, J.; Lewis, K.; Behdad, S. Blockchain for the future of sustainable supply chain management in Industry 4.0. Resour. Conserv. Recycl. 2020, 163, 105064. [Google Scholar] [CrossRef]

- Yadav, G.; Luthra, S.; Jakhar, S.K.; Mangla, S.K.; Rai, D.P. A framework to overcome sustainable supply chain challenges through solution measures of industry 4.0 and circular economy: An automotive case. J. Clean. Prod. 2020, 254, 120112. [Google Scholar] [CrossRef]

- Ojo, O.O.; Shah, S.; Coutroubis, A. Impacts of Industry 4.0 in sustainable food manufacturing and supply chain. Int. J. Integr. Supply Manag. 2020, 13, 140. [Google Scholar] [CrossRef]

- You, Z.; Feng, L. Integration of Industry 4.0 Related Technologies in Construction Industry: A Framework of Cyber-Physical System. IEEE Access 2020, 8, 122908–122922. [Google Scholar] [CrossRef]

- Furstenau, L.B.; Sott, M.K.; Kipper, L.M.; Machado, Ê.L.; Lopez-Robles, J.R.; Dohan, M.S.; Cobo, M.J.; Zahid, A.; Abbasi, Q.H.; Imran, M.A. Link between sustainability and Industry 4.0: Trends, challenges and new perspectives. IEEE Access 2020, 8, 140079–140096. [Google Scholar] [CrossRef]

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart Factory of Industry 4.0: Key Technologies, Application Case, and Challenges. IEEE Access 2018, 6, 6505–6519. [Google Scholar] [CrossRef]

- Meneghello, F.; Calore, M.; Zucchetto, D.; Polese, M.; Zanella, A. IoT: Internet of threats? A Survey of practical security vulnerabilities in real IoT devices. IEEE Internet Things J. 2019, 6, 8182–8201. [Google Scholar] [CrossRef]

- Xu, H.; Yu, W.; Griffith, D.; Golmie, N. A survey on Industrial Internet of Things: A cyber-physical systems perspective. IEEE Access 2018, 6, 78238–78259. [Google Scholar] [CrossRef]

- Weking, J.; Stöcker, M.; Kowalkiewicz, M.; Böhm, M.; Krcmar, H. Leveraging industry 4.0—A business model pattern framework. Int. J. Prod. Econ. 2020, 225, 107588. [Google Scholar] [CrossRef]

- Schniederjans, D.G.; Curado, C.; Khalajhedayati, M. Supply chain digitisation trends: An integration of knowledge management. Int. J. Prod. Econ. 2020, 220, 107439. [Google Scholar] [CrossRef]

- Palmaccio, M.; Dicuonzo, G.; Belyaeva, Z.S. The internet of Things and corporate business models: A systematic literature review. J. Bus. Res. 2021, 131, 610–618. [Google Scholar] [CrossRef]

- Echchakoui, S.; Barka, N. Industry 4.0 and its impact in plastics industry: A literature review. J. Ind. Inf. Integr. 2020, 20, 100172. [Google Scholar]

- Li, Y.; Dai, J.; Cui, L. The impact of digital technologies on economic and environmental performance in the context of industry 4.0: A moderated mediation model. Int. J. Prod. Econ. 2020, 229, 107777. [Google Scholar] [CrossRef]

- de la Peña, Z.I.; Soeane, M.J.F.; Bermúdez, B.L. Industry 4.0 in the port and maritime industry: A literature review. J. Ind. Inf. Integr. 2020, 20, 100173. [Google Scholar]

- Rossit, D.A.; Tohmé, F.; Frutos, M. A data-driven scheduling approach to smart manufacturing. J. Ind. Inf. Integr. 2019, 15, 69–79. [Google Scholar] [CrossRef] [Green Version]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Culot, G.; Nassimbeni, G.; Orzes, G.; Sartor, M. Behind the definition of Industry 4.0: Analysis and open questions. Int. J. Prod. Econ. 2020, 226, 107617. [Google Scholar] [CrossRef]

- Reinhardt, I.C.; Oliveira, J.C.; Ring, D.T. Current perspectives on the development of Industry 4.0 in the pharmaceutical sector. J. Ind. Inf. Integr. 2020, 18, 100131. [Google Scholar] [CrossRef]

- Hannibal, M.; Knight, G. Additive manufacturing and the global factory: Disruptive technologies and the location of international business. Int. Bus. Rev. 2018, 27, 1116–1127. [Google Scholar] [CrossRef]

- Raj, A.; Dwivedi, G.; Sharma, A.; Jabbour, A.B.L.D.S.; Rajak, S. Barriers to the adoption of industry 4.0 technologies in the manufacturing sector: An inter-country comparative perspective. Int. J. Prod. Econ. 2020, 224, 107546. [Google Scholar] [CrossRef]

- Benitez, G.; Ayala, N.F.; Frank, A.G. Industry 4.0 innovation ecosystems: An evolutionary perspective on value cocreation. Int. J. Prod. Econ. 2020, 228, 107735. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Industry 4.0 integration with socio-technical systems theory: A systematic review and proposed theoretical model. Technol. Soc. 2020, 61, 101248. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Choi, T.-M.; Cai, Y.-J.; Shen, B. Sustainable fashion supply chain management: A system of systems analysis. IEEE Trans. Eng. Manag. 2018, 66, 730–745. [Google Scholar] [CrossRef]

- Liotta, G.; Kaihara, T.; Stecca, G. Optimization and simulation of collaborative networks for sustainable production and transportation. IEEE Trans. Ind. Inform. 2016, 12, 417–424. [Google Scholar] [CrossRef]

- Dossou, P.-E. Development of a new framework for implementing industry 4.0 in companies. Procedia Manuf. 2019, 38, 573–580. [Google Scholar] [CrossRef]

- Bai, C.; Dallasega, P.; Orzes, G.; Sarkis, J. Industry 4.0 technologies assessment: A sustainability perspective. Int. J. Prod. Econ. 2020, 229, 107776. [Google Scholar] [CrossRef]

- Mangla, S.K.; Luthra, S.; Rich, N.; Kumar, D.; Rana, N.P.; Dwivedi, Y.K. Enablers to implement sustainable initiatives in agri-food supply chains. Int. J. Prod. Econ. 2018, 203, 379–393. [Google Scholar] [CrossRef] [Green Version]

- Govindan, K.; Rajeev, A.; Padhi, S.S.; Pati, R.K. Supply chain sustainability and performance of firms: A meta-analysis of the literature. Transp. Res. Part E Logist. Transp. Rev. 2020, 137, 101923. [Google Scholar] [CrossRef]

- Cole, R.; Aitken, J. The role of intermediaries in establishing a sustainable supply chain. J. Purch. Supply Manag. 2020, 26, 100533. [Google Scholar] [CrossRef]

- Mani, V.; Gunasekaran, A.; Delgado, C. Enhancing supply chain performance through supplier social sustainability: An emerging economy perspective. Int. J. Prod. Econ. 2018, 195, 259–272. [Google Scholar] [CrossRef]

- Di Vaio, A.; Palladino, R.; Hassan, R.; Escobar, O. Artificial intelligence and business models in the sustainable development goals perspective: A systematic literature review. J. Bus. Res. 2020, 121, 283–314. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, X.; Tang, O.; Price, L.; Zhang, S.; Zhu, W. Supply chain collaboration for sustainability: A literature review and future research agenda. Int. J. Prod. Econ. 2017, 194, 73–87. [Google Scholar] [CrossRef]

| Journal | Number | Impact Factor |

|---|---|---|

| International Journal of Production Economics | 13 | 5.1 |

| IEEE Access | 7 | 3.7 |

| Transportation Research Part E IEEE Access | 5 | 4.6 |

| Journal of Industrial Information Integration | 5 | 10.6 |

| Journal of Purchasing and Supply Management | 4 | 3.3 |

| Journal of Business Research | 4 | 4.8 |

| Transportation Research Part D | 3 | 4.0 |

| Journal of Cleaner Production | 2 | 7.2 |

| Technology in Society | 2 | 2.4 |

| Energy and Built Environment | 1 | 2.2 |

| International Journal of Integrated Supply Chain | 1 | 1.7 |

| Sustainability | 1 | 2.5 |

| Technological Forecasting & Social Change | 1 | 5.8 |

| Journal of Building Engineering | 1 | 3.3 |

| Computers and Industrial Engineering | 1 | 4.1 |

| Resources, Conservation & Recycling | 1 | 7.5 |

| International Business Review | 1 | 3.9 |

| IEEE Transactions on Engineering Management | 1 | 2.0 |

| IEEE Transactions on Industrial Informatics | 1 | 8.4 |

| Total | 55 |

| Authors (Year) | Author’s Affiliation | Citations |

|---|---|---|

| Yang Lu (2017) | University of Kentucky, Lexington, USAUniversity of Manchester, UK | 1383 |

| Chen et al. (2017) | School of Mechanical and Automotive Engineering, South China University of Technology, China | 439 |

| Frank et al. (2019) | Organizational Engineering Group (Núcleo de Engenharia Organizational, NEO), Department of Industrial Engineering, Brazil | 418 |

| Dalenogare et al. (2018) | Organizational Engineering Group (Núcleo de Engenharia Organizacional, NEO), Department of Industrial Engineering, Universidad, Brazil | 395 |

| Chen et al. (2017) | China-Europe International Business School (CEIBS), China | 208 |

| Manavalan et al. (2019) | School of Mechanical Engineering, VIT University, Vellore, India | 162 |

| Mani et al. (2018) | Montpellier Business School, 2300, Avenue des Moulins, France | 148 |

| Goodchild et al. (2018) | Department of Civil and Environmental Engineering, University of Washington, Seattle, USA | 143 |

| Hansong Xu et al. (2018) | Department of Computer and Information Sciences, Towson University, Towson, USA | 142 |

| Bechtsis et al. (2017) | Laboratory of Statistics and Quantitative Analysis Methods, Department of Mechanical Engineering, Aristotle University of Thessaloniki, P.O. Box 461, 54124, Thessaloniki, Greece | 110 |

| References | Industry 4.0 | SSC | Focus | Research Method | Results | ||||

|---|---|---|---|---|---|---|---|---|---|

| AGV | IoT | Drone | CPS | SF | |||||

| [1] | √ | √ | √ | √ | √ | √ | Study the role of lean and GSCM in the Industry 4.0 paradigm to achieve competitiveness in SC network. | Literature review methodology was used to fulfill the aim of the study. | Based on literature, a conceptual model was introduced that links lean and GSCM characteristics with Industry 4.0. |

| [2] | √ | √ | √ | Address the impact of the IoT on purchasing and supply chain sustainability, and also remove the tensions associated with the IoT. | Used systematic inductive research approach. | Provided a framework that reduces the tensions associated with the IoT emergence in PSM. | |||

| [3] | √ | √ | √ | √ | Aims to check to what extend internal logistics equipment is capable of working in the Industry 4.0 CPS system. | Design science research (DSR) methodology was used and execution was divided into three steps; relevance, rigor, and design. | Proposed the methods to check the adherence of internal logistics equipment with CPS in Industry 4.0, having a measurement error lower than 1.3%. | ||

| [4] | √ | √ | √ | Analyze the risks and security issues associated with the AGV in SC and check how Blockchain overcomes these issue. | A systematic literature review approach was adopted. | Presented a systematic literature review on existing AGV security issues and their countermeasures. In addition, explained how the blockchain linked with AGV in SC to minimize these security issues. | |||

| [5] | √ | √ | √ | √ | √ | The focus was integrating the automatic guided vehicle (AGV) with supply chain sustainability by following the systematic way adopted from the literature review. | A taxonomy approach was adopted for the literature review. The methodological approach is divided into two steps; literature identification and decision-making framework development. | Based on the literature, presented sustainable supply chain cube (SSC2) which helps to integrate the SSC with AGV, and also discussed how AGV contributes to achieving economic, environmental, and social sustainability. | |

| [6] | √ | √ | √ | √ | √ | The study aimed to combine the diverse perspectives and findings of the smart factory in Industry 4.0 based on a literature review to develop a research model for SF. | This study adopted a systematic literature review and applied research methodology. | Based on the literature review, qualitative content analysis and qualitative coding approach; a research model for the smart factory was introduced with eight key technologies as a factor. | |

| [8] | √ | √ | √ | √ | √ | √ | Aimed to find the key enablers of industry 4.0 that drives the supply chain sustainability. | Systematic literature review methodology was used in the field of Industry 4.0 and SSC. | Through the literature review, this study finds 13 enablers of Industry 4.0 that impact the sustainability of the supply chain. |

| [10] | √ | √ | √ | √ | √ | √ | Examined and reviewed the literature based on Industry 4.0, sustainability in the supply chain, and big data. | This study used bibliometric and used network analysis techniques within the literature review approach | Reviewed the literature since 2009, including their similarities and differences, and six research categories were proposed. |

| [13] | √ | √ | √ | The target was to give an overview of barriers and issues associated with AGV adoption. | Employed a mixed research methodology to fulfill the objectives of this study. | A framework was proposed that explains the issues and barriers for AGV in the company and helps future researchers to find the best suitable solution to overcome these barriers. | |||

| [14] | √ | √ | √ | The focus was on highlighting the factors that resist the adoption of automatic guided vehicles and robotics in the construction industry. | Used mixed research methods that includes a literature review and qualitative and quantitative data analysis. | Findings include four main factors that include contractor side, client-side, technical, and work-culture economic factors. | |||

| [15] | √ | √ | √ | √ | √ | √ | The purpose was to give an overview of the role of logistics management practices in Industry 4.0. | A qualitative research methodology was adopted for this study. | This study proposed research questions for further studies. It also discussed the technologies of Industry 4.0 and their impacts on logistics effectiveness. |

| [16] | √ | √ | √ | √ | √ | √ | Aimed to check the effect of new industrial technologies in Industry 4.0 on logistics centers. | The literature review and fuzzy multi-criteria decision-making methodology were used. | Proposed the research model for new logistics centers and gave the strategy map which is helpful for other industries and researchers. |

| [17] | √ | √ | √ | √ | √ | √ | The purpose of this study was to link the technologies of Industry 4.0 with the industries to explain their side effects. | Secondary data analysis was done on data collected from questionnaires. | This study explained the expected benefits of the adoption of Industry 4.0 technologies by proposing a framework. |

| [18] | √ | √ | √ | Aimed to check whether drone delivery in the industry will contribute to achieving sustainability by reducing CO2 emission. | Comparative analysis was used and models were developed for each scenario. | Results show that drone delivery plays a positive role in overcome carbon emissions. | |||

| [19] | The purpose was to establish an IoT-based logistics dispatching system to integrate robotics and customers. | IoT technology, a dynamic multi-objective method, and control theory were adopted in this study. | Developed an intelligent dispatching system that will further help researchers and industries to understand the need for this system. | ||||||

| [20] | √ | √ | √ | The purpose of this study was to examine the benefits and challenges associated with the HFW logistics system. | This study used a multi-objective mathematical model and a comparative analysis was used to justify the validity of the system. | The results of this paper explained the risks and benefits of a humanitarian flying warehouse system by analyzing the case studies. Helps researchers to further investigate the efficacy of this system. | |||

| [21] | √ | √ | Aimed to check the adoption of UAVs in sub-Saharan Africa by reviewing existing literature | A systematic literature review approach was adopted to perform this study. | The result shows that UAV adoption in the sub-region is still in the early-stage and the industry is more concerned from social and technical perspectives. | ||||

| [22] | √ | √ | √ | The purpose of this study was to examine the pros and cons of automatic guided vehicles, both on the ground and in the air, used for delivery services to reduce carbon emissions. | Modeling techniques were adopted to measure the defined variables. | Results show that these technologies have more benefits than risks in reducing the CO2 emissions in the industry. | |||

| [23] | √ | √ | √ | The purpose of this study was to do a comparison between truck-based and drone-based delivery systems. | The modeling technique was used to develop an energy consumption model for the drone. | Results show that the use of only a drone-based parcel system is not acceptable at all and companies must move to mix modes of transport. | |||

| [24] | √ | √ | The concept of this paper was to give a detailed review of the IoT in Industry 4.0 and discuss its impact on SSC. | Research review methodology was used in this paper. | This paper contributes by combining their findings in developing a framework for the IoT that drives a company to achieve SSC. | ||||

| [25] | √ | √ | √ | √ | The purpose of the study was to provide knowledge about blockchains in Industry 4.0 and discuss its importance in supply chain sustainability. | A four-step literature review method was used in this study. | This study reveals the research gaps based on literature and gave five research directions for further research. | ||

| [26] | √ | √ | √ | √ | √ | √ | The aim was to find the solution to the challenges related to SSC adoption in the industry in the context of Industry 4.0 and the circular economy. | The literature review approach and hybrid BWM-ELECTRE approach were used to test the case. | Key findings of this study include a framework that helps to resolve 28 SSCM challenges by defining 22 solutions based on the literature review. |

| [27] | √ | √ | √ | √ | √ | √ | The goal of the study was to connect Industry 4.0 with a sustainable supply chain in sustainable food manufacturing. | A qualitative research methodology along with a literature review approach was used. | Proposed the framework that would be helpful to achieve sustainability in the food manufacturing industry. |

| [28] | √ | √ | √ | √ | √ | √ | The idea of this study was to examine digital technologies (Industry 4.0) and their effects on the construction industry | A systematic literature review approach was adopted in this study. | Developed the framework on the CPS system that integrates the Industry 4.0 technologies and helps to boost the construction industry. |

| [29] | √ | √ | √ | √ | √ | √ | This study was conducted to check the challenges, benefits, and issues related to Industry 4.0 and sustainability in SCM. | The bibliometric performance and network analysis (BPNA) were used to perform this study. | Key findings of this research were involved in defining 12 research clusters and the network structure of each cluster was tested. It also explained the challenges and issues that occur during the integration process of Industry 4.0 and sustainability. |

| [30] | √ | √ | √ | √ | The aim was to integrate the physical factory with the digital factory to build a smart factory in-ear of digitalization. | Qualitative research methods and case applications were used to complete the purpose of the study. | This study proposed the hierarchal structure of a smart factory and gave details of each layer that exists in a smart factory. | ||

| [31] | √ | √ | The purpose of the study includes the IoT-related threats and security issues in both the public and private sector. | Literature review methodology was adopted in this study. | Results explained the threats associated with the IoT and gave the countermeasures to overcome these threats. | ||||

| [32] | √ | √ | The aim was to outline the properties of the industrial IoT system and its applications in the context of CPS. | Literature review methodology was used to conduct this study. | Proposed the three-dimensional framework to fix the problems associated with the industrial IoT and explained issues and challenges for future research. | ||||

| [33] | √ | √ | √ | √ | √ | √ | The goal was to redesign the business model in the context of Industry 4.0. | A review of 32 case studies collected from literature was used as a methodology. | This paper created an integrated BM design for Industry 4.0 that will be useful for businesses and future studies. |

| [34] | √ | √ | √ | √ | √ | √ | The purpose of this study was to involve a knowledge management approach in Industry 4.0 to achieve digitization in the supply chain. | Content analysis and statistical analysis were adopted in this study. | The framework was developed to show how supply chain management and knowledge management integration achieves digitization. |

| [35] | √ | √ | This paper emphasized the role of the IoT and business models by assessing the literature review. | Systematic literature review methodology was used. | Developed the systematic connection between the IoT and business model by proposing a framework extracted from literature. | ||||

| [36] | √ | √ | √ | √ | √ | √ | The purpose of this study was to extend the understanding and the current knowledge on Industry 4.0 specifically in the plastic industry. | This study adopted bibliometric analysis in the context of the literature review. | This paper provided integrated knowledge of Industry 4.0 resulting from the bibliometric analysis. |

| [37] | √ | √ | √ | √ | √ | √ | The idea of this study was to check the impact of digital technologies on economic and environmental performance in the context of supply chain | The qualitative research methodology was used in this study. | The study finds that these digital technologies have a positive impact on economic and environmental performance based on data collected from Chinese enterprises. |

| [38] | √ | √ | √ | √ | √ | √ | The goal of the study was to check the influence of Industry 4.0 on the maritime industry. | Bibliometric analysis was used in this study. | Results show that each technology has its benefits and issues after implementing these digital technologies in the maritime industry. |

| [39] | √ | √ | The purpose of the study was to enhance the efficiency of the scheduling process in smart manufacturing. | Proposed the scheduling system based on real-time data available in CPS; this system is better used for the decision-making process. | |||||

| [40] | √ | √ | √ | √ | √ | The study aimed to check how fast companies adopt Industry 4.0 technology and under what conditions. | A cross-sectional survey was done to perform this study. | Proposed the framework explaining the layers of Industry 4.0 technologies and conditions for the adoption of these technologies. | |

| [41] | √ | √ | √ | √ | √ | The purpose was to integrate the concepts of Industry 4.0 to make a single presentable definition and scope of Industry 4.0. | This study adopted a systematic literature review approach. | Explained the series of definitions related to Industry 4.0 and created a more scientific definition of Industry 4.0. | |

| [42] | √ | √ | √ | √ | √ | The goal was to check the knowledge of Industry 4.0 based on experience and seniority levels in the pharmaceutical industry. | The qualitative research methodology was adopted by this study. | This study concludes that having more experience in the industry led to more knowledge of Industry 4.0. to implement Industry 4.0 in the industry. They also state that it is better to have a clear understanding of Industry 4.0 with peers of organization. | |

| [43] | √ | √ | The purpose of this paper was to check how addictive manufacturing modifies the industrial production system in the context of globalization. | The qualitative research methodology was adopted in this study | Proposed a model that explains the effect of additive manufacturing on different industry sectors. These findings can also be helpful for future studies. | ||||

| [44] | √ | √ | √ | √ | √ | √ | The goal of the study was to check the issues and barriers related to implementing Industry 4.0 technologies in the manufacturing sector | The Grey Decision-Making Trial and Evaluation Laboratory (DEMATEL) approach was adopted to analyze results. | The results of this study are helpful for decision-makers and policymakers to educate the industrial sector so that they may adopt these technologies to enhance their productivity. |

| [45] | √ | √ | √ | √ | √ | √ | The goal was to examine the role of Industry 4.0 in small and medium enterprises to add value creation. | This study adopted case study analysis and a qualitative research methodology. | Results explained that the adoption of 4.0 technologies in SMEs requires more resources and each technology has its conditions for adoption. It is a necessity to adopt the right technology at the right time. |

| [46] | √ | √ | √ | √ | √ | The study aimed to check the socio-technical role of Industry 4.0 in the industrial sector. | A systematic literature review was used for this study. | Proposed an integrated framework that includes both human and non-human involvement in Industry 4.0 technologies. | |

| [47] | √ | √ | The focus of the study was to give brief insights into Industry 4.0 technologies and their scope based on previous studies. | The two-state approach for literature review was used in this study. | A framework was proposed that explains the four major key technologies of Industry 4.0 and their applications in the industrial sector. | ||||

| [48] | √ | The purpose was to investigate how sustainability can be achieved in the fashion industry by applying the system of system theory. | The multi-methodological research approach was adopted by this study. | A framework and action matrix were developed to achieve sustainability in the fashion industry and check its applications in real cases. | |||||

| [49] | √ | The focus was to integrate the production and transport system of the supply chain to achieve sustainability in the environment and production system | The multi-stage optimization and simulation methodology was used to develop the methodological model. | Proposed the methodological framework related to the optimization of production and transport systems based on computer simulations. | |||||

| [50] | √ | √ | √ | √ | √ | √ | The paper emphasizes enabling sustainability into the industry in the new technological world (Industry 4.0). | AI, machine learning, and the expert system were used in this study. | An integrated framework was proposed by combining sustainability and Industry 4.0. Practical implications were shown through an example. |

| [51] | √ | √ | √ | √ | √ | √ | The concept of this study was to check how the adoption of Industry 4.0 technologies leads to achieving society’s sustainability. | Multiple methodologies such as HFS, CPT, and VIKOR were used. | The key finding of this paper was to develop a framework that explains the Industry 4.0 key technologies with respect to sustainability. |

| [52] | √ | The purpose of the study was to analyze the role of the key enablers of sustainability in the agriculture and food sector. | Integrated ISM and the fuzzy DEMATEL research methodology were used. | The ten key enablers were defined, which can be used to achieve supply chain sustainability in A-FSCs. | |||||

| [53] | √ | √ | This study’s focus was to check which type of sustainability (social, environmental, and economic) approach has a greater impact on firm performance. | Literature review methodology and Psychometric meta-analysis were adopted. | The results of the study revealed that adopting social and environmental sustainability practices in any type of the industry, it will led to an increase in firm financial and operational performance. | ||||

| [54] | √ | √ | The goal of the study was to check how intermediates in the supply chain system resolve the buyer and suppliers’ problems when there is a lack of sustainability. | The qualitative research methodology was used and IRR was adopted to perform the reliability analysis. | Results explained that intermediates play a positive role in the built connection between buyer and supplier and help both parties to achieve sustainability. | ||||

| [55] | √ | The goal was to find the social issues regarding suppliers and find the enablers that can resolve these issues by achieving social sustainability in SC. | Qualitative research methods and structural equation modeling were used. | The results revealed 18 different supplier social sustainability measures that underline five dimensions. | |||||

| [56] | √ | √ | √ | √ | √ | √ | The aim was to check how computers technologies (AI) influence the production and resources of a company to achieve SCS. | This paper adopted a systematic literature review approach. | Proposed a framework of AI-based on literature and explained the factor that led the company to achieve sustainability in the supply chain system. |

| [57] | √ | The purpose of this study was to check the effect of supply chain collaboration on supply chain performance to achieve sustainability. | This study was performed by using a literature review methodology. | This study reveals that supply chain collaboration has a positive effect on supply chain performance by proposing a framework based on literature. | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naseem, M.H.; Yang, J. Role of Industry 4.0 in Supply Chains Sustainability: A Systematic Literature Review. Sustainability 2021, 13, 9544. https://doi.org/10.3390/su13179544

Naseem MH, Yang J. Role of Industry 4.0 in Supply Chains Sustainability: A Systematic Literature Review. Sustainability. 2021; 13(17):9544. https://doi.org/10.3390/su13179544

Chicago/Turabian StyleNaseem, Muhammad Hamza, and Jiaqi Yang. 2021. "Role of Industry 4.0 in Supply Chains Sustainability: A Systematic Literature Review" Sustainability 13, no. 17: 9544. https://doi.org/10.3390/su13179544

APA StyleNaseem, M. H., & Yang, J. (2021). Role of Industry 4.0 in Supply Chains Sustainability: A Systematic Literature Review. Sustainability, 13(17), 9544. https://doi.org/10.3390/su13179544